Influence of Sealing Surface Microstructure Characteristics on Flow Resistance and Leakage Between Contact Surfaces

Abstract

1. Introduction

2. Materials and Methods

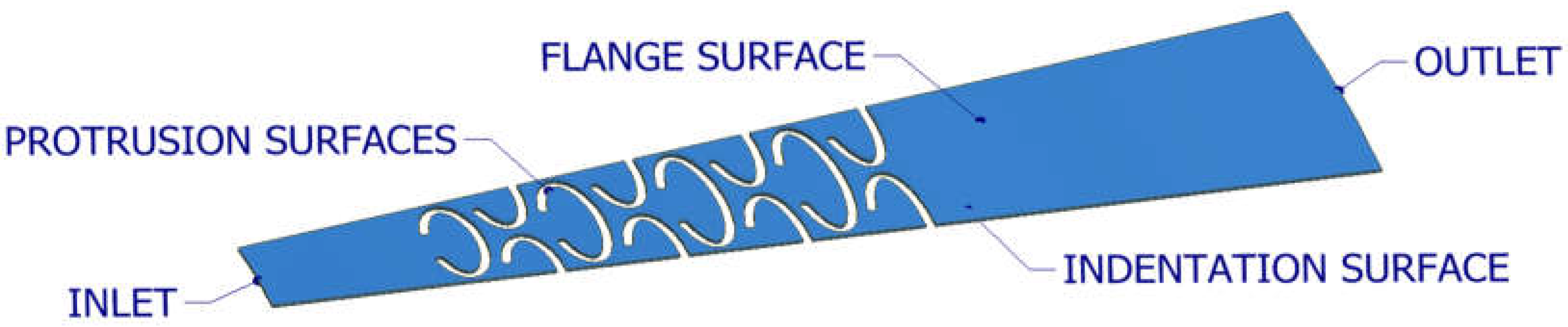

2.1. Research Object

- The depth of the microstructure, perpendicular to the formed surface (the height of the microprotrusions), equals ;

- The microstructure is located within a closed, concentric limiting ring positioned at the outer diameter of the gasket;

- The microstructure consists of a series of concentrically arranged microprotrusions forming a staggered pattern in the radial direction;

- The microprotrusions are formed as split ellipses, with the minor axis oriented parallel to the radial direction and the split located on the side of the sealed medium. However, in one of the variants tested, unsplit ellipses were applied;

- The microprotrusions were arranged on pitch diameters at constant intervals, with equal spacing between the outer walls in both the radial and circumferential directions. The number of microprotrusions on each pitch diameter is , while the number of rows in the radial direction is ;

- On every second pitch diameter, the pattern was angularly shifted by an angle equal to ;

- All ellipses are characterized by the same length of the minor axis.

2.2. Methodology of Numerical Calculations

- The use of a periodic segment of the upper/lower gap, omitting the ring section at the outlet—to evaluate the influence of the microgeometry on leakage;

- No deformation of the protrusions during gasket operation—constant gap height;

- The sealed medium was water;

- The leak was modeled considering only the flow at the interface between the sealing surfaces, whereas in reality it also includes flow through the porous structure of the material;

- The roughness and waviness of the flanges and the roughness of the microstructure walls were not included—only the effect of the microprotrusion geometry on leakage was assessed.

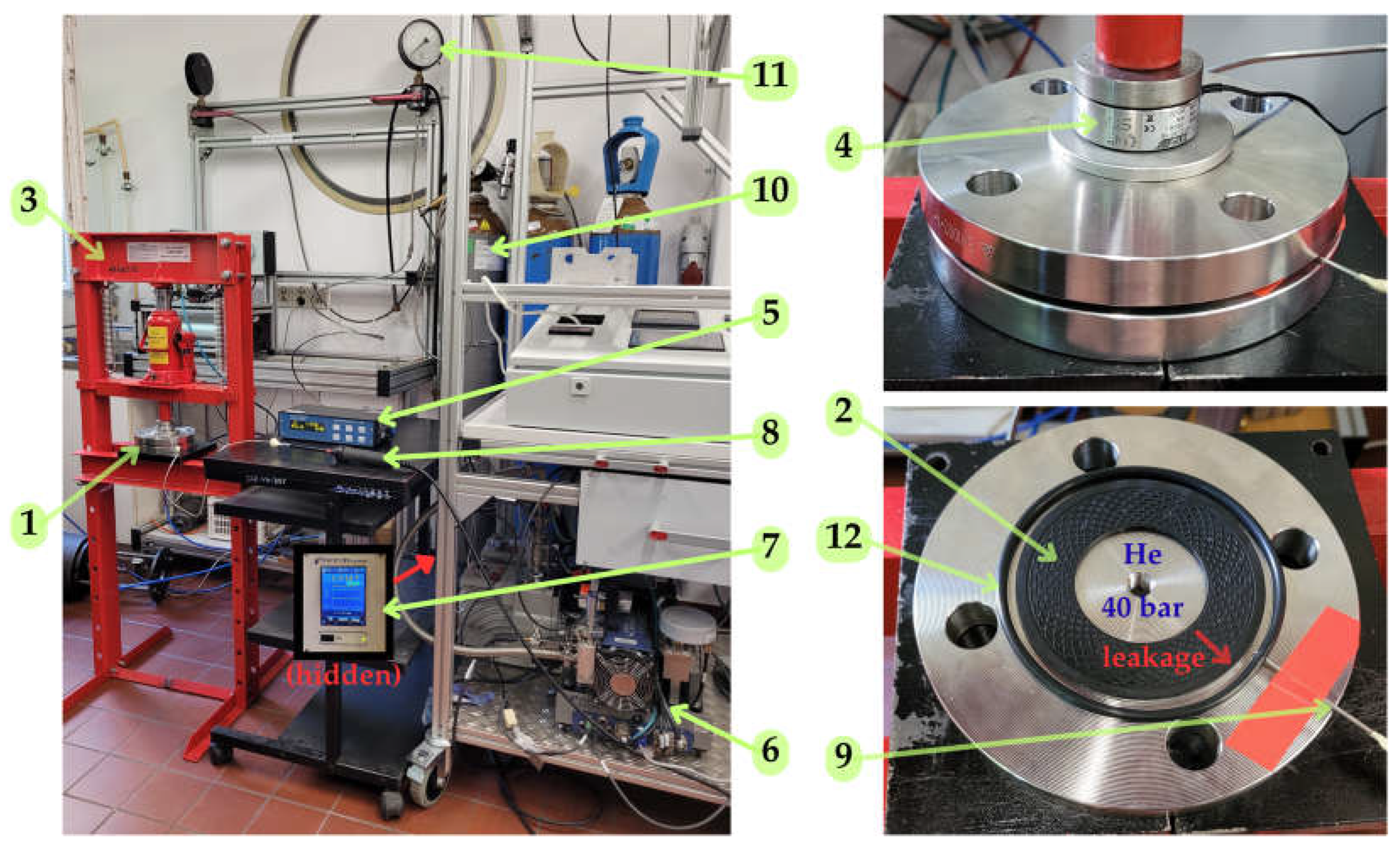

2.3. Methodology of Experimental Studies

3. Results and Discussion

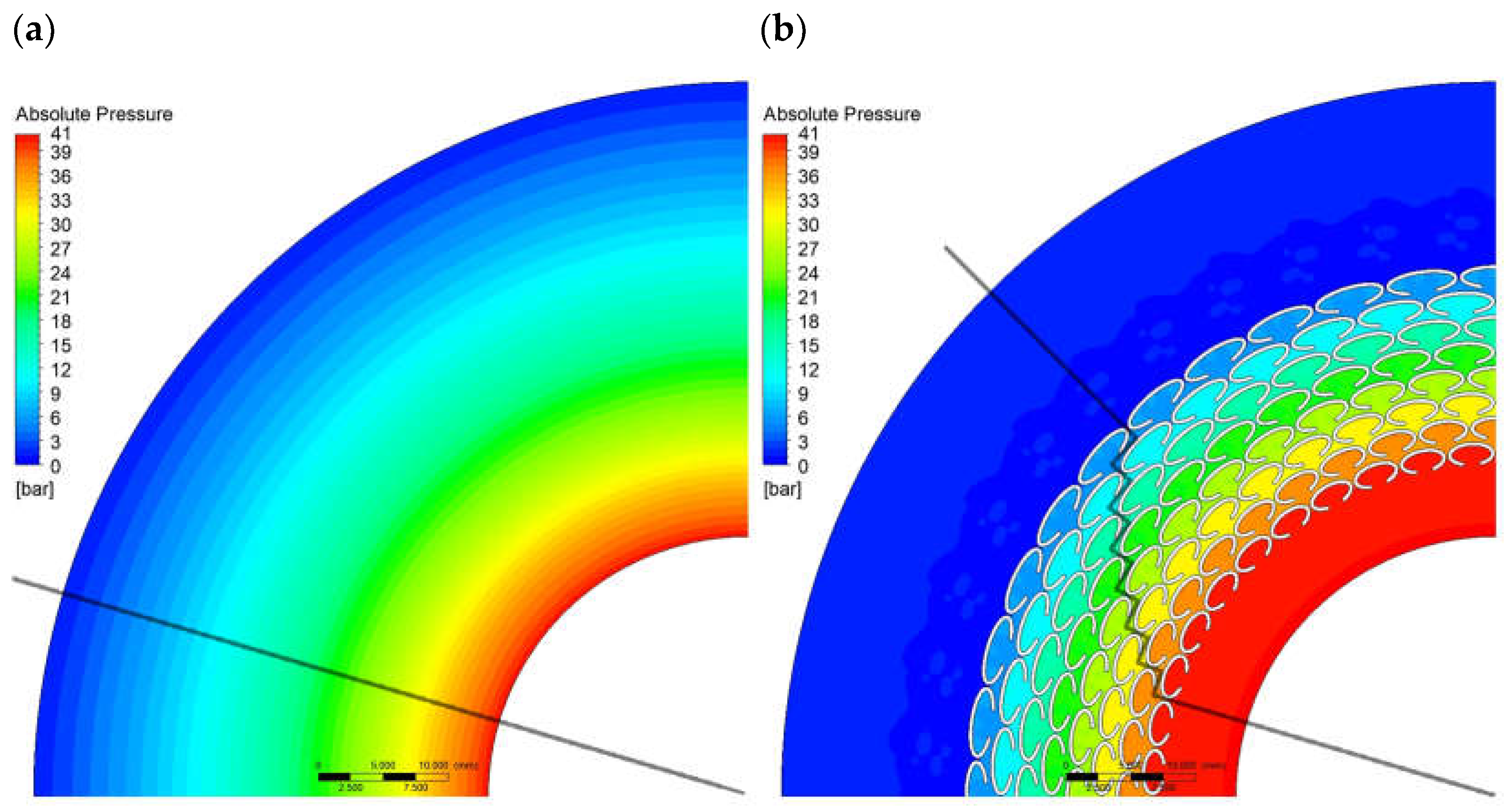

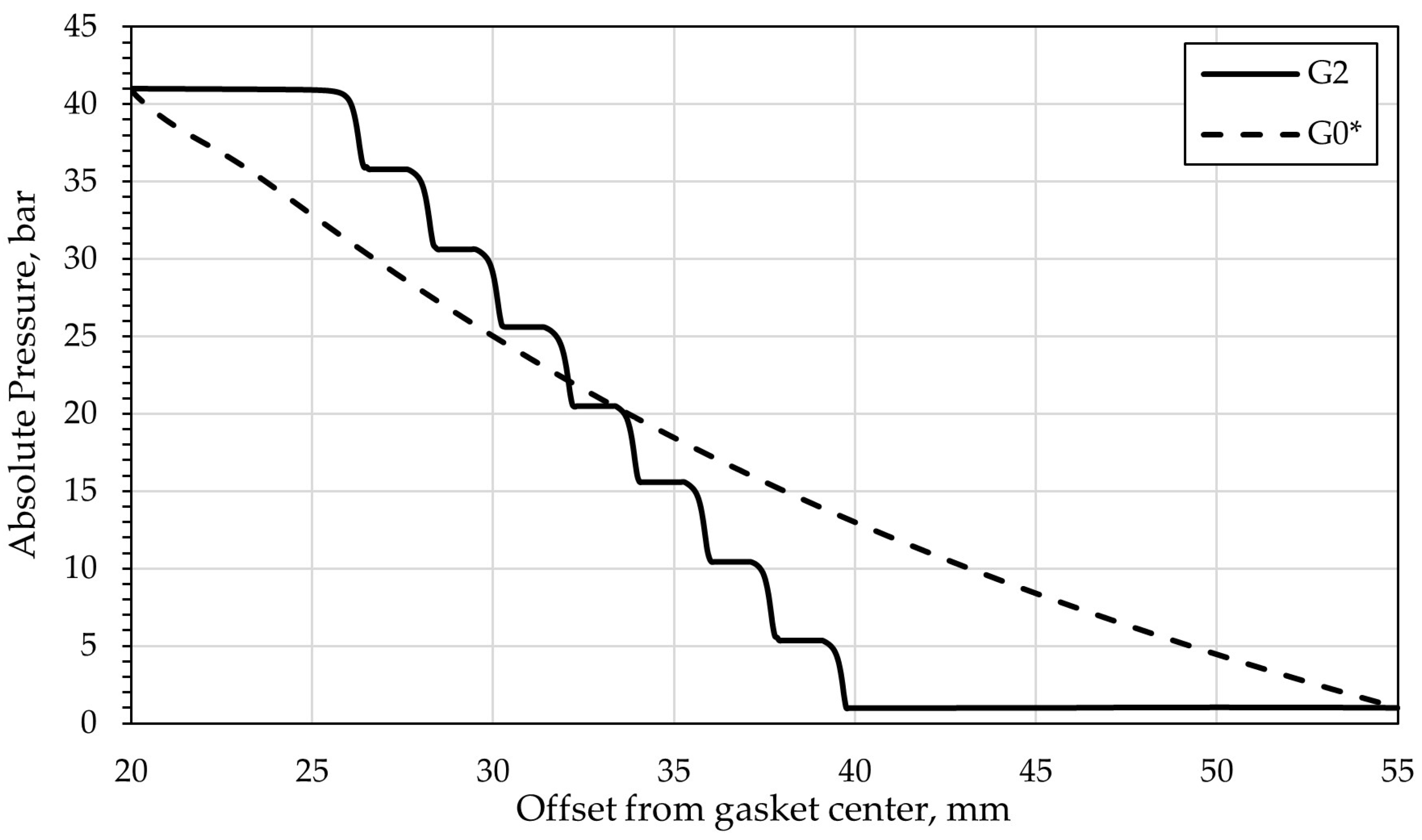

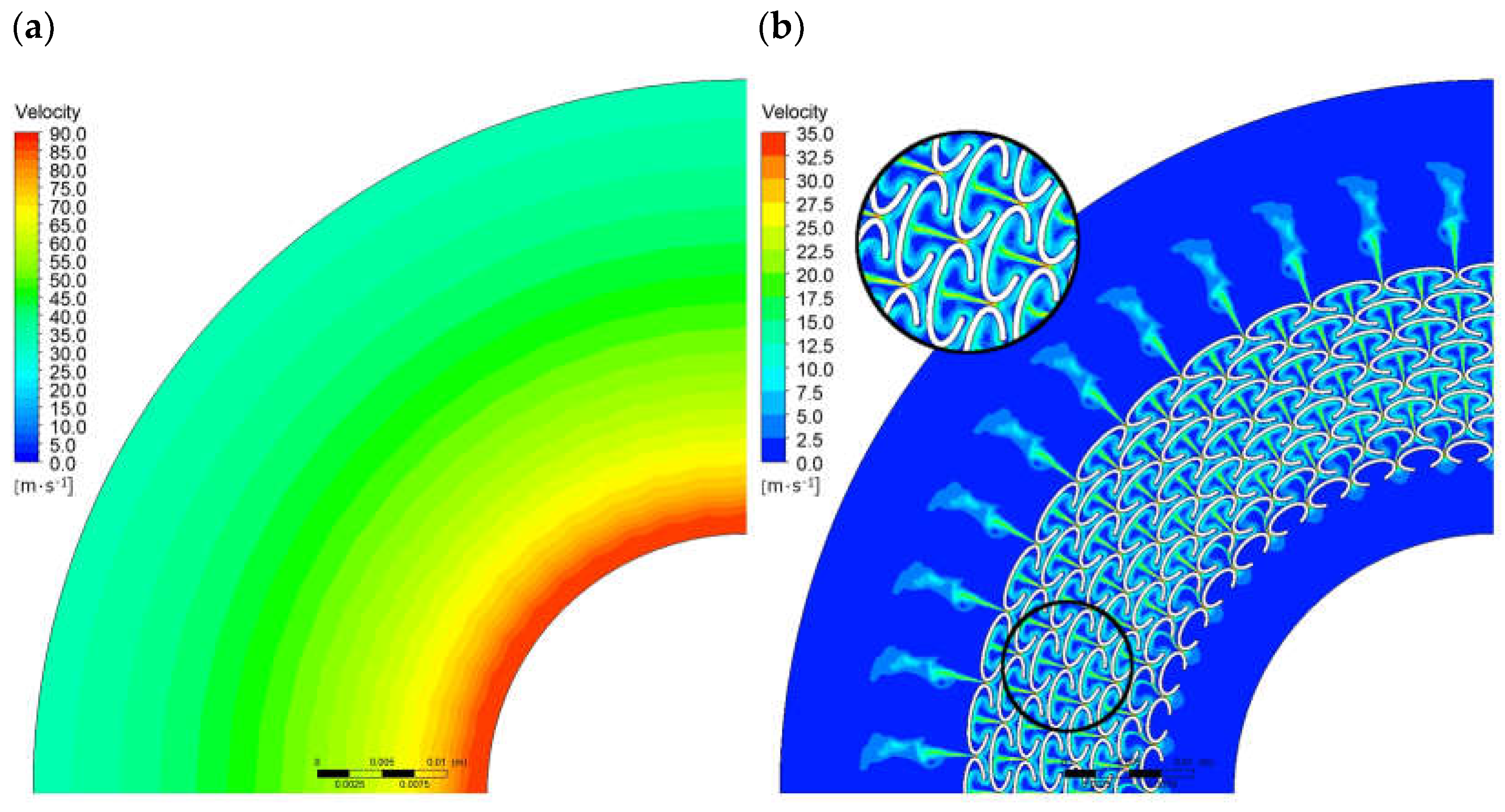

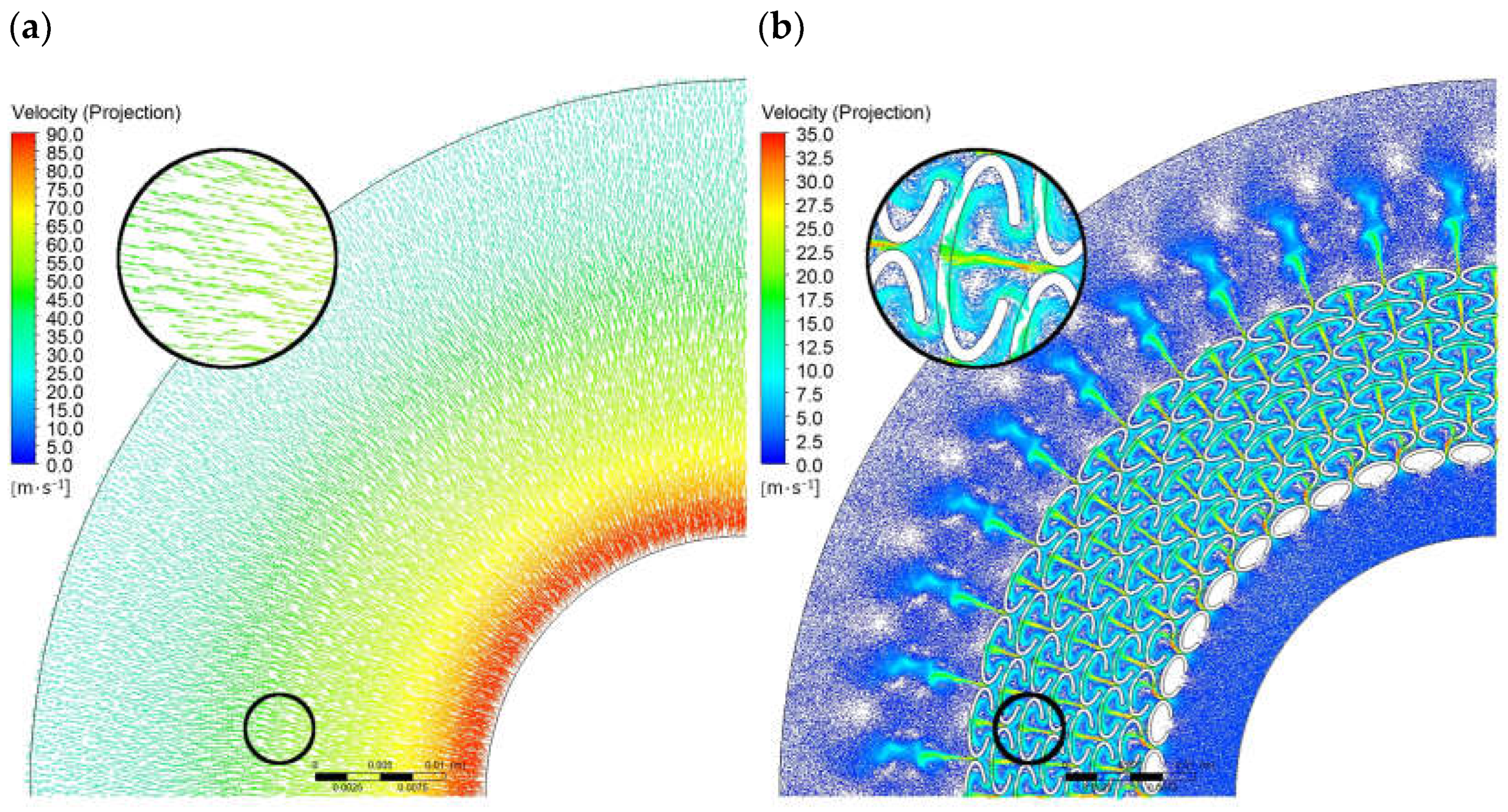

3.1. Numerical Calculations

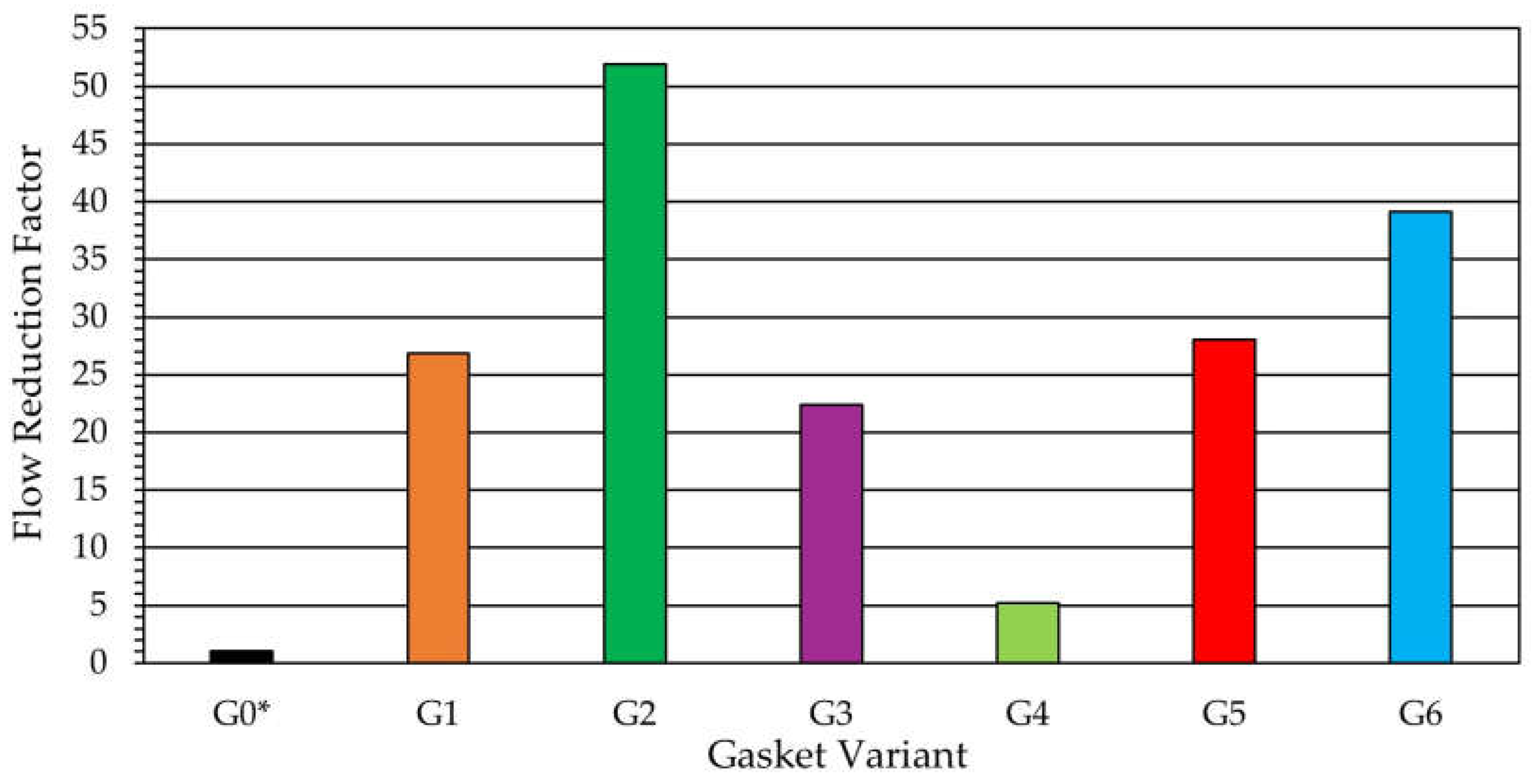

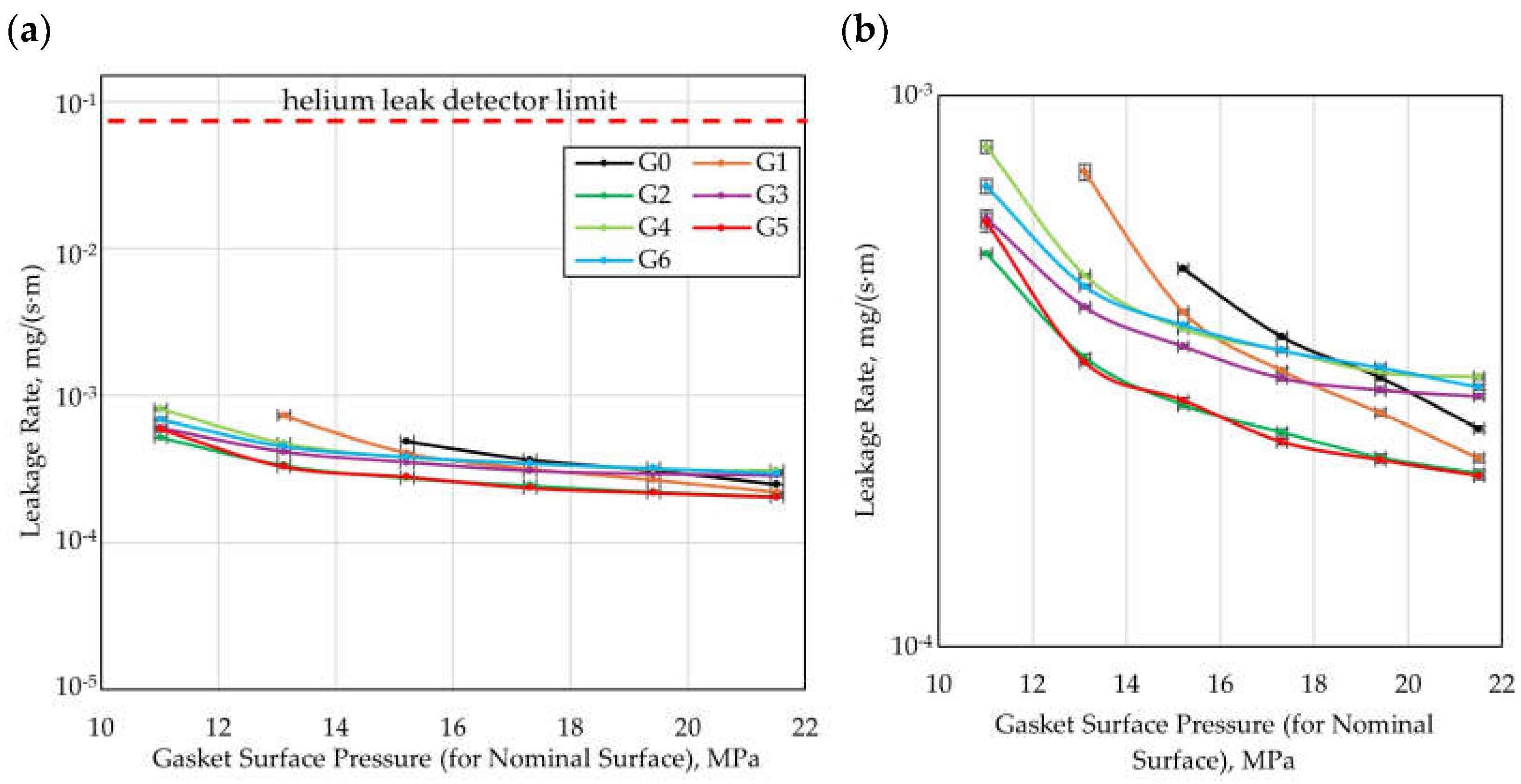

3.2. Experimental Studies

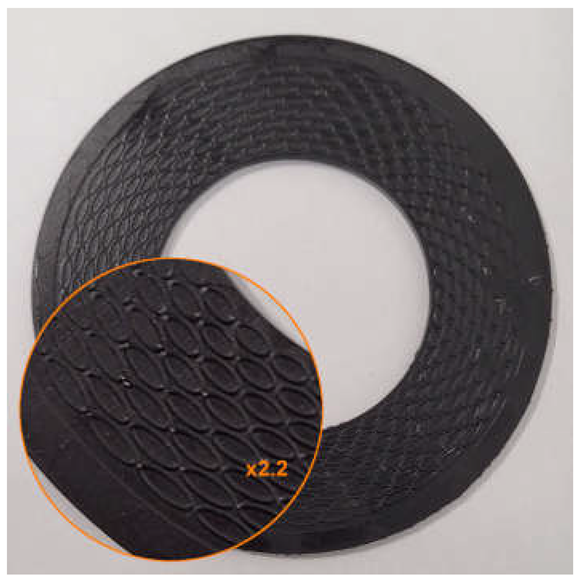

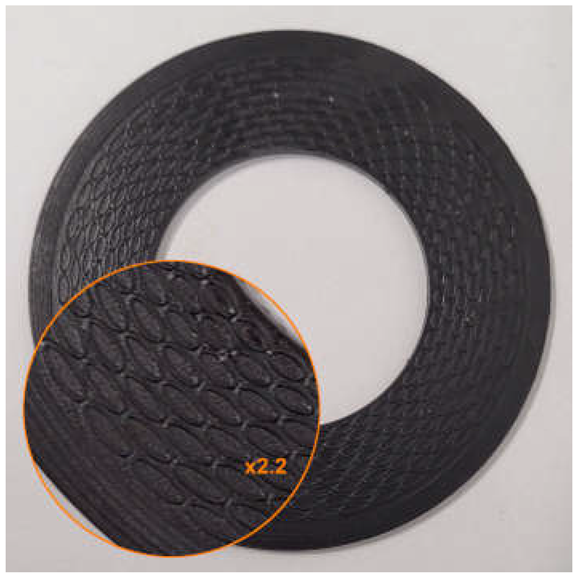

- The numerical calculations were carried out for an undeformed flow gap, while during the experiments the gaskets underwent deformations, as confirmed by the images of the samples before and after testing, presented in Table 5 (concentric contact traces originating from the flange surface are visible, particularly in the ring region of the structured gaskets). The geometry of the surface mating with the gasket (i.e., the flange surface), consisting of rings with sharp edges, promoted the formation of concentric contact areas, causing indentation of the flanges into the surface of the gaskets manufactured from photopolymer resin. Due to the relatively low mechanical strength of this material, the microstructure was already deformed under relatively low clamping forces of the flange joint. Additionally, with lower clamping forces, measurements were limited by the upper detection threshold of the helium detector used. Future research will be extended to include measurements conducted on a test stand enabling experiments within a wider range of gasket loads and with an increased leakage detection range;

- The numerical model was preliminary and simplified. The ring in the microstructure of the structured gaskets, as well as the roughness and waviness of the flange surfaces and the roughness of the gasket surfaces, were not accounted for, and water was adopted as the medium instead of the actual gas (helium) used in the experiment. To more precisely model the flow phenomena associated with leakage through the gasket, it is necessary to improve the numerical model. In future research, the use of a more accurate numerical model that incorporates the real gas will be considered.

4. Conclusions

- The application of a microstructure of the external sealing surface inspired by the operating principle of the Tesla one-way valve leads to improved sealing performance compared to a quasi-smooth gasket;

- CFD simulations demonstrated that the introduction of a microstructure on a sealing surface can induce local circulation of the fluid, resulting in increased flow resistance and reduced leakage. The numerical calculations indicated that the critical geometric parameters influencing leakage reduction through the generation of fluid circulation are the gap width between the microprotrusions, the packing density of the microprotrusions, and their height;

- Experimental studies confirmed the higher effectiveness of structured gaskets compared to quasi-smooth gaskets, particularly in the range of lower contact pressures;

- An analysis accounting for the effective contact surface indicates that the improvement in sealing performance results both from intensified local contact pressures and from the flow effects generated by the microprotrusions;

- In agreement with the predictions of the CFD calculations, the experimental results showed that among the structured gaskets, the highest sealing performance at the lowest contact pressures was achieved by Variant G2. The minimum leakage rate was 2.06 · 10−4 mg/(s·m) at a residual clamping force of 102.5 kN.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Name | Unit |

| Courant-Friedrichs-Lewy number | - | |

| microstructure depth (microprotrusions height) | mm | |

| flow reduction factor | - | |

| height of split of ellipse | mm | |

| minor axis of ellipse | mm | |

| mass | g | |

| molar mass | g/mol | |

| number of microprotrusions in circumferential direction | - | |

| number of microprotrusions in radial direction | - | |

| pressure | Pa | |

| mass leakage rate | g/s | |

| volumetric leakage rate | mbar·L/s | |

| gas constant | J/(mol·K) | |

| Reynolds number | - | |

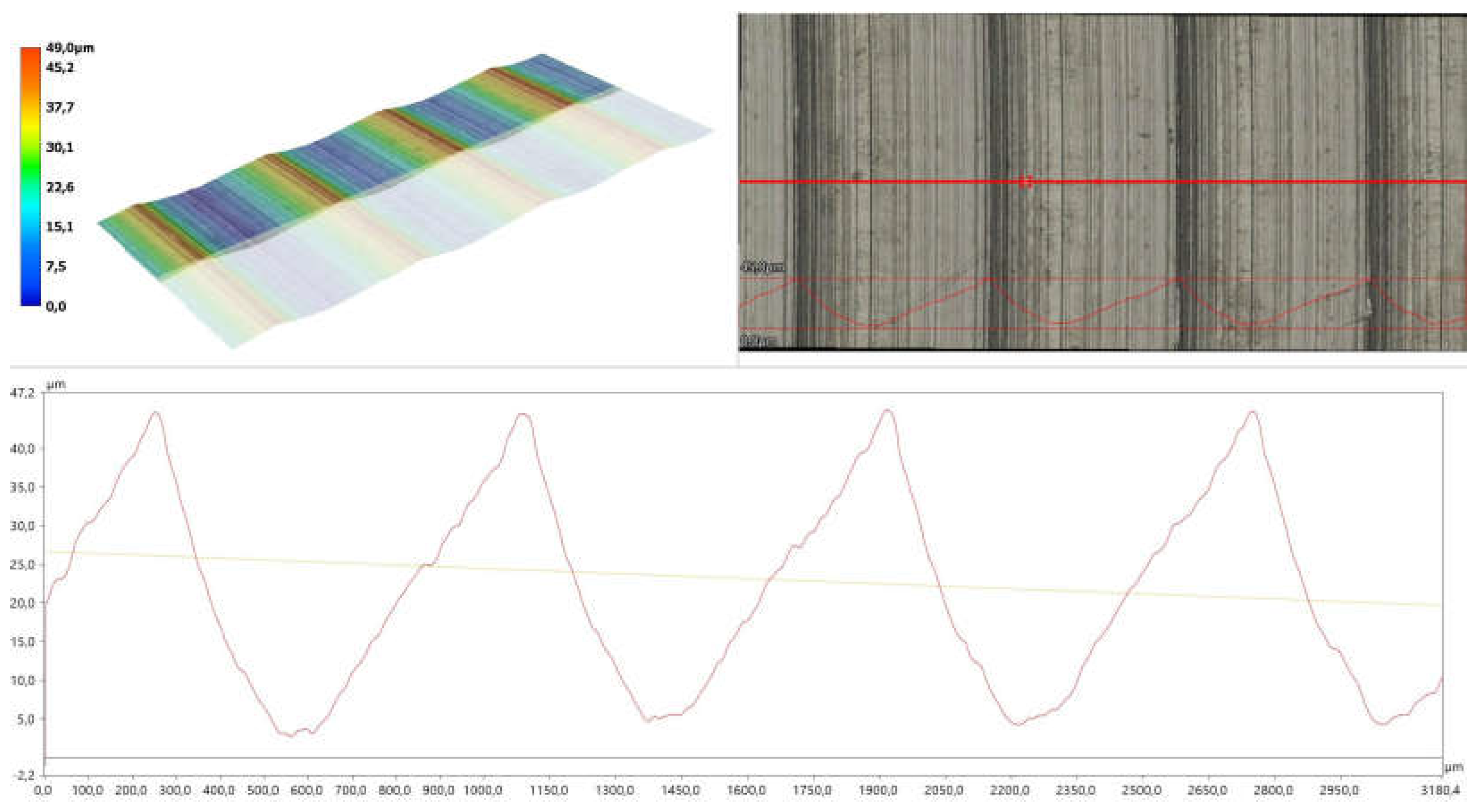

| arithmetical mean height of profile | μm | |

| maximum height of profile | μm | |

| temperature | K | |

| thickness of the microprotrusions | mm | |

| volume | m3 | |

| gap width | mm | |

| + | + parameter | - |

| Subscripts | ||

| index of gasket variant | - | |

References

- Arghavani, J.; Derenne, M.; Marchand, L. Effect of Surface Characteristics on Compressive Stress and Leakage Rate in Gasketed Flanged Joints. Int. J. Adv. Manuf. Technol. 2003, 21, 713–732. [Google Scholar] [CrossRef]

- Nakano, M.; Sasaki, H. Radiation Resistance of Rubber Compounds for Gaskets (Second Report). In Proceedings of the 2012 20th International Conference on Nuclear Engineering and the ASME 2012 Power Conference, Anaheim, CA, USA, 30 July–3 August 2012. [Google Scholar]

- Lin, X.; Du, Z. Study on Leakage Model of Typical Penetration of Closed Structures Based on Porous Media Seepage Theory. Math. Probl. Eng. 2022, 2022, 6901534. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Albohr, O.; Tartaglino, U.; Volokitin, A.I.; Tosatti, E. On the Nature of Surface Roughness with Application to Contact Mechanics, Sealing, Rubber Friction and Adhesion. J. Phys. Condens. Matter 2005, 17, R1–R62. [Google Scholar] [CrossRef] [PubMed]

- Persson, B.N.J.; Yang, C. Theory of the Leak-Rate of Seals. J. Phys. Condens. Matter 2008, 20, 315011. [Google Scholar] [CrossRef]

- Lorenz, B.; Persson, B.N.J. Leak Rate of Seals: Comparison of Theory with Experiment. Europhys. Lett. 2009, 86, 44006. [Google Scholar] [CrossRef]

- Lorenz, B.; Persson, B.N.J. Leak Rate of Seals: Effective-Medium Theory and Comparison with Experiment. Eur. Phys. J. E 2010, 31, 159–167. [Google Scholar] [CrossRef]

- Persson, B.N.J. Leakage of Metallic Seals: Role of Plastic Deformations. Tribol. Lett. 2016, 63, 42. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Huang, Y.; Chen, Y. Fractal Modeling of Fluidic Leakage through Metal Sealing Surfaces. AIP Adv. 2018, 8, 045310. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Huang, Y.; Zhang, X. An Experimental Study of the Leakage Mechanism in Static Seals. Appl. Sci. 2018, 8, 1404. [Google Scholar] [CrossRef]

- Morag, Y.; Etsion, I. Resolving the Contradiction of Asperities Plastic to Elastic Mode Transition in Current Contact Models of Fractal Rough Surfaces. Wear 2007, 262, 624–629. [Google Scholar] [CrossRef]

- Yu, B.; Cheng, P. A Fractal Permeability Model for Bi-Dispersed Porous Media. Int. J. Heat Mass Transf. 2002, 45, 2983–2993. [Google Scholar] [CrossRef]

- Zheng, Q.; Xu, J.; Yang, B.; Yu, B. A Fractal Model for Gaseous Leak Rates through Contact Surfaces under Non-Isothermal Condition. Appl. Therm. Eng. 2013, 52, 54–61. [Google Scholar] [CrossRef]

- Pérez-Ràfols, F.; Larsson, R.; Almqvist, A. Modelling of Leakage on Metal-to-Metal Seals. Tribol. Int. 2016, 94, 421–427. [Google Scholar] [CrossRef]

- Jaszak, P.; Oredsson, J.; Grzejda, R. Modelling of Fluid Permeability at the Interface of the Metal-to-Metal Sealing Surface. Materials 2024, 17, 5194. [Google Scholar] [CrossRef]

- Grün, J.; Feldmeth, S.; Bauer, F. Multiphase Computational Fluid Dynamics of Rotary Shaft Seals. Lubricants 2022, 10, 347. [Google Scholar] [CrossRef]

- Kaszowski, P.; Dzida, M. CFD Analysis of Fluid Flow through the Labyrinth Seal. Trans. Inst. Fluid-Flow Mach. 2015, 130, 71–82. [Google Scholar]

- Zhang, F.; Liu, J.; Ding, X.; Yang, Z. An Approach to Calculate Leak Channels and Leak Rates Between Metallic Sealing Surfaces. J. Tribol. 2017, 139, 011708. [Google Scholar] [CrossRef]

- Saeed, H.A.; Izumi, S.; Sakai, S.; Haruyama, S.; Nagawa, M.; Noda, H. Development of New Metallic Gasket and Its Optimum Design for Leakage Performance. J. Solid Mech. Mater. Eng. 2008, 2, 105–114. [Google Scholar] [CrossRef]

- Haruyama, S.; Nurhadiyanto, D.; Choiron, M.A.; Kaminishi, K. Influence of Surface Roughness on Leakage of New Metal Gasket. Int. J. Press. Vessel. Pip. 2013, 111–112, 146–154. [Google Scholar] [CrossRef]

- Karohika, I.M.G.; Haruyama, S. Analysis of Three-Layer Gasket Performance Affected by Flange Surface. EUREKA Phys. Eng. 2022, 4, 57–66. [Google Scholar] [CrossRef]

- Du, P.; Lu, J.; Tuo, J.; Wang, X. Research on the Optimization Design of Metallic Gasket Based on DOE Methodology. IOP Conf. Ser. Mater. Sci. Eng. 2019, 569, 032027. [Google Scholar] [CrossRef]

- Zhou, F.; Dong, X.; Jiang, W.; Wang, X.; Xie, Y. Contact Mechanical Behavior and Leakage Prediction of Metal Lenticular Gaskets in Bolt Flange Joints of Ultrahigh Pressure Pipelines. Int. J. Press. Vessel. Pip. 2023, 206, 105038. [Google Scholar] [CrossRef]

- Adamek, K.; Jaszak, P. Design Method of Enhancing the Tightness of a Spiral Wound Gasket with PTFE Filling. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 332. [Google Scholar] [CrossRef]

- Aweimer, A.S.O.; Bouzid, A.-H. Evaluation of Interfacial and Permeation Leaks in Gaskets and Compression Packing. J. Nucl. Eng. Radiat. Sci. 2019, 5, 011013. [Google Scholar] [CrossRef]

- Jenco, J.M.; Hunt, E.S. Generic Issues Affecting Spiral-Wound Gasket Performance. Int. J. Press. Vessel. Pip. 2000, 77, 825–830. [Google Scholar]

- Veiga, J.C.; Cipolatti, C.F.; Kavanagh, N.; Castro, F.; Zandoná, V. Serrated Metal Graphite Faced Gaskets for Ring Joint Flanges. In Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012; pp. 199–204. [Google Scholar]

- Jaszak, P. The Elastic Serrated Gasket of the Flange Bolted Joints. Int. J. Press. Vessels Pip. 2019, 176, 103954. [Google Scholar] [CrossRef]

- Du, H.; Liu, Z.; Zhang, X.; Jiao, Y.; Che, R. Improving the Sealing Performance of Honeycomb Seal by Drilling Double Wall-Holes. Int. Commun. Heat Mass Transf. 2024, 155, 107562. [Google Scholar] [CrossRef]

- Ledrappier, F.; Juliaa, J.-F.; Teissier, M.; Lefrancois, M.; David, T.; Zaouter, T. Metal Seal Comprising a Textured Outer Sealing Layer. Patent Application No. US 2022/0057029 A1, 24 February 2022. [Google Scholar]

- Etsion, I.; Kligerman, Y.; Halperin, G. Analytical and Experimental Investigation of Laser-Textured Mechanical Seal Faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Wang, T.; Huang, W.; Liu, X.; Li, Y.; Wang, Y. Experimental Study of Two-Phase Mechanical Face Seals with Laser Surface Texturing. Tribol. Int. 2014, 72, 90–97. [Google Scholar] [CrossRef]

- Keller, D.; Jacobs, G.; Neumann, S. Development of a Low-Friction Radial Shaft Seal: Using CFD Simulations to Optimise the Microstructured Sealing Lip. Lubricants 2020, 8, 41. [Google Scholar] [CrossRef]

- Tesla, N. Valvular Conduit. Patent Application No. US 1329559 A, 3 February 1920. [Google Scholar]

- Purwidyantri, A.; Prabowo, B.A. Tesla Valve Microfluidics: The Rise of Forgotten Technology. Chemosensors 2023, 11, 256. [Google Scholar] [CrossRef]

- PN-EN 1514-1:2025-01; Flanges and Their Joints, Dimensions of Gaskets for PN-Designated Flanges, Part 1: Non-Metallic Flat Gaskets with or Without Inserts. Polish Committee for Standardization: Warsaw, Poland, 2025.

- PN-EN 1092-1:2018-08; Flanges and Their Joints, Circular Flanges for Pipes, Fittings, Valves, Connectors, and Accessories with PN Marking, Part 1: Steel Flanges. Polish Committee for Standardization: Warsaw, Poland, 2018.

- Menter, F.R.; Ferreira, J.C.; Esch, T.; Konno, B. The SST Turbulence Model with Improved Wall Treatment for Heat Transfer Predictions in Gas Turbines. In Proceedings of the International Gas Turbine Congress 2003, Tokyo, Japan, 2–7 November 2003. [Google Scholar]

- Menter, F.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- CFX-Solver Modeling Guide. Available online: https://ansyshelp.ansys.com/public/account/secured?returnurl=///////Views/Secured/corp/v242/en/cfx_mod/cfx_mod.html (accessed on 18 September 2025).

- Langtry, R.; Menter, F. Transition Modeling for General CFD Applications in Aeronautics. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005. [Google Scholar]

- Menter, F.R.; Langtry, R.B.; Likki, S.R.; Suzen, Y.B.; Huang, P.G.; Volker, S. A correlation-based transition model using local variables—Part I: Model formulation. ASME J. Turbomach. 2006, 128, 413–422. [Google Scholar] [CrossRef]

- Langtry, R.B.; Menter, F.R.; Likki, S.R.; Suzen, Y.B.; Huang, P.G.; Völker, S. A Correlation Based Transition Model Using Local Variables—Part II: Test Cases and Industrial Applications. ASME J. Turbomach. 2006, 128, 423–434. [Google Scholar]

- Salim, M.S.; Cheah, S.C. Wall Y+ Strategy for Dealing with Wall-Bounded Turbulent Flows. In Proceedings of the International MultiConference of Engineers and Computer Scientists, Hong Kong, China, 18–20 March 2009. [Google Scholar]

- Black Resin Formlabs. Available online: https://formlabs.com/eu/store/materials/black-resin/?srsltid=AfmBOorTLWG4BHFETioeaL18pa4LuLReW2a9k-dkTZW9CbEyA3_Advpo (accessed on 19 March 2025).

- Masavetas, K.A. The Mere Concept of an Ideal Gas. Math. Comput. Model. 1989, 12, 651–657. [Google Scholar] [CrossRef]

- PN-EN 13555:2021-07; Flanges and Their Joints, Gasket Parameters and Test Procedures for the Design Principles of Flanged Connections with a Gasket. Polish Committee for Standardization: Warsaw, Poland, 2021.

- PN-EN ISO 21920-2:2022-06; Product Geometry Specifications (GPS), Geometric Structure of Surfaces: Profile, Part 2: Terms, Definitions and Parameters of Geometric Structure of Surfaces. Polish Committee for Standardization: Warsaw, Poland, 2022.

| Characteristic Dimension | G1 | G2 | G3 | G4 | G5 | G6 |

|---|---|---|---|---|---|---|

| Microstructure depth , mm | 0.1 | 0.1 | 0.1 | 0.4 | 0.1 | 0.1 |

| Minor axis of ellipse , mm | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 3.2 |

| Height of the split of ellipse , mm | 0.08 | 0.08 | 0 | 0.08 | 0.08 | 0.16 |

| Thickness of microprotrusions , mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.15 | 0.3 |

| Gap width , mm | 0.6 | 0.45 | 0.6 | 0.6 | 0.45 | 0.6 |

| Number of microprotrusions in the circumferential direction | 44 | 44 | 44 | 44 | 44 | 22 |

| Number of microprotrusions in the radial direction | 8 | 8 | 8 | 8 | 8 | 4 |

| Gasket Variant | Elements (Segment) | Elements (Full Geometry) | Average Orthogonal Quality | Average Skewness | Average Aspect Ratio |

|---|---|---|---|---|---|

| G0* | 35,294,278 | 3,105,896,464 | 1.00000 | 0.000157 | 3.5064 |

| G1 | 28,766,516 | 2,531,453,408 | 0.98596 | 0.043230 | 3.5573 |

| G2 | 28,614,974 | 2,518,117,712 | 0.98617 | 0.041943 | 3.5602 |

| G3 | 22,584,124 | 1,987,402,912 | 0.98941 | 0.035120 | 3.5151 |

| G4 | 77,160,800 | 6,790,150,400 | 0.97051 | 0.073682 | 2.3141 |

| G5 | 30,232,240 | 2,660,437,120 | 0.98696 | 0.041728 | 3.5407 |

| G6 | 58,938,288 | 2,593,284,672 | 0.99284 | 0.026865 | 3.5359 |

| Property | Post-Cured at Room Temperature for 5 min | Post-Cured at 60 °C for 15 min |

|---|---|---|

| Ultimate Tensile Strength, MPa | 57 | 61 |

| Tensile Modulus, MPa | 2450 | 2700 |

| Elongation at break, % | 14 | 10 |

| Heat Deflection Temperature at 0.45 MPa, °C | 61 | 69 |

| Measuring Instrument | Measurement Range | Accuracy |

|---|---|---|

| Helium pressure gauge RP T 95 62 (KFM, Wloclawek, Poland) | 0–10 MPa | ±0.05 MPa (CL 0.6) |

| Force sensor CL20-18 (ZEPWN, Marki, Poland) | 0–200 kN | ±0.01 kN |

| Helium leak detector LDS3000 (INFICON, Koln, Germany) | 10−7–10−1 mbar·L/s | ± 0.1 · 10n mbar·L/s |

| Gasket Variant | Pre-Test Image | Post-Test Image |

|---|---|---|

| G3 |  |  |

| G4 |  |  |

| G6 |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaszak, P.; Piwowar, A.; Bieganowski, M. Influence of Sealing Surface Microstructure Characteristics on Flow Resistance and Leakage Between Contact Surfaces. Materials 2025, 18, 4474. https://doi.org/10.3390/ma18194474

Jaszak P, Piwowar A, Bieganowski M. Influence of Sealing Surface Microstructure Characteristics on Flow Resistance and Leakage Between Contact Surfaces. Materials. 2025; 18(19):4474. https://doi.org/10.3390/ma18194474

Chicago/Turabian StyleJaszak, Przemysław, Anna Piwowar, and Marcin Bieganowski. 2025. "Influence of Sealing Surface Microstructure Characteristics on Flow Resistance and Leakage Between Contact Surfaces" Materials 18, no. 19: 4474. https://doi.org/10.3390/ma18194474

APA StyleJaszak, P., Piwowar, A., & Bieganowski, M. (2025). Influence of Sealing Surface Microstructure Characteristics on Flow Resistance and Leakage Between Contact Surfaces. Materials, 18(19), 4474. https://doi.org/10.3390/ma18194474