1. Introduction

Carbon-fiber-reinforced polymers (CFRPs) are characterized by their light weight, high strength, and excellent corrosion resistance, significantly addressing issues associated with traditional steel cables, such as their susceptibility to corrosion and poor fatigue performance [

1,

2,

3]. Compared to their traditional steel rebars, CFRP cables offer the following advantages: (1) CFRPs exhibit strong corrosion resistance, with negligible performance degradation under acidic, alkaline, saline, and freeze–thaw conditions [

4,

5,

6]. (2) The tensile strength of CFRP cables exceeds that of steel cables, meeting the load requirements for ultra-long cables. However, due to CFRP cables’ significant anisotropy (i.e., the transverse tensile strength is less than 10% of the longitudinal tensile strength), optimizing these advantages largely depends on the cable’s anchorage system [

7,

8]. Currently, the main types of CFRP anchorage devices include bonded anchorages [

9,

10], mechanical anchorages [

11], and hybrid anchorages [

12,

13]. Hybrid anchorages combine the benefits of both mechanical and bonded anchorages, although their assembly process is relatively complex. Compared to mechanical anchorage systems, bonded anchorage systems are better suited for CFRP cables and offer wider application potential in cable structures.

Bonded anchorages typically consist of an anchorage cylinder and a load transfer medium, exhibiting better anchorage performance and fatigue resistance compared to mechanical anchorages. Some researchers have conducted pull-out tests on the bonded anchorage systems of CFRP cables at room temperature, assessing their anchorage performance and the bonding effect between the CFRP cable and the bonding medium [

14,

15,

16]. The results indicate that the mechanical properties of the bonding medium significantly influence the interaction of and friction between CFRP cables and LTM interfaces, making it one of the key factors affecting the anchoring performance of bonded anchorage systems. Currently, the most commonly used bonding media in bonded anchorage systems are resin-based materials and cement-based materials. Compared to cement-based bonding media, resin-based bonding media have higher bonding strength but poorer high-temperature resistance. The interface between CFRP cables and the bonding medium is prone to fire, which also limits the further development of bonded anchorage systems in cable structures. In this context, Xu et al. [

17] investigated the fire resistance of a high-temperature-resistant (HTR) CFRP tendon and showed that the tensile strength retention of the CFRP cables was 19% at 600 °C and that high initial stress (stress level of 0.57) exacerbated the damage to the CFRP tendon at high temperatures. Jiang et al. [

18,

19] investigated the performance of CFRP cables under high-temperature conditions. The results showed that the effect of a high temperature on the modulus of elasticity was more significant than that on the tensile strength. They also established a prediction model for the creep strain of CFRP cables at high temperatures. The fire resistance limits of CFRP cables with pre-tension ratios of 0.2~0.6 ranged from 3.26 to 15.40 min, and their fire resistance properties were poor. It is necessary to improve their fire resistance to expand their engineering applications.

In a study on the durability of CFRP anchoring systems, Hao et al. [

20] studied the durability of CFRP cable anchoring systems in marine environments, identifying five stages of axial force and shear stress changes over time. They also recommended the optimal placement angles for CFRP cable anchors in offshore pit engineering. Ai et al. [

21] found that self-anchored CFRP systems exhibit minimal creep and relaxation, maintaining excellent residual tensile properties. Xian et al. [

22] developed a pre-stressed stretching device for CFRP plates, assessing the stress loss in anchorage systems under coupled temperature, humidity, and sustained load conditions and predicting the long-term tensile strength of CFRP plates. Pan et al. [

23] evaluated the effects of corrosion damage and sustained loading on CFRP-reinforced RC beams, finding significant reductions in the load-bearing capacity under severe corrosion. Xie et al. [

24,

25] conducted extensive research on the durability of adhesive-type CFRP anchoring systems under various environmental factors. Their studies revealed that cyclic loading at frequencies above 12 Hz causes temperature rises within the anchorage system, leading to irreversible damage. Furthermore, they demonstrated that the water absorption increases with an early immersion time, weakening the bonding medium’s mechanical properties, including Young’s modulus, tensile strength, and interfacial fracture toughness. These deteriorations contribute to the degradation of the anchorage system’s tensile capacity, highlighting the critical impact of environmental factors on the long-term performance of adhesive-type CFRP anchorages. Zhu et al. [

26] found that while water immersion and cyclic loading deform internal tendons, they do not affect the anchorage performance or cause corrosion. Similarly, Feng et al. [

27] highlighted that the stress range significantly impacts the fatigue durability, with a linear axial strain under cyclic loading.

Despite these advancements, this literature review highlights a significant gap in our understanding of the mechanical properties of CFRP adhesive-type anchorages under long-term temperature effects, even though temperature is a critical factor influencing their durability. The environmental temperature adversely impacts the bond performance at the CFRP-LTM interface of adhesive anchorages, which is vital for the overall anchorage performance [

28]. Given this gap, further investigation into the degradation of bond performance at the CFRP-LTM interface under prolonged temperature exposure is necessary.

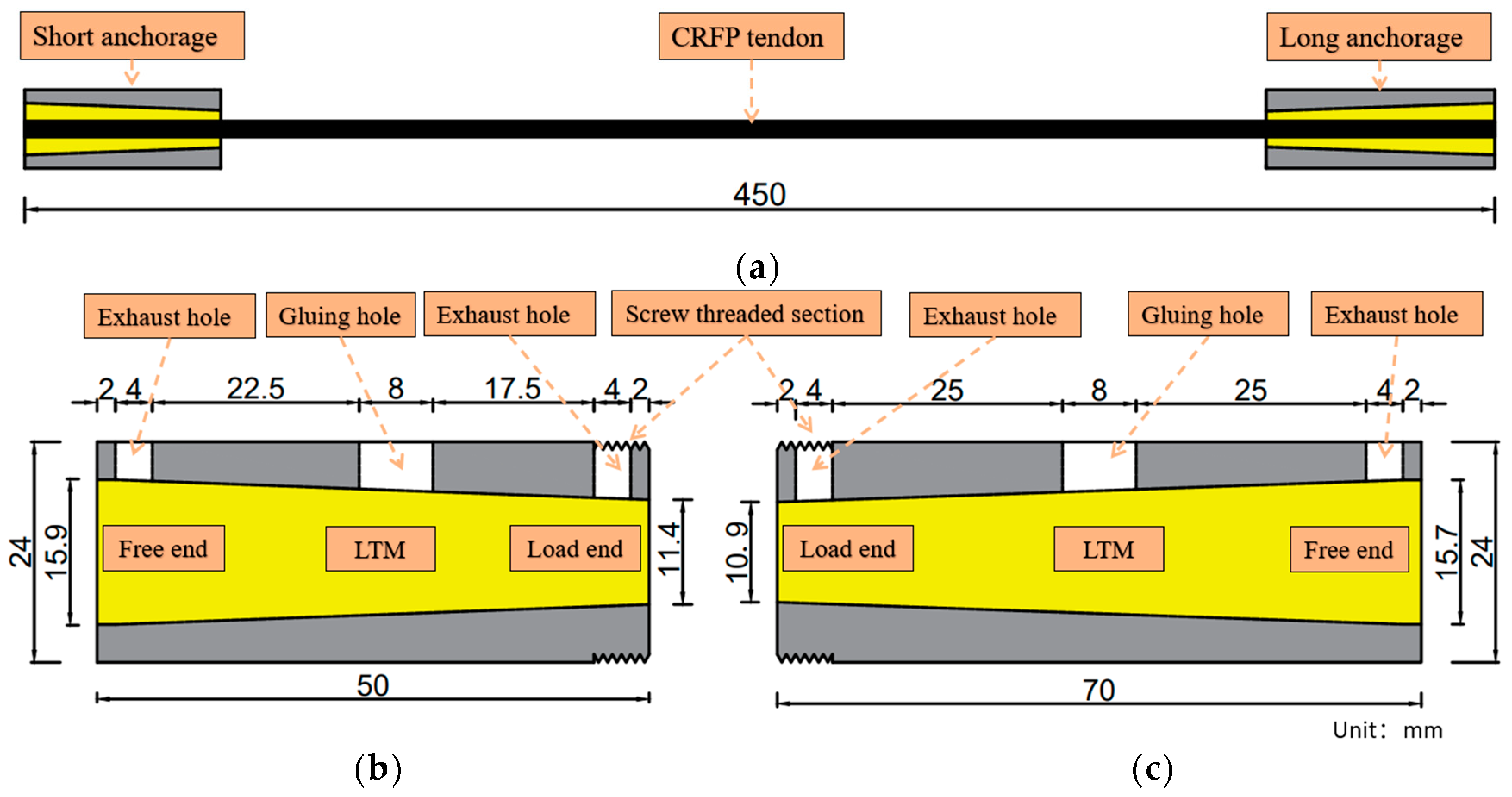

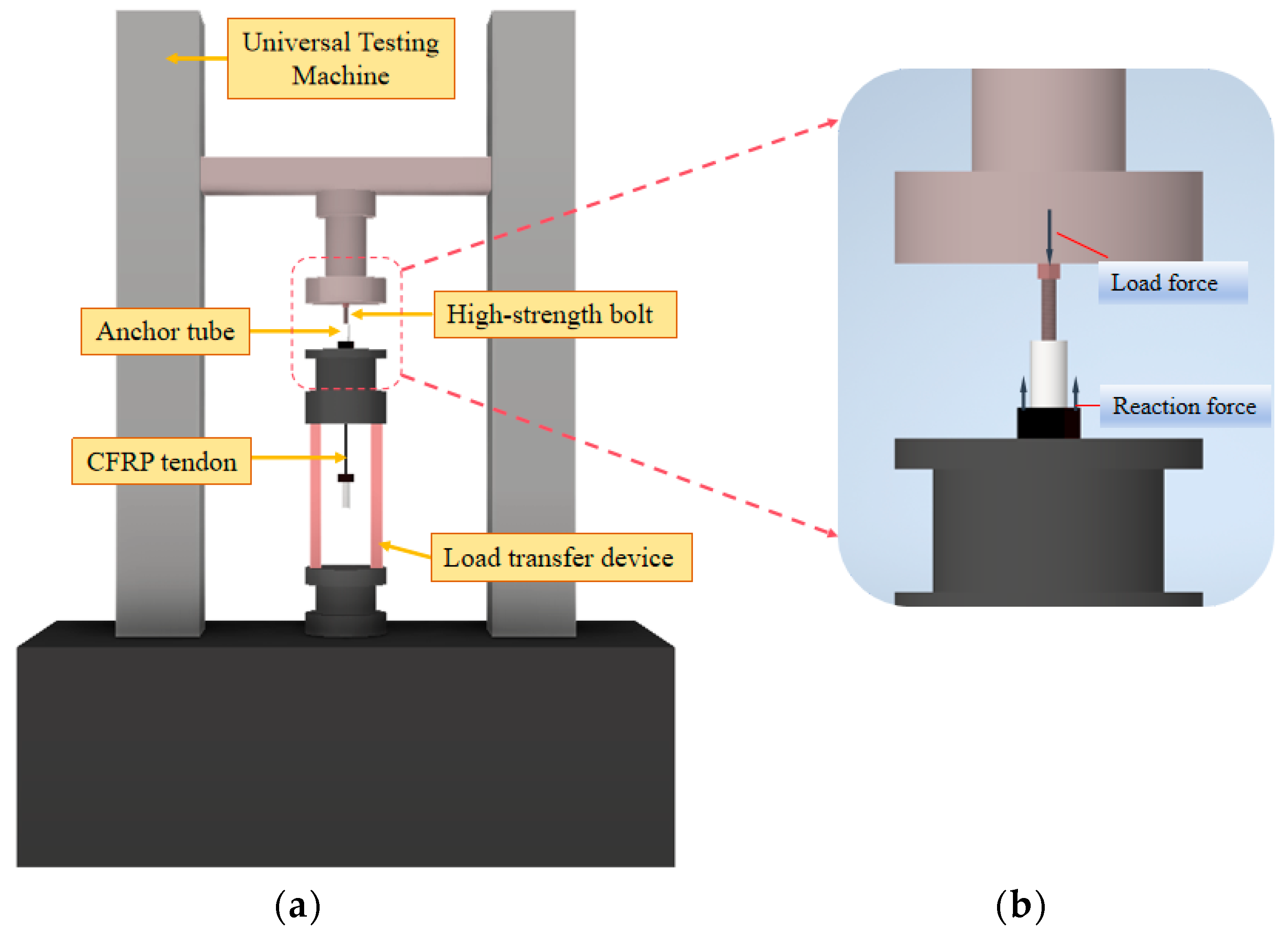

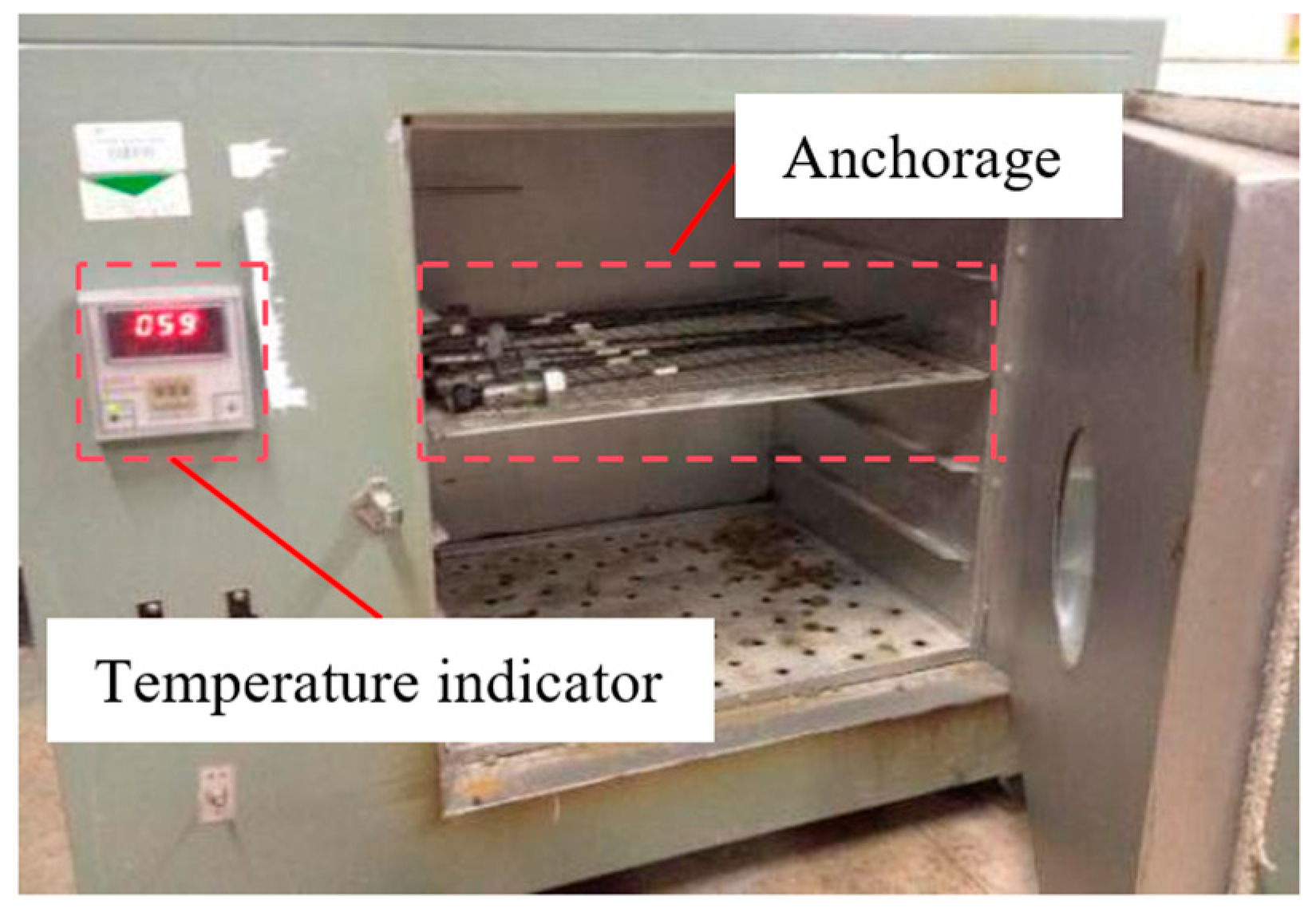

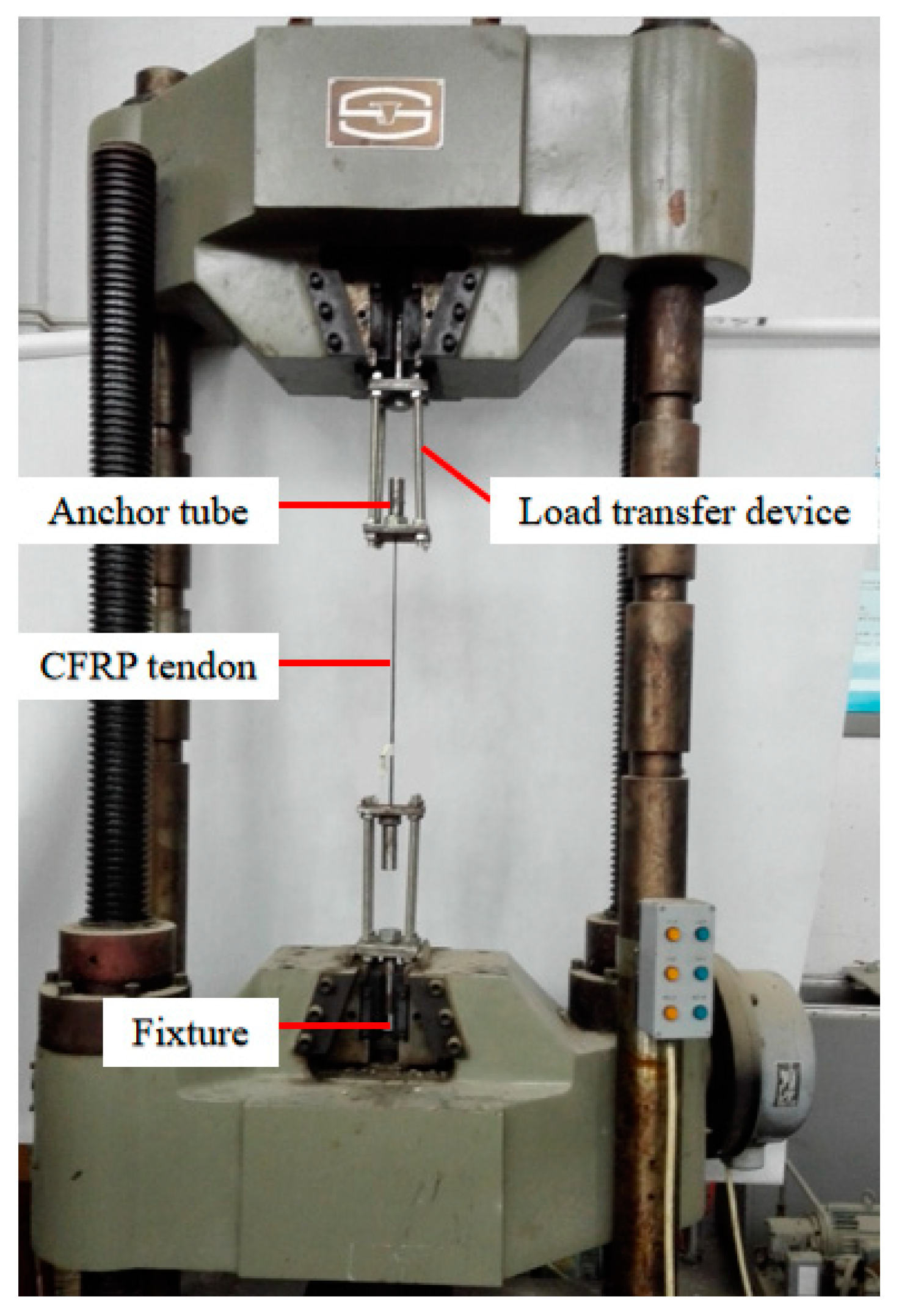

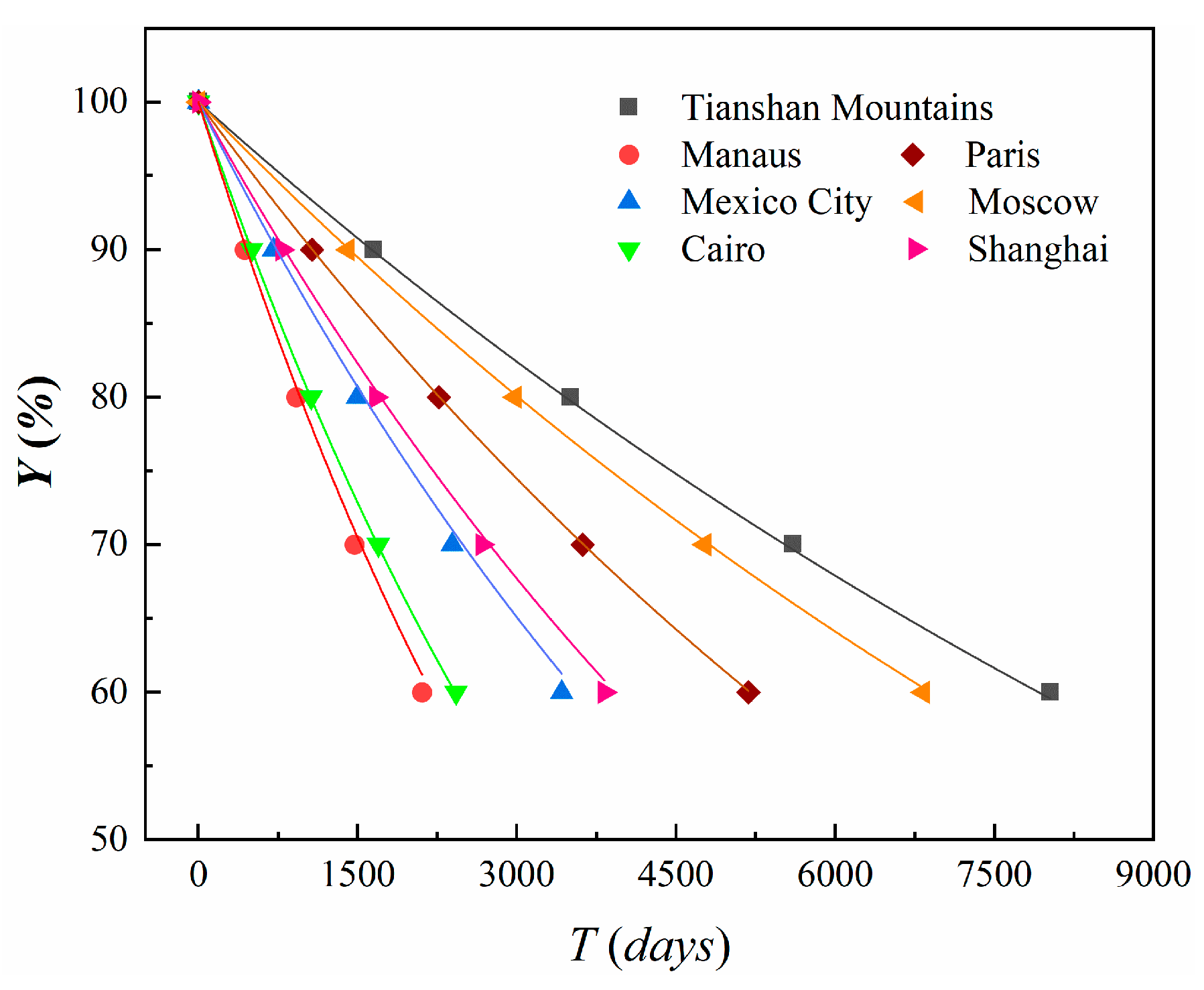

To better evaluate the mechanical performance of CFRP cable-bonded anchorage systems using epoxy resin as the bonding medium under long-term temperature effects, this study conducted accelerated aging tests on 30 CFRP cable-bonded anchorage specimens. These specimens were subjected to elevated temperature conditions to simulate long-term exposure. Subsequently, pull-out tests were performed to measure the degradation rates of the maximum and residual bonding strengths at the CFRP cable–LTM interface under varying temperature conditions. By integrating performance assessment methods with the Arrhenius durability model, this study aimed to assess the long-term degradation of anchorage performance due to temperature exposure. Additionally, it provided predictions of the temperature-related durability of CFRP cable anchorages across representative climatic regions worldwide. The results presented here are expected to contribute to improving the reliability and durability of CFRP adhesive-type anchoring systems in diverse environmental conditions.

2. Bond Strength Assessment Model

The pull-out force

F that is required for the specimen at the ultimate state of the anchorage interface is given by the following equation:

where

represents the diameter of the CFRP reinforcement;

refers to the effective anchorage length of the anchorage; and

is the average bond strength at the interface, which is composed of the adhesion force

, the interlocking force

, and the friction force

.

If a compressive stress

p is applied at the interface, the maximum bond strength at the interface just before failure can be expressed as follows:

where

represents the average shear strength of the epoxy resin at the interface,

is the friction coefficient at the failure interface when the gel is sheared, and

is the friction coefficient at the moment of initial failure. The specific interface force transfer mechanism is shown in

Figure 1.

From Equation (2), it can be seen that primarily depends on the surface geometry of the CFRP cable, the compressive stress at the interface, and the material properties of both the reinforcement and the epoxy resin.

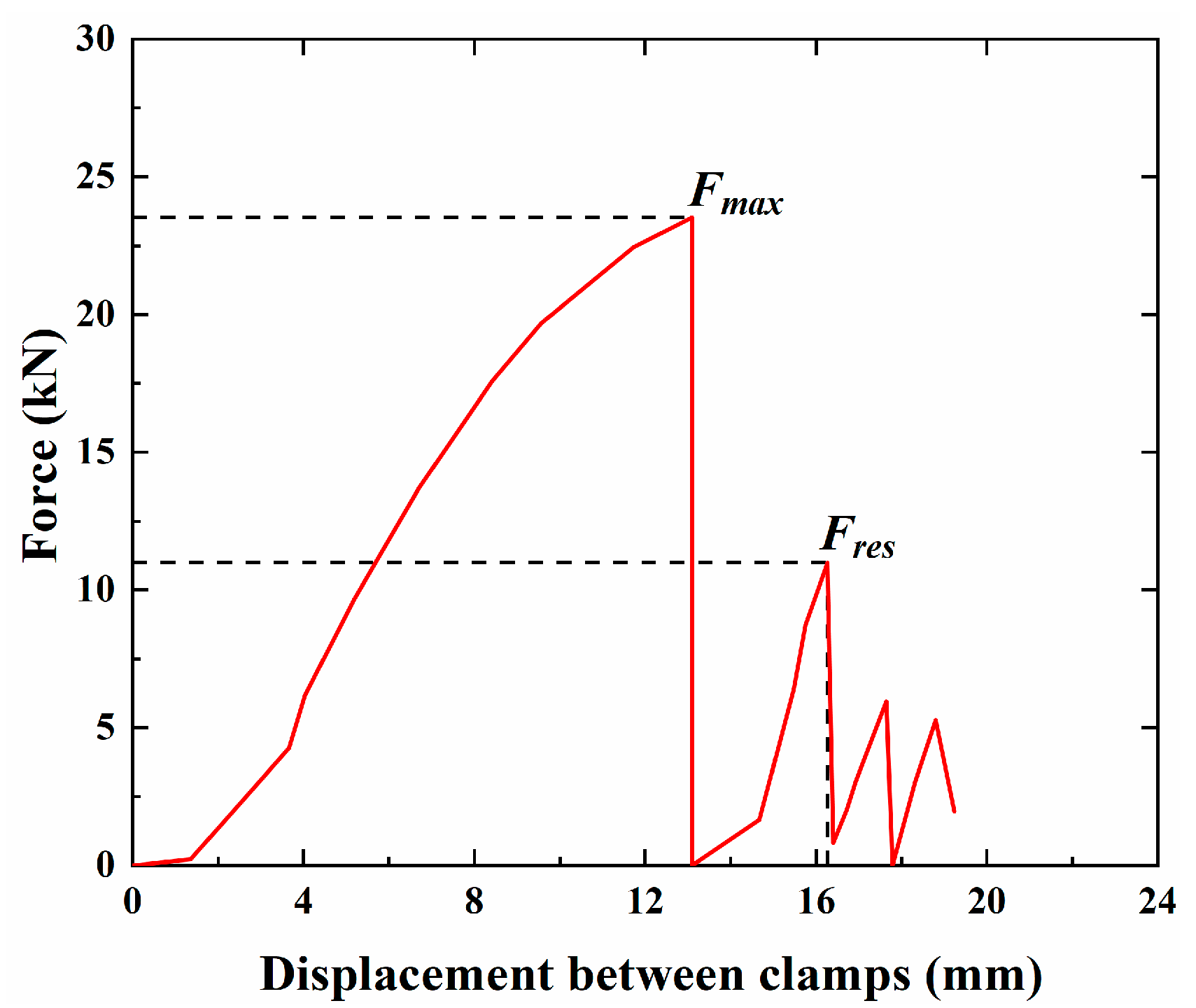

The stress distribution at the CFRP-LTM interface of bonded anchorages is quite complex, making it difficult to reliably measure the load capacity of the conical CFRP cable anchorage system. During the pull-out process, in the initial stage of loading, there is almost no relative displacement between the CFRP reinforcement and the transfer medium, and the bond strength at their interface is primarily composed of adhesion and interlocking forces. As the tensile force increases, it reaches the ultimate state, at which point relative sliding occurs, leading to failure. The loading then enters the second stage, where residual bond strength still exists, typically greater than 30% of the peak interface stress. Thus, it is proposed that the residual bond strength can be used to assess whether the anchorage system can provide reliable anchoring capacity, with a linear relationship between the retention rate of the residual bond strength and the retention rate of anchorage capacity.

The value of

is influenced by the surface geometry of the CFRP reinforcement, the mechanical properties of the transfer medium, and the radial compressive stress at the interface. Zhuge [

29] proposed that the elastic elongation δ of the CFRP reinforcement in the anchorage zone under ultimate loading conditions can conservatively determine the residual bond strength

. The relationship between the residual bond strength and radial compressive stress can be expressed as follows:

where

represents the radial compressive stress on the anchorage.

The residual bearing capacity

can be expressed as follows:

where

represents the number of CFRP strands;

is the diameter of the CFRP filaments;

is the residual shear stress at position

; and

is the reduction coefficient, which accounts for the uneven tension between CFRP strands [

30].

6. Conclusions

This study investigated the degradation of bonding performance at the CFRP cable-bonded anchorage interface under prolonged temperature exposure. The key findings are as follows:

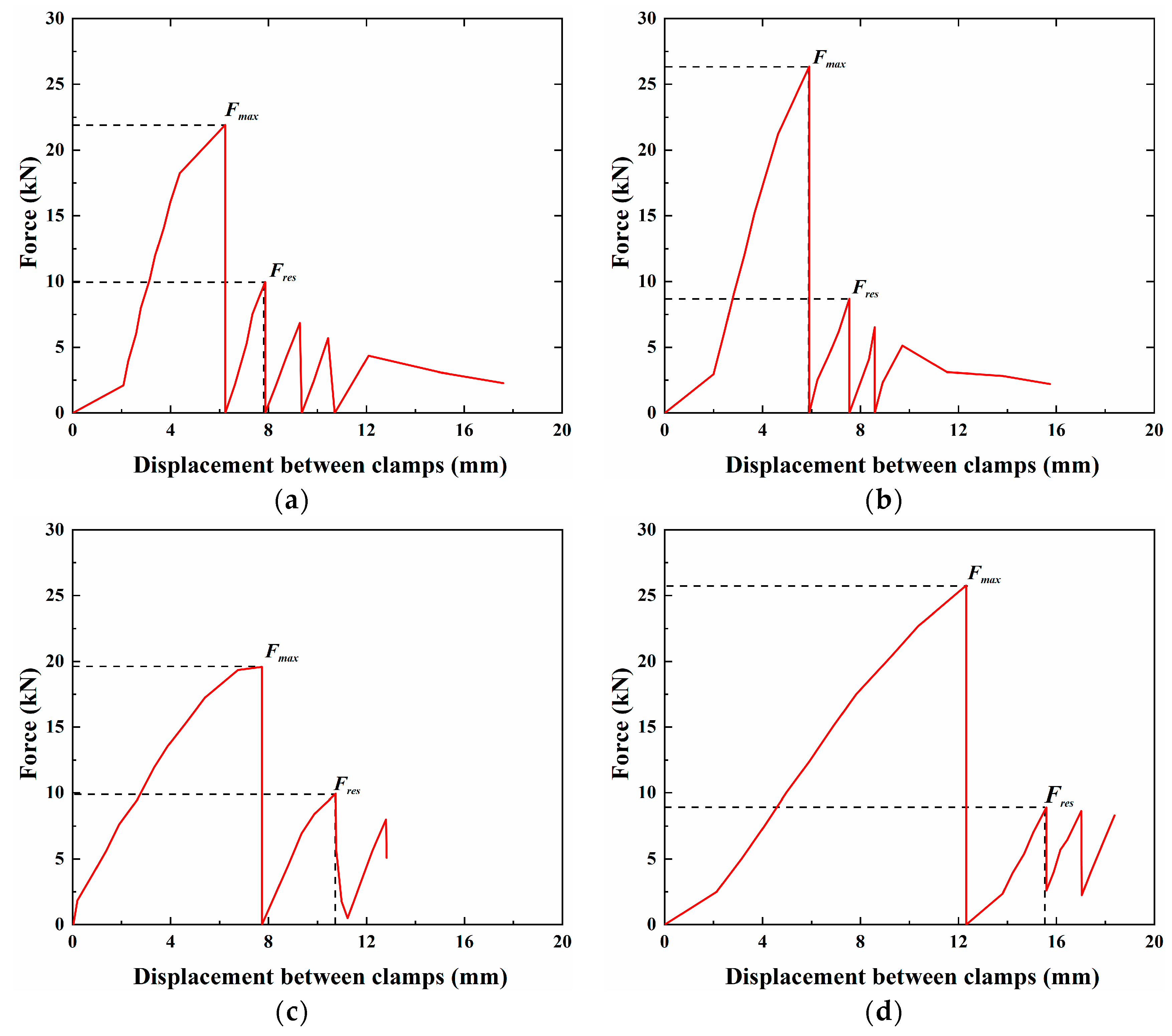

1. After 30 days at 50 °C, 60 °C, and 70 °C, the maximum bonding strength degraded by 6.02%, 8.58%, and 19.18%, respectively. However, after 150 and 210 days, the bonding strength increased by 5.86%, 6.60%, and 14.63% and 5.09%, 13.29%, and 16.39%, respectively.

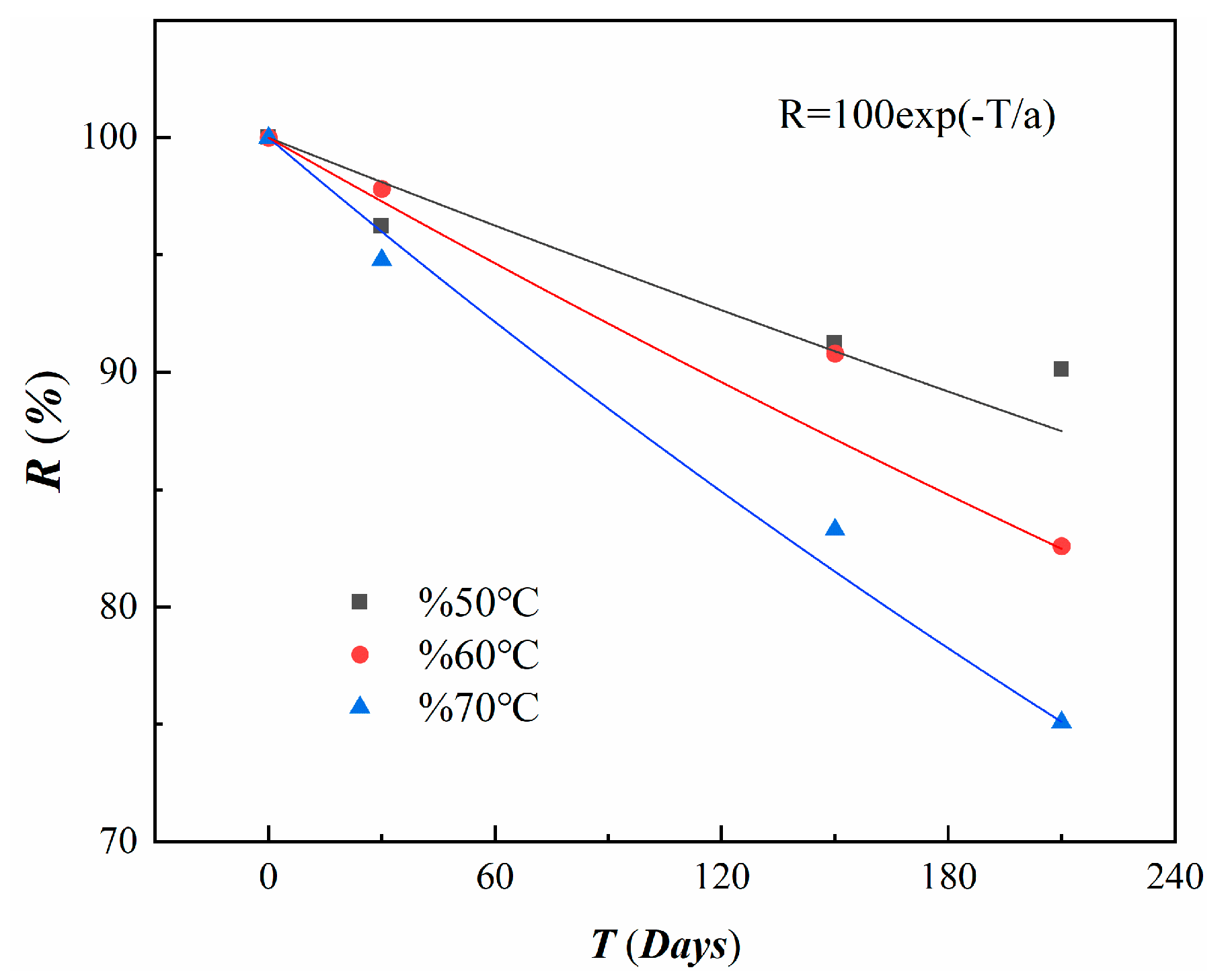

2. The residual bonding strength continuously decreased, with degradation rates of 3.72%, 2.16%, and 6.02% after 30 days at 50 °C, 60 °C, and 70 °C. After 210 days, the rates increased to 9.97%, 17.45%, and 24.88%.

3. Higher temperatures and longer exposure times lead to faster degradation, but the rate of degradation slows over time, eventually stabilizing.

4. In regions with average annual temperatures of 0 °C, 10 °C, and 20 °C, after 10, 30, and 50 years, the anchorage capacity degrades by 18.35%, 45.57%, and 63.72%; 30.14%, 65.90%, and 83.36%; and 44.50%, 82.90%, and 94.73%, respectively.

These findings highlight the significant long-term impact of temperature on CFRP anchorage systems, necessitating more conservative designs in regions with higher temperatures.

Based on the findings of this study, the following directions for further research are proposed to enhance the long-term durability of CFRP cable anchorages under different temperature conditions and improve their application in engineering.

1. Temperature–Humidity Interaction Study: Future research should investigate the combined effects of temperature and humidity on the mechanical performance of CFRP cable anchorages. Understanding how water absorption and temperature fluctuations interact will provide valuable insights into the performance of CFRP anchorages in real-world environments.

2. Combined Effects of Thermal Aging and Dynamic Loading: In practice, CFRP cable anchorages face both high temperatures and dynamic loads. Future studies should examine how thermal aging combined with dynamic loading affects the long-term performance of these anchorages, using both experimental testing and numerical simulations.

3. Design Optimization for Enhanced Durability: Future research should focus on optimizing the design of CFRP cable anchorages to improve their durability under high-temperature conditions. This includes exploring modifications to their geometry, interface treatments, and use of advanced materials to enhance the thermal stability and resistance to aging.

By addressing these areas, future studies can contribute to developing more reliable and durable CFRP cable anchorage systems for long-term use in high-temperature environments.