Failure Analysis of a Novel Ceramic-Coated Floating Oil Seal Considering O-Ring Initial Assembly Deformation

Abstract

1. Background & Summary

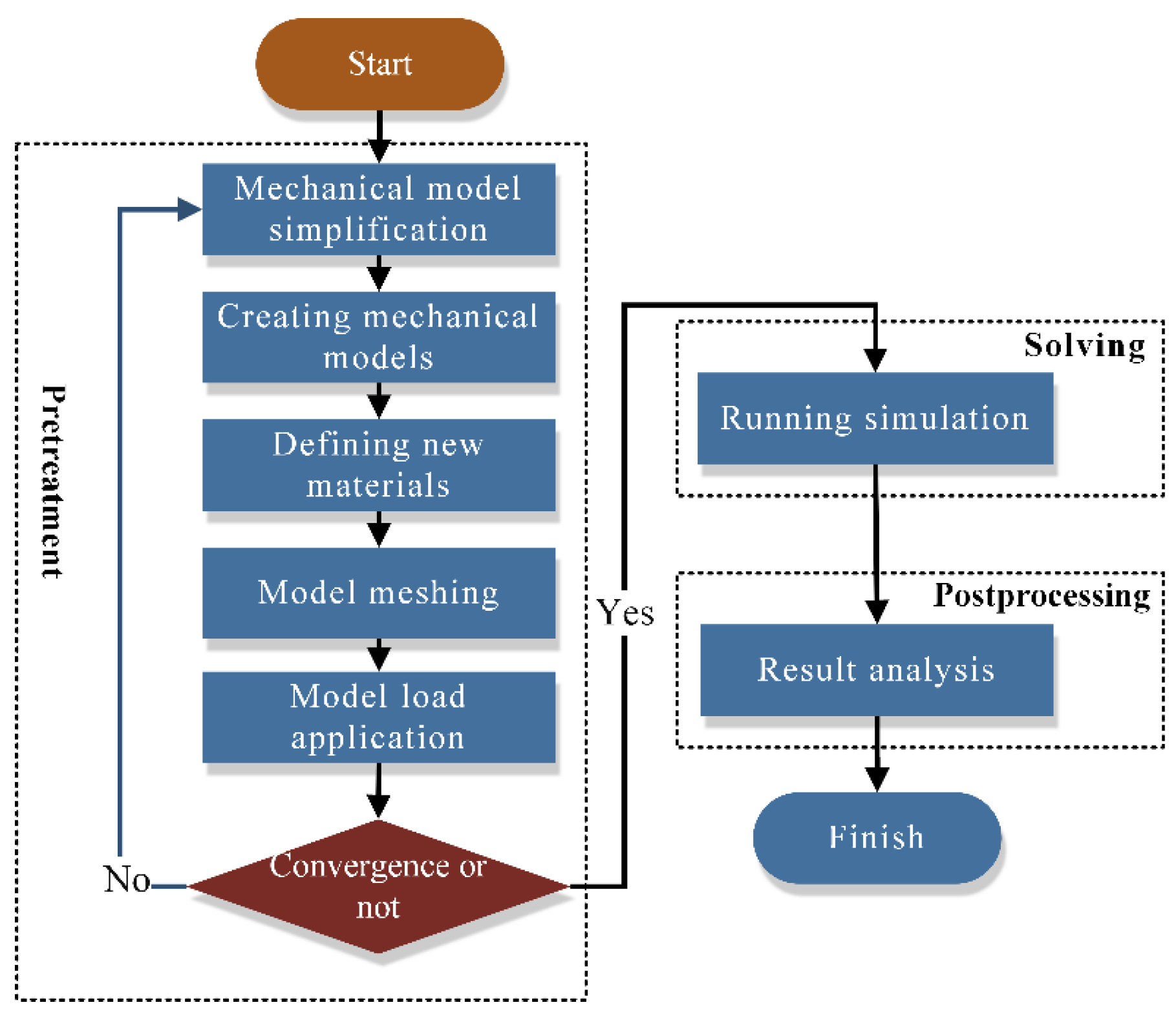

2. Methods

2.1. Constitutive Equation of Rubber Material Constitutive Model

2.2. Finite Element Modeling of the Ceramic-Coated Floating Oil Seal

3. Simulation Results Analysis

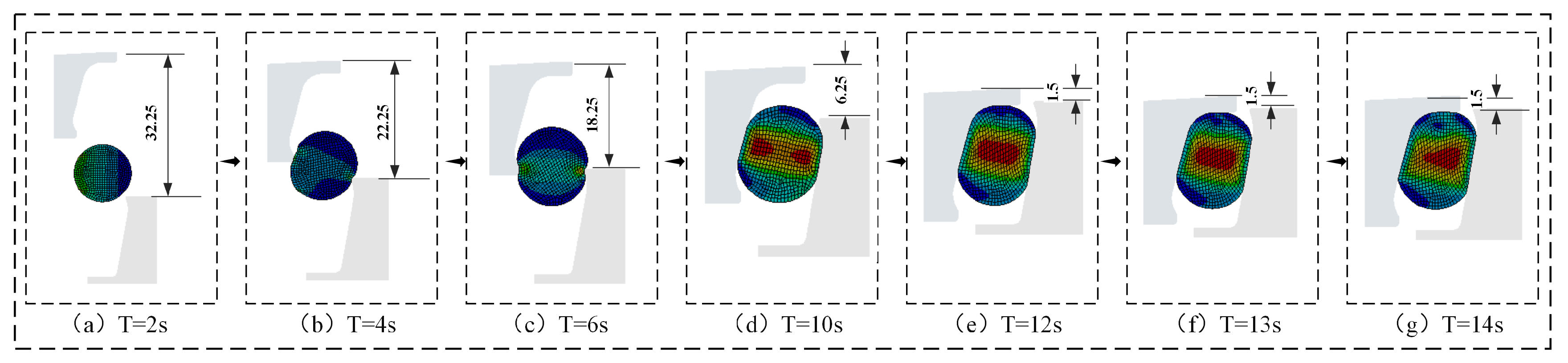

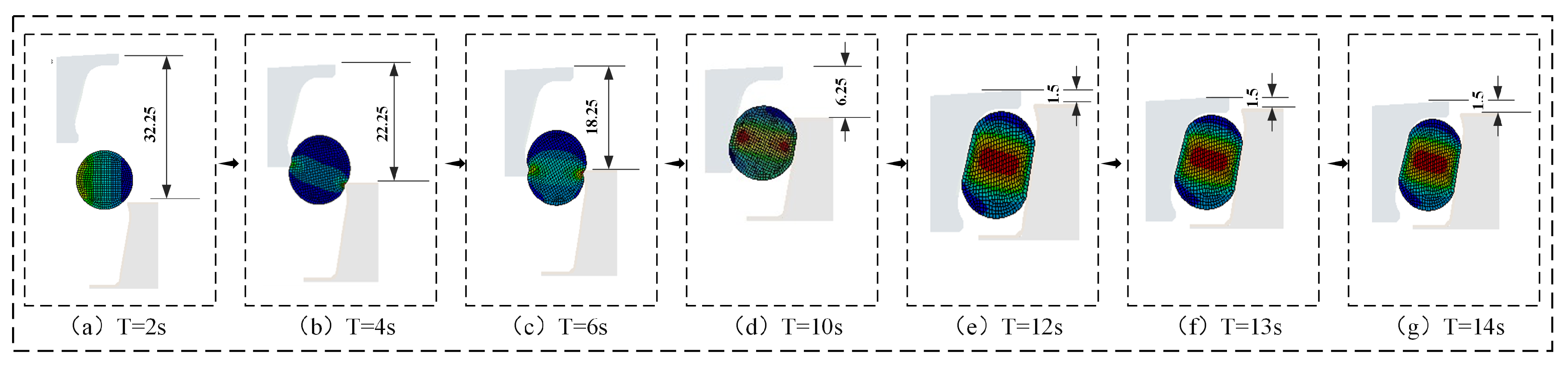

3.1. Contact Analysis of Floating Oil Seals with Assembly Process Effects

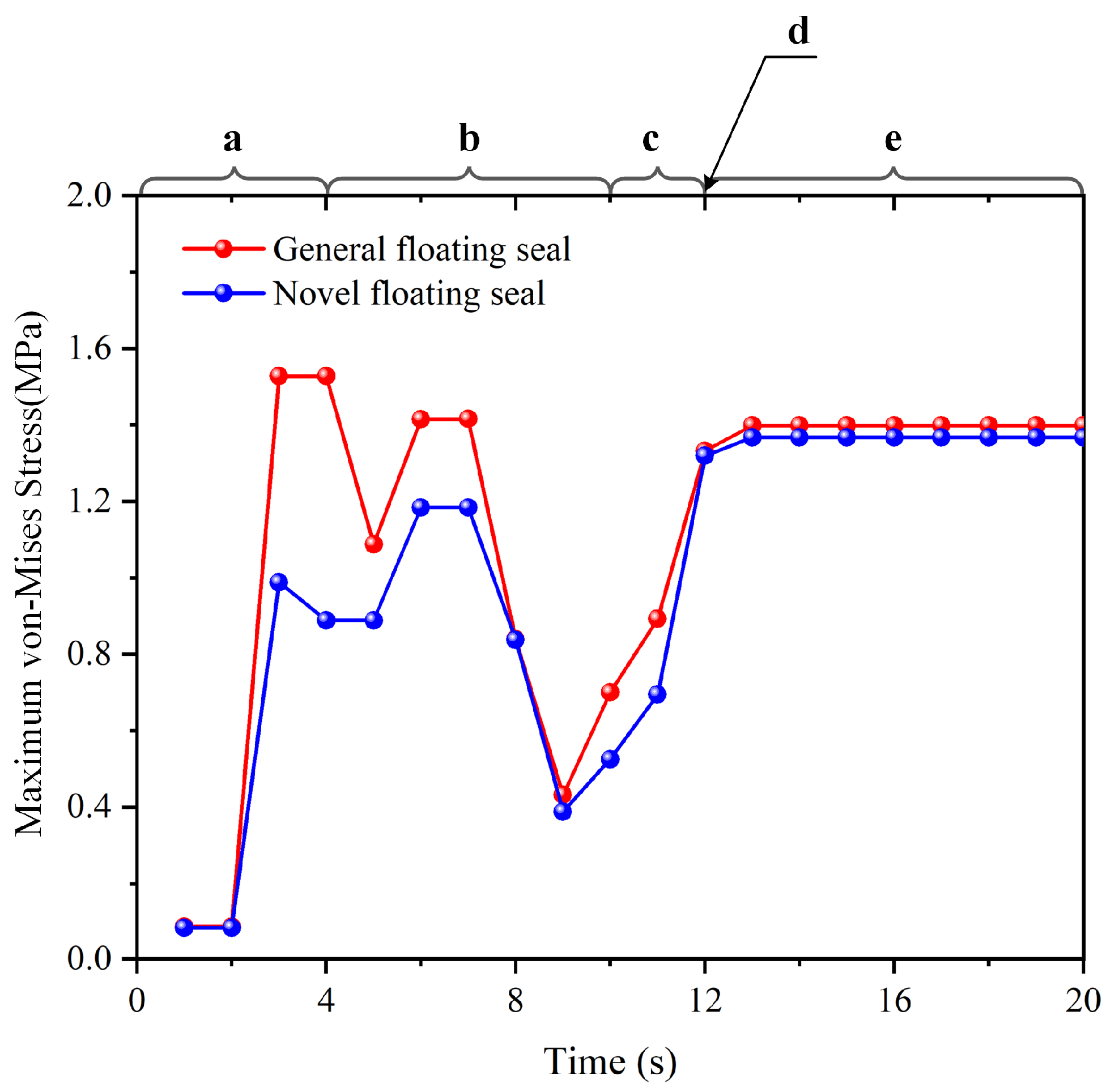

3.2. Effect of Assembly Process on Maximum Von Mises Stress (VMS) in O-Ring

- (a)

- 0 s ≤ T < 4 s: During initial contact between the simulated O-ring and floating seal ring, maximum von Mises stress increased progressively in both conventional and novel floating oil seals due to tightening fit.

- (b)

- 4 s ≤ T < 10 s: As the floating seal ring descended, conventional FOS O-ring stress exhibited a rapid descending–ascending–descending–ascending cyclic trend. Novel NCCFOS O-ring stress showed a stable–rising–stable–falling–rising cycle trend. This stabilized variation reduces wear risk in the novel seal design.

- (c)

- 10 s ≤ T < 12 s: During final positioning between the floating seal ring’s outer cone and seal seat cavity, both seal types showed rapid von Mises stress escalation.

- (d)

- T = 12 s: When the O-ring is precisely located in the inner cavity of the floating seal seat to achieve the state of assembly clearance, the general and novel floating oil seal O-rings will produce radial and axial forces on the floating seal ring, thus achieving an effective floating seal effect.

- (e)

- 12 s < T < 20 s: After the loading of oil pressure, the maximum VMS of the O-ring of the FOS gradually increases and tends to be stable, while that of the NCCFOS O-ring gradually decreases and tends to be stable. This indicates that the novel floating oil seal can distribute stress more effectively under oil pressure loading, thus significantly reducing the maximum VMS of the O-ring.

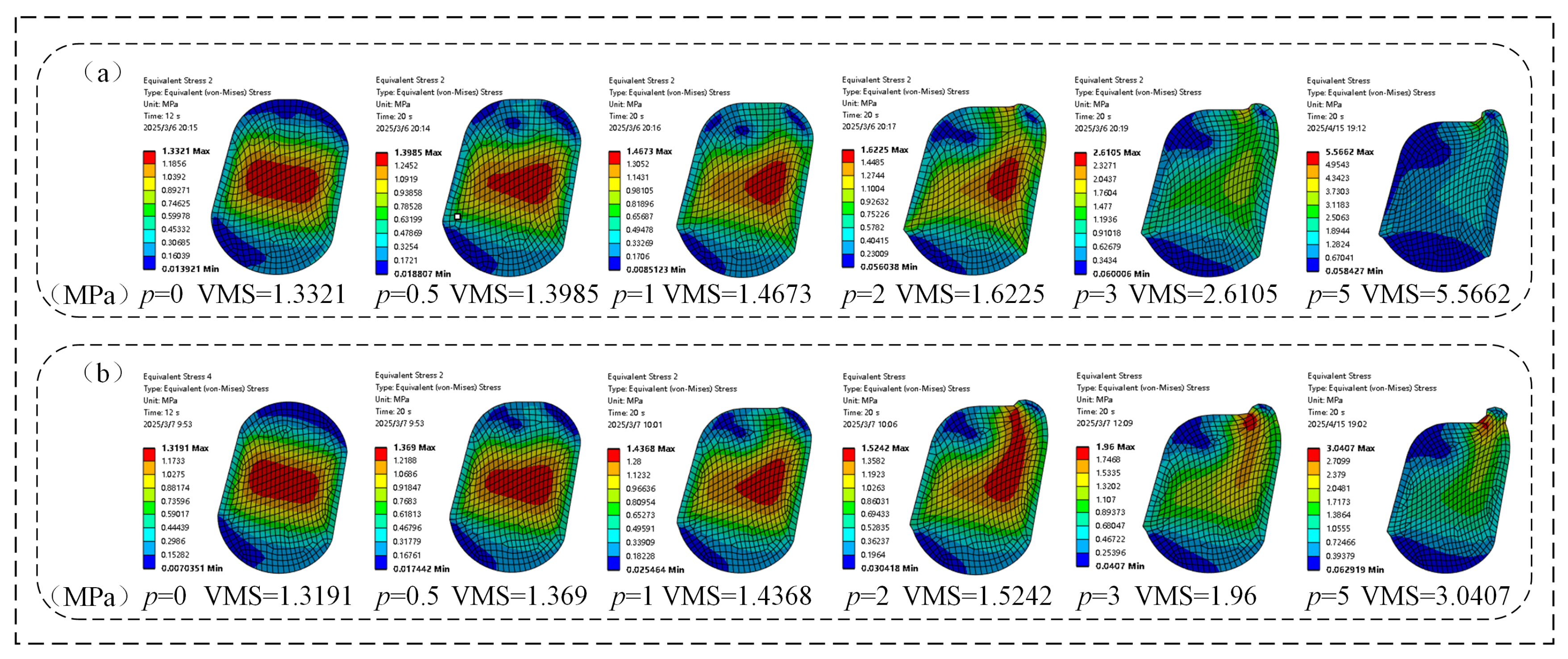

3.3. Case 1: Effect of Oil Pressure on the VMS of O-Ring

3.4. Case 2: Effect of Oil Pressure on Contact Pressure of O-Ring

3.5. Case 3: Effect of Oil Pressure on O-Ring Contact Friction Stress

3.6. Case 4: Effect of Assembly Clearance on O-Ring Stress and Contact Friction Stress

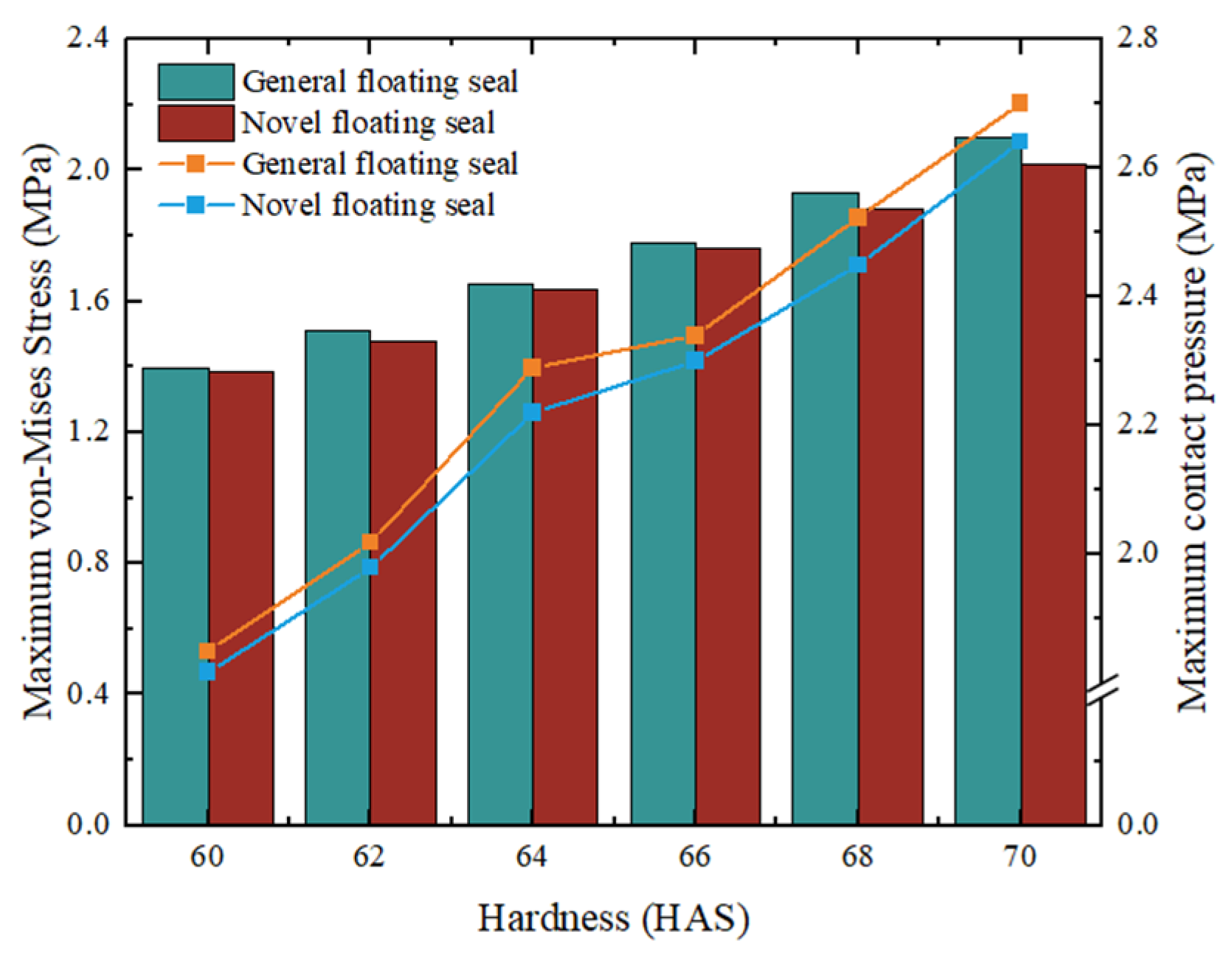

3.7. Case 5: Effect of Hardness on VMS and Contact Pressure of O-Rings

4. Conclusions

- Incorporating the actual assembly process significantly improved analytical accuracy, particularly in determining the supporting reaction force on the floating seal ring end face. This approach yielded more reliable results compared to methods neglecting assembly considerations.

- The NCCFOS demonstrated superior performance across various pressure ranges, effectively reducing fatigue accumulation and wear to extend O-ring service life. Particularly under medium-to-high pressure conditions, it enhanced sealing performance while preventing over-compression issues.

- By optimizing the design, the NCCFOS achieved lower von Mises stress and contact pressure under the influence of oil pressure and O-ring hardness, resulting in improved performance and reliability.

- Alumina ceramic plates were embedded at the contact between the floating seal ring, the inner wall of the floating seal seat, and the O-ring, and the anti-friction layer design was optimized. Considering the interaction between parameters, this optimized new structure significantly enhanced sealing performance and reduced wear, offering valuable insights for further research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FOS | floating oil seal |

| NCCFOS | novel ceramic-coated floating oil seal |

| FEM | finite element model |

| VMS | von Mises stress |

| MP | maximum pressure |

| MFS | maximum frictional stress |

References

- Kawahara, Y.; Hirabayashi, H. A study of sealing phenomena on oil seals. ASLE Trans. 1979, 22, 46–55. [Google Scholar] [CrossRef]

- Kuroki, M.; Miyake, M.; Hirama, H. Life improvement of floating seal. Komatsu Tech. Rep. 2015, 61, 1–6. [Google Scholar]

- Yamabe, J.; Nishimura, S.; Nakao, M. Blister fracture of rubbers for O-ring exposed to high pressure hydrogen gas. In Proceedings of the 2008 International Hydrogen Conference, ASM International, Materials Park, OH, USA, 7–10 September 2008; pp. 389–396. [Google Scholar]

- Green, I.; English, C. Stresses and deformation of compressed elastomeric O-ring seals. In Proceedings of the 14th International Conference on Fluid Sealing, Firenze, Italy, 6–8 April 1994; pp. 83–95. [Google Scholar]

- Wang, B.Q.; Peng, X.D.; Meng, X.K. A thermo-elastohydrodynamic lubrication model for hydraulic rod O-ring seals under mixed lubrication conditions. Tribol. Int. 2019, 129, 442–458. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J.Y.; Zhang, Y.H. Contact characteristics of floating oil seal considering initial installation deformation of O-ring. Lubr. Eng. 2022, 47, 71–77. [Google Scholar]

- Li, X.; Wang, B.; Peng, X. Effect of nitrile butadiene rubber hardness on the sealing characteristics of hydraulic O-ring rod seals. J. Zhejiang Univ. A 2024, 25, 63–78. [Google Scholar] [CrossRef]

- Dong, J.; Deng, Y.; Cao, W. Wear failure analysis of suction valve for high pressure and large flow water hydraulic plunger pump. Eng. Fail. Anal. 2022, 134, 106095. [Google Scholar] [CrossRef]

- Green, I.; English, C. Analysis of elastomeric O-ring seals in compression using the finite element method. Tribol. Trans. 1992, 35, 83–88. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, D.; Pang, H. Extrusion-occlusion dynamic failure analysis of O-ring based on floating bush of water hydraulic pump. Eng. Fail. Anal. 2020, 109, 104358. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, J. Investigation of static and dynamic seal performances of a rubber O-ring. J. Tribol. 2018, 140, 42202. [Google Scholar] [CrossRef]

- Zhou, C.; Zheng, J.; Gu, C. Sealing performance analysis of rubber O-ring in high-pressure gaseous hydrogen based on finite element method. Int. J. Hydrogen. Energy 2017, 42, 11996–12004. [Google Scholar] [CrossRef]

- Hu, D.Y.; Wang, R.Q.; Ren, Q.B. Finite element analysis of O-ring seal structure. Beijing Univ. Aeron. Astron. 2005, 31, 255–260. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, T.; Li, J. The effect of the O-ring on the end face deformation of mechanical seals based on numerical simulation. Tribol. Int. 2016, 97, 278–287. [Google Scholar] [CrossRef]

- Wu, J.B.; Li, L. Influence of ambient pressure on sealing performance of O-ring in deep-sea hydraulic system. Ocean Eng. 2022, 245, 110440. [Google Scholar] [CrossRef]

- Bahloul EEl Aissaoui, H.; Diany, M. Finite element analysis of the o-ring behavior under uniform squeeze levels and internal pressure. WSEAS Trans. Appl. Theor. Mech. 2022, 17, 226–234. [Google Scholar] [CrossRef]

- Shi, R.; Lv, X. Static contact stress analysis of floating oil sealing ring for coal mining machine. China Rubber/Plast. Technol. Equip. 2019, 45, 36–39. [Google Scholar] [CrossRef]

- Huang, Z.; Li, G. Optimization of cone bit bearing seal based on failure analysis. Adv. Mech. Eng. 2018, 10, 1–12. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.D.; Chang, X.P. Wear morphology analysis and structural optimization of cone bit bearing seals. Ind. Lubr. Tribol. 2018, 170, 59–67. [Google Scholar] [CrossRef]

- Zhao, H.; Li, G.; Zhai, Z. Wear characteristics of textured floating oil seal surfaces: A simulation and experimental study. Coatings 2024, 14, 1087. [Google Scholar] [CrossRef]

- He, Z.; Guo, Y.; Si, J. Numerical optimization analysis of floating ring seal performance based on surface texture. Lubricants 2024, 12, 241. [Google Scholar] [CrossRef]

- Merkle, L.; Baumann, M.; Bauer, F. Influence of alternating temperature levels on the wear behavior of radial lip seals: Test rig design and wear analysis. Appl. Eng. Lett. J. Eng. Appl. Sci. 2021, 6, 111–123. [Google Scholar] [CrossRef]

- Tan, J.; Yang, W.M.; Ding, Y.M. Finite element analysis of the sealing performance of O-ring seal structure. Lubr. Eng. Huangpu 2006, 9, 65–69. [Google Scholar] [CrossRef]

- Niu, S. Sealing performance analysis of rubber O-ring in static seal based on FEM. Int. J. Eng. Adv. Res. Technol. 2015, 1, 32–34. [Google Scholar]

- Liang, B.; Yang, X.; Wang, Z.; Su, X.; Liao, B.; Ren, Y.; Sun, B. Influence of randomness in rubber materials parameters on the reliability of rubber O-ring seal. Materials 2019, 12, 1566. [Google Scholar] [CrossRef]

- Yao, T.; Liu, W. FEM analysis of the sealing structure to rubber gasket’s compressive rate. Mech. Manag. Dev. 2014, 29, 16–19. [Google Scholar] [CrossRef]

- Wang, Z.H.; He, K.K. Nonlinear finite element analysis of rubber O-sealing ring. Aerosp. Manuf. Technol. 2016, 106, 4–8. [Google Scholar]

- Cui, K.B.; Qin, J.Q.; Di, C.C. Finite element analysis and simulation of the sealing performance of y-ring rubber seal. Appl. Mech. Mater. 2014, 444, 1379–1383. [Google Scholar] [CrossRef]

| Hardness (HSA) | C10 | C01 | D1 | E (MPa) |

|---|---|---|---|---|

| 60 | 0.4825000 | 0.120624 | 0.00331600 | 3.618750 |

| 62 | 0.5229820 | 0.130745 | 0.00305800 | 3.922360 |

| 64 | 0.5679630 | 0.141991 | 0.00281700 | 4.259722 |

| 66 | 0.6182350 | 0.154559 | 0.00258800 | 4.636765 |

| 68 | 0.6747920 | 0.168698 | 0.00237100 | 5.060937 |

| 70 | 0.7388889 | 0.184721 | 0.00216542 | 5.541667 |

| Setting Name | General Model | Novel Model |

|---|---|---|

| 2D type | Axisymmetric | Axisymmetric |

| Contact type | Frictional | Frictional and bonded |

| Friction coefficient | 0.2 | 0.2 and 0.06 |

| Contact algorithm | Augmented Lagrange | Normal Lagrange |

| Automatic time step | on | on |

| Large deformation | on | on |

| Weak spring | off | off |

| Pressure Condition | Low Pressure | Medium Pressure | High Pressure |

|---|---|---|---|

| Pressure range (MPa) | 0.1~0.5 | 0.5~3.0 | 3.0~10 |

| Working Conditions | Plane183 | |||||

|---|---|---|---|---|---|---|

| Cases | Constant Parameters | Varying Parameters | FOS | NCCFOS | ||

| Element | Node | Element | Node | |||

| Case 1 | H = 60 HSA I = 3 mm | p = 0, 0.5, 1, 2, 3, 5 MPa | 847 | 2744 | 893 | 1041 |

| Case 2 | ||||||

| Case 3 | ||||||

| Case 4 | H = 60 HSA p = 0 MPa | I = 2, 3, 4 mm | ||||

| Case 5 | p = 0.5 MPa I = 3 mm | H = 60, 62, 64, 66, 68, 70 HSA | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, F.; Li, Z.; Sun, B.; Chen, T.; Wang, J. Failure Analysis of a Novel Ceramic-Coated Floating Oil Seal Considering O-Ring Initial Assembly Deformation. Materials 2025, 18, 4592. https://doi.org/10.3390/ma18194592

Zhang Y, Wang F, Li Z, Sun B, Chen T, Wang J. Failure Analysis of a Novel Ceramic-Coated Floating Oil Seal Considering O-Ring Initial Assembly Deformation. Materials. 2025; 18(19):4592. https://doi.org/10.3390/ma18194592

Chicago/Turabian StyleZhang, Yuehao, Fengsen Wang, Zhumin Li, Bozhao Sun, Tianci Chen, and Jiao Wang. 2025. "Failure Analysis of a Novel Ceramic-Coated Floating Oil Seal Considering O-Ring Initial Assembly Deformation" Materials 18, no. 19: 4592. https://doi.org/10.3390/ma18194592

APA StyleZhang, Y., Wang, F., Li, Z., Sun, B., Chen, T., & Wang, J. (2025). Failure Analysis of a Novel Ceramic-Coated Floating Oil Seal Considering O-Ring Initial Assembly Deformation. Materials, 18(19), 4592. https://doi.org/10.3390/ma18194592