Experimental Study on the Application of Limestone Mine Dust Filter Slag as Concrete Admixture

Abstract

1. Introduction

2. Material Analysis and Test Plan Design

2.1. Test Materials

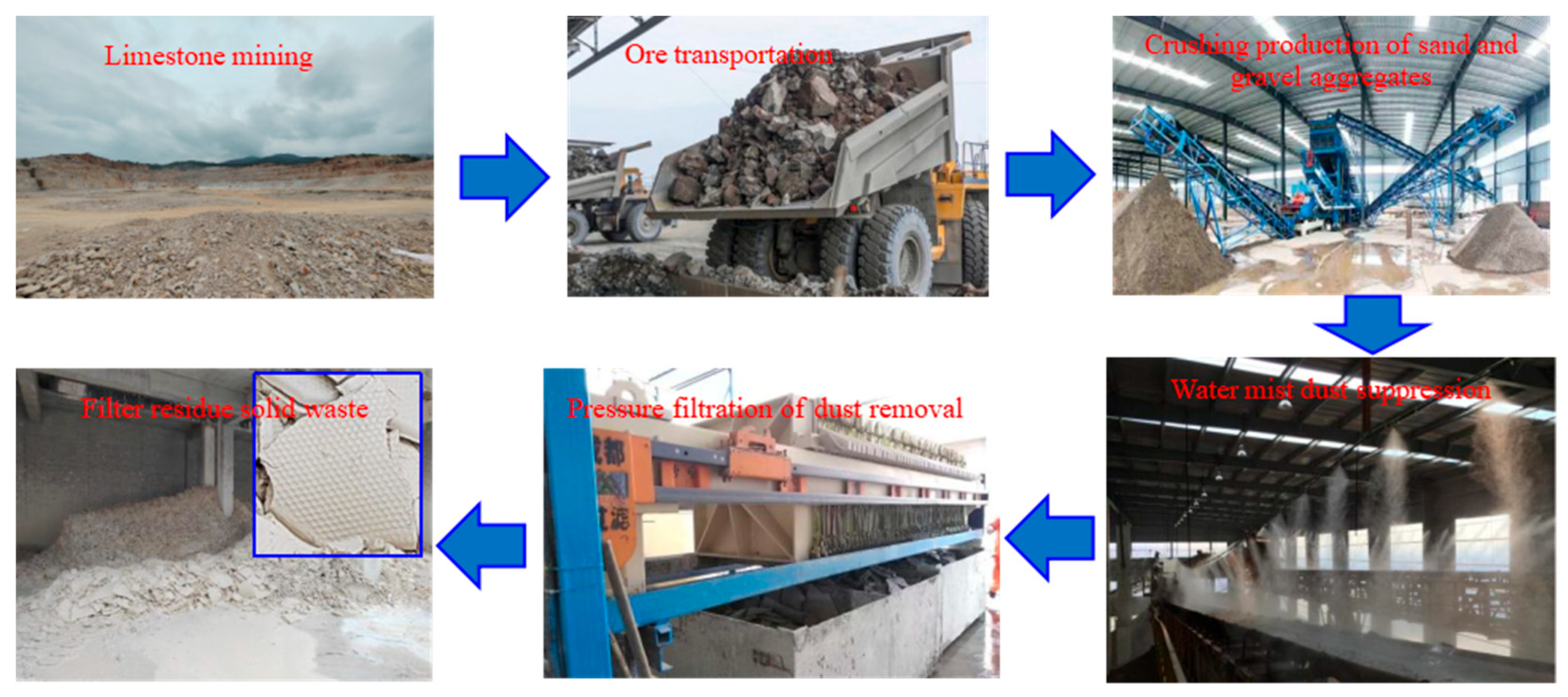

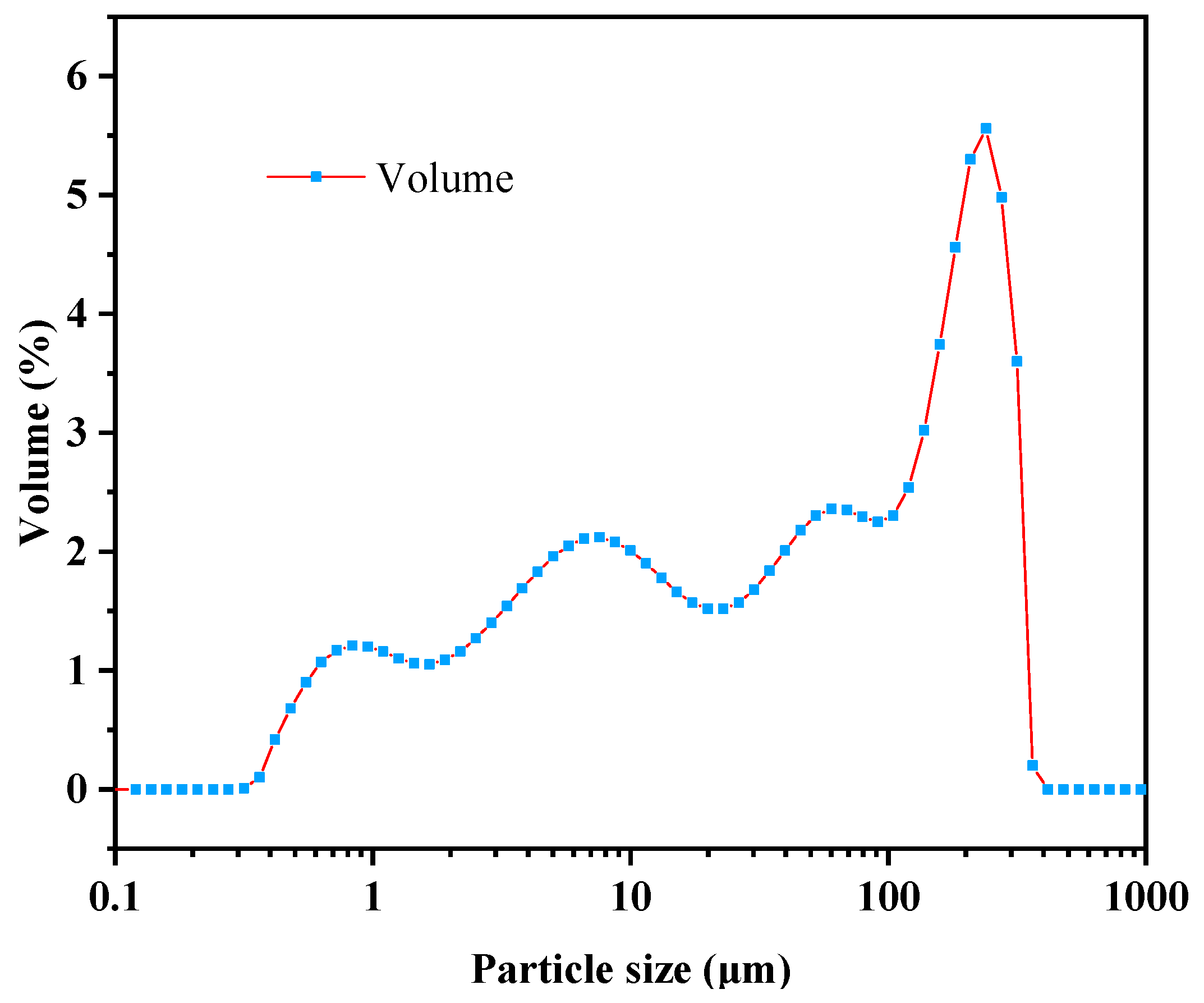

2.1.1. LMDFR

2.1.2. FA

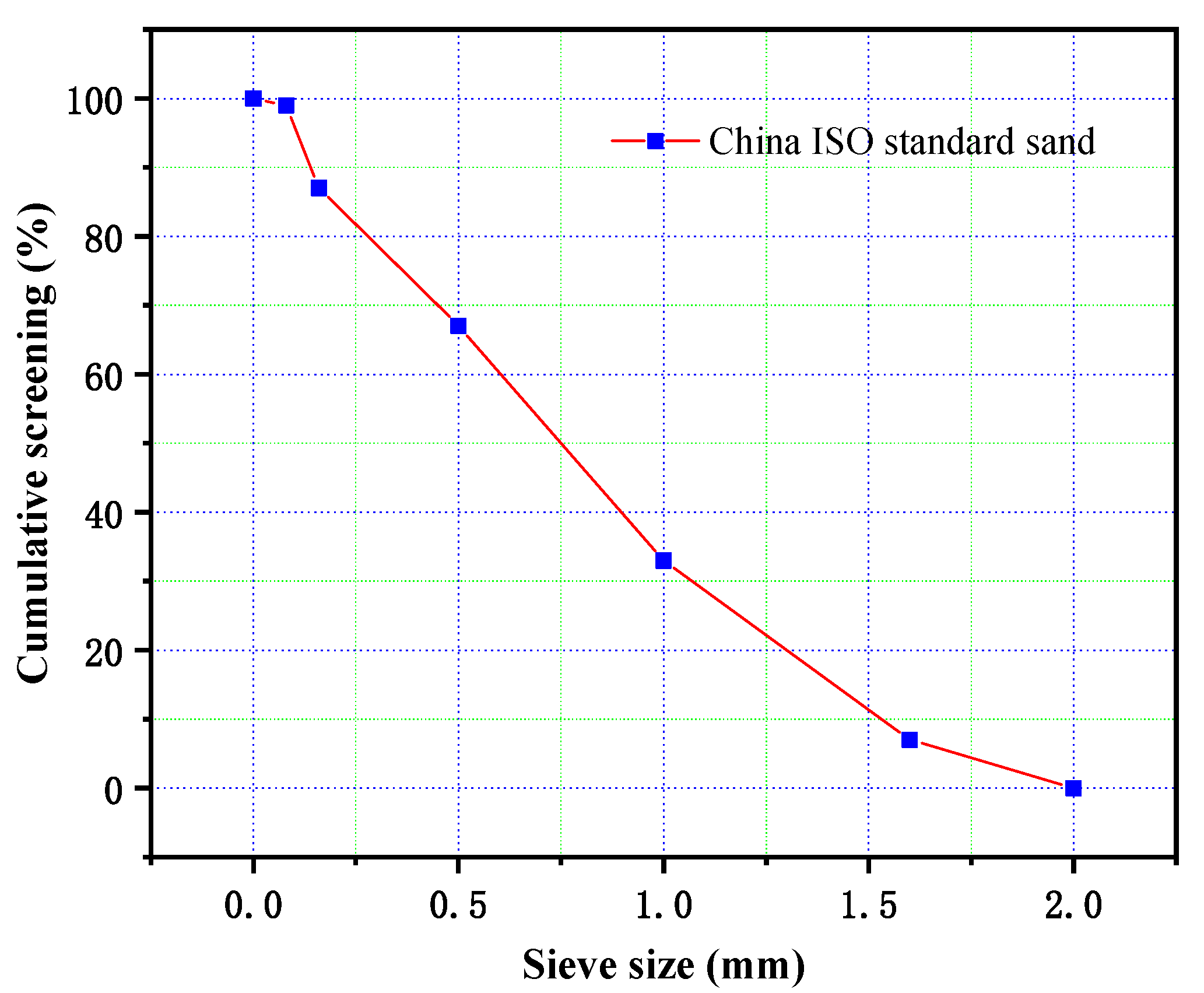

2.1.3. Other Test Materials

2.2. Test Plan Design and Method

3. Flowability and Hydration Activity Test Analysis

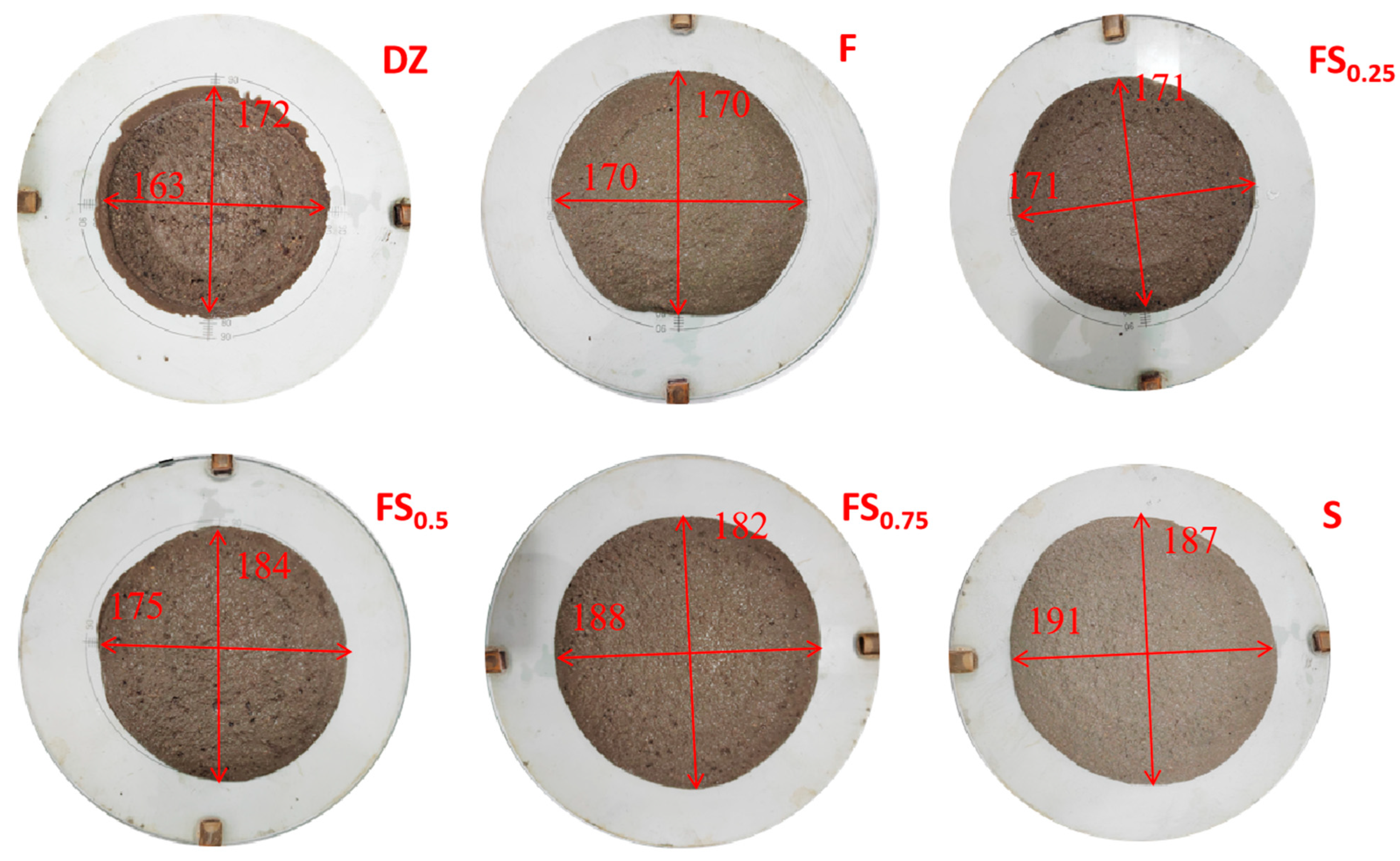

3.1. Fluidity

3.2. Flexural Strength, Compressive Strength, and Activity Index

4. Microscopic Analysis

4.1. SEM Analysis of Test Materials and Cement Mortar Specimens

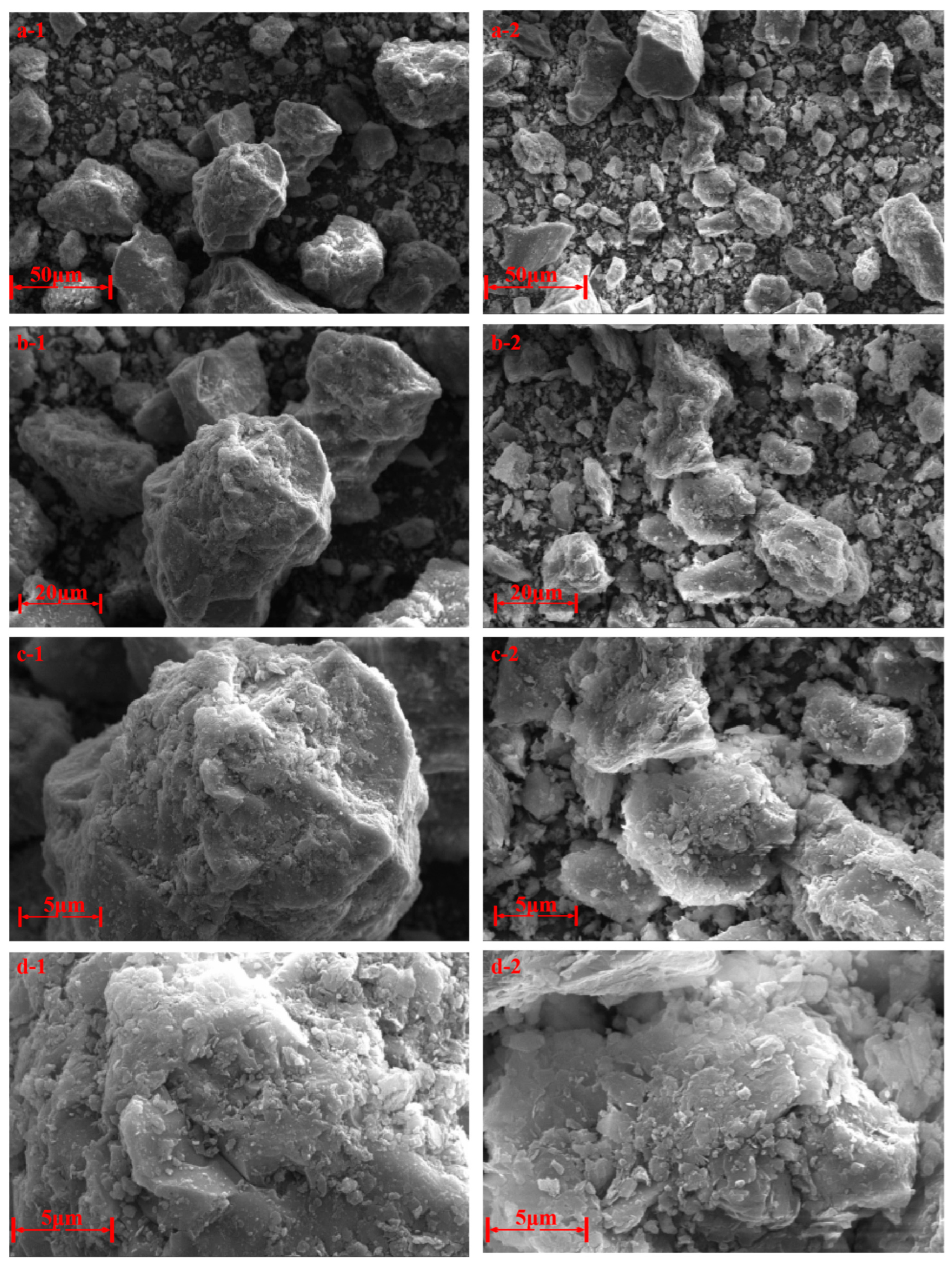

4.1.1. SEM Analysis of Test Materials

- (a)

- SEM Analysis of LMDFR

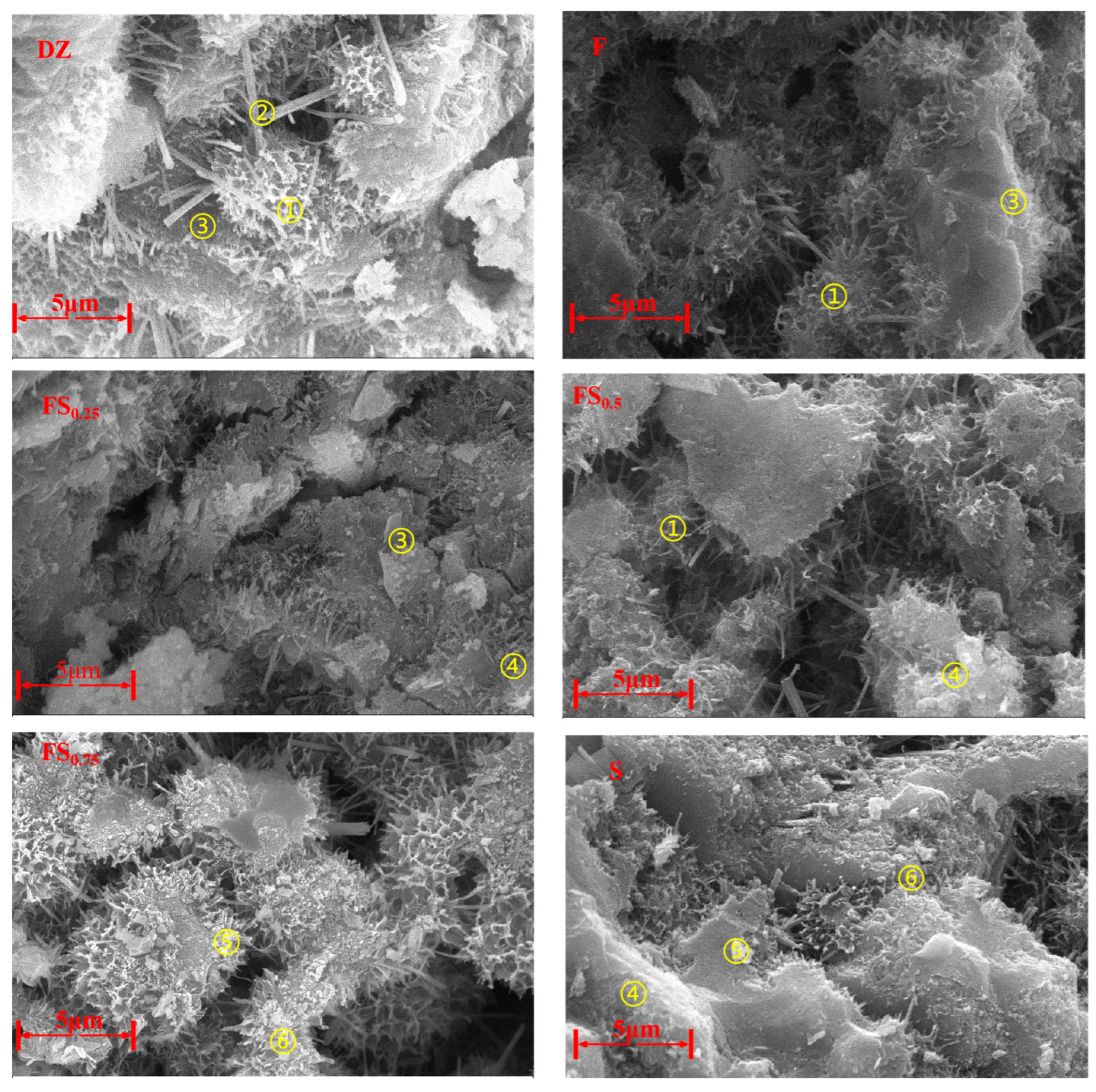

4.1.2. SEM Analysis of Cement Mortar Specimens

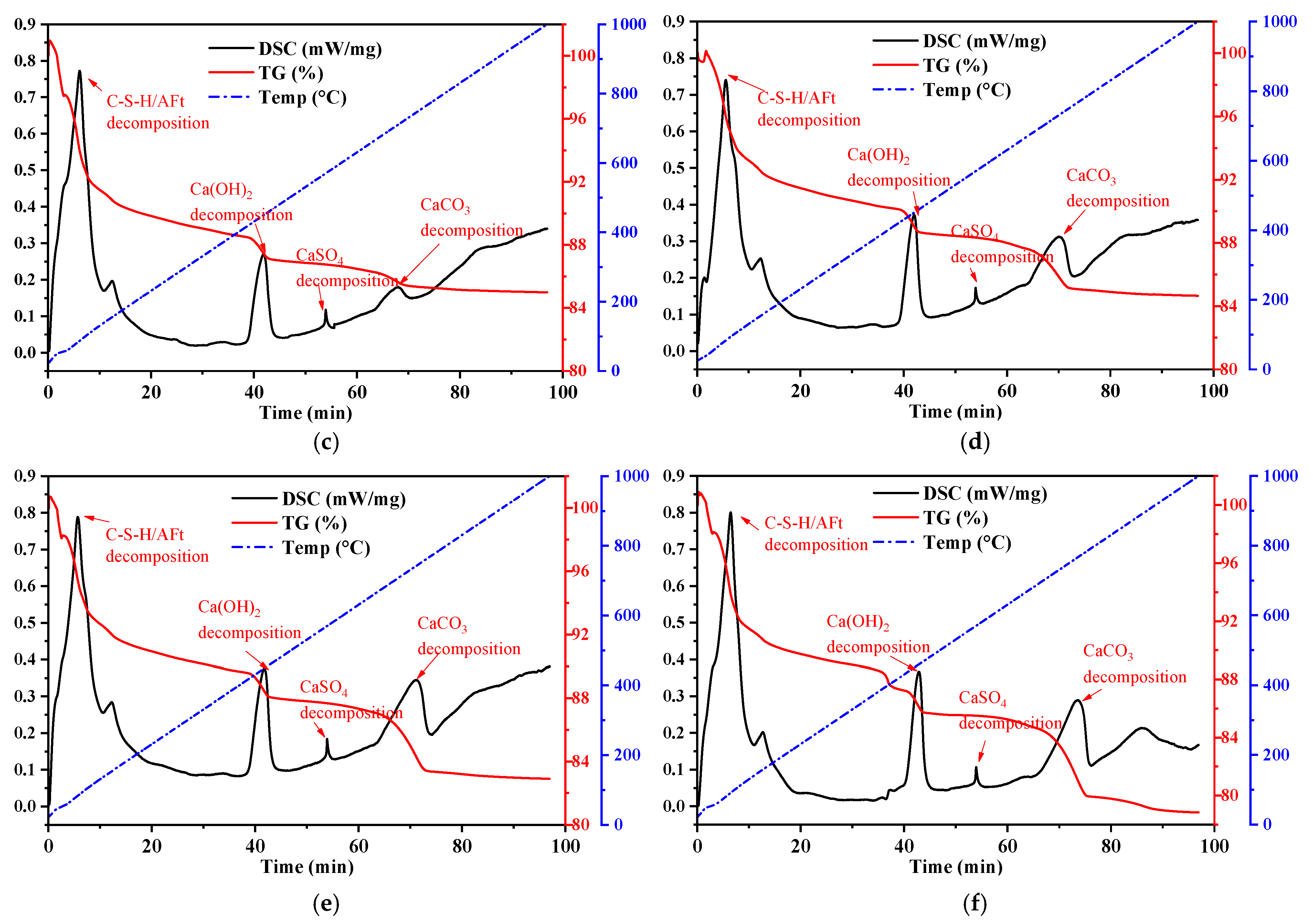

4.2. TG and DSC Analysis of Cement Mortar

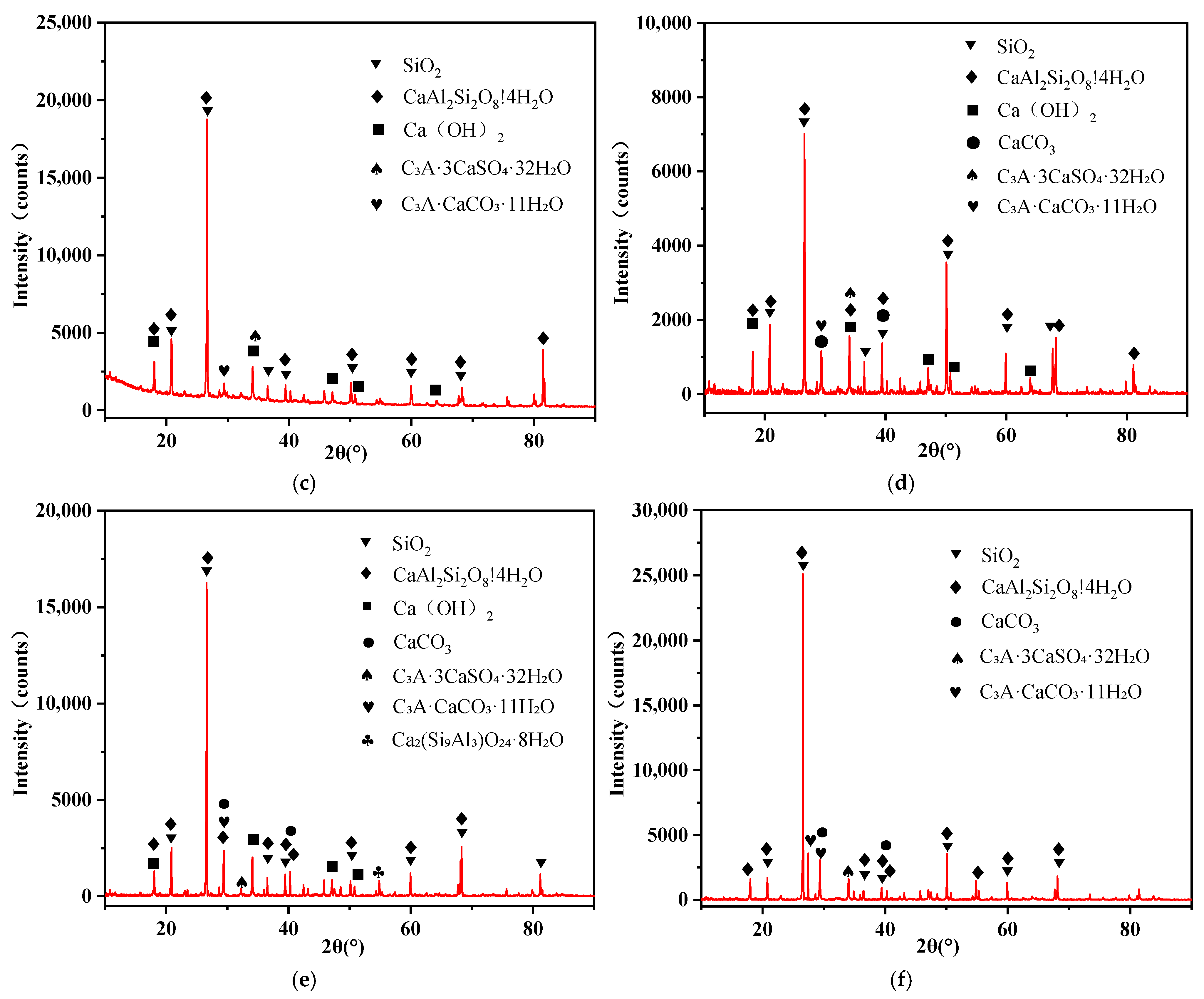

4.3. XRD Analysis of Test Materials and Cement Mortar

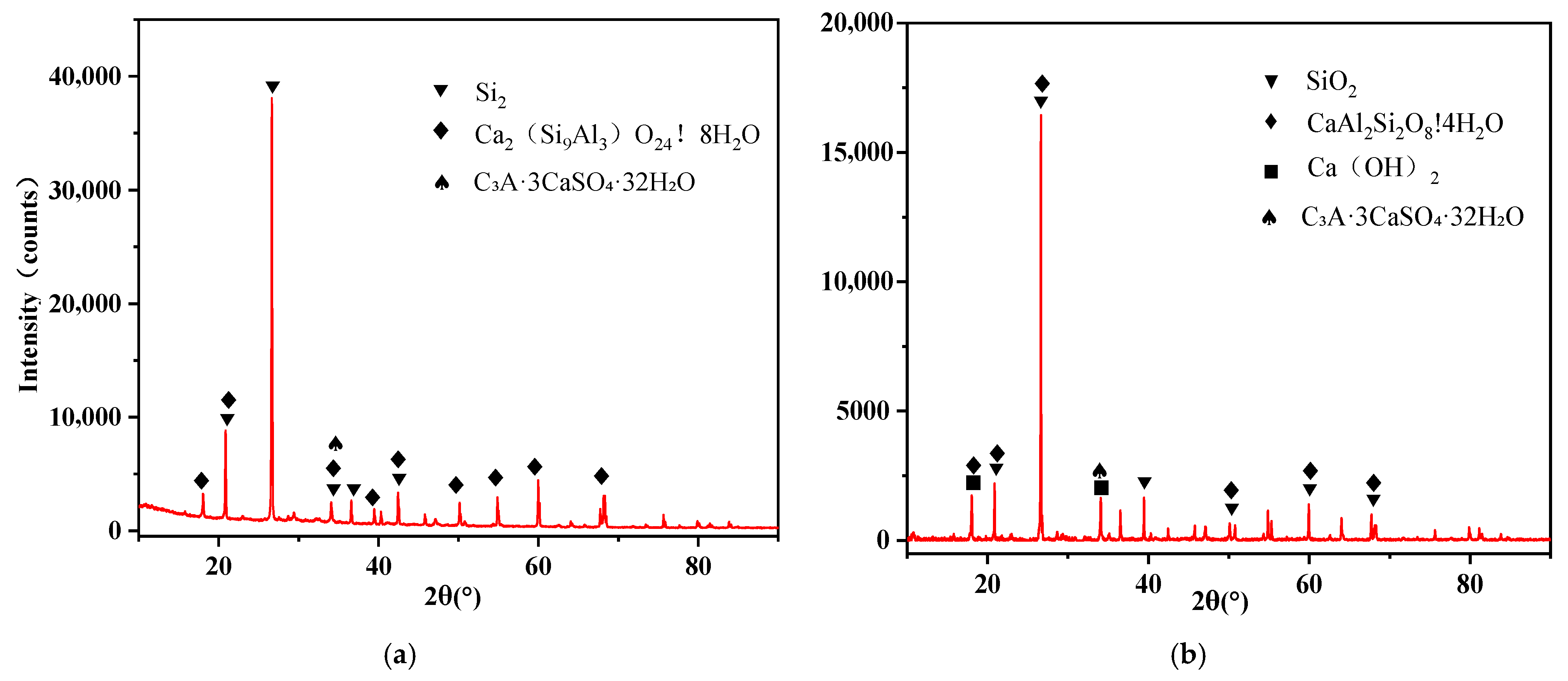

4.3.1. XRD Analysis of Test Materials

4.3.2. XRD Analysis of Cement Mortar

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qin, Z.; Xiao, J.; Zhang, J.; Zou, K. Practical Experience to Theoretical Innovation: A Model for Recovering Metal Resources from Industrial Solid Waste—A Case Study of Copper Smelting Slag. Sep. Purif. Technol. 2025, 354, 129395. [Google Scholar] [CrossRef]

- Wu, F.; Liu, X.; Qu, G.; Ning, P. A Critical Review on Extraction of Valuable Metals from Solid Waste. Sep. Purif. Technol. 2022, 301, 122043. [Google Scholar] [CrossRef]

- Nie, X.; Lang, L.; Liu, L.; Li, J.; Long, S. Development of Low-Carbon Cementitious Materials Utilizing Electrolytic Manganese Residue and Industrial Solid Wastes: Environmental Performance and Strength Mechanisms. Sustain. Chem. Pharm. 2025, 43, 101916. [Google Scholar] [CrossRef]

- Niveditha, M.; Palanisamy, T. Oxalic Acid Optimization for Iron-Based Solid Waste Conversion into a Carbon-Sequestering Composite Building Material. Sustain. Chem. Pharm. 2025, 43, 101875. [Google Scholar]

- Zhao, W.; Qian, G.; Yang, Q. Sustainable Pavement Design: A Comprehensive Study on Incorporating 100% Recycled Asphalt Pavement and Utilizing 100% Industrial Solid Waste. Constr. Build. Mater. 2025, 462, 139972. [Google Scholar] [CrossRef]

- Liu, Y.; Han, F.; Li, N.; Dong, F.; An, C.; Yang, W.; Li, T. Study on the Synergistic Preparation of Functional Soil from Multiple Coal-Based Solid Wastes. Front. Environ. Sci. 2025, 12, 1502552. [Google Scholar] [CrossRef]

- Yu, X.; Yang, K.; He, X.; Hou, Y.; Fang, J.; He, S. Research Progress on Multi-source Coal-Based Solid Waste (Mcsw) Resource Utilization and Backfill Mining Basic Theory: A Systematic Literature Review. Process Saf. Environ. Prot. 2025, 195, 106670. [Google Scholar] [CrossRef]

- Zhang, D.; Hao, Y.; Wen, H.; Sun, W.; Zhai, X. Properties Optimization and Hydration Mechanism of Coal-Based Solid Waste Paste Filling Materials. Powder Technol. 2025, 455, 120751. [Google Scholar] [CrossRef]

- Santra, N.; Ghosh, T.; Kayal, N. Fabrication and Characterization of Silicon Carbide Ceramic Filtration Media via Recycling of Waste Red Mud. Int. J. Appl. Ceram. Technol. 2025, 22, e14908. [Google Scholar] [CrossRef]

- Lv, T.; Zhang, J.; Hou, D.; Long, W.-J.; Dong, B. Mechanical-Thermal Activated Dredged Sludge as a Supplementary Cementitious Material: Microstructure Reconstruction and Pozzolanic Activity Enhancement. Constr. Build. Mater. 2025, 476, 141256. [Google Scholar] [CrossRef]

- Wang, J.; Miao, J.; Shi, D.; Zhang, J.; Zhao, Y.; Xia, Y. Sustainable Stabilization/Solidification of Electroplating Sludge Using a Low-Carbon Ternary Cementitious Binder. J. Environ. Chem. Eng. 2025, 13, 115022. [Google Scholar] [CrossRef]

- Ma, X.; Yang, Y. Single-Component Low-Carbon Sustainable Geopolymer Synthesis Using Calcium Carbide Residue, Gypsum, Sewage Sludge Ash, And Ground Granulated Blast Slag. Sustain. Mater. Technol. 2025, 43, e01314. [Google Scholar] [CrossRef]

- Xiao, X.; Santoso, H.S.; Unluer, C.; Yang, E.-H. The Use of Waste Concrete Sludge as Alkali Source to Recover Reactive Mgo from Reject Brine. Desalination 2025, 600, 118470. [Google Scholar] [CrossRef]

- Jie, W.; Yuehua, L. Application of Concrete Produced from Reused Ready-Mixed Concrete Wastewater Filtration Residue. J. Mater. Res. Technol. 2023, 25, 2826–2840. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S.; Zheng, W. Innovative reuse of concrete slurry waste from ready-mixed concrete plants in construction products. J. Hazard. Mater. 2016, 312, 65–72. [Google Scholar] [CrossRef]

- Singh, V.; Singh, A. Briquetting Technologies for Minerals and Metallurgical Applications: A Review. Miner. Process. Extr. Metall. Rev. 2025, 1–20. [Google Scholar] [CrossRef]

- Mandolia, R.; Kalla, P.; Nagar, R.; Khichad, J.S. Effect of Fine Aggregate Replacement with Limestone Slurry Waste in Self Compacting Concrete: A Microstructural Approach. Mater. Lett. 2025, 381, 137779. [Google Scholar] [CrossRef]

- Hlaváček, O.; Vagenknechtová, A.; Beňo, Z. The Use of Waste Limestone from Paint Shops for Flue-Gas Desulfurization. Energy Sources Part A Recover. Util. Environ. Eff. 2025, 47, 642–656. [Google Scholar] [CrossRef]

- Pastor, J.L.; Gutierrez, E.; Cano, M.; Tomás, R.; Riquelme, A.; Hino, T. Embankment Construction with Limestone Powder Waste: From Laboratory to Full-Scale Implementation. Transp. Geotech. 2025, 50, 101476. [Google Scholar] [CrossRef]

- Tamta, S.; Chaudhury, R.; Sharma, U.; Hanifa, M.; Thapliyal, P.; Singh, L. Low Lime–low Carbon Cement: Achieving Sustainability Through Reduction of Co2 Emissions and Utilizing Limestone Mining Rejects. Constr. Build. Mater. 2025, 470, 140476. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Bing, Y.; Wu, Y.; Zheng, L.; Ding, H.; Zheng, C.; Su, L. Study on the Mechanics Performance and Deformation Characteristics of Polypropylene Fiber-Reinforced Solid Waste-Based Fill Material. J. Mater. Sci. 2025, 60, 3178–3199. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Bing, Y.; Ding, H.; Zheng, C.; Geng, J.; Wu, Y.; Zheng, L.; Su, L. Study on the Mechanical Properties and Failure Mechanism of Polypropylene Fiber–rubber-Modified Solid Waste-Based Backfill. J. Mater. Sci. 2025, 60, 4053–4077. [Google Scholar] [CrossRef]

- Wulandari, C.; Indah, S.; Bachtiar, V. Combination of Lime Stone and Fly Ash in the Adsorption of Iron (Fe) Metal from Coal Acid Mine Drainage. TEKNOSAINS J. Sains Teknol. Dan Inform. 2025, 12, 34–39. [Google Scholar] [CrossRef]

- Li, T.; Tang, X.; Xia, J. Multi-functional Properties of Low-Carbon Travertine Aggregate Pervious Concrete Modified by Waste Limestone Powder. Dev. Built Environ. 2025, 21, 100590. [Google Scholar] [CrossRef]

- Yeluri, M.; Tarabishi, M.A.; Allena, S. Investigating the Effects of Partial Fly Ash Replacement with Limestone Powder in Concrete. Adv. Civ. Eng. Mater. 2025, 14, 73–89. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wu, Y.; Yu, J.; Pang, H.; Lv, H. Effect of Limestone Powder Fineness on the Physical and Mechanical Performance of Concrete. Materials 2025, 18, 835. [Google Scholar] [CrossRef]

- GB/T 19077-2016/ISO 13320:2009; Particle Size Analysis-Laser Diffraction Methods Cement and Concrete Composites. China Quality Inspection Press: Beijing, China, 2016. (In Chinese)

- GB/T50123-2019; Standard for Geotechnical Testing Method Cement and Concrete Composites. China Quality Inspection Press: Beijing, China, 2019. (In Chinese)

- GB/T 1596-2017; Fly Ash Used for Cement and Concrete Cement and Concrete Composites. China Quality Inspection Press: Beijing, China, 2017. (In Chinese)

- GB/T2419-2024; Test Method for Fluidity of Cement Mortar Cement and Concrete Composites. China Quality Inspection Press: Beijing, China, 2024. (In Chinese)

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method) Cement and Concrete Composites. China Quality Inspection Press: Beijing, China, 2021. (In Chinese)

- GB/T 51003-2014; Technical Code for Application of Mineral Admixtures Cement and Concrete Composites. China Quality Inspection Press: Beijing, China, 2014. (In Chinese)

- Shi, C.; Wang, D.; Jia, H.; Liu, J. Role of Limestone Powder and Its Effect on Durability of Cement-Based Materials. J. Chin. Ceram. Soc. 2017, 45, 1582–1593. (In Chinese) [Google Scholar]

- Enhadji, Y.; Escadeillas, G.; Mouli, M.; Khelafi, H.; Benosman. Influence of Natural Pozzolan, Silica Fume and Limestone Fine on Strength, Acid Resistance and Microstructure of Mortar. Powder Technol. 2014, 254, 314–323. [Google Scholar] [CrossRef]

- Mahi, M.S.H.; Ridoy, T.A.; Nibir, M.F.A.; Sheikh, M.S. Limestone Powder in Concrete Mixes: A Review of Mechanical Enhancements. Smart Green Mater. 2025, 2, 11–21. [Google Scholar] [CrossRef]

- Pera, J.; Husson, S.; Guilhot, B. Influence of Finely Ground Limestone on Cement Hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef]

- Zhang, C.M.; Ramachandran, V.S. Influence of Calcium Carbonate as a Fine Filler on the Hydration of Tricalcium Silicate. J. Chin. Ceram. Soc. 1988, 6, 52–57. [Google Scholar]

- Bentz, D.P. Modeling the Influence of Limestone Filler on Cement Hydration Using CEMHYD3D. Cem. Concr. Compos. 2006, 28, 124–129. [Google Scholar] [CrossRef]

- Weerdt, K.D.; Haha, M.B.; Saout, G.L.; Kjellsen, K.; Justnes, H.; Lothenbach, B. Hydration Mechanisms of Ternary Portland Cements Containing Limestone Powder and Fly Ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Zajac, M.; Rossberg, A.; Saout, G.L.; Lothenbach, B. Influence of Limestone and Anhydrite on the Hydration of Portland Cements. Cem. Concr. Compos. 2014, 46, 99–108. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.; Zhang, Z.; Ma, Y.; Wang, H. Thermal Stability of Limestone Calcined Clay Cement (Lc3) at Moderate Temperatures 100–400 °C. Cem. Concr. Compos. 2023, 135, 104832. [Google Scholar] [CrossRef]

- Hang, S.H.; Lu, D.Y.; Ling, K.; Xu, J.T.; Xu, Z.G. Effects of Dolomite and Limestone Powders on Strength and Hydration of Cement Mortars. J. Chin. Ceram. Soc. 2016, 44, 1126–1133. [Google Scholar]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A Review on Effects of Limestone Powder on the Properties of Concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Das, S.; Aguayo, M.; Dey, V.; Kachala, R.; Mobasher, B.; Sant, G.; Neithalath, N. The Fracture Response of Blended Formulations Containing Limestone Powder: Evaluations Using Two-Parameter Fracture Model and Digital Image Correlation. Cem. Concr. Compos. 2014, 53, 316–326. [Google Scholar] [CrossRef]

- Sathiparan, N.; Subramaniam, D.N. Optimizing Fly Ash and Rice Husk Ash as Cement Replacements on the Mechanical Characteristics of Pervious Concrete. Sustain. Struct. 2025, 5, 000065. [Google Scholar] [CrossRef]

| Test Items (i) | Fineness | Water Requirement Ratio | Loss on Ignition | Moisture Content | SO3 Content |

|---|---|---|---|---|---|

| Indicator requirements | ≤30% | ≤105% | ≤8% | ≤1% | ≤3% |

| Test results | 26% | 102% | 4.1% | 0.9% | 0.6% |

| Test items (ii) | Density | Stability (Reilich method) | Intensity activity Index | SiO2 + Al2O3 + Fe2O3 | |

| Indicator requirements | ≤1% | ≤2.6 g/cm3 | ≤5 mm | ≥70% | ≥70% |

| Test results | 0.2% | 2.4 g/cm3 | 2.1 mm | 71.52% | 74.5% |

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2Oeq | Loss | Cl− | |

|---|---|---|---|---|---|---|---|---|---|---|

| Content | 22.89 | 4.58 | 3.51 | 64.05 | 2.15 | 2.40 | 0.52 | 0.90 | 1.13 | 0.012 |

| Fineness | Density | Specific Surface Area | Standard Consistency | Stability (Lei’s Method) | Setting Time | 3-Day | ||

|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Coagulation | Flexural Strength | Compressive Strength | |||||

| 0.9% | 3.15 g/cm3 | 341 m2/kg | 24.8% | 0.1 mm | 140 min | 189 min | 5.4 MPa | 26.2 MPa |

| SiO2 | Moisture Content | Mud Content | Firing Loss | Cl- | Float Content |

|---|---|---|---|---|---|

| >98% | ≤0.18% | ≤0.18% | <0.47% | ≤0.0070% | ≤0.0020 |

| Serial Number | Cement /g | Composite Admixture/g | ISO Sand /g | Water /g | Remarks | |

|---|---|---|---|---|---|---|

| FA | LMDFR | |||||

| DZ | 450 ± 2 | 0 | 0 | 1350 ± 2 | 225 ± 1 | Without admixtures |

| F | 315 ± 1 | 135 | 0 | 1350 ± 2 | 225 ± 1 | FA only |

| FS0.25 | 315 ± 1 | 101.25 | 33.75 | 1350 ± 2 | 225 ± 1 | LMDFR:FA = 1:3 |

| FS0.5 | 315 ± 1 | 67.5 | 67.5 | 1350 ± 2 | 225 ± 1 | LMDFR:FA = 1:1 |

| FS0.75 | 315 ± 1 | 33.75 | 101.25 | 1350 ± 2 | 225 ± 1 | LMDFR:FA = 3:1 |

| S | 315 ± 1 | 0 | 135 | 1350 ± 2 | 225 ± 1 | LMDFR only |

| NO. | Serial Number | Transverse | Longitudinal | Mean Mobility | Flow Ratio |

|---|---|---|---|---|---|

| 1 | DZ | 163 | 172 | 168 | 100.00% |

| 2 | F | 170 | 170 | 170 | 101.19% |

| 3 | FS0.25 | 171 | 171 | 171 | 101.79% |

| 4 | FS0.5 | 175 | 184 | 180 | 106.85% |

| 5 | FS0.75 | 188 | 182 | 185 | 110.12% |

| 6 | S | 191 | 187 | 189 | 112.50% |

| Serial Number | Flexural Strength/MPa | Compressive Strength/MPa | Activity Index | |||

|---|---|---|---|---|---|---|

| 7-Day | 28-Day | 7-Day | 28-Day | 7-Day | 28-Day | |

| DZ | 6.5 | 7.4 | 39.1 | 44.6 | 100.00% | 100.00% |

| F | 5.5 | 6.3 | 27.3 | 31.9 | 69.82% | 71.52% |

| FS0.25 | 5.2 | 7.3 | 37.0 | 29.9 | 94.63% | 67.04% |

| FS0.5 | 5.3 | 6.9 | 38.9 | 37.1 | 99.49% | 83.18% |

| FS0.75 | 5.6 | 6.5 | 31.2 | 33.3 | 79.80% | 74.66% |

| S | 5.3 | 6.7 | 34.2 | 27.3 | 87.47% | 61.21% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Wang, J. Experimental Study on the Application of Limestone Mine Dust Filter Slag as Concrete Admixture. Materials 2025, 18, 3970. https://doi.org/10.3390/ma18173970

Liang Y, Wang J. Experimental Study on the Application of Limestone Mine Dust Filter Slag as Concrete Admixture. Materials. 2025; 18(17):3970. https://doi.org/10.3390/ma18173970

Chicago/Turabian StyleLiang, Yuehua, and Jie Wang. 2025. "Experimental Study on the Application of Limestone Mine Dust Filter Slag as Concrete Admixture" Materials 18, no. 17: 3970. https://doi.org/10.3390/ma18173970

APA StyleLiang, Y., & Wang, J. (2025). Experimental Study on the Application of Limestone Mine Dust Filter Slag as Concrete Admixture. Materials, 18(17), 3970. https://doi.org/10.3390/ma18173970