Polar Cryogenic Impact Behavior of Selective Laser Melted Ti-6Al-4V Alloy: Effects of Scanning Strategies and Notch Orientation

Abstract

1. Introduction

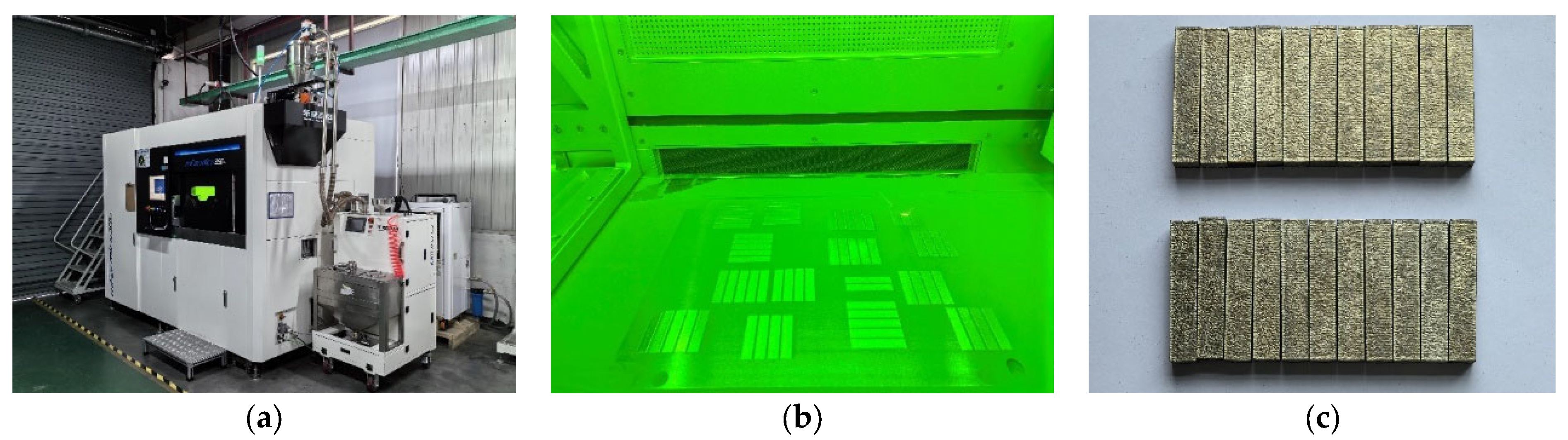

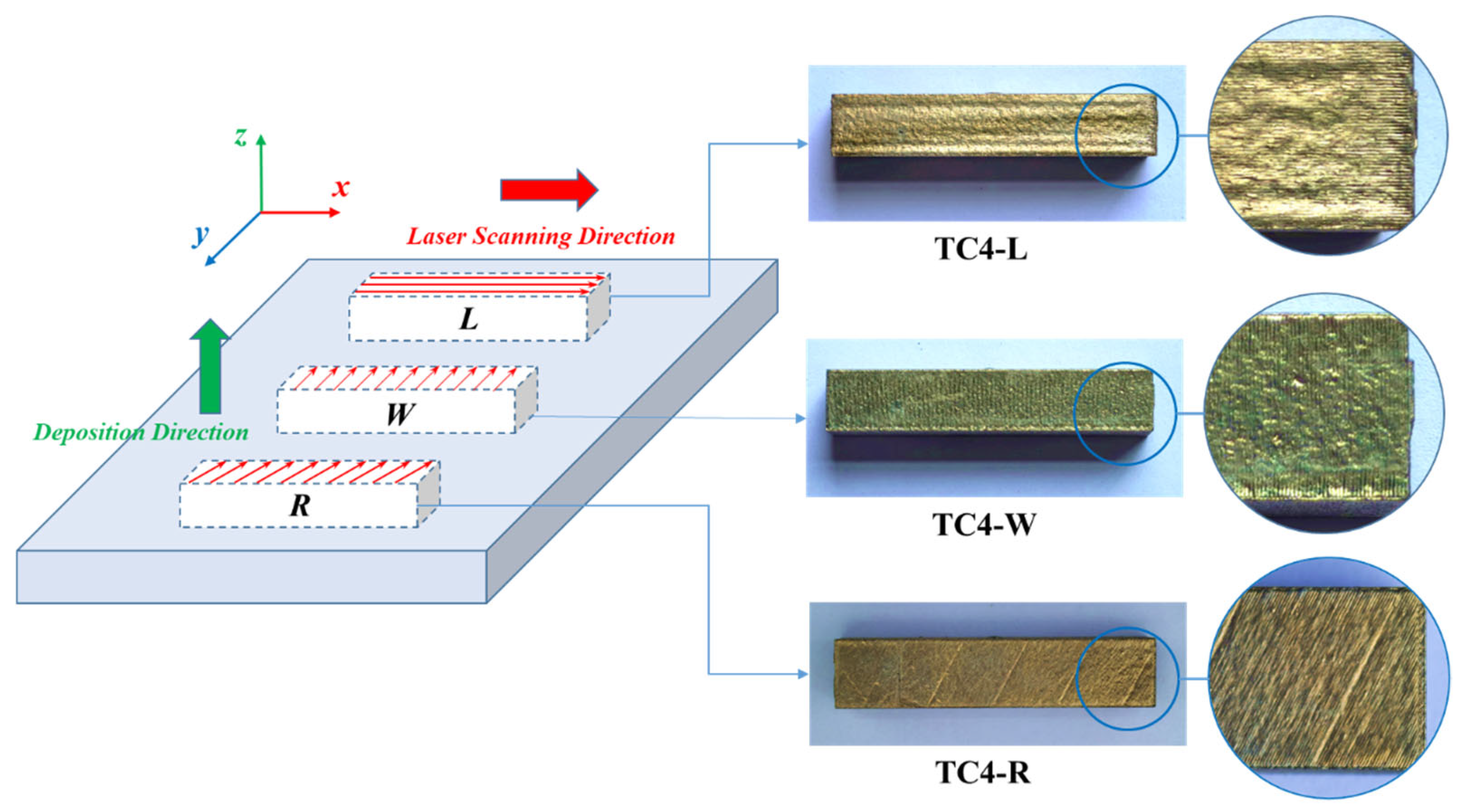

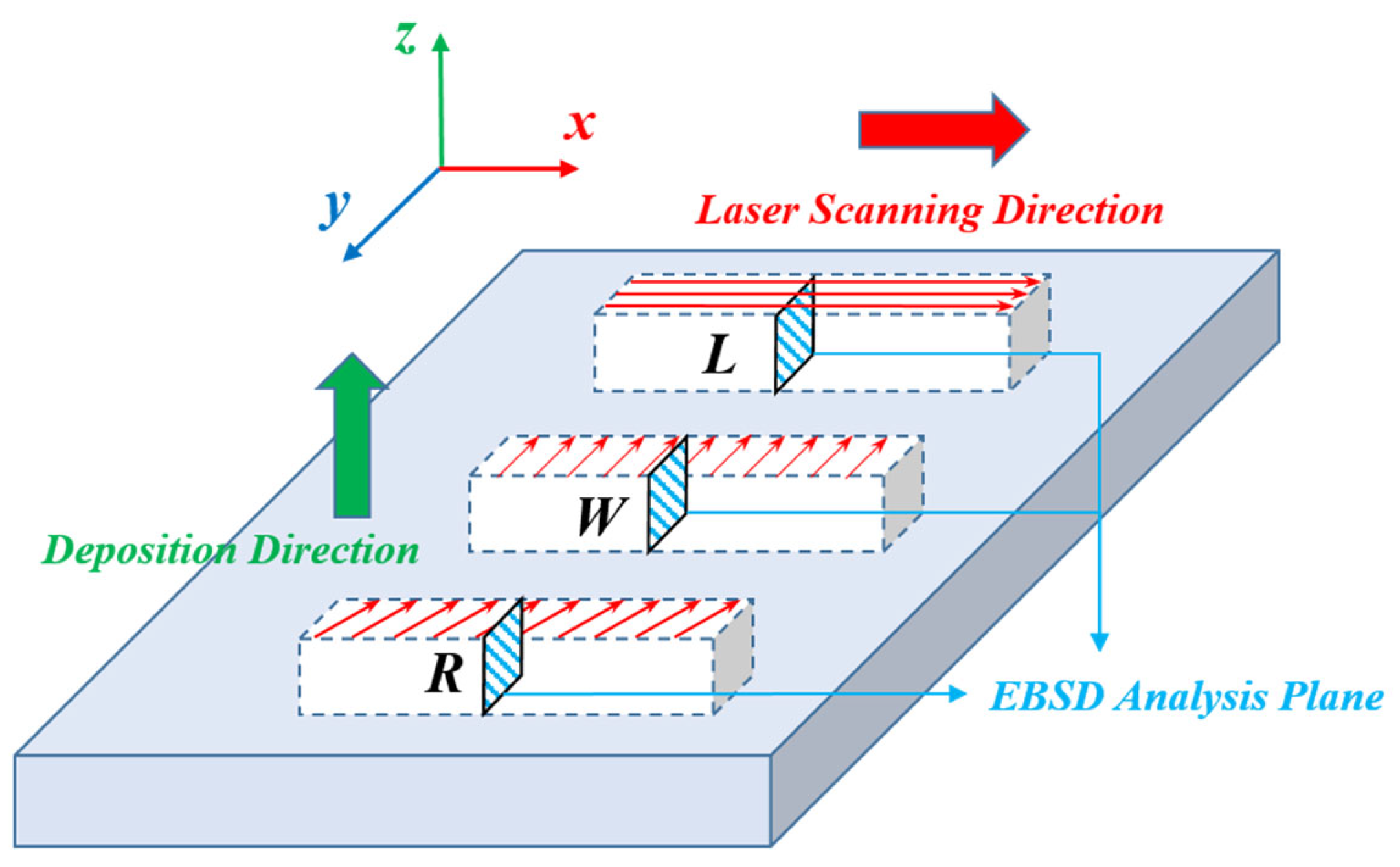

2. Materials and Methods

2.1. Test Materials

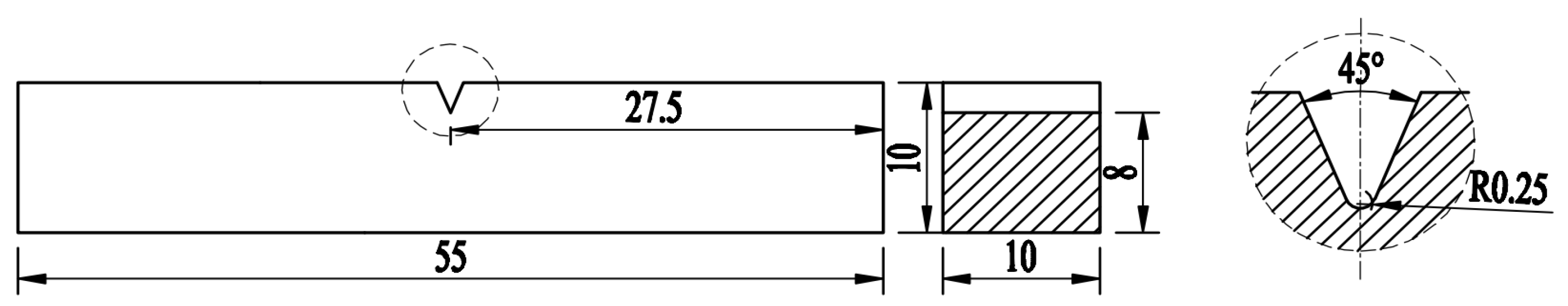

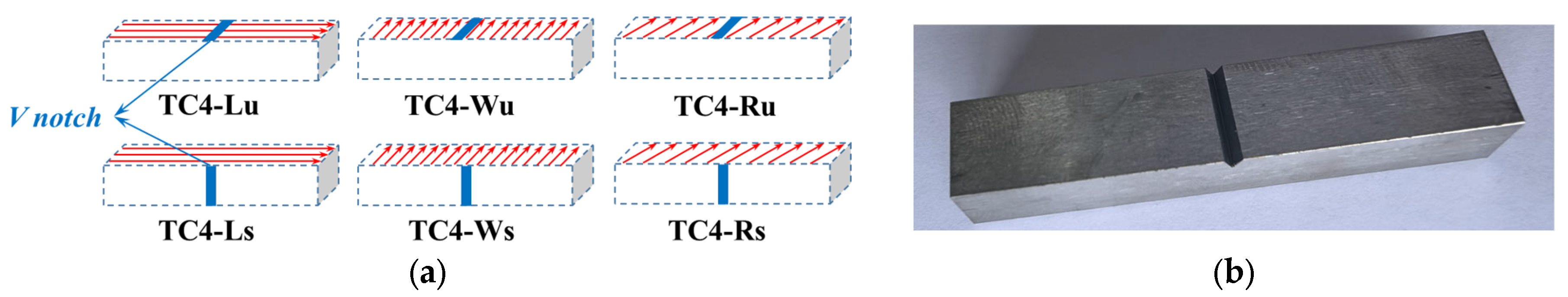

2.2. Specimen Preparation

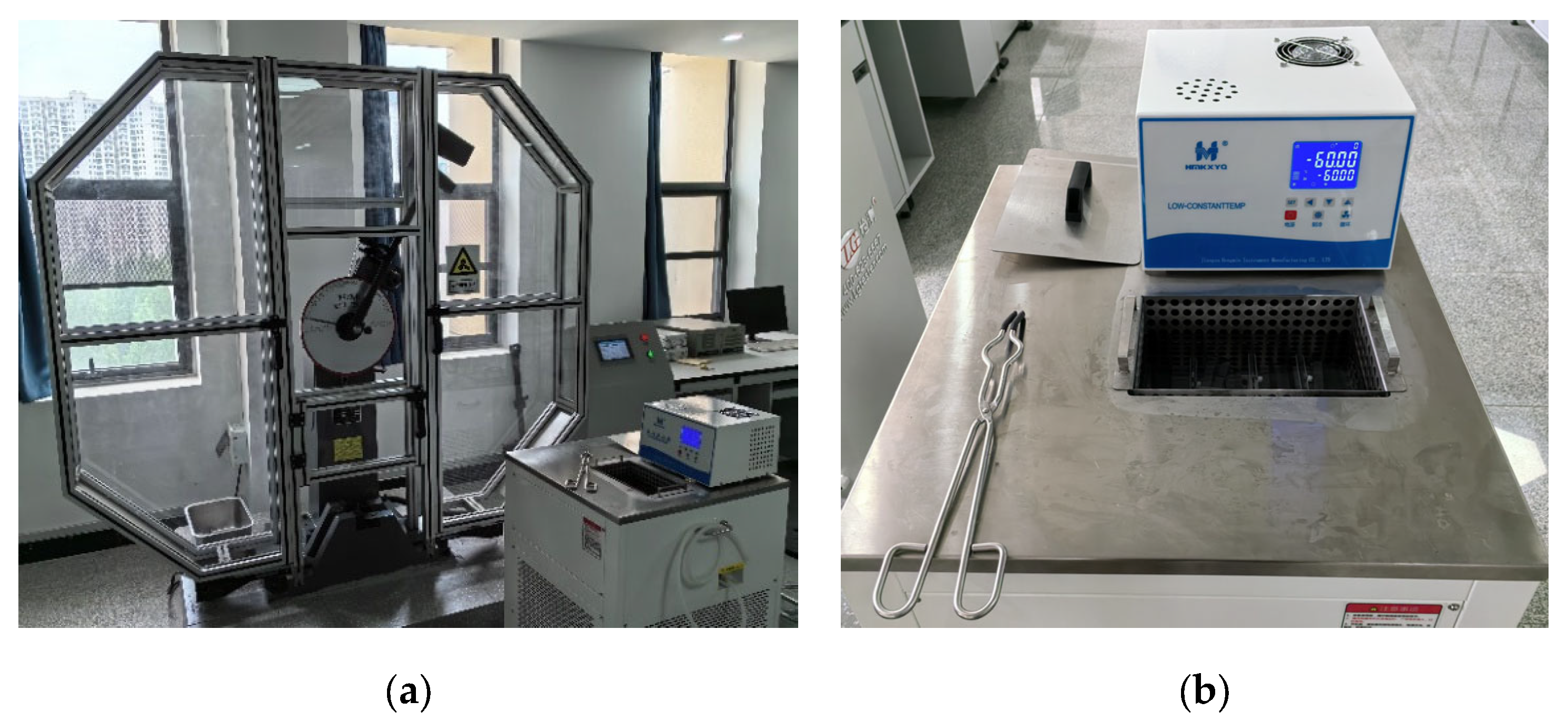

2.3. Charpy Pendulum Impact Test

3. Results and Analysis of the Charpy Pendulum Impact Test

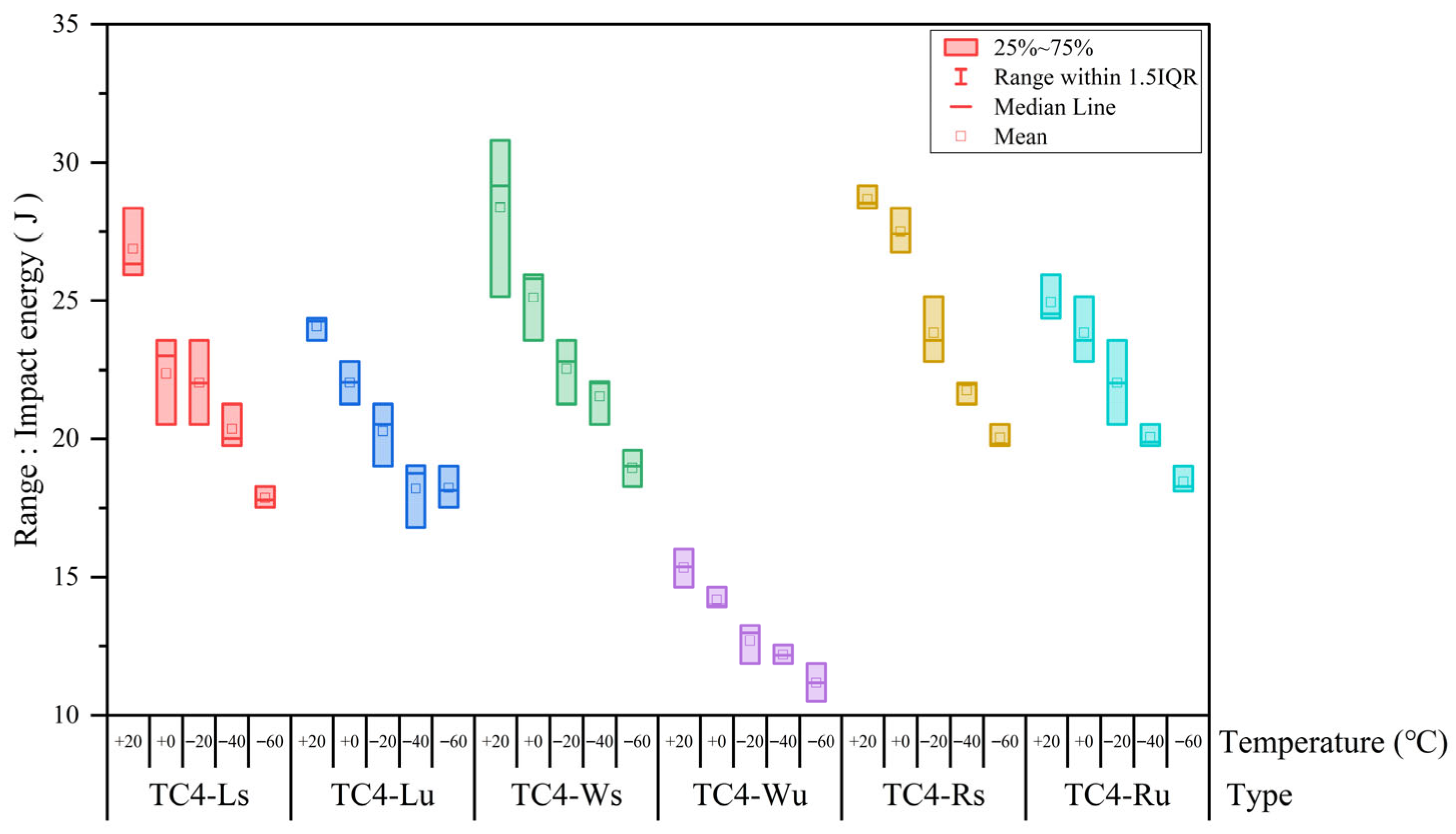

3.1. Consistency Analysis of Impact Energy Data

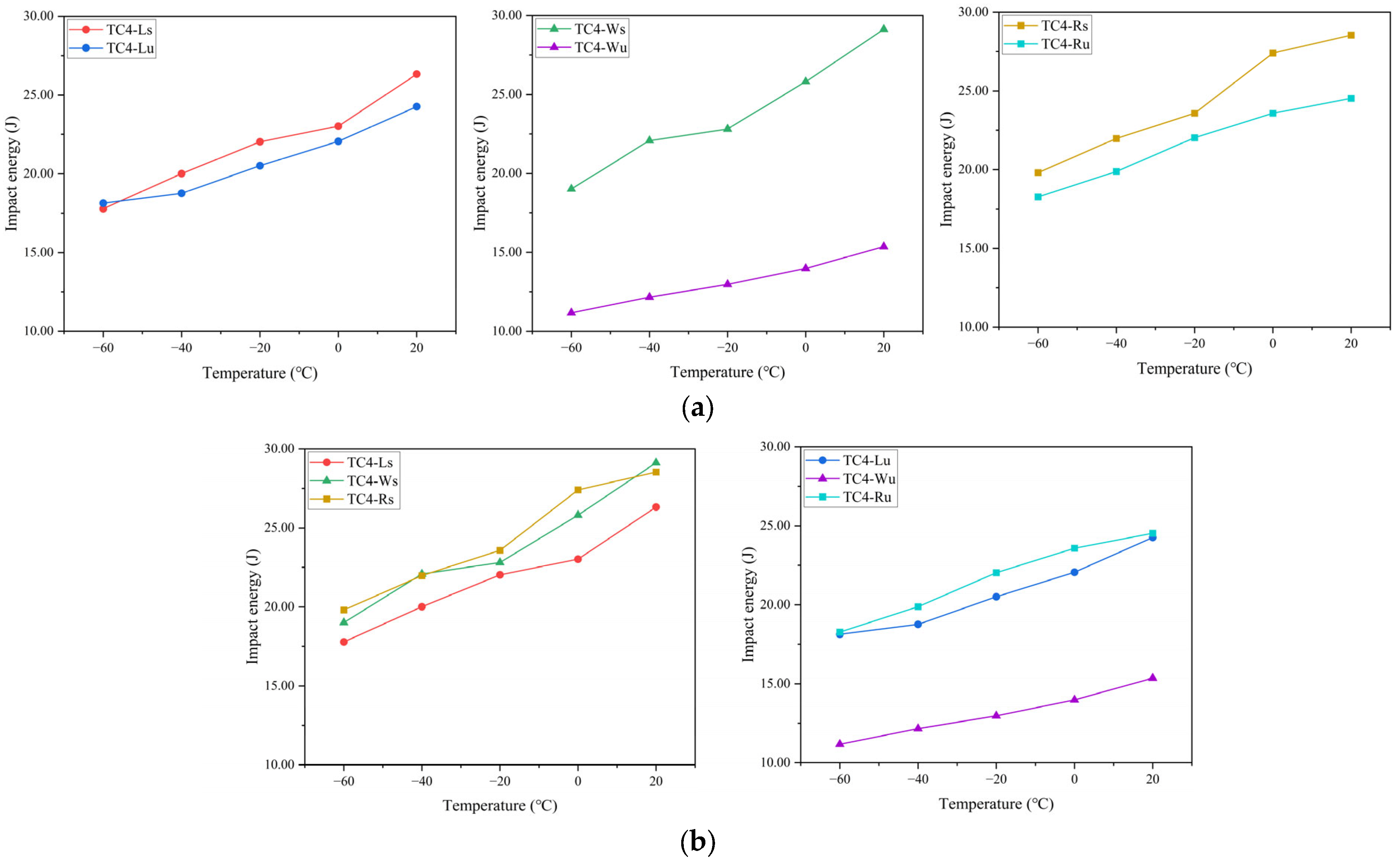

3.2. Temperature–Impact Energy Curves

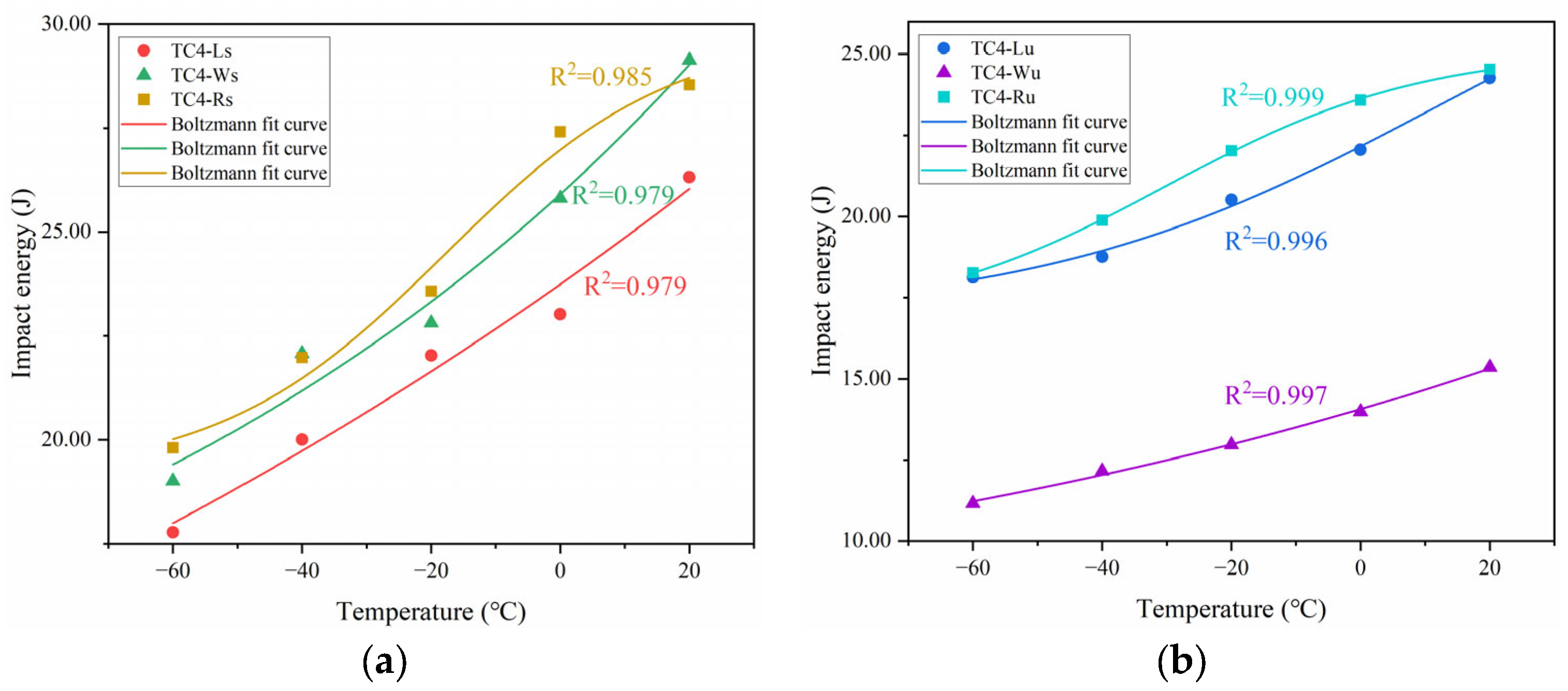

3.3. Ductile-to-Brittle Transition Temperature (DBTT)

4. Fracture Behavior and Microstructural Characteristics

4.1. Fractographic Analysis

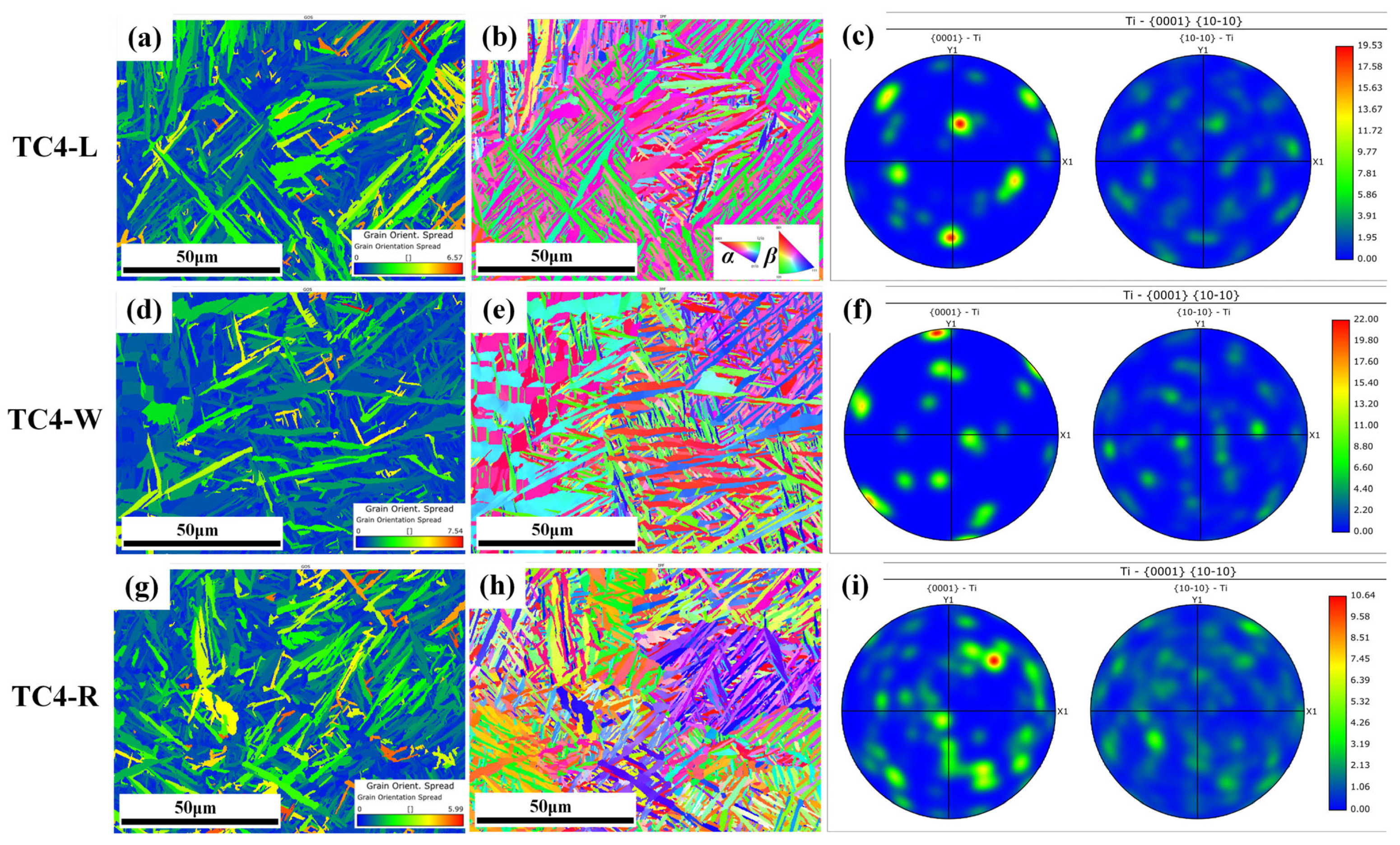

4.2. Microstructural Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, G.; Zhou, H.J.; Shen, Y. Exploration and Technical Requirements for the Development of China's Polar Marine Equipment. Ship Boat 2024, 35, 1–10. (In Chinese) [Google Scholar]

- Yu, L.; Guo, W.; Cao, C.; Li, M.; Wu, Z.; Wang, T.; Chen, H.; Pan, X. Experimental Study on the Fatigue Crack Propagation Rate of 925A Steel for a Ship Rudder System. Materials 2024, 17, 1808. [Google Scholar] [CrossRef]

- Chen, S.; Guo, W.; Cao, C.; Huang, J.; Zhang, J.; Yu, L.; Chen, H. Fatigue Life Analysis of the Submarine Rudder Stock Mechanism at Arctic Low Temperatures. Appl. Sci. Eng. 2023, 13, 127. [Google Scholar] [CrossRef]

- Huang, J. Research on the Influence of Arctic Navigation on the Navigation Performance of Submarine. Ship Electron. Eng. 2020, 40, 62–66. [Google Scholar]

- Cao, F.; Chandran, K.; Kumar, P. New Approach to Achieve High Strength Powder Metallurgy Ti-6Al-4V Alloy through Accelerated Sintering at β-Transus Temperature and Hydrogenation-Dehydrogenation Treatment. Scr. Mater. 2017, 130, 29–32. [Google Scholar] [CrossRef]

- Magnus, C.; Tarrant, T.; Orekunrin, A. Tribological behaviour of novel network-like Ti6Al4V-Ti3SiC2-TiC metal-ceramic composite structure. Wear 2025, 562–563, 205645. [Google Scholar] [CrossRef]

- Srivastava, M.; Jayakumar, V.; Udayan, Y.; Sathishkumar, M.; Muthu, S.M.; Gautam, P.; Nag, A. Additive manufacturing of titanium alloy for aerospace applications: Insights into the process, microstructure, and mechanical properties. Appl. Mater. Today 2024, 41, 102481. [Google Scholar] [CrossRef]

- Zhao, Q.; Chen, Y.; Xu, Y.; Zhao, Y. Progress and prospect of low-cost preparation technology of titanium alloy materials. Chin. J. Nonferrous Met. 2021, 11, 3127. [Google Scholar]

- Wang, Z.; Jia, L.; Miao, Q.; Li, M.; Zhao, P.; Liu, W.; Yang, S. Research progress on preparation technology of marine titanium alloy. China Metall. 2024, 6, 14–25. [Google Scholar]

- Shah, S.W.A.; Ali, S.; Mubashar, A.; Ullah, H.; Din, E.U.; Saad, M. Material characterization of Ti6Al4V alloy additively manufactured using selective laser melting technique. J. Mater. Res. Technol. 2024, 33, 1756–1763. [Google Scholar] [CrossRef]

- Rautio, S.; Valtonen, I. Supporting military maintenance and repair with additive manufacturing. J. Mil. Stud. 2022, 11, 23–36. [Google Scholar] [CrossRef]

- de Sotto, M.R.; Longère, P.; Doquet, V.; Papasidero, J. A constitutive model for a rate and temperature-dependent, plastically anisotropic titanium alloy. Int. J. Plast. 2020, 134, 102777. [Google Scholar] [CrossRef]

- Lin, H.; Jin, G.; Zhan, Q.; Wang, G.; Han, J. Mechanical Properties and Constitutive Model of TC4 Titanium Alloy at Cryogenic. J. Mater. Eng. Perform. 2024, 33, 13731–13743. [Google Scholar] [CrossRef]

- Semenova, I.; Modina, J.; Polyakov, A.; Klevtsov, G.; Klevtsova, N.; Pigaleva, I.; Valiev, R. Charpy absorbed energy of ultrafine-grained Ti-6Al-4V alloy at cryogenic and elevated temperatures. Mater. Sci. Eng. A 2019, 743, 581–589. [Google Scholar] [CrossRef]

- Lv, H.; Li, D.; Li, Y.; Li, X. Hot Tensile Deformation Behavior of Ti-6Al-4V Titanium Alloy Made by Laser Melting Deposition. Machines 2022, 10, 553. [Google Scholar] [CrossRef]

- Qian, G.; Li, Y.; Paolino, D.; Tridello, A.; Berto, F.; Hong, Y. Very-high-cycle Fatigue Behavior of Ti-6Al-4V Manufactured by Selective Laser Melting: Effect of Build Orientation. Int. J. Fatigue 2020, 136, 105628. [Google Scholar] [CrossRef]

- Ji, W.; Deng, R.; Dai, S.; Liu, C. Effects of Milling on Surface Integrity and Fatigue Performance of TC4 Titanium Alloy by SLM. China Mech. Eng. 2023, 34, 208–217, 225. [Google Scholar]

- Wang, B. Design and Optimization of Additive Manufacturing Process of TC4 Component in Ultra-Low Temperature Application Environment. Master’s Thesis, North China University of Technology, Beijing, China, 2023. [Google Scholar]

- Kok, Y.; Tan, X.; Wang, P.; Nai, M.; Loh, N.; Liu, E.; Tor, S. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- ABS. Guide for Vessels Operating in Low-Temperature Environments; American Bureau of Shipping: Houston, TX, USA, 2021. [Google Scholar]

- GB/T 229-2020; Metallic Materials—Charpy Pendulum Impact Test Method. Standards Press of China: Beijing, China, 2020. (In Chinese)

- Wang, F.; Lian, X. Selection of the mathematical model on ductile-brittle transition temperature curve of impact test. Phys. Test. Chem. Anal. 2009, 45, 617–620+632. [Google Scholar]

- Liao, X.; Wang, Y.; Feng, L.; Ban, H.; Chen, Y. Fatigue crack initiation and energy-based life analysis for Q345qD bridge steel at low temperatures. J. Constr. Steel Res. 2021, 180, 106571. [Google Scholar] [CrossRef]

- Lei, L.; Zhao, Y.; Zhao, Q.; Wu, C.; Huang, S.; Jia, W.; Zeng, W. Impact toughness and deformation modes of Ti-6Al-4V alloy with different microstructures. Mater. Sci. Eng. A 2021, 801, 140411. [Google Scholar] [CrossRef]

| Al | Fe | O | C | V | H | N | Ti |

|---|---|---|---|---|---|---|---|

| 6.05 | 0.15 | 0.12 | 0.03 | 3.90 | 0.002 | 0.005 | bal. |

| Laser Scanning Strategy | Laser Power /W | Scan Speed /(mm·s−1) | Hatch Spacing /μm | Layer Thickness /μm |

|---|---|---|---|---|

| Interlayer unidirectional (along x/y-axis) | 300 | 1200 | 100 | 61 |

| 67°-rotated scanning between layers | 300 | 1200 | 100 | 61 |

| Group | 20 °C | 0 °C | −20 °C | −40 °C | −60 °C |

|---|---|---|---|---|---|

| TC4-Ls | 26.32 | 23.02 | 22.03 | 20.01 | 17.78 |

| TC4-Lu | 24.26 | 22.06 | 20.51 | 18.76 | 18.13 |

| TC4-Ws | 29.13 | 25.81 | 22.81 | 22.08 | 19.01 |

| TC4-Wu | 15.36 | 13.98 | 12.97 | 12.16 | 11.17 |

| TC4-Rs | 28.54 | 27.41 | 23.58 | 21.98 | 19.81 |

| TC4-Ru | 24.53 | 23.58 | 22.03 | 19.88 | 18.27 |

| Group | Linear Fitting Equation (E = kT + b) * | R2 |

|---|---|---|

| TC4-Ls | E = 0.183T + 26.4 | 0.965 |

| TC4-Lu | E = 0.128T + 24.3 | 0.932 |

| TC4-Ws | E = 0.208T + 28.6 | 0.973 |

| TC4-Wu | E = 0.088T + 15.3 | 0.985 |

| TC4-Rs | E = 0.184T + 28.4 | 0.975 |

| TC4-Ru | E = 0.120T + 24.7 | 0.915 |

| Phase Name | TC4-L | TC4-W | TC4-R |

|---|---|---|---|

| α phase | 96.91 | 97.46 | 96.75 |

| β phase | 0.88 | 0.51 | 1.09 |

| Unknown phase | 2.21 | 2.03 | 2.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Guo, W.; Li, X.; Pan, X.; Zhang, J.; Yu, L.; Zeng, Y. Polar Cryogenic Impact Behavior of Selective Laser Melted Ti-6Al-4V Alloy: Effects of Scanning Strategies and Notch Orientation. Materials 2025, 18, 4177. https://doi.org/10.3390/ma18174177

Chen H, Guo W, Li X, Pan X, Zhang J, Yu L, Zeng Y. Polar Cryogenic Impact Behavior of Selective Laser Melted Ti-6Al-4V Alloy: Effects of Scanning Strategies and Notch Orientation. Materials. 2025; 18(17):4177. https://doi.org/10.3390/ma18174177

Chicago/Turabian StyleChen, Hantao, Wenyong Guo, Xiaofeng Li, Xinglong Pan, Jianxiang Zhang, Li Yu, and Yan Zeng. 2025. "Polar Cryogenic Impact Behavior of Selective Laser Melted Ti-6Al-4V Alloy: Effects of Scanning Strategies and Notch Orientation" Materials 18, no. 17: 4177. https://doi.org/10.3390/ma18174177

APA StyleChen, H., Guo, W., Li, X., Pan, X., Zhang, J., Yu, L., & Zeng, Y. (2025). Polar Cryogenic Impact Behavior of Selective Laser Melted Ti-6Al-4V Alloy: Effects of Scanning Strategies and Notch Orientation. Materials, 18(17), 4177. https://doi.org/10.3390/ma18174177