6.1. Comparison Between BP and Improved BP Models

In this study, a second-order multivariate regression function was employed to establish a quantitative relationship between three key input variables—weld width (w), weld height (h), and weld spacing ratio (a = λ/w)—and the corresponding response variable, surface flatness deviation (∆h). This modeling approach was based on experimental data obtained from 17 systematically designed test schemes that followed a Box–Behnken design as part of the response surface methodology (RSM). The RSM framework is widely adopted in engineering optimization studies because of its ability to efficiently capture linear, interaction, and quadratic effects among variables using a relatively small number of experiments.

The functional form of the response surface was chosen to be a second-order polynomial due to its flexibility and well-established use in modeling nonlinear behaviors between process inputs and output responses. The regression coefficients were determined through least-squares fitting using the experimental data, ensuring statistical significance of the model. The resulting predictive equation is presented in Equation (3), which is derived from our experimental data:

This regression model captures the main effects, pairwise interactions, and second-order (quadratic) influences of the three input parameters on surface flatness. For example, the negative coefficient of a indicates that increased weld spacing ratio tends to reduce surface flatness, while the significant positive coefficient of a2 reflects curvature in that effect. The model allows both prediction and optimization of surface flatness across the explored parameter space and serves as the basis for subsequent algorithmic optimization. The fitting quality was validated using R-squared and residual analyses, confirming the model’s suitability for representing the experimental data trends.

To evaluate the performance of the derived response surface model and assess its fitting accuracy, an analysis of variance (ANOVA) and goodness-of-fit test were conducted using Design-Expert software (version 13, Stat-Ease, Inc., Minneapolis, MN, USA,

https://www.statease.com/software/design-expert/, accessed on 7 August 2025). As shown in

Table 8, the ANOVA results for the response surface model of

are presented. The F-value represents the result of the

F-test, which is primarily used to determine the statistical significance of the regression relationship between the input variables and the response variable. The mathematical expression for the F-value is provided in Equation (4).

In the above equations, k denotes the degrees of freedom of the sample, and n represents the number of experimental runs, which is 17 in this study. The regression sum of squares (SSR) and residual sum of squares (SSE) for the 17 experimental schemes are calculated as follows: SSR = ∑(ŷ − ȳ)2, SSE = ∑(y − ŷ)2 Here, y represents the observed experimental value, corresponding to the response variable () in this study; ȳ is the arithmetic mean of the response values; and ŷ is the predicted value from the response surface regression model. Therefore, SSR reflects the variation in the response variable due to changes in the input variables, while SSE measures the deviation between the model predictions and the experimental results.

Based on these values, the Design-Expert software automatically calculates the p-value corresponding to each F-test. A smaller p-value indicates a more statistically significant effect of the associated input variable. Generally, a term is considered significant if p ≤ 0.05 and highly significant if p ≤ 0.01, implying a strong influence on the response variable.

The p-value is defined as: where F0 is the calculated F-statistic, and the p-value is automatically computed by the software.

The lack-of-fit term represents the proportion of the total error attributable to the model’s inability to explain systematic variations in the data. A large lack-of-fit indicates that the regression model fails to adequately capture the underlying trend of the data.

As shown in

Table 8, the

p-values corresponding to the terms AB, A

2, and B

2 are greater than 0.05, indicating that these terms have no statistically significant effect on the response variable (

). Therefore, when fitting the functional relationship between the input variables and the response variable, and under the assumption that the interaction effects among input variables are negligible, these non-significant terms were excluded. A revised response surface model for the response variable (

) was then re-fitted accordingly. The modified regression equation is presented in Equation (5).

The analysis of the revised response surface regression model is shown in

Table 9. As shown, the

p-value for the overall model is less than 0.0001, indicating that the newly fitted regression equation describes a statistically significant relationship between the input variables and the response variable. Furthermore, the

p-values corresponding to the

F-tests for all other terms in the table are also significantly less than 0.05, demonstrating that each term included in the revised response surface model is statistically significant. In summary, the updated regression model is considered to be both accurate and reliable, and can be confidently applied in the context of this study.

To determine whether a response surface model can serve as a meaningful approximation of the original experimental data, it is essential to evaluate the goodness of fit of the model to the response values. In this study, the coefficient of determination (R

2) is introduced as a key metric for assessing the fitting accuracy of the response surface model, as defined in Equation (6)

In this equation, SSR denotes the regression sum of squares, and SST represents the total sum of squares. Similar to the correlation coefficient R used in the performance evaluation of the previously discussed BP neural network, the coefficient of determination R2 ranges from 0 to 1. A value of R2 approaching 1 indicates a higher accuracy of the response surface model, suggesting that the predicted values closely match the experimental data. Conversely, an R2 value near 0 implies a more scattered distribution of sample points and a weaker correlation between input and response variables.

However, the use of

R2 as a measure of model-fitting accuracy can be influenced by the number of input variables. When the number of variables is small and all are included in the model, the

R2 value may be artificially inflated, leading to an overestimation of the model’s performance. To address this, the adjusted coefficient of determination

is introduced. This statistic accounts for the number of input variables and provides a more accurate assessment of the fitting performance of the response surface model, as shown in Equation (7).

where

SSE denotes the residual sum of squares,

SST is the total sum of squares,

n represents the number of experimental runs (17 in this study), and

k is the number of degrees of freedom. The closer the adjusted coefficient of determination (

) is to the unadjusted coefficient (

R2), and the closer both are to 1, the more strongly it suggests that the relationship between the input and response variables is significant and necessary in the response surface model. In this study, the response surface model for the surface flatness (

) of single-layer multi-pass welds yields a coefficient of determination R

2 = 0.9922, indicating a strong correlation between the predicted and experimental values. The adjusted coefficient of determination

= 0.9876 further confirms the high fitting accuracy and reliability of the developed model.

To further evaluate the accuracy and validity of the response surface model, a normal probability plot of the studentized residuals was used to assess its statistical characteristics. The expression for the studentized residuals is given in Equation (8):

where,

denotes the studentized residual,

is the ordinary residual,

represents the estimated standard error, and

is the leverage (the diagonal element of the hat matrix). It can be seen that the studentized residual is derived from the ordinary residual by applying studentization, which removes the influence of both measurement units and leverage on the residuals. If the points in the normal probability plot of the studentized residuals form an approximately straight line, it can be concluded that the residuals follow a normal distribution.

Figure 9 presents the normal probability plot of the studentized residuals for the response surface model of surface flatness (

) in single-layer multi-pass welds. As shown in the figure, all data points lie closely along a straight line, indicating that the response surface model is statistically accurate and valid.

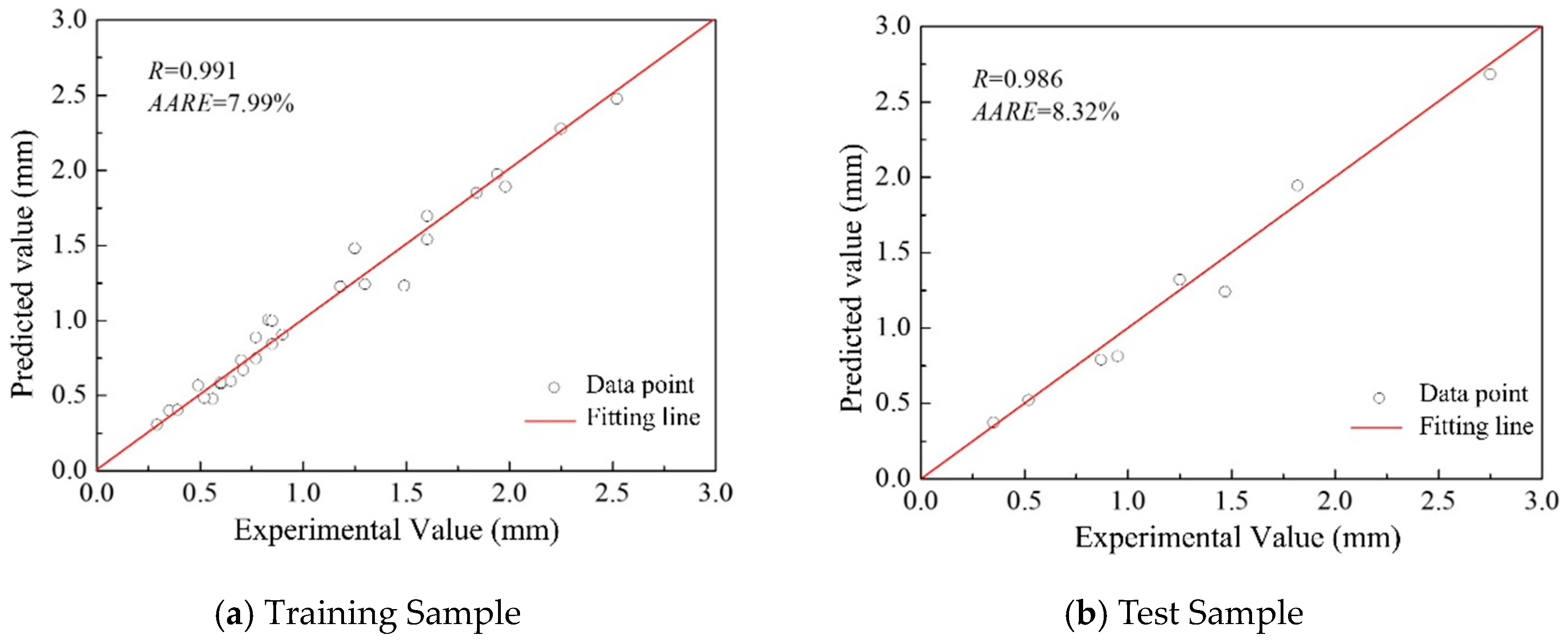

Figure 10 shows a comparison between the predicted values obtained from the response surface model developed in this study and those predicted by the BP neural network. It can be observed that all data points are closely clustered around the reference line (

y =

x), indicating a high level of agreement between the two models. This demonstrates that the response surface model reliably captures the relationship between the input variables and the response.

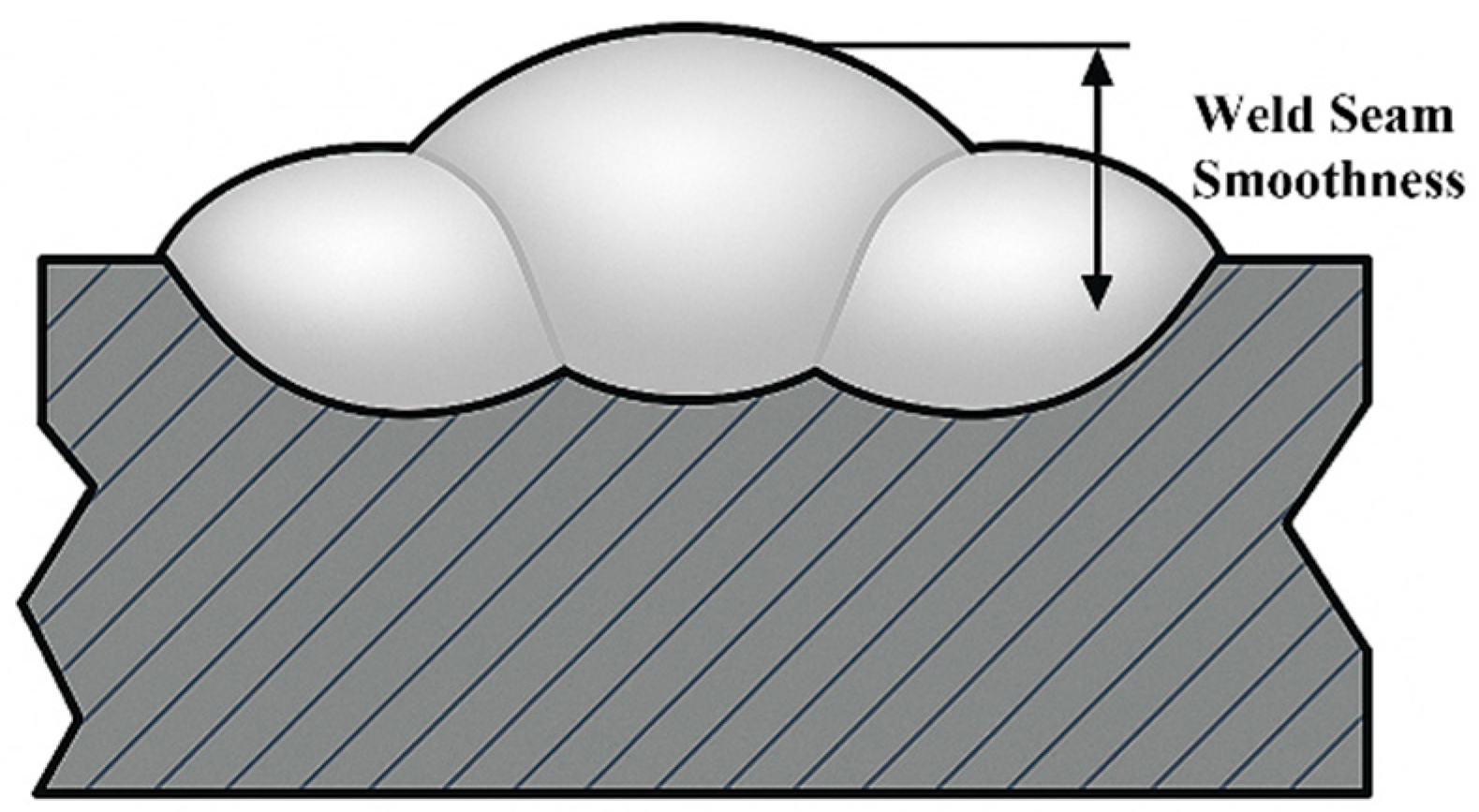

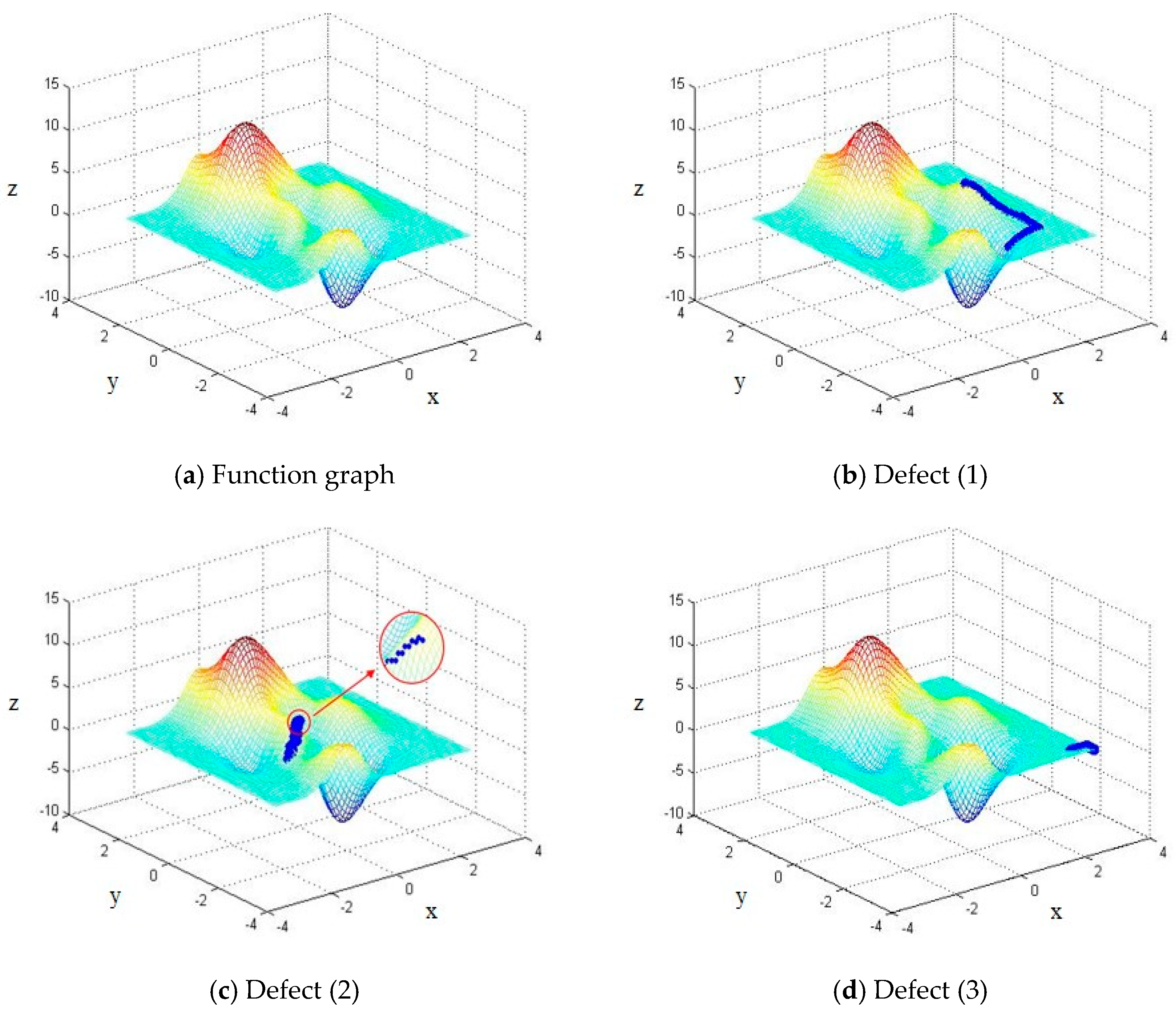

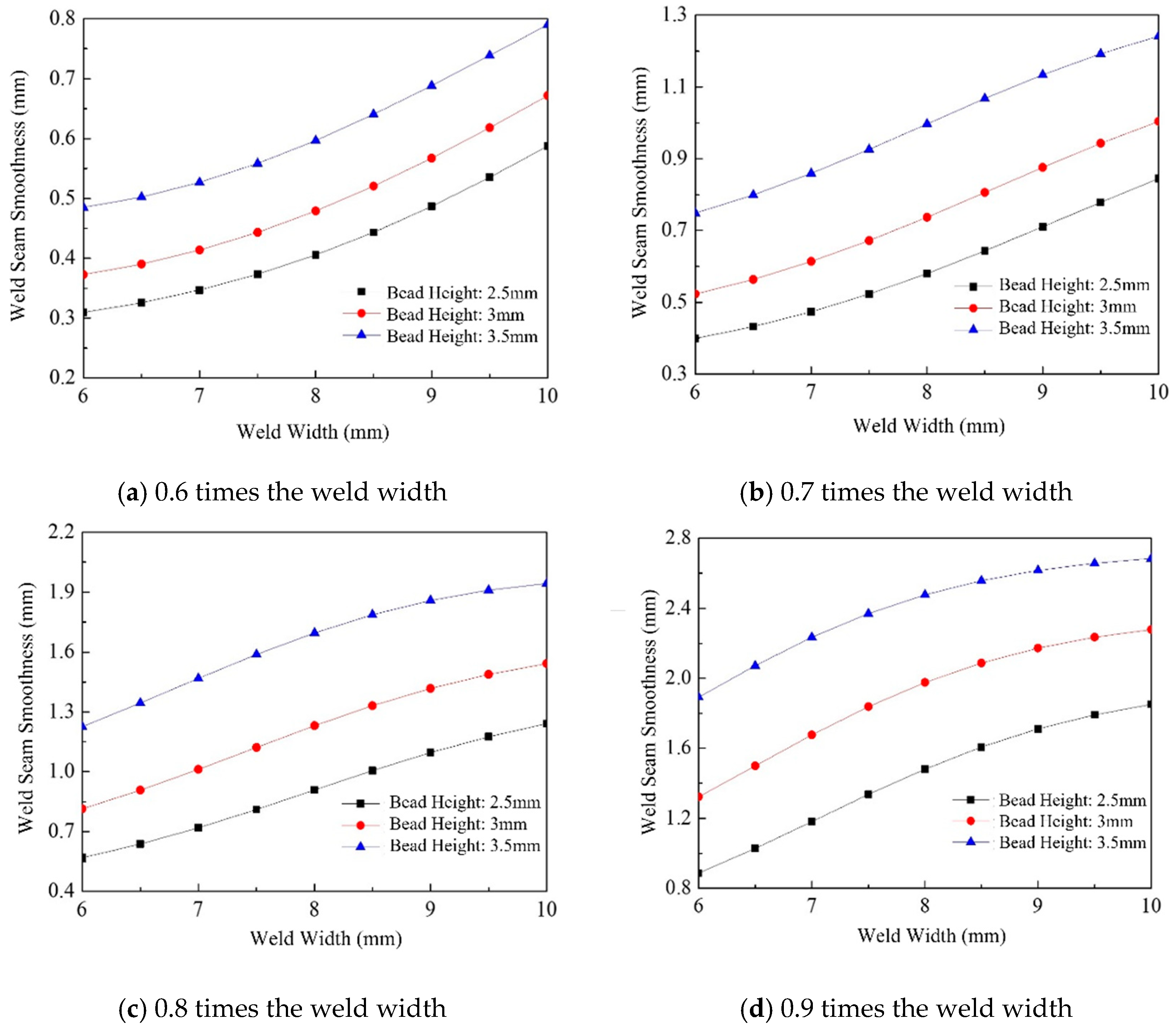

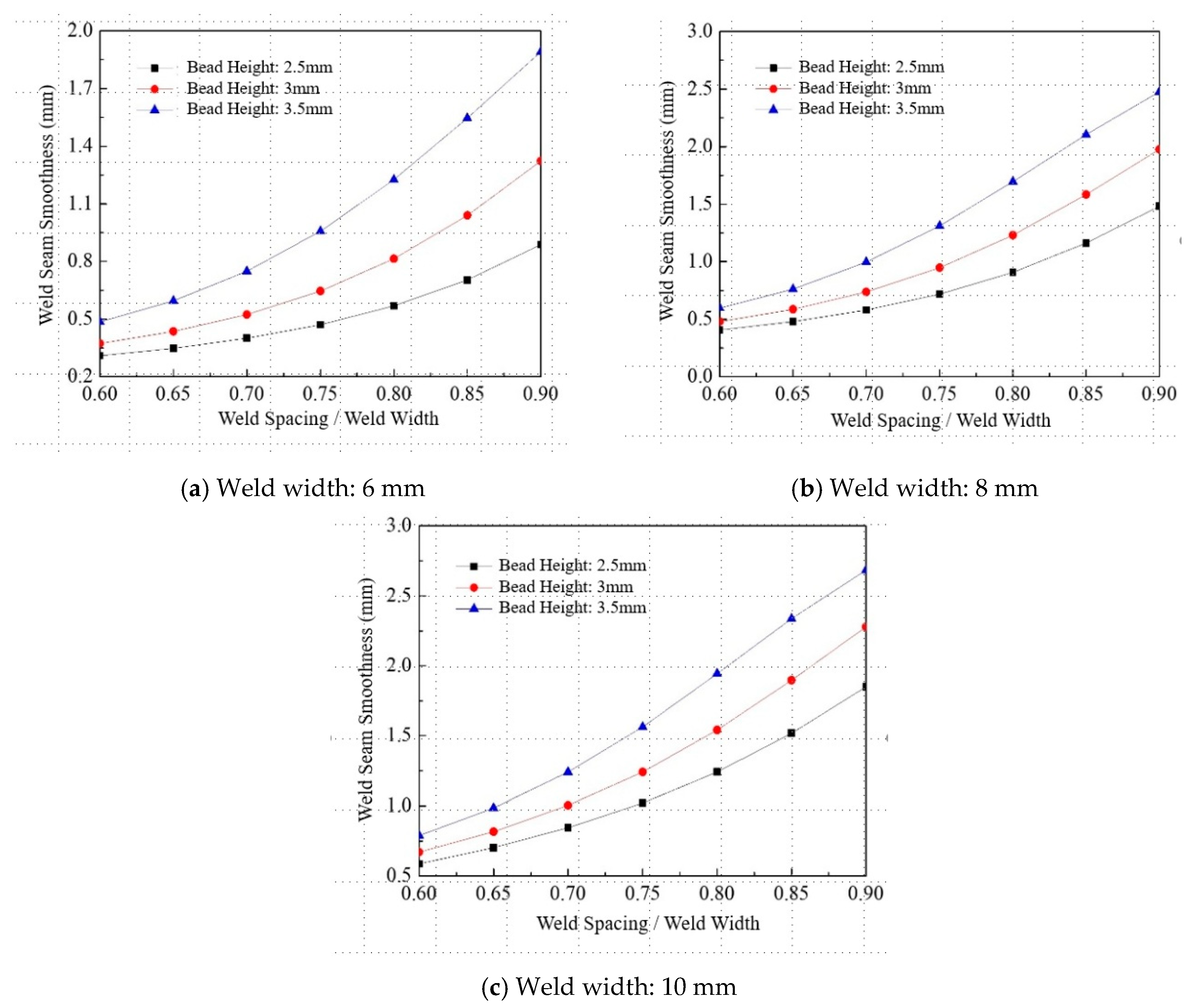

Figure 11 presents the response surface of surface flatness (

) for single-layer multi-pass welds. The results indicate that when the weld spacing is held constant, the surface flatness increases with both weld width and weld height, and this increasing trend remains generally consistent across the examined range. When the weld height is fixed, surface flatness increases with both weld width and weld spacing. Notably, the influence of weld spacing becomes increasingly significant as it increases, whereas the effect of weld width on surface flatness remains relatively uniform. Furthermore, when the weld width is kept constant, surface flatness also increases with weld height and weld spacing. The overall trends observed in this case are similar to those in the previous two scenarios. These findings suggest that all three parameters—weld width, weld height, and weld spacing—exert a positive and cumulative influence on the surface flatness of multi-pass welds.

6.3. Optimization Results and Process Parameter Recommendations

The response surface model developed in this study has been thoroughly validated using multiple verification methods from different analytical perspectives. The model has proven to be both accurate and reliable within the parameter range defined by the experimental design. However, to ensure its applicability in real-world production environments, incorporating actual manufacturing constraints into the optimization process is essential.

In the specific production scenario addressed in this work, a mechanical hammering operation is applied after each single-layer weld pass to mitigate residual welding stress. This operation utilizes a pneumatic hammer driven by compressed air at a pressure of 0.5 MPa to deliver impacts to the weld surface. Empirical measurements indicate that this post-weld treatment consistently reduces the weld height by approximately 0.5 mm.

To ensure a smooth and uniform surface profile after hammering, the target surface flatness for single-layer multi-pass welds was set to 0.5 mm. Based on this requirement, the weld geometry parameters were optimized. A subset of the optimization results is presented in

Table 10, which includes various combinations of weld width (w), weld height (h), and weld spacing (a) that meet the post-hammering surface flatness constraint (

≈ 0.5 mm).

Among the candidate parameter sets, the 7th configuration was selected due to its favorable balance between weld quality and production efficiency. This set features a weld width of 7.99 mm, a pre-hammering weld height of 2.5 mm, and an inter-bead spacing of approximately 5.35 mm, resulting in a post-hammering flatness deviation of 0.51 mm, which is within the acceptable tolerance.

By applying inverse prediction through a previously trained backpropagation (BP) neural network tailored for weld profile modeling, the optimal process parameters were determined to be a welding voltage of 30.3 V, a wire feed speed of 12,600 mm/min, and a welding speed of 950 mm/min, effectively ensuring the desired weld geometry is achieved.

To validate the predicted optimal parameter set, we conducted an additional welding experiment using these parameters (arc voltage: 30.3 V, wire feed speed: 12,600 mm/min, and welding speed: 950 mm/min). The weld produced under these conditions was measured after the standard hammering treatment and exhibited a surface flatness deviation of approximately 0.5 mm, matching the model’s prediction. This successful validation confirms that the optimized parameter combination is practically achievable and effective, even though the required voltage and wire feed speed slightly exceed the initial experimental range, ensuring that the welding process remains efficient and stable under these settings.