Investigation on Drying Shrinkage of Basalt Fiber-Reinforced Concrete with Coal Gangue Ceramsite as Coarse Aggregates

Abstract

1. Introduction

2. Experiments

2.1. Materials

2.2. Test Method

2.2.1. Compressive Strength Test

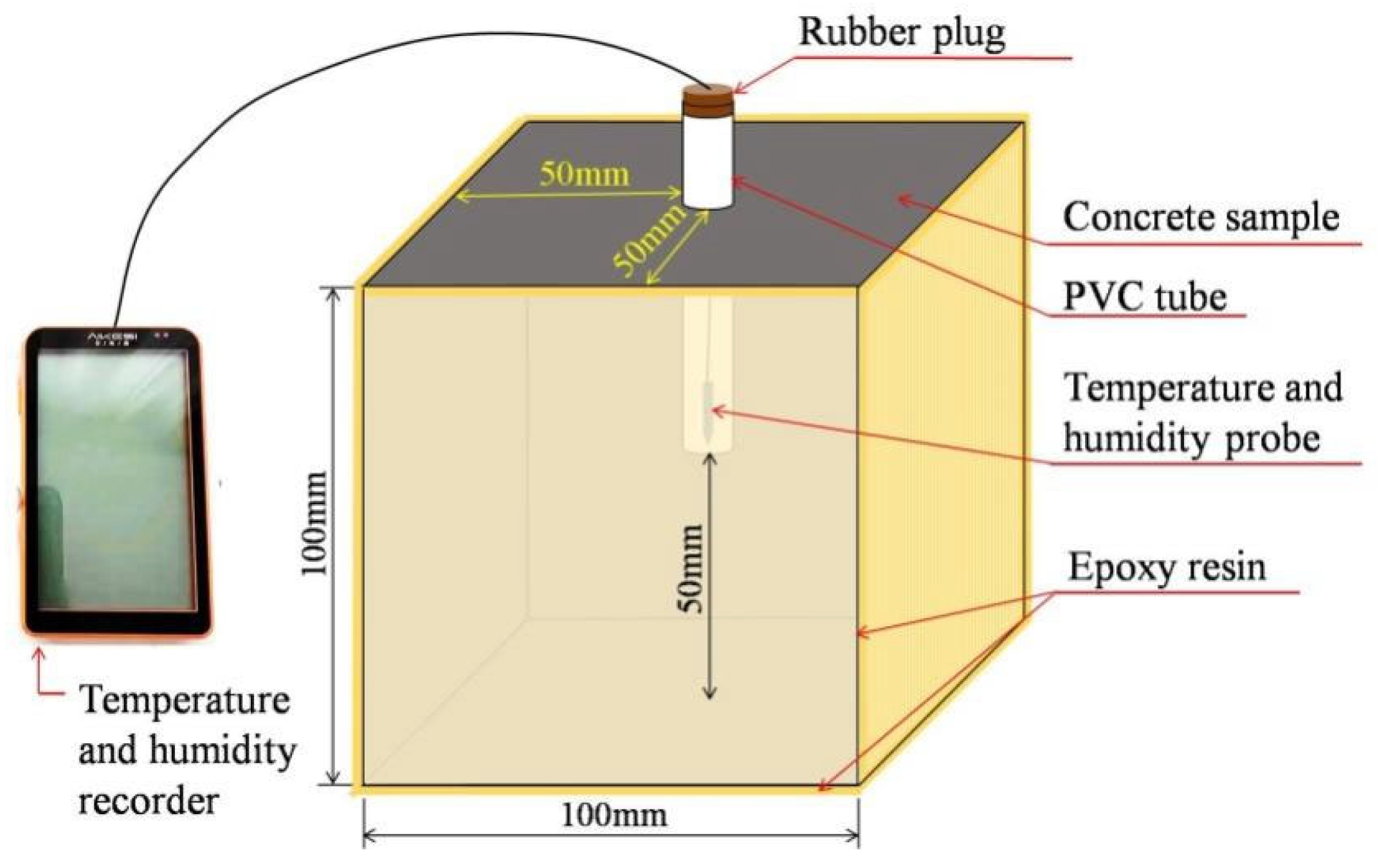

2.2.2. Internal Humidity Test

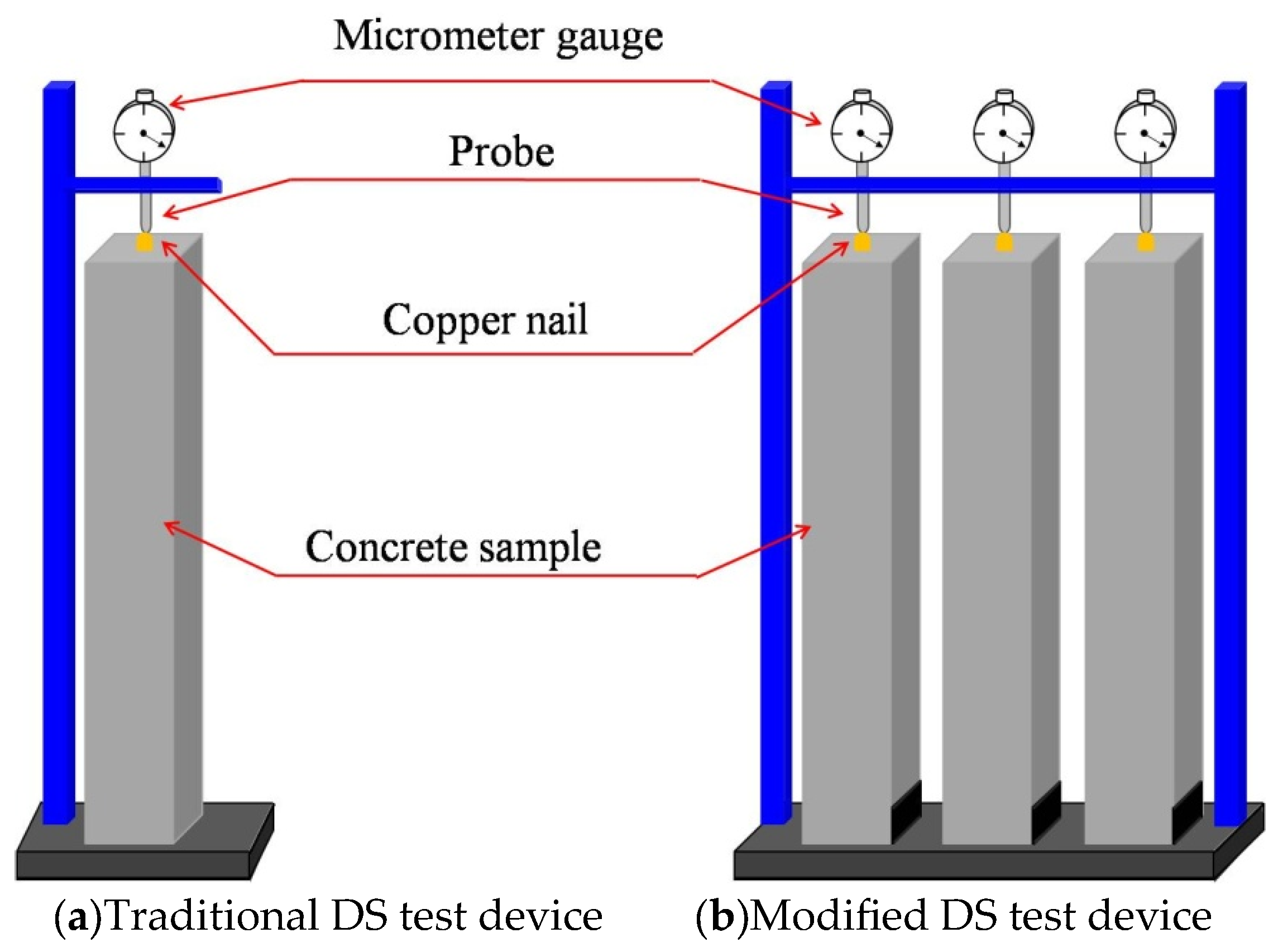

2.2.3. Drying Shrinkage Test

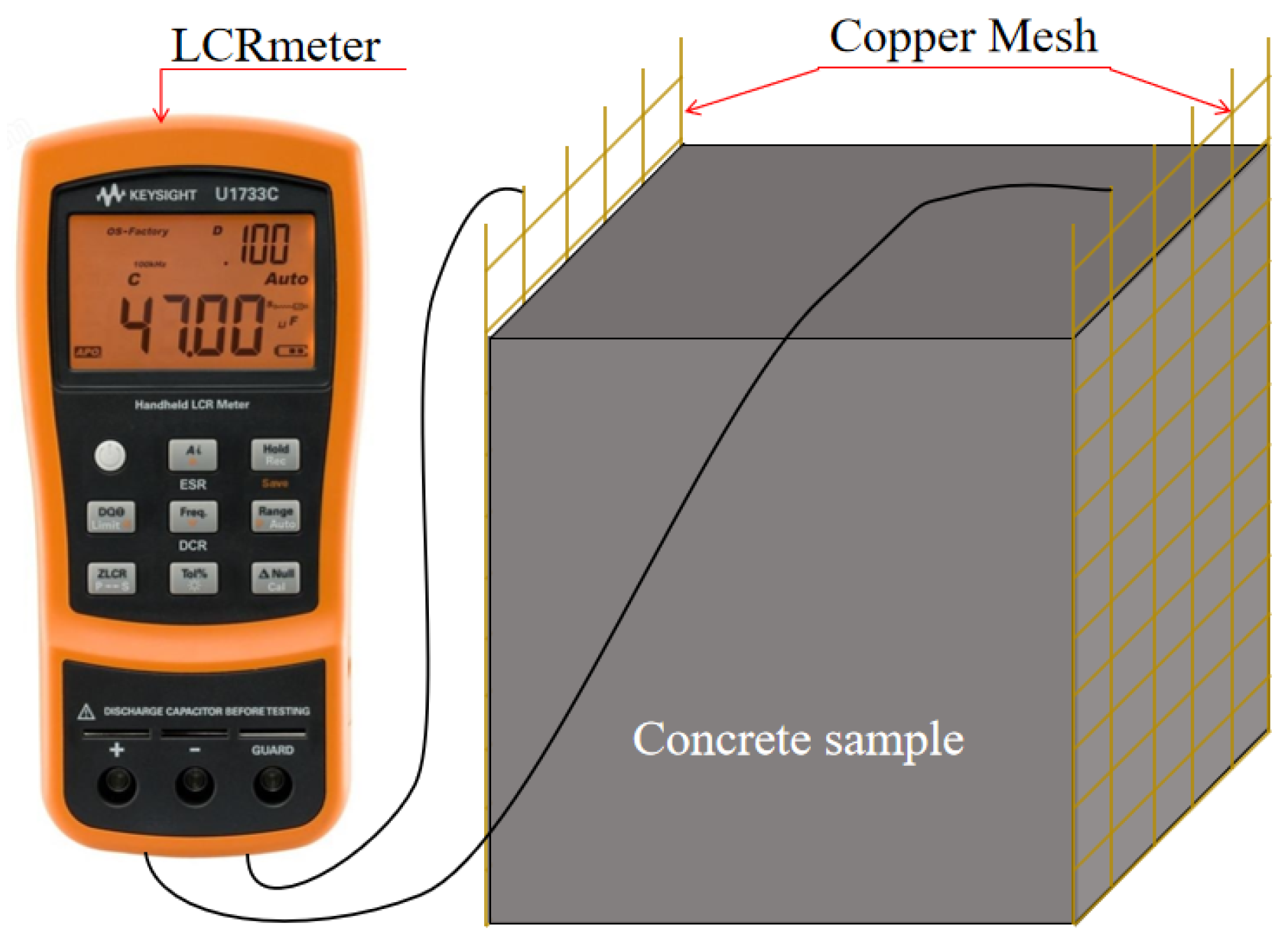

2.2.4. Electrical Resistivity Test

3. Results and Discussion

3.1. Compressive Strength

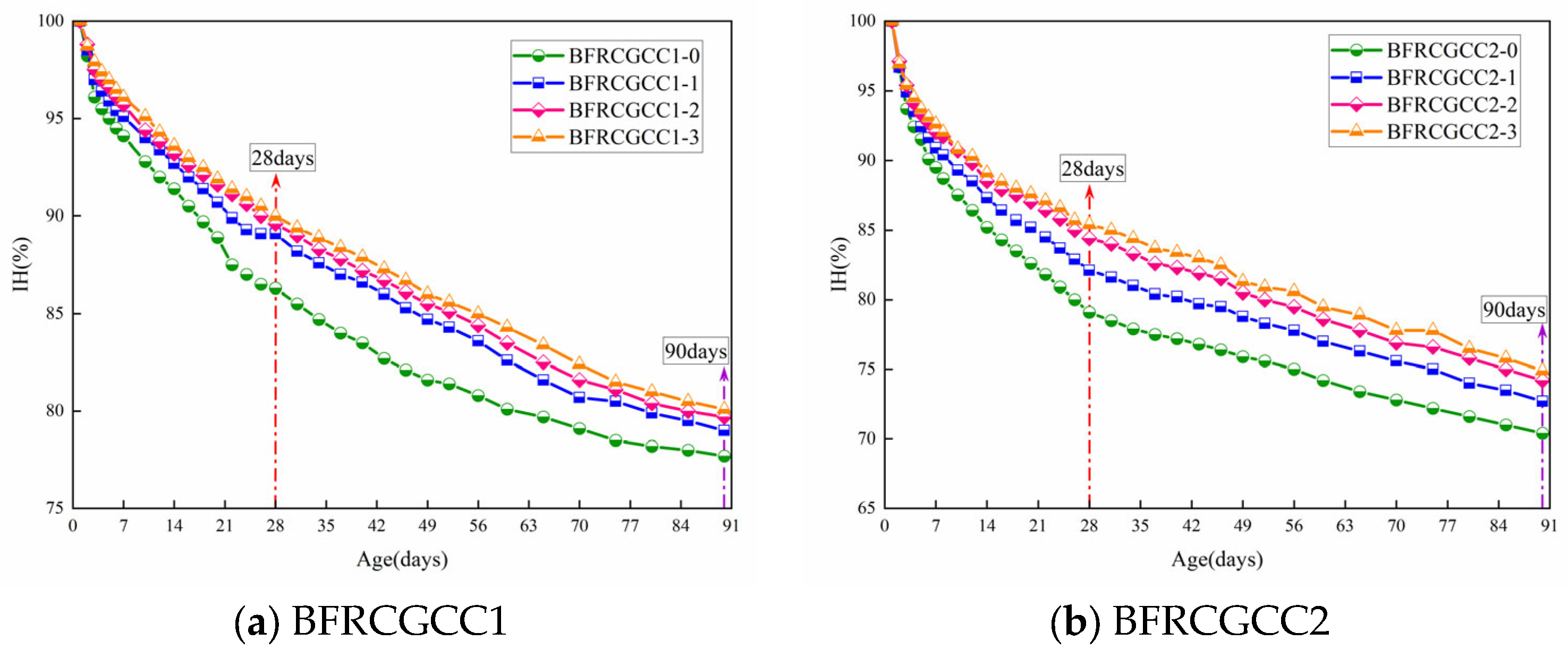

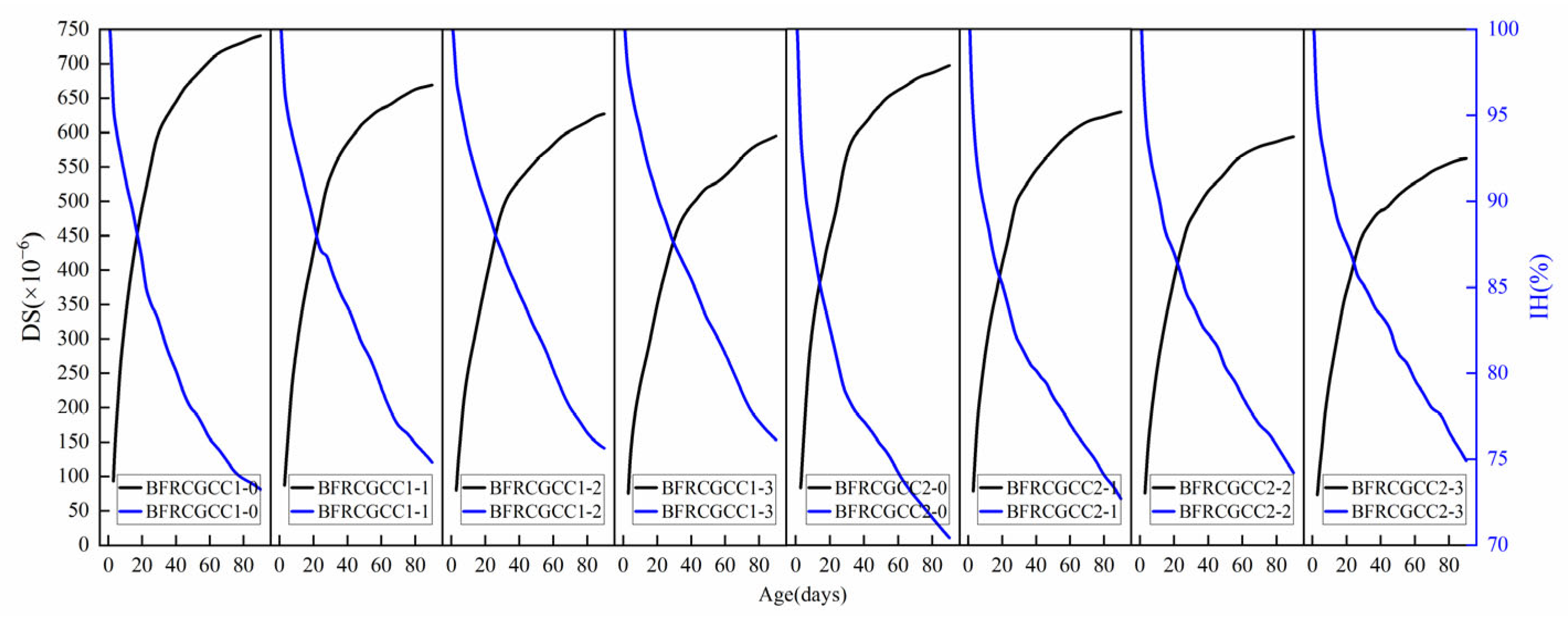

3.2. Internal Humidity

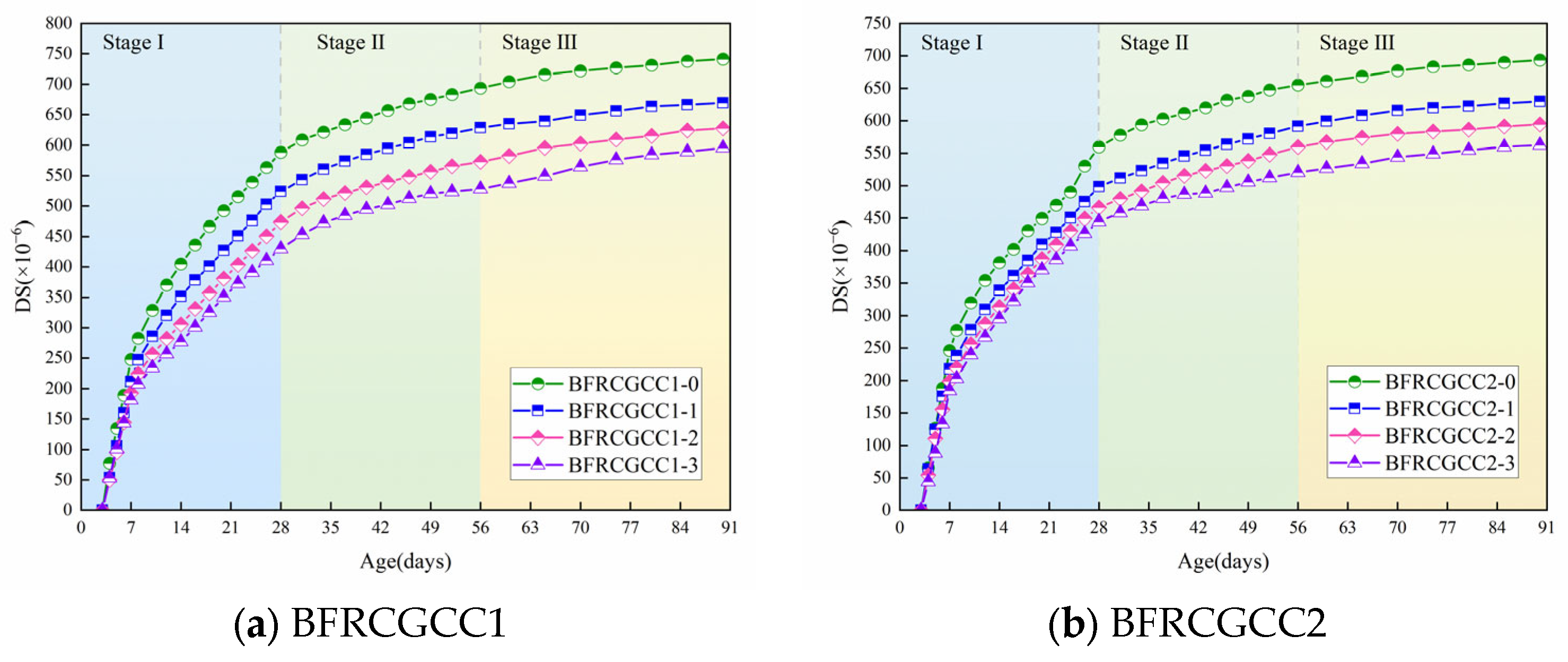

3.3. Drying Shrinkage

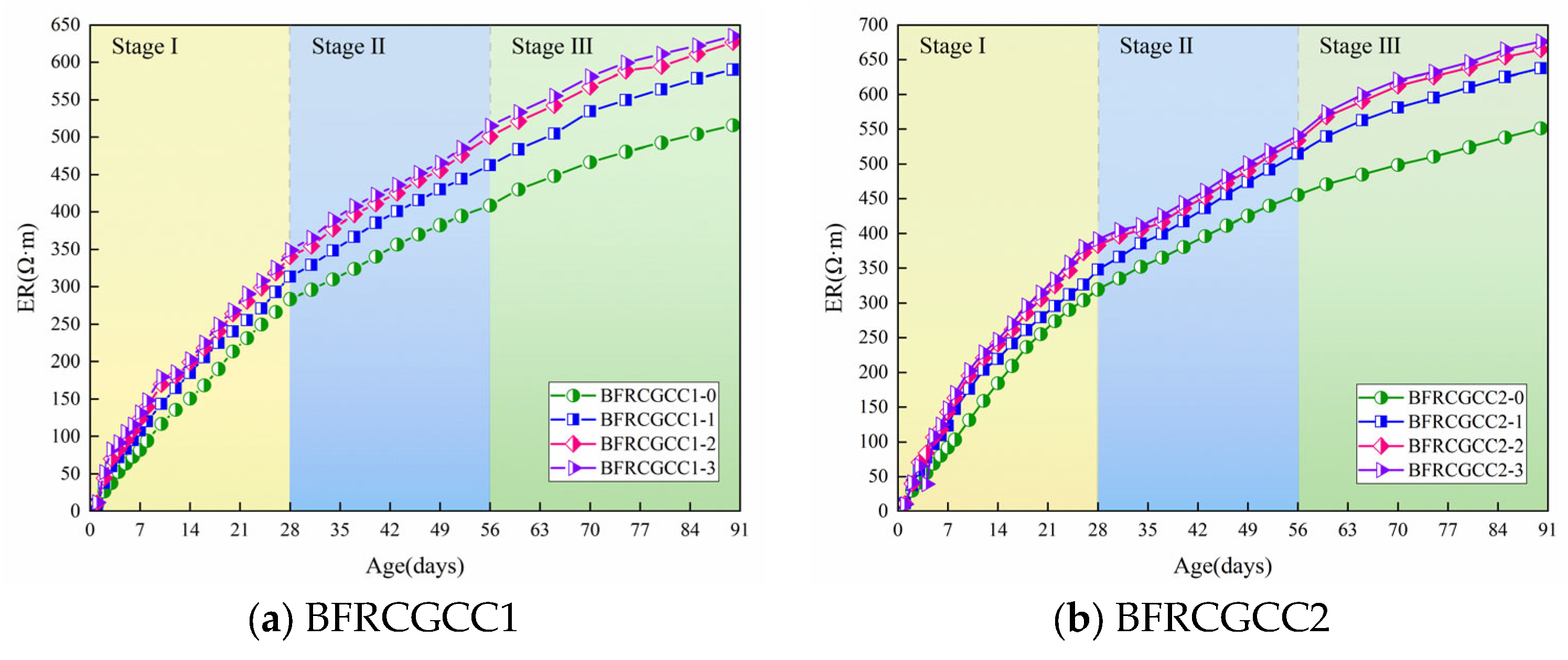

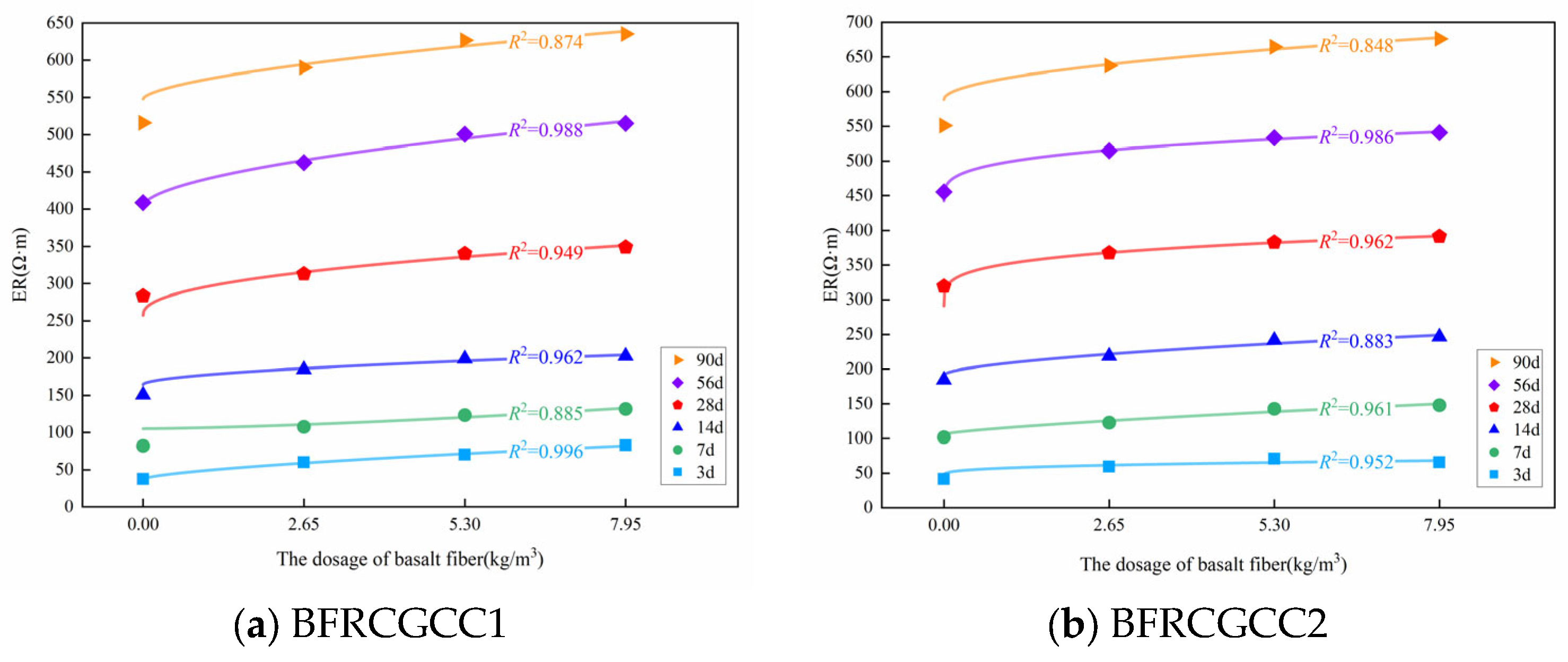

3.4. Electrical Resistivity

4. Prediction Models

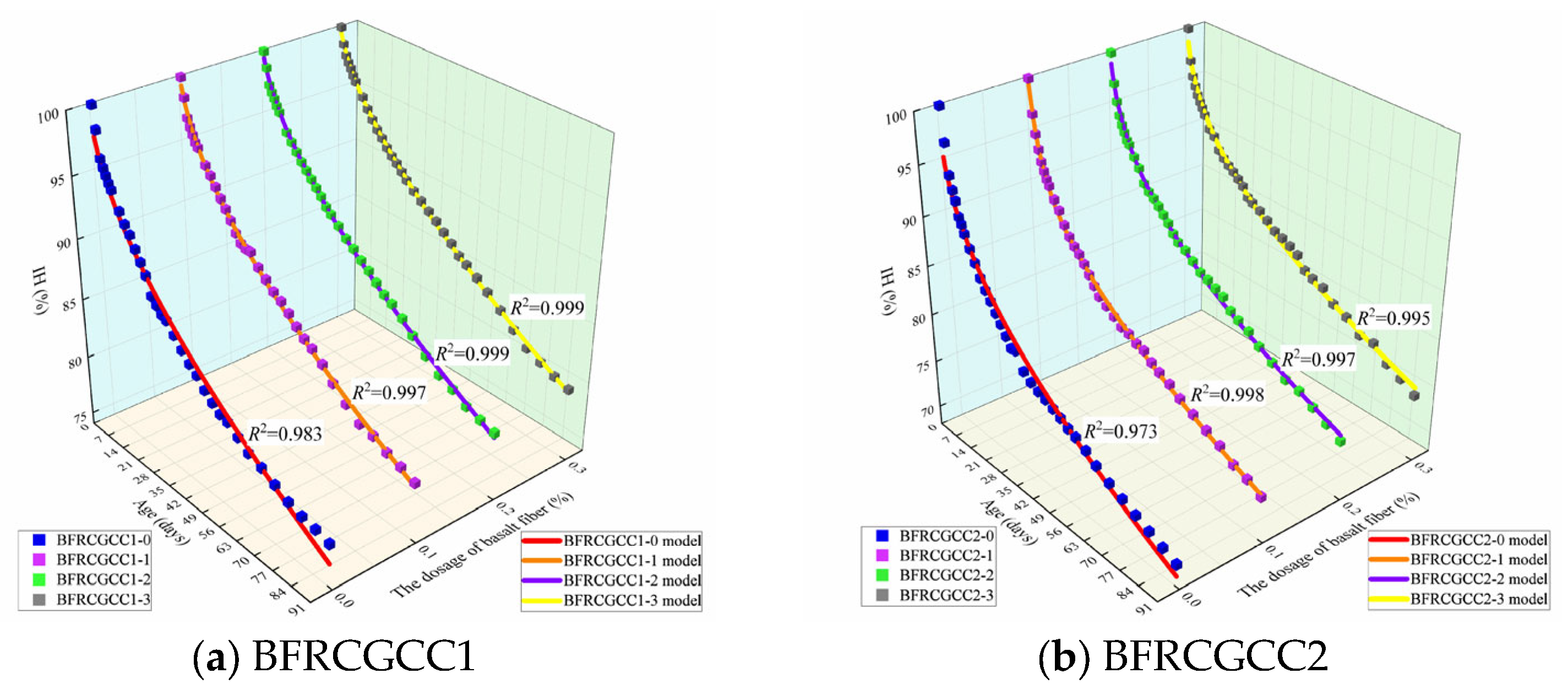

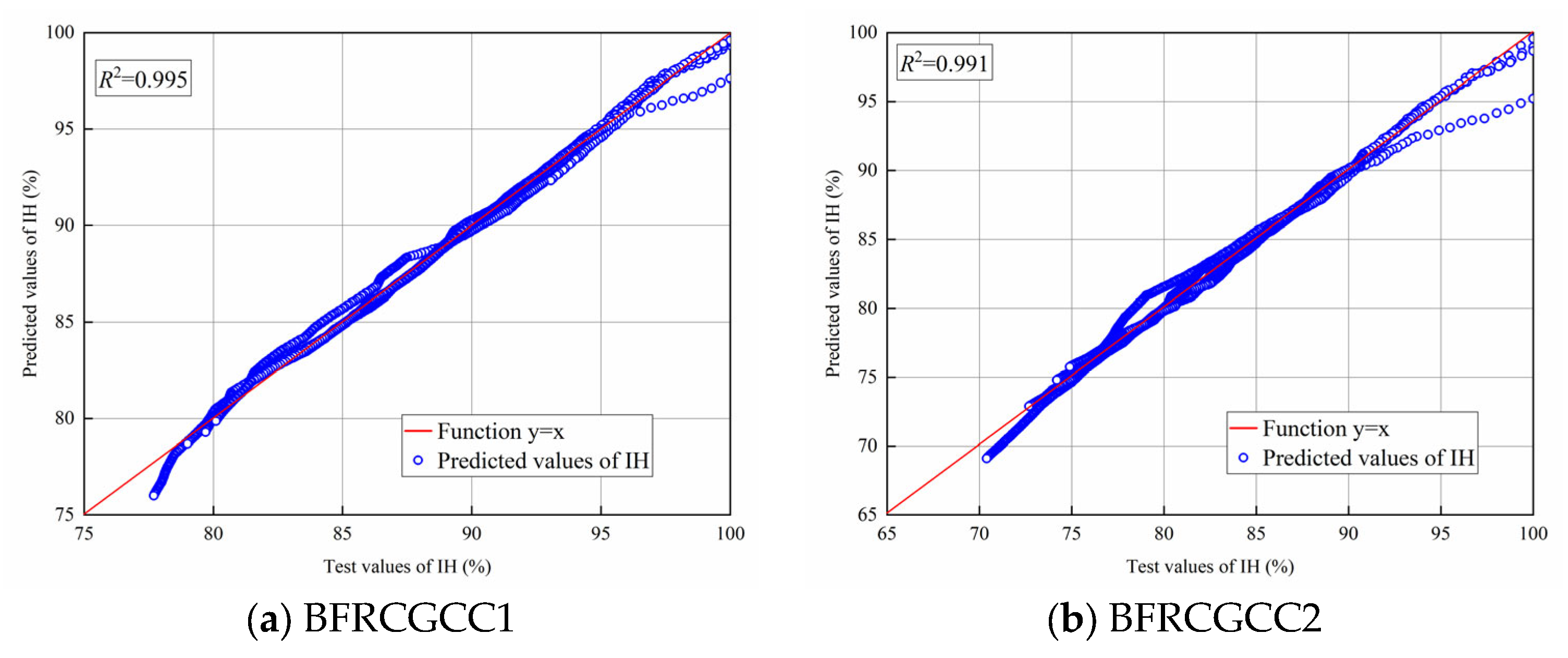

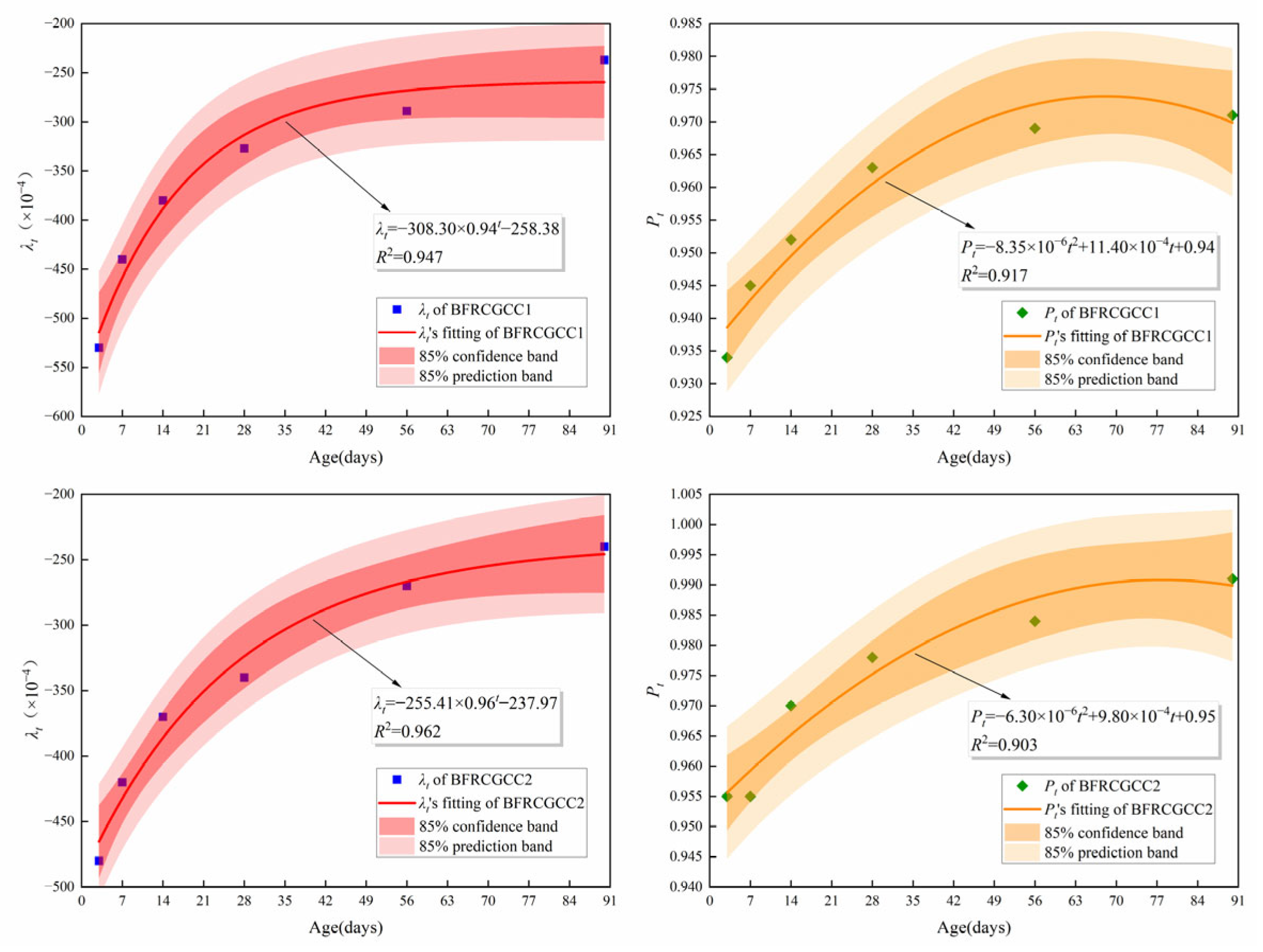

4.1. Prediction Model for Internal Humidity

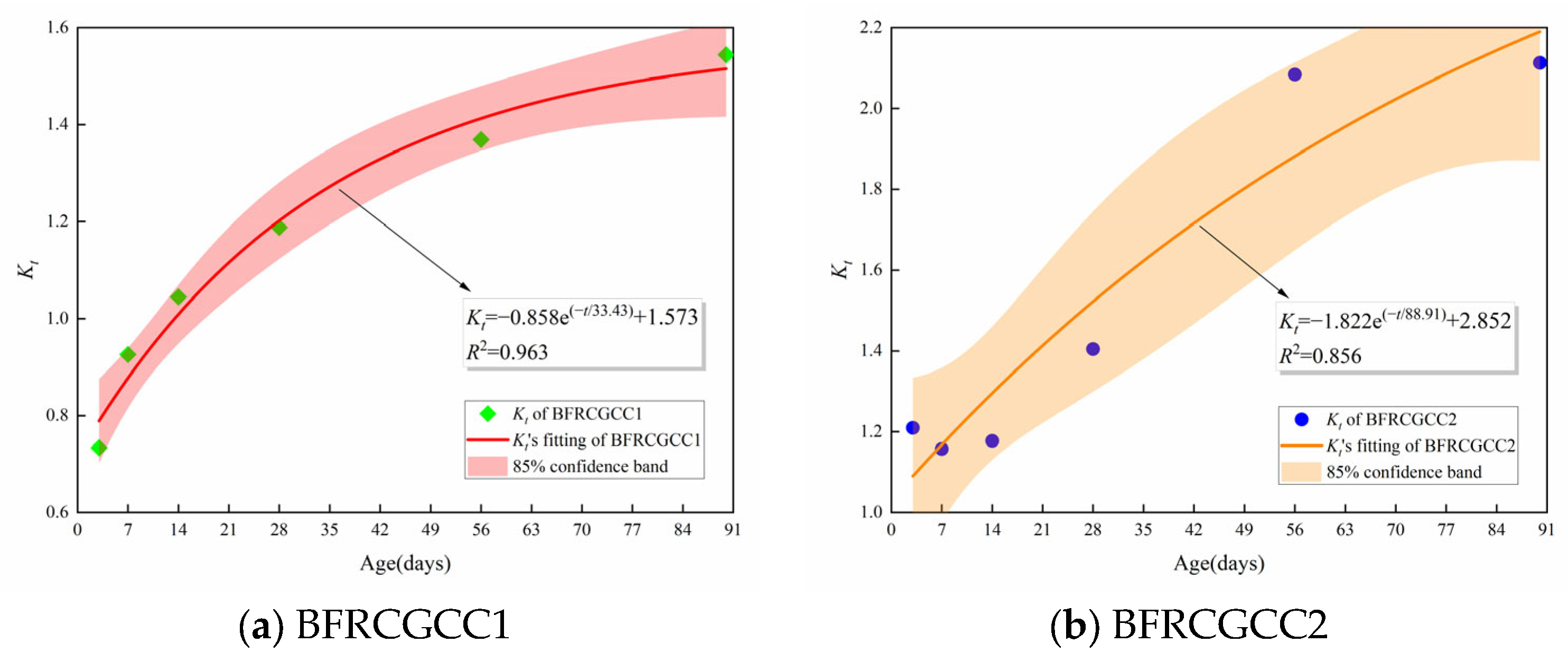

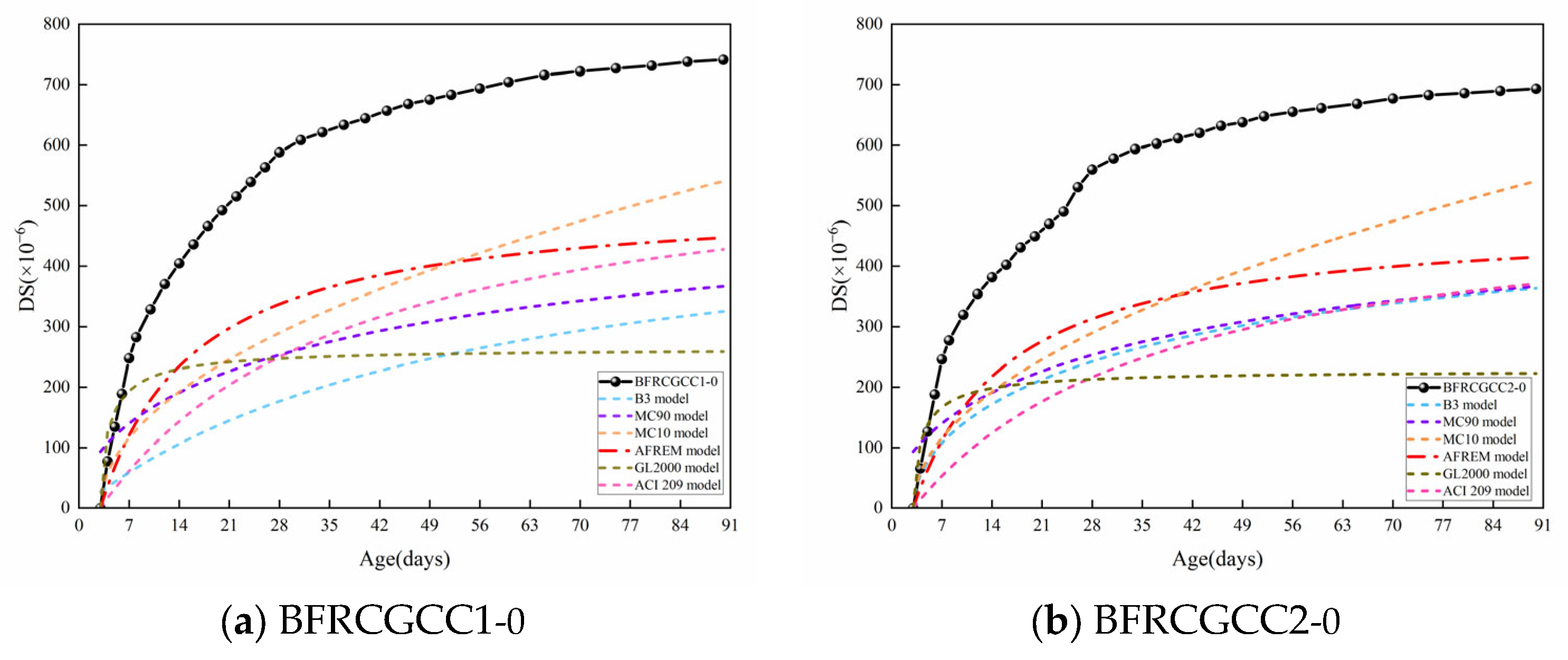

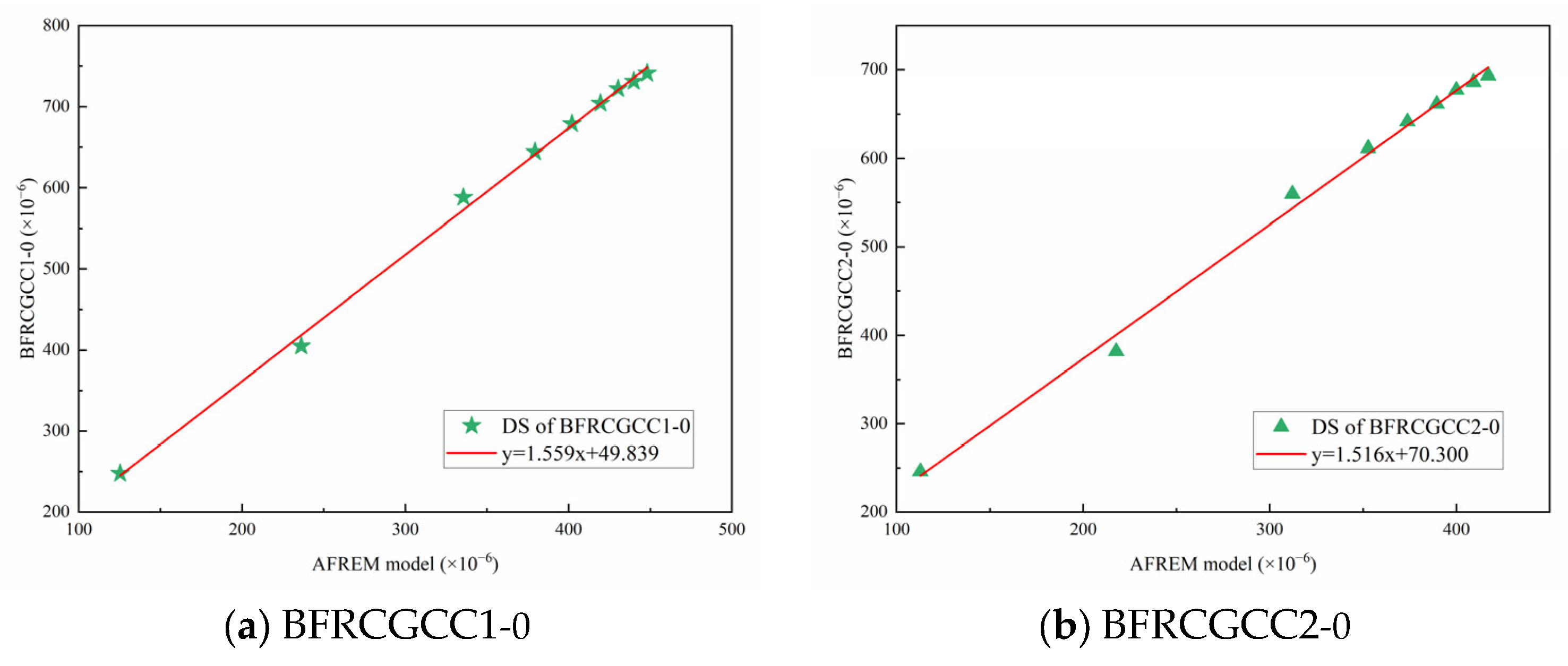

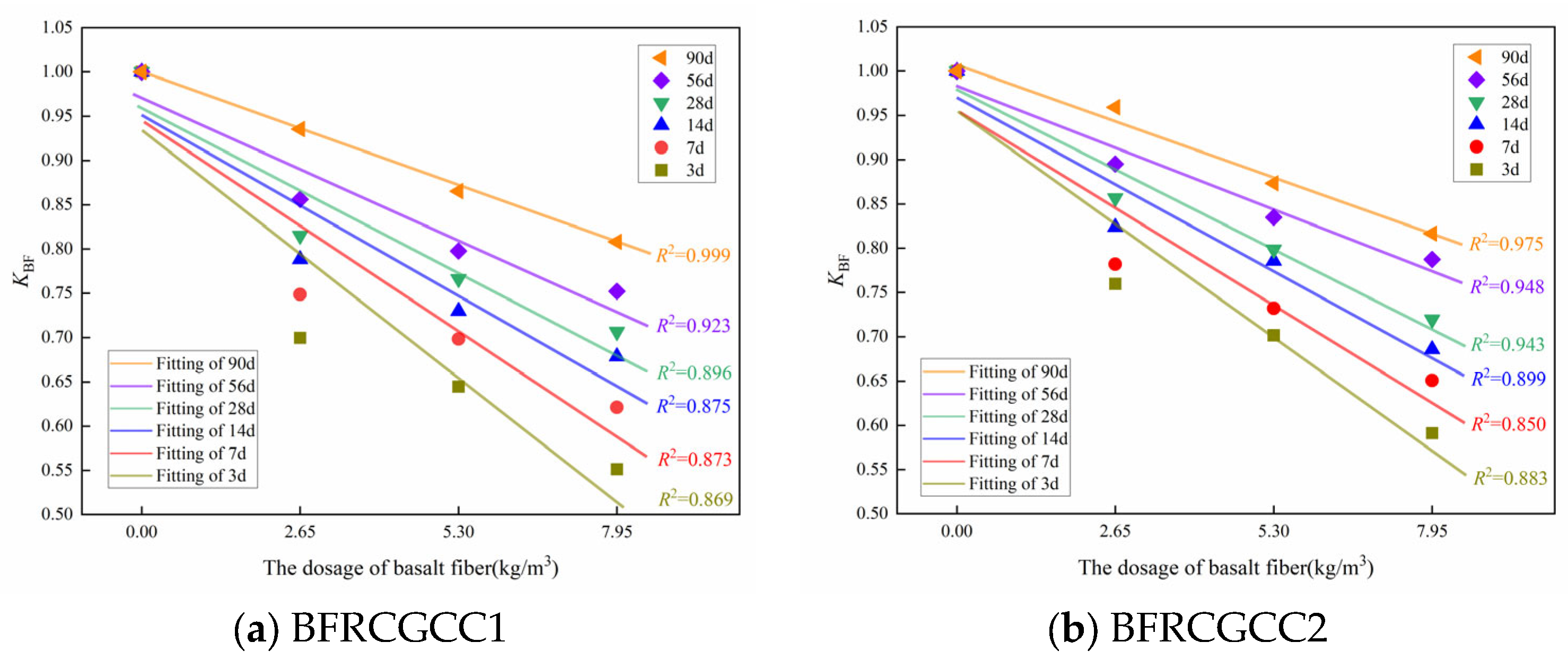

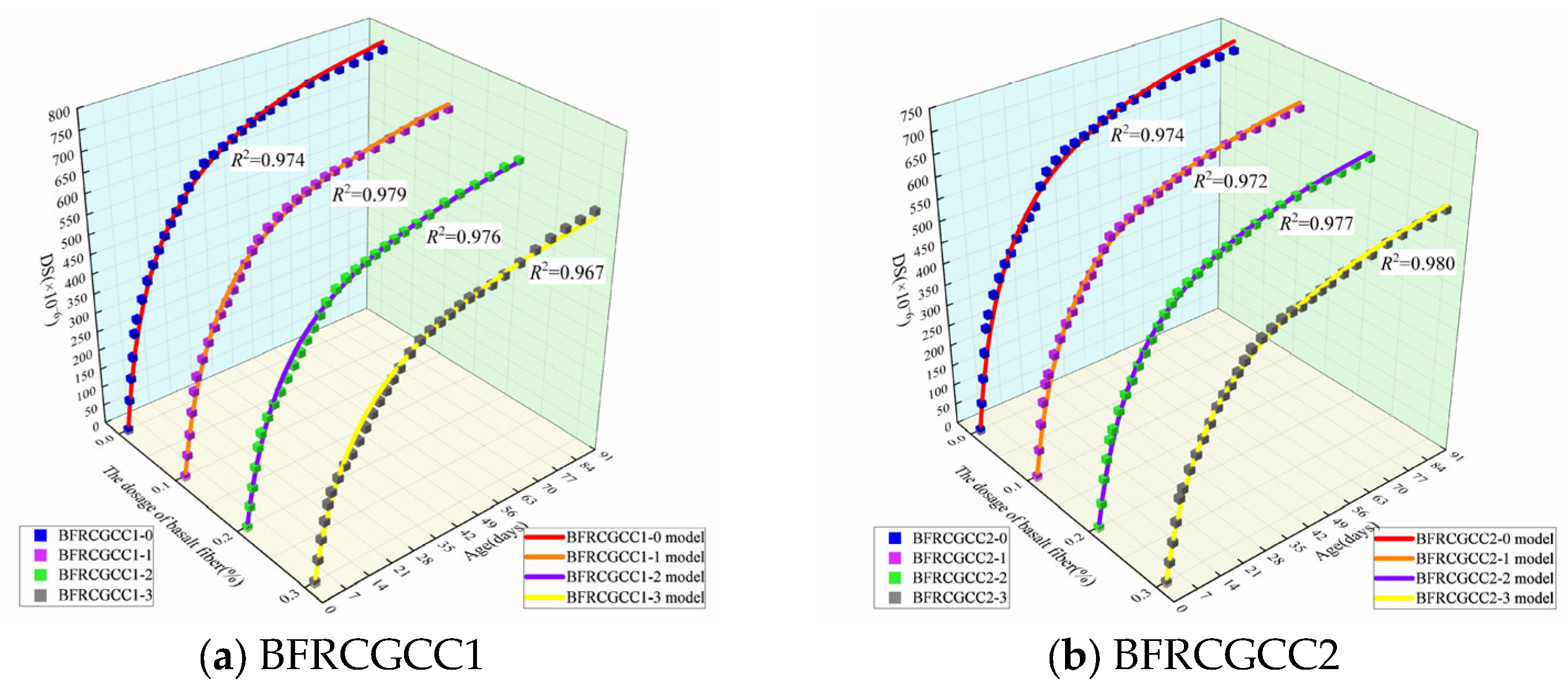

4.2. Prediction Model for Drying Shrinkage

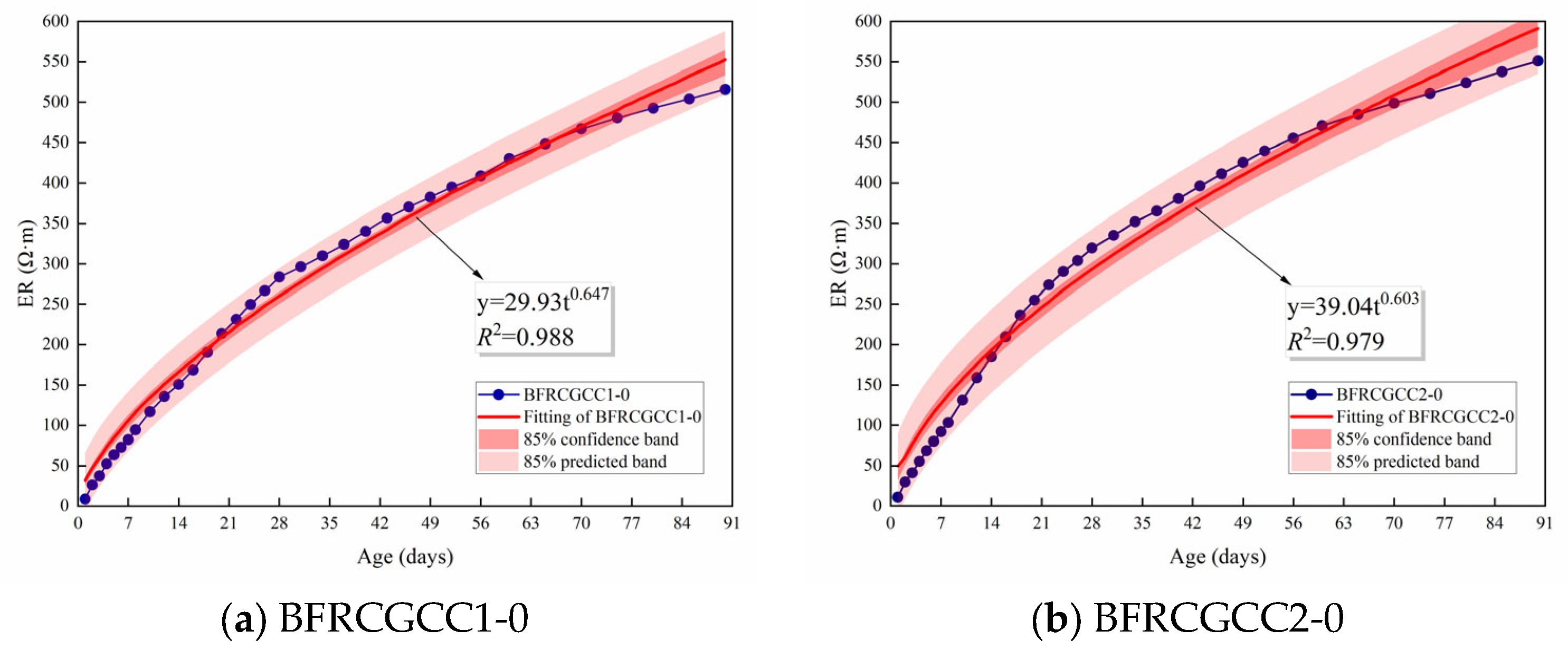

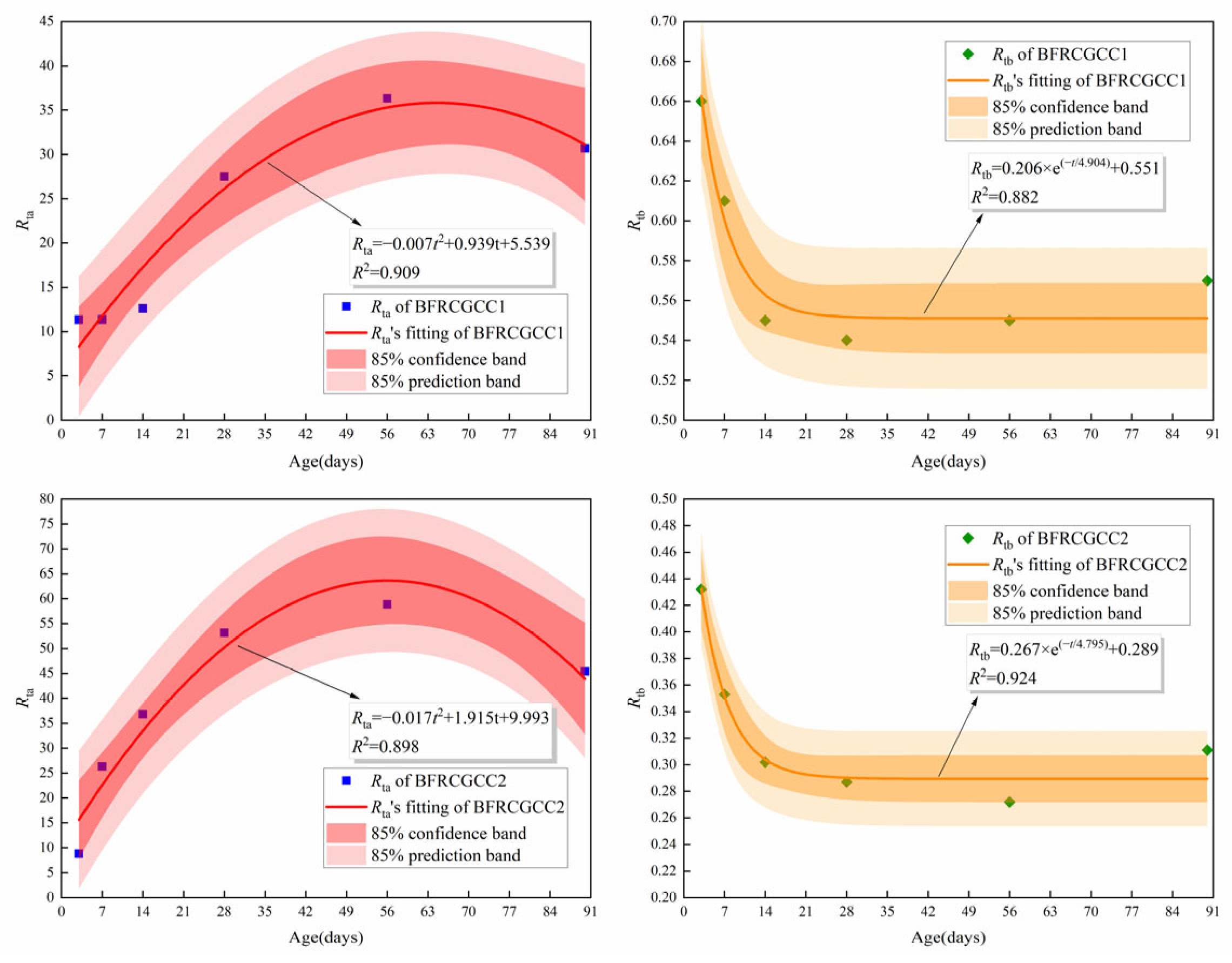

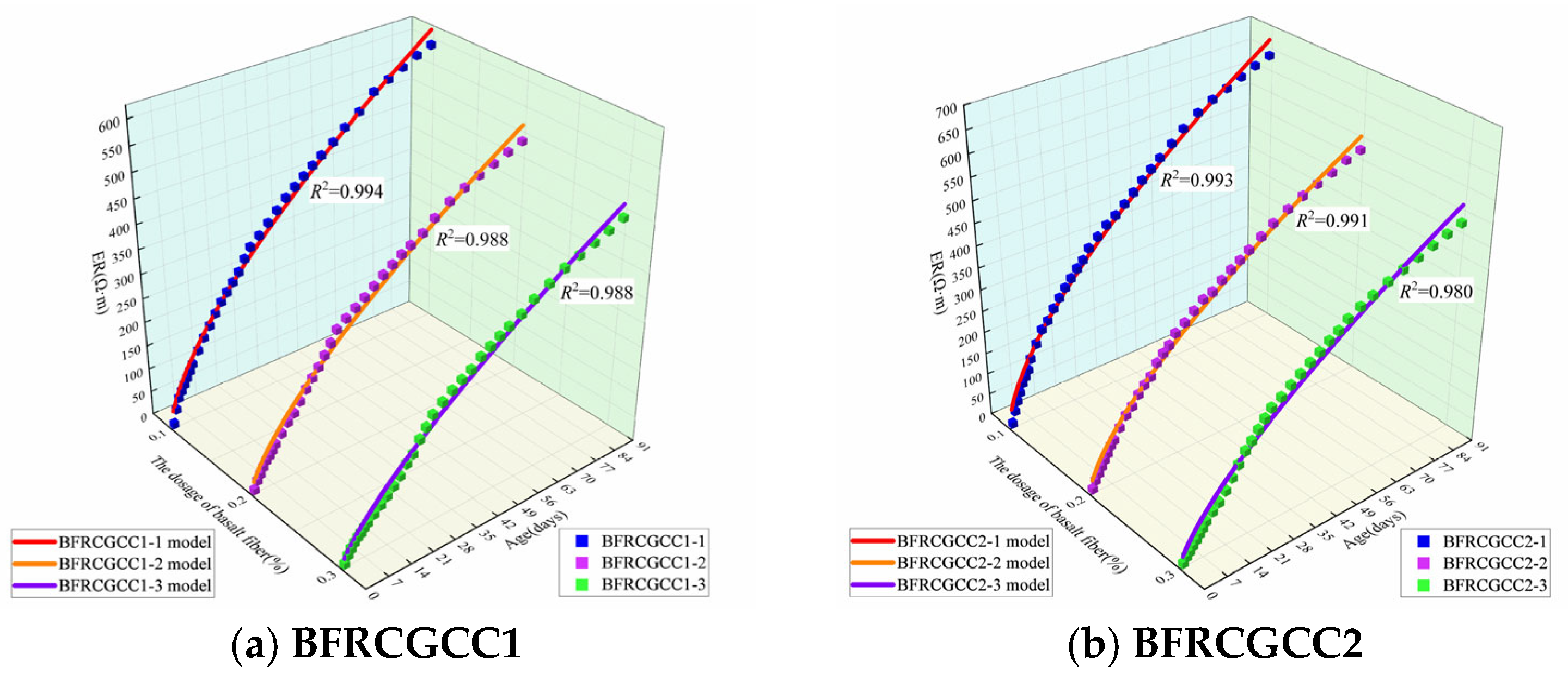

4.3. Prediction Model for Electrical Resistivity

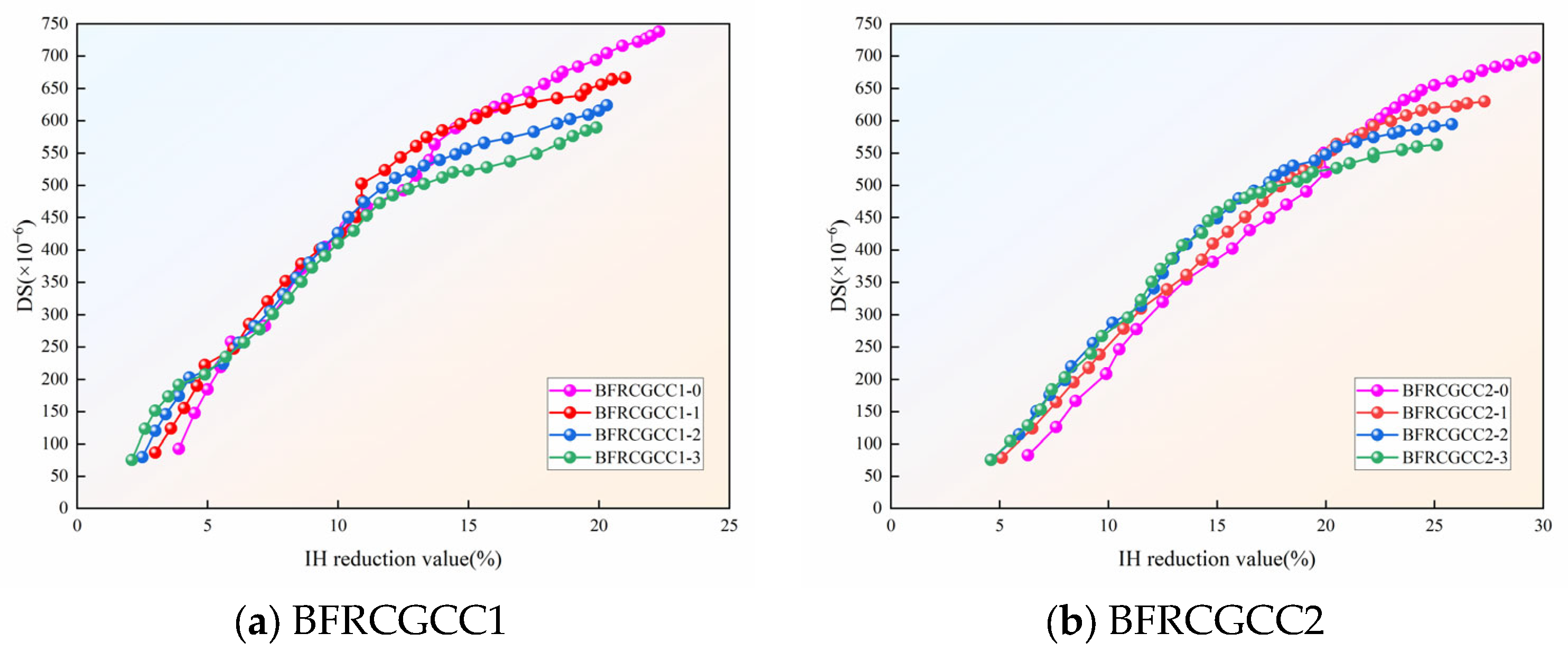

4.4. Relationship Between the IH and DS

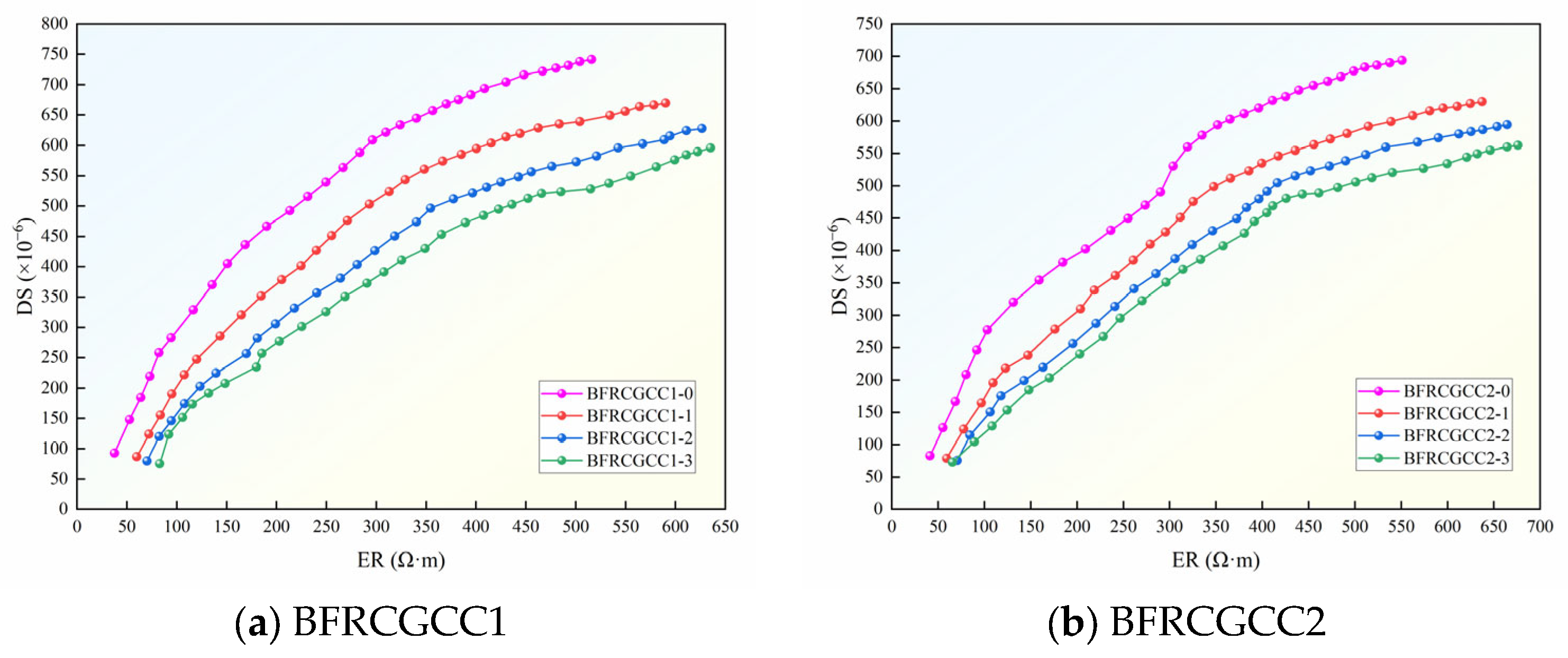

4.5. Relationship Between the ER and DS

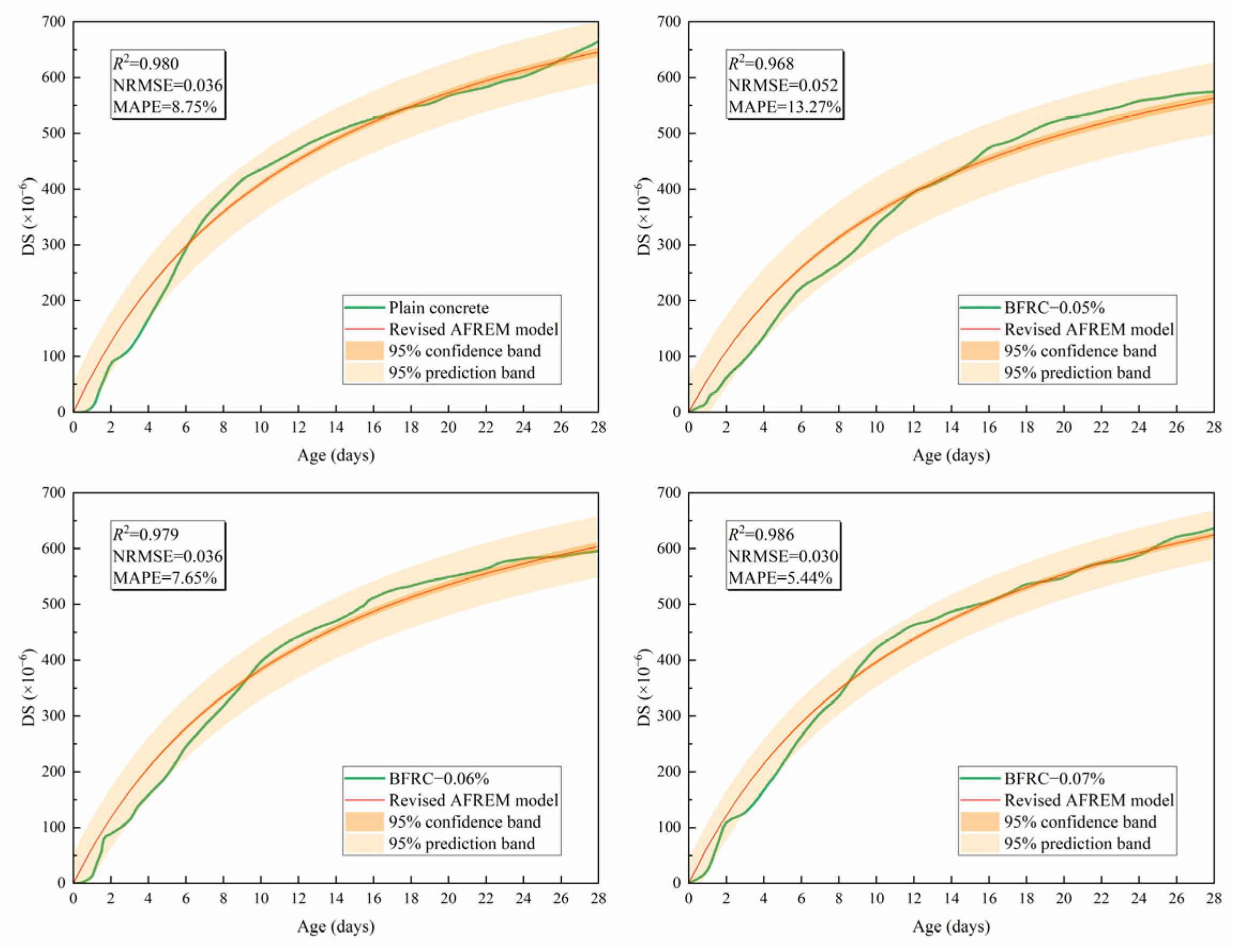

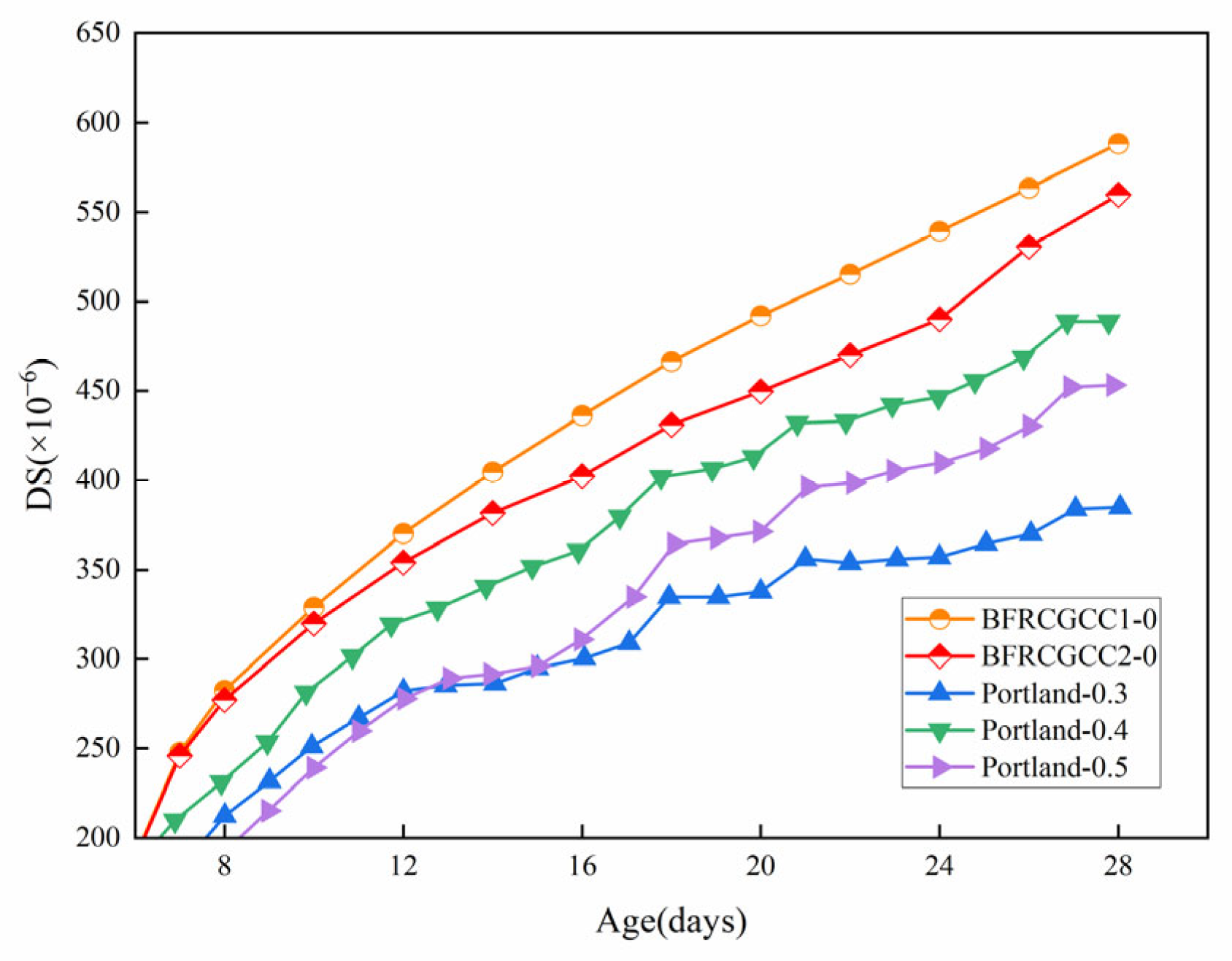

4.6. Comparison of Measured Values with Those of Portland Cement Concrete

5. Conclusions

- The addition of basalt fiber affects the internal humidity and electrical resistivity of CGCC; both the internal humidity and the electrical resistivity increased with the increment of fiber dosage.

- CGCC exhibits rapid drying shrinkage development during the initial stage, followed by progressive stabilization in the subsequent stage. It was found that a basalt fiber dosage of 0.3% was optimal, reducing the 90 d drying shrinkage by 20.67%.

- Variations in the internal humidity and electrical resistivity of the concrete serve as indicators for the drying shrinkage of the matrix. The internal humidity and the electrical resistivity may be introduced to verify the drying shrinkage of BFRCGCC.

- The improved AFREM model’s predicted values of drying shrinkage are consistent with the test values, providing an effective tool for predicting drying shrinkage of the BFRCGCC. The findings can serve as a theoretical basis for shrinkage control and structural design of CGCC, offering significant technical guidance for engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karimaei, M.; Dabbaghi, F.; Sadeghi-Nik, A.; Dehestani, M. Mechanical performance of green concrete produced with un-treated coal waste aggregates. Constr. Build. Mater. 2020, 233, 117264. [Google Scholar] [CrossRef]

- Liu, M.; Yao, P.; Zhao, Z.-W.; Li, D.; Wang, J.-L. Experimental and numerical studies on mechanical behavior of coal gangue concrete filled round-ended steel tube stub columns under double local compression. Structures 2025, 74, 108640. [Google Scholar] [CrossRef]

- Ashfaq, M.; Heeralal, M.; Moghal, A.A.B. Characterization studies on coal gangue for sustainable geotechnics. Innov. Infrastruct. Solutions 2020, 5, 15. [Google Scholar] [CrossRef]

- Querol, X.; Izquierdo, M.; Monfort, E.; Alvarez, E.; Font, O.; Moreno, T.; Alastuey, A.; Zhuang, X.; Lu, W.; Wang, Y. Environmental characterization of burnt coal gangue banks at Yangquan, Shanxi Province, China. Int. J. Coal Geol. 2008, 75, 93–104. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of coal gangue as coarse aggregates in structural concrete. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- He, Y.; Li, G.; Li, H.; Lü, L.; He, L. Ceramsite containing iron oxide and its use as functional aggregate in microwave absorbing cement-based materials. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 133–138. [Google Scholar] [CrossRef]

- Ghone, M.O.; Long, G.; Yang, K.; Ma, X.; Islam, N. Toughness improvement of low strength ceramsite lightweight concrete by polypropylene fiber and recycled rubber particle. Constr. Build. Mater. 2024, 422, 135716. [Google Scholar] [CrossRef]

- Ma, S.; Tan, S.; Pan, Y.; Gu, Y. Experimental study on fiber-reinforced ceramsite concrete composite wall panel and correction of seismic damage model. Structures 2024, 59, 105805. [Google Scholar] [CrossRef]

- Pettmann, M.; Beaucour, A.-L.; Eslami, J.; Tysmans, T.; Aggelis, D.G.; Noumowe, A. A comprehensive study of damage mechanisms in very lightweight aggregates concretes submitted to high temperatures. Constr. Build. Mater. 2023, 404, 133251. [Google Scholar] [CrossRef]

- Palamarchuk, A.; Yudaev, P.; Chistyakov, E. Polymer Concretes Based on Various Resins: Modern Research and Modeling of Mechanical Properties. J. Compos. Sci. 2024, 8, 503. [Google Scholar] [CrossRef]

- Li, M.; Wang, Y.; Ren, J.; Zhao, H.; Zhuang, S.; Wang, J. Evaluation and prediction of fatigue life for ceramsite lightweight concrete considering the effects of ceramsite aggregate size and content. Case Stud. Constr. Mater. 2024, 21, e03613. [Google Scholar] [CrossRef]

- Ma, H.; Zhu, H.; Wu, C.; Fan, J.; Yang, S.; Hang, Z. Effect of shrinkage reducing admixture on drying shrinkage and durability of alkali-activated coal gangue-slag material. Constr. Build. Mater. 2021, 270, 121372. [Google Scholar] [CrossRef]

- Zhang, J.; Victor, C.L. Influences of Fibers on Drying Shrinkage of Fiber-Reinforced Cementitious Composite. J. Eng. Mech. 2001, 127, 37–44. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Teng, S. Experiments on drying shrinkage and creep of high performance hybrid-fiber-reinforced concrete. Cem. Concr. Compos. 2020, 106, 103481. [Google Scholar] [CrossRef]

- Yousefieh, N.; Joshaghani, A.; Hajibandeh, E.; Shekarchi, M. Influence of fibers on drying shrinkage in restrained concrete. Constr. Build. Mater. 2017, 148, 833–845. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Elshazli, M.T.; Ramirez, K.; Ibrahim, A.; Badran, M. Mechanical, Durability and Corrosion Properties of Basalt Fiber Concrete. Fibers 2022, 10, 10. [Google Scholar] [CrossRef]

- Ramesh, B.; Eswari, S. Mechanical behaviour of basalt fibre reinforced concrete: An experimental study. Mater. Today Proc. 2021, 43, 2317–2322. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Ministry of Housing and Urban Rural Development of the People’s Republic of China. Standard for Test Methods of Concrete Physical and Mechanical Properties. China State Engineering and Construction Press: Beijing, China, 2019. (In Chinese)

- ISO 1920-4:2005; Testing of Concrete—Part 4: Strength of Hardened Concrete. ISO: Geneva, Switzerland, 2005.

- EN 12390-1:2012; Testing Hardened Concrete—Part 1: Shape, Dimensions and other Requirements for Specimens and Moulds. CEN: Brussels, Belgium, 2012.

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. CEN: Brussels, Belgium, 2019.

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. CEN: Brussels, Belgium, 2019.

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. CEN: Brussels, Belgium, 2019.

- EN 13578:2003; Testing of Concrete in Structures-Determination of Moisture Condition. CEN: Brussels, Belgium, 2003.

- Shen, D.; Liu, C.; Wang, M.; Jin, X.; Tang, H. Prediction model for internal relative humidity in early-age concrete under different curing humidity conditions. Constr. Build. Mater. 2020, 265, 119987. [Google Scholar] [CrossRef]

- Shen, D.; Wang, T.; Chen, Y.; Wang, M.; Jiang, G. Effect of internal curing with super absorbent polymers on the relative humidity of early-age concrete. Constr. Build. Mater. 2015, 99, 246–253. [Google Scholar] [CrossRef]

- Jiayu, H.; Yuanzhen, L.; Zhaoxu, W.; Xiaowei, D. Prediction model of internal humidity and drying shrinkage of recycled aggregate thermal insulation concrete. Acta Mater. Compos. Sin. 2022, 39, 4788–4800. (In Chinese) [Google Scholar]

- Chindaprasirt, P.; Rukzon, S.; Sirivivatnanon, V. Effect of carbon dioxide on chloride penetration and chloride ion diffusion coefficient of blended Portland cement mortar. Constr. Build. Mater. 2008, 22, 1701–1707. [Google Scholar] [CrossRef]

- Jin, M.; Jiang, L.; Zhu, Q. Monitoring chloride ion penetration in concrete with different mineral admixtures based on embedded chloride ion selective electrodes. Constr. Build. Mater. 2017, 143, 1–15. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.; Wang, P. Internal relative humidity distribution in high-performance cement paste due to moisture diffusion and self-desiccation. Cem. Concr. Res. 2006, 36, 320–325. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, X.; Zhang, J.; Wang, Y. Internal relative humidity distribution in concrete considering self-desiccation at early ages. Int. J. Phys. Sci. 2011, 6, 1604–1610. [Google Scholar]

- GB/T 50082-2024; Ministry of Housing and Urban Rural Development of the People’s Republic of China. Standard for Test Methods of Long-Term Performance and Durability of Concrete. China State Engineering and Construction Press: Beijing, China, 2024. (In Chinese)

- EN 12390-16:2019; Testing Hardened Concrete—Part 16: Determination of the Shrinkage of Concrete. CEN: Brussels, Belgium, 2019.

- Chu, H.-Y.; Chen, J.-K. The experimental study on the correlation of resistivity and damage for conductive concrete. Cem. Concr. Compos. 2016, 67, 12–19. [Google Scholar] [CrossRef]

- Han, B.; Guan, X.; Ou, J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors. Sensors Actuators A Phys. 2007, 135, 360–369. [Google Scholar] [CrossRef]

- Niu, D.; Su, L.; Luo, Y.; Huang, D.; Luo, D. Experimental study on mechanical properties and durability of basalt fiber reinforced coral aggregate concrete. Constr. Build. Mater. 2020, 237, 117628. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Ding, Y.; Zhang, Y.; Thomas, A. The investigation on strength and flexural toughness of fibre cocktail reinforced self-compacting high performance concrete. Constr. Build. Mater. 2009, 23, 448–452. [Google Scholar] [CrossRef]

- Naaman, A.E. Fiber Reinforced Cement and Concrete Composites; Techno Press: Sarasota, FL, USA, 2018. [Google Scholar]

- Li, J.; Zha, W.; Lv, W.; Xu, T.; Wang, B.; Wang, B. Mechanical properties and sulfate resistance of basalt fiber-reinforced alkali-activated fly ash-slag-based coal gangue pervious concrete. Case Stud. Constr. Mater. 2024, 21, e03961. [Google Scholar] [CrossRef]

- Plagué, T.; Desmettre, C.; Charron, J.-P. Influence of fiber type and fiber orientation on cracking and permeability of reinforced concrete under tensile loading. Cem. Concr. Res. 2017, 94, 59–70. [Google Scholar] [CrossRef]

- Hsie, M.; Tu, C.; Song, P. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater. Sci. Eng. A 2008, 494, 153–157. [Google Scholar] [CrossRef]

- Wu, D.; Cai, S.-J. Coupled effect of cement hydration and temperature on hydraulic behavior of cemented tailings backfill. J. Central South Univ. 2015, 22, 1956–1964. [Google Scholar] [CrossRef]

- Shen, D.; Wang, M.; Chen, Y.; Wang, T.; Zhang, J. Prediction model for relative humidity of early-age internally cured concrete with pre-wetted lightweight aggregates. Constr. Build. Mater. 2017, 144, 717–727. [Google Scholar] [CrossRef]

- Li, Z.; Lara, M.A.P.; Bolander, J. Restraining effects of fibers during non-uniform drying of cement composites. Cem. Concr. Res. 2006, 36, 1643–1652. [Google Scholar] [CrossRef]

- Li, Y.; Shen, A.; Wu, H. Fractal Dimension of Basalt Fiber Reinforced Concrete (BFRC) and Its Correlations to Pore Structure, Strength and Shrinkage. Materials 2020, 13, 3238. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Isomoisio, H.; Karhu, M.; Illikainen, M. Mechanical and acoustic properties of fiber-reinforced alkali-activated slag foam concretes containing lightweight structural aggregates. Constr. Build. Mater. 2018, 187, 371–381. [Google Scholar] [CrossRef]

- Deng, G.; Guo, R.; Ma, L.; Long, Z.; Xu, F.; Yin, C.; Xu, X. Study on dynamic mechanical properties and microstructure of basalt fiber reinforced coral sand cement composite. Constr. Build. Mater. 2024, 425, 136024. [Google Scholar] [CrossRef]

- Yang, W.; Tang, Z.; Wu, W.; Zhang, K.; Yuan, J.; Li, H.; Feng, Z. Effect of different fibers on impermeability of steam cured recycled concrete. Constr. Build. Mater. 2022, 328, 127063. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; He, Y.; Huang, G.; Li, J.; Niu, Z.; Gao, B. A review on durability of basalt fiber reinforced concrete. Compos. Sci. Technol. 2022, 225, 109519. [Google Scholar] [CrossRef]

- Liao, Y.; Wei, X.; Li, G. Early hydration of calcium sulfoaluminate cement through electrical resistivity measurement and microstructure investigations. Constr. Build. Mater. 2011, 25, 1572–1579. [Google Scholar] [CrossRef]

- Xiao, L.; Li, Z. Early-age hydration of fresh concrete monitored by non-contact electrical resistivity measurement. Cem. Concr. Res. 2008, 38, 312–319. [Google Scholar] [CrossRef]

- Lee, N.K.; Tafesse, M.; Lee, H.K.; Alemu, A.S.; Kim, S.W.; Kim, H.-K. Electrical resistivity stability of CNT/cement composites after further hydration: A simple evaluation with an accelerated method. Constr. Build. Mater. 2022, 317, 125830. [Google Scholar] [CrossRef]

- Peng, Y.; Gong, F.; Wang, Z.; Zhao, Y.; Jin, W.; Meng, T.; Maekawa, K. Experimental study on time-dependent DC resistivity of cement-based material considering microstructure and ion concentration. Constr. Build. Mater. 2022, 363, 129830. [Google Scholar] [CrossRef]

- Yousuf, F.; Xiaosheng, W. Early strength development and hydration of cement pastes at different temperatures or with superplasticiser characterised by electrical resistivity. Case Stud. Constr. Mater. 2022, 16, e00911. [Google Scholar] [CrossRef]

- Su, J.; Yang, C.; Wu, W.; Huang, R. Effect of moisture content on concrete resistivity measurement. J. Chin. Inst. Eng. 2002, 25, 117–122. [Google Scholar] [CrossRef]

- Sun, Z.; Niu, D.; Zhang, L.; Zhang, J. Resistivity model of basalt-polypropylene fiber reinforced concrete. J. Funct. Mater. 2021, 52, 12190–12195. (In Chinese) [Google Scholar] [CrossRef]

- Bazant, Z.P.; Baweja, S. Creep and Shrinkage Prediction Model for Analysis and Design of Concrete Structures: Model B3-Short Form. SP-194: The Adam Neville Symposium: Creep and Shrinkage-Structural Design Effects. ACI Spec. Publ. 2000, 194, 85–100. [Google Scholar]

- Gardner, N.J.; Lockman, M. Design provisions for drying shrinkage and creep of normal-strength concrete. Mater. J. 2001, 98, 159–167. [Google Scholar]

- Comite Euro-International du Beton. CEB-FIP Model Code 1990. Bull. D’Information 1993, 42, 43–50. [Google Scholar]

- Walraven, J.C.; Bigaj-van Vliet, A. The 2010 fib Model Code for Structural Concrete: A new approach to structural engineering. Struct. Concr. 2011, 12, 139–147. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, J.; Tang, Y.; Duan, Z.; Poon, C.-S. Long-term shrinkage and mechanical properties of fully recycled aggregate concrete: Testing and modelling. Cem. Concr. Compos. 2022, 130, 104527. [Google Scholar] [CrossRef]

- Bryant, A.H.; Vadhanavikkit, C. Creep, shrinkage-size, and age at loading effects. Mater. J. 1987, 84, 117–123. [Google Scholar]

- Leroy, R. The AFREM code type model for creep and shrinkag of high-performance concrete. In Proceedings of the 4th International Symposium on Utilization of High-Strength/High-Performance Concrete, Paris, France, 29–31 May 1996; pp. 387–389. [Google Scholar]

- Huang, Y.; Fu, J.; Wang, R.; Rao, R.; Ma, N. Experimental study on creep behavior of high-strength concrete filled steel tubular (HSCFST) columns. Case Stud. Constr. Mater. 2023, 20, e02690. [Google Scholar] [CrossRef]

- Wang, Y.; Geng, Y.; Ranzi, G.; Zhang, S. Time-dependent behaviour of expansive concrete-filled steel tubular columns. J. Constr. Steel Res. 2011, 67, 471–483. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, S.; Kim, M.-J. Comparative shrinkage behavior of ultra-high-performance fiber-reinforced concrete under ambient and heat curing conditions. Constr. Build. Mater. 2018, 162, 406–419. [Google Scholar] [CrossRef]

- Lv, Z.; Liu, C.; Zhu, C.; Bai, G.; Qi, H. Experimental Study on a Prediction Model of the Shrinkage and Creep of Recycled Aggregate Concrete. Appl. Sci. 2019, 9, 4322. [Google Scholar] [CrossRef]

- Zhang, J.; Dongwei, H.; Wei, S. Experimental study on the relationship between shrinkage and interior humidity of concrete at early age. Mag. Concr. Res. 2010, 62, 191–199. [Google Scholar] [CrossRef]

- Yang, Y.Z.; Li, M.G.; Deng, H.W.; Liu, Q. Effects of Temperature on Drying Shrinkage of Concrete. Appl. Mech. Mater. 2014, 584–586, 1176–1181. [Google Scholar] [CrossRef]

| Types | Cement | Water | Sand | Coal Gangue Ceramsite | Water Reducer |

|---|---|---|---|---|---|

| CGCC1 | 380 | 152 | 653 | 641 | 3.8 |

| CGCC2 | 450 | 162 | 623 | 658 | 4.5 |

| Type | Density/ (kg/m3) | Specific Surface Area/ (m2/kg) | Particle Size Distribution/μm | Standard Consistency Water Consumption/% | Condensation Time/Min | Compressive Strength/MPa | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | Initial Condensation | Final Condensation | 3 Days | 28 Days | ||||

| P·O42.5 | 3010 | 343 | 2.72 | 16.88 | 57.42 | 26.1 | 181 | 240 | 27.9 | 51.8 |

| Bulk Density/(kg/m3) | Apparent Density/(kg/m3) | Cylinder Compressive Strength/MPa | Mud Content/% | Water Absorption Rate/% |

|---|---|---|---|---|

| 844 | 1321 | 6.2 | <0.1 | 8.4 |

| Length/mm | Diameter/μm | Density/(kg/m3) | Modulus of Elasticity/GPa | Tensile Strength/MPa | Ultimate Elongation/% |

|---|---|---|---|---|---|

| 35 | 7~15 | 2650 | 100 | 4200 | 2~3 |

| Types | Fiber Dosage | |

|---|---|---|

| BFRCGCC1 | BFRCGCC1-0 | 0 |

| BFRCGCC1-1 | 0.1% | |

| BFRCGCC1-2 | 0.2% | |

| BFRCGCC1-3 | 0.3% | |

| BFRCGCC2 | BFRCGCC2-0 | 0 |

| BFRCGCC2-1 | 0.1% | |

| BFRCGCC2-2 | 0.2% | |

| BFRCGCC2-3 | 0.3% | |

| Types | Compressive Strength /MPa | Variation/% | 95% Confidence Interval/MPa |

|---|---|---|---|

| BFRCGCC1-0 | 37.3 | -- | 34.8~37.7 |

| BFRCGCC1-1 | 36.7 | −1.6 | |

| BFRCGCC1-2 | 35.8 | −4.0 | |

| BFRCGCC1-3 | 35.3 | −5.4 | |

| BFRCGCC2-0 | 51.2 | -- | 49.4~51.3 |

| BFRCGCC2-1 | 50.4 | −1.6 | |

| BFRCGCC2-2 | 50.1 | −2.1 | |

| BFRCGCC2-3 | 49.8 | −2.7 |

| Types | a | b | R2 |

|---|---|---|---|

| BFRCGCC1-0 | 2.38 | 0.51 | 0.982 |

| BFRCGCC2-0 | 4.81 | 0.41 | 0.971 |

| Types | Parameter | Age/d | |||||

|---|---|---|---|---|---|---|---|

| 3 | 7 | 14 | 28 | 56 | 90 | ||

| BFRCGCC1 | Kt | 0.734 | 0.926 | 1.045 | 1.188 | 1.369 | 1.544 |

| R2 | 0.956 | 0.926 | 0.939 | 0.959 | 0.992 | 0.899 | |

| BFRCGCC2 | Kt | 1.21 | 1.158 | 1.178 | 1.405 | 2.084 | 2.113 |

| R2 | 0.889 | 0.977 | 0.960 | 0.864 | 0.989 | 0.861 | |

| Types | BFRCGCC1-0 | BFRCGCC1-1 | BFRCGCC1-2 | BFRCGCC1-3 | BFRCGCC2-0 | BFRCGCC2-1 | BFRCGCC2-2 | BFRCGCC2-3 |

|---|---|---|---|---|---|---|---|---|

| RMSE | 0.834 | 0.293 | 0.209 | 0.165 | 0.897 | 0.316 | 0.348 | 0.429 |

| MAPE | 0.79% | 0.28% | 0.19% | 0.14% | 0.93% | 0.31% | 0.31% | 0.39% |

| Types | Coefficients | Age/d | |||||

|---|---|---|---|---|---|---|---|

| 3 | 7 | 14 | 28 | 56 | 90 | ||

| BFRCGCC1 | λt | −530.44 | −441.25 | −378.93 | −327.04 | −289.92 | −237.43 |

| Pt | 0.934 | 0.945 | 0.952 | 0.963 | 0.969 | 0.971 | |

| R2 | 0.916 | 0.926 | 0.941 | 0.927 | 0.982 | 0.947 | |

| BFRCGCC2 | λt | −482.24 | −418.88 | −370.09 | −340.46 | −268.54 | −241.15 |

| Pt | 0.955 | 0.955 | 0.970 | 0.978 | 0.984 | 0.991 | |

| R2 | 0.905 | 0.927 | 0.950 | 0.964 | 0.949 | 0.961 | |

| Types | BFRCGCC1-0 | BFRCGCC1-1 | BFRCGCC1-2 | BFRCGCC1-3 | BFRCGCC2-0 | BFRCGCC2-1 | BFRCGCC2-2 | BFRCGCC2-3 |

|---|---|---|---|---|---|---|---|---|

| RMSE | 15.433 × 10−6 | 11.098 × 10−6 | 12.308 × 10−6 | 15.111 × 10−6 | 19.520 × 10−6 | 14.828 × 10−6 | 11.165 × 10−6 | 9.281 × 10−6 |

| NRMSE | 0.020 | 0.016 | 0.020 | 0.026 | 0.027 | 0.023 | 0.018 | 0.016 |

| MAPE | 3.78% | 2.59% | 2.88% | 4.50% | 4.67% | 4.27% | 3.29% | 2.49% |

| Types | Coefficients | Age/d | |||||

|---|---|---|---|---|---|---|---|

| 3 | 7 | 14 | 28 | 56 | 90 | ||

| BFRCGCC1 | Rta | 11.34 | 11.35 | 12.61 | 27.5 | 36.34 | 30.69 |

| Rtb | 0.66 | 0.61 | 0.55 | 0.54 | 0.55 | 0.57 | |

| R2 | 0.954 | 0.726 | 0.816 | 0.832 | 0.982 | 0.811 | |

| BFRCGCC2 | Rta | 8.82 | 26.33 | 36.82 | 53.16 | 58.86 | 45.42 |

| Rtb | 0.432 | 0.353 | 0.302 | 0.287 | 0.272 | 0.311 | |

| R2 | 0.772 | 0.819 | 0.772 | 0.945 | 0.941 | 0.861 | |

| Types | BFRCGCC1-1 | BFRCGCC1-2 | BFRCGCC1-3 | BFRCGCC2-1 | BFRCGCC2-2 | BFRCGCC2-3 |

|---|---|---|---|---|---|---|

| RMSE | 12.779 | 15.713 | 13.962 | 15.784 | 14.795 | 20.680 |

| NRMSE | 0.022 | 0.032 | 0.032 | 0.025 | 0.028 | 0.042 |

| MAPE | 1.50% | 1.76% | 1.34% | 1.71% | 1.58% | 2.19% |

| Types | A1 | B1 | C1 | R2 |

|---|---|---|---|---|

| BFRCGCC1-0 | −640.40 | 436.35 | 1.55 | 0.997 |

| BFRCGCC1-1 | −380.91 | 349.17 | 1.70 | 0.986 |

| BFRCGCC1-2 | −462.85 | 354.41 | 2.01 | 0.986 |

| BFRCGCC1-3 | −578.60 | 373.91 | 3.72 | 0.985 |

| BFRCGCC2-0 | −1533.07 | 630.83 | 6.32 | 0.993 |

| BFRCGCC2-1 | −1103.46 | 511.45 | 4.50 | 0.992 |

| BFRCGCC2-2 | −624.39 | 380.87 | 1.15 | 0.986 |

| BFRCGCC2-3 | −459.27 | 327.72 | 0.39 | 0.982 |

| Types | A2 | B2 | C2 | R2 |

|---|---|---|---|---|

| BFRCGCC1-0 | −1210.3 | 340.13 | 34.89 | 0.992 |

| BFRCGCC1-1 | −1185.85 | 304.93 | 29.34 | 0.951 |

| BFRCGCC1-2 | −1180.7 | 289.61 | 27.03 | 0.998 |

| BFRCGCC1-3 | −906.22 | 244.51 | 25.09 | 0.997 |

| BFRCGCC2-0 | −1611.41 | 360.96 | 71.01 | 0.993 |

| BFRCGCC2-1 | −1452.6 | 321.53 | 55.09 | 0.993 |

| BFRCGCC2-2 | −1188.24 | 280.61 | 40.53 | 0.996 |

| BFRCGCC2-3 | −890.37 | 233.90 | 30.68 | 0.999 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Rong, X.; Wei, S.; Li, D. Investigation on Drying Shrinkage of Basalt Fiber-Reinforced Concrete with Coal Gangue Ceramsite as Coarse Aggregates. Materials 2025, 18, 4627. https://doi.org/10.3390/ma18194627

Liu S, Rong X, Wei S, Li D. Investigation on Drying Shrinkage of Basalt Fiber-Reinforced Concrete with Coal Gangue Ceramsite as Coarse Aggregates. Materials. 2025; 18(19):4627. https://doi.org/10.3390/ma18194627

Chicago/Turabian StyleLiu, Shi, Xiaojian Rong, Shuchao Wei, and Dong Li. 2025. "Investigation on Drying Shrinkage of Basalt Fiber-Reinforced Concrete with Coal Gangue Ceramsite as Coarse Aggregates" Materials 18, no. 19: 4627. https://doi.org/10.3390/ma18194627

APA StyleLiu, S., Rong, X., Wei, S., & Li, D. (2025). Investigation on Drying Shrinkage of Basalt Fiber-Reinforced Concrete with Coal Gangue Ceramsite as Coarse Aggregates. Materials, 18(19), 4627. https://doi.org/10.3390/ma18194627