Mechanical Properties of Bio-Printed Mortars with Bio-Additives for Green and Sustainable Construction

Abstract

1. Introduction

2. Materials and Methods

2.1. Selected Materials

2.2. Development of Mortars

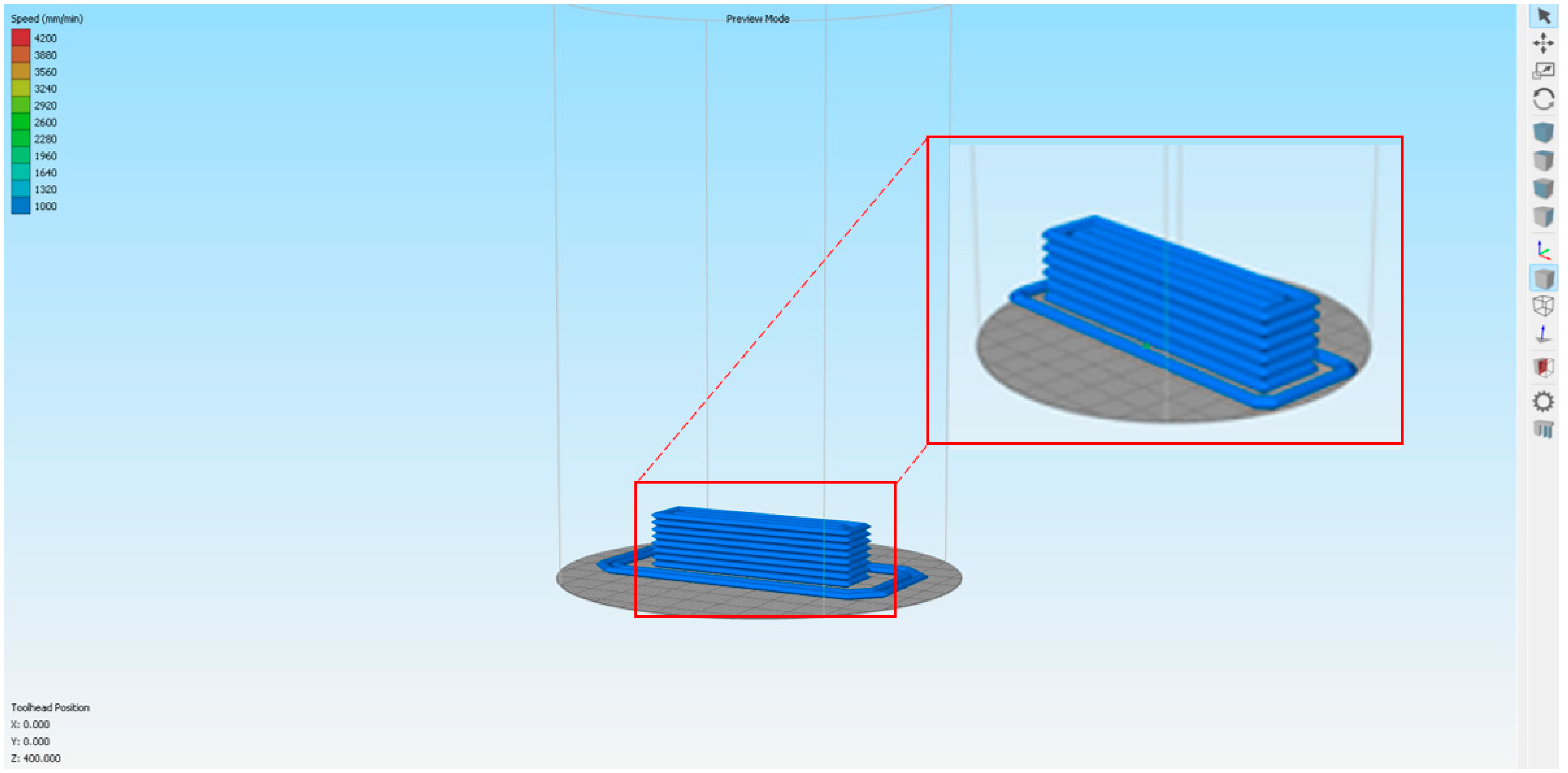

2.3. Design of the Specimens

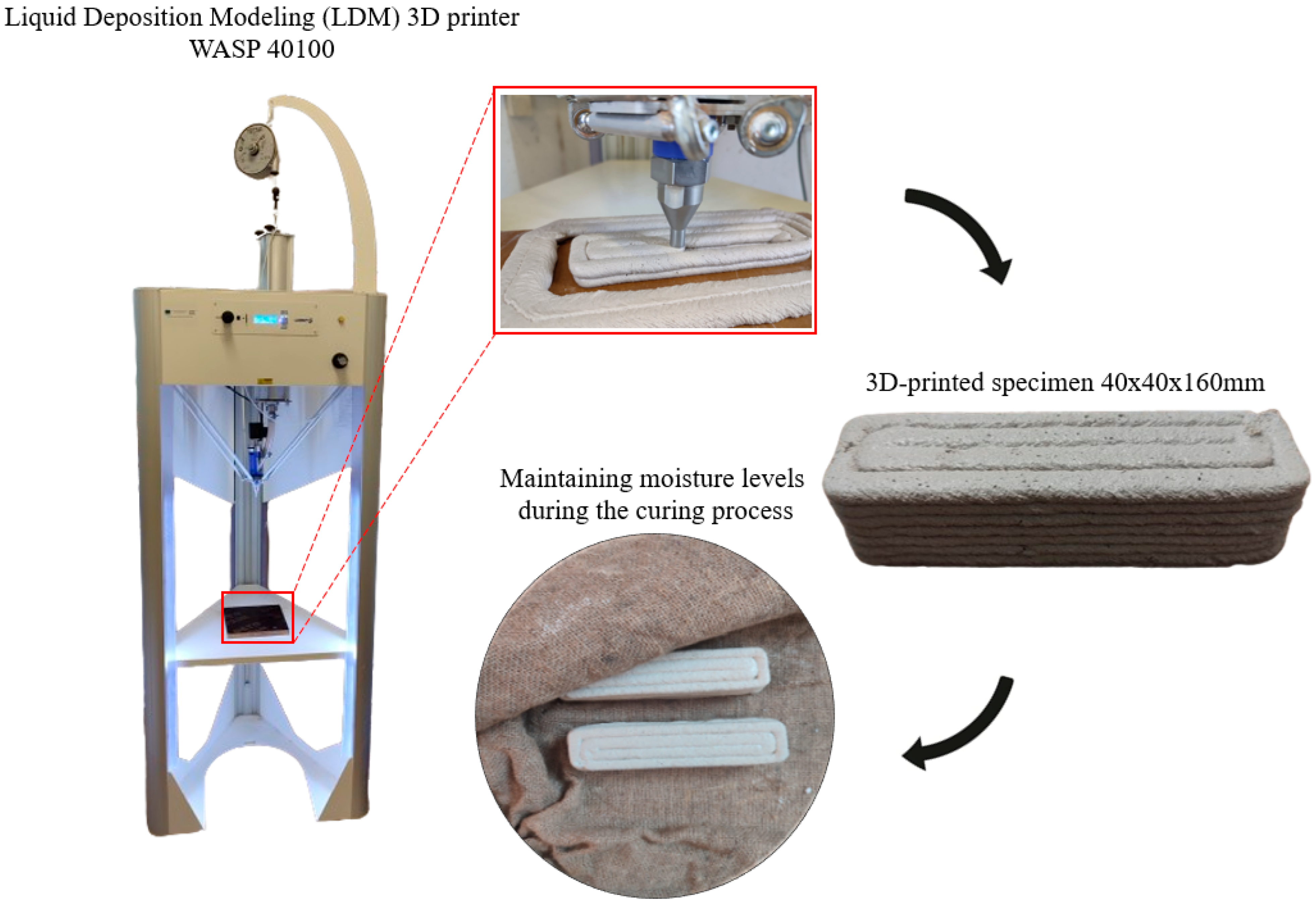

2.4. Three-Dimensional Printing of the Developed Mortars

2.5. Molded Specimens—Casting Procedure

2.6. Conducted Measurements

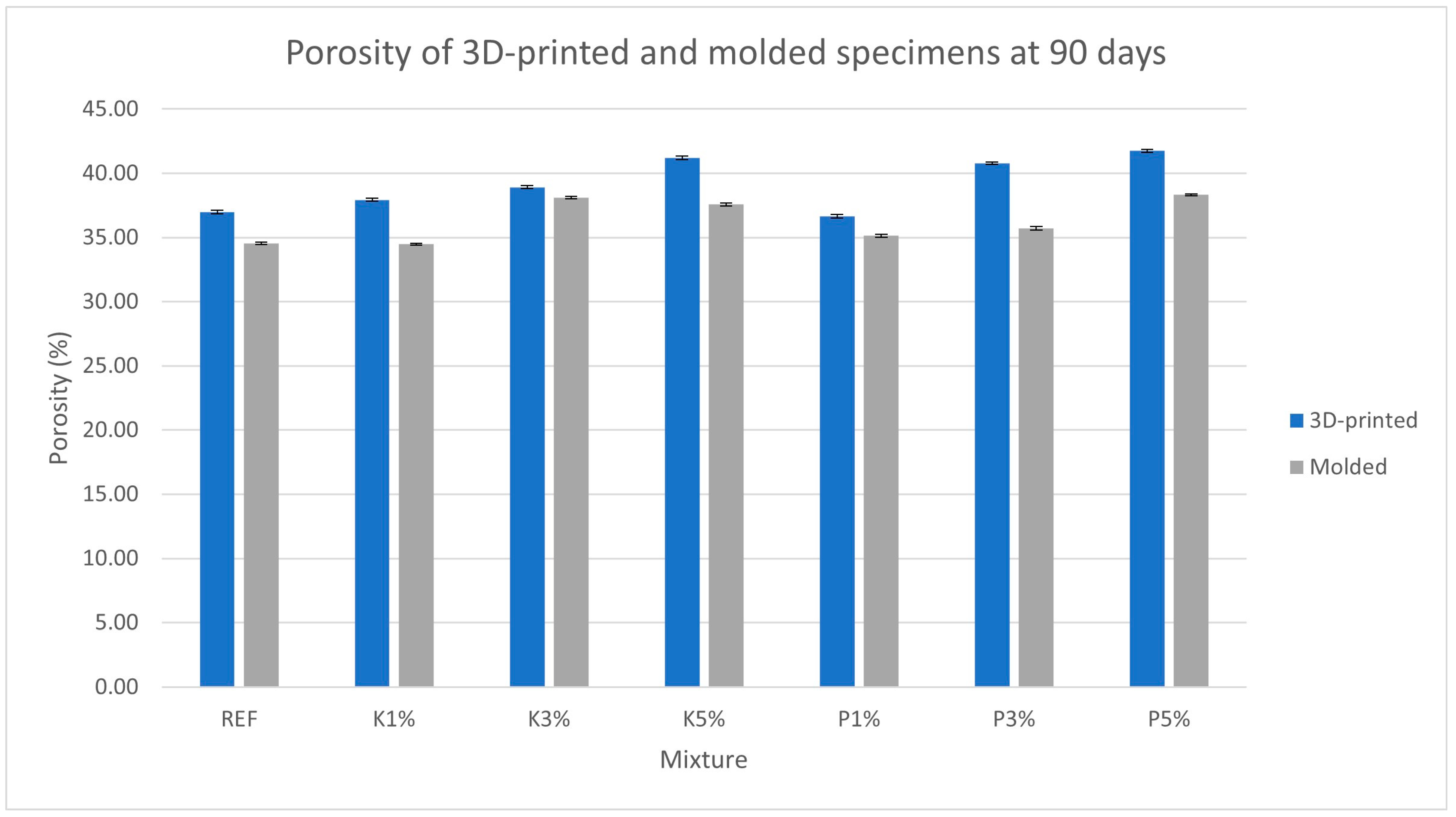

2.6.1. Physical Properties

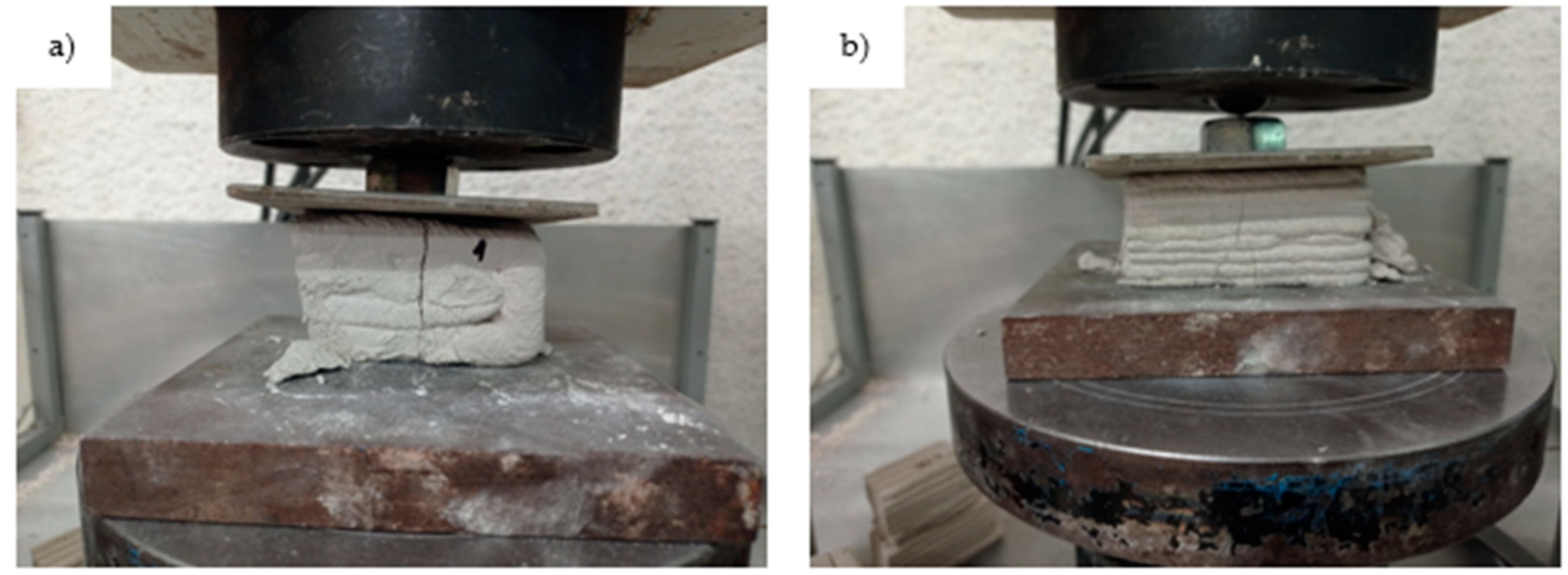

2.6.2. Flexural and Compressive Strength

2.6.3. Stereoscopic Analysis

3. Results

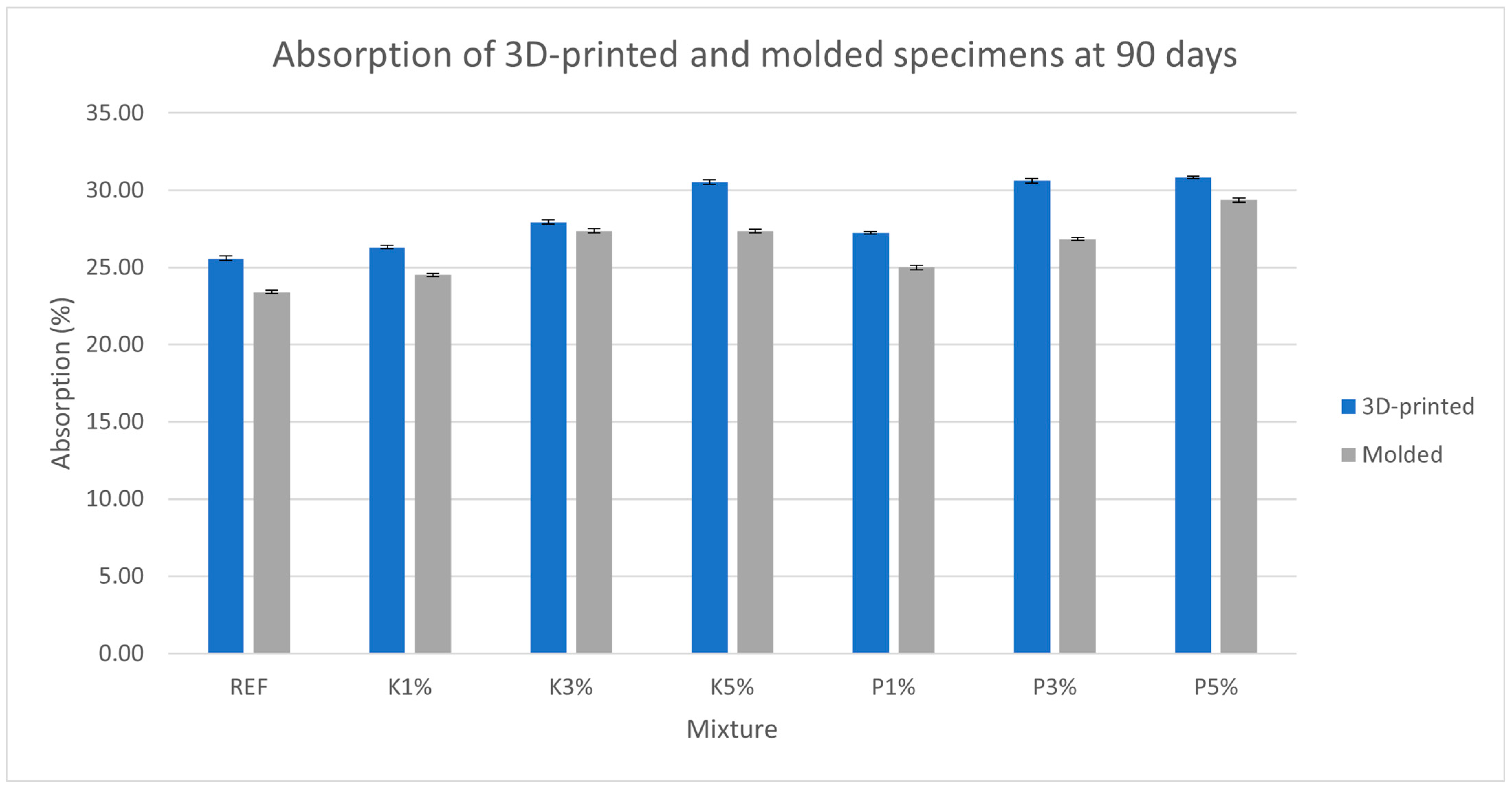

3.1. Physical Properties

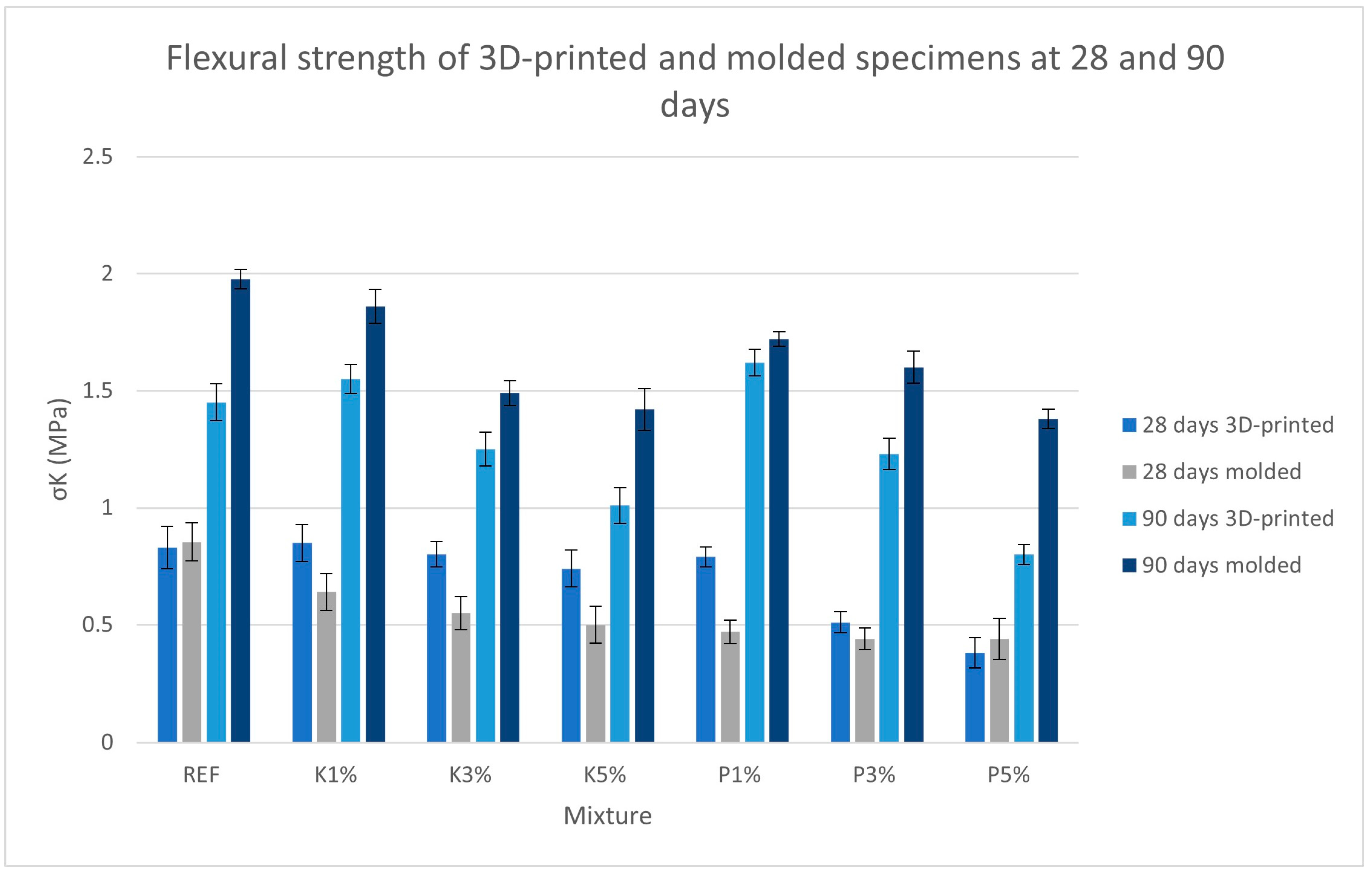

3.2. Flexural Strength

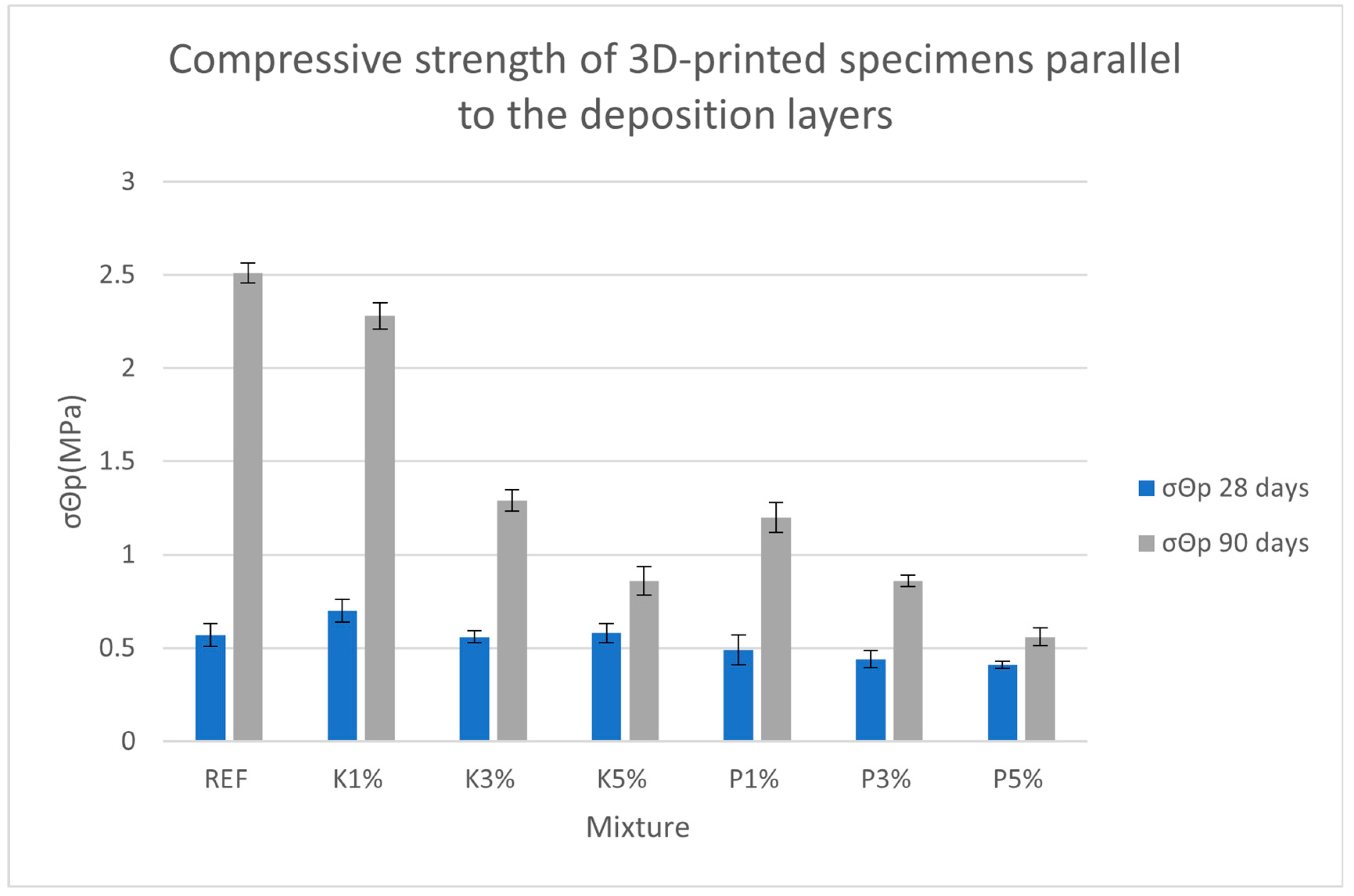

3.3. Compressive Strength

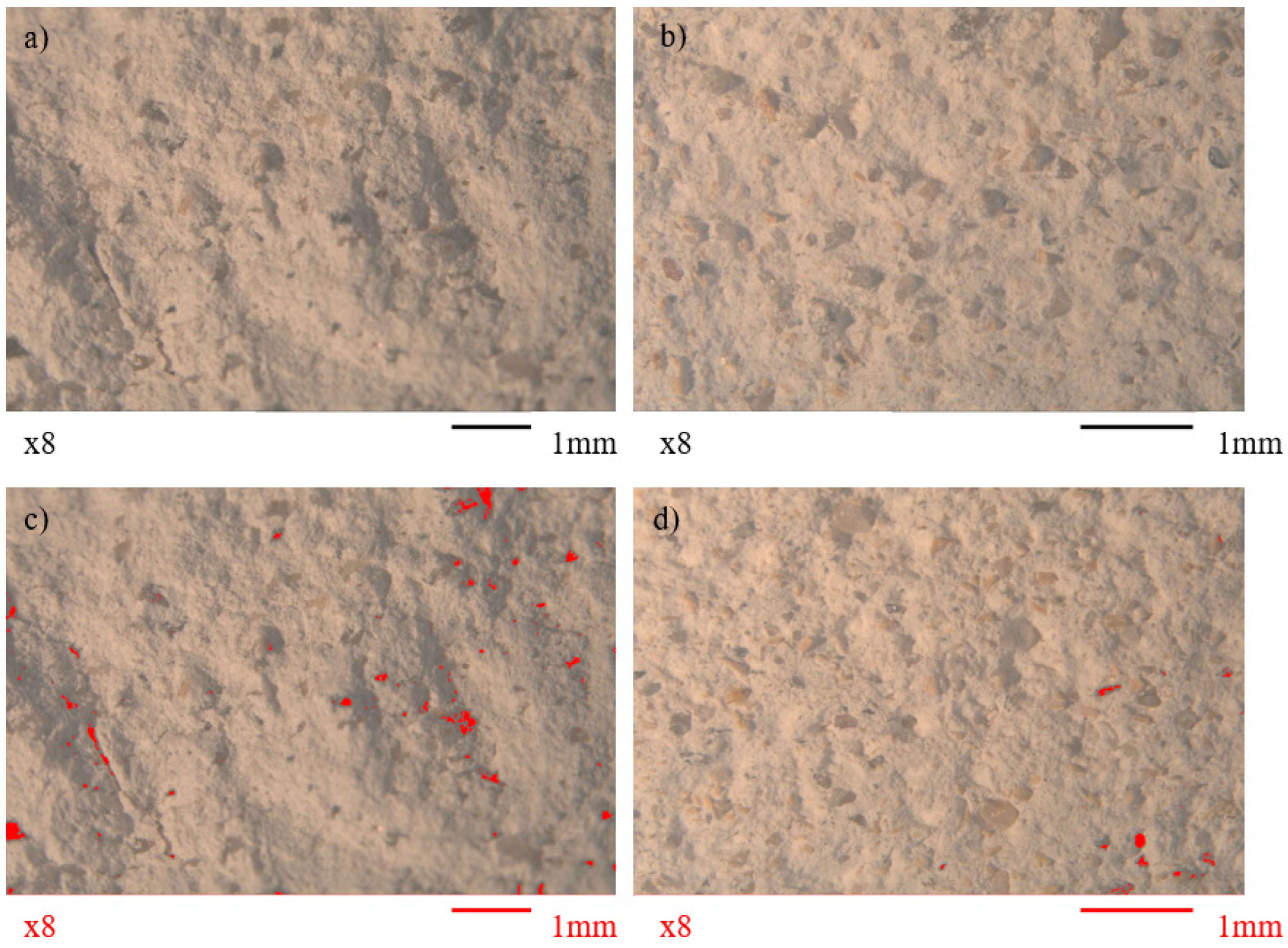

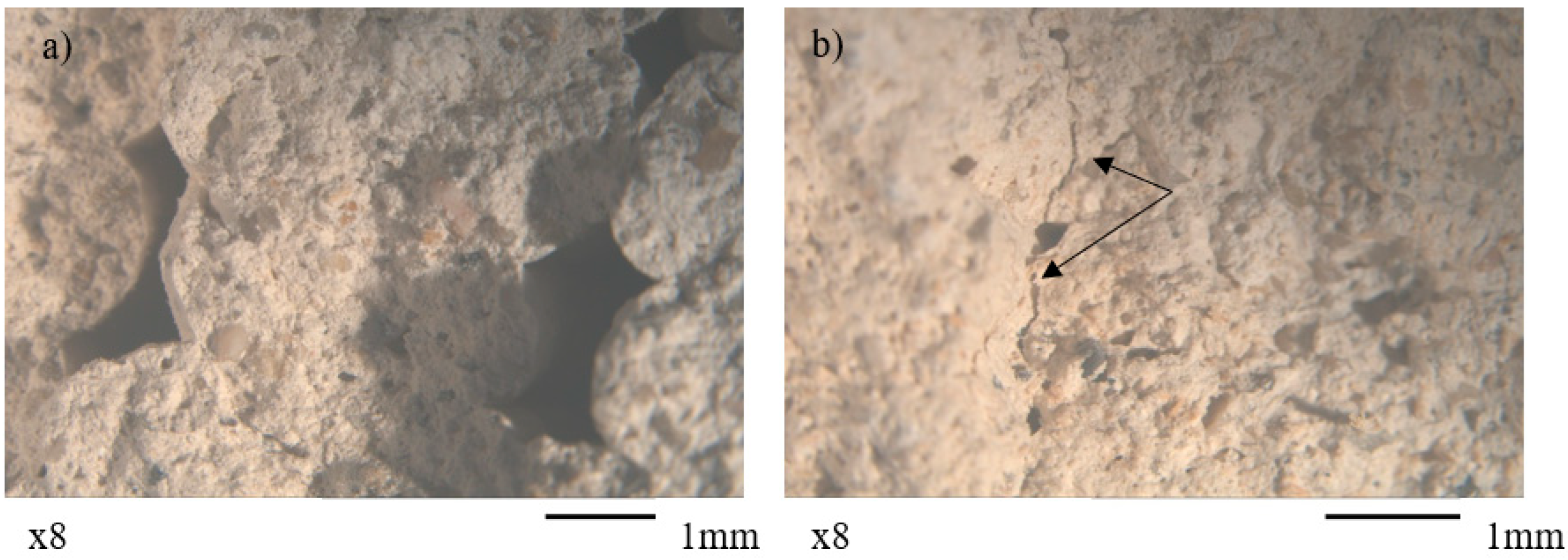

3.4. Stereoscopic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohsen, M.O.; Al-Diseet, M.M.; Aburumman, M.O.; Taha, R.; Taqa, A.A.; Senouci, A.; Naji, K. 3D-Printed Clay Enhanced with Graphene Nanoplatelets for Sustainable and Green Construction. Buildings 2023, 13, 2321. [Google Scholar] [CrossRef]

- Tabassum, T.; Ahmad Mir, A. A review of 3d printing technology-the future of sustainable construction. Mater. Today Proc. 2023, 93, 408–414. [Google Scholar] [CrossRef]

- Pemas, S.; Kladovasilakis, N.; Pechlivani, E.M.; Natsios, I.; Melidis, L.; Chortis, A.; Konstantinidis, A.A.; Katakalos, K.; Tzetzis, D.; Tzovaras, D.; et al. Utilizing LDPE as a Second Life of Waste Plastic Through Pellet Extruder 3D Printing. In The Supply Chains; Kostavelis, I., Folinas, D., Aidonis, D., Achillas, C., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 26–38. [Google Scholar]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Pemas, S.; Sougioultzi, K.; Kouroutzidou, C.; Stefanidou, M.; Konstantinidis, A.A.; Pechlivani, E.M. Enhancing Clay-Based 3D-Printed Mortars with Polymeric Mesh Reinforcement Techniques. Polymers 2024, 16, 2182. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Li, S.; Duan, Y.; Du, Z.; Zuo, X.; Dong, J.; Cheng, H. Influence of Printing Interval on the Imbibition Behavior of 3D-Printed Foam Concrete for Sustainable and Green Building Applications. Sustainability 2024, 16, 7841. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Pemas, S.; Pechlivani, E.M. Computer-Aided Design of 3D-Printed Clay-Based Composite Mortars Reinforced with Bioinspired Lattice Structures. Biomimetics 2024, 9, 424. [Google Scholar] [CrossRef] [PubMed]

- Pemas, S.; Gkiliopoulos, D.; Samiotaki, C.; Bikiaris, D.N.; Terzopoulou, Z.; Pechlivani, E.M. Valorization of Tomato Agricultural Waste for 3D-Printed Polymer Composites Based on Poly(lactic acid). Polymers 2024, 16, 1536. [Google Scholar] [CrossRef] [PubMed]

- Kladovasilakis, N.; Natsios, I.; Pech-livani, E.M.; Tzetzis, D.; Tzovaras, D. Valorizing Automotive Tire Waste via Additive Manufacturing Technologies. In The Supply Chains; Kostavelis, I., Folinas, D., Aidonis, D., Achillas, C., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 39–51. [Google Scholar]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- El Sakka, F.; Hamzeh, F. 3D Concrete Printing in the Service of Lean Construction. Available online: https://apo.org.au/node/304784 (accessed on 24 February 2025).

- Sriram, M.; Aswin Sidhaarth, K.R. Various properties of natural and artificial fibers with cementitious composites in hybrid form—A review. Mater. Today Proc. 2022, 60, 2018–2025. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar] [CrossRef]

- Liampas, S.; Kladovasilakis, N.; Tsongas, K.; Pechlivani, E.M. Recent Advances in Additive Manufacturing of Fibre-Reinforced Materials: A Comprehensive Review. Appl. Sci. 2024, 14, 10100. [Google Scholar] [CrossRef]

- Nazir, M.H.; Al-Marzouqi, A.H.; Ahmed, W.; Zaneldin, E. The potential of adopting natural fibers reinforcements for fused deposition modeling: Characterization and implications. Heliyon 2023, 9, e15023. [Google Scholar] [CrossRef] [PubMed]

- Dias, J.; Brandão, F.; Figueiredo, B.; Cruz, P. The Potential of Natural Fiber Reinforcement in 3d Printed Concrete: A Review. In Proceedings of the Digital Concrete 2024—Supplementary Proceedings, Munich, Germany, 4–6 September 2024. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Properties of 3D-Printed Polymer Fiber-Reinforced Mortars: A Review. Polymers 2022, 14, 1315. [Google Scholar] [CrossRef] [PubMed]

- Adesanya, D.A. Evaluation of blended cement mortar, concrete and stabilized earth made from ordinary Portland cement and corn cob ash. Constr. Build. Mater. 1996, 10, 451–456. [Google Scholar] [CrossRef]

- Okeke, F.O.; Ahmed, A.; Imam, A.; Hassanin, H. A review of corncob-based building materials as a sustainable solution for the building and construction industry. Hybrid Adv. 2024, 6, 100269. [Google Scholar] [CrossRef]

- Komisyonu, A. The European Green Deal—European Commission. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 26 February 2025).

- Sesana, M.M.; Dell’Oro, P. Sustainability and Resilience Assessment Methods: A Literature Review to Support the Decarbonization Target for the Construction Sector. Energies 2024, 17, 1440. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Akemah, T.; Ben-Alon, L. Developing 3D-Printed Natural Fiber-Based Mixtures. In The Bio-Based Building Materials; Amziane, S., Merta, I., Page, J., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 555–572. [Google Scholar]

- Juárez, C.; Durán, A.; Valdez, P.; Fajardo, G. Performance of “Agave lecheguilla” natural fiber in portland cement composites exposed to severe environment conditions. Build. Environ. 2007, 42, 1151–1157. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Ghaffar, S.H.; Pan, J.; Dai, J.-G. Properties of additively manufactured geopolymer incorporating mineral wollastonite microfibers. Constr. Build. Mater. 2022, 331, 127282. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Łagoda, G.; Gajda, T. Change of Mechanical Properties of Repair Mortars after Frost Resistance Rests. Materials 2021, 14, 3199. [Google Scholar] [CrossRef] [PubMed]

- Netinger Grubeša, I.; Marković, B.; Vračević, M.; Tunkiewicz, M.; Szenti, I.; Kukovecz, Á. Pore Structure as a Response to the Freeze/Thaw Resistance of Mortars. Materials 2019, 12, 3196. [Google Scholar] [CrossRef] [PubMed]

- Maia, J.; Ramos, N.M.M.; Veiga, R. Assessment of test methods for the durability of thermal mortars exposure to freezing. Mater. Struct. 2019, 52, 112. [Google Scholar] [CrossRef]

- Stefanidou, M. Principles of Sustainability in Byzantine Mortar Construction Technology. In The Networks, Markets & People; Calabrò, F., Madureira, L., Morabito, F.C., Piñeira Mantiñán, M.J., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 297–302. [Google Scholar]

- Tsardaka, E.-C.; Stefanidou, M. The different action mechanisms of silica and alumina nanoparticles in lime-pozzolan pastes. Case Stud. Constr. Mater. 2023, 19, e02474. [Google Scholar] [CrossRef]

- EN 1015-11:2019; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. UNI: Milan, Italy, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/14596d4c-119b-4a78-94e1-3fe481a29bde/en-1015-11-2019 (accessed on 6 March 2025).

- EN 1015-3:1999; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee for Standardization: Brussels, Belgium, 1999.

- Recommendation, R. CPC 11.3. Absorption d’eau par immersion sous vide. Matér. Constr. 1984, 17, 391–394. [Google Scholar] [CrossRef]

| Method | Hydrated Lime | Pozzolan | Cypress Wood Shavings | Pine Wood Shavings | |

|---|---|---|---|---|---|

| Density (g/cm3) | Gas pycnometry | 2.4708 | 2.3785 | 1.4398 | 1.4178 |

| Particle size | LD | d (0.1): 1.216 µm d (0.5): 3.326 µm d (0.9): 16.176 µm | d (0.1): 1.498 µm d (0.5): 5.033 µm d (0.9): 33.787 µm | - | - |

| CaO % | XRF | 87.4 | 1.37 | - | - |

| MgO % | XRF | 0.84 | 0.36 | - | - |

| SO3 % | XRF | 0.49 | 0.15 | - | - |

| Fe2O3 % | XRF | 0.08 | 1.34 | - | - |

| Al2O3 % | XRF | 0.03 | 14.60 | - | - |

| SiO2 % | XRF | - | 69.81 | - | - |

| K2O % | XRF | - | 3.02 | - | - |

| Na2O % | XRF | - | 2.87 | - | - |

| TiO2 % | XRF | - | 0.36 | - | - |

| Mortar | Mortar Abbreviation | Hydrated Lime | Pozzolan | River Sand | Water | VM | Superplasticizer | Pine Biofibers | Cypress Biofibers |

|---|---|---|---|---|---|---|---|---|---|

| Hydrated Lime–Pozzolan | REF | 0.5 | 0.5 | 0.5 | 0.40 | 0.5% of binder | 2% of binder | - | - |

| Hydrated Lime–Pozzolan–1% Pine | P1% | 0.5 | 0.5 | 0.5 | 0.41 | 0.5% of binder | 2% of binder | 1% of binder | - |

| Hydrated Lime–Pozzolan–3% Pine | P3% | 0.5 | 0.5 | 0.5 | 0.42 | 0.5% of binder | 2% of binder | 3% of binder | - |

| Hydrated Lime–Pozzolan–5% Pine | P5% | 0.5 | 0.5 | 0.5 | 0.42 | 0.5% of binder | 2% of binder | 5% of binder | - |

| Hydrated Lime–Pozzolan–1% Cypress | K1% | 0.5 | 0.5 | 0.5 | 0.41 | 0.5% of binder | 2% of binder | - | 1% of binder |

| Hydrated Lime–Pozzolan–3% Cypress | K3% | 0.5 | 0.5 | 0.5 | 0.42 | 0.5% of binder | 2% of binder | - | 3% of binder |

| Hydrated Lime–Pozzolan–5% Cypress | K5% | 0.5 | 0.5 | 0.5 | 0.42 | 0.5% of binder | 2% of binder | - | 5% of binder |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pemas, S.; Baliakas, D.; Pechlivani, E.M.; Stefanidou, M. Mechanical Properties of Bio-Printed Mortars with Bio-Additives for Green and Sustainable Construction. Materials 2025, 18, 3375. https://doi.org/10.3390/ma18143375

Pemas S, Baliakas D, Pechlivani EM, Stefanidou M. Mechanical Properties of Bio-Printed Mortars with Bio-Additives for Green and Sustainable Construction. Materials. 2025; 18(14):3375. https://doi.org/10.3390/ma18143375

Chicago/Turabian StylePemas, Sotirios, Dimitrios Baliakas, Eleftheria Maria Pechlivani, and Maria Stefanidou. 2025. "Mechanical Properties of Bio-Printed Mortars with Bio-Additives for Green and Sustainable Construction" Materials 18, no. 14: 3375. https://doi.org/10.3390/ma18143375

APA StylePemas, S., Baliakas, D., Pechlivani, E. M., & Stefanidou, M. (2025). Mechanical Properties of Bio-Printed Mortars with Bio-Additives for Green and Sustainable Construction. Materials, 18(14), 3375. https://doi.org/10.3390/ma18143375