Increased Heat Absorption by the Walls of Exchangers Sprayed with Coatings Exhibiting High Heat Absorption and Conductivity

Abstract

1. Introduction

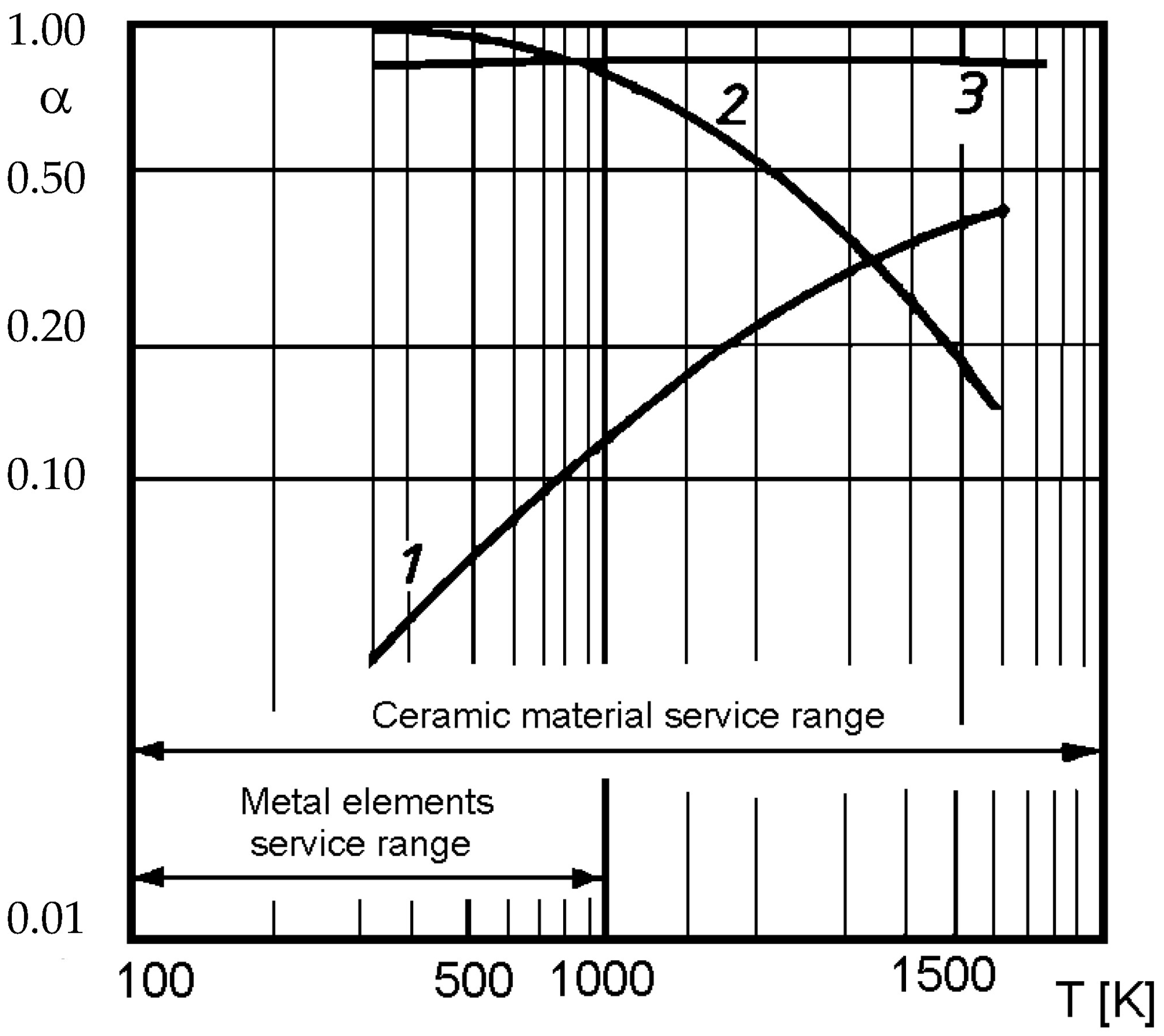

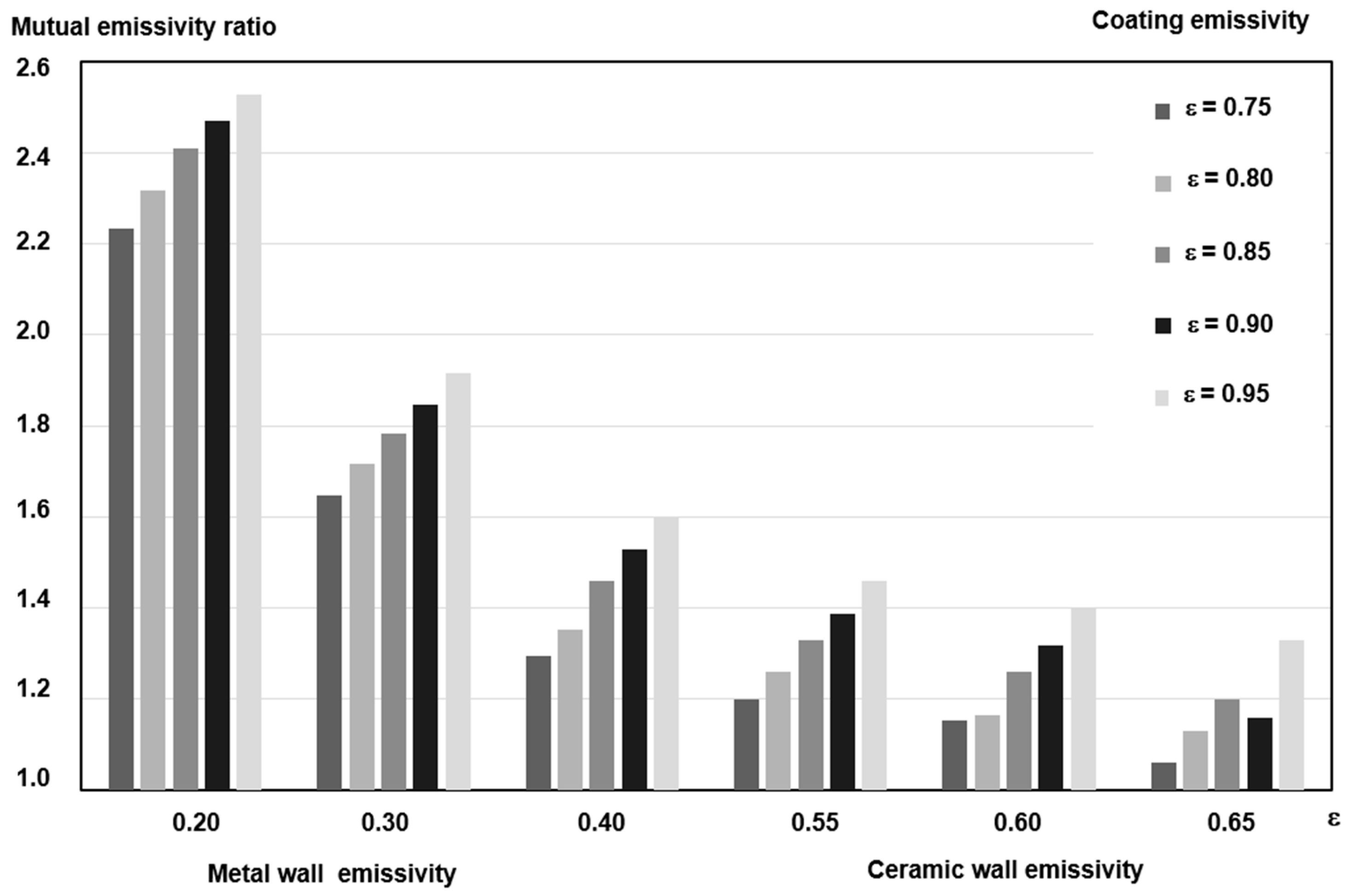

2. The Issue of Selecting Materials for Coatings

3. An Analytical Approach to Determining the Optimal Value of the Mutual Emissivity Coefficient (εₚ) Depending on the Amount of Absorbed Heat

- −

- high temperature of heating agents,

- −

- high emissivity of heating agents,

- −

- high emissivity of walls (furnaces and devices) participating in radiant heat exchange,

- −

- high thermal conductivity or insulation of walls participating in heat exchange.

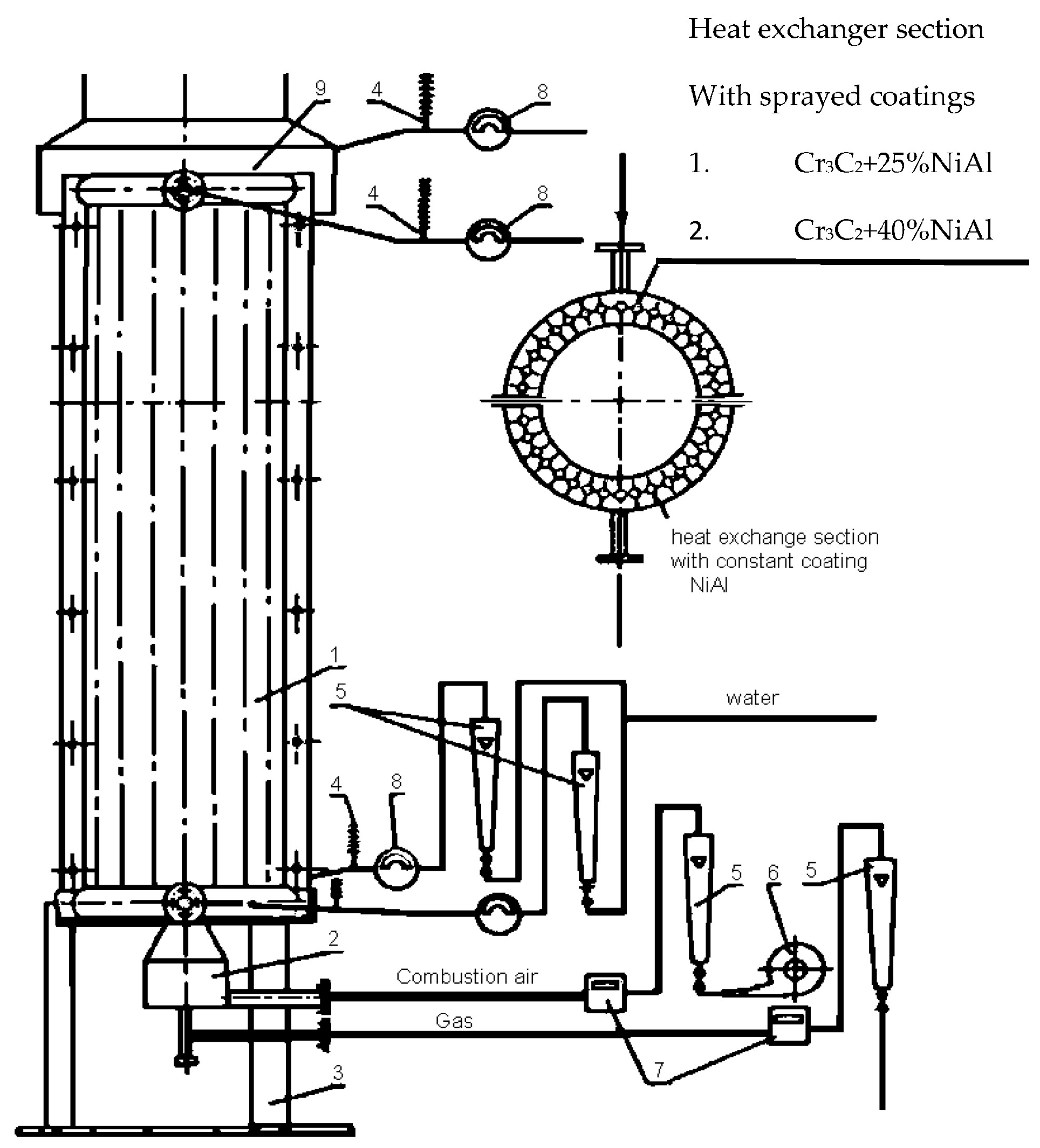

4. Research Position

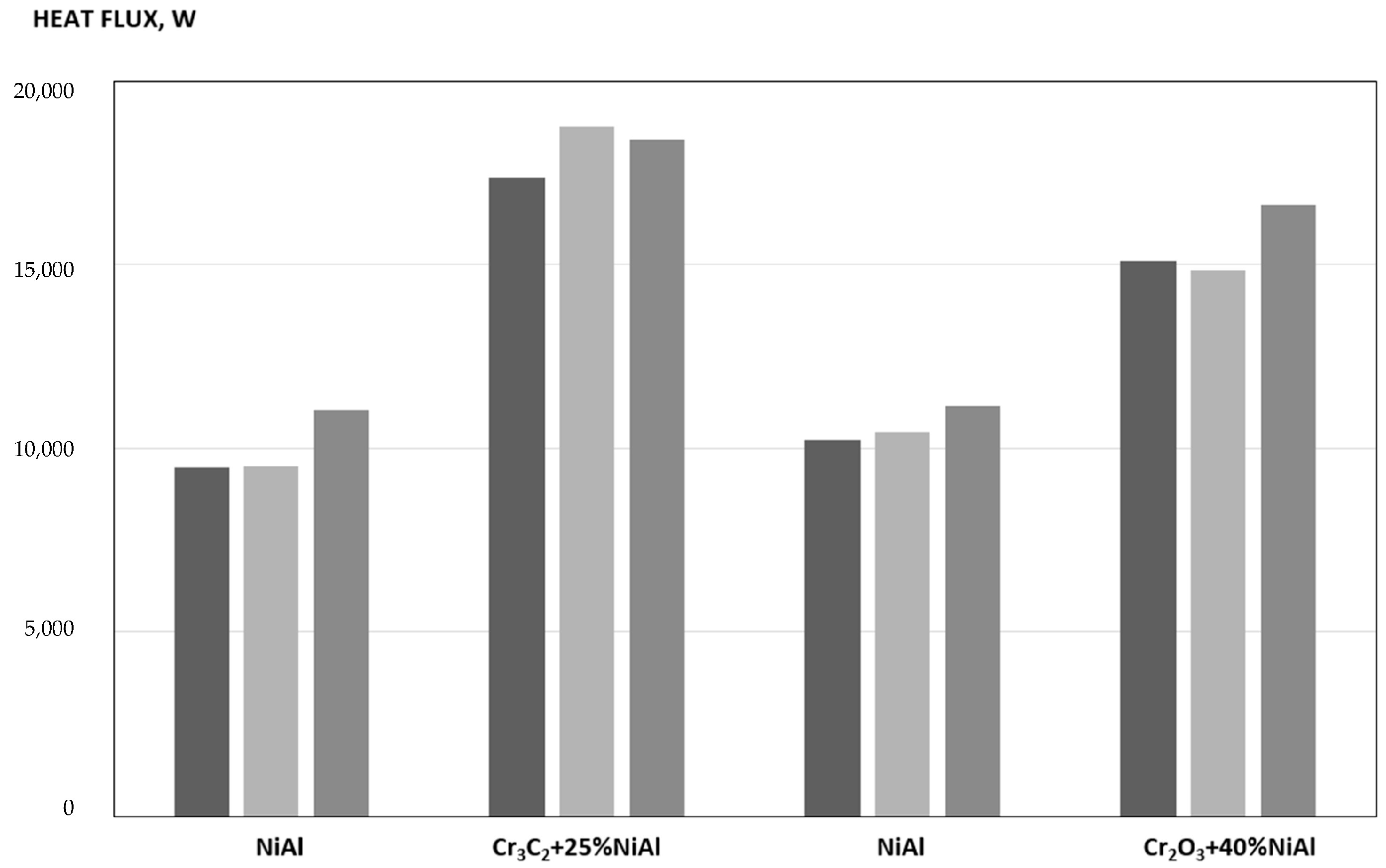

5. Analysis of the Results Obtained from Experimental Research

- −

- from half-cylinder 1 sprayed with NiAl coating—9496 W (100%),

- −

- from half-cylinder 2 sprayed with Cr3C2 + 25%NiA1 coating—18,779 W (198%), which is twice the value obtained in half-cylinder 1 sprayed with NiAl.

6. Conclusions

- The selection of appropriate spray coatings to protect furnace components and heat exchangers is a key factor in extending the service life of heating equipment, improving its energy efficiency, and reducing its negative impact on the environment. In the face of rising energy costs, rational thermal energy management is becoming increasingly important. Instead of focusing on acquiring new energy sources, it is necessary to conduct intensive research and development work aimed at modernizing existing equipment and optimizing its operating parameters. Furthermore, it has been proven that the systematic implementation of coating spraying technology in equipment such as heat exchangers, waste incinerators, and metallurgical industry installations—one of the most energy-intensive industries—can lead to better energy utilization, reduced heat loss, and reduced pollutant emissions.

- Experimental studies have confirmed that both ceramic and cermet coating systems with a rough surface have a high heat absorption capacity. The emissivity of coating systems decreases with the addition of a metal component to the ceramic. At the same time, it has been established that the emissivity of metal coating systems exceeds the emissivity coefficient of the same metals in the solid state by more than two times.

- The use of Cr3C2 + 25% NiAl spray coatings instead of the base NiAl system significantly increases the thermal efficiency of heat exchangers. The tests carried out showed that thanks to the use of an absorption-conductive post-coating system, it was possible to double the amount of heat transferred to the working medium (water) compared to the base state.

- The increase in heat transfer efficiency from 66.7% to 97.7% confirms the high effectiveness of chromium carbide coatings in intensifying heat exchange with exhaust gases. This results in a reduction in exhaust gas temperature, which leads to a decrease in their volume and, in industrial conditions, to an increase in the concentration of dust in the waste gases. This phenomenon contributes to increased dust removal efficiency by intensifying the process of solid particle precipitation in dust collectors.

- Studies conducted on the impact of spray-applied coating systems on equipment components used in laboratories and industrial conditions have shown that in the presence of cermet coating systems with high heat emission and conduction values, there was an increase in the amount of heat carried away by the heated media flowing in the exchangers (water or air).

- Furthermore, it has been established that the values of the emissivity coefficient of the outer layer of the coating system correlate with the relationship ew = 1/(1/eg + 1/es − 1) and affect the value of the heat flux absorbed by the heated working fluids flowing in the boiler with coatings formed on their surfaces.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, L.; Khor, K.A.; Ng, H.W.; Teo, T.N. Non-destructive evaluation of plasma sprayed functionally graded thermal barrier coatings. Surf. Coat. Technol. 2000, 130, 233–239. [Google Scholar] [CrossRef]

- Łatka, L.; Pawłowski, L.; Winnicki, M.; Sokołowski, P.; Małachowska, A.; Kozerski, S. Review of functionally graded thermal sprayed coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Hardwicke, C.U.; Lau, Y.C. Advances in thermal spray coatings for gas turbines and energy generation: A review. J. Therm. Spray Technol. 2013, 22, 564–576. [Google Scholar] [CrossRef]

- Kaßner, H.; Siegert, R.; Hathiramani, D.; Vaßen, R.; Stoever, D. Application of Suspension Plasma Spraying (SPS) for Manufacture of Ceramic Coatings. J. Therm. Spray Technol. 2008, 17, 115. [Google Scholar] [CrossRef]

- Killinger, A. Status and Future Trends in Suspension Spray Techniques. In Future Development of Thermal Spray Coatings; Elsevier: Amsterdam, The Netherlands, 2015; pp. 81–122. [Google Scholar] [CrossRef]

- Wilson, S. Abradable Thermal Spray Applications and Technology. In ASM Handbook, Volume 5A: Thermal Spray Technology; ASM International: Almere, The Netherlands, 2013; pp. 287–295. [Google Scholar]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Thermal conductivity and thermal cyclic fatigue of multilayered Gd2Zr2O7/YSZ thermal barrier coatings processed by suspension plasma spray Surf. Coat. Technol. 2015, 283, 329–336. [Google Scholar] [CrossRef]

- Armada, S.; Schmid, R.; Johnsen, H.; Espallargas, N. Functionalized Thermal Spray Coatings. In Future Development of Thermal Spray Coatings; Elsevier: Amsterdam, The Netherlands, 2015; pp. 207–228. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Lu, F.; Huang, W.; Liu, H. Thermal shock resistance and failure analysis of plasma-sprayed thick 8YSZ-Al2O3 composite coatings. Surf. Coat. Technol. 2020, 384, 125290. [Google Scholar] [CrossRef]

- Mittal, R.; Singh, M.; Kumar, P. Characterization of detonation gun thermal spray coatings on SA213T91 in simulated boiler environment. Mater. Today Proc. 2019, 18, 4952–4962. [Google Scholar] [CrossRef]

- Singh, P.K.; Mishra, S.B.; Mishra, S.; Yadav, P. Comparative studies on oxidation behaviour of cobalt-based D-gun coatings on boiler steel. Surf. Coat. Technol. 2023, 474, 130055. [Google Scholar] [CrossRef]

- Reddy, G.M.S.; Prasad, C.D.; Patil, P.; Ramesh, M.R.; Rao, N. Hot corrosion behavior of plasma-sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ cermets coatings on alloy steel. Surf. Interfaces 2021, 22, 100810. [Google Scholar] [CrossRef]

- Curry, N.; Tang, Z.; Markocsan, N.; Nylén, P. Influence of bond coat surface roughness on the structure of axial suspension plasma spray thermal barrier coatings—Thermal and lifetime performance. Surf. Coat. Technol. 2015, 268, 15–23. [Google Scholar] [CrossRef]

- Basu, S.N.; Ye, G.; Khare, R.; McCandless, B.; Gevelber, M.; Wroblewski, D. Dependence of splat remelt and stress evolution on surface roughness length scales in plasma sprayed thermal barrier coatings. Int. J. Refract. Met. Hard Mater. 2009, 27, 479–484. [Google Scholar] [CrossRef]

- Girolamo, G.D.; Brentari, A.; Blasi, C.; Serra, E. Microstructure and mechanical properties of plasma sprayed alumina-based coatings. Ceram. Int. 2014, 40, 12861–12867. [Google Scholar] [CrossRef]

- Gualco, C.; Cordano, E.; Fignino, F.; Gambaro, C.; Ahmaniemi, S.; Tuurna, S.; Mantyla, T.; Vuoristo, P. An Improved Deposition Process for Very Thick Porous Thermal Barrier Coatings; Lugscheider, E., Berndt, C.C., Eds.; International Thermal Spray Conference: Dusseldorf, Germany, 2002; pp. 195–201. [Google Scholar]

- Sampath, S. Thermal spray applications in electronics and sensors: Past, present, and future. J. Therm. Spray Technol. 2010, 19, 921–949. [Google Scholar] [CrossRef]

- Khan, Z.S.; Zou, B.; Huang, W.; Fan, X.; Gu, L.; Chen, X.; Zeng, S.; Wang, C.; Cao, X. Synthesis and characterization of Yb and Er based monosilicate powders and durability of plasma sprayed Yb2SiO5 coatings on C/C–SiC composites. Mater. Sci. Eng. B 2012, 177, 184–189. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, A.B. Dussoubs Quo Vadis Thermal Spraying? J. Therm. Spray Technol. 2001, 10, 44–66. [Google Scholar] [CrossRef]

- Wang, Y.; Bai, Y.; Yuan, T.; Chen, H.Y.; Kang, Y.X.; Shi, W.J.; Song, X.L.; Li, B.Q. Failure analysis of fine-lamellar structured YSZ based thermal barrier coatings with submicro/nano-grains Surf. Coat. Technol. 2017, 319, 95–103. [Google Scholar] [CrossRef]

- Wang, Q.; Zahang, Y.; Yan, S.; Wang, G.; Li, H. Coating Ca2+–Fe3+ co-doped LaAlO3 on high-temperature electric furnace for energy-saving. Int. J. Therm. Sci. 2023, 194, 108553. [Google Scholar] [CrossRef]

- Cen, Q.M.; Yu, L. Residual stress distribution along interfaces in thermal barrier coating system under thermal cycles. Ceram. Int. 2017, 43, 3089–3100. [Google Scholar] [CrossRef]

- Cheng, B.; Yang, G.J.; Zhang, Q.; Yang, N.; Zhang, M.; Zhang, Y.; Li, C.X.; Li, C.J. Gradient thermal cyclic behaviour of La2Zr2O7/YSZ DCL-TBCs with equivalent thermal insulation performance. J. Eur. Ceram. Soc. 2018, 38, 1888–1896. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mulik, R.S.; Mahapatra, M.M. Mechanical property evaluation of carbon nanotubes reinforced plasma sprayed YSZ-alumina composite coating. Ceram. Int. 2018, 44, 6980–6989. [Google Scholar] [CrossRef]

- Rätzer-Scheibe, H.-J.; Schulz, U.; Krell, T. The effect of coating thickness on the thermal conductivity of EB-PVD PYSZ thermal barrier coatings. Surf. Coat. Technol. 2006, 200, 5636–5644. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Jonnalagadda, K.P.; Peng, R.L.; Markocsan, N.; Nylén, P. Influence of YSZ layer thickness on the durability of gadolinium zirconate/YSZ double-layered thermal barrier coatings produced by suspension plasma Surf. Coat. Technol. 2019, 357, 456–465. [Google Scholar] [CrossRef]

- Lima, C.R.C.; de Souza, N.F.C.; Camargo, F. Study of wear and corrosion performance of thermal sprayed engineering polymers. Surf. Coat. Technol. 2013, 220, 140–143. [Google Scholar] [CrossRef]

- Montemor, M.F. Functional and smart coatings for corrosion protection: A review of recent advances Surf. Coat. Technol. 2014, 258, 17–37. [Google Scholar] [CrossRef]

- Gaur, A.; Pandel, U.; Sharma, S. A study of investigating the effects of variables and assessing the efficiency of air plasma spray as a coating technique. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Nath, S.; Manna, I.; Jha, A.K.; Sharma, S.C.; Pratihar, S.K.; Majumdar, J.D. Thermophysical behavior of thermal sprayed yttria stabilized zirconia based composite coatings. Ceram. Int. 2017, 43, 11204–11217. [Google Scholar] [CrossRef]

- Kiilakoski, J.; Trache, R.; Björklund, S.; Joshi, S.; Vuoristo, P. Process parameter impact on suspension-HVOF-sprayed Cr2O3 coatings. J. Therm. Spray Technol. 2019, 28, 1933–1944. [Google Scholar] [CrossRef]

- Crawmer, D.E. Thermal Spray Processes. In Handbook of Thermal Spray Technology; ASM International: Almere, The Netherlands, 2013; pp. 54–76. [Google Scholar] [CrossRef]

- Crawmer, D.E. Introduction to coatings, equipment, and theory. In Handbook of Thermal Spray Technology; ASM International: Materials Park, OH, USA, 2008; pp. 43–46. [Google Scholar]

- Schilke, P.W. Advanced Gas Turbine Materials and Coatings; GE Energy: Schenectady, NY, USA, 2004; Available online: https://api.semanticscholar.org/CorpusID:233239767 (accessed on 24 May 2025).

- Tarasi, F.; Medraj, M.; Dolatabadi, A.; Oberste-Berghaus, J.; Moreau, C. Structural considerations in plasma spraying of the alumina–zirconia composite. Surf. Coat. Technol. 2011, 205, 5437–5443. [Google Scholar] [CrossRef]

- Tarasi, F.; Medraj, M.; Dolatabadi, A.; Oberste-Berghaus, J.; Moreau, C. Amorphous and crystalline phase formation during suspension plasma spraying of the alumina-zirconia composite. J. Eur. Ceram. Soc. 2011, 31, 2903–2913. [Google Scholar] [CrossRef]

- Tarasi, F.; Medraj, M.; Dolatabadi, A.; Lima, R.S.; Moreau, C. Thermal cycling of suspension plasma sprayed alumina-YSZ coatings containing amorphous phases. J. Am. Ceram. Soc. 2012, 95, 2614–2621. [Google Scholar] [CrossRef]

- Morel, S.Ł. The influence of a radiated heat exchanger surface on heat transfer. Arch. Thermodyn. 2015, 36, 161–174. [Google Scholar] [CrossRef]

- Morel, S.Ł. Application of plasma-sprayed coatings in heat absorption by radiated walls. Arch. Energetyki 2011, 41, 111–126. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BSL9-0055-0023 (accessed on 24 May 2025).

- Morel, S.; Morel, S.Ł. Sposób Wyznaczania Współczynnika Absorpcji i Emisji Promieniowania Cieplnego Ciał Stałych. Patent NR 163658, April 1994. [Google Scholar]

- Morel, S.; Morel, S.Ł. Sposób Wyznaczania Współczynnika Przewodzenia Ciepła Powłok. Patent NR 164710, April 1994. [Google Scholar]

| No. | Coating Type | Protective Properties | Thermal Properties | Suitability for Spraying | ||||

|---|---|---|---|---|---|---|---|---|

| Thermal Shock Resistance | Erosion Resistance | Internal Porosity | Total Points | Heat Radiation Absorption Ability {ε} | Thermal Conductivity {λ} | Membrane Heat Exchangers | ||

| W m−1 K−1 | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Number of temperature change cycles | Points for 1 g coating loss time | Points for gas pressure equalization time | 3 + 4 + 5 | 1 point for each 0.01 above 0.7 | actual value of λ | 6 + 7 + 8 for p > 40 is good | ||

| 1 | Al2O3 | 0 | 10 | 6.8 | 17 | 16 (0.86) | 3 | 36 |

| 2 | Al2O3 + 10% NiAl | 2 | 10 | 6.0 | 18 | 13 | 9 | 40 |

| 3 | Al2O3 + 25% NiAl | 6 | 10 | 6.5 | 23 | 9 | 13 | 45 |

| 4 | Al2O3 + 40% NiAl | 9 | 5 | 5.4 | 19 | 6 | 16 | 41 |

| 5 | Cr2O3 | 0 | 8 | 6.3 | 14 | 22 (0.92) | 5 | 41 |

| 6 | Cr2O3 + 10% NiAl | 4 | 8 | 6.0 | 18 | 16 | 9 | 43 |

| 7 | Cr2O3 + 25% NiAl | 4 | 7 | 5.7 | 17 | 12 | 19 | 48 |

| 8 | Cr2O3 + 40% NiAl | 8 | 6 | 5.0 | 19 | 9 | 21 | 49 |

| 9 | ZrO2 | 0 | 1 | 11.5 | 13 | 15 (0.85) | 1 | 29 |

| 10 | ZrO2+10% NiAl | 1 | 2 | 10.0 | 13 | 10 | 4 | 27 |

| 11 | ZrO2 + 25% NiAl | 5 | 3 | 8.0 | 16 | 5 | 7 | 28 |

| 12 | ZrO2 + 40% NiAl | 7 | 4 | 7.2 | 18 | 2 | 9 | 29 |

| 13 | Cr3C2 + 25% NiAl | 11 | 12 | 4.5 | 28 | 13 (0.93) | 29 | 70 |

| 14 | Cr3C2 + 40% NiAl | 12 | 11 | 4.0 | 27 | 10 | 32 | 69 |

| Stage Series | Coating Type | Burner Feed Parameters | Flowing Water Parameters | Heat Flux Carried by Water | ||||

|---|---|---|---|---|---|---|---|---|

| Temperature | Temperature | Mass | ||||||

| Gas | Air | Inlet | Outlet | Increase | Flux | |||

| m3h−1 | m3h−1 | °C | °C | °C | g s−1 | W | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| I.1 | NiAl | 2 | 18 | 11.1 | 24.9 | 13.8 | 164 | 9460 |

| Cr3C2 + 25% NiAl | 11.1 | 30.9 | 19.8 | 210 | 17,380 | |||

| I.2 | NiAl | 2 | 18 | 11.1 | 26.0 | 14.2 | 160 | 9496 |

| Cr3C2 + 25% NiAl | 11.1 | 32.6 | 20.8 | 216 | 18,779 | |||

| I.3 | NiAl | 2 | 18 | 11.1 | 25.5 | 14.5 | 182 | 11,031 |

| Cr3C2 + 25% NiAl | 11.1 | 30.5 | 19.5 | 226 | 18,421 | |||

| II.4 | NiAl | 2 | 18 | 11.1 | 25.0 | 13.9 | 176 | 10,226 |

| Cr2O3 + 40% NiAl | 11.1 | 30.3 | 19.1 | 189 | 15,089 | |||

| II.5 | NiAl | 2 | 18 | 11.1 | 26.1 | 14.7 | 170 | 10,445 |

| Cr2O3 + 40% NiAl | 11.1 | 29.8 | 184 | 193 | 14,844 | |||

| II.6 | NiAl | 2 | 18 | 11.1 | 25.1 | 14.1 | 189 | 11,140 |

| Cr2O3 + 40% NiAl | 11.1 | 30.4 | 19.4 | 180 | 16,637 | |||

| No. | Coating Characteristics | Obtained Results | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coating Description | Composition | Thermal Parameter Values | Effects Achieved on Laboratory Stands | Effects Achieved in Industrial Conditions | ||||||||

| εT | λ Wm−1K−1 | Without Coating W | With Coating W | Increase in Thermal Efficiency | Element Name | Obtained Result, incl. | ||||||

| Thermal Effects | No. of Campaigns Endured | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| 1 | Absorptive and conductive | Cr3C2 + 25% NiAl | 0.75 | 30 | 9490 | 173,780 | 84% | furnace roof supporting beams | 30% increase in steam amount | 3 campaigns | ||

| 2 | Absorptive and conductive | Cr3C2 + 25% NiAl | 0.75 | 30 | 9490 | 17,380 | 84% | charging door frames | 30% increase in steam amount | 3 campaigns | ||

| 3 | Absorptive and conductive | Cr3C2 + 40% NiAl | 0.86 | 20 | 10,226 | 15,089 | 48% | boiler hopper | in operation | |||

| 4 | Absorptive and conductive | Cr3C2 + 40% NiAl | 0.86 | 20 | 10,226 | 15,089 | 48% | heat treatment furnace crucible | in operation | |||

| 5 | Absorptive and insulating | int. ZrO2 out. Cr2O3 | - 0.82 | 1 5 | tair tburn. | 89 °C 184 °C | 104 °C 172 °C | 23% 6% | recuperator segment | in operation | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morel, S.; Górska, M. Increased Heat Absorption by the Walls of Exchangers Sprayed with Coatings Exhibiting High Heat Absorption and Conductivity. Materials 2025, 18, 4619. https://doi.org/10.3390/ma18194619

Morel S, Górska M. Increased Heat Absorption by the Walls of Exchangers Sprayed with Coatings Exhibiting High Heat Absorption and Conductivity. Materials. 2025; 18(19):4619. https://doi.org/10.3390/ma18194619

Chicago/Turabian StyleMorel, Sławomir, and Monika Górska. 2025. "Increased Heat Absorption by the Walls of Exchangers Sprayed with Coatings Exhibiting High Heat Absorption and Conductivity" Materials 18, no. 19: 4619. https://doi.org/10.3390/ma18194619

APA StyleMorel, S., & Górska, M. (2025). Increased Heat Absorption by the Walls of Exchangers Sprayed with Coatings Exhibiting High Heat Absorption and Conductivity. Materials, 18(19), 4619. https://doi.org/10.3390/ma18194619