Influence of Tension and Tension Fluctuation on the Structure and Mechanical Properties of Polyester Fibers During the Spinning Process Based on Non-Contact Tension Detection

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Preparation

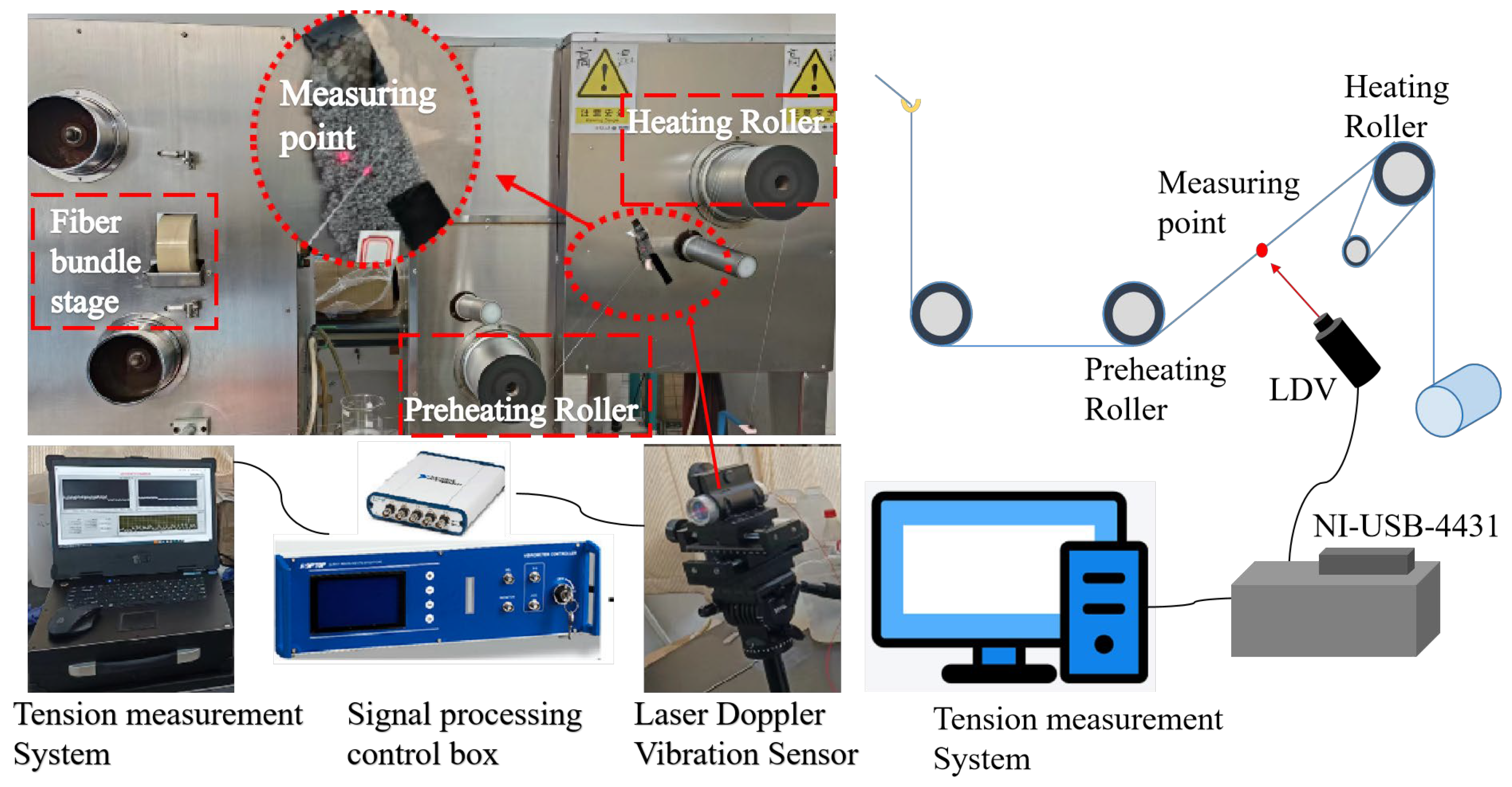

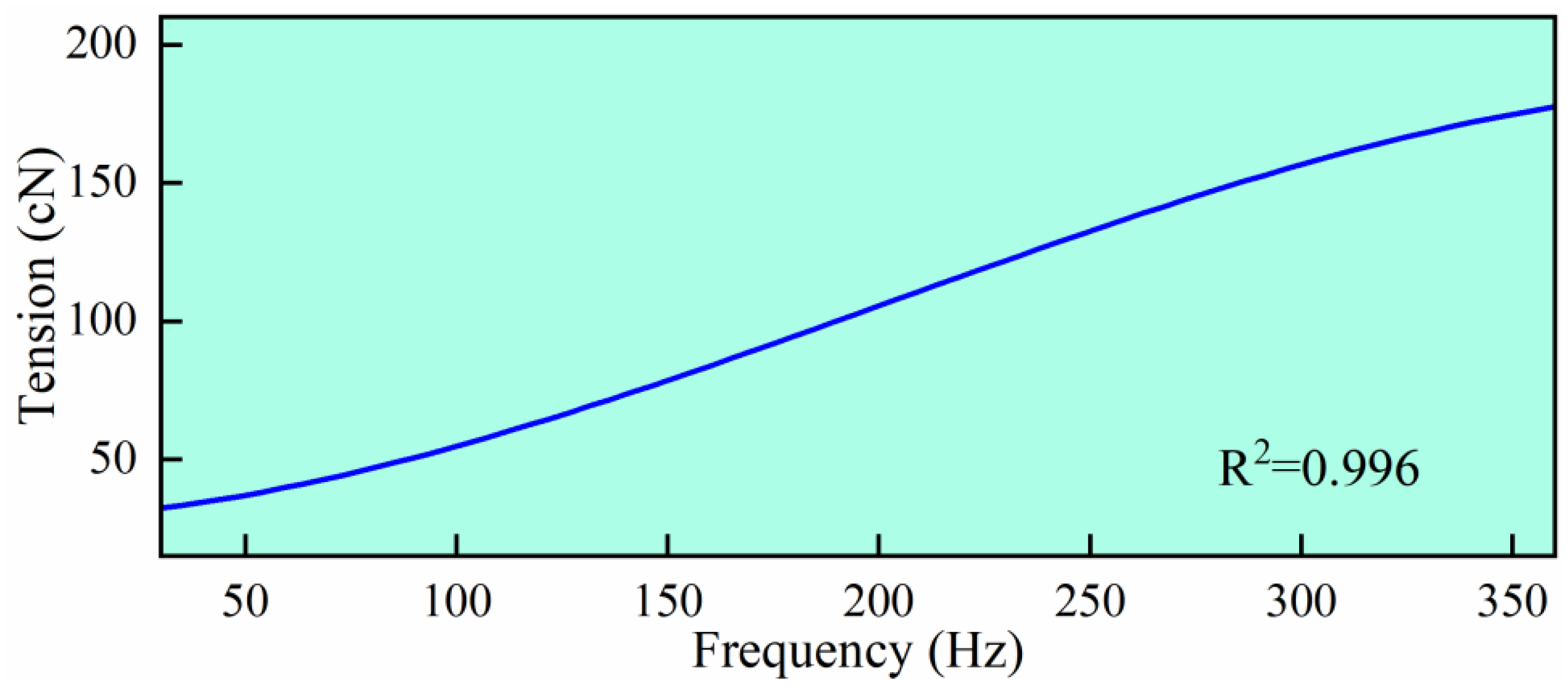

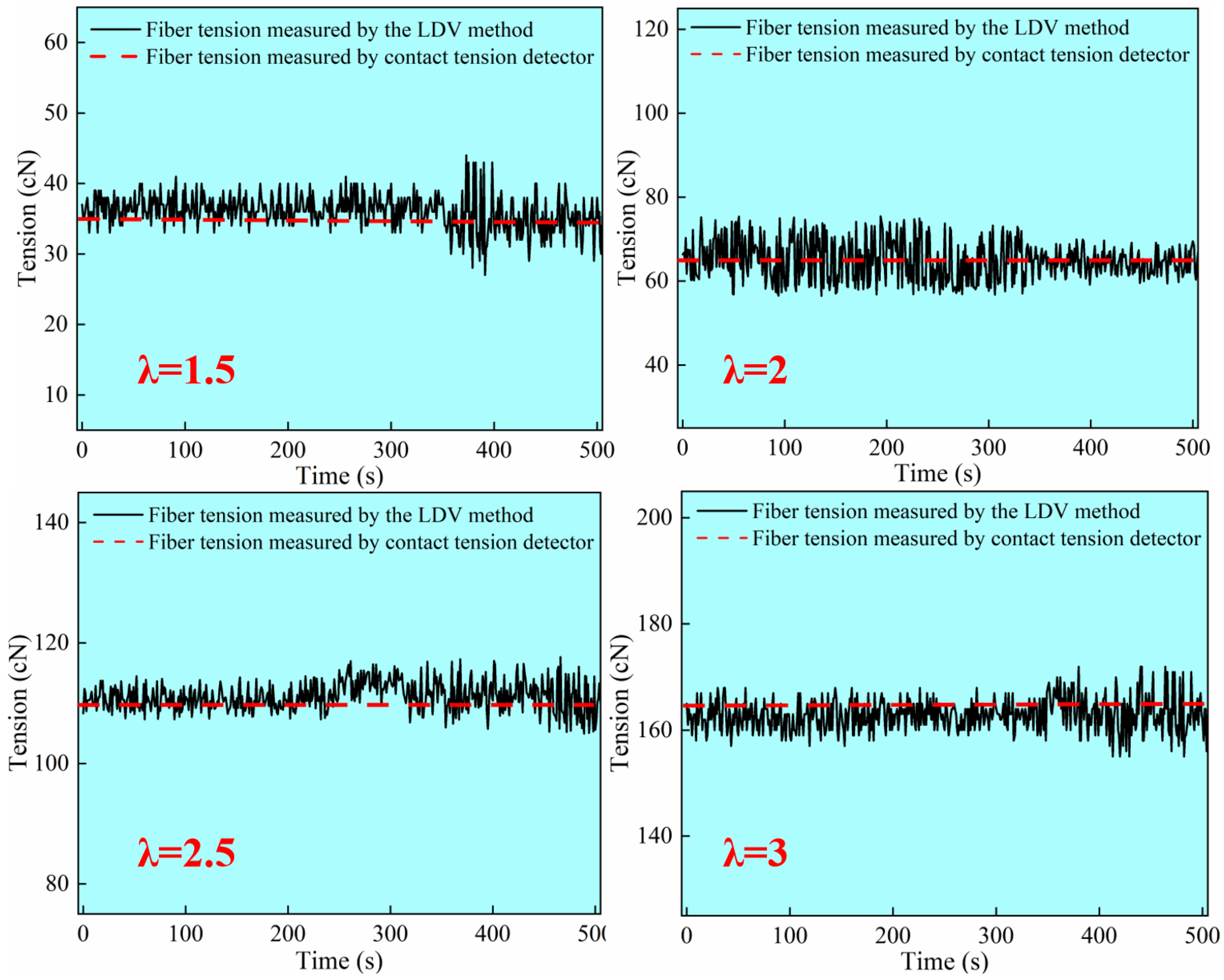

2.3. Measurement of Fiber Tension

2.4. Testing and Characterization

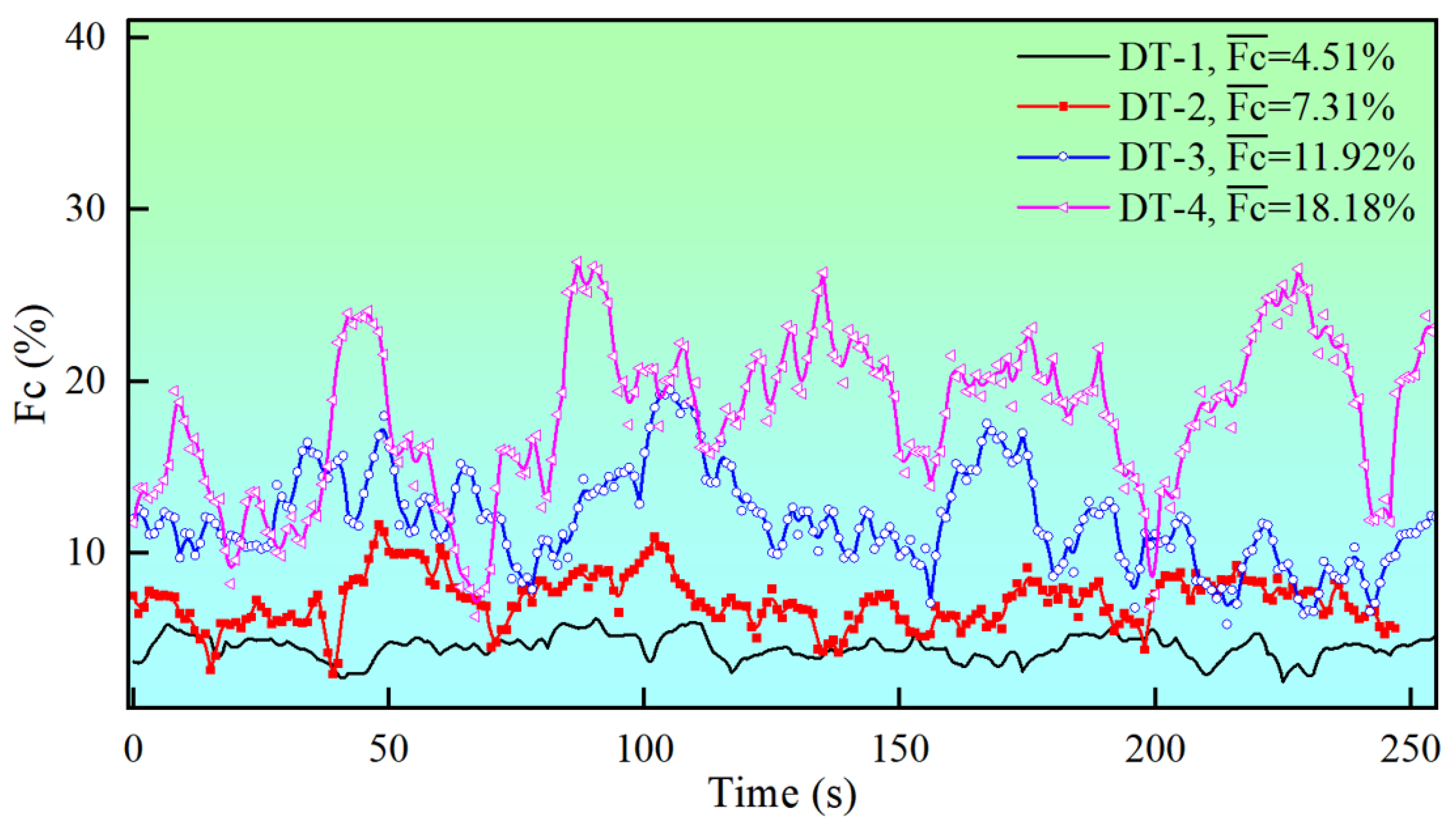

2.5. Establishment of Tension Fluctuation Coefficient

3. Results and Discussion

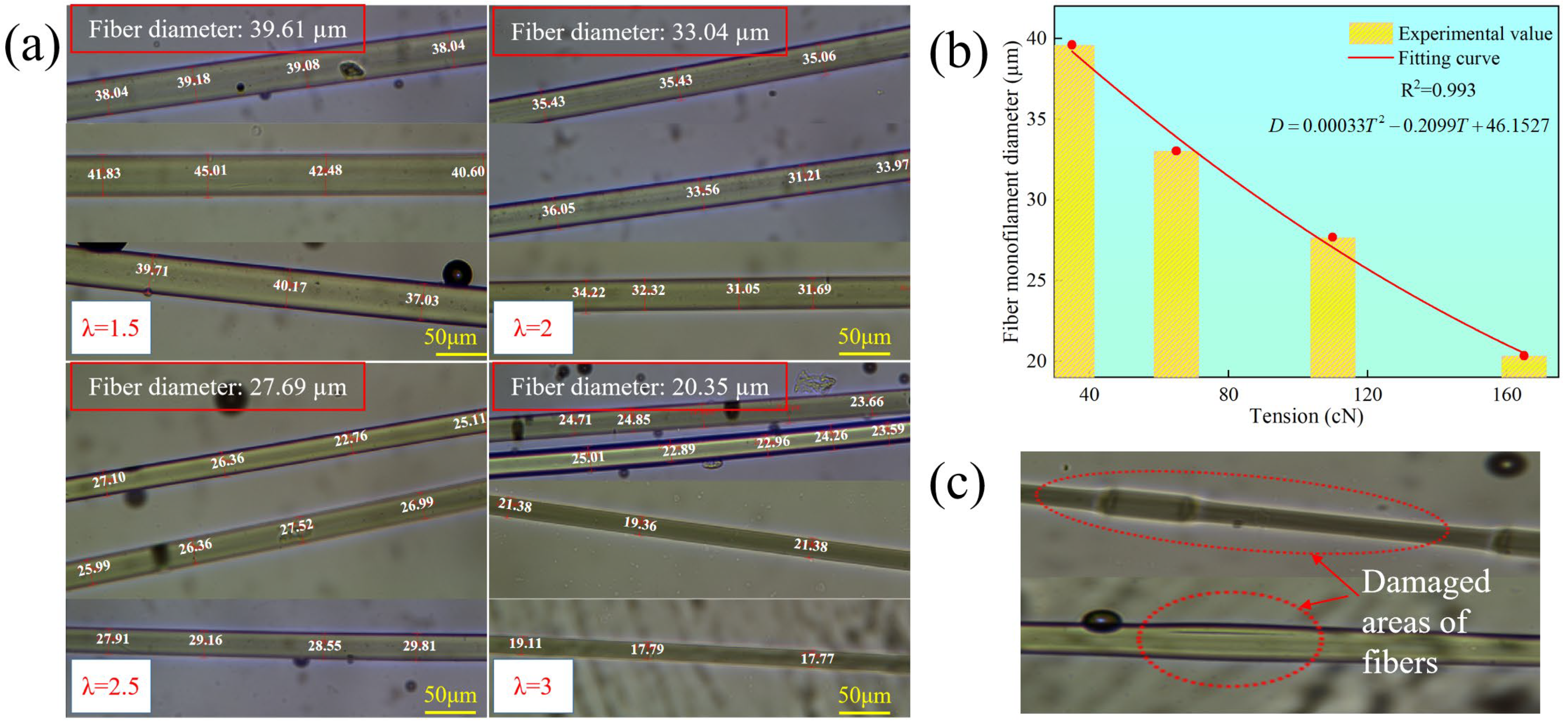

3.1. Fiber Monofilament Diameter Evolution at Different Tensions and Tension Fluctuation Coefficients

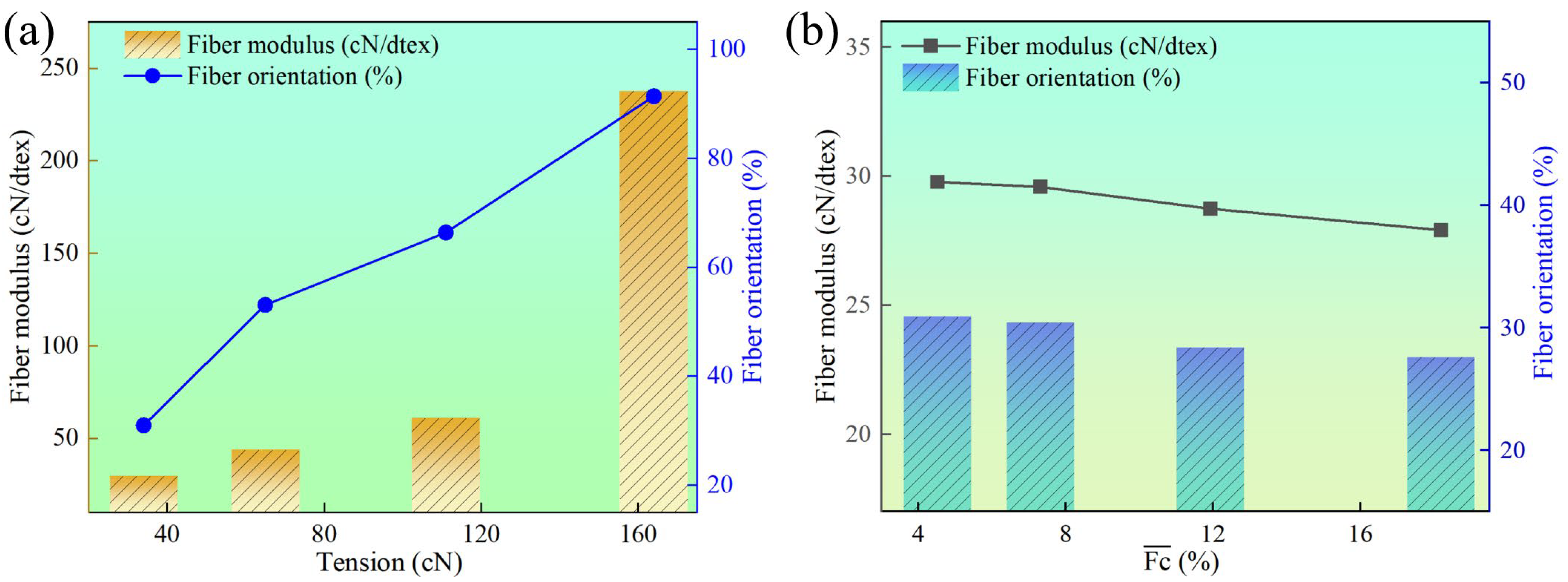

3.2. Fiber Orientation Evolution at Different Tensions and Tension Fluctuation Coefficients

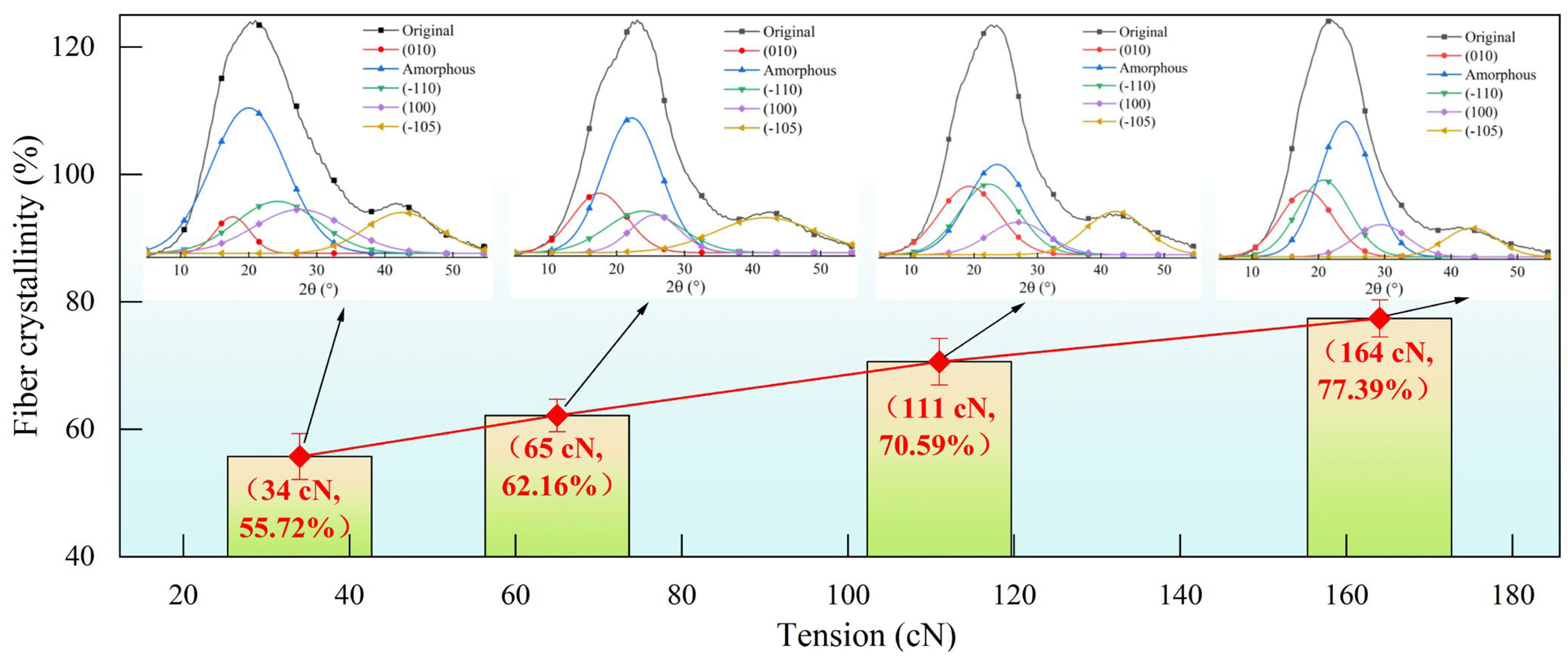

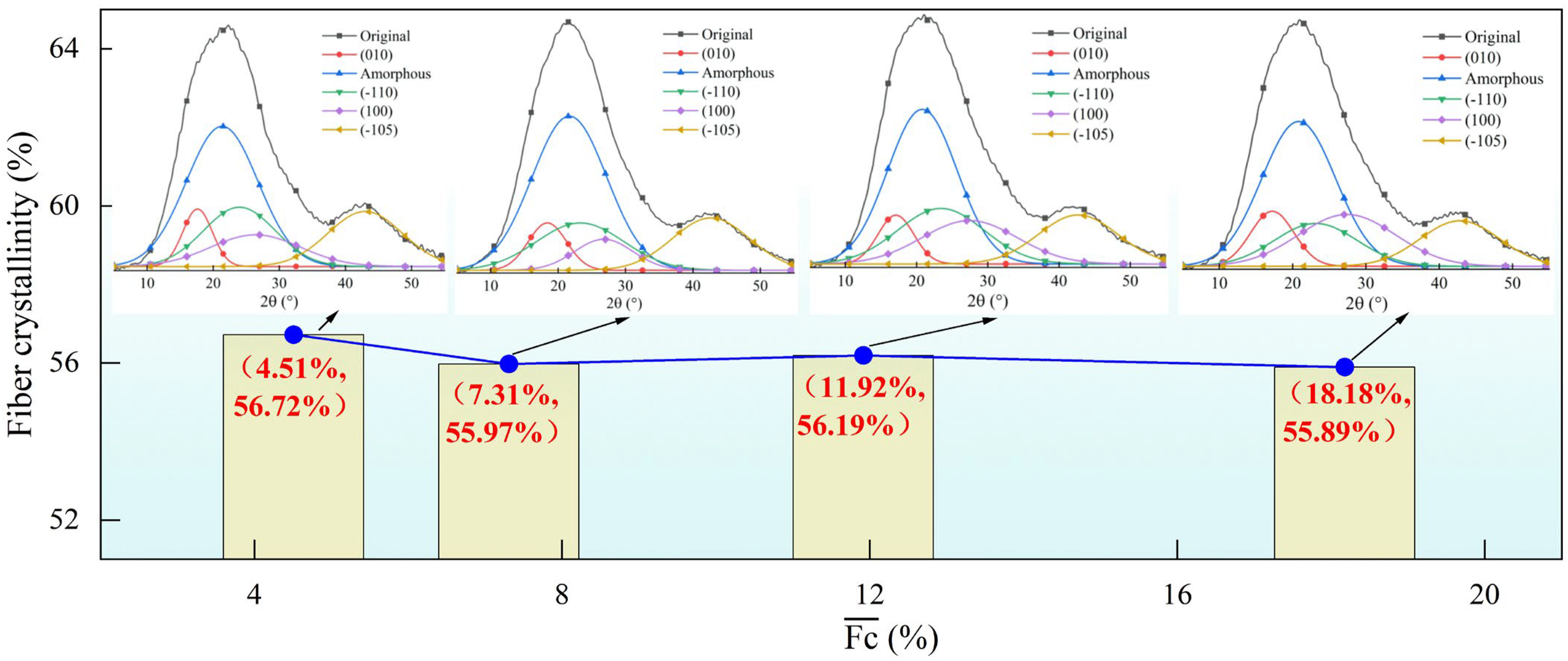

3.3. Fiber Crystallinity Evolution at Different Tensions and Tension Fluctuation Coefficients

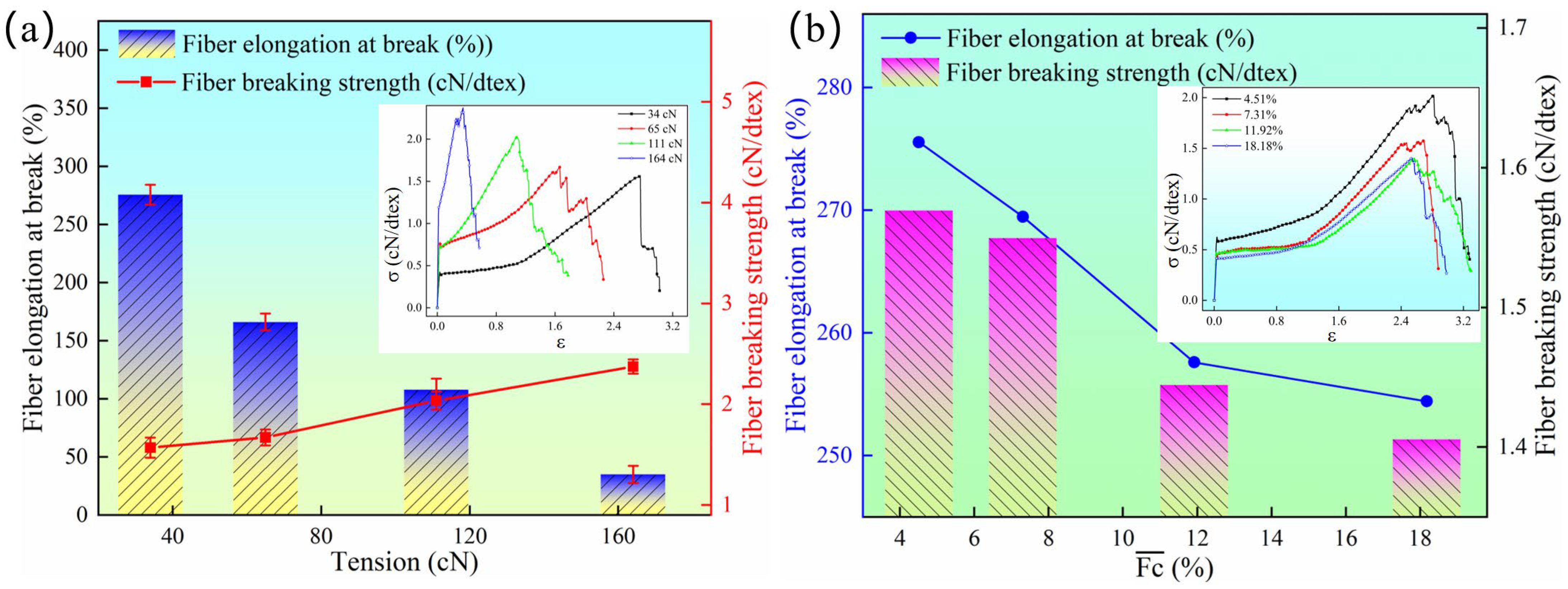

3.4. Fiber Mechanical Properties Evolution at Different Tensions and Tension Fluctuation Coefficients

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, H.; Xu, G.; Yang, S.; Jiang, W.; Jiang, L.; Xu, W. A method to regulate the shape of yarn balloon and its effect on the tension and quality of ring spun yarn. Fibers Polym. 2024, 25, 1149–1162. [Google Scholar] [CrossRef]

- Chattopadhyay, S.K.; Venugopal, B. An experimental verification on existence of air-drag force influencing yarn tension during rotor spinning. Res. J. Text. Appar. 2020, 24, 84–96. [Google Scholar] [CrossRef]

- Mahdiyeh, D.; Esfandiyar, E. Review of distribution of fiber tension at the spinning triangle. J. Text. Inst. 2014, 105, 1167–1177. [Google Scholar] [CrossRef]

- Kim, J.T.; Netravali, A.N. Mercerization of sisal fibers: Effect of tension on mechanical properties of sisal fiber and fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1245–1252. [Google Scholar] [CrossRef]

- Patel, R.M.; Doufas, A.K.; Paradkar, R.P. Raman spectroscopy for spinline crystallinity measurements. II. Validation of fundamental fiber-spinning models. J. Appl. Polym. Sci. 2008, 109, 3398–3412. [Google Scholar] [CrossRef]

- Cheng, L.; Zheng, C.; Li, Y.; Chen, C.; Zhang, S.; Wu, J.; Dong, H.; Ke, Y. Fiber tension prediction and control methods in automated fiber placement. Polym. Compos. 2024, 45, 14888–14904. [Google Scholar] [CrossRef]

- Yang, C.; Wu, H.; Dai, Y.; Zhang, D.; Xu, R.; Luo, L.; Liu, X. Constructing mainstay-body structure in heterocyclic aramid fiber to simultaneously improve tensile strength and toughness. Compos. Part B Eng. 2020, 202, 108411. [Google Scholar] [CrossRef]

- Kong, H.; Xu, Q.; Yu, M. Microstructural Changes of Aramid Fiber Due to Reaction with Toluene 2,4-diisocyanate under Tension in scCO2. Polymers 2019, 11, 1110. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, H.; Shi, Y. Precision tension control technology of composite fiber tape winding molding. J. Thermoplast. Compos. Mater. 2018, 31, 925–945. [Google Scholar] [CrossRef]

- Hong, Q.; Shi, Y.; Chen, Z. Dynamics modeling and tension control of composites winding system based on ASMC. IEEE Access 2020, 8, 102795–102810. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Z.; Wang, Z.; Li, X.; Meng, Z. Yarn tension model and vibration analysis during unwinding of carbon fiber bobbins. J. Ind. Text. 2023, 53, 15280837231178944. [Google Scholar] [CrossRef]

- Duan, Y.; Liang, J.; Liu, J.; Gao, H.; Li, Y.; Zhang, J.; Wen, X. Research on Anti-Fluctuation Control of Winding Tension System Based on Feedforward Compensation. Comput. Model. Eng. Sci. (CMES) 2024, 139, 1239–1261. [Google Scholar] [CrossRef]

- Du, Y.; He, L.; An, Z.; Qi, B.; Dong, B.; Wang, Y. Tension fluctuation analysis and structure optimization of yarn carriers in the carbon fiber braiding machine. Polym. Compos. 2025, 46, 6494–6508. [Google Scholar] [CrossRef]

- Li, S.; Ma, X.; Hou, X.; Wang, S.; Wang, Y. A dynamic modeling approach to the moving filament during high-speed winding by absolute nodal coordinate formulation. Text. Res. J. 2022, 92, 3903–3919. [Google Scholar] [CrossRef]

- Zhang, R.; Feng, P.; Yang, C. A study on the unwinding tension control of an elastic yarn. Text. Res. J. 2022, 92, 4587–4595. [Google Scholar] [CrossRef]

- Feng, P.; Liu, D.; Yang, C. High efficiency covering technology for covered yarn production: Controlling the spandex yarn draw ratio. Fibres Text. East. Eur. 2020, 28, 24–28. [Google Scholar] [CrossRef]

- Hossain, M.; Abdkader, A.; Nocke, A.; Unger, R.; Krzywinski, F.; Hasan, M.M.B.; Cherif, C. Measurement methods of dynamic yarn tension in a ring spinning process. Fibres Text. East. Eur. 2016, 24, 36–43. [Google Scholar] [CrossRef]

- Ling, Y.; Chen, M.; Liu, Y.; Yin, R. A Modified Hand-Held Force Meter to Measure Yarn Tension in the Ring Spinning Process. Fibers Polym. 2023, 24, 2967–2975. [Google Scholar] [CrossRef]

- Wang, L.; Peng, L.; Xiong, X.; Li, Y.; Qi, Y.; Hu, X. Research on high-speed constant tension spinning control strategy based on vibration detection and enhanced firefly algorithm based FOPID controller. Measurement 2025, 254, 117789. [Google Scholar] [CrossRef]

- Lü, X.; Lu, W.; Zhu, C. Compensated SAW yarn tension sensor. IEEE Trans. Instrum. Meas. 2014, 63, 3162–3168. [Google Scholar] [CrossRef]

- Srimontriphakdi, T.; Mahasuwanchai, P.; Athisakul, C.; Leelataviwat, S.; Klaycham, K.; Poovarodom, N.; Magteppong, N.; Chucheepsakul, S. A non-contact approach for cable tension evaluation based on 3D laser scanning data and nonlinear finite element analysis. Measurement 2023, 212, 112680. [Google Scholar] [CrossRef]

- Rinaldi, C.; Lepidi, M.; Potenza, F.; Gattulli, V. Identification of cable tension through physical models and non-contact measurements. Mech. Syst. Signal Process. 2023, 205, 110867. [Google Scholar] [CrossRef]

- Zhang, D.; Fan, W.; Qian, C.; Li, G.; Huang, P.; Gan, X. Transverse vibration characteristics and plane stress distribution of the carbon fiber prepreg tape subjected to nonuniform tension. Text. Res. J. 2024, 95, 252–261. [Google Scholar] [CrossRef]

- Zhang, D.; Ma, Q.; Tan, Y.; Liao, H.; Lu, C.; Tang, F.; Liu, X.; Fu, Y.; Wang, X.; Gan, X. Non-contact detection of polyester filament yarn tension in the spinning process by the laser Doppler vibrometer method. Text. Res. J. 2022, 92, 919–928. [Google Scholar] [CrossRef]

- Chen, K.; Liu, Y.; Ji, H.; Zhang, Y.; Wang, Y.; Zhang, Y.; Wang, H. Structural evolutions during creep deformation of polyester industrial fiber via in situ synchrotron small-angle X-ray scattering/wide-angle X-ray scattering. J. Ind. Text. 2022, 51, 8035S–8054S. [Google Scholar] [CrossRef]

- Sun, N.; Zou, J.; Zhang, Y.; Zhang, Y. The competition mechanism of orientation and disorientation of PET chains during spinning based on the pre-oriented polyester industrial yarns. Polymer 2024, 300, 126991. [Google Scholar] [CrossRef]

- Senthil, T.; Divakaran, N.; Wang, J.; Wang, R.; Wu, L. Evolution of structural, electrical, and mechanical response of 3D robust network and conducting mechanically modified glass fabric-polyester composites with devisable 1D VGCNF. Compos. Sci. Technol. 2018, 163, 171–179. [Google Scholar] [CrossRef]

- Kenned, J.J.; Sankaranarayanasamy, K.; Suresh Kumar, C. Anatomical, mechanical and fractographic characterization of needle punched Musa Sapientum cellulosic fiber/UPE composites. J. Test. Eval. 2021, 49, 740–757. [Google Scholar] [CrossRef]

- Gizem, G.K.; Kenan, E.E. A research on tensile and abrasion properties of fabrics produced from conventional and fire resistant type polyester yarns. Ind. Textila 2017, 68, 407. [Google Scholar] [CrossRef]

- Zhang, D.; Ma, Q.; Dong, H.; Liao, H.; Liu, X.; Zha, Y.; Zhang, X.; Qian, X.; Liu, J.; Gan, X. Time-delayed feedback bistable stochastic resonance system and its application in the estimation of the Polyester Filament Yarn tension in the spinning process. Chaos Solitons Fractals 2023, 168, 113133. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Y.; Fan, W.; Yang, S.; Du, W.; Yu, K.; Qian, C.; Huang, P.; Gan, X. Time-delayed feedback multistable stochastic resonance in combination with ensemble empirical mode decomposition method and its application in the measurement of the varnished wire tension. Chaos Solitons Fractals 2025, 196, 116442. [Google Scholar] [CrossRef]

- Zhang, D.; Tan, Y.; Ma, Q.; Liao, H.; Lu, C.; Liu, X.; Fu, Y.; Wang, X.; Han, F.; Gan, X. Real-time tension estimation in the spinning process based on the natural frequencies extraction of the Polyester Filament Yarn. Measurement 2022, 188, 110514. [Google Scholar] [CrossRef]

- Liu, F.; Liu, X.; Ai, W.; You, S.; Wang, Y.; Yang, H.; Bai, Z.; Liu, H. Optimization of the pre-tension and separation distance for measurement of the dynamic elastic modulus and macromolecular orientation of a polypropylene monofilament via the sonic velocity method. Rev. Sci. Instrum. 2020, 91, 123906. [Google Scholar] [CrossRef]

- Liu, H.; Wang, H.; Li, S.; Di, Q.; Wang, L.; Zhang, H.; Zhang, X.; Hu, W. Luminescent Organic Single Crystals for Flexible Optical Fiber Scintillators and X-ray Imaging. Cryst. Growth Des. 2024, 24, 902–9029. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, G.; Shi, J.; Guo, H.; Chen, C. Exploring the high elongation at break of windmill palm fiber. Ind. Crops Prod. 2024, 222, 119912. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, W.; Zhang, D.; Fan, W.; Yang, S.; Gan, X. Influence of Tension and Tension Fluctuation on the Structure and Mechanical Properties of Polyester Fibers During the Spinning Process Based on Non-Contact Tension Detection. Materials 2025, 18, 3972. https://doi.org/10.3390/ma18173972

Du W, Zhang D, Fan W, Yang S, Gan X. Influence of Tension and Tension Fluctuation on the Structure and Mechanical Properties of Polyester Fibers During the Spinning Process Based on Non-Contact Tension Detection. Materials. 2025; 18(17):3972. https://doi.org/10.3390/ma18173972

Chicago/Turabian StyleDu, Wanhe, Dongjian Zhang, Wei Fan, Shuzhen Yang, and Xuehui Gan. 2025. "Influence of Tension and Tension Fluctuation on the Structure and Mechanical Properties of Polyester Fibers During the Spinning Process Based on Non-Contact Tension Detection" Materials 18, no. 17: 3972. https://doi.org/10.3390/ma18173972

APA StyleDu, W., Zhang, D., Fan, W., Yang, S., & Gan, X. (2025). Influence of Tension and Tension Fluctuation on the Structure and Mechanical Properties of Polyester Fibers During the Spinning Process Based on Non-Contact Tension Detection. Materials, 18(17), 3972. https://doi.org/10.3390/ma18173972