Fatigue Performance of Nitrided H13 Tool Steel Pre-Treated with Fine Particle Peening

Abstract

1. Introduction

2. Material and Experimental Procedures

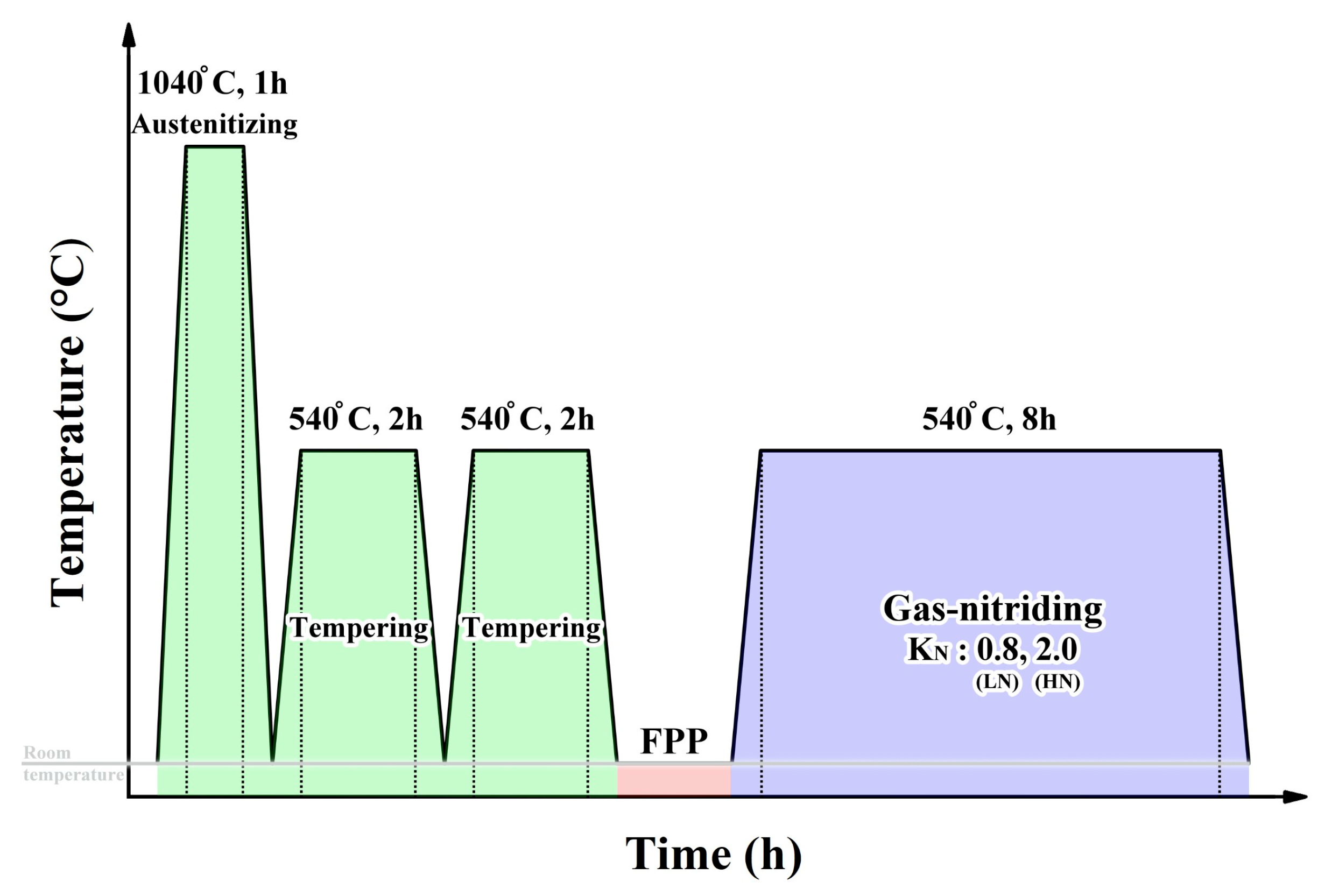

2.1. Preparation of the Samples

2.2. Measurement of Hardness and Fatigue Testing

2.3. Microstructural Observation

2.4. Measurement of Residual Stress

3. Results

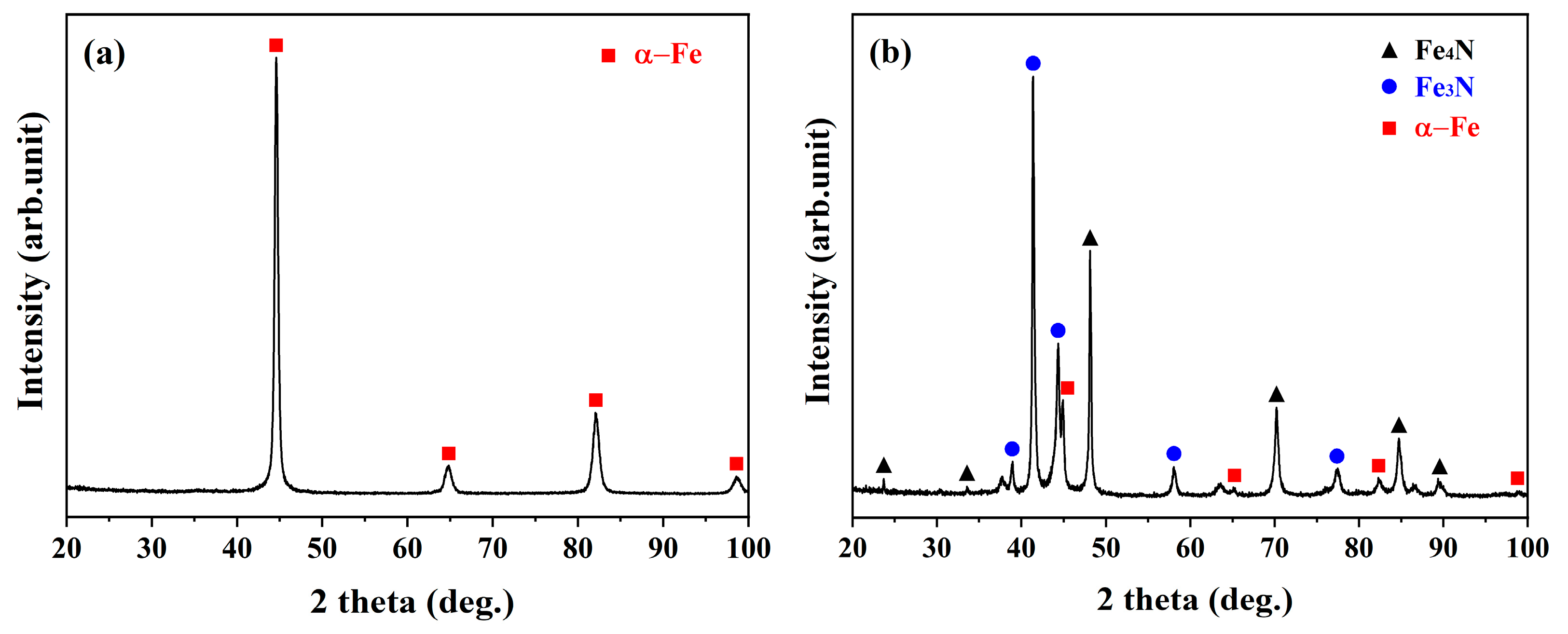

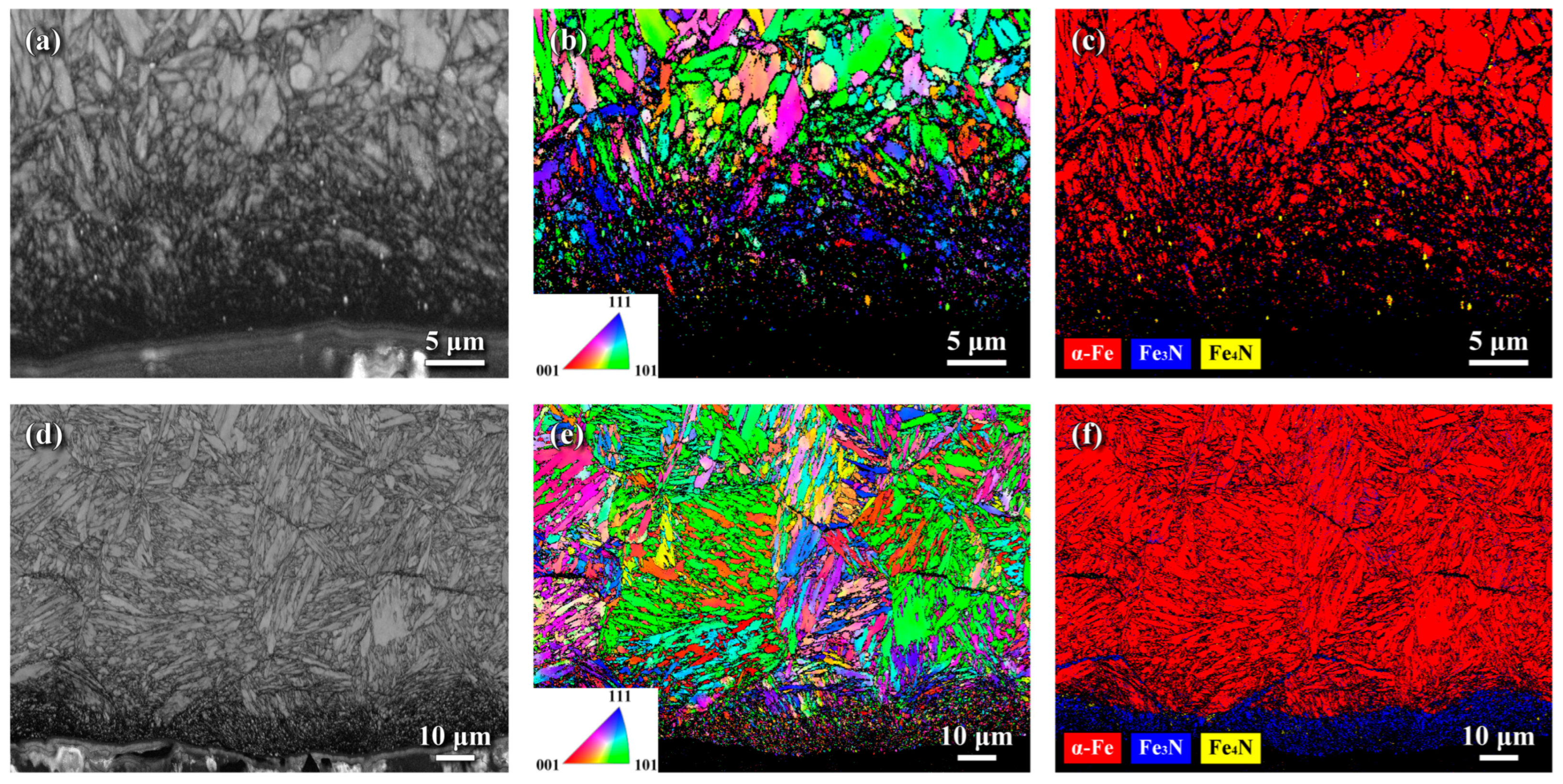

3.1. Microstructure Identification and EBSD Analysis

3.2. Surface Texture of the Nitrided Samples

3.3. Microstructure of the Tested Samples

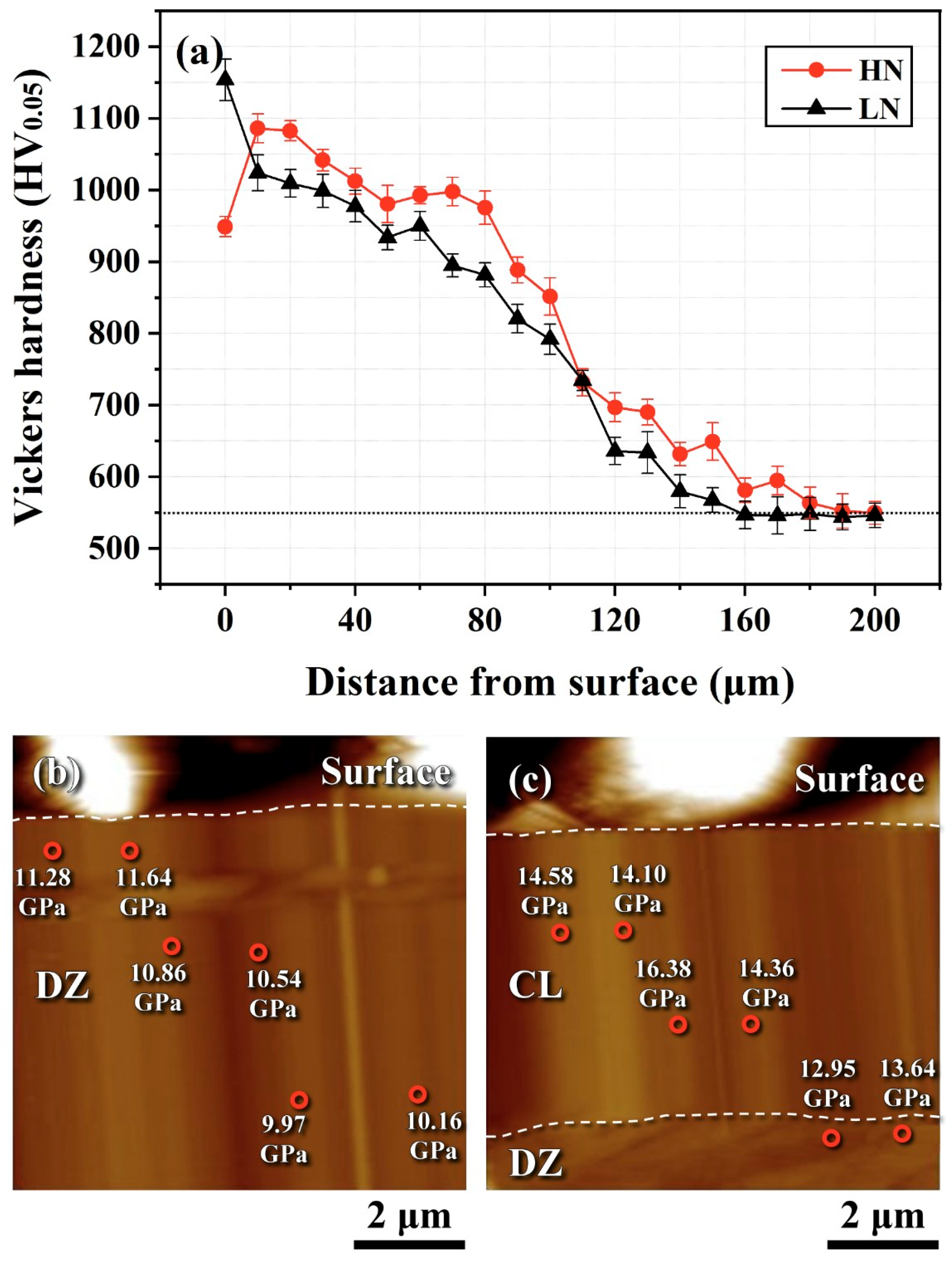

3.4. Hardness Profile of the Nitrided Samples

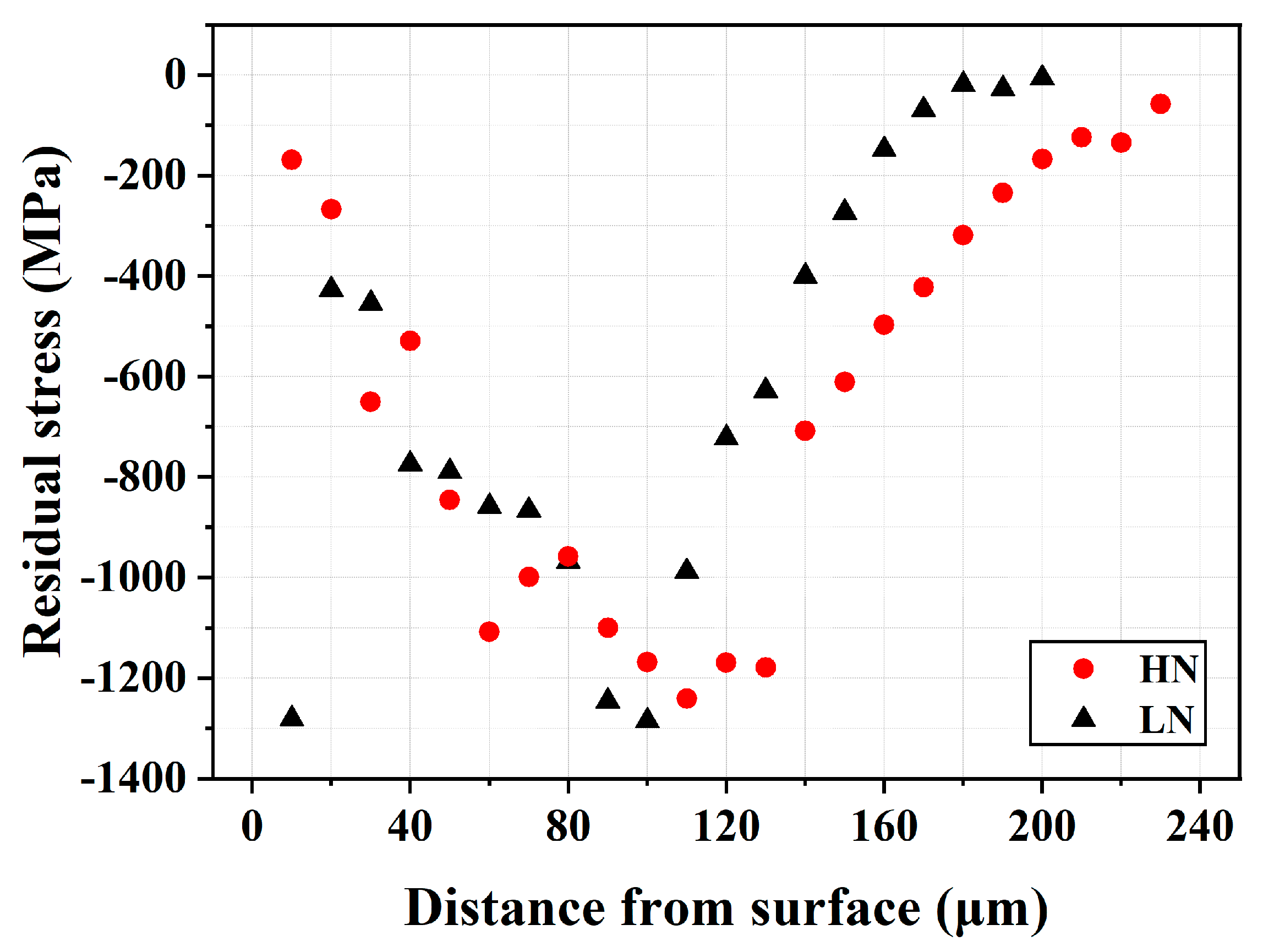

3.5. Residual Stress Measurements

3.6. Fatigue Tests

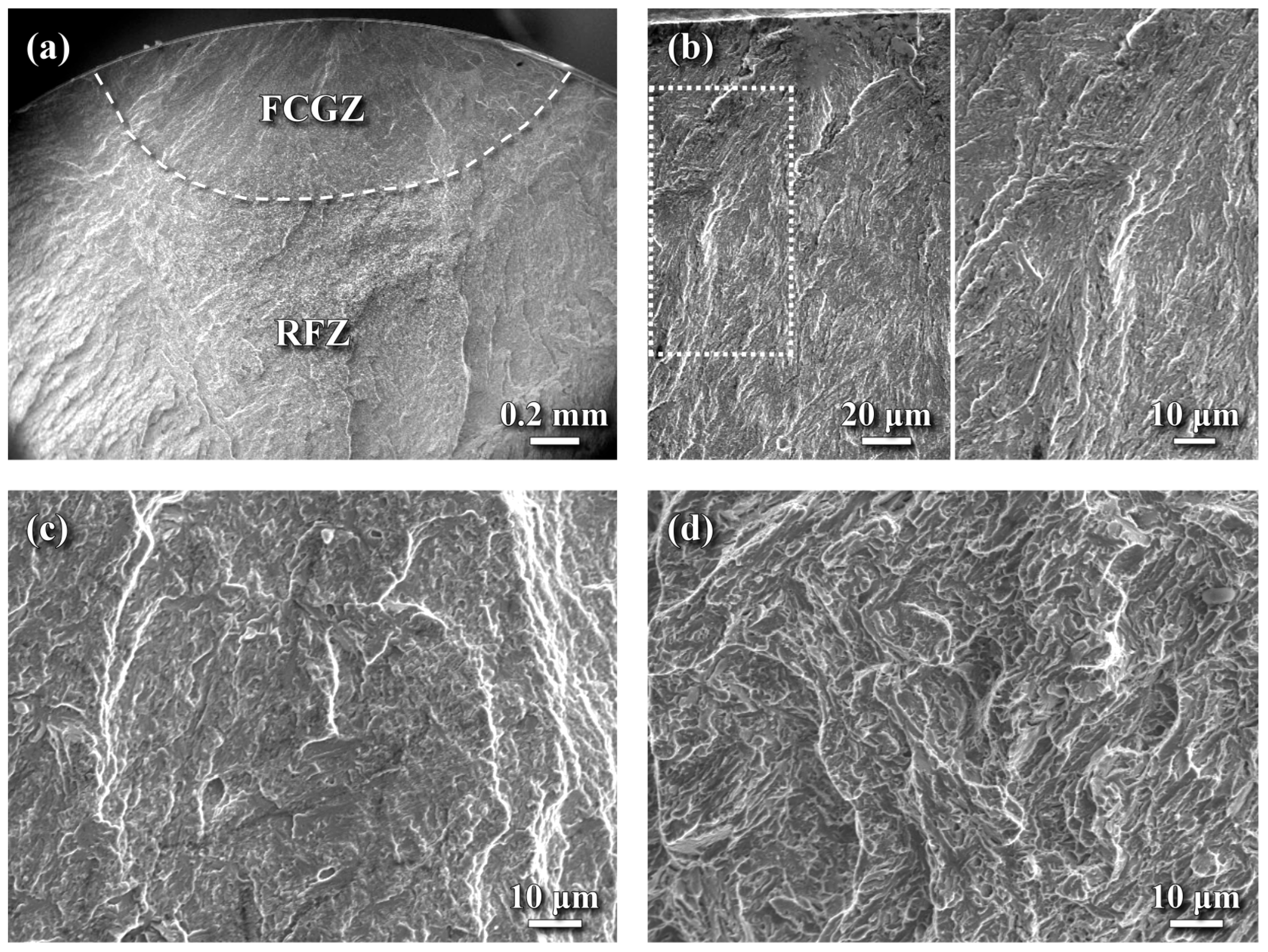

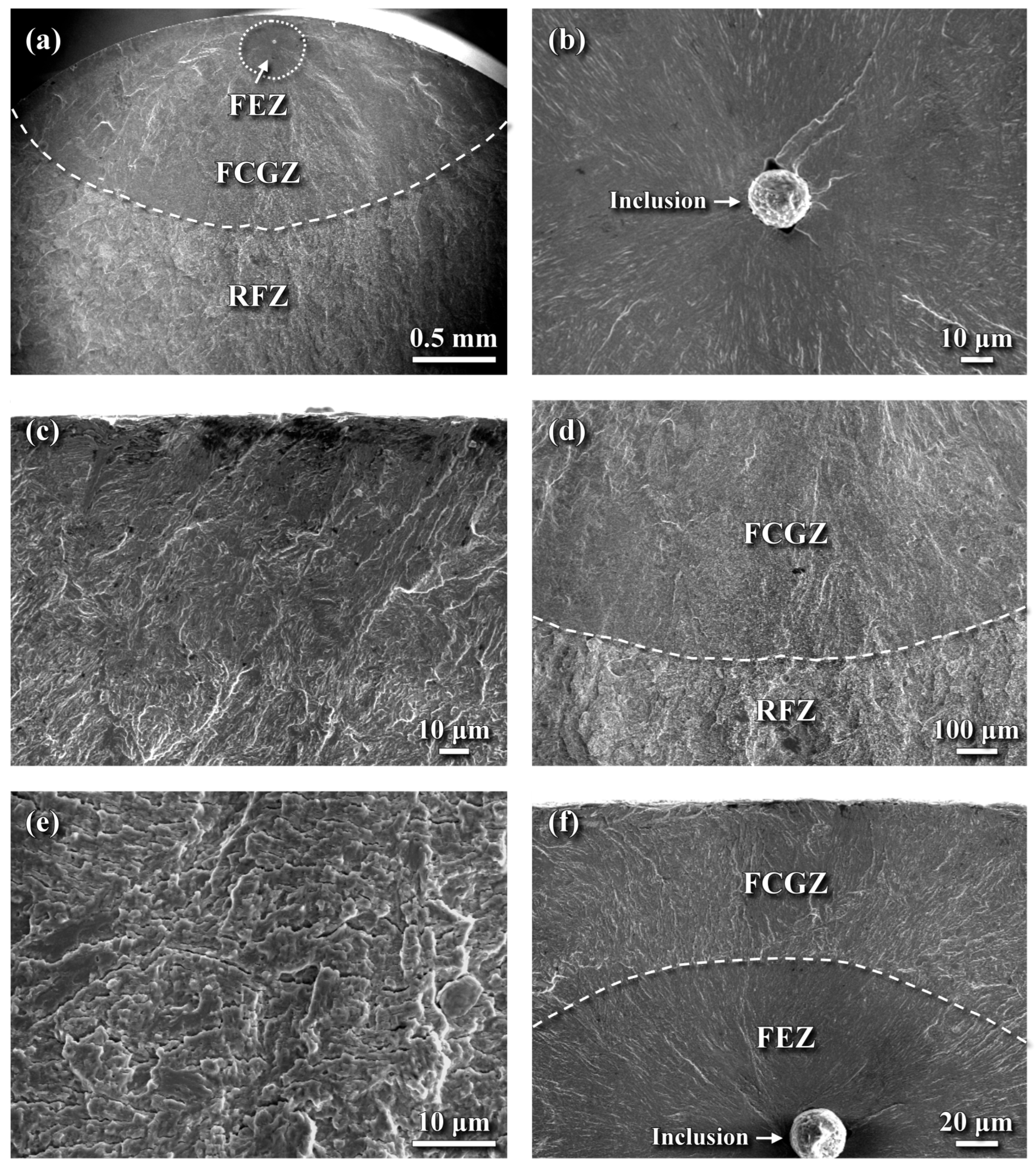

3.7. Fractured Surface Examinations

4. Discussion

5. Conclusions

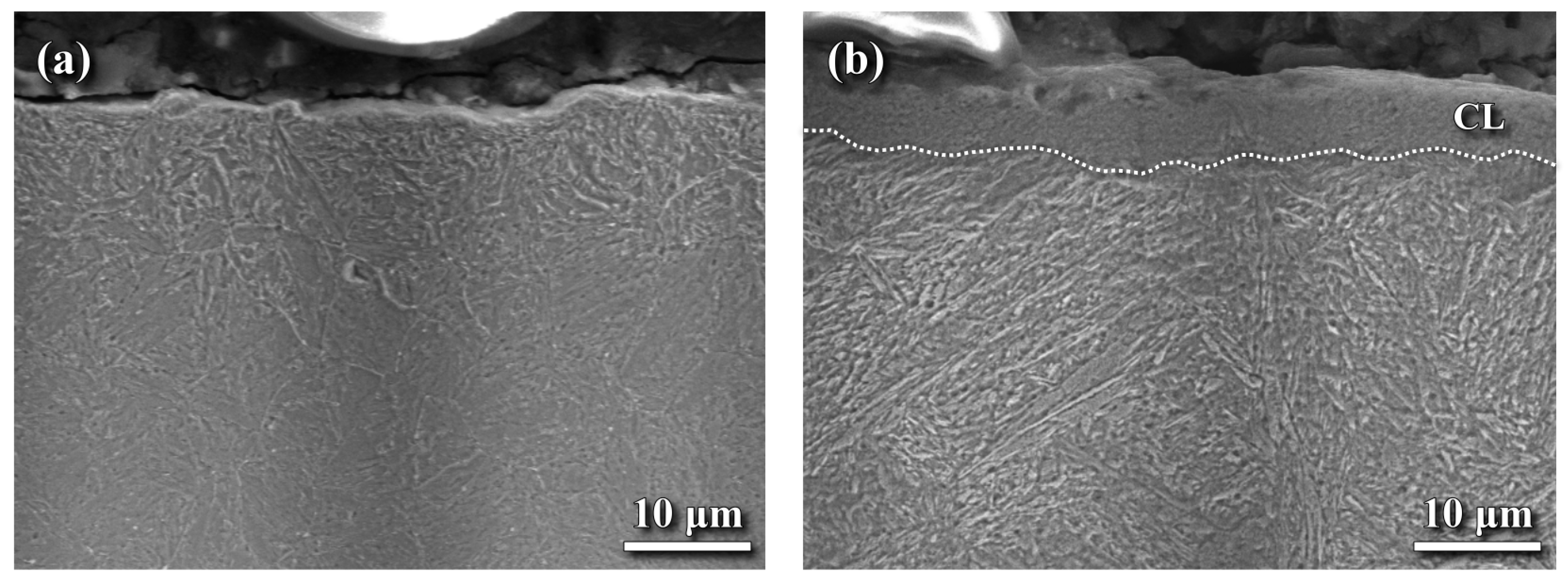

- Fine particle peening was performed prior to gas nitriding under two nitrogen potentials: KN = 0.8 (designated as LN) and KN = 2.0 (designated as HN). Among the tested samples, the substrate (SB) sample exhibited the lowest surface roughness, while the HN sample showed the highest. Gas nitriding following fine particle peening resulted in only a slight increase in surface roughness. Reducing the nitriding potential (KN) from 2.0 to 0.8 suppressed the formation of the compound layer and led to a slight reduction in case depth. The compound layer in the HN sample was primarily composed of Fe3N with some Fe4N. Phase mapping indicated that nitrogen atoms preferentially diffused along refined grain boundaries and austenite grain boundaries.

- Nanohardness measurements confirmed that the compound layer in the HN sample was harder than the underlying diffusion zone. EPMA analysis revealed a significant difference in nitrogen content between the compound layer and the diffusion zone. The outermost compound layer contained more than 4 wt% nitrogen and the diffusion zone contained approximately 1.6 wt%. Comparing the nanohardness of the LN and HN samples in diffusion zone, the HN sample (~13 GPa) was clearly harder than the LN sample (~11 GPa). This difference may be partly resulted from the reduced nitrogen diffusion into the H13 steel under the lower KN.

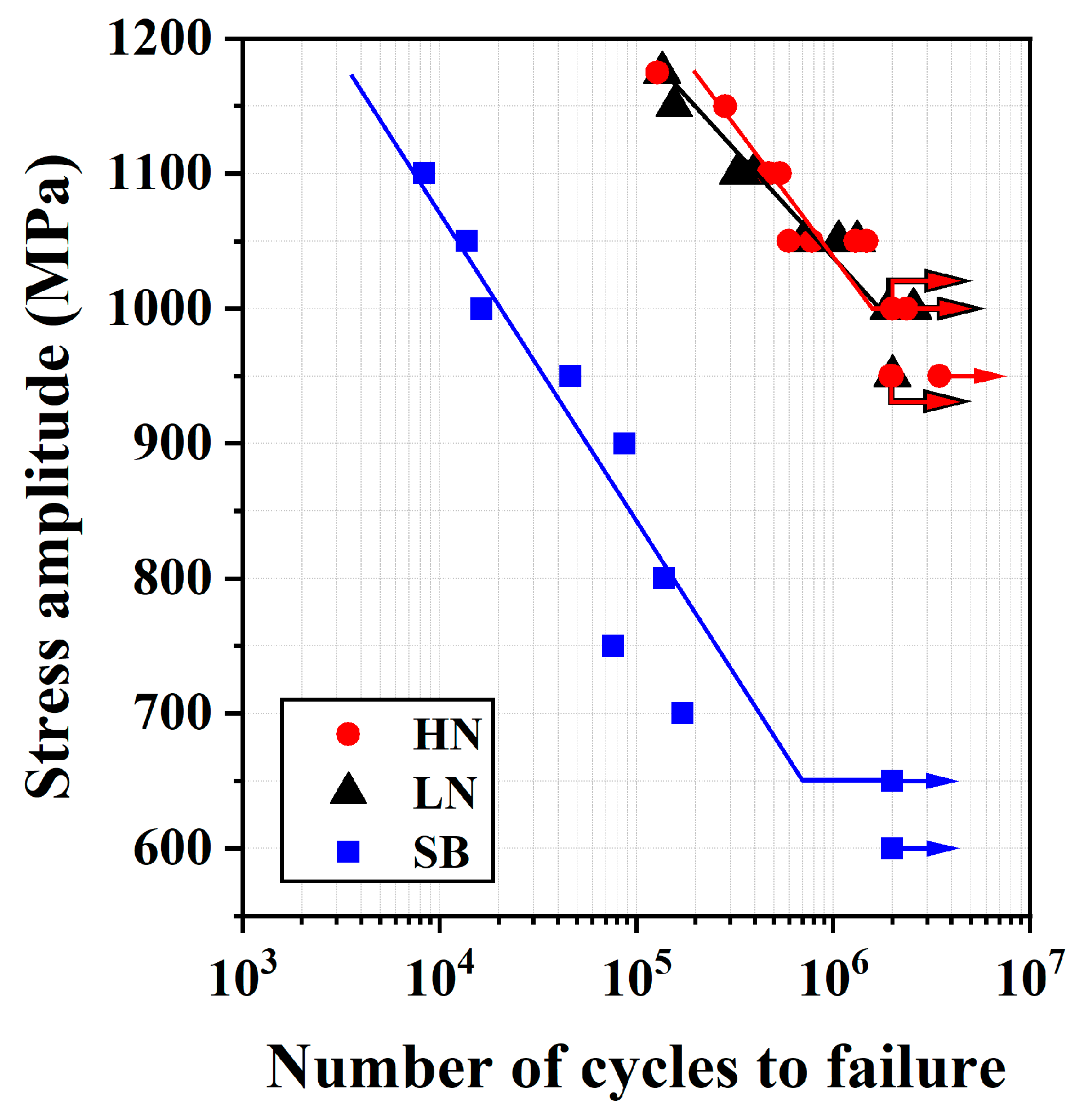

- Both the LN and HN samples demonstrated superior fatigue strength and life compared to the SB sample. The synergistic effect of the compressive residual stress and the hardened case inhibited the occurrence of slips at the external surface, thereby delaying the initiation and propagation of superficial fatigue cracks in the nitrided H13 steel pre-treated by fine particle peening. Similar fatigue performance of the LN and HN samples was likely due to their comparable compressive residual stress fields.

- Subsurface fatigue crack initiation in the LN and HN samples was associated with the formation of a fish-eye zone, characterized by a smooth, cleavage-like fracture with radial traces originating from an inclusion. In the HN sample, a deflected crack path was observed between the fish-eye zone and the outermost layer. Compared to the fish-eye zone, the diffusion zone beneath the compound layer in the HN sample exhibited a relatively rough fracture surface and lath martensitic texture. Notably, no cracking or spalling of the compound layer occurred under distinct loading conditions in this work. It was suggested that the compound layer, exhibiting a rubbed surface rather than a cleavage-like fracture, was subjected to compressive residual stress, promoting crack closure. With respect to the crack initiation site, the defective CL on the top surface of the HN sample was detrimental to its fatigue resistance, whereas no such feature was found in the LN sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Xu, Z.; Lu, X. Effect of the quenching and tempering temperatures on the microstructure and mechanical properties of H13 steel. J. Mater. Eng. Perform. 2020, 29, 1849–1859. [Google Scholar] [CrossRef]

- Cho, K.T.; Song, K.; Oh, S.H.; Lee, Y.; Lee, W.B. Surface hardening of shot peened H13 steel by enhanced nitrogen diffusion. Surf. Coat. Technol. 2013, 232, 912–919. [Google Scholar] [CrossRef]

- Korad, T.; Ponboon, M.; Chumchery, N.; Pearce, J.T.H. Application of Flow Analysis in Improving Gas Nitriding Conditions in a Vacuum Furnace. Chiang Mai J. Sci. 2013, 40, 909–922. [Google Scholar]

- Terčelj, M.; Kugler, G. An approach to increasing the service lifetimes of nitrided dies for aluminum hot extrusion: A case study. Wear 2017, 376–377, 1779–1788. [Google Scholar] [CrossRef]

- Akhtar, S.S.; Arif, A.F.M.; Yilbas, B.S. Influence of multiple nitriding on the case hardening of H13 tool steel: Experimental and numerical investigation. Int. J. Adv. Manuf. Technol. 2012, 58, 57–70. [Google Scholar] [CrossRef]

- Tercelj, M.; Smolej, A.; Vecko-Pirtovsek, T.; Turk, R. The Microstructures and Wear Resistance of Gas-Nitrided and Ionically Nitrided AISI H10 Dies with Narrow Gaps Designed for the Hot Extrusion of Aluminum. JSME Int. J. Ser. C 2006, 49, 121–127. [Google Scholar] [CrossRef]

- Terčelj, M.; Smolej, A.; Fajfar, P.; Turk, R. Laboratory assessment of wear on nitrided surfaces of dies for hot extrusion of aluminum. Tribol. Int. 2007, 40, 374–384. [Google Scholar] [CrossRef]

- Birol, Y.; Yuksel, B. Performance of gas nitrided and AlTiN coated AISI H13 hot work tool steel in aluminum extrusion. Surf. Coat. Technol. 2012, 207, 461–466. [Google Scholar] [CrossRef]

- Terres, M.A.; Laalat, N.; Sidhom, H. Effect of Nitriding and Shot-Peening on the Fatigue Behavior of 42CrMod Steel Experimental Analysis and Predictive Approach. Mater. Des. 2012, 35, 741–748. [Google Scholar] [CrossRef]

- Limadin, N.; Verreman, Y. Fatigue strength improvement of a 4140 steel by gas nitriding Influence of notch severity. Mater. Sci. Eng. A 2006, 435–436, 460–467. [Google Scholar] [CrossRef]

- Zagonel, L.; Bettini, J.; Basso, R.; Paredez, P.; Pinto, H.; Lepienski, C.; Alvarez, F. Nanosized precipitates in H13 tool steel low temperature plasma nitriding. Surf. Coat. Technol. 2012, 207, 72–78. [Google Scholar] [CrossRef]

- Kugler, G.; Turk, R.; Večko-Pirtovšek, T.; Terčelj, M. Wear beahaviour of nitrided microstructures of ALSL H13 dies for hot extrusion of aluminium. Metalurgija 2006, 45, 21–29. [Google Scholar]

- Wang, B.; Zhao, X.; Li, W.; Qin, M.; Gu, J. Effect of nitrided-layer microstructure control on wear behavior of AISI H13 hot work die steel. Appl. Surf. Sci. 2018, 431, 39–43. [Google Scholar] [CrossRef]

- Hubicki, R.; Richert, M.; Wiewióra, M. An experimental study of temperature effect on properties of nitride layers on X37CRMOV51 tool steel used in extrusion aluminum industry. Materials 2020, 13, 2311. [Google Scholar] [CrossRef]

- Fazel, Z.A.; Elmkhah, H.; Nouri, M.; Fattah-Alhosseini, A. Effect of compound layer on the corrosion behavior of plasma nitrided AISI H13 tool steel. Mater. Res. Express 2019, 6, 056412. [Google Scholar] [CrossRef]

- Lin, G.W.; Chen, T.C.; Hsu, H.H.; Tsay, L.W. Synergetic Effects of Micro-Shot Peening and Gas Nitriding on the Fatigue Performance of AISI 4140 Steel. Surf. Coat. Technol. 2024, 485, 130856. [Google Scholar] [CrossRef]

- Weidner, A.; Lippmann, T.; Biermann, H. Crack initiation in the very high cycle fatigue regime of nitride 42CrMo4 steel. J. Mater. Res. 2017, 32, 4305–4316. [Google Scholar] [CrossRef]

- Shinde, T.; Chavan, R.; Savadekar, P.; Patil, I.; Walke, O.; Wagh, G. Analysis of nitrided H13 steel in rotating bending fatigue. Mater. Today Proc. 2021, 44, 2507–2510. [Google Scholar] [CrossRef]

- Chang, S.; Lee, S.; Tang, T. Effect of shot peening treatment on forging die life. Mater. Trans. 2008, 49, 619–623. [Google Scholar] [CrossRef][Green Version]

- Jia, Z.; Ji, J. Influence analysis of shot peening on hot forging die. Int. J. Adv. Manuf. Technol. 2016, 90, 1779–1787. [Google Scholar] [CrossRef]

- Chang, S.; Tang, T.; Tai, F. Enhancement of thermal cracking and mechanical properties of H13 tool steel by shot peening treatment. Surf. Eng. 2011, 27, 581–586. [Google Scholar] [CrossRef]

- Ivanov, V.V.; Ferguson, W.G.; Paine, I.R. Study of Thermal Fatigue of H13 Die Steel with Various Surface Treatments. Int. J. Mod. Phys. B 2003, 17, 1671–1677. [Google Scholar] [CrossRef]

- Gasem, Z.M. Cracking in a multiple gas-nitrided H13 aluminum extrusion mandrel. Eng. Fail. Anal. 2013, 31, 68–75. [Google Scholar] [CrossRef]

- Farrahi, G.; Ghadbeigi, H. An investigation into the effect of various surface treatments on fatigue life of a tool steel. J. Mater. Process. Technol. 2006, 174, 318–324. [Google Scholar] [CrossRef]

- Akhtar, S.S.; Arif, A.F.M.; Yilbas, B.S.; Sheikh, A.K. Influence of surface preparation on the kinetics of controlled Gas-Nitrided AISI H13 steels used in extrusion dies. J. Mater. Eng. Perform. 2010, 19, 347–355. [Google Scholar] [CrossRef]

- Mochtar, M.A.; Aldila, R. Application of shot peening and shot blasting to increase hardness and depth of nitride hardened layer to the modified H13 steel as die casting die materials. Adv. Mater. Res. 2013, 789, 313–319. [Google Scholar] [CrossRef]

- Kikuchi, S.; Komotori, J. Evaluation of the Gas Nitriding of Fine Grained. AISI 4135 Steel Treated with Fine Particle Peening and Its Effect on the Tribological Properties. Mater. Trans. 2015, 56, 556–562. [Google Scholar] [CrossRef]

- Morita, T.; Noda, S.; Kagaya, C. Influences of Fine-Particle bombarding and conventional shot peening on surface properties of steel. Mater. Trans. 2014, 55, 646–652. [Google Scholar] [CrossRef]

- Lu, G.X.; Chen, T.C.; Shiue, R.K.; Tsay, L.W. Effects of Surface Modifications on Rotating Bending Fatigue of Ni-Al Bronze Alloy. Metals 2025, 15, 19. [Google Scholar] [CrossRef]

- Su, C.H.; Chen, T.C.; Ding, Y.S.; Lu, G.X.; Tsay, L.W. Effects of Micro-Shot peening on the fatigue strength of anodized 7075-T6 alloy. Materials 2023, 16, 1160. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, J.; Yang, B.; Zhang, J.; Wu, M.; Lu, L. Effects of Micro-Shot peening, Conventional Shot Peening and Their Combination on Fatigue Property of EA4T Axle Steel. J. Mater. Process. Technol. 2020, 275, 116320. [Google Scholar] [CrossRef]

- Li, W.; Lu, L.; Zeng, D. The Contribution of Topography Formed by Fine Particle Peening Process in Reduction Friction Coefficient of Gear Steel. Tribol. Trans. 2019, 63, 9–19. [Google Scholar] [CrossRef]

- Zhang, J.; Li, W.; Wang, H.; Song, Q.; Lu, L.; Wang, W.; Liu, Z. A comparison of the effects of traditional shot peening and micro-shot peening on the scuffing resistance of carburized and quenched gear steel. Wear 2016, 368–369, 253–257. [Google Scholar] [CrossRef]

- Tanaka, K. The cosα method for X-ray residual stress measurement using two-dimensional detector. Mech. Eng. Rev. 2019, 6, 18-00378. [Google Scholar] [CrossRef]

- Tanaka, K. X-ray measurement of triaxial residual stress on machined surfaces by the cosα method using a two-dimensional detector. J. Appl. Crystallogr. 2018, 51, 1329–1338. [Google Scholar] [CrossRef]

- Xie, G.; Gui, X.; Liu, X.; Yang, Y.; Cao, Y.; Liu, D.; Yang, K.; Zhang, S. Insight into the ablation behaviors and mechanism of duplex surface treated TC11 titanium alloy via dynamic shot peening and plasma nitriding. Mater. Charact. 2025, 223, 114887. [Google Scholar] [CrossRef]

- Chen, H.; Chen, T.C.; Hsu, H.H.; Tsay, L.W. Effect of microstructure and compressive residual stress on the fatigue performance of AISI 4140 steel with QPQ salt bath nitro-carburizing. Materials 2025, 18, 1995. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Zhan, Z.; Zhang, S. Influence of inclusion parameter and depth on the rotating bending fatigue behavior of bearing steel. Metals 2024, 14, 907. [Google Scholar] [CrossRef]

- Zhang, J.W.; Lu, L.T.; Shiozawa, K.; Zhou, W.N.; Zhang, W.H. Effect of nitrocarburizing and post-oxidation on fatigue behavior of 35CrMo alloy steel in very high cycle fatigue regime. Int. J. Fatigue 2011, 33, 880–886. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, L.; Shiozawa, K.; Zhou, W.; Zhang, W. Effects of nitrocarburizing on fatigue property of medium carbon steel in very high cycle regime. Mater. Sci. Eng. 2011, 528A, 7060–7067. [Google Scholar] [CrossRef]

- Shot Machine A One Polish, Toyo Kenmazai Kogyo Ltd. Available online: http://www.toyo-kenmazai-kogyo.jp/ (accessed on 21 June 2025).

| Sample | Surface Roughness (μm) | ||

|---|---|---|---|

| Sa 1 | Sp 2 | Sv 3 | |

| SB | 0.14 | 0.86 | 0.55 |

| SP | 0.39 | 1.70 | 1.60 |

| LN | 0.45 | 1.75 | 2.29 |

| HN | 0.55 | 1.94 | 2.36 |

| Location | Distance from Surface (μm) | Chemical Composition in wt% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | N | O | Mn | Si | Cr | Mo | V | Fe | ||

| Compound layer | 2 | 0.23 | 4.14 | 0.03 | 0.34 | 0.94 | 5.02 | 1.19 | 0.67 | Bal. |

| 4 | 0.33 | 4.19 | 0.02 | 0.38 | 0.96 | 4.82 | 1.04 | 0.57 | Bal. | |

| 6 | 0.40 | 3.66 | 0.02 | 0.37 | 0.93 | 4.85 | 1.02 | 0.56 | Bal. | |

| Diffusion zone | 15 | 0.44 | 1.61 | 0.07 | 0.43 | 1.05 | 5.85 | 1.24 | 0.74 | Bal. |

| 45 | 0.46 | 1.05 | 0.04 | 0.40 | 0.95 | 5.66 | 1.15 | 0.71 | Bal. | |

| 75 | 0.35 | - | 0.03 | 0.39 | 0.91 | 5.33 | 1.16 | 0.66 | Bal. | |

| 140 | 0.38 | - | 0.01 | 0.41 | 0.95 | 5.56 | 1.10 | 0.76 | Bal. | |

| Substrate | 200 | 0.35 | - | 0.01 | 0.47 | 0.93 | 5.62 | 1.13 | 0.71 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-C.; Chen, T.-C.; Chen, W.-H.; Tsay, L.-W. Fatigue Performance of Nitrided H13 Tool Steel Pre-Treated with Fine Particle Peening. Materials 2025, 18, 4121. https://doi.org/10.3390/ma18174121

Lee H-C, Chen T-C, Chen W-H, Tsay L-W. Fatigue Performance of Nitrided H13 Tool Steel Pre-Treated with Fine Particle Peening. Materials. 2025; 18(17):4121. https://doi.org/10.3390/ma18174121

Chicago/Turabian StyleLee, Hung-Chi, Tai-Cheng Chen, Wen-Han Chen, and Leu-Wen Tsay. 2025. "Fatigue Performance of Nitrided H13 Tool Steel Pre-Treated with Fine Particle Peening" Materials 18, no. 17: 4121. https://doi.org/10.3390/ma18174121

APA StyleLee, H.-C., Chen, T.-C., Chen, W.-H., & Tsay, L.-W. (2025). Fatigue Performance of Nitrided H13 Tool Steel Pre-Treated with Fine Particle Peening. Materials, 18(17), 4121. https://doi.org/10.3390/ma18174121