Microstructure and Mechanical Properties of Hot-Rolled ZrAl14Ti3 and ZrAl14Ti9 Alloys

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. XRD Results

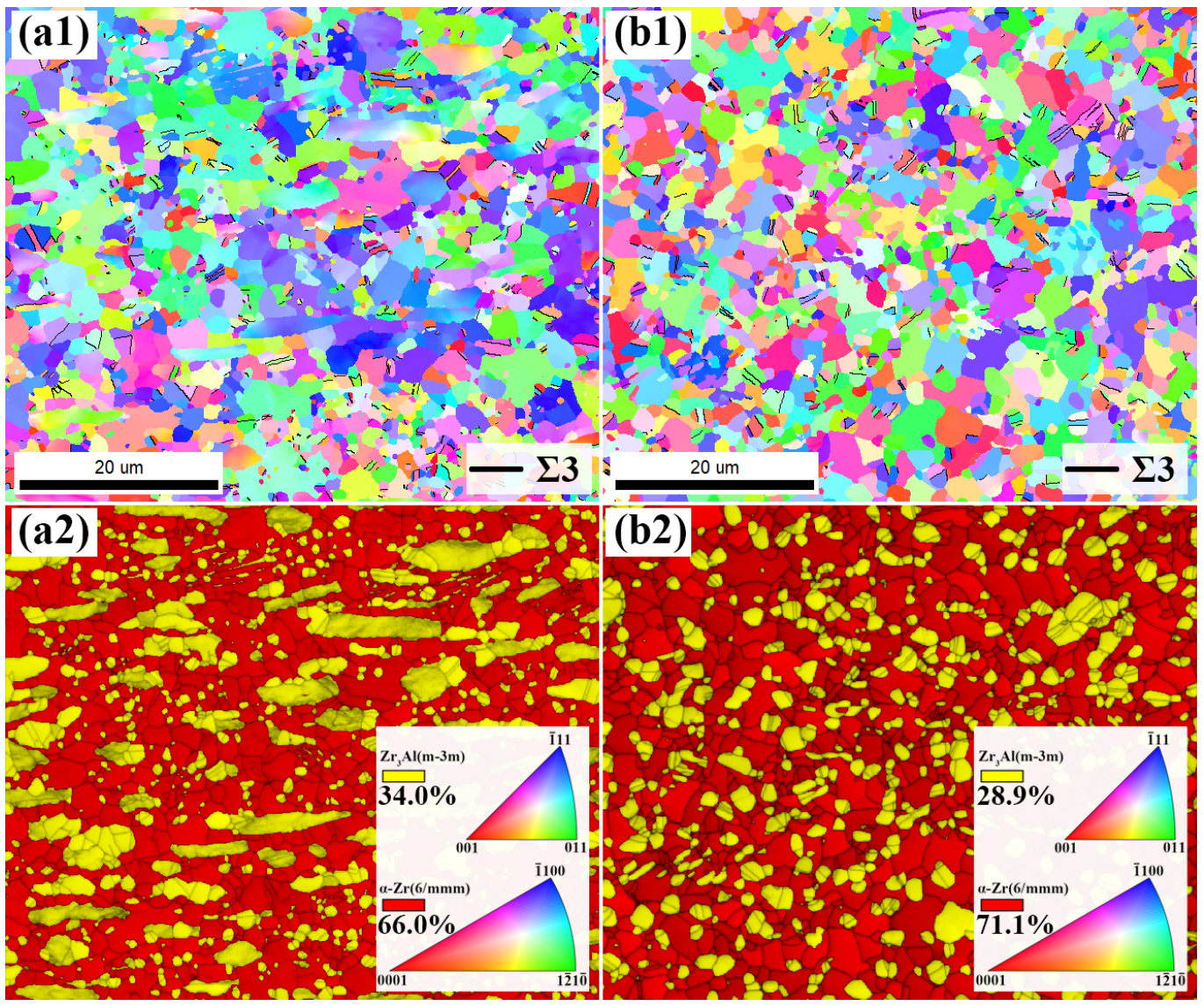

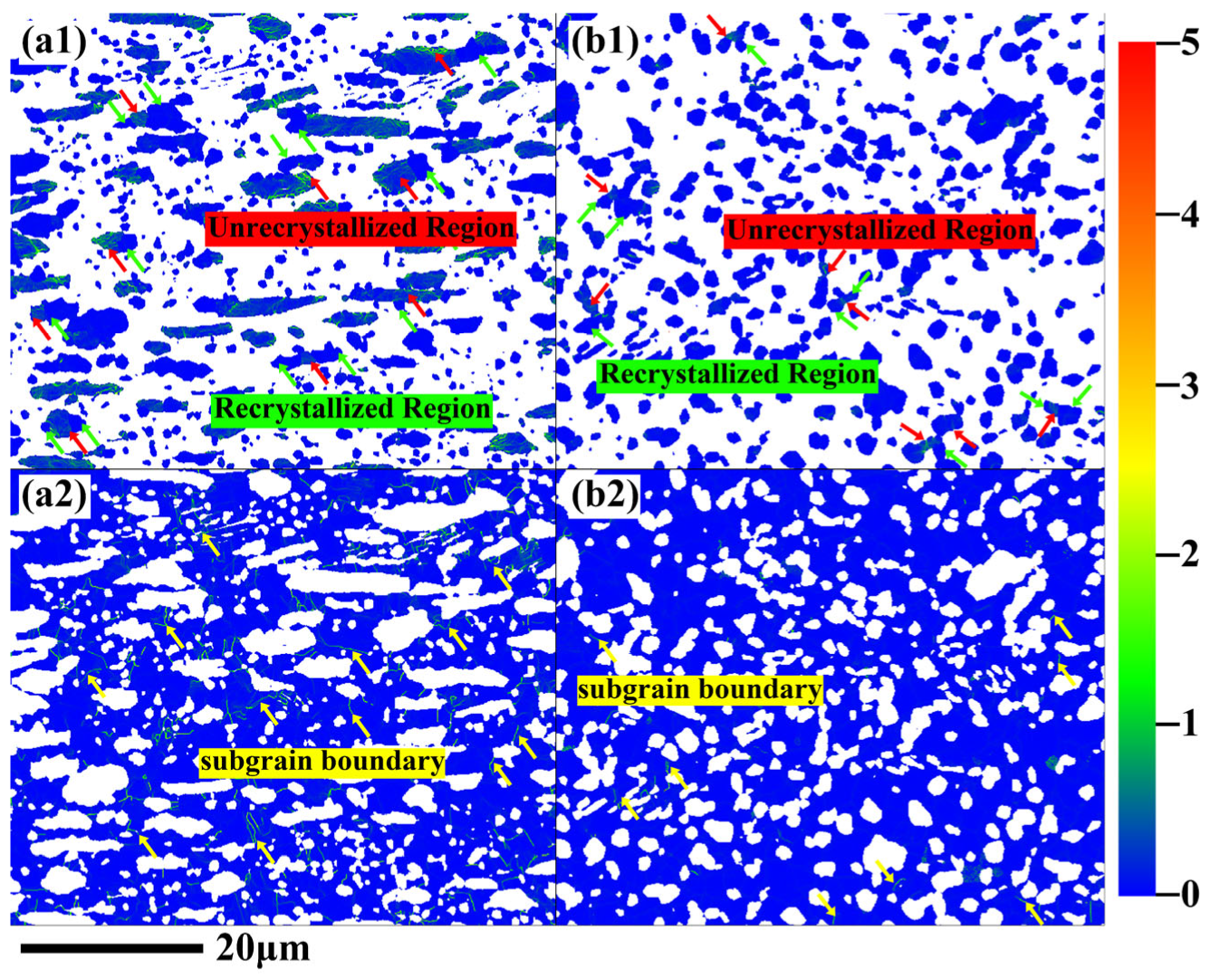

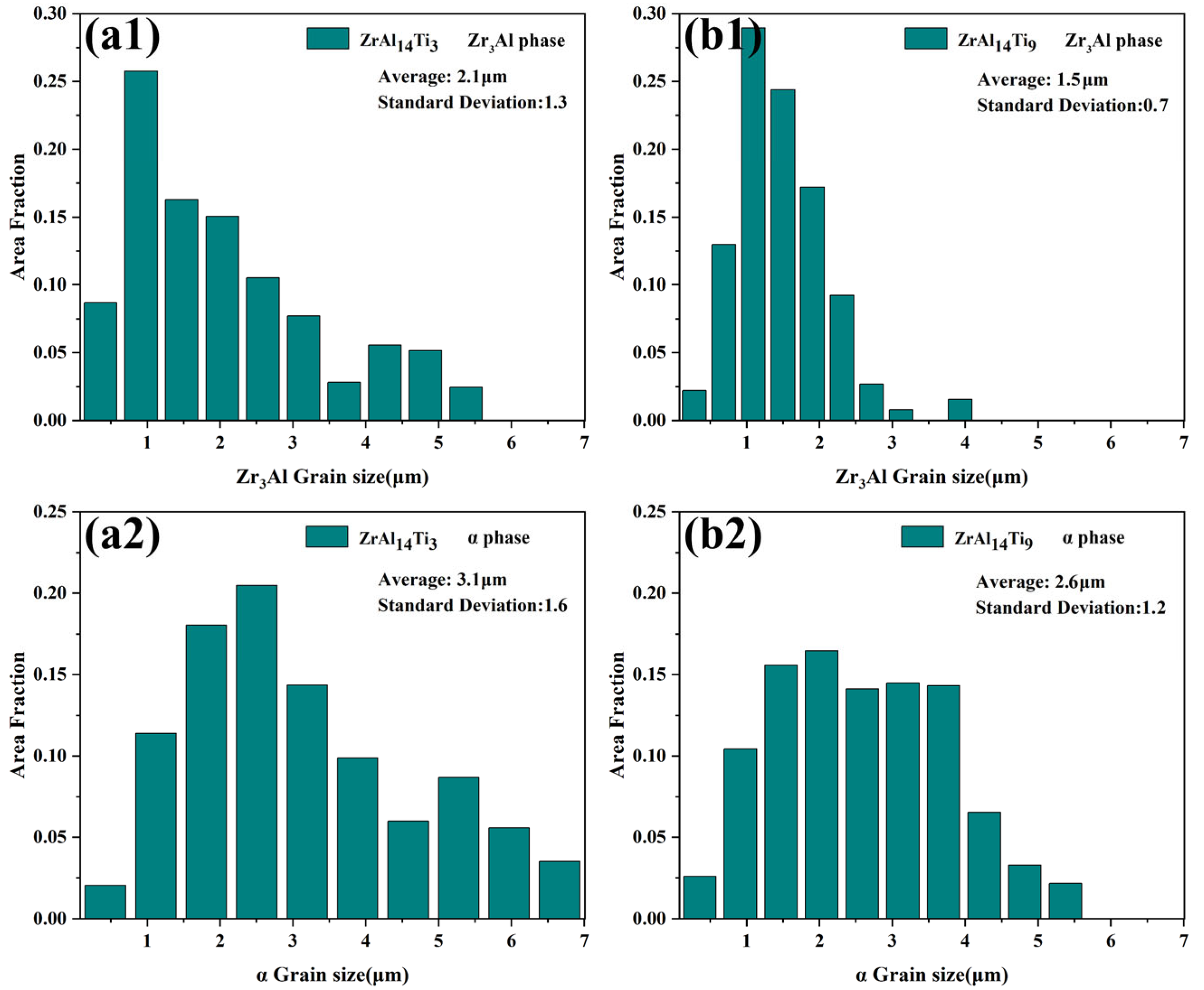

3.2. Microstructure Evolution

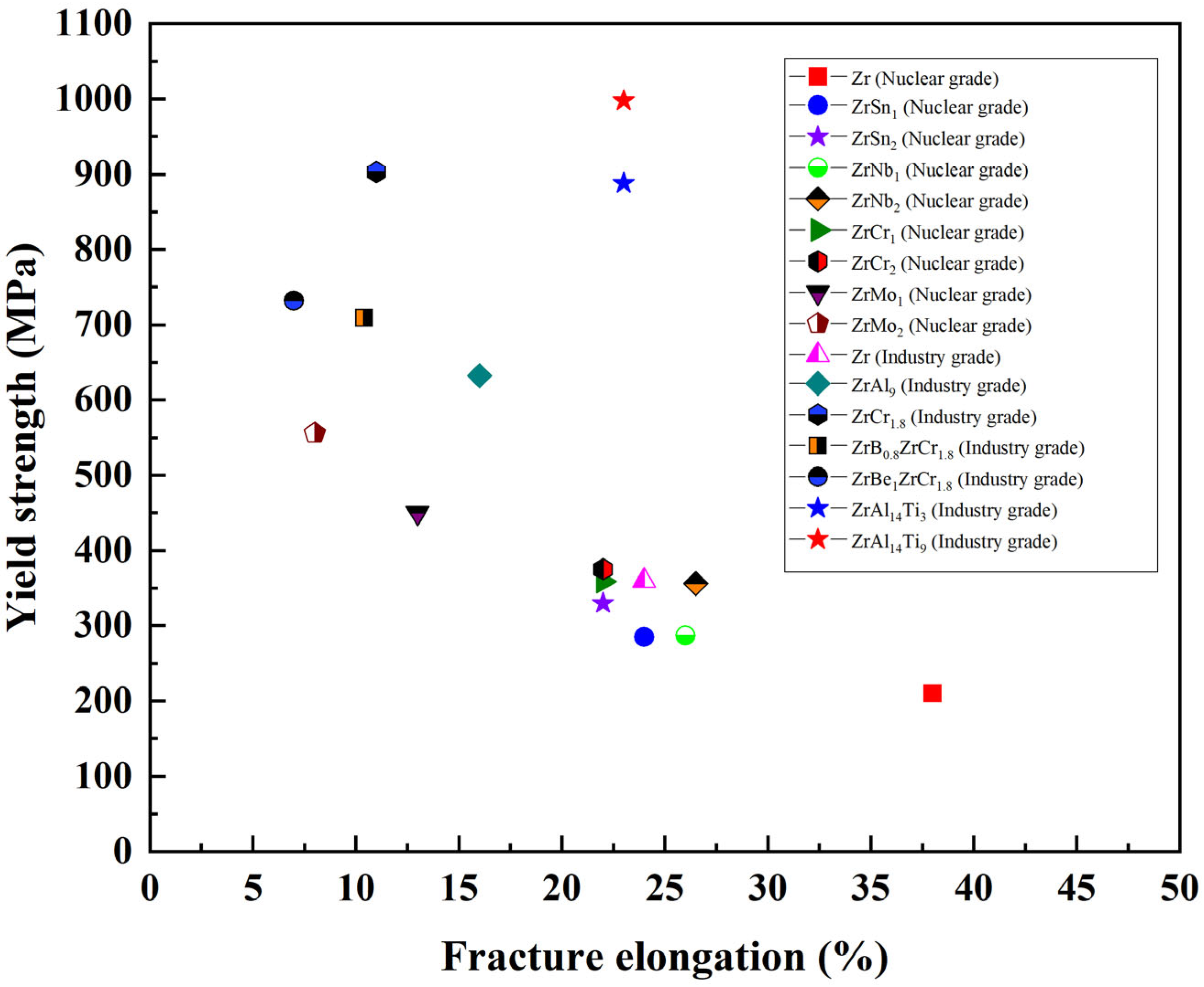

3.3. Mechanical Properties

4. Conclusions

- (1)

- The addition of Ti reduces the dissolution temperature of Zr3Al in the α-Zr matrix, enhancing Al solubility in α-Zr and decreasing the equilibrium Zr3Al phase fraction.

- (2)

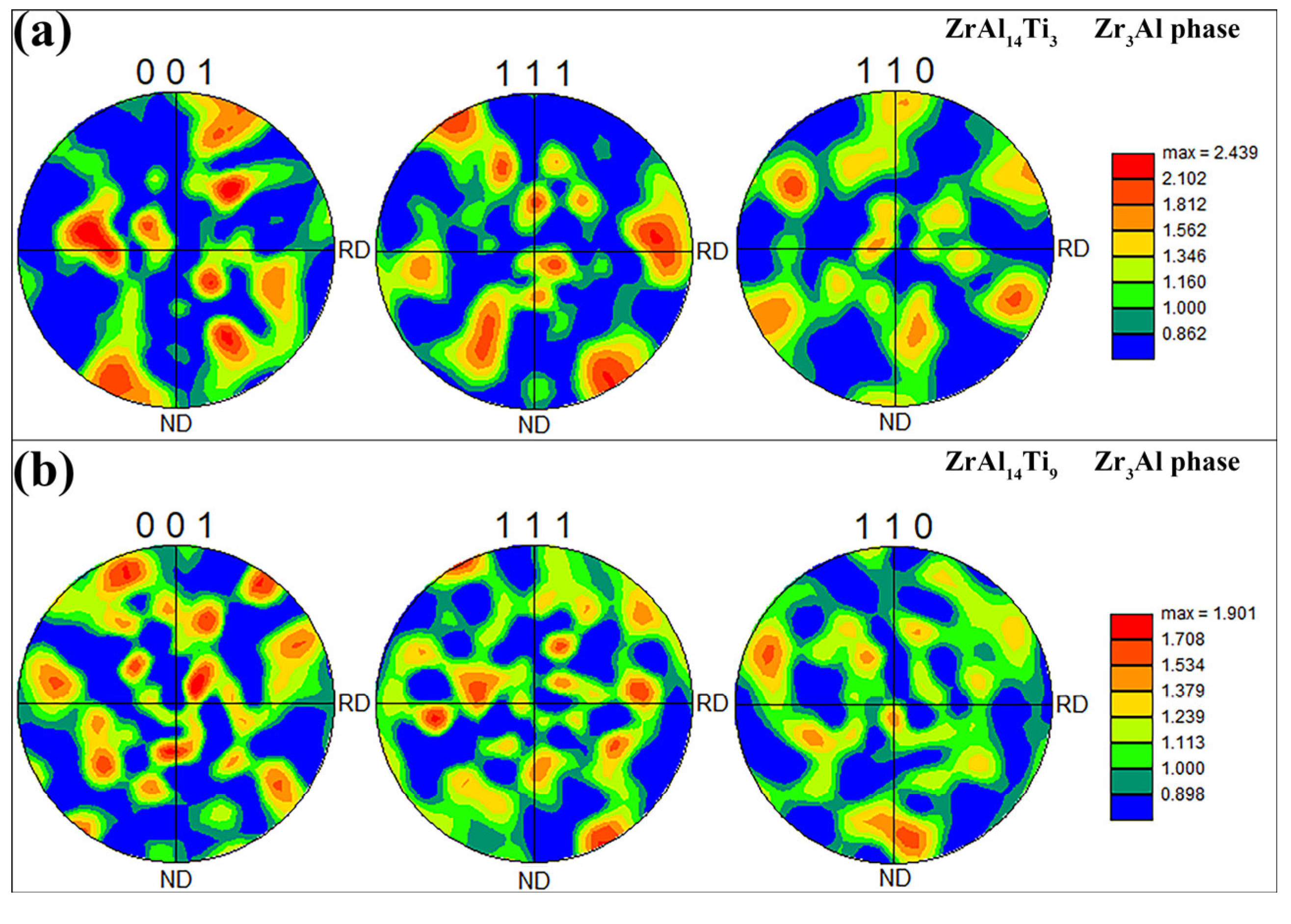

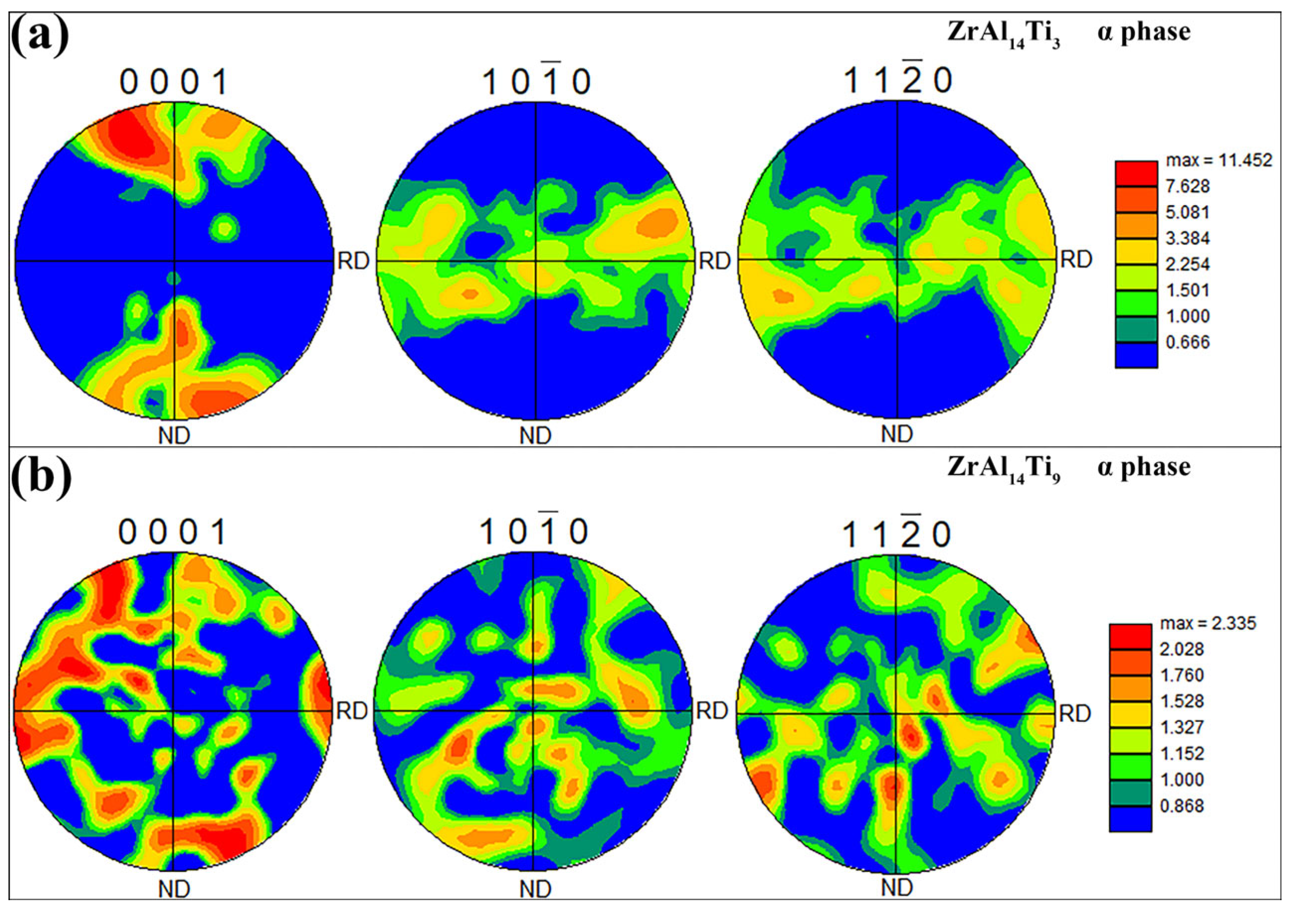

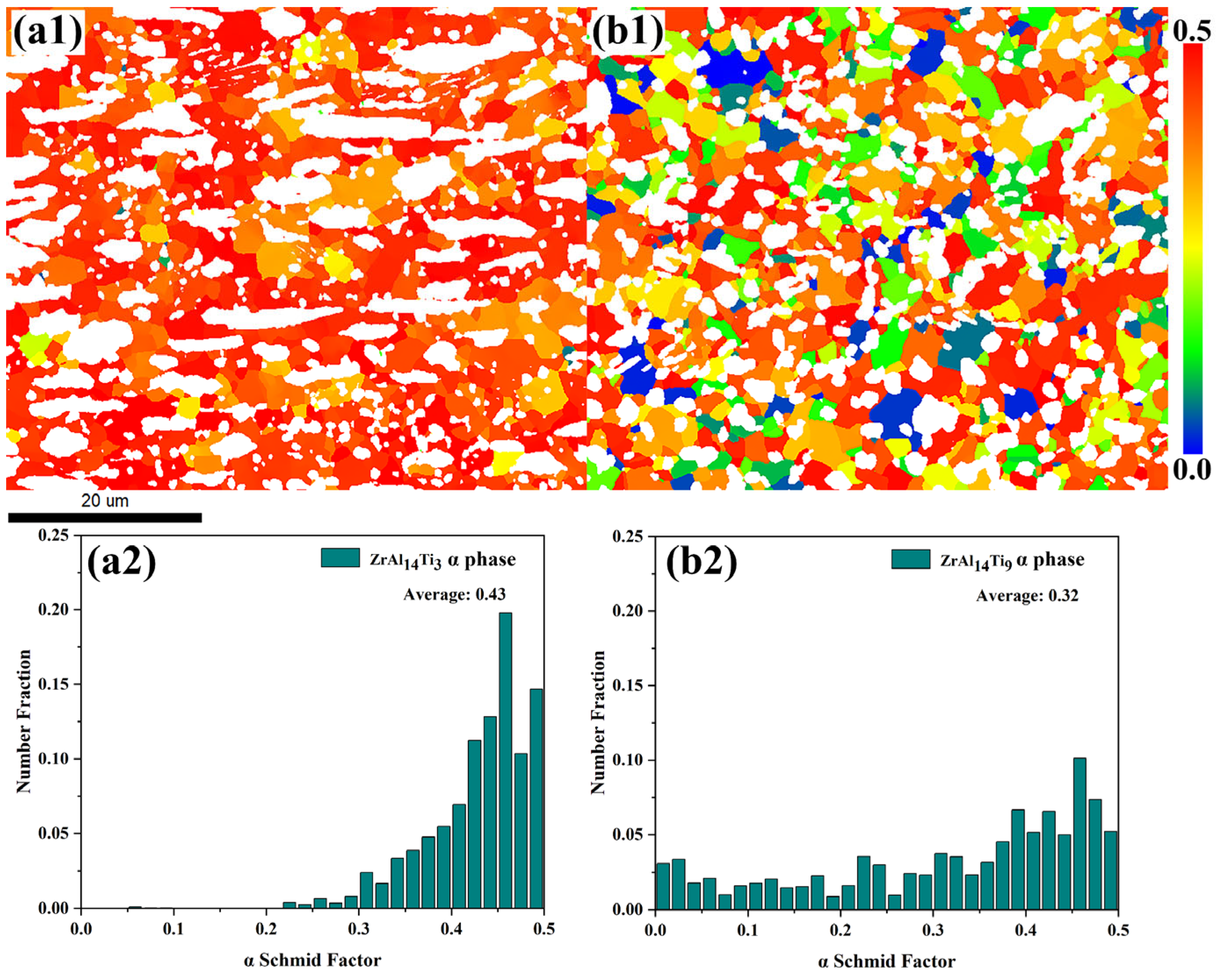

- The addition of Ti promotes the recrystallization of the Zr3Al phase and the globularization of the α-Zr phase, refines the grains, and eliminates the basal texture in the α-Zr phase.

- (3)

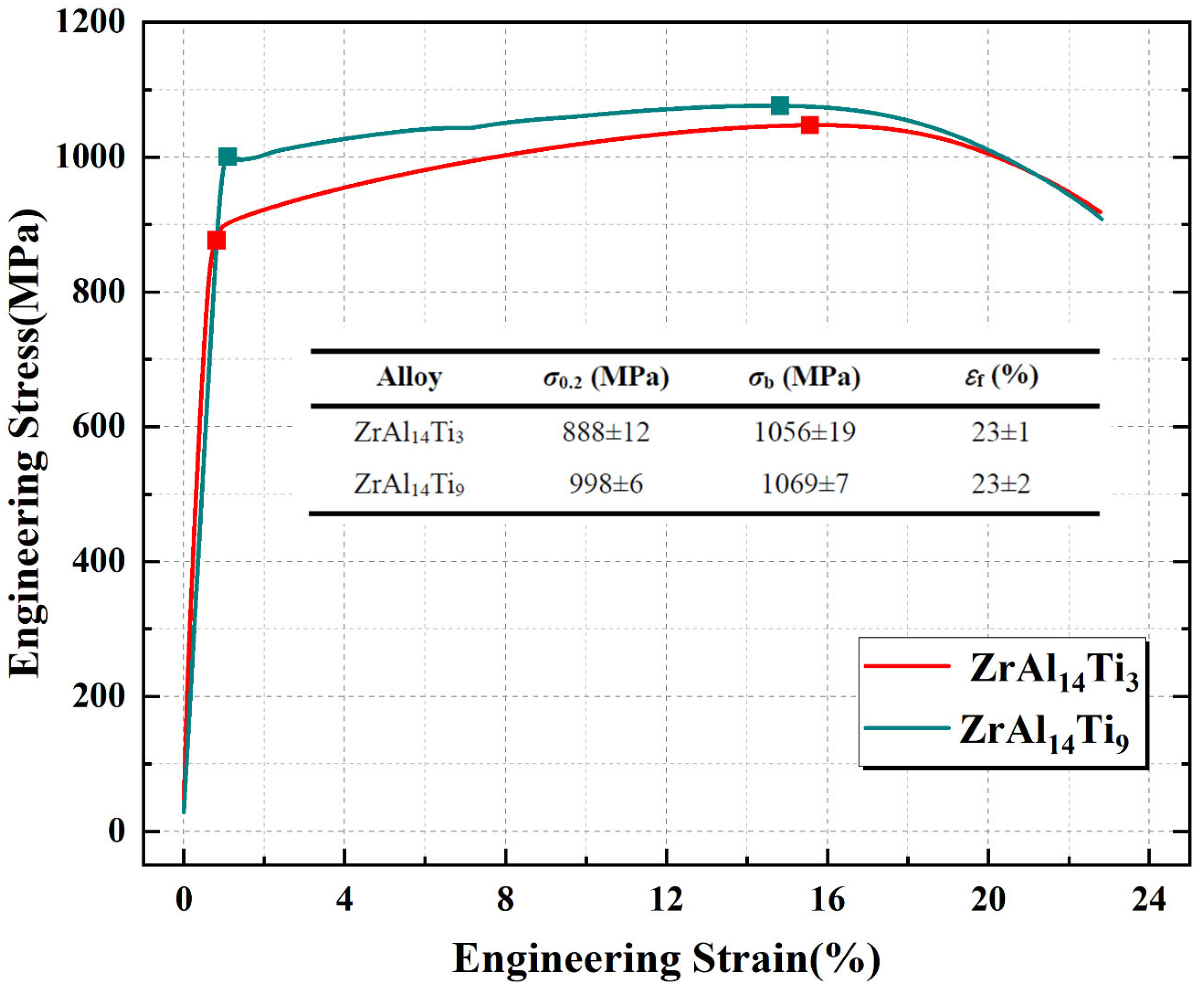

- The ZrAl14Ti9 alloy exhibits an offset yield strength of 998 ± 6 MPa, tensile strength of 1069 ± 7 MPa, and fracture elongation of 23% ± 2. Compared with the ZrAl14Ti3 alloy, the offset yield strength is increased by 110 MPa, the tensile strength is increased by 13 MPa, while the fracture elongation remains unchanged. The main strengthening mechanisms include solid-solution strengthening, grain refinement, an increased fraction of the harder α-Zr phase, and orientation hardening.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jarugula, R.; Halodová, P.; Zimina, M.; Sundararaman, M.; Malá, M.; Klouzal, J.; Ševeček, M.; Běláč, J.; Řeháček, R.; Linhart, S. Effect of neutron irradiation on microstructural evolution and deformation behavior of Zirconium (Zr-1Nb) alloy. J. Nucl. Mater. 2025, 605, 155596. [Google Scholar] [CrossRef]

- Zhang, N.; Xia, C.; Qin, J.; Li, Q.; Zhang, X.; Liu, R. Research progress of novel zirconium alloys with high strength and toughness. J. Met. Mater. Miner. 2022, 32, 23–36. [Google Scholar] [CrossRef]

- Kautz, E.; Gwalani, B.; Yu, Z.F.; Varga, T.; Geelhood, K.; Devaraj, A.; Senor, D. Investigating zirconium alloy corrosion with advanced experimental techniques: A review. J. Nucl. Mater. 2023, 585, 154586. [Google Scholar] [CrossRef]

- King, D.J.M.; Knowles, A.J.; Bowden, D.; Wenman, M.; Capp, S.; Gorley, M.; Shimwell, J.; Packer, L.; Gilbert, M.; Harte, A. High temperature zirconium alloys for fusion energy. J. Nucl. Mater. 2022, 559, 153431. [Google Scholar] [CrossRef]

- Slobodyan, M. High-energy surface processing of zirconium alloys for fuel claddings of water-cooled nuclear reactors. Nucl. Eng. Des. 2021, 382, 111364. [Google Scholar] [CrossRef]

- Lecomte, J.S.; Crépin, J.; Barberis, P. Critical Resolved Shear Stress and Work Hardening Determination in HCP Metals: Application to Zr Single Crystals. Metals 2024, 14, 1101. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, C.; Wu, J.; Yang, Z.; Liu, H.; Jia, X.; Liu, R.; Zhang, Y. Achieving high strength and plasticity in zirconium alloy by introducing bimodal microstructure composed of lamellar microstructure and recrystallized grains. Mater. Sci. Eng. A 2025, 924, 147794. [Google Scholar] [CrossRef]

- Banerjee, S.; Mukhopadhyay, P. Phase Transformations: Examples from Titanium and Zirconium Alloys; Elsevier: Oxford, UK, 2010. [Google Scholar]

- Schulson, E.M. The tensile and corrosion behaviour of ordered Zr3Al-based alloys. J. Nucl. Mater. 1974, 50, 127–138. [Google Scholar] [CrossRef]

- Schulson, E.M.; Roy, J.A. Work-hardening of the L12 phase Zr3Al. Acta Metall. 1978, 26, 15–28. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, B.; Liu, S.G.; Xia, C.; Zhang, X.; Ma, M.; Liu, R. Microstructures and mechanical properties of Zr–Al binary alloys processed by hot-rolling. Mater. Sci. Eng. A 2020, 773, 138723. [Google Scholar] [CrossRef]

- Chen, B.H.; Liu, S.G.; Zhang, X.Y.; Ma, M.; Liu, R. Effect of Al change on microstructure and mechanical properties of hot-rolled ZrSnAl alloy. Mater. Lett. 2020, 267, 127552. [Google Scholar] [CrossRef]

- ASTM E8/E8M-24; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- Gagne, M.; Schulson, E.M. The effects of annealing on cold-worked Zr3Al. Metall. Trans. A 1976, 7, 1775–1783. [Google Scholar] [CrossRef]

- Li, L.; Li, M.Q.; Luo, J. Mechanism in the β phase evolution during hot deformation of Ti–5Al–2Sn–2Zr–4Mo–4Cr with a transformed microstructure. Acta Mater. 2015, 94, 36–45. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Flow behavior and globularization kinetics during hot working of Ti–6Al–4V with a colony alpha microstructure. Mater. Sci. Eng. A 1999, 263, 257–271. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Bieler, T.R. The effect of alpha platelet thickness on plastic flow during hot working of TI–6Al–4V with a transformed microstructure. Acta Mater. 2001, 49, 3565–3573. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Murzinova, M.; Salishchev, G.; Semiatin, S. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011, 59, 4138–4150. [Google Scholar] [CrossRef]

- Zhu, K.Y.; Bacroix, B.; Chauveau, T.; Chaubet, D.; Castelnau, O. Texture evolution and associated nucleation and growth mechanisms during annealing of a Zr alloy. Metall. Mater. Trans. A 2009, 40, 2423–2434. [Google Scholar] [CrossRef]

- Prakash, D.G.L.; Preuss, M.; Dahlbäck, M.; da Fonseca, J.Q. Microstructure and texture evolution during thermomechanical processing of β-quenched Zr. Acta Mater. 2015, 88, 389–401. [Google Scholar] [CrossRef]

- Banerjee, S.; Vijayakar, S.J.; Krishnan, R. Strength of zirconium-titanium martensites and deformation behaviour. Acta Metall. 1978, 26, 1815–1831. [Google Scholar] [CrossRef]

- Banerjee, S.; Krishnan, R. Martensitic transformation in Zr− Ti alloys. Metall. Trans. 1973, 4, 1811–1819. [Google Scholar] [CrossRef]

- Yang, H.; Shen, J.; Matsukawa, Y.; Satoh, Y.; Kano, S.; Zhao, Z.; Li, Y.; Li, F.; Abe, H. Effects of alloying elements (Sn, Nb, Cr, and Mo) on the microstructure and mechanical properties of zirconium alloys. J. Nucl. Sci. Technol. 2015, 52, 1162–1173. [Google Scholar] [CrossRef]

- Feng, Z.H.; Xia, C.Q.; Jing, R.; Jiang, X.; Zhou, Y.; Zhong, H.; Zhang, X.; Ma, M.; Liu, R. Microstructure and mechanical properties of ZrBe alloys processed by hot rolling. Mater. Sci. Eng. A 2016, 667, 286–292. [Google Scholar] [CrossRef]

- Xia, C.Q.; Jiang, X.J.; Wang, X.Y.; Zhou, Y.; Feng, Z.; Liang, S.; Tan, C.; Ma, M.; Liu, R. Microstructure and mechanical properties of hot-rolled ZrB alloys. Mater. Sci. Eng. A 2015, 628, 168–175. [Google Scholar]

- Zhang, Z.G.; Zhou, Y.K.; Jiang, X.J.; Feng, Z.; Xia, C.; Zhang, X.; Ma, M.; Liu, R. A novel Zr-based alloy microstructure with high strength and excellent ductility. Mater. Sci. Eng. A 2016, 651, 370–375. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Knight, B.E.; Schuh, C.A. Six decades of the Hall–Petch effect–a survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar]

- Schulson, E.M.; Roy, J.A. The yield strength of the L12 phase Zr3Al. Acta Metall. 1978, 26, 29–38. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yang, Y.; Yang, M.; Li, W.; Li, Z. Microstructure and Mechanical Properties of Hot-Rolled ZrAl14Ti3 and ZrAl14Ti9 Alloys. Materials 2025, 18, 4459. https://doi.org/10.3390/ma18194459

Zhang X, Yang Y, Yang M, Li W, Li Z. Microstructure and Mechanical Properties of Hot-Rolled ZrAl14Ti3 and ZrAl14Ti9 Alloys. Materials. 2025; 18(19):4459. https://doi.org/10.3390/ma18194459

Chicago/Turabian StyleZhang, Xing, Yujing Yang, Mingchao Yang, Wang Li, and Zhixin Li. 2025. "Microstructure and Mechanical Properties of Hot-Rolled ZrAl14Ti3 and ZrAl14Ti9 Alloys" Materials 18, no. 19: 4459. https://doi.org/10.3390/ma18194459

APA StyleZhang, X., Yang, Y., Yang, M., Li, W., & Li, Z. (2025). Microstructure and Mechanical Properties of Hot-Rolled ZrAl14Ti3 and ZrAl14Ti9 Alloys. Materials, 18(19), 4459. https://doi.org/10.3390/ma18194459