Changes in the Tribological and Mechanical Properties of Nimonic 90 Superalloy After Irradiation with Swift Xenon Ions

Highlights

- Swift Xe ion irradiation alters wear resistance of Nimonic 90.

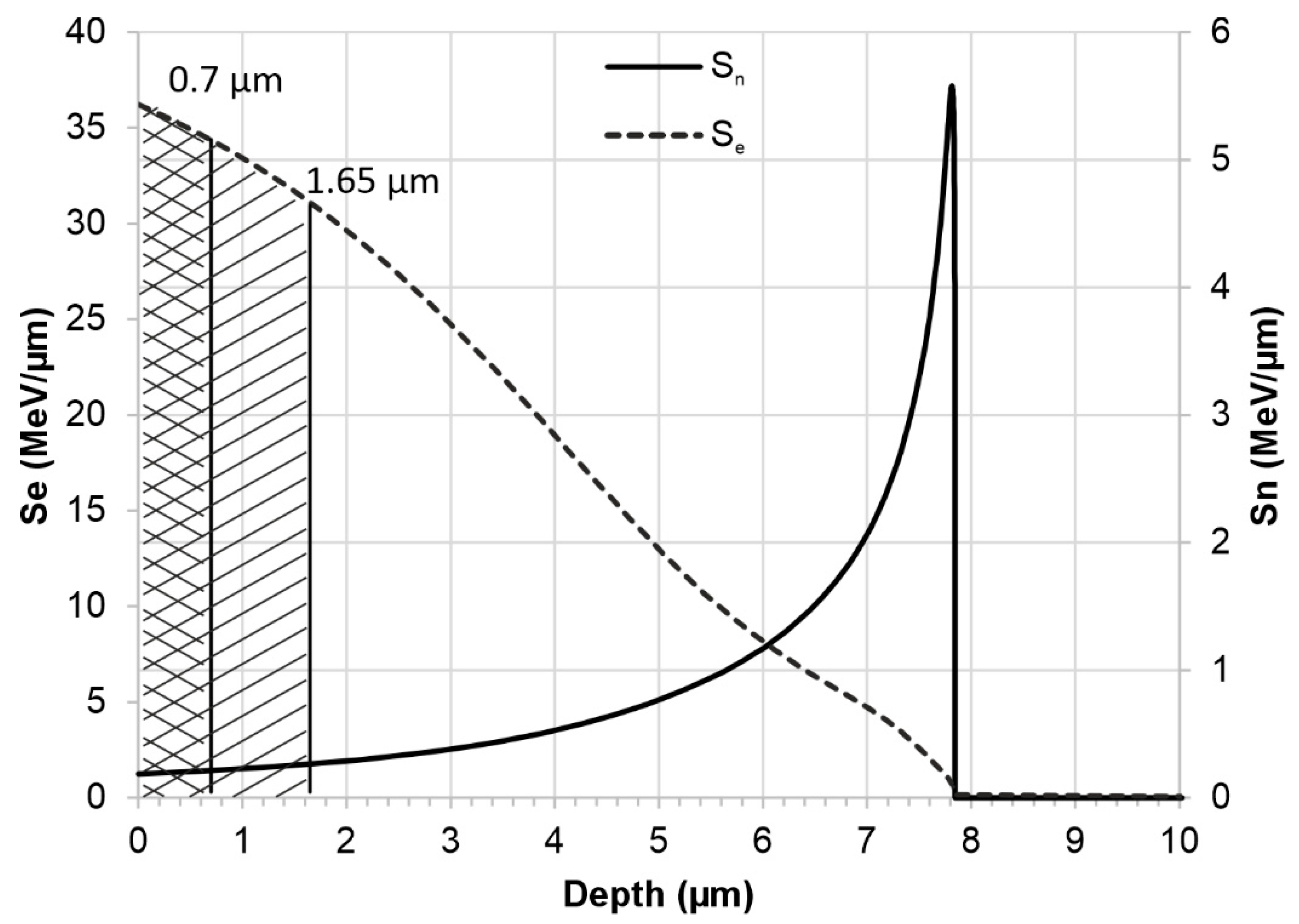

- Long-range effect observed beyond projected ion range.

- High fluence (5 × 1014) induces radiation annealing and hardness recovery.

- Nimonic 90 is limited in tribological applications under irradiation.

- Radiation damage can both degrade and partially heal surface layers.

- Nimonic 90 remains valuable in aerospace and reactor components, but not in friction nodes.

Abstract

1. Introduction

2. Materials and Methods

3. Results

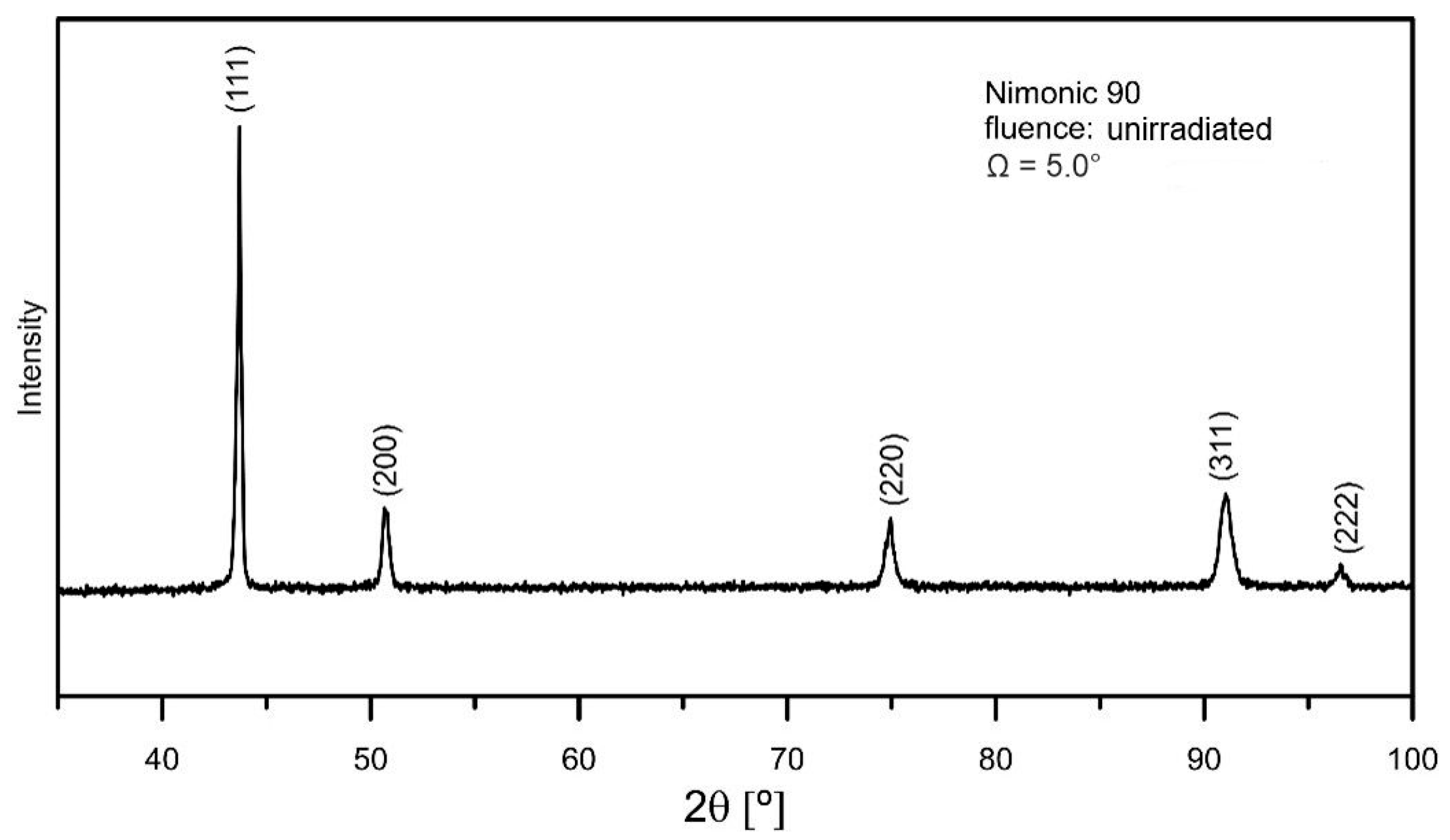

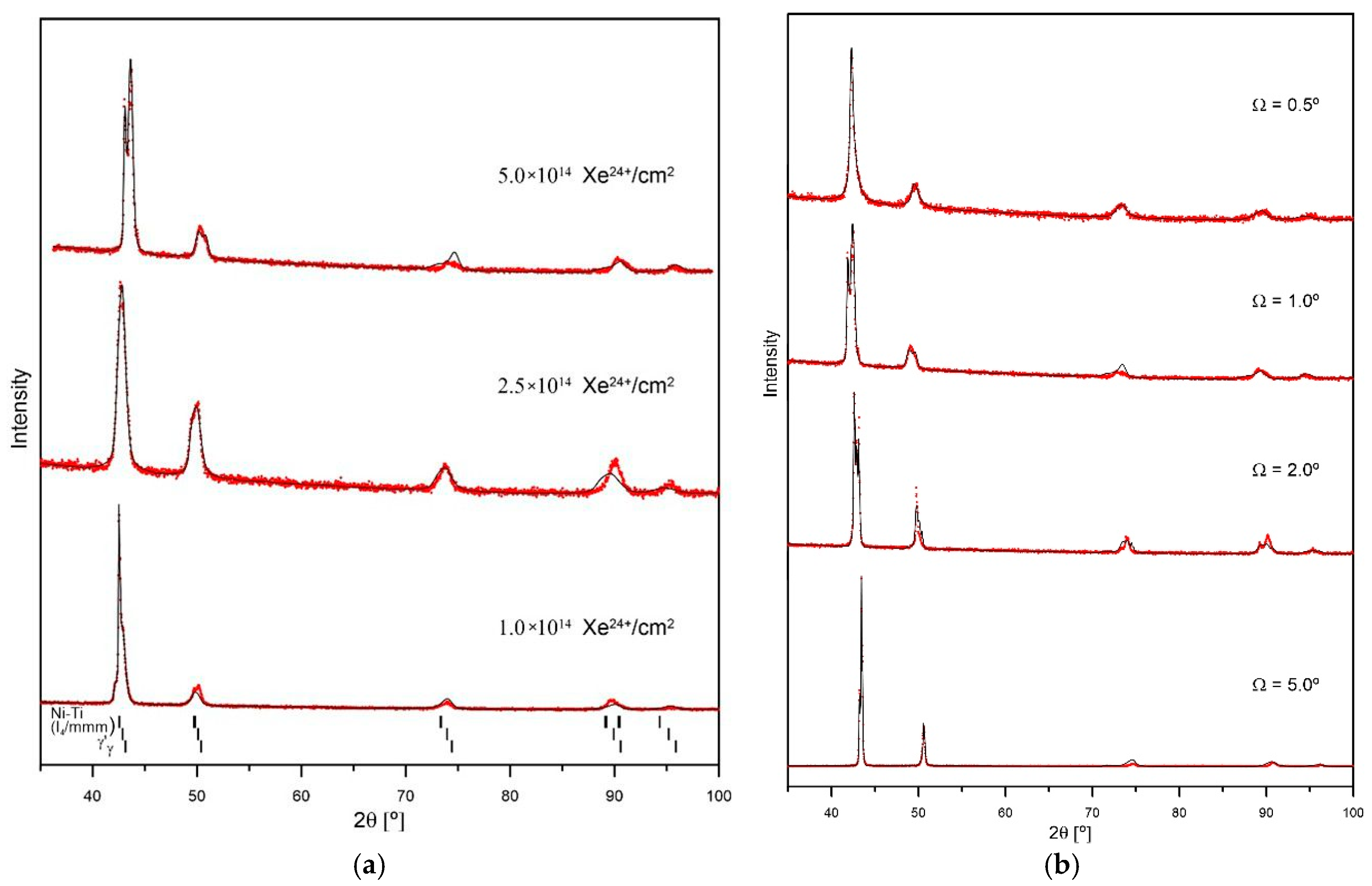

3.1. Crystalline Structure

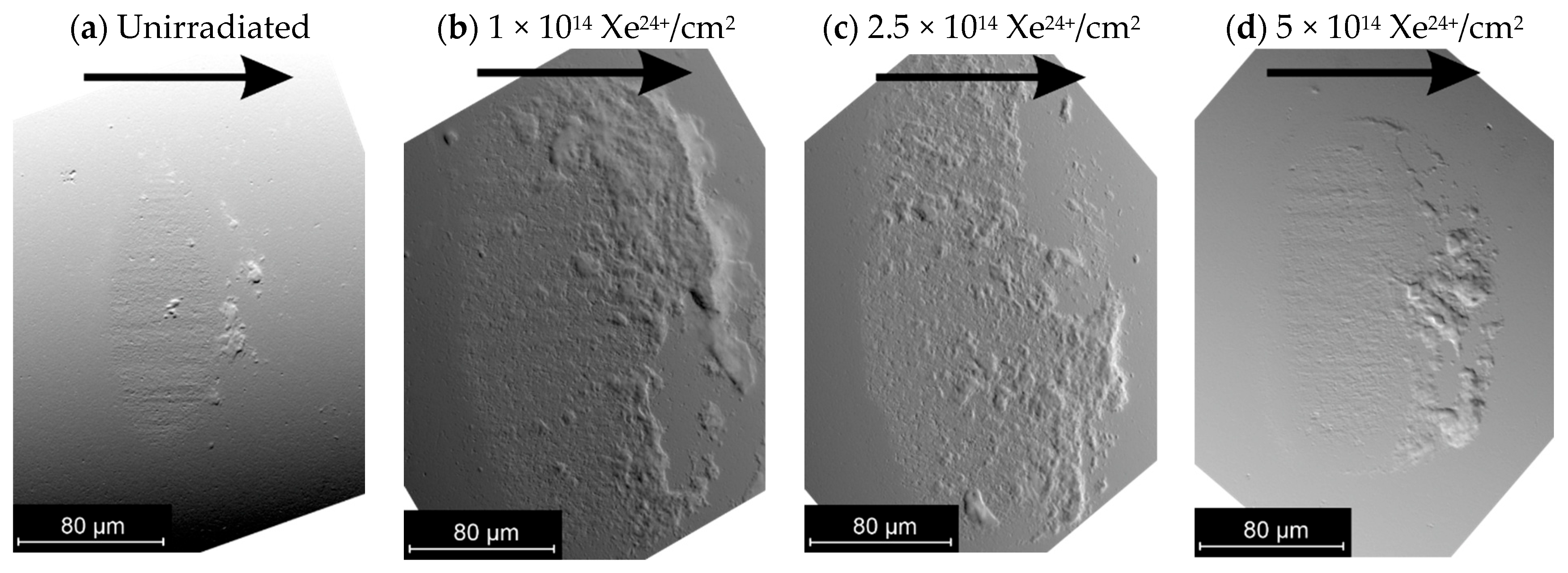

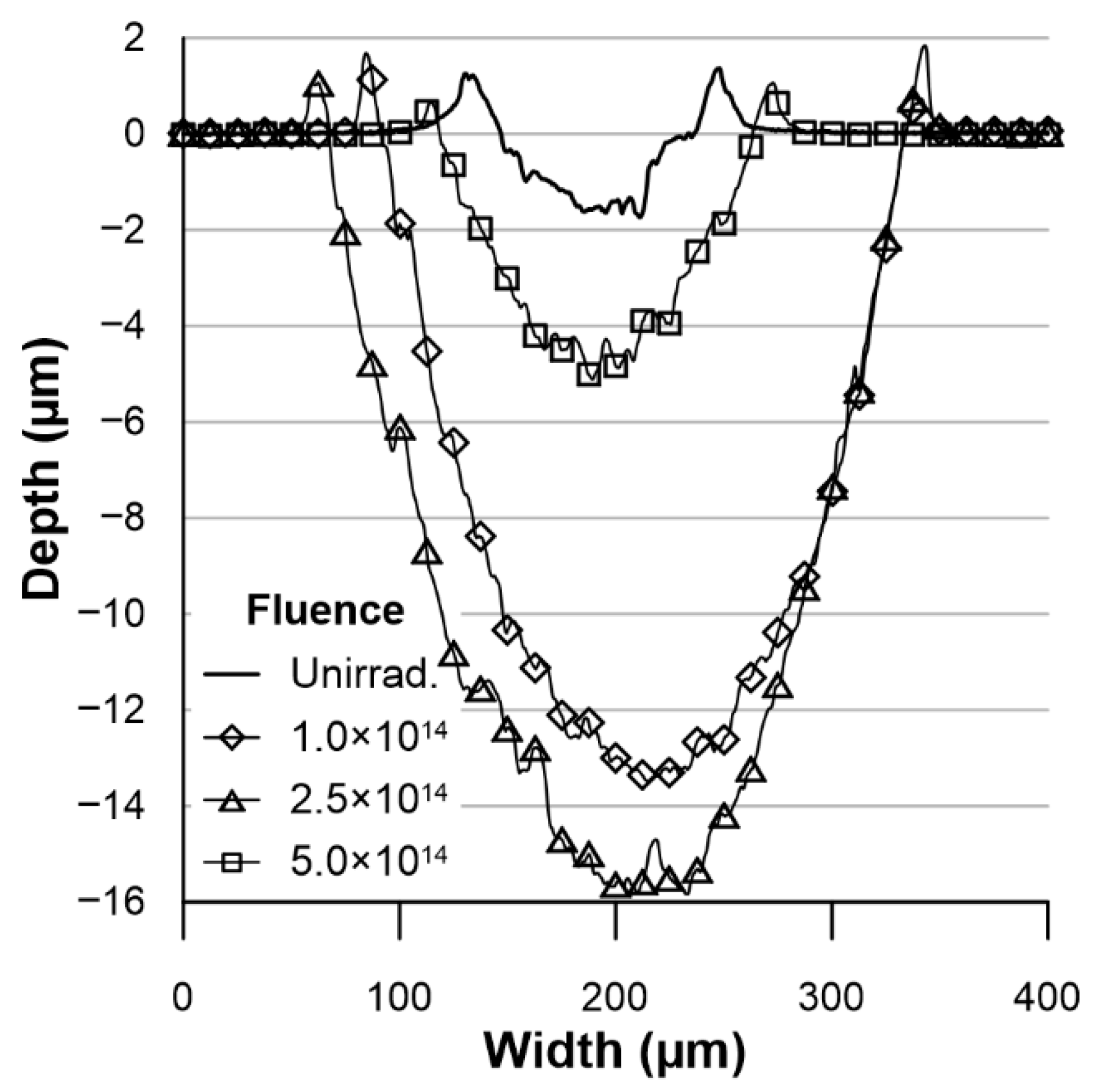

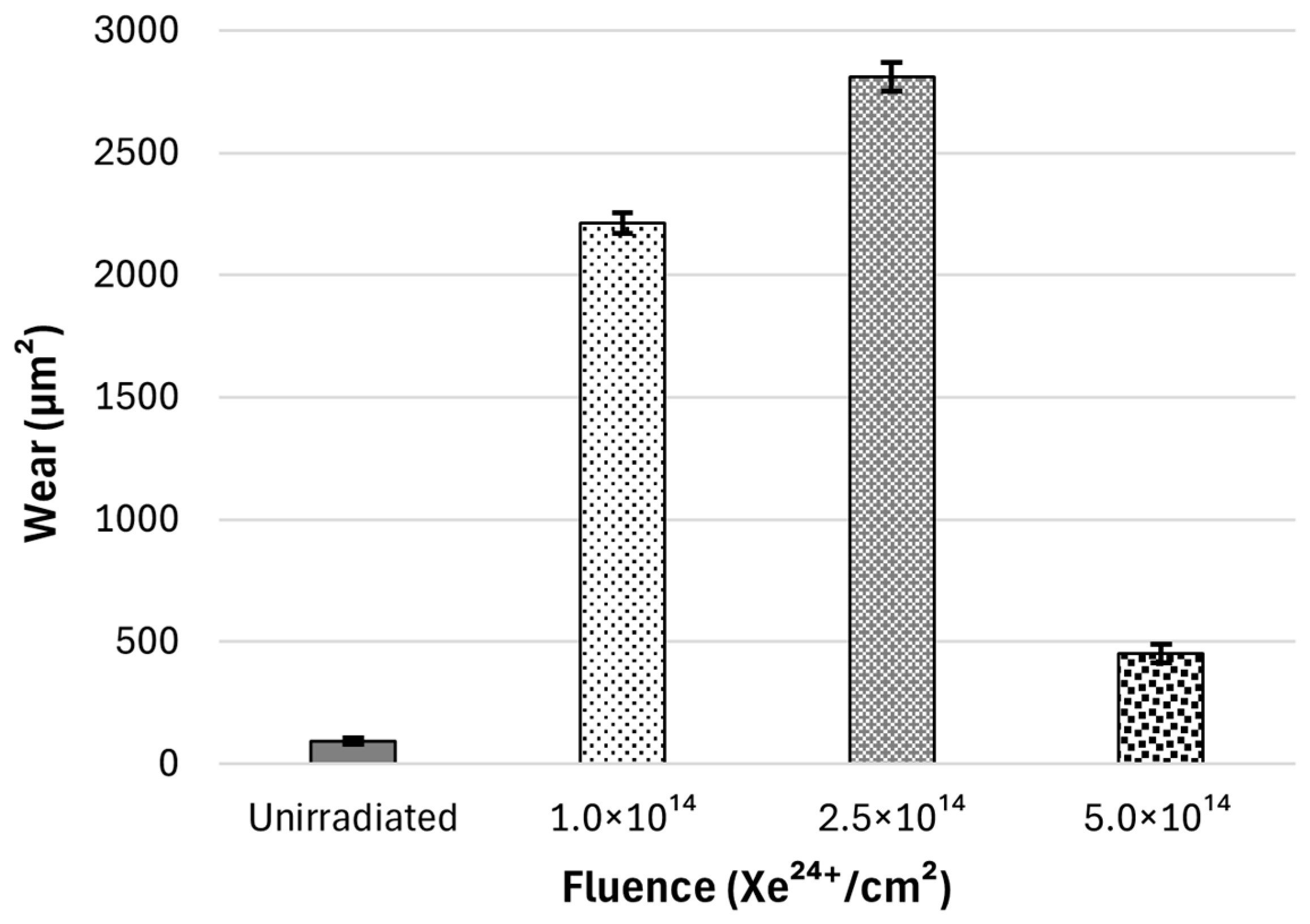

3.2. Tribological Measurements

3.2.1. Friction

3.2.2. Tribological Wear

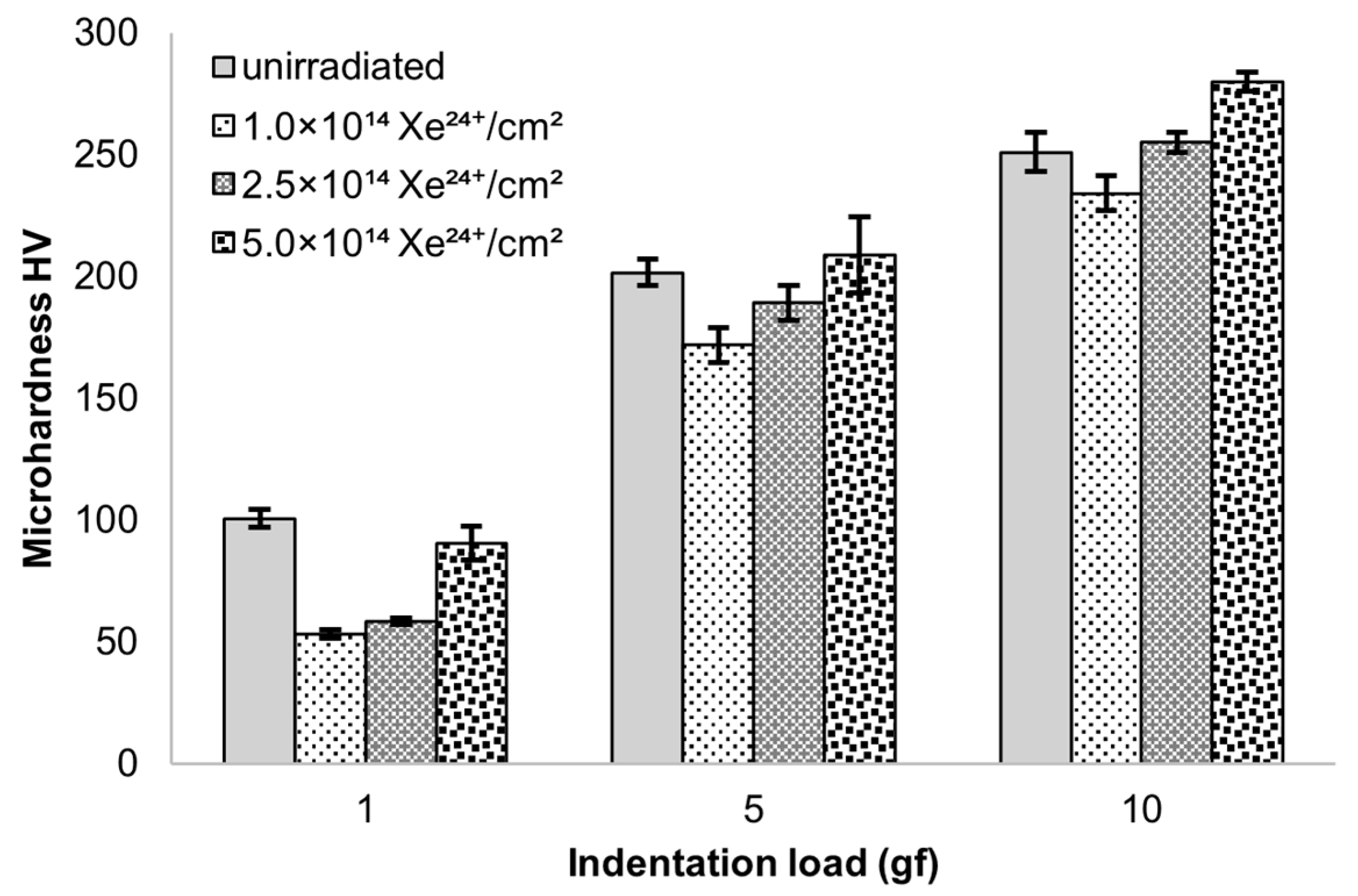

3.3. Microhardness

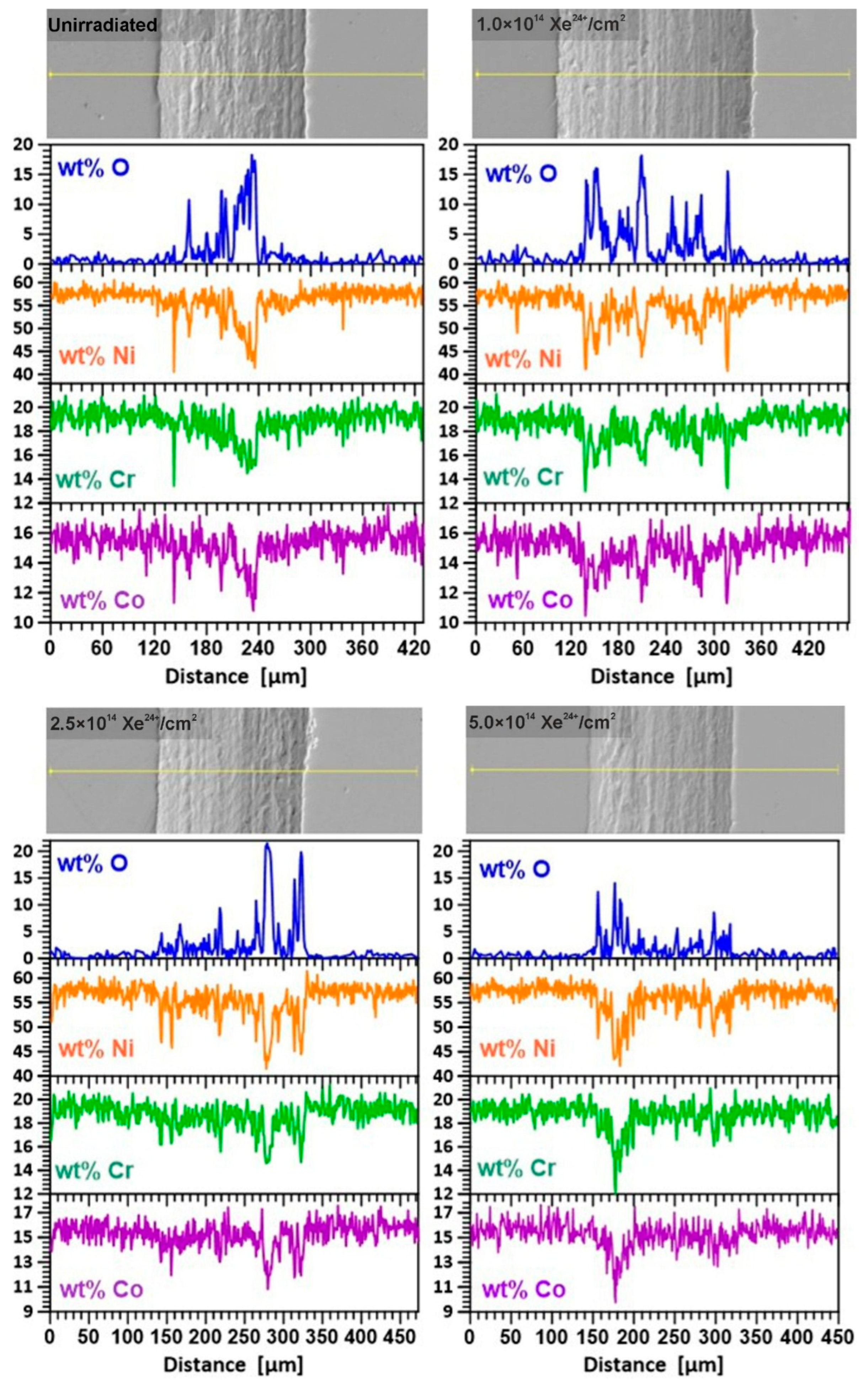

3.4. Chemical Composition

4. Discussion

5. Conclusions

- Tribological test results indicate that Nimonic 90 superalloy should not be used as a structural material in friction nodes exposed to environments with high fluence of swift ions.

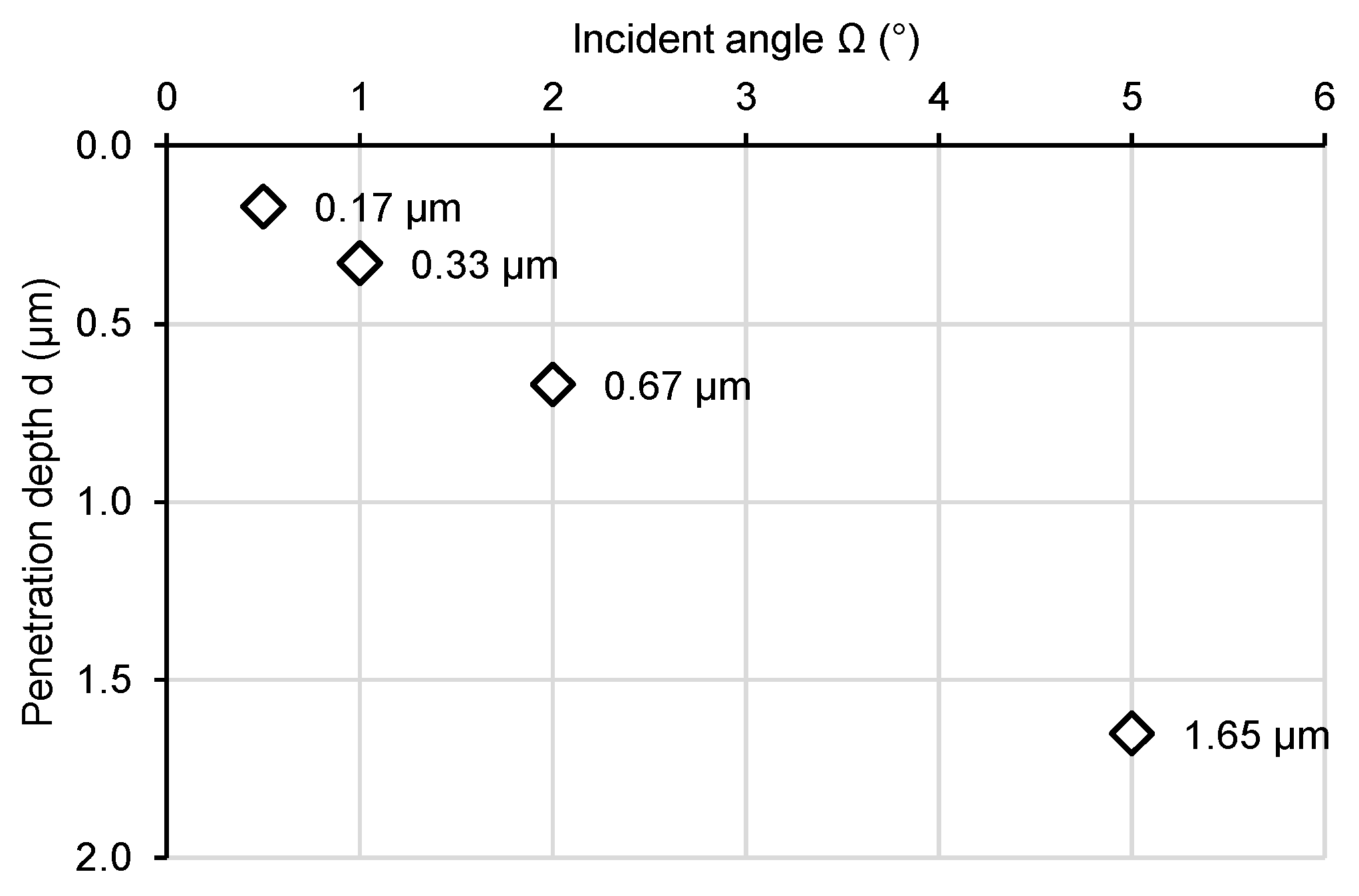

- Measurements of the coefficient of friction and wear show that irradiation with swift xenon ions changes the properties of Nimonic 90 superalloy at a depth more than twice the depth of ion penetration. Changes in the target’s properties at depths beyond the ion penetration are referred to as long-range effects.

- To our knowledge, under the present irradiation and test conditions, irradiation with lower fluences of fast ions (1.0 and 2.5 × 1014 Xe24+/cm2) led to an increase in the coefficient of friction and wear, whereas at the highest fluence (5.0 × 1014 Xe24+/cm2) a partial reversal of these effects was observed.

- The smallest deterioration in tribological properties after irradiation with swift xenon ions is seen in samples irradiated with a fluence of 5 × 1014 Xe24+/cm2. In this case, there is even an increase in the microhardness of the samples, and the resistance to friction wear and the coefficient of friction remain similar (slightly higher) to those of unirradiated samples. However, this fact has no practical application for neutron-irradiated devices operating under real conditions. Before the radiation-induced healing of defects occurs due to irradiation and the tribological properties improve as a result of increased total irradiation fluence, the device will operate for a long time under adverse conditions, leading to deterioration of its tribological properties.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Davis, J.R. (Ed.) Nickel, Cobalt, and Their Alloys; ASM Specialty Handbook; ASM International: Novelty, OH, USA, 2000; ISBN 978-0-87170-685-0. [Google Scholar]

- Srinivasa, N.; Prasad, Y.V.R.K. Hot Working Characteristics of Nimonic 75, 80A and 90 Superalloys: A Comparison Using Processing Maps. J. Mater. Process. Technol. 1995, 51, 171–192. [Google Scholar] [CrossRef]

- Garner, F.A.; Oliver, B.M.; Greenwood, L.R.; James, M.R.; Ferguson, P.D.; Maloy, S.A.; Sommer, W.F. Determination of Helium and Hydrogen Yield from Measurements on Pure Metals and Alloys Irradiated by Mixed High Energy Proton and Spallation Neutron Spectra in LANSCE. J. Nucl. Mater. 2001, 296, 66–82. [Google Scholar] [CrossRef]

- Ganesh Sundara Raman, S.; Padmanabhan, K. Room-Temperature Low-Cycle Fatigue Behaviour of a Ni-Base Superalloy. Int. J. Fatigue 1994, 16, 209–215. [Google Scholar] [CrossRef]

- Chetan; Ghosh, S.; Rao, P.V. Performance Evaluation of Deep Cryogenic Processed Carbide Inserts during Dry Turning of Nimonic 90 Aerospace Grade Alloy. Tribol. Int. 2017, 115, 397–408. [Google Scholar] [CrossRef]

- Özgün, Ö.; Gülsoy, H.Ö.; Findik, F.; Yilmaz, R. Microstructure and Mechanical Properties of Injection Moulded Nimonic-90 Superalloy Parts. Powder Metall. 2012, 55, 405–414. [Google Scholar] [CrossRef]

- Chen, Q.; Lin, Y.-R.; Zhu, P.; Thier, R.; Chen, S.; Qi, Z.; Zhao, Y.; Wang, L.; Nagaraja, N.K.; Ravikumar, S.; et al. Microstructural Evolution and Hardness Changes in Ion Irradiated Nickel-Based Haynes 282 Superalloy. J. Nucl. Mater. 2025, 615, 156006. [Google Scholar] [CrossRef]

- Kamiński, M.; Budzyński, P.; Surowiec, Z.; Wiertel, M. Effect of 160 MeV Xenon Ion Irradiation on the Crystal Structure and Tribological Properties of Inconel 718 Superalloy. Wear 2025, 571, 205813. [Google Scholar] [CrossRef]

- Eliasen, K.; Christiansen, T.; Somers, M. Low Temperature Gaseous Nitriding of Ni Based Superalloys. Surf. Eng. 2010, 26, 248–255. [Google Scholar] [CrossRef]

- Lou, D.C.; Akselsen, O.M.; Solberg, J.K.; Onsoien, M.I.; Berget, J.; Dahl, N. Silicon-Boronising of Nimonic 90 Superalloy. Surf. Coat. Technol. 2006, 200, 3582–3589. [Google Scholar] [CrossRef]

- Lou, D.C.; Solberg, J.K.; Akselsen, O.M.; Dahl, N. Microstructure and Property Investigation of Paste Boronized Pure Nickel and Nimonic 90 Superalloy. Mater. Chem. Phys. 2009, 115, 239–244. [Google Scholar] [CrossRef]

- Yagodkin, Y.D.; Pastuhov, K.M.; Vandenrisschi, G.; De Monicault, J.-M.; Dewulf, J.-M. Surface Modification of Superalloys and Heat Resistant Steels by Irradiation of Low and High Energy Ion Beams. Surf. Coat. Technol. 1997, 89, 52–57. [Google Scholar] [CrossRef]

- Goel, A.K.; Sharma, N.D.; Mohindra, R.K.; Ghosh, P.K. Influence of N2+ and 11B+ Ion Implantation on Microhardness in Nimonic-90 Alloy. Ind. J. Phys. 1990, 64, 30–35. [Google Scholar]

- Goel, A.K.; Sharma, N.D.; Mohindra, R.K.; Ghosh, P.K.; Bhatnagar, M.C. Surface Composition and Microhardening in Nitrogen and Boron Implanted Nimonic-90 Alloy. Thin Solid Films 1992, 213, 192–196. [Google Scholar] [CrossRef]

- Varatharajan, K.; Nandedkar, R. Microhardness—Microstructure Study of Aged Nimonic 90 Irradiated with Helium. In Effects of Radiation on Materials: 14th International Symposium (Volume I); ASTM International: West Conshohocken, PA, USA, 1990; pp. 263–270. ISBN 978-0-8031-1266-7. [Google Scholar]

- Budzyński, P. Long-Range Effect in Nitrogen Ion-Implanted AISI 316L Stainless Steel. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 342, 1–6. [Google Scholar] [CrossRef]

- Budzyński, P. Effect of Ion Irradiation on the Properties of Metals and Alloys; Routledge, Taylor & Francis Group: Abingdon, UK, 2024; ISBN 978-1-032-62958-2. [Google Scholar]

- Budzyński, P.; Kamiński, M.; Turek, M.; Wiertel, M. Impact of Nitrogen and Manganese Ion Implantation on the Tribological Properties of Stellite 6 Alloy. Wear 2020, 456–457, 203360. [Google Scholar] [CrossRef]

- Peterson, R.J. Nuclear Fission Induced by Pi Mesons. J. Nucl. Radiochem. Sci. 2010, 11, R1–R19. [Google Scholar] [CrossRef]

- Takagi, S.; Aritomo, Y.; Hirose, K.; Nishio, K. Analysis of the Kinetic Energy from Fission Fragments Using Dynamical Model. EPJ Web Conf. 2024, 306, 01048. [Google Scholar] [CrossRef]

- Horodek, P.; Dryzek, J.; Skuratov, V.A. Studies of Iron Exposed to Heavy Ion Implantation Using Positron Annihilation Spectroscopy. Radiat. Phys. Chem. 2016, 122, 60–65. [Google Scholar] [CrossRef]

- Horodek, P.; Dryzek, J. Positron Lifetime Studies of Defects Distribution in Xe26+ Irradiated Pure Titanium. Surf. Coat. Technol. 2018, 355, 247–251. [Google Scholar] [CrossRef]

- Dryzek, J.; Horodek, P.; Dryzek, M. Damage Range in Swift Xe26+ Ion-Irradiated Polycrystalline Iron and Silver Studied by Positron Annihilation Technique, Long-Range Effect. Appl. Phys. A 2018, 124, 451. [Google Scholar] [CrossRef]

- Horodek, P.; Siemek, K. Positron Beam Characteristics of Heavy Ion Irradiated Silver. Acta Phys. Pol. A 2022, 142, 697. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

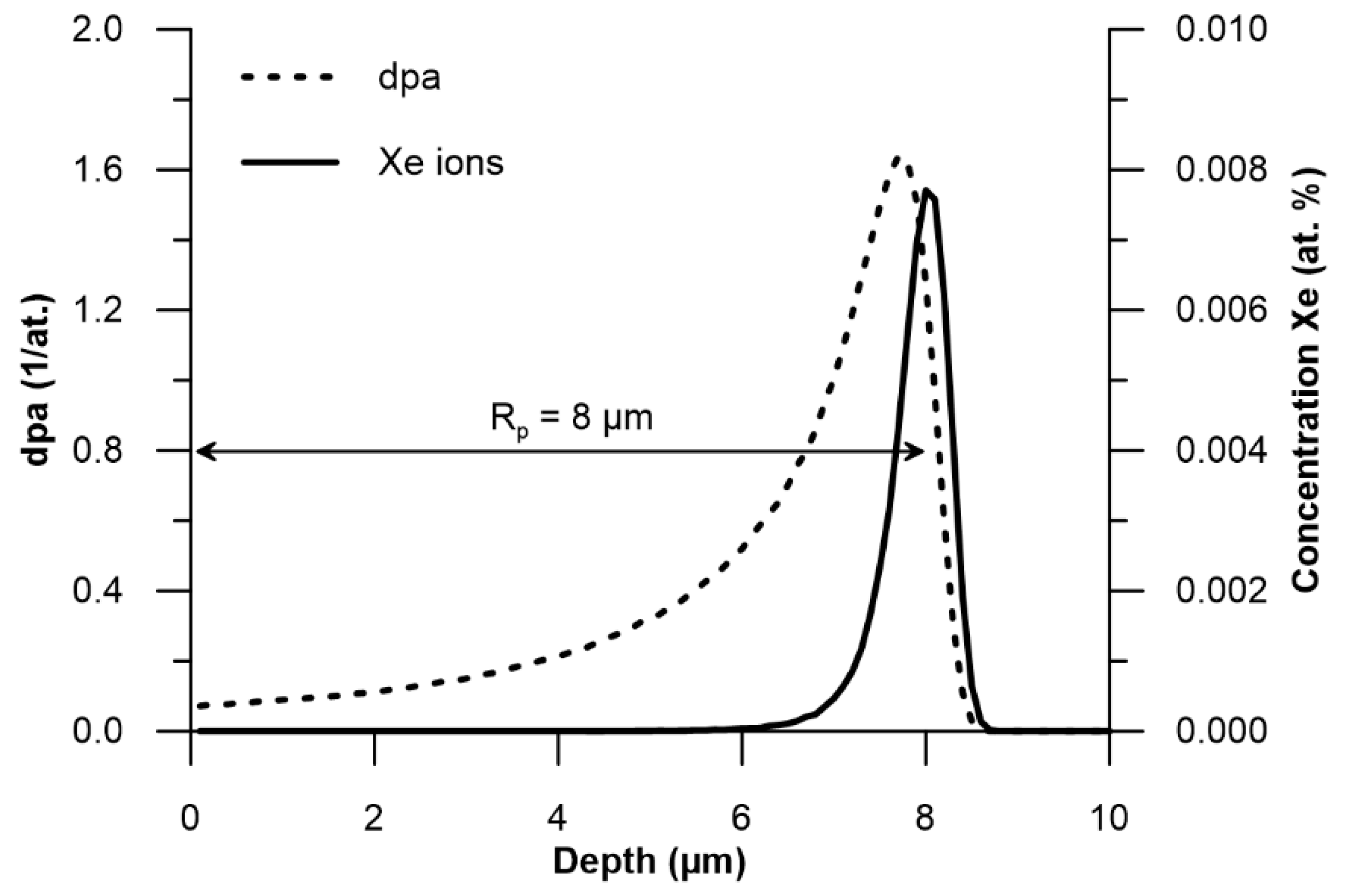

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The Stopping and Range of Ions in Matter. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Konobeyev, A.Y.; Fischer, U.; Korovin, Y.A.; Simakov, S.P. Evaluation of Effective Threshold Displacement Energies and Other Data Required for the Calculation of Advanced Atomic Displacement Cross-Sections. Nucl. Energy Technol. 2017, 3, 169–175. [Google Scholar] [CrossRef]

- Wirth, B.; Hu, X.; Kohnert, A.; Xu, D. Modeling Defect Cluster Evolution in Irradiated Structural Materials: Focus on Comparing to High-Resolution Experimental Characterization Studies. J. Mater. Res. 2015, 30, 1440–1455. [Google Scholar] [CrossRef]

- Welzel, U.; Ligot, J.; Lamparter, P.; Vermeulen, A.C.; Mittemeijer, E.J. Stress Analysis of Polycrystalline Thin Films and Surface Regions by X-Ray Diffraction. J. Appl. Crystallogr. 2005, 38, 1–29. [Google Scholar] [CrossRef]

- Rustamov, I.; Cheng, Y.; Kaniev, D.; Wang, B.; Xiang, L.; Sabirova, O.; Wang, Y.; Wang, Z. Triple Heat Treatment Effects of Inconel X-750 Superalloy on Its Microstructure, Hardness, and High-Temperature Fretting Wear Characteristics. Wear 2023, 534–535, 205128. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Kotval, P.S. The Microstructure of Superalloys. Metallography 1969, 1, 251–285. [Google Scholar] [CrossRef]

- Durand-Charre, M. The Microstructure of Superalloys; Routledge: London, UK, 2017; ISBN 978-0-203-73638-8. [Google Scholar]

- Zinkle, S.J.; Snead, L.L. Opportunities and Limitations for Ion Beams in Radiation Effects Studies: Bridging Critical Gaps between Charged Particle and Neutron Irradiations. Scr. Mater. 2018, 143, 154–160. [Google Scholar] [CrossRef]

- Doyle, P.J.; Benensky, K.M.; Zinkle, S.J. Modeling the Impact of Radiation-Enhanced Diffusion on Implanted Ion Profiles. J. Nucl. Mater. 2018, 509, 168–180. [Google Scholar] [CrossRef]

- Khajuria, G.; Wani, M.F. High-Temperature Friction and Wear Studies of Nimonic 80A and Nimonic 90 Against Nimonic 75 Under Dry Sliding Conditions. Tribol. Lett. 2017, 65, 100. [Google Scholar] [CrossRef]

- Didenko, A.N.; Kozlov, E.V.; Sharkeev, Y.P.; Tailashev, A.S.; Rjabchikov, A.I.; Pranjavichus, L.; Augulis, L. Observation of Deep Dislocation Structures and “Long-Range Effect” in Ion-Implanted α-Fe. Surf. Coat. Technol. 1993, 56, 97–104. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Kozlov, E.V.; Didenko, A.N.; Kolupaeva, S.N.; Vihor, N.A. The Mechanisms of the Long-Range Effect in Metals and Alloys by Ion Implantation. Surf. Coat. Technol. 1996, 83, 15–21. [Google Scholar] [CrossRef]

- Liu, X.-Y. Mechanism for Recombination of Radiation-Induced Point Defects at Interphase Boundaries. Phys. Rev. B 2012, 85, 012103. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Z.; Xun, K.; Asta, M.; Ding, J.; Ma, E. Minimizing the Diffusivity Difference between Vacancies and Interstitials in Multi-Principal Element Alloys. Proc. Natl. Acad. Sci. USA 2024, 121, e2314248121. [Google Scholar] [CrossRef]

- Huang, L.; Nastar, M.; Schuler, T.; Messina, L. Multiscale Modeling of the Effects of Temperature, Radiation Flux, and Sink Strength on Point-Defect and Solute Redistribution in Dilute Fe-Based Alloys. Phys. Rev. Mater. 2021, 5, 033605. Available online: https://journals.aps.org/prmaterials/abstract/10.1103/PhysRevMaterials.5.033605 (accessed on 30 September 2025). [CrossRef]

- Chimi, Y.; Iwase, A.; Iwata, T. Defect Production and Radiation Annealing in Platinum Irradiated with High-Energy Heavy Ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2003, 209, 159–164. [Google Scholar] [CrossRef]

- Ovchinnikov, V.V.; Murtazaev, A.K.; Khazanov, E.A.; Sergeev, A.M. Equilibrium and Highly Nonequilibrium States of Condensed Matter (Scientific Session of the Physical Sciences Division of the Russian Academy of Sciences, 21 April 2008). Phys.-Uspekhi 2008, 51, 955–974. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Budzyński, P.; Kamiński, M.; Surowiec, Z.; Wiertel, M. Changes in the Tribological and Mechanical Properties of Nimonic 90 Superalloy After Irradiation with Swift Xenon Ions. Materials 2025, 18, 4876. https://doi.org/10.3390/ma18214876

Budzyński P, Kamiński M, Surowiec Z, Wiertel M. Changes in the Tribological and Mechanical Properties of Nimonic 90 Superalloy After Irradiation with Swift Xenon Ions. Materials. 2025; 18(21):4876. https://doi.org/10.3390/ma18214876

Chicago/Turabian StyleBudzyński, Piotr, Mariusz Kamiński, Zbigniew Surowiec, and Marek Wiertel. 2025. "Changes in the Tribological and Mechanical Properties of Nimonic 90 Superalloy After Irradiation with Swift Xenon Ions" Materials 18, no. 21: 4876. https://doi.org/10.3390/ma18214876

APA StyleBudzyński, P., Kamiński, M., Surowiec, Z., & Wiertel, M. (2025). Changes in the Tribological and Mechanical Properties of Nimonic 90 Superalloy After Irradiation with Swift Xenon Ions. Materials, 18(21), 4876. https://doi.org/10.3390/ma18214876