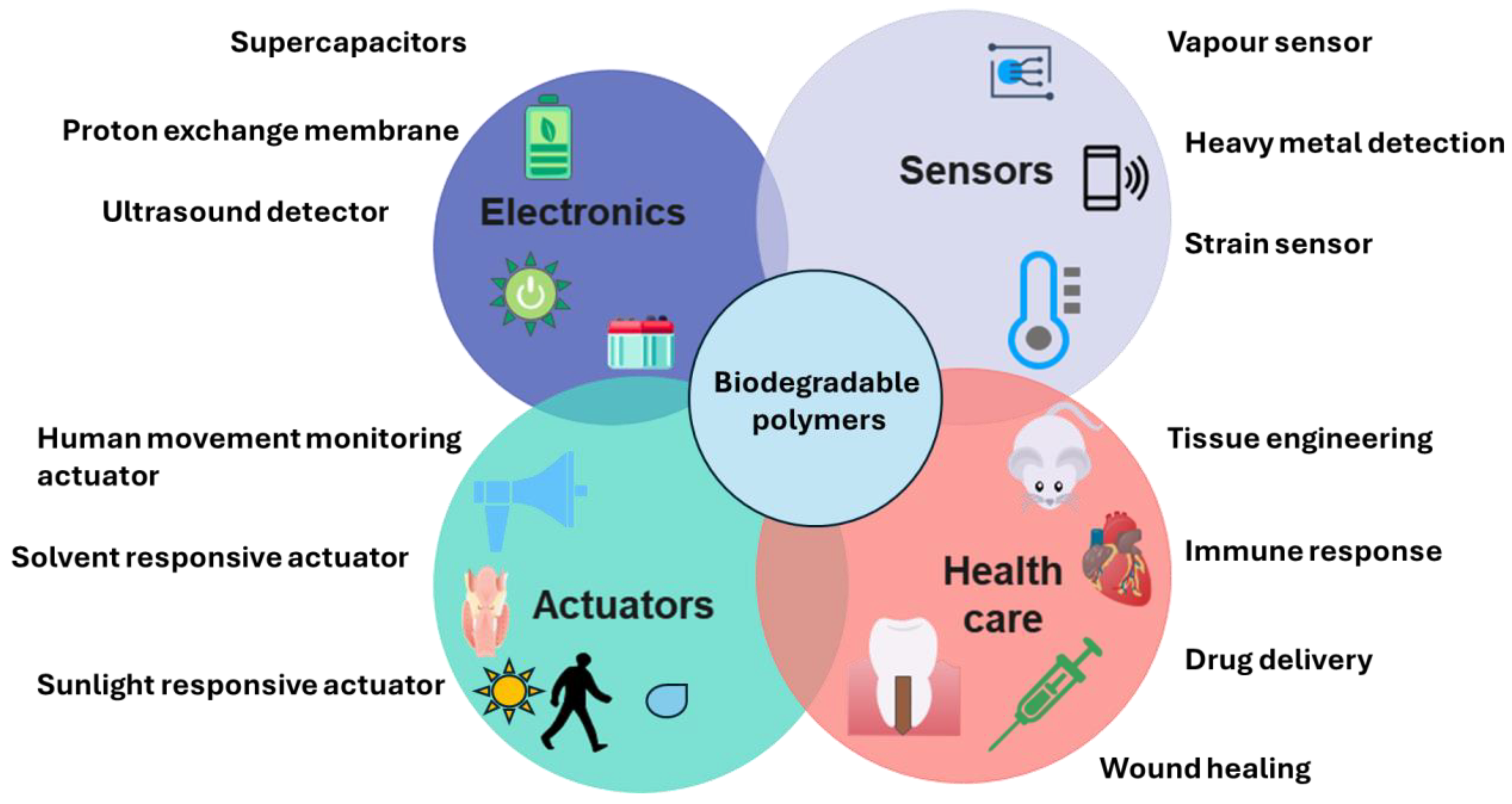

1. Introduction

The ubiquitous presence of plastic and electronic devices in modern society has led to a dual crisis: the escalating accumulation of plastic waste and the global surge in electronic waste (e-waste). Each year, global plastic production exceeds 390 million metric tons, with a significant subset entering landfills or the natural environment, persisting for centuries, and fragmenting into microplastics that infiltrate the food chain and threaten ecosystems and human health [

1]. Concomitantly, e-waste is increasing at an alarming rate. In 2022, global e-waste reached 62 million tons, an 82% rise since 2010, with only about 22% formally recycled [

2]. The convergence of these environmental and health concerns has catalyzed an urgent quest for sustainable material solutions, especially in the design and fabrication of next-generation electronic devices, sensors, actuators, and medical technologies.

Traditional plastics and electronic materials are primarily derived from fossil resources, are non-renewable, and are inherently resistant to degradation [

3,

4]. Beyond their persistence, conventional electronics typically incorporate toxic heavy metals and halogenated flame retardants. This intensifies the environmental impact when these products reach the end of life, often resulting in hazardous leachates that contaminate soil and water, or air pollutants released by incineration [

4,

5]. Inappropriate management and disposal raise public health risks and accelerate ecological degradation, challenging the very foundation of circular economy principles and sustainable development. Biodegradable polymers constitute a diverse family of macromolecules distinguished by their ability to undergo fragmentation, assimilation, and mineralization into non-toxic byproducts through chemical, physical, or biological processes. They can be classified according to their origin (natural vs. synthetic), chemical structure, or application-specific properties [

6,

7]. Natural Biopolymers are produced by living organisms or derived from renewable bioresources. These include polysaccharides (cellulose, chitosan, alginate, starch), proteins (collagen, gelatin, silk fibroin), and polyesters (polyhydroxyalkanoates, or PHAs) [

8,

9]. Natural biopolymers are inherently biocompatible, making them attractive for biomedical and environmental applications; however, they often exhibit high batch-to-batch variability and limited tunability of their mechanical and electrical properties. Synthetic Biodegradable Polymers, on the other hand, are synthesized via industrial polymerization processes; these materials offer more consistent physicochemical properties and tailorability. Common examples include polylactic acid (PLA), polyglycolic acid (PGA), polycaprolactone (PCL), poly(butylene succinate) (PBS), and poly(lactic-co-glycolic acid) (PLGA). Their degradation is mainly mediated by hydrolyzable ester, anhydride, or amide bonds, and their rates can be adjusted via copolymer composition, crystallinity, or molecular weight [

6,

10,

11]. Regardless of their origin, these materials play a crucial role in emerging electronics and healthcare applications.

Table 1 presents some representative applications of these materials. Traditionally, these polymers lack the conductive properties for integration in electronics, sensing, and actuation. Conductivity is achieved by dispersing conductive additives, such as carbon nanotubes (CNTs), graphene, polyaniline (PANI), polypyrrole (PPy), metallic nanoparticles, or ionic salts, into the biodegradable polymer matrix. This approach creates percolative pathways for efficient charge transport while leveraging the host polymer’s biodegradability [

12,

13].

Life cycle assessment (LCA) measures the environmental impact of products throughout their lifecycle [

14]. However, most biopolymer LCAs focus mainly on global warming potential and fossil energy, making biopolymers seem more environmentally friendly due to their biogenic carbon [

15]. This ignores key trade-offs like land use, eutrophication, water use, and toxicity. End-of-life (EoL) modeling is often simplified or omitted, despite its critical influence on decisions like composting, anaerobic digestion, recycling, or landfilling. According to the International Organization for Standardization (ISO), Life Cycle Assessment and its applications are defined in ISO-14040 and ISO-14044 [

14]. The ISO’s LCA framework involves a four-step process: (1) defining the goal and scope, (2) analyzing inventory, (3) analyzing impact, and (4) interpreting the results. To provide accurate inventories for all processes related to a product’s production, use, and end-of-life, LCAs require extensive data. A comprehensive view requires combining impact categories with realistic EoL scenarios. The fate of materials at the end of their life (EoL) can substantially influence the results of conventional plastics and warrants equal consideration within biopolymer LCAs [

16]. However, the reported results are not always directly comparable, as various studies tend to model diverse and sometimes non-realistic end-of-life scenarios, including landfilling, recycling, incineration, or composting [

17]. This has caused recurring demand to conduct end-of-life in a deeper manner, despite the inventory data on biopolymer production and waste pathways becoming more refined and capable of being used to model them in greater detail. Thus, to mitigate a typical shortcoming, it would be preferable to explicitly model realistic EoL scenarios, such as landfill, industrial composting, and recycling. This will be a true indicator of the fact that the disposal options would have significant effects on the total life-cycle implications of such materials. Waste electrical and electronic equipment (WEEE, or e-waste) has become one of the fastest-growing global waste streams, reflecting society’s increasing demand for digital devices. The European Union and other jurisdictions have established comprehensive policy frameworks aimed at minimizing environmental impact, with a focus on repairability, reuse, recycling, eco-design, and principles of the circular economy. Nevertheless, in practical terms, the volume of e-waste generated continues to exceed the capacity of formal collection and recycling systems, highlighting the necessity for broader adoption and more effective implementation of these measures [

18]. Over the past two decades, policy reforms have clarified responsibility and promoted eco-design and cleaner or greener treatment methods, thereby enhancing material recovery and alleviating ecological and resource-related concerns. However, recycling efforts remain inconsistent, with capacity still dependent on resource-intensive traditional techniques. Fourth-Industrial Revolution technologies, such as AI, Internet of Things (IoT), robotics, and advanced analytics, have the potential to enhance design, traceability, and recovery rates, provided that their deployment is equitable and regionally inclusive.

In this article, the term “biopolymers” refers to polymers derived from natural or renewable resource sources, such as PLA, starch, and cellulose. Biodegradable polymers like PCL and PHA are broken down through the action of microbial enzymes, which form environmentally benign end-products such as CO

2, biomass, water in aerobic conditions, and methane in anaerobic conditions [

14]. These properties are shaped by specific environmental conditions and testing standards because biodegradation depends on certain factors; for example, industrially compostable PLA cups meet EN 13432:2000, and soil-biodegradable mulch films comply with EN 17033:2018 [

19]. On the other hand, biopolymeric materials are engineered, application-driven systems consisting of a single or more polymers combined with plasticizers, stabilizers, fillers, reinforcements, dopants, or coatings, such as a PCL/PLA blend or a cellulose-based composite. Their performance and end-of-life performance are, therefore, dependent on the comprehensive formulation and not only on the base polymer [

6]. This perspective article intends to comment on the start of advances in biodegradable polymers for electronics, sensing, actuation, and healthcare applications. While doing so, we also want to highlight the significant prospects these polymers offer in these domains.

Table 1.

Representative Biodegradable Polymers, Origins, and Key Properties.

Table 1.

Representative Biodegradable Polymers, Origins, and Key Properties.

| Polymer | Source | Key Properties | Degradation Mechanism | Representative Applications | Limitations | Ref. |

|---|

| Cellulose | Plant | High strength, renewable | Enzymatic hydrolysis | Paper electronics, substrates, sensors | High reprocessing costs, moisture sensitive. | [20,21,22] |

| Chitosan | Animal | Biocompatible, antimicrobial | Enzymatic, hydrolytic | Wound healing, scaffolds, biosensors | Weak mechanical properties | [23,24] |

| PLA | Synthetic | Tunable, transparent | Hydrolysis | Packaging, 3D-printing, medical implants | Low melting point, Brittleness | [25,26,27,28,29] |

| PLGA | Synthetic | Sensitivity towards temperature, FDA-approved | Hydrolysis | Drug carriers, bioresorbable electronics | Production of acid upon degradation | [30,31,32,33,34] |

| PCL | Synthetic | Flexible, slow-degrading | Hydrolysis | Scaffolds, adhesives, sutures | Slow degradation | [35,36,37,38] |

| PHAs | Microbial | Elastomeric, hydrophobic, excellent mechanical properties | Enzymatic hydrolysis | Actuators, implants, drug delivery | Low flexibility | [39,40,41] |

2. Advances of Biodegradable Polymers in Electronics Applications

Biopolymers must demonstrate a distinctive combination of mechanical, chemical, and electrical properties to be regarded as valuable in active electronic applications beyond passive utilizations. The intrinsic design and architecture, featuring a tunable elastic modulus and excellent tensile strength, provide significant flexibility and mechanical stability, which are essential for electronic components to function adequately as flexible electronics. The ability of chemical modification, surface engineering, specific absorption, ionic conductivity, and interfacial interactions of biopolymers, which necessitate the presence of functional groups such as hydroxyl, carboxyl, and amino, is vital for sensing and conducting functionalities. In addition, many biopolymers have inherent dielectric strength, conductivity, hydrophobicity, and biocompatibility, making them all well-suited towards implanted and wearable biomedical applications [

42]. However, biopolymers suffer from limited thermal stability, and, hence, it is challenging to utilize them in high-temperature environments. Fundamental thermal properties such as glass transition temperature (T

g), melting temperature (T

m), and degradation temperature depend on their chemical structure, crystallinity, and functional groups associated with the polymeric backbone. Despite these challenges, new methods of molecular engineering, including cross-linking, doping, and blending, have provided researchers with the ability to tailor these materials to multifunctional, high-performance bioelectronic applications. Cellulose nanocrystals (CNCs) derived primarily through sulfuric acid hydrolysis exhibit high crystallinity, mechanical strength, and low thermal stability due to the presence of surface sulfate groups. However, the incorporation of reinforcement agents has enhanced the time of onset of degradation and tolerance to heat [

43].

Considering mechanical properties, most biopolymers derived from starch exhibit high hydrophilicity and water-absorption capabilities, which result in poor mechanical strength relative to synthetic polymers. Nevertheless, the addition of urea as a plasticizer in corn starch has been observed to exhibit better mechanical properties, whereby the higher the urea concentration, the stronger the film, implying both higher strength and elasticity in the plasticized properties [

44]. The electrical properties of chitosan are relatively low in conductivity because it lacks mobile hydrogen ions in the polymer structure. However, doping with electrochemically active species (e.g., acids or inorganic salts) may further provide extra charge sites, which facilitate proton migration. In addition, the electrostatic interaction between the acid groups and the basic amine groups of chitosan also facilitates proton transportation, therefore, significantly contributing to proton conductivity in the chitosan membrane [

45]. In this discussion, we elaborate on how these structural and functional characteristics are utilized and reengineered to meet the increasing demands of flexible and sustainable electronic technologies [

46,

47,

48].

Starch-based biopolymer gel electrolytes have gained significant attention due to their simple fabrication process and cost-effectiveness. Finkenstadt et al. [

49] found that incorporating metal halides into extruded starch films greatly improved electrical conductivity, increasing it from 10

−11 to 10

−6 S/cm. Hou et al. [

50] observed that starch hydrogels formed with inorganic salt solutions achieved conductivities of 0.2–0.3 S/cm. Wang et al. [

51] and Zhang et al. [

52] demonstrated that plasticizing starch with ionic liquids, such as 1-allyl-3-methylimidazolium chloride and 1-ethyl-3-methylimidazolium acetate, can increase conductivity to 10

−3 S/cm and 0.0118 S/cm, respectively. However, this often reduces mechanical strength because water content weakens the interactions between starch chains. Notably, Zhang’s study revealed a Young’s modulus of 3–4 MPa, whereas Hou’s findings suggested a value of approximately 1 kPa.

Chitosan (CS) is another renewable polysaccharide derived from the deacetylation of chitin. It has higher crystallinity and a greater chemical reactivity, which is contributed to by its molecular structure that is rich in three functional groups: hydroxyl (-OH), primary amine (-NH

2), and ether (C-O-C) groups [

53]. However, the pristine polymer displays low proton conductivity along with a lack of physicochemical stability, hence restricting its applicability in proton-exchange membranes (PEMs). Consequently, structural modification, i.e., doping, crosslinking, blending, and composite membranes, is required to reengineer it for optimal use in this field. Rosli et al. [

54] prepared an enhanced proton conductor via a structurally modified CS derivative, N-methylene phosphonic chitosan (NMPC with polyvinyl alcohol (PVA), by adopting the solution-casting method. Following the same method, SiO

2 was incorporated into NMPC/PVA membranes. The proton exchange behavior of the membranes is closely related to their proton conductivity, ion-exchange capacity (IEC), and water uptake. Increasing concentration of modified CS in the NMPC/PVA system enhances water uptake and increases proton conductivity, because of the large numbers of hydrophilic H-bonding -OH, -NH

2, and -PO

3H

2 groups present that allow the formation of hydrated networks and subsequent proton transport. The addition of SiO

2 also increases the water content to 55.7%, IEC to 0.56 meq/g, and proton conductivity to 5.08

10

−4 S/cm at 100 °C because of the presence of more proton-transporting pathways provided by the interaction of -Si-OH and by increases in hydration. A similar study by Kamjornsupamitr et al. [

55] also utilized CS/PVA and sulfonic acid decorated SiO

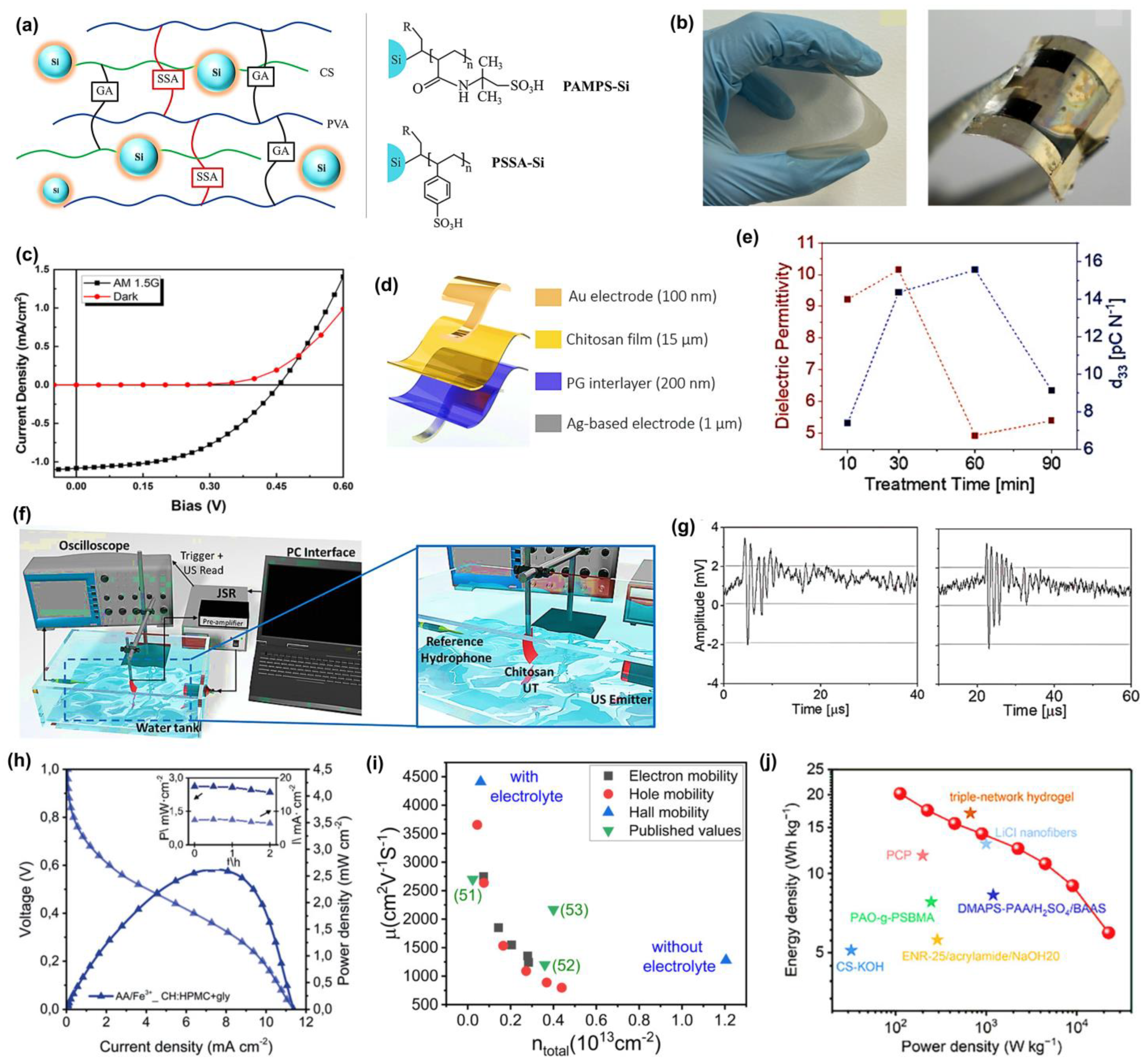

2 nanoparticles to fabricate an interpenetrating network (IPN) for low-cost proton conduction. They prepared CS and PVA crosslinked with sulfosuccinic acid (SSA), combined with glutaraldehyde, as shown in

Figure 1a, where each plays a specific role: SSA as a proton source, glutaraldehyde was also added to minimize the water uptake and increase the mechanical strength. Further improvements to increase proton conductivity and hydrolytic stability, poly(2-acrylamido-2-methyl-1-propanesulfonic acid) (PAMPS-Si) or poly(styrene sulfonic acid) (PSSA-Si) nanoparticles were also added to the polymer matrix. The proton conductivity of CS-PVA-1.5SSA-GA reached a maximum of 1.1

10

−3 S/cm. The effects of loading different nanoparticles (both PAMPS-Si and PSSA-Si) on water vapor absorption, water uptake, and IEC were not apparent. However, conductivity was also enhanced in the presence of nanoparticles, reaching a maximum of 3.83 to 3.9

10

−3 S/cm in the composite membranes. The presence of a polymeric shell did not have a significant effect on proton conductivity in this work since comparable percentages of polymer weight (4.0% and 5.1%) were applied to the SiO

2 particles, and the water uptakes of these composite membranes at the same loading were significantly comparable. Di Franco et al. [

56] used ionotropic gelation to fabricate a PEM that showed excellent proton conductivity at low temperature, which makes use of CS and silicotungstic acid for H

2-O

2 fuel cells. These membranes functioned successfully as proton conductors in a low-temperature (25 °C) fuel cell system fueled on hydrogen with a power density maximum of 268 mW/cm

2 and a Pt loading of 0.5 mg/cm

2. Another group has studied cellulose nanocrystals (CNCs) for biopolymer-based fuel cell applications [

57]. The protic ionic liquid (PIL) combined with imidazole was introduced into CNCs to produce self-standing and strong membranes through the simple solution casting procedure. These composite membranes have a high proton conductivity range 10

−4–10

−3 S/cm at 160–120 °C, which is essential to proton exchange at high temperatures for membrane fuel cells (HT-PEMFCs). According to the conductivity, these membranes are comparable to membranes made from synthetic polymers. Additionally, the temperature range for optimal performance of CNC/Im/PIL exceeds the target temperature for future non-humidified fuel cell devices. The simultaneous presence of imidazole and imidazolium in the PIL, along with the lower activation energy measured, indicates that these materials are suitable for proton conduction. The principles behind the proton conduction mechanism are proposed to be hydrogen bonding and ionic mobility in the constrained nanostructure of CNCs and the PIL. Their investigation on a nanoscale level showed that PILs tend to alter the crystallites, which could be due to a direct interaction between the imidazolium cations and the biopolymer. Zhang et al. [

58] suggested an alkali-resistant hydrogel electrolyte membrane prepared through the graft copolymerization of a carboxylated chitosan hydrogel. Compared to PAAS electrolyte, the prepared membranes have better properties, including high ionic conductivity 7.82

10

−2 S/cm, and high electrolyte uptake of 524%. The alkaline supercapacitor has a commendable energy density of 4.39 Wh/kg and a power density of 224.99 W/kg in a quasi-solid state. They explained that these biopolymeric gel electrolytes can also be utilized in acidic and neutral electrolytes.

In the case of starch-based hydrogels, their mechanical properties are usually limited due to the rigid and highly branched nature of the amylopectin structure, which hinders intermolecular interactions. However, amylose-rich starches have more linear chains, resulting in stronger hydrogen bonding and entanglement, and, therefore, superior mechanical properties [

59]. Recent developments of high-amylose starch with calcium chloride have worked, creating flexible and strain-responsive hydrogels that can be used as wearable sensors [

60]. The addition of inorganic salts, such as CaCl

2, MgCl

2, and ZnCl

2, also increases plasticity and provides mobility of ions, which significantly enhances electric conductivity, a factor crucial in flexible electronics [

61]. Based on these reports, Ma et al. [

62] developed high-amylose-rich starch using CaCl

2 and glycerol, which exhibited improved mechanical resilience (elongation at break of ~208%) and potential applications in flexible bioelectronics. Moreover, this starch-based Zn-Cu battery-based system is also a self-powered wearable sensor that can detect minute motions of the human body, such as a pulse on a wrist and throat vibration under compressive stresses, with a high sensitivity of 1.5371 kPa

−1.

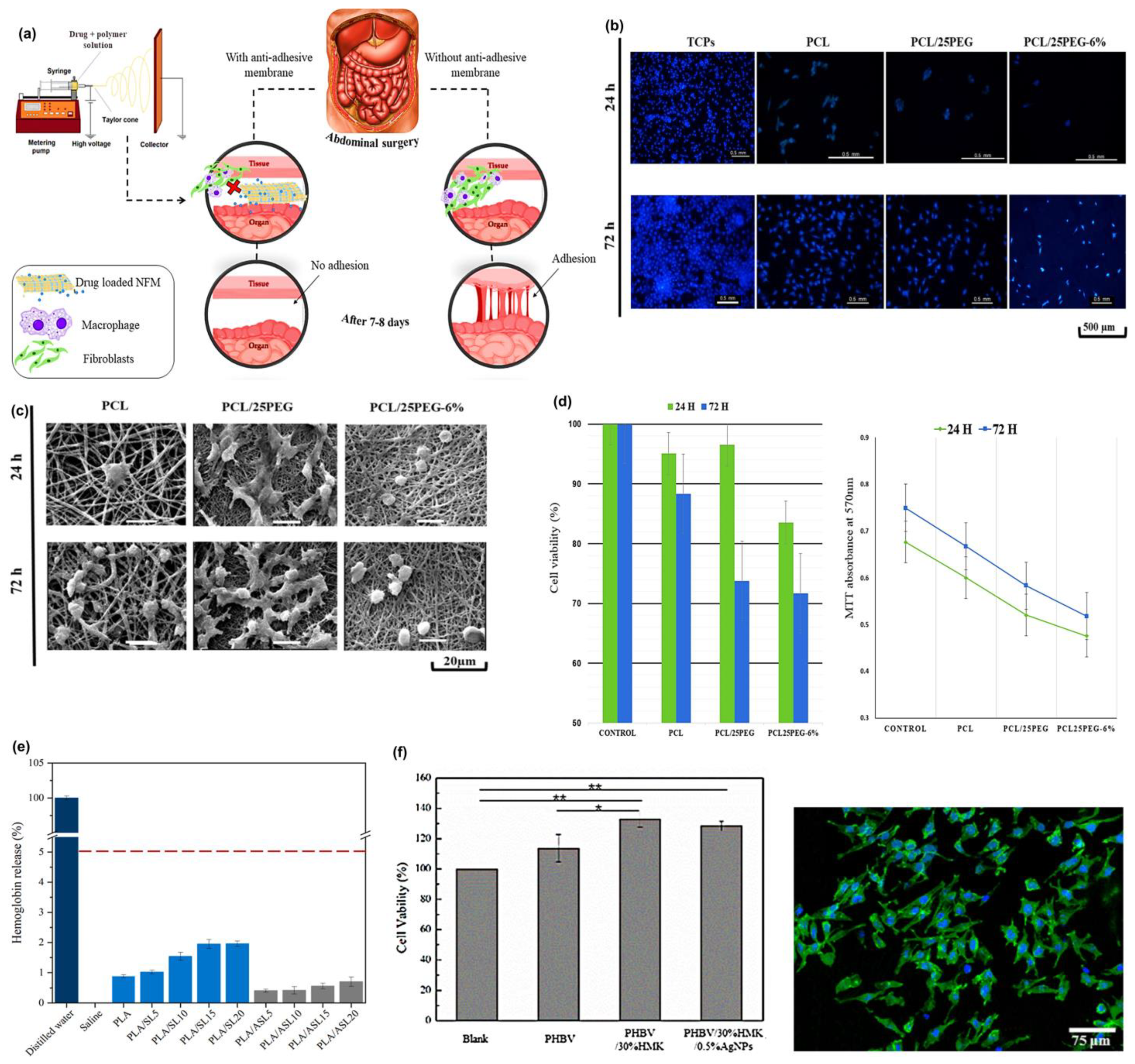

Saha and coworkers [

63] have examined porous polylactic acid (PLA)/polyethylene glycol (PEG) films, 25:75 wt% as separators for supercapacitors, with ionic conductivities determined at room temperature to be 1.1 times 10

−1 S/cm and 0.6 times 10

−2 S/cm in 1 M H

2SO

4 and 1 M Na

2SO

4 inert electrolytes, respectively. The porous PLA film was prepared through a phase inversion process, and the scanning electron microscope (SEM) cross-sectional images showed a porous interconnected structure to facilitate ionic diffusion. Radio frequency (RF) treatment, which uses air plasma, was used to enhance wettability by modifying the separator surface. A sustainable organic photovoltaic was prepared by das Neves et al. [

64] by the casting and slot-die printing technique. In the casting approach, chitosan was combined with a polysulfone solution, after which they were cast onto a substrate to form flexible membranes, as shown in

Figure 1b, left, and an optoelectronic device membrane, as shown in

Figure 1b, right. For the slot-die method, the chitosan solution was printed onto a heated substrate at 70 °C, resulting in thin (~10 µm) and flexible films without the need for any additional polymer or polysulfone solution. The membrane has the characteristics of a rectifier diode, short-circuit current of 1.1 mA/cm

2, and open-circuit voltage of 0.45 V during illumination in darkness (black squares) and under light (red circles), shown in

Figure 1c. It can be successfully combined with conductive polymers (e.g., PEDOT:PSS), which permits making efficient charge transport interfaces without sacrificing the expense and brittle nature of transparent electrodes like ITO. Moreover, the optical transmittance (>70%) and mechanical stability of the chitosan-based membrane can be easily restored after repeated bending, making it an interesting green candidate material for the flexibility and printability of photovoltaic devices. Another interesting study using CS demonstrated a simple method to enhance the piezoelectric coefficient. The first piezoelectric transducers based on chitosan were demonstrated by de Marzo et al. [

65] They produced a transparent chitosan film, giving a piezoelectric coefficient of 15 pC/N, which is more than twice the reference value of 6 pC/N. They develop the initial prototypes of a flexible ultrasonic transducer (UT) with a high sensitivity of 80 mV/kPa and a semi-transparent pMUT chitosan. A stretchable, flag-like UT was fabricated using chitosan films modified with a pair of asymmetric electrodes of different types, gold (Au) and silver (Ag), referred to as CT-Au/Ag, as shown in

Figure 1d. The first step in the fabrication process was 3D printing of silver nanoparticle ink, printed using LDM printer on glass, subsequently spin-coated with 200 nm thick PEDOT:PSS mixed with 4% glycerol to make the material conductive and adhesive. Films were cast from a chitosan solution over the treated surface and air-dried. The result of the electrical characterization was that the capacitance of all samples was in the nanofarad range and decreased at higher frequencies (2 Hz to 1 MHz). They compare dielectric permittivity and piezoelectric coefficient versus time to calculate the figure of merit, as shown in

Figure 1e. The highest figure of merit was attained at 5.6 GPa, suggesting that the electromechanical conversion efficiency was better. The maximum sensitivity like 80 mV/kPa was observed with the maximum output of the device like 32 mV and the linear working range being 0–0.5 kPa. This is one of the highest sensitivities reported for both biodegradable and conventional flex piezoelectric transducers. In particular, it was responsive to finger tapping (1.25 kPa), and human blowing (25 Pa), which are relevant pressure ranges. The immersion transducer (1 MHz frequency) was used to analyze the ultrasonic sensing as depicted in

Figure 1f. All parts were immersed in a water tank to enable propagation of ultrasounds.

Figure 1g shows the signal registered with CT-Au/Ag (left) and the ultrasound signal at 1 MHz registered with (right) pMUT, the measured peaks-to-peak output voltages after amplification, which were 5.3 mV in CT-Au/Ag and 5.4 mV in pMUT. The maximum range at which all devices could detect the ultrasound signal was 10 cm, with a Time-of-Flight (ToF) of ~70 µs. Alday et al. [

66] explored environmentally benign biopolymer electrolyte membranes (BioPEMs) made of chitosan (CH), cellulose (hydroxypropyl methylcellulose, HPMC), and starch, which is comparable in performance to Nafion™ (DuPont, Wilmington, DE, USA) membranes. BioPEMs based on chitosan-cellulose (CH:HPMC) doped with ionic liquids (ILs) have successfully found application in primary redox batteries. Crossover experiments involving eco-friendly redox species: hydroquinone sulfonic acid (H

2BQ), ascorbic acid (AA), p-benzoquinone (p-BQ), as well as Fe

3+ were conducted to reveal that CH:HPMC+gly was of high selectivity to limit species migration, especially species with charge. They subsequently tested these BioPEMs in battery-based systems with two different redox chemistries (AA/Fe

3+ and H

2BQ/p-BQ), which showed a high open circuit voltage (0.75 and 0.90 V) and specific power densities of up to 2.5 mW/cm

2 at greater than 90% stability over time, as shown in

Figure 1h. Prajapati et al. [

67] provide a detailed study of biopolymer blend electrolyte membranes (BPBEs) composed of chitosan, PVA, and PEG-200, doped with different concentrations of Mg(NO

3)

2, for use as an electrode in electric double layer capacitors, EDLCs. Electrical characterization of the membranes showed that the optimized composition (BPBE-4, 30 wt% Mg(NO

3)

2) had the highest bulk dc conductivity of 1.20

10

−4 S/cm at 30 °C with the ionic transference number of 0.99, indicating that it was ion-dominated conduction. The sample also exhibited the lowest activation energy of 0.20 eV, indicating efficient ionic transport due to the increased amorphous content. AC conductivity obeyed the Jonscher power law and the power exponent 0.60 s, whereas the dielectric analysis showed a single relaxation peak corresponding to polymer chain dynamics. The membrane was determined to have an ion diffusivity of 1.33

10

−1 cm

2/s, charge carrier density (N) as 1.48

10

21 cm

−3, and the mobility (µ) as 5.08

10

−7 cm

2/V.s. Linear sweep voltammetry also determines an electrochemical stability window between −2.0 and 2 V, verifying that it is suitable to use with EDLC devices. The peak specific capacitance, energy density, and power density of the optimized BPBE membrane when assembled into an EDLC were found to be 6.05 F/g, 2.26 Wh/kg, and 61.42 W/kg, respectively, at 1.5 V and 0.5 µA/cm

2, indicating its potential use as a sustainably high-performance energy storage device.

The use of solid biopolyelectrolytes with 2D materials has not been extensively examined. Alshehri et al. [

68] solve the critical problem of electronic waste with biodegradable and renewable biopolymers capable of forming stable electric double layers (EDLs), permitting effective gating at low voltage (<1 V) and high mobility ~5000 cm

2/V.s. Moreover, this work reports on gate-dependent EDL capacitance of monolayer graphene devices, effectively distinguishing the effect of quantum capacitance of graphene and EDL capacitance. They used chitosan, xanthan gum, and sodium alginate. Its rational formulation involved glycerol plasticization to increase the film’s flexibility and raise its ionic conductivity. Chitosan-based transistors demonstrated significant improvement of the hall mobility of 1200 cm

2/V.s (without chitosan) to 4411 cm

2/V.s (presence of chitosan membrane) and reduction in the carrier concentration of 6.1 × 10

11 cm

−2 with electrolyte gating, shown in

Figure 1i. Such improved performance is due to the screening effects of the layer of chitosan. It confirms gate dielectric performance by field-effect and Hall measurements and makes these biopolymers viable options for low-power applications in eco-friendly, scalable electronics. Tang and coworkers [

69] have developed an RCC composite membrane that functions as both a separator and an electrode for supercapacitors using a one-pot approach, comprising reduced graphene oxide (RGO), cellulose nanocrystals, and cellulose nanofibers. The hydrophilicity and the mechanical properties of RCC composite membranes were more favourable than those of traditional membranes. Furthermore, the specific capacitance of the RCC composite membrane was 171.3 F/cm

3. As a result, a symmetric and flexible supercapacitor in solid-state (FASC) was fabricated using nanocellulose, and a porous cellulose membrane was used as a separator. This exhibited 164.3 F/cm

3 of specific capacitance and an energy density of 3.7 mWh/cm

3 that surpassed FASCs that have ever been reported. Recently, Li et al. [

70] demonstrated a sustainable approach toward the fabrication of supercapacitors by utilizing sodium alginate (SA) via in situ carbonization of Ca

2+ crosslinked alginate with urea. They obtained a remarkable gravimetric capacitance of 233.6 F/g and an impressive areal capacitance of 29.2 µF/cm

2 at a current density of 0.25 A/g at 6 M KOH. The device exhibits a high energy density of 20.2 Wh/kg or 112.5 W/kg, which is maintained at 6 Wh/kg at 22.5 kW/kg, with 95.9% cycling stability over 10,000 cycles at 10 A/g, as shown in

Figure 1j. This alginate-based system makes biomass-based materials for energy storage a reality.

However, biopolymer-based electronics have a major limitation to thermal stability, with heat and humidity potentially causing softening, hydrolysis, and interfacial degradation that can negatively affect electrical and mechanical performance. Zhu et al. [

71] have introduced chitosan-hydroxyapatite aerogels, demonstrating an effective stabilization method. Covalent crosslinking and freeze drying yield anisotropic porosity to form a honeycomb network. This leads to a low radial thermal conductivity of 28.16 to 37.43 mW/m·K, slower degradation, higher char yields at 800 °C, and reduced heat release rates during combustion, while maintaining high porosity and a reinforcing matrix. These properties collectively serve as a thermal shield, providing a viable blueprint for bioelectronic substrates or encapsulants that can withstand changes in temperature. In light of this evidence, design principles aim to enhance the softening of the window through the use of crosslinking biocompatible and thermally stable fillers, which improve char formation, directional heat pathways, and ensure property retention at operating temperatures and relative humidity levels, in addition to conventional thermal properties. Similarly, Darius et al. [

72] engineered a biosensor with encapsulation that can maintain the functionality of the device at high temperatures by overlaying a 2D perovskite with silk-fibroin. Under 40 °C, the biosensor maintained approximately 85% sensitivity after 1–2 days and 57.8% sensitivity after 7 days, in contrast with ~13% without silk. Notably, performance at the sensing level (LOD 10 pg/mL of cTnI) remained, and the film could be washed off after storage to measure it. This exhibits, with a benign biopolymer barrier, a low-energy, cold-chain-free route to thermally robust bioelectronics. In the case of biopolymer energy-storage devices, the thermal stability of the electrolyte plays a vital role in device safety, shelf life, and capacity sustainability during heating processes associated with operation and charging. In a recent study, Naveen et al. [

73] investigated a solid polymer electrolyte based on gelatine and PVA doped with MgCl

2. They discovered that the higher salt level of 8 wt% forms a more amorphous structure, which yields a 4.1 × 10

−3 S/cm ionic conductivity at room temperature. TGA curves from 0 to 350 °C show that the main mass loss begins around 200–220 °C, indicating sufficient thermal stability of low-voltage EDLCs. Additionally, the optimal film has the lowest activation energy of 0.21 eV in the Arrhenius analysis. The gelatine/PVA/MgCl

2 system is a potential candidate in green supercapacitors under the condition that the operating temperature does not reach the point of thermal degradation. As such, in general, with benign encapsulation, crosslinking or stereocomplexation, and thermally stable fillers, biopolymer electronics can attain the thermal profile required to ensure reliable operation in real-world temperature variations and end-of-life sustainability.

Thus, biopolymers have proven versatile in sustainable electronics due to their tunable physicochemical, electrical, and mechanical properties through various structural modifications. Applications in proton exchange membranes based on chitosan, as well as the ionic conductivity of cellulose, supercapacitors constructed from alginate, and PLA-based electronics demonstrate that these materials hold great promise for next-generation electronic, energy, and sensing systems. As molecular engineering and surface modification of biopolymers continue, biopolymers are expected to dominate the world of flexible, high-performance, and low-energy-consumption electronic systems. A comparative study of biodegradable polymer composites and their key characteristics is provided in

Table 2.

Figure 1.

(

a) Schematic illustration of CS/PVA IPN membrane system. Adapted with permission [

55]. Copyright 2020 Elsevier. (

b) Photograph of the CP membrane (

left) and the device fabricated on the CP membrane (

right). Adapted with permission [

64]. Copyright 2025 American Chemical Society. (

c) J-V characteristic curves for the device. Adapted with permission [

64]. Copyright 2025 American Chemical Society. (

d) Scheme of the device using a CS membrane. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

e) Plot of dielectric permittivity and piezoelectric coefficient values over treatment time. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

f) Diagram showing the setup for ultrasound measurements. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

g) Ultrasound signal at 1 MHz. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

h) Polarization curves for redox batteries. Adapted with permission [

66]. Copyright 2019 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (

i) Comparison of mobility and carrier concentration in CVD graphene on Si/SiO

2. Adapted with permission [

68]. Copyright 2025 American Chemical Society. (

j) Comparison of Ragone plots for AQS and other reported SCs. Adapted with permission [

70]. Copyright 2025 Wiley-VCH GmbH.

Figure 1.

(

a) Schematic illustration of CS/PVA IPN membrane system. Adapted with permission [

55]. Copyright 2020 Elsevier. (

b) Photograph of the CP membrane (

left) and the device fabricated on the CP membrane (

right). Adapted with permission [

64]. Copyright 2025 American Chemical Society. (

c) J-V characteristic curves for the device. Adapted with permission [

64]. Copyright 2025 American Chemical Society. (

d) Scheme of the device using a CS membrane. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

e) Plot of dielectric permittivity and piezoelectric coefficient values over treatment time. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

f) Diagram showing the setup for ultrasound measurements. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

g) Ultrasound signal at 1 MHz. Adapted with permission [

65]. Copyright 2023 Wiley-VCH GmbH. (

h) Polarization curves for redox batteries. Adapted with permission [

66]. Copyright 2019 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (

i) Comparison of mobility and carrier concentration in CVD graphene on Si/SiO

2. Adapted with permission [

68]. Copyright 2025 American Chemical Society. (

j) Comparison of Ragone plots for AQS and other reported SCs. Adapted with permission [

70]. Copyright 2025 Wiley-VCH GmbH.

![Materials 18 04485 g001 Materials 18 04485 g001]()

3. Advances of Biodegradable Polymers in Sensing Applications

The characteristic features of biopolymers make them highly desirable in sensor development due to their biocompatible, biodegradable, functional group versatility, and sustainable nature. In wearable, flexible, or electrochemical sensing applications, it is crucial that the materials are mechanically stable, exhibit excellent hydrophilicity, have high adsorption capacity, and possess chemical sensitivity. Additionally, incorporating reactive functional groups, such as hydroxyl, amine, and carboxyl groups, is beneficial. These attributes help immobilize bioreceptors, promote interactions with their targets, and promote effective signal transduction [

74]. Despite potential limitations such as low solubility and thermal stability, biopolymers like starch, chitosan, cellulose, and PVA are often combined with conductive additives like metal oxides, carbon nanotubes, or conducting polymers to address these issues. Compared to synthetic or carbon-based alternatives that depend on possibly toxic processes, biopolymer composites are a more environmentally friendly option for developing sensitive, selective, and multifunctional biosensors.

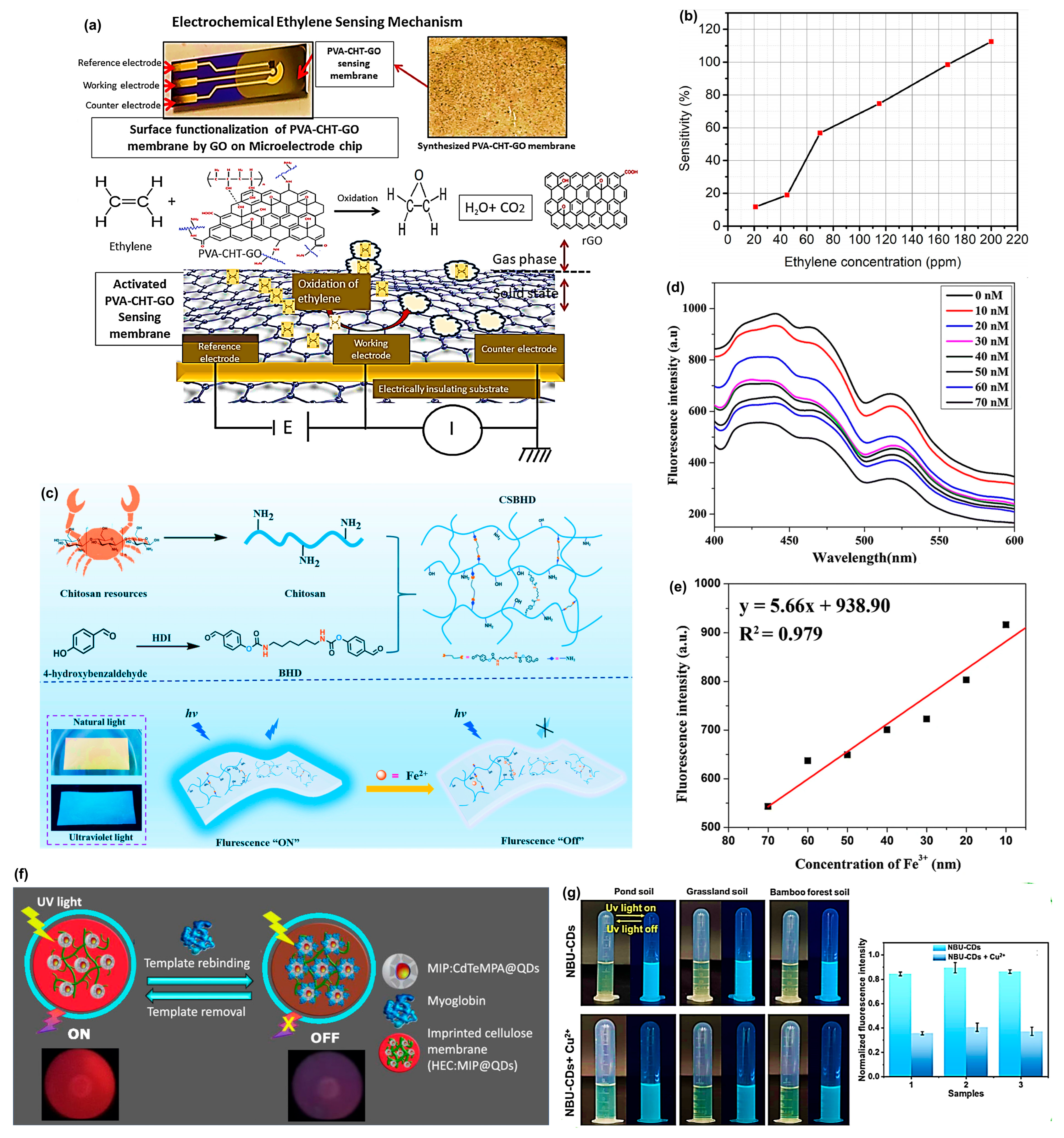

The biodegradable membrane, with chitosan (CHT), polyvinyl alcohol (PVA), and graphene oxide (GO), was first reported by Roy et al. [

75] to address the urgent need for high-sensitivity ethylene detection, shown in

Figure 2a. PVA is a strong film-forming polymer network with hydrophilic characteristics, and chitosan has high chain mobility and rich amine groups, allowing for extended interaction with GO and gaseous molecules. GO insertion into the PVA-CHT mixture, and subsequent aqueous GO-assisted surface activation resulted in a large enhancement of the oxygenated functional group and defect density and, therefore, allowed rapid charge transport and higher ethylene adsorption. Such an arrangement allowed redox interaction between ethylene and the GO-activated composite. The analysis of the cyclic voltammetry (CV) also found that prior to exposure to ethylene, the membrane had an anodic peak and a cathodic peak of potentials of 0.05–0.10 V and 0.02–0.13 V, respectively. After the introduction of 180 ppm ethylene, the anodic peak shifted towards 0.03 to 0.07 V, and peak currents were considerably reduced at all applied potentials, meaning that ethylene was quickly oxidized and the electrons were transferred through the GO layers. The decrease in ethylene concentration (from 30 ppm) exhibited gradual changes in peak amplitudes that persisted for more than 100 min. Conversely, at a higher concentration (180 ppm), the disappearance of peaks occurred within 30 min, with faster saturation levels resulting from a stronger interaction between ethylene and graphene oxide (GO). The membrane exhibited better sensitivity, which was calculated up to 200 ppm of ethylene at ~80% using the GO-activated PVA-CHT-GO membrane, as shown in

Figure 2b.

A similarly important category of sensors includes portable and biodegradable membranes used for detecting heavy metals. Wei et al. [

76] explored a fluorescent hydrogel membrane based on chitosan (CSBHD) for the detection and adsorption of ferrous ions (Fe

2+). Chitosan was crosslinked with bis(benzaldehyde) (BHD) to form a Schiff base hydrogel that exhibits significant fluorescence, as shown in

Figure 2c. The CSBHD membrane emits intense blue fluorescence over a wide range when excited by 405 nm and emits at 475 nm. It exhibited a linear dynamic response of 0–160 µM accompanied by a great limit of detection (LOD) of only 0.55 µM in a selective quenching reaction with Fe

2+. The adsorption capacity of the hydrogel to Fe

2+ was also found to be high, reaching 223.5 mg/g with a concentration of 500 mg/L. Similarly, Rijin et al. [

77] designed a portable sensor utilizing PCL electrospun membranes by impregnating them with a fluorophore, 4,4′-fluoresceinoxy bisphthalonitrile (FPN). The membrane exhibits strong fluorescence quenching upon increasing concentrations of Fe

3+ due to chelation by cyanide.

Figure 2d indicates that the fluorescence signal with various metal ion solutions of Fe

3+ at 414 nm gradually decreased with an increasing concentration of Fe

3+ (10–70 nM), thereby confirming successful quenching. The linear calibration curve is shown in

Figure 2e, allowing the calculation of the limit of detection (LOD), which was 2.94 nM, demonstrating that the membrane sensor is highly sensitive. Recently, Liu et al. [

78] designed a chitosan-based fluorescence membrane for detecting and adsorbing Pb

2+ in groundwater. The membrane can also be incorporated in a portable laser-induced fluorescence (LIF) spectrometer to perform on-site detection, with removal efficiency of over 99% and an adsorption capacity of Pb

2+ of 247.6 mg/g, and it is primarily governed by chemisorption. It allows real-time results of Pb

2+ detection in groundwater by using the smartphone-based RGB (Red, Green, Blue) colour analysis and a portable LIFs platform, with satisfactory results.

Wang et al. [

79] prepared a flexible strain sensor utilizing PVA, lignin, and multi-walled carbon nanotubes (MWCNT). Lignin was added to improve the electrical conductivity, mechanical properties, and piezoresistive sensitivity of the PVA substrate. The resulting conductive paths created between the lignin-rich zones under the action of strain are highly adaptive to deformation and so are measured in changes in the resistance. It has the minimum and maximum gauge factor values of 137.3 and 2746.4, respectively, in the strain range of 0–160% and 160–240% with the capability of repeatability (

10,000 tensile cycles). A fast, responsive, and recyclable sensor based on N-doped carbon dots (NCDs) modified PVA membrane is constructed to detect arginine (essential amino acid) by Yang et al. [

80]. This is because PVA interacts with CDs, causing a self-assembly process that forms clusters and results in an increase in fluorescence due to aggregation-induced enhanced emission (AIEE). In the same AIEE effect, Liu et al. [

81] have designed a PVA-coated gold nanocluster membrane and applied it as a pH sensor. The nanoclusters were stabilized by the PVA, which enhanced their fluorescence to a large extent by AIEE. The addition of PVA to adenosine 5′-monophosphate-capped gold nanoclusters (AuNCs@AMP) increased the emission to 35.4% by enhancing emission because of more aggregation in a less polar environment, and the particle emission peak shifted to 380 nm. PVA and AMP exhibited strong hydrogen bonding between the hydroxyl and amino groups, which hindered molecular movements, resulting in a decrease in non-radiative decay and an increase in luminescence.

As a recent advancement in chitosan-based optical fiber sensors, they can selectively and significantly detect the presence of polyphenolic compounds, such as caffeic acid and chlorogenic acid. In the case of caffeic acid, researchers used a molecularly imprinted chitosan (MIP) membrane as the sensing probe of a bent optical fiber sensor [

82]. The MIP membrane crosslinked with glutaraldehyde and caffeic acid molecules as the template created selective detection sites to enable selective solid phase microextraction. This setup demonstrated an exceptional detection limit of 5.2 ng/mL (tens of times more sensitive) as compared to the traditional HPLC-UV/Vis methods. The same group employed for chlorogenic acid utilized a bent optical fiber probe with a chitosan coating to leverage the inherent strength of hydrogen bonds and electrostatic attractions provided by the polymer [

83]. An increased sensitivity of 2400-fold was achieved when this sensor reached a detection limit of 0.018 µg CGA/mL.

Kyung Hyun and coworkers [

84] introduce a highly sensitive biodegradable pressure sensor using a nanofibrous dielectric membrane based on a composite of polylactic-co-glycolic acid (PLGA) and polycaprolactone (PCL). The use of PLGA gives it superior dielectric characteristics (dielectric constant ~3.3–4.4), whereas PCL makes it more mechanically flexible and processable. The sensor reported a very high sensitivity of 0.863 ± 0.025 kPa

−1 at the low-pressure range (0 to 1.86 kPa) and 0.062 ± 0.005 kPa

−1 at the higher-pressure range (1.86 to 4.6 kPa) with a low detection limit of 1.24 Pa. The degradation study indicated that it lost approximately 60% of its weight within 2 weeks and exhibited a 19.5% reduction in low-pressure sensitivity after one week of incubation, with minimal change in high-pressure sensitivity. In a recent study by Zhu et al. [

85] investigated a flexible pressure sensor realized using a grid-patterned membrane made of PCL, thermoplastic polyurethane (TPU), and MWCNTs. Grid design significantly enhances the sensitivity of 2.24 kPa

−1, with a response time of 9.17 ms and the response range of 105 dB compared to a planar sensor. The device accurately records all finger motions, and repeated tests during 1200 s of cyclic testing have shown excellent stability and durability; therefore, it portrays a significant potential for wearable electronics and gesture recognition. Liu and co-workers [

86] present electrospun PLA membranes modified with CNT and layered double hydroxide (LDH), which can simultaneously serve as super oil-water separators and for real-time press sensing. This membrane forms a sea urchin-like structure that enhances dispersion and electrical conductivity. The material reduces the fiber diameter and pore size, increases hydrophobicity, and delivers high oil absorption (up to 35 g/g) and quick response to press-sensing. Li et al. [

87] introduced reversible non-covalent crosslinks in the carboxymethyl starch, PVA, and silver nanoparticles (AgNP) to achieve a complete recyclable bioelectronics. They designed a sensor that can monitor small movements (drinking, speaking) as well as large movements (moving, jumping, elbow movements) with high sensitivity and cycling stability. The sensor shows excellent sensitivity (gauge factor as high as 4.02), high conductivity (0.1753 S/m), low detection limit (0.5%), and long-term antibacterial activities (more than 7 days).

Suvarnaphaet et al. [

88] developed an electrode patch to monitor the electrocardiogram (ECG) based on a composite membrane consisting of graphene and polyhydroxyalkanoate (PHA) biopolymer, which aims to overcome the problems of skin irritation and the gel-based application of conventional Ag/AgCl electrodes. The rationale for this potential innovation lies in the combination of graphene’s electrical conductivity and biocompatibility with the flexibility and biodegradability of PHA. The last electrode patch had a resistance of 20 kΩ and in-circuit performance could sense normal (60 BPM, 1 mV amplitude) and abnormal ECG signals (AFIB, VFIB, VTACH) with an equally similar output to that of commercial electrodes. Particularly, electrodes based on graphene/PHA registered no signal drop during 100 cycles, and they successfully separated ECG signals with minimal noise, which affirmed the usefulness of their conductivity and mechanical strength. Notably, the patch also exhibited good signal clarity during limited bending, which points towards the possible implementation of the same in wearable and portable, environmentally friendly biomedical sensors.

A recent study by Vrážel et al. [

89] demonstrates the application of PHA-based membranes as a potent tool for detecting aromatic hydrocarbons (BTX: benzene, toluene, and xylene) in aqueous solutions through mid-infrared (MIR) spectroscopy. Its detection principle is based on the diffusion and adsorption of BTX molecules onto ZnSe prisms coated with PHA, followed by their subsequent determination through ATR-FTIR spectroscopy. PHA membranes were prepared using the phase inversion process and then subsequently deposited either by knife or spin coating onto infrared-transparent substrates such as ZnSe prisms and chalcogenide glass-coated wafers. The detection was tested at 50 ppm in BTX solutions. PHA-based membrane demonstrates that only the low crystallinity samples, PHO (19% crystallinity) and amorphous P3HB4HB, exhibited the characteristic BTX absorptions in the fingerprint region (650–900 cm

−1). More crystalline PHAs, including P3HB3HV (43% crystallinity), did not provide measurable peaks due to the limited diffusion pathways. Regeneration tests proved that this can be reused after simple washing with water. In this sense, the crystallinity of PHA remains a challenging criterion. Ren et al. [

90] developed a fluorescent cellulose-based membrane sensor, aimed at highly selective detection of harmful toluene gas. The membrane was prepared by uniformly loading carbon quantum dots (CQDs) prepared via a green hydrothermal process using glycerol and betaine into a carboxymethyl cellulose matrix. The resulting membrane exhibited high fluorescence, with a quantum yield of 18.34% and a lifetime of 5.3 ns. There was a distinct linear fluorescence response due to an increase in toluene concentration (200 to 1400 ppm), and a low detection limit of 0.452 ppm was attained. Therefore, the sensor offers a highly inexpensive, visual, and environmentally friendly real-time platform for toluene detection in industrial and environmental settings.

Another interesting sensor was developed by Piloto et al. [

91] a fluorescent biopolymeric membrane that was made up of molecularly imprinted polymer-coated cadmium telluride quantum dots (MIP@QDs) and hydroxyethyl cellulose (HEC) gel-based sensitizer that enables a pathway to specific and sensitive assay of cardiac biomarker myoglobin (Myo), shown in

Figure 2f. Fluorescent quenching in tyrosinated membrane by the Myo showed a linear detection range of 7.39–291.3 pg/mL of 1000-fold diluted human serum and a limit of detection (LOD) of 3.08 pg/mL as compared to the clinical cutoff of 23 ng/mL of myocardial infarction. The specificity of a MIP-based recognition system was reaffirmed by an imprinting factor of 1.65, which was more than the controls of non-imprinting.

Recently, Cui et al. [

92] suggested a biomass nanofiber membrane (NBU-CDs), which consists of xylan-derived carbon dots (U-CDs) in a blend of PLA and PCL, prepared through in situ electrospinning. The sensitivity of this novel membrane toward Cu

2+ is truly impressive, with a detection limit of 0.83 µM. The binding between Cu

2+ ions and the plasma surface -NH

2 functional groups led to photo-induced electron transfer (PET), resulting in fluorescence quenching. The addition of NBU-CDs to soil extracts showed bright blue fluorescence,

Figure 2g, and the addition of Cu

2+ led to a dark colour (quenching), proving the qualitative detection. The inset bar graph in the figure indicates a significant decrease in fluorescence intensity after exposure to Cu

2+. NBU-CDs also exhibited a high quantum yield (23.3%), rapid visual responses, and over 97–104% recovery in models of lake water, soil, and zebrafish. Mohammed-Sadhakathullah et al. [

93] demonstrated the synthesis of nanostructured membranes composed of biodegradable PLA/PEG, in which a lipophilic molecule, cholesterol, is incorporated covalently. The PEG-cholesterol units exhibited a strong attraction to both hydrophilic binding materials, ascorbic acid (AA) and Trolox, with detection limits of 8.12 µM for AA and 3.53 µM for Trolox, respectively, in an aqueous salt solution. The bio-inspired membrane offers the opportunity to combine antioxidant capacity and facilitate the fabrication of anti-stress biosensors and electrodes for detecting vitamin C or vitamin E.

Figure 2.

(

a) Electrochemical ethylene sensing mechanism. Adapted with permission [

75]. Copyright 2024 Elsevier. (

b) Effect of ethylene concentration on detection sensitivity. Adapted with permission [

75]. Copyright 2024 Elsevier. (

c) Schematic representation and detection mechanism of the CSBHD hydrogel membrane probe. Adapted with permission [

76]. Copyright 2024 Elsevier. (

d) Fluorescence spectra of PCL/7.5FPN. Adapted with permission [

77]. Copyright 2019 Springer. (

e) Calibration curve for LOD calculation. Adapted with permission [

77]. Copyright 2019 Springer. (

f) Schematic representation of the assembly of the imprinted cellulose membranes. Adapted with permission [

91]. Copyright 2021 American Chemical Society. (

g) Fluorescence colour change and fluorescence intensity change observed in the soil extract solution mixed with NBU-CDs for Cu

2+ detection. Adapted with permission [

92]. Copyright 2023 Elsevier.

Figure 2.

(

a) Electrochemical ethylene sensing mechanism. Adapted with permission [

75]. Copyright 2024 Elsevier. (

b) Effect of ethylene concentration on detection sensitivity. Adapted with permission [

75]. Copyright 2024 Elsevier. (

c) Schematic representation and detection mechanism of the CSBHD hydrogel membrane probe. Adapted with permission [

76]. Copyright 2024 Elsevier. (

d) Fluorescence spectra of PCL/7.5FPN. Adapted with permission [

77]. Copyright 2019 Springer. (

e) Calibration curve for LOD calculation. Adapted with permission [

77]. Copyright 2019 Springer. (

f) Schematic representation of the assembly of the imprinted cellulose membranes. Adapted with permission [

91]. Copyright 2021 American Chemical Society. (

g) Fluorescence colour change and fluorescence intensity change observed in the soil extract solution mixed with NBU-CDs for Cu

2+ detection. Adapted with permission [

92]. Copyright 2023 Elsevier.

Joshi et al. [

94] suggested that shellac could be used to derive reduced graphene oxide (rGO) films by heat treating to form the thermally decomposed rGO (TrGO) that had high carbon content, good crystallinity, and low sheet resistance. Label-free electrochemical immunosensors that detect H1N1 influenza were generated by dispersing TrGO flakes into indium tin oxide electrodes/glass with the help of drop-casting techniques to identify the specified influenza using electrochemical impedance spectroscopy. The sensors showed very high stability and reproducibility, presumably because the phenolic-OH groups provide a strong adhesion and reach detection limits of 26 and 33 PFU in phosphate-buffered saline and diluted saliva, respectively. This method highlights the prospect that TrGO could be a valuable, low-cost, dependable nanomaterial that could be used in biosensors in the field of clinical diagnostics.

Jonas and coworkers [

95] proved that biopolymers provided a structural network to entrap the ionic liquid to form stable ionogels and used them as the active sensing layer. The gelling agents, gelatin, agar, and sodium alginate, have formed H-bond and electrostatic interactions with the ionic liquid (EMIMDCA) and created a three-dimensional structure that ensured there was ionic mobility, but mechanical integrity was achieved to coat the interdigitated electrodes, the structural illustration of all biopolymers, including the EMIMDCA shown in

Figure 3a. The vapors infiltrated the ionogel on exposure to volatile organic compounds (VOCs) and changed the ionic conductivity by influencing their polarity and dielectric environment. The change in conductance was recognized as a variation, and the relative response (Ra) was, therefore, computed according to the difference between the initial and the final conductance readings. The sensors showed specific responses to each solvent, and average Ra values would be used to distinguish them effectively. For example, the array achieved a classification accuracy of ≥96% for all VOCs, and in some cases, 100% using machine learning algorithms. Reproducibility was validated with relative standard deviations between 0.03 and 0.56 and long-term testing of over 100 cycles at 40 °C, as shown in

Figure 3b, which showed stable responses in signal to show the ionic transport under the intact characteristic of the biopolymer-ionic liquid bonding.

Figure 3c represents the final 10 cycles, indicating no signal drift, so that the biopolymer-ionic liquid network retained its conductivity and structure, thus ensuring that the sensor would be reliable in the long term.

Ara et al. [

96] fabricate a wearable strain sensor based on gellan gum, polyacrylamide-co-butyl acrylate. It demonstrates remarkable strength in uninterrupted stretching and relaxing cycles without compromising its structural stability. Moreover, a broad sensing range and superior sensitivity to various strains, and a gauge factor (GF) of 31.51 were obtained in dual crosslinked hydrogel strain sensors. The conductivity was found to be 0.32 S/m, as NaCl is present in it. As such, the hydrogels act as wearable sensors at the vocal cord that can detect drinking, yawning, coughing, and the repeated pronunciation of the word cat. In

Figure 3d–g, it becomes clear that the hydrogel was very helpful in monitoring both drinking water and the occurrence of yawning. The results also show that hydrogel consistently triggers the same reactions, followed by repeated drinking and yawning, and repeated pronunciation of the word cat. Interestingly Cui et al. [

97] fabricated a multifunctional human movement monitoring sensor based on a starch/PVA system incorporated with CaCl

2. Despite their poor freezing resistance and low electrical conductivity, starch exhibited remarkable stretchability of 478.1% and superior mechanical strength of 2.1 MPa. The sensor demonstrates high sensitivity (gauge factor = 0.74) and provides consistent performance over a broad strain range, making it ideal for real-time monitoring of physical activities and body temperature signals.

Biopolymers need to be designed to exhibit multiple characteristics, including mechanical resilience, high stretchability, good tensile strength, electrical conductivity, thermal stability, and environmental stability, as well as biocompatibility, to ensure the reliable performance of flexible and wearable sensing systems. Furthermore, properties such as fast response rates, sensing for volatile materials, anti-freezing efficiency, recyclability, and long operational time are crucial for real-time physiological monitoring and long-term use. These characteristics make the biopolymer-based sensors capable of withstanding repetitive mechanical deformations and retaining signal integrity. Recent research, which includes the use of plasticizers (e.g., CaCl

2, glycerol), conductive fillers (e.g., graphene, CNTs), and crosslinking agents, has been effective in improving these characteristics. Thanks to these efforts, several biopolymer systems now show promise in competing with traditional materials in terms of gauge factors, conductivity, and durability, ultimately gaining credibility as biodegradable alternatives in wearable electronics. The comparative summary is provided below in

Table 3.

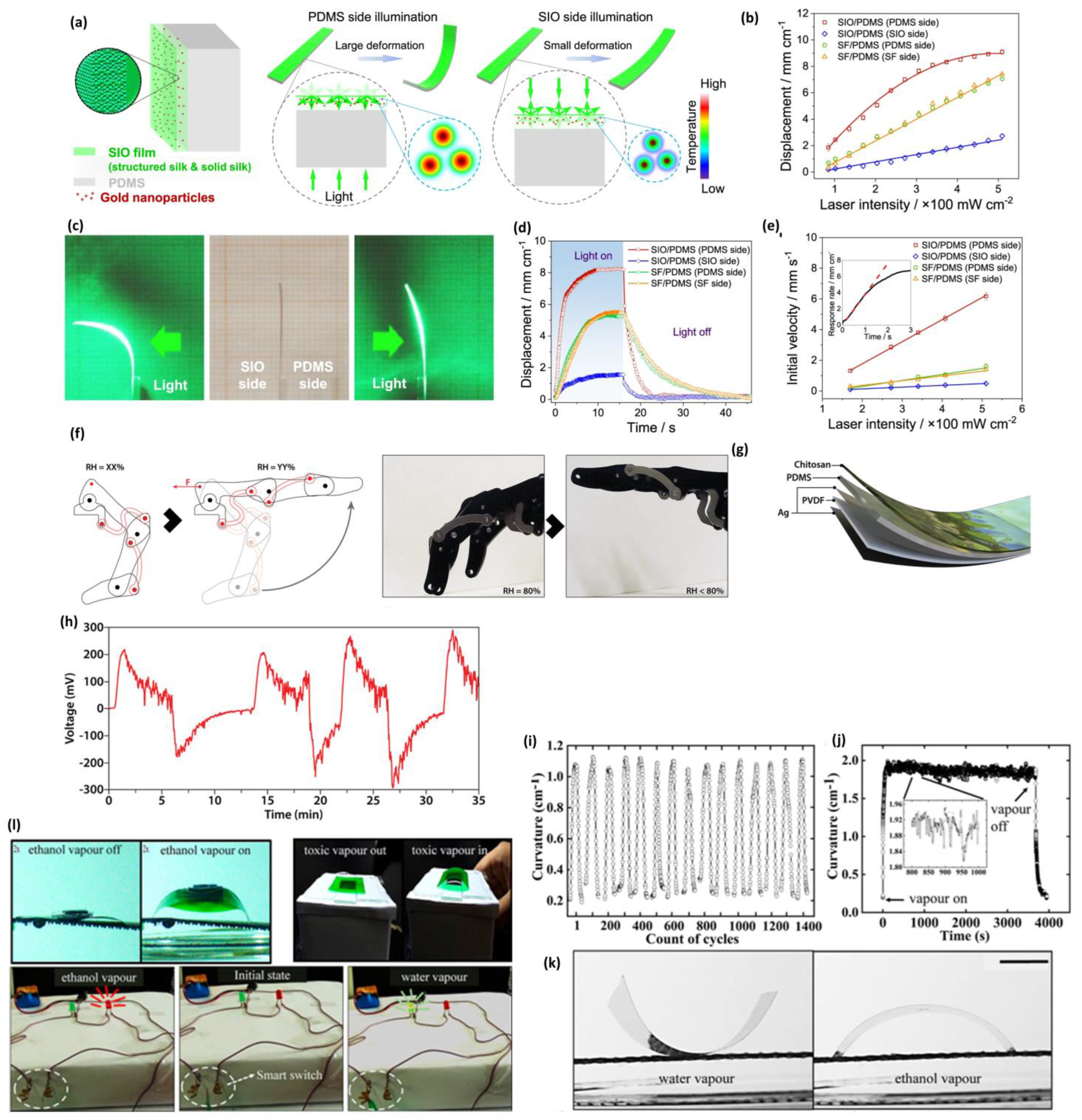

4. Advances of Biodegradable Polymers in Actuation Applications

Compared to conventional dielectric elastomer actuators, which require high-voltage drivers and non-degradable materials, biopolymer actuators are more suitable for many applications due to their low-voltage operation, soft stimuli, and end-of-life compatibility [

98]. Ionic and hygroscopic biopolymers can achieve large curvatures and effective blocking forces under typical environmental conditions, such as humidity or light. These devices are more energy-efficient because they eliminate the need for high-voltage electronics, which are common in systems like wearables and biointerfaces [

99]. They are soft, tissue-like, hydrophilic, and have tunable crosslinking networks, leading to soft, tissue-like mechanochemical behavior, stability in wet environments, and natural biocompatibility—making them safe to interface with skin and biological fluids without encapsulation. It is important to note that biopolymers can be recycled or composted when they are properly designed, as they are also renewable. It enables actuators to provide the correct force and displacement to fit into particular applications with minimal material hazard, promote safer failure modes, and facilitates the benefits of the circular economy that traditional elastomeric actuators, despite their large maximum strain rate, cannot inherently offer. The important characteristic that actuator materials or composites must possess is unique reversible swelling/deswelling, deformation with respect to different stimuli (electric, magnetic, thermal, and chemical), excellent water retention, and shape adaptability, as well as durability to emerge as a potential candidate. Biopolymers, in particular, including chitosan, gelatin, alginate, and xanthan gum, which nanoparticles or crosslinkers may modify, fulfill these requirements due to the ability to deliver soft, safe, and programmable actuation [

100]. They are responsive to electric fields, temperature, magnetic fields, or moisture, making them suitable for wearable health monitors, soft robotic grippers, artificial muscles, and drug delivery. The inclusion of biopolymeric microneedle patches and biomimetic adhesives can significantly enhance skin interaction, highlighting their potential application in flexible, responsive, and biodegradable actuating systems.

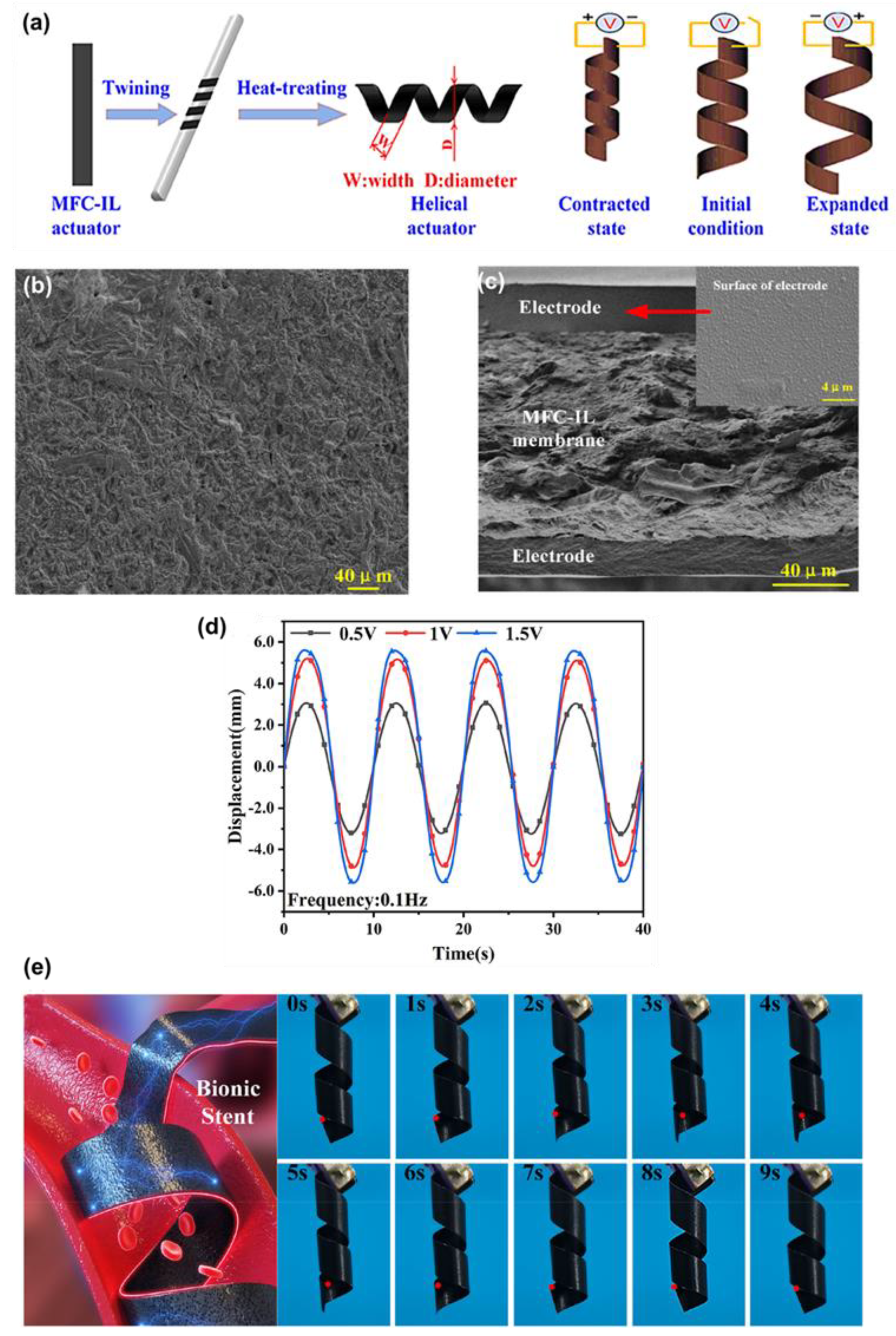

Xinhai He and coworkers [

101] synthesized a biopolymer membrane consisting of chitosan (CS), polyvinyl alcohol (PVA), and azobenzene (Azo) using an evaporation-induced self-assembly technique, which was utilized as a controlled photo and humidity-responsive membrane. The membrane allows the extensive hydrogen bonding of CS, PVA and Azo to develop an effectively oriented surface structure with the use of a grooved silicon mold, in order to exhibit controllability of directional actuation upon light and humidity stimulus. The film prepared with 10 wt% Azo showed the maximum photoresponse under UV light (1 mW, 365 nm), as evidenced by a bending angle of 85° in 50 s. It bent to 144° under natural sunlight in 55 s and was moderately actuated under LED (5000 K). Under humidity (e.g., fingertip contact), the film could bend to 155 with a bending time of 30 s (2.5 wt% Azo), the 10 Azo film could bend to 140 and reverse to −180 under sunlight. These performances are owed to reversible cis-trans isomerization of Azo and the difference in swelling of the hydrophilic CS/PVA matrix. Moreover, the actuator could lift a staple (20 mg), 5 times as heavy as itself (4 mg), to a height of 12 cm in 75 s using sunlight, which is indicative of the conversion of light to mechanical energy. Hydrogen bonds on the exposed surface are disrupted by moisture, leading to the formation of new bonds with water. Consequently, the surface swells, a through-thickness gradient develops, and the film bends. Drying restores the original network structure, returning the film to a flat shape. Azo imparts photosensitivity, under UV or sunlight, it undergoes a conformational change from trans to cis on the Azo-rich surface, resulting in a local volume change that prompts rapid reverse bending. Increased Azo loadings result in microphase separation and enhanced stiffness, which diminishes the responses to humidity and light. Films devoid of Azo recover gradually following humidity exposure but do not revert to their bent form, thereby supporting the notion that recovery speed is improved by light-responsive behavior and facilitating reversible actuation. By blending with CS, the tensile strength and modulus of PVA were enhanced in the mechanical analysis due to the high intermolecular hydrogen bonding. However, when more than 10 wt% of Azo was added, phase separation occurred, resulting in a decrease in mechanical properties.

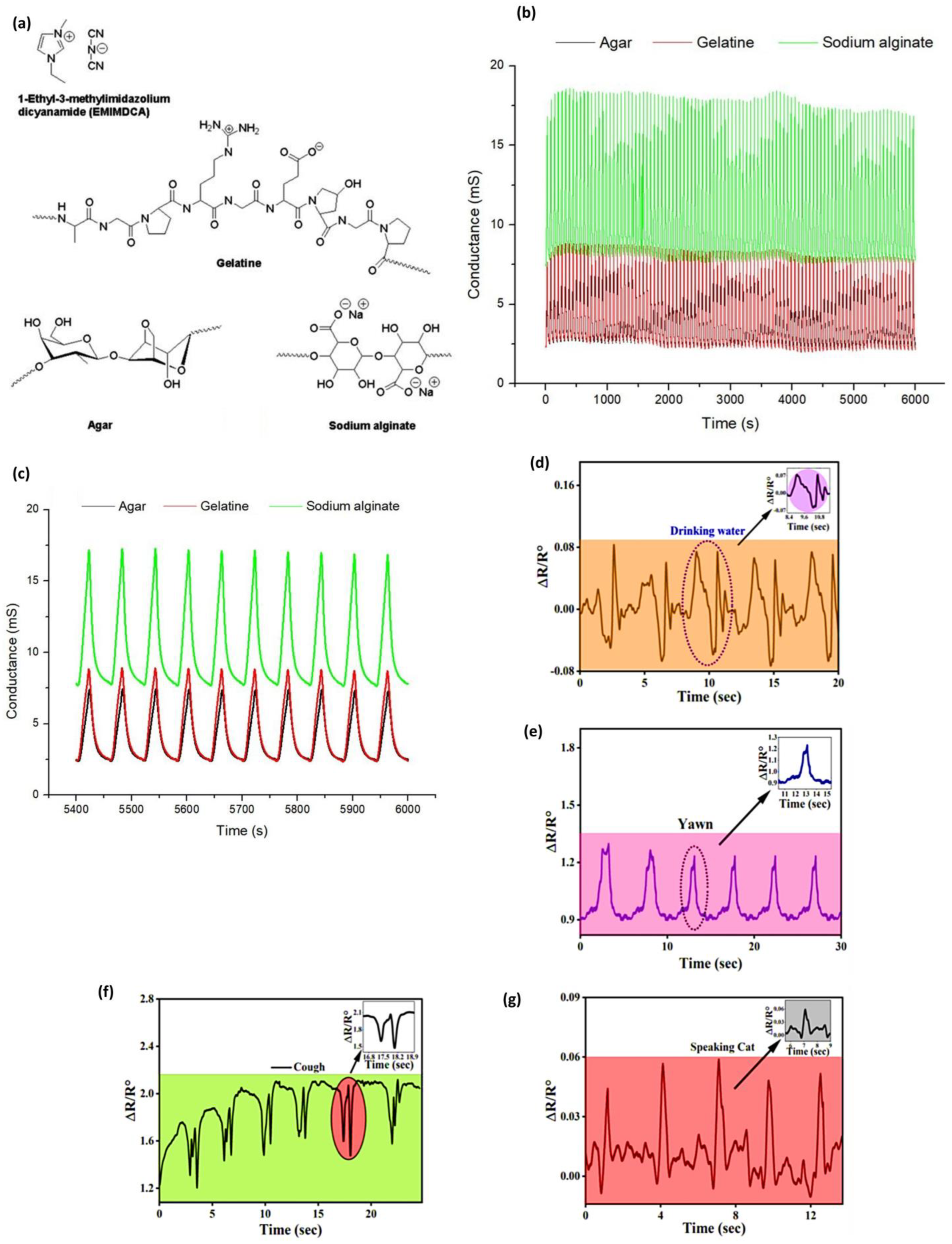

Wang et al. [

102] report a high-performance ionic electroactive polymer actuator (IEPA) synergistically built with carboxylated bacterial cellulose (CBC), ionic liquid (IL), and MWCNT and PEDOT:PSS electrodes. The actuator utilizes the excellent ionic interactions and crosslinking between CBC nanofibers, IL, and MWCNT, remarkably overcoming the drawbacks of traditional actuators. The actuator showed mechanical properties of Young’s modulus 349.1 MPa, and superior electrochemical properties with specific capacitance of 76.97 mF/cm

2. They also showed that the CBC-IL-MWCNT actuator in biomimetic robotic fingers can be used to interact with touchscreen electronic devices. With the application of low voltage, the ions of the ionic liquid move and concentrate on the electrode interfaces, thereby creating electric double layers, and creating osmotic/pressure and electrostatic gradients across the thickness; at the same time, the electrochemical doping/de-doping of the PEDOT:PSS layers takes place. The redistribution of the asymmetric ions and the interfacial volume change generate a bending moment. The actuator had been tested under a low voltage of 1 V DC to conduct two specific human-like applications, namely, turning on and shutting down one timer application with exact timing at 10 s, and swiping across the display of a smartphone to change pictures. Similarly, Shen and coworkers [

103] explored microfibrillated cellulose (MFC) for ionic soft actuator as shown in

Figure 4a. The ionic interactions, especially those between hydroxyl moieties of the MFC and IL, strongly contributed to the ion transport through the membrane, as evidenced by the SEM images shown in

Figure 4b.

Figure 4c indicates the cross-sectional SEM image of uniform electrode adhesion. This interaction was verified using FTIR, where new characteristic peaks at 795 and 1259 cm

−1 were detected, and XRD showed a reduction to 48.44%, signifying high amorphous regions which facilitate easy migration of ions. The MFC-based membrane actuator system demonstrated a high peak-to-peak displacement of 11.21 mm at an excitation frequency of 0.1 Hz, as shown in

Figure 4d. It also exhibited low actuation voltage and superior durability (98% maintained after 2 h), along with controllability, due to the strong ionic interactions between MFC fibers and IL. The helical MFC-IL ionic actuator was further designed as a heat treatment, and it was possible that this actuator could be used to create a biomedical active stent that is in a position to control the radius of the actuators, which depends on changing the applied voltage and frequency (1.5 V sinusoidal excitation at 0.1 Hz), which is shown in

Figure 4e. Thummarungsan et al. [

104] designed a magneto-responsive smart actuator using poly(butylene succinate-co-butylene adipate) (PBSA) and integrating magnetite (Fe

3O

4) nanoparticles as an alternative to sustainable and non-toxic materials. This combination significantly enhanced both the magnetic sensitivity and mechanical strength of the actuator. When exposed to a non-uniform magnetic field, the Fe

3O

4 particles acquire dipole moments and experience magnetic forces or torque, causing them to align themselves with the field. The particles are incorporated within a compliant PBSA film, and via this field-induced particle interaction, a through-thickness body force forms, which bends the cantilever towards the magnet. The PBSA is soft, thus high curvature can be achieved; interfacial interactions facilitate load transfer, and small Fe

3O

4 loadings are tolerant to flexibility. The optimized amount with 3.0%

v/

v Fe

3O

4 shows a bending displacement of 15.6 mm in just 10 s. The actuator produced a magnetophoretic force (0.14 mN) in a relatively low magnetic field (1300 Gauss), with magnetization (1.719 emu/g), making it promising in low-field, fast-response soft robotics and biomedical applications.

Jaehwan Kim [

105] explored an electrospun silk membrane coated with a sulfonated chitosan membrane. The investigation revealed that the material’s interdigitated structures had stable mechanical and electrochemical properties, making it suitable for fabricating high-performance ionic biopolymer actuators. Specifically, the introduction of sulfonated chitosan-ionic liquid decreases the mechanical stiffness of the electrospun silk. This enhances the ionic conductivity, causing the ion pathways within the interdigitated silk-chitosan domain. This actuator with the graphene-PEDOT:PSS electrodes exhibits a 165% bending enhancement. The proposed biopolymer actuator, with notable improvements, can be a candidate of interest for the formation of skin-attachable devices. The design of the carboxymethyl chitosan (CMCS) and the tannic acid (TA), by Fang et al. [

106] involved the fabrication of an electrical response actuator of driver membranes using the vacuum freeze-drying method. Electrode membranes with sodium alginate (SA) and MWCNTs are produced via vacuum drying. Their findings revealed that the high output, specific capacitance, and strain in the absence of tannic acid solution are 1.95 mN, 68.36 mF/g, and 102.22%, respectively. When the amount of TA added to the samples is 14 mg, the maximum output force, specific capacitance, and strain of the samples increased to 6.12 mN, 99.82 mF/g, and 151.23%. The mechanism is examined through ion migration. The distribution of the driver membrane pores becomes increasingly uniform, and eventually, a large pore structure with filament crosslinking will form. This leads to improved driver and electrochemical performance.

Interestingly, Lv et al. [

107] observe the effects of carboxymethyl cellulose (CMC) mass on the sodium alginate-carboxymethyl cellulose ion actuator (SCIA). They recorded its displacement on deflection and output force. Experiments indicated that the general performance of the SCIA sample was 0.25 g, which resulted in good output force, excellent channel of ions, and a fast response speed. The maximum electrochemical performance with force is 2.675 mN, dynamic speed is 0.176 mm/s, displacement is 17.137 mm, and the specific capacitance is 96.95 mF/g. Nevertheless, the performance of SCIA samples decreased as the CMC content increased and with excessive cross-linking. When exposed to an electric field, the SA/CMC network becomes a polyanionic gel: the remaining hydroxyl groups in SA are dissociated, and ions move to the anode, resulting in asymmetric anode ion accumulation and osmotic swelling, and cathode contraction. The resulting bending moment towards the cathode (cathode deflection behavior). Adding CMC creates a fiber network that dilates ion-transport channels and elevates specific capacitance, increasing the output force, deflection, and response speed to an optimal loading of CMC. It is vital to mention, though, that excesses of crosslinking may paralyze channels and considerably reduce performance. Instead, Glycerol plasticizes the network, assists in water retention, and is responsible for actuation stabilization.

Sodium alginate-PVA membrane obtained via freeze-drying was assembled on an electrode membrane to form a three-layer structure electric actuator (SPEA), prepared by Jia et al. [

108] PVA is rich with hydroxyl groups, and sodium alginate has carboxyl and hydroxyl groups. PVA, when dispersed in water, has high hydrophilicity and can interpenetrate sodium alginate and construct a network structure, consequently destroying the original hydrogen bonds of sodium alginate. This enhances mobility between chains of the polymers. With PVA doping, the intermolecular forces are weakened, and sodium alginate can be easily deformed, which positively affects the output force. Nonetheless, excessive PVA may lead to a high rate of output force, which destroys the membrane and shortens SPEA’s lifespan. The sodium alginate network, when subjected to an electric field in NaCl, moves ions and charges the electric double-layer at the interfaces of the gel and electrodes. The resulting asymmetric ion build-up through thickness causes a bending force and a production force. PVA is a hydrogen-bonded network that interpenetrates sodium alginate, which is freeze-dried to form a porous 3D microstructure, which enhances water retention and ion movement, increases specific capacitance, and stabilizes actuation. The optimum amount of PVA for better performance was 1.0 wt%. The stable output force achieved at 5 V was 3.459 mN, 1.64 times stronger than that of the SPEA without PVA. The SPEA material exhibited a specific capacitance that was 1.4 times larger than that of the SPEA sample without PVA addition. Also, the water retention was improved using PVA. The internal architecture of the SPEA featured an outstanding three-dimensional pore network, through which conductive ions flowed to produce a force that countered stress and converted electrical energy into mechanical energy. Thus, strong conductivity and performance in actuation capabilities will also be reinforced in a definite ratio of doping.

Zheng et al. [

109] investigated a PVA biopolymer membrane for a humidity-responsive and reprogrammable actuator, synthesized by grafting with 9-anthracenecarboxylic acid (9-AN), then blending with 2,2′,4,4′-tetrahydroxybenzophenone (THBP), followed by photo-crosslinking. The hydroxyl groups on the PVA allow quick moisture uptake and reversible swelling, making it an ideal candidate. Anthracene photodimerizes at 365 nm, where the illumination is applied, and THBP absorbs light across the thickness. This results in an irreversible crosslink density gradient, with more crosslinking on the irradiated side, and the internal and back surfaces being less crosslinked. When wet, PVA absorbs water and causes different levels of swelling due to the expansion of the loosely crosslinked region more than that of the closely crosslinked region; this causes a through-thickness mismatch strain, which leads to bending in the direction of the irradiation. The bending pattern can be reprogrammed: exposure to light shorter than 254 nm cleaves the anthracene dimers locally, and subsequent exposure to light longer than 365 nm rewrites it, allowing the local cleavage to be patterned with photomasks. At a constant humidity (RH = 20 to 90%), it attained the bending angle with an average velocity of 4.20°/s, followed by 2.53°/s and 0.92°/s. In a nonuniform humidity field of 182.20° of the bending angle at an average speed of 22.78°/s, full recovery was achieved in 92 s. The actuator remained stable over more than 10 cycles, demonstrating its durability. Significantly, the anthracene groups were UV responsive, thus providing programmable and reversible shape changes with selective crosslinking (365 nm UV) and cleavage (254 nm UV) to achieve complicated biomimetic applications such as a soft walking robot (rate 1.08 mm/min) and a flower-like actuator.

Similarly, Kumar et al. [

110] have reported a dual-responsive soft actuator composed of a single layer of cassava starch and PEDOT:PSS, aiming to simplify fabrication and increase durability, as bilayer systems often experience the problem of delamination. The actuator demonstrated sensitivity to solvent vapors (water, acetone, and alcohol) as well as light (sunlight and infrared), exhibiting different directional deformations in response to each of the triggers. It also folded in opposite directions toward water vapors compared to alcohol vapors, and under light. Programmable bending direction was also supported by geometric surface patterns. The performance of the actuator was demonstrated by experimental forms in wearable fabrics, soft robotics, and smart gadgets.

Vahid Hasantabar and coworkers [

111] demonstrated that a soft bio-electronic muscular actuator was designed on the flexible membrane of a double-network hydrogel (DNH), biopolymers of κ-Carrageenan (κ-Car) and PVA. To improve the membrane properties, the P(AA-co-AMPS), where acrylic acid (AA) and 2-Acrylamido-2-methylpropane sulfonic acid (AMPS) copolymers were grafted to κ-Car, which resulted in adding ionic groups (the -COOH and -SO

3H) into the chains. The membrane was made functionally more capable of ionic conductivity, water uptake, and ion-exchange potential, and these functional groups did not compromise its biocompatibility and flexibility. When a low voltage is applied in the electrolyte, the mobile cations begin to migrate and charge the electric double layers at the hydrogel-electrode interfaces, creating an uneven distribution of ions and solvent across the thickness. The resulting osmotic pressure gradient causes an increase in the swelling on the cathodic side and a bending moment, which causes the strip to be turned away towards the anode. Carbon electrodes have high interfacial capacitance and flexibility that facilitate efficient charge storage and allow for maintaining repeatable curvature. The mechanical flexibility characteristic of PVA rendered it flexible enough to form a double-network together with κ-Car, which was further crosslinked both physically by KCl/ZrOCl

2 and chemically by glutaraldehyde to provide an elastic, transparent, and strong membrane capable of performing actuator functions. The actuator was produced by placing the DNH free membrane between the two spray-coated/hot-pressed Vulcan carbon/functionalized multi-walled carbon nanotube (V/

f-MWCNT) electrodes. The actuator with a membrane grafted with 50 wt% P(AA-co-AMPS)-κ-Car/PVA demonstrated the best performance, exhibiting a tip deflection of 49.3 mm, bending strains of 0.8%, water uptake of 58.8%, and a maximum ionic conductivity of 4.76

10

−5 S/cm, a specific capacitance of 0.54 Mf/cm

2, and a low charge transfer resistance of 2.39

10

3 Ω.cm