Research on the Milling Characteristics of SBS Modified Asphalt Pavement with Different Service Years Using the Discrete Element Method

Highlights

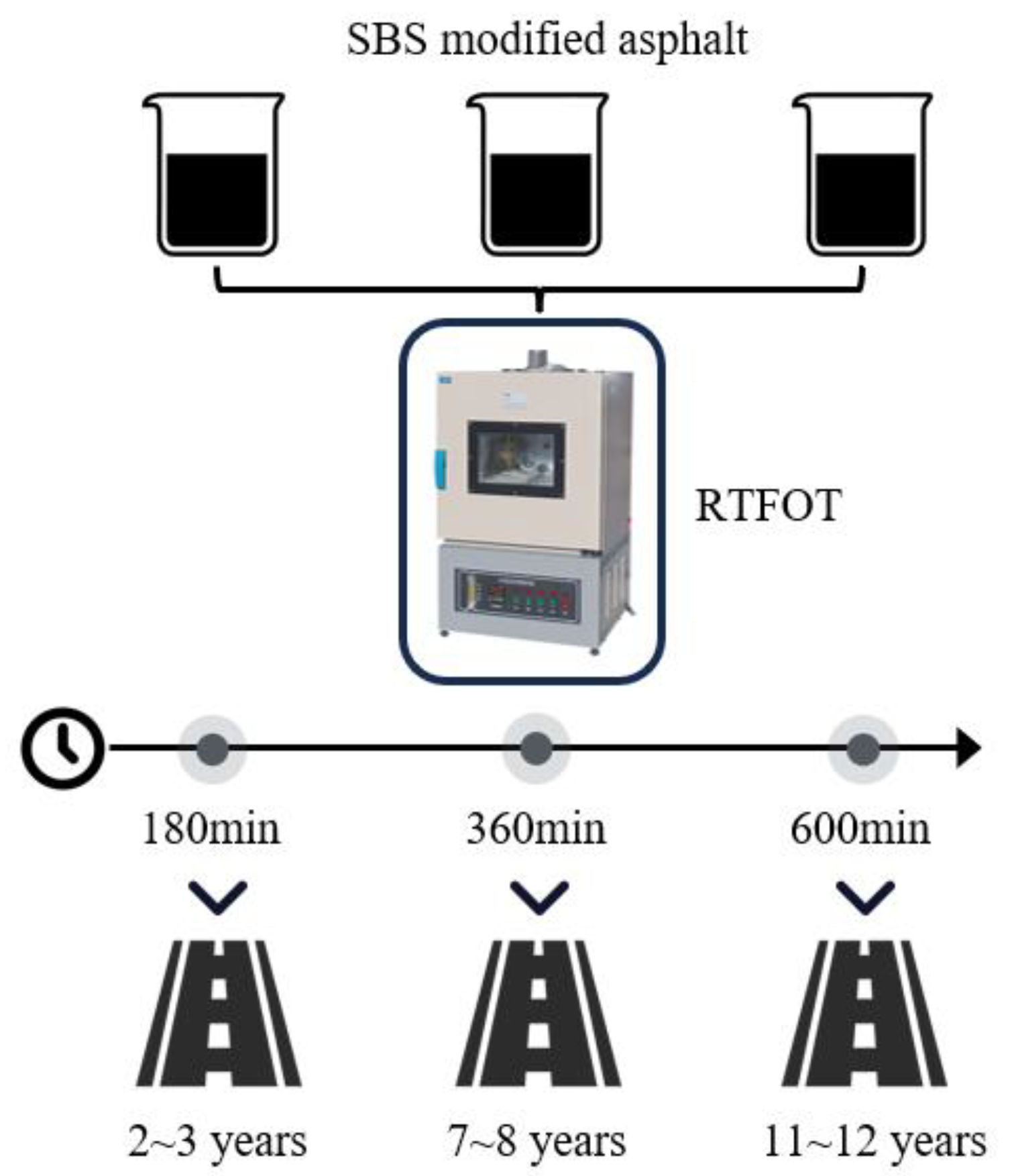

- The relationship between the RTFOT aging time of SBS-modified asphalt and the service years of the pavement was summarized;

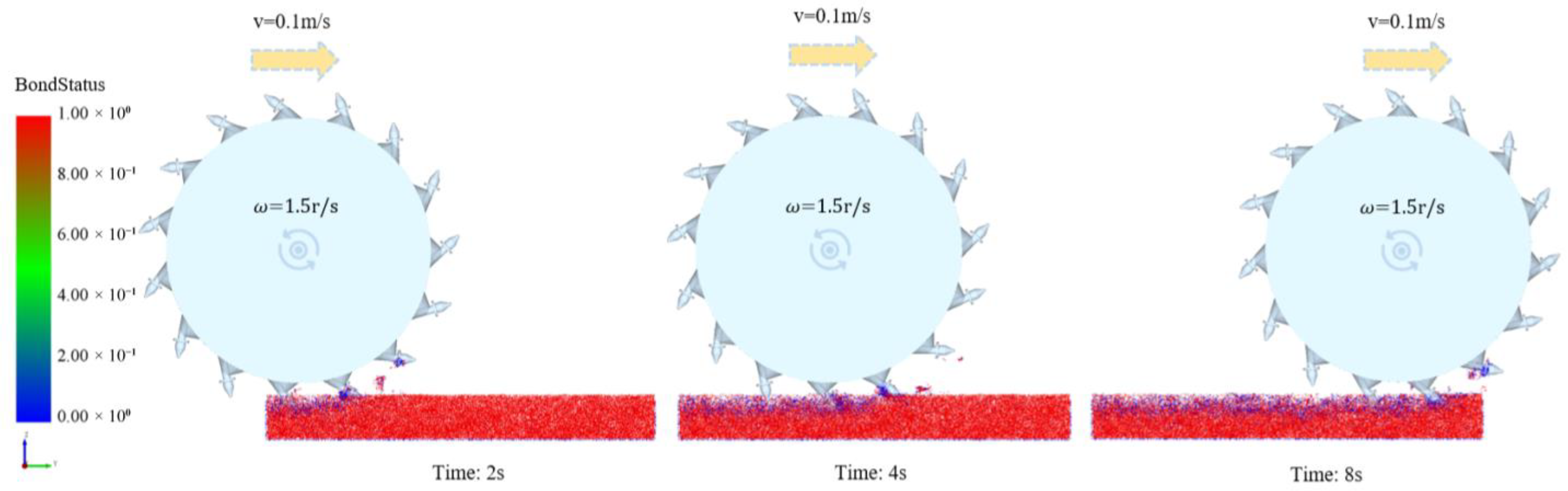

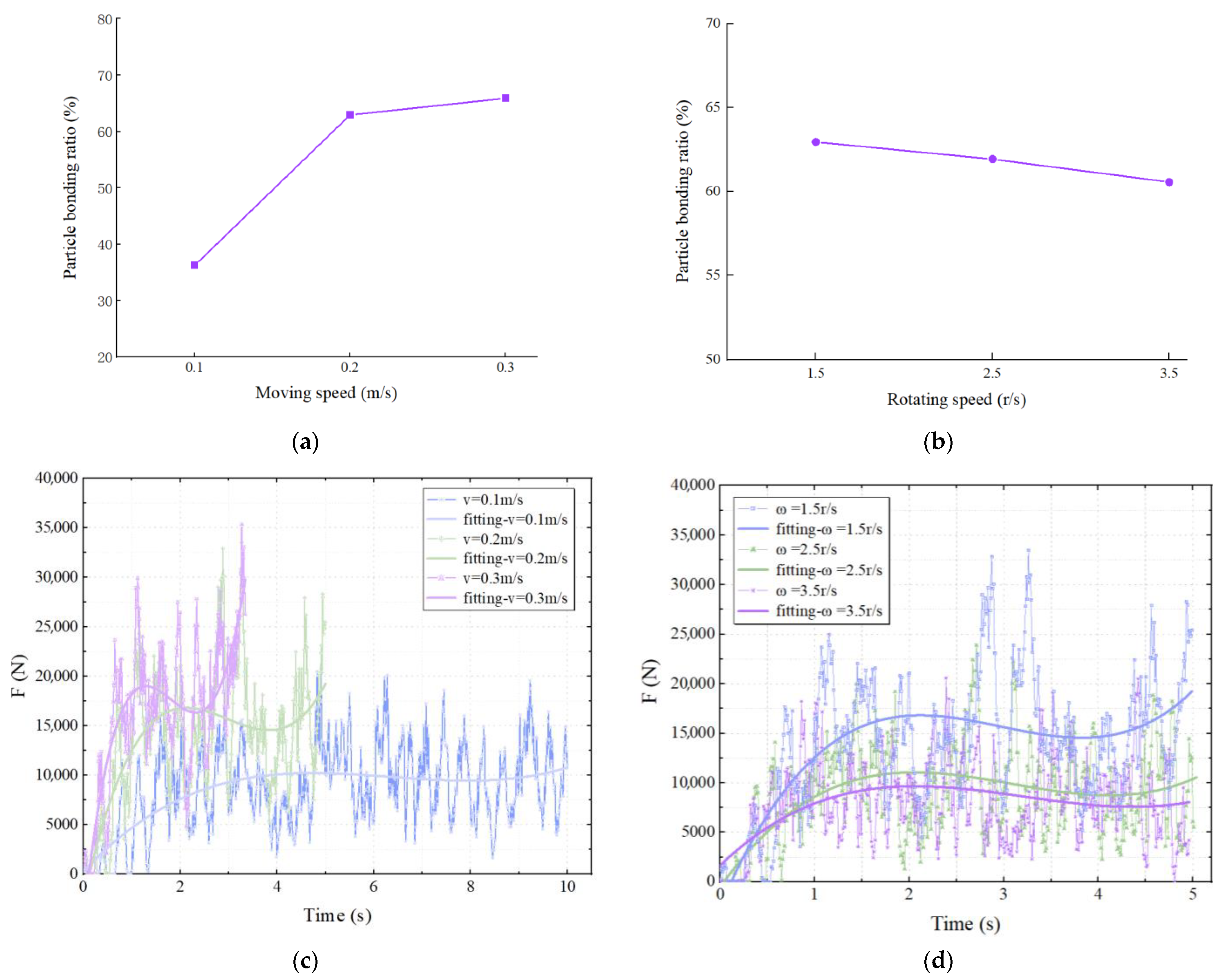

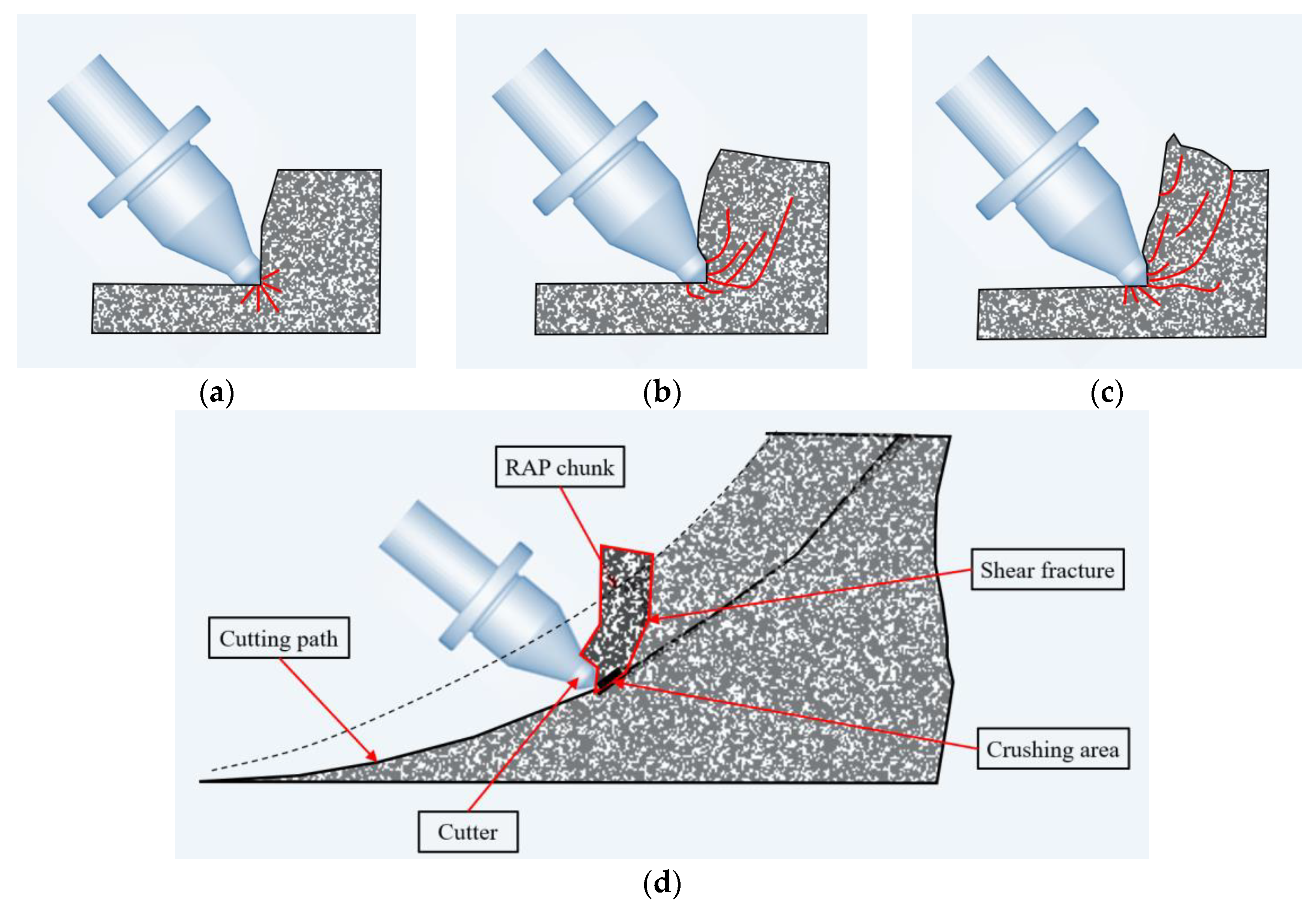

- The influence of the moving speed and rotating speed of the milling rotor on the particle bonding ratio and rotor average force was determined;

- The mechanism underlying the influence of milling parameters and service years on test indexes was analyzed;

- The milling characteristics of SBS-modified asphalt pavements with different service years were investigated.

Abstract

1. Introduction

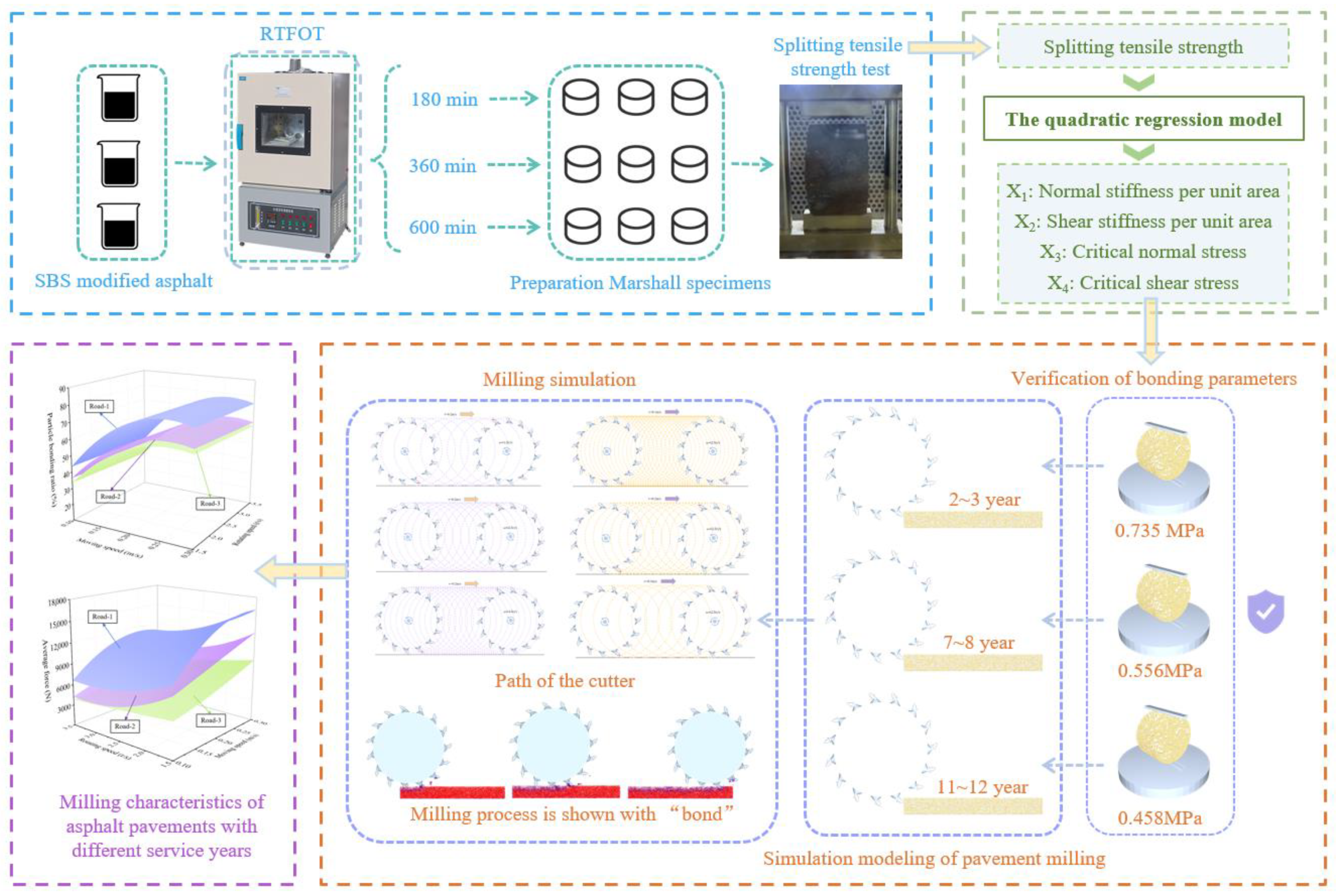

2. Methodology

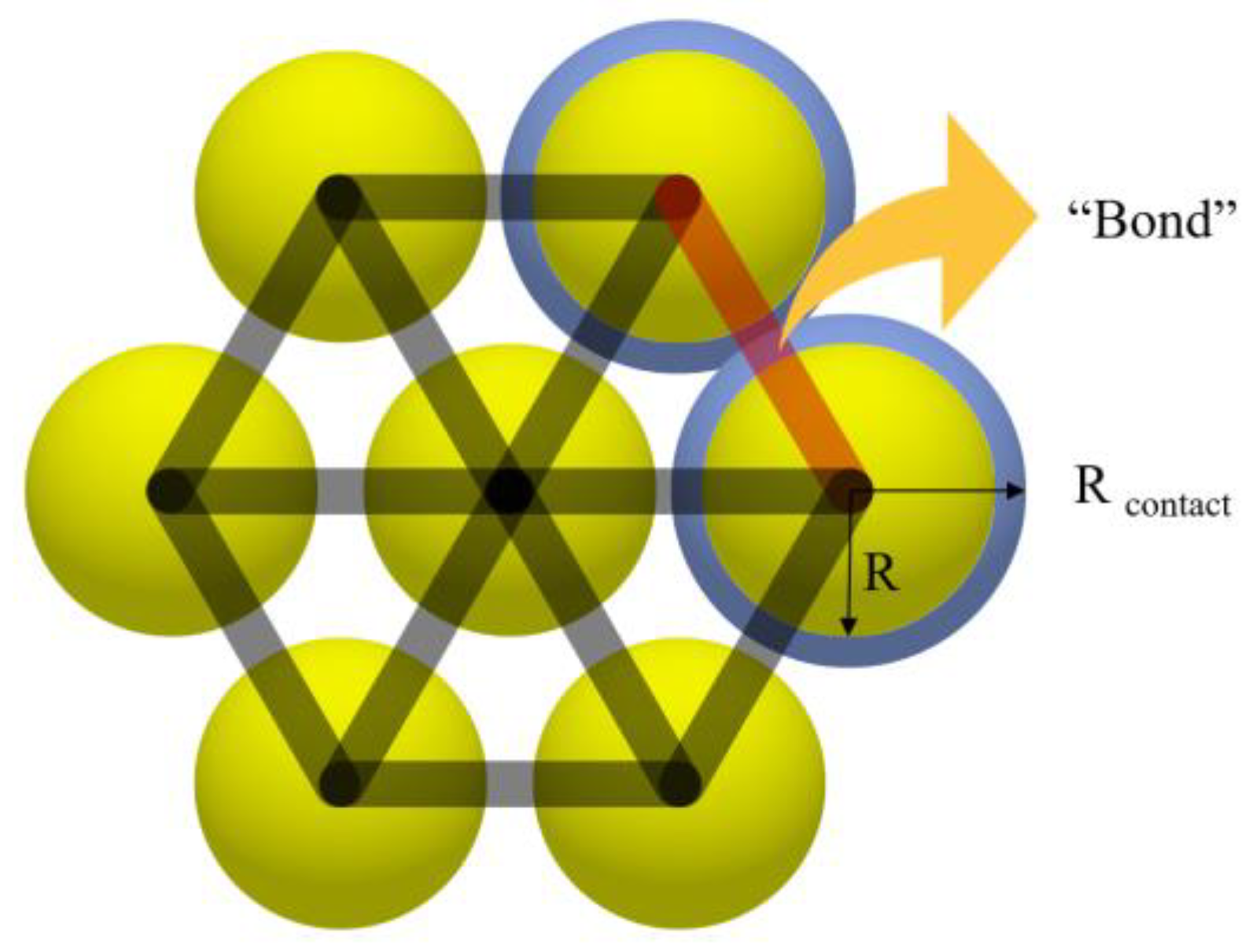

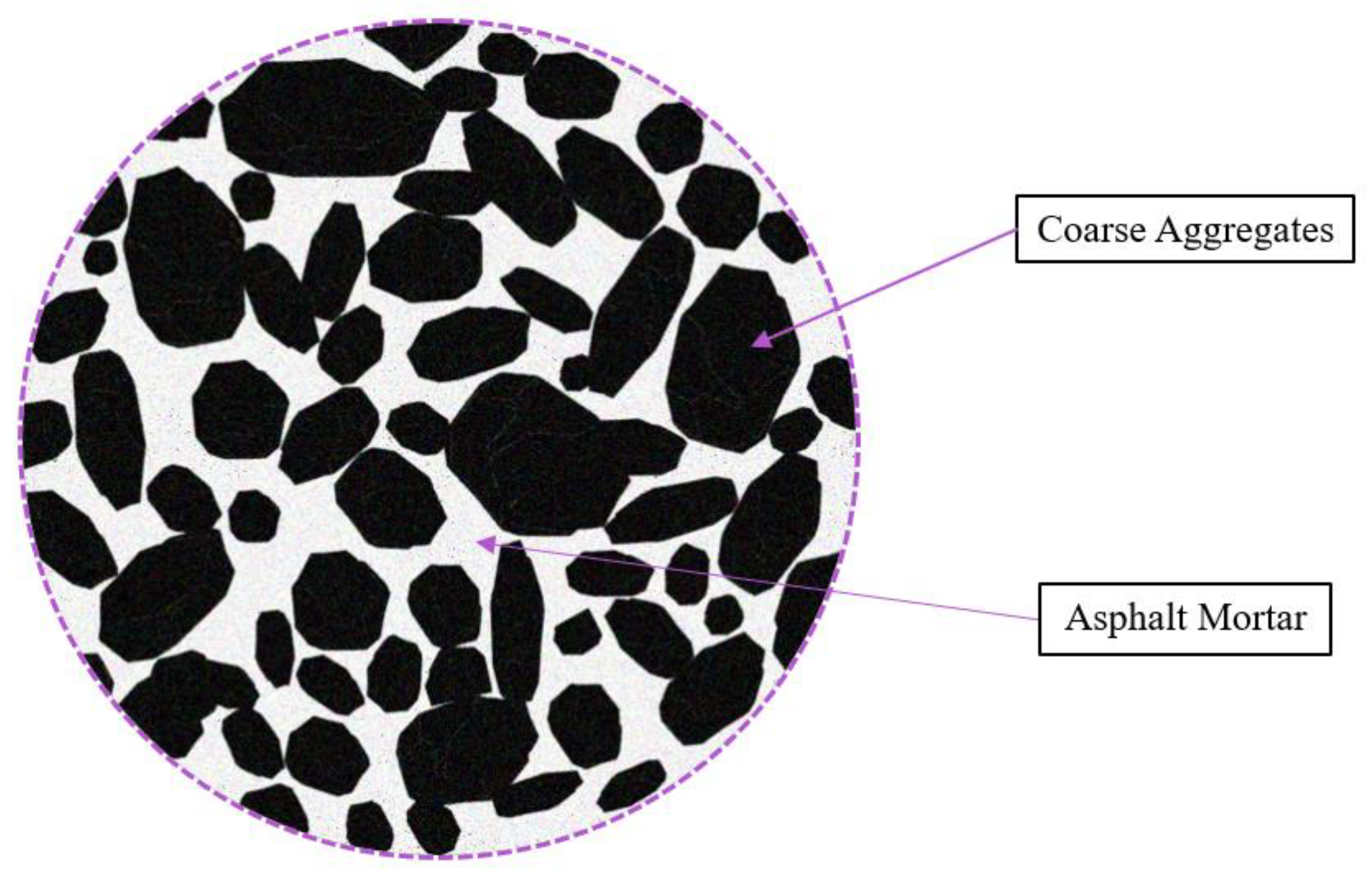

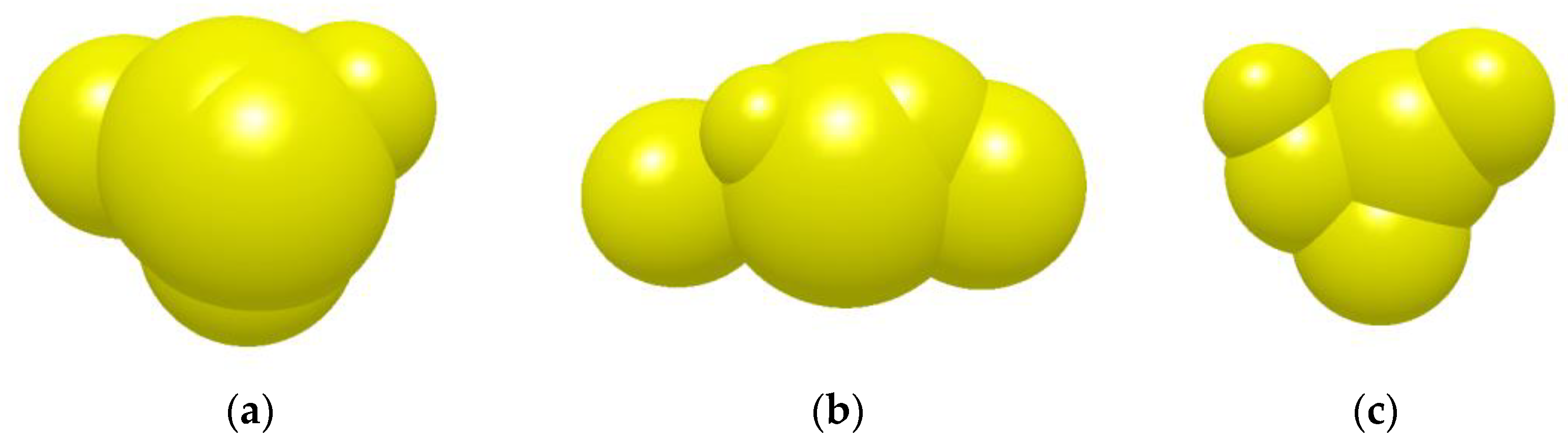

2.1. Calibration of Bonding Parameters for EDEM Simulation Models

2.1.1. Rolling Thin Film Oven Test

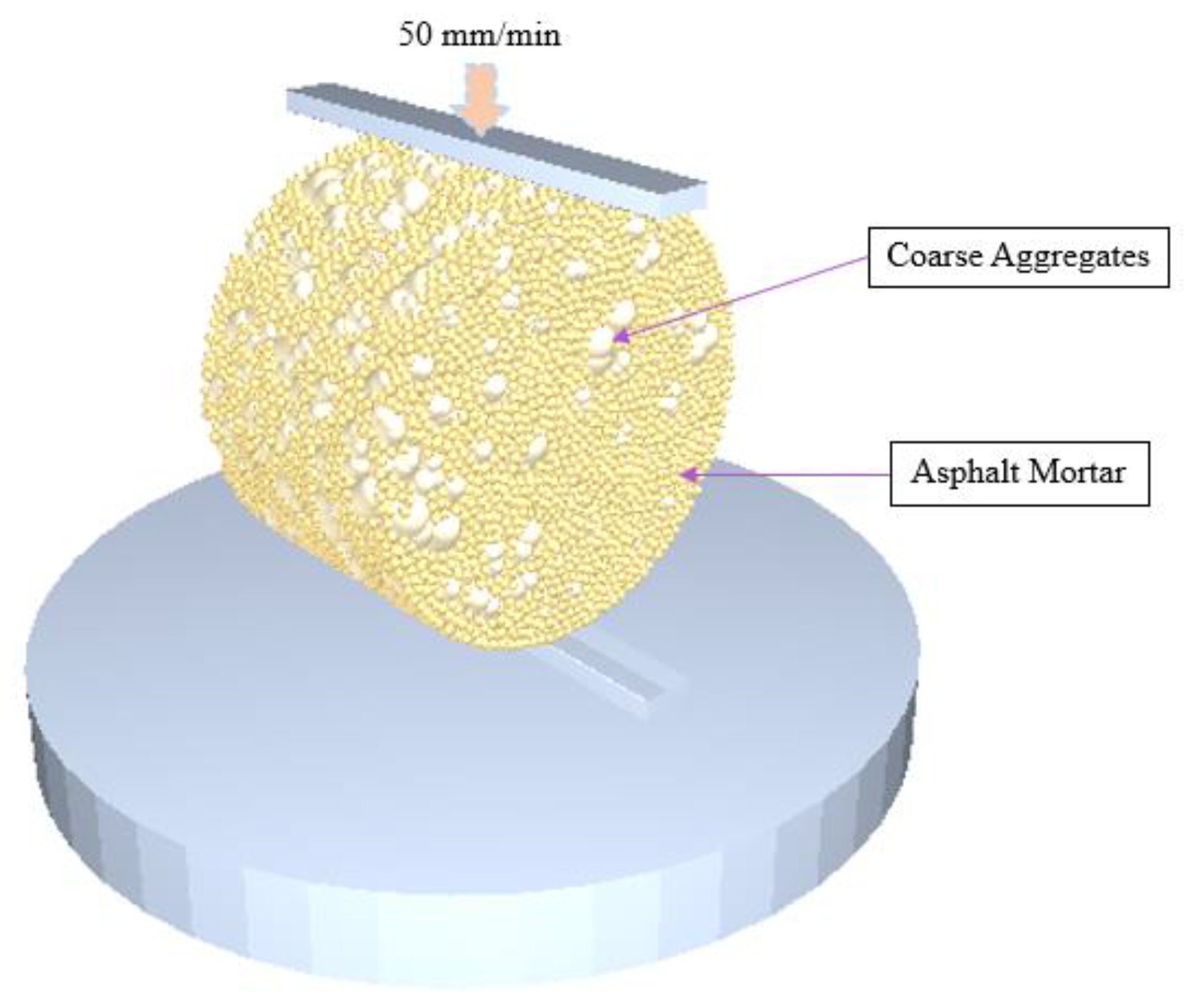

2.1.2. Indoor Splitting Tensile Strength Test

2.1.3. Calibration and Verification of Bonding Parameters

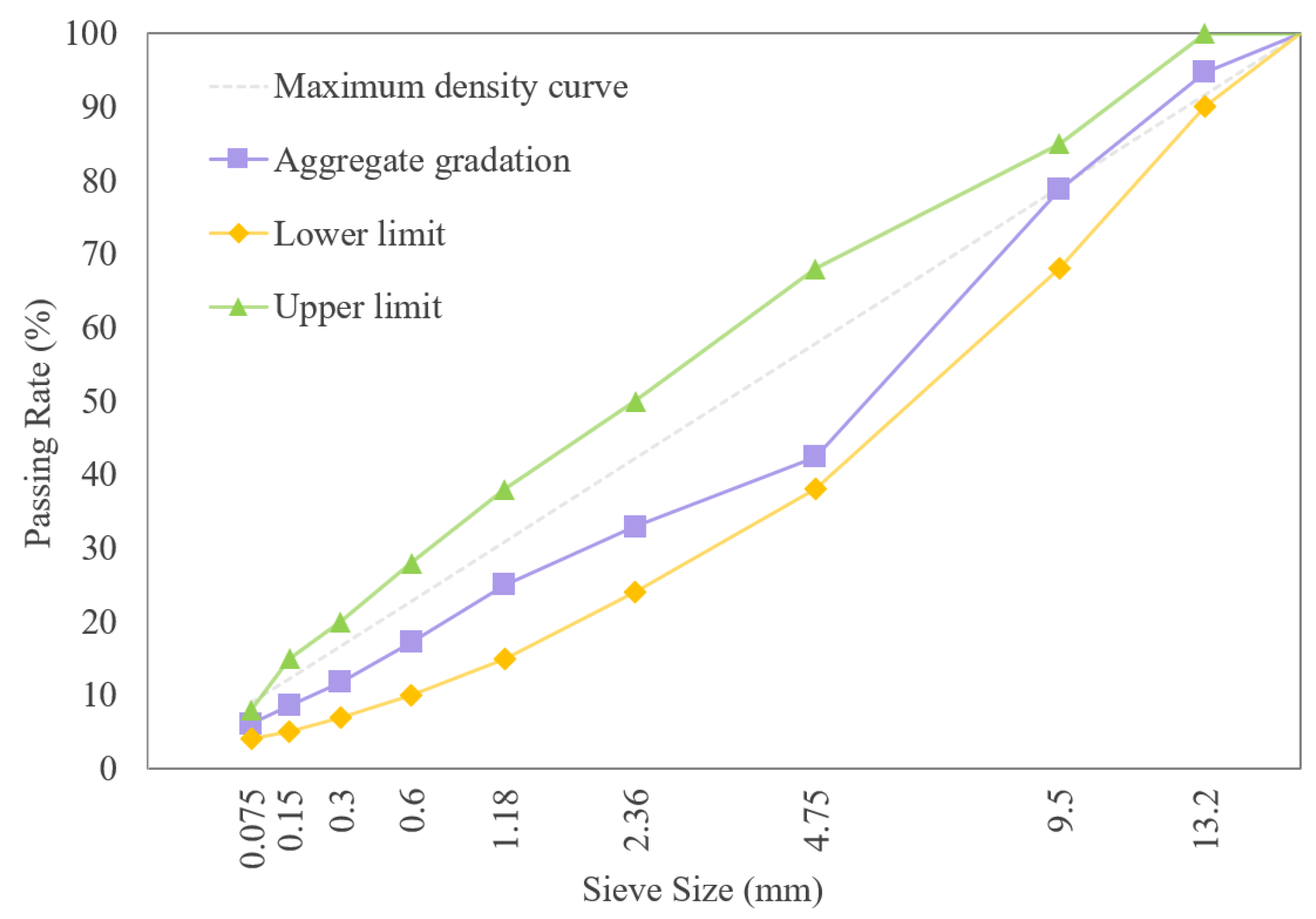

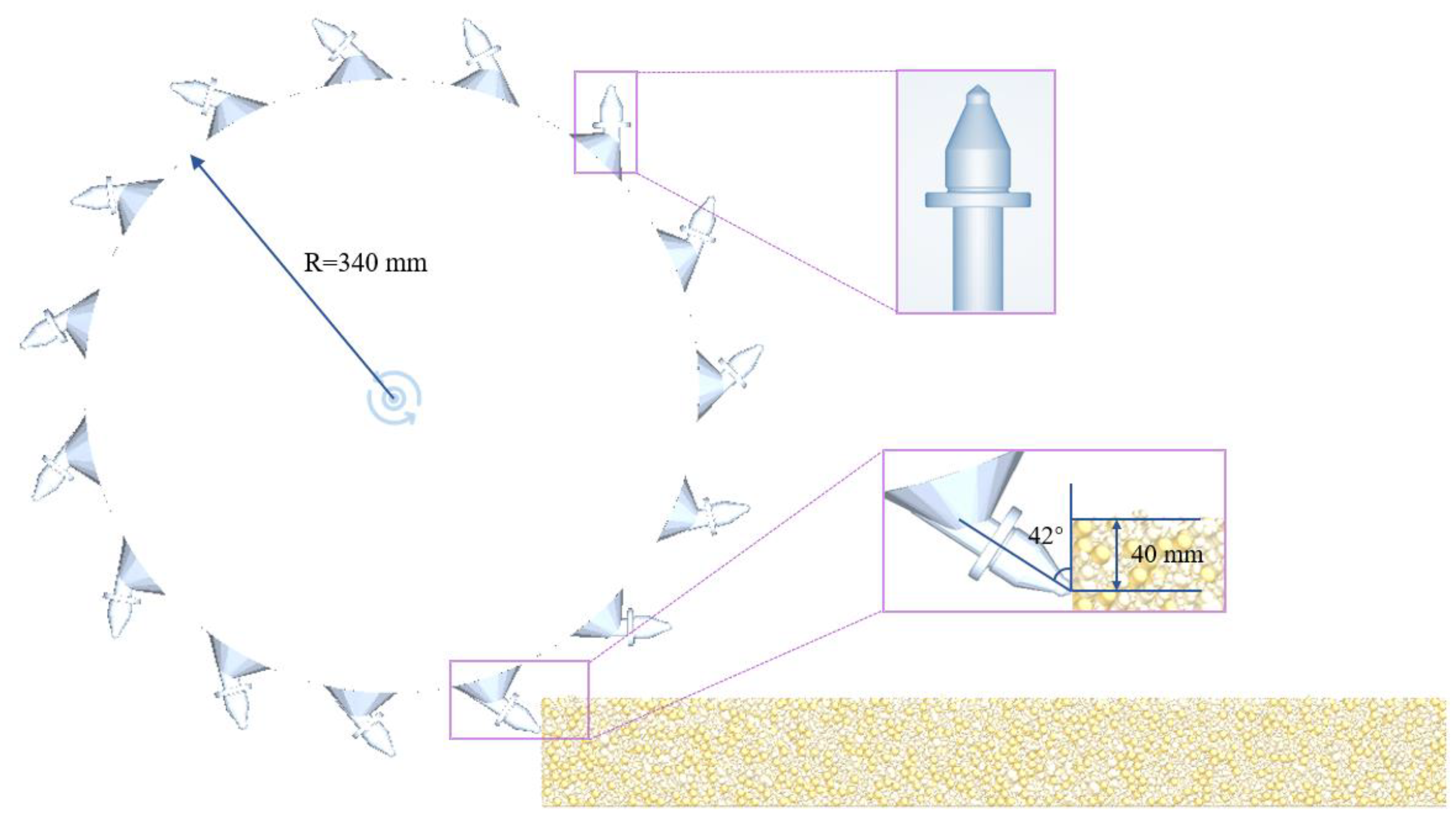

2.2. Research on Milling Characteristics of Old Asphalt Pavement

3. Results and Discussion

4. Conclusions

- (1)

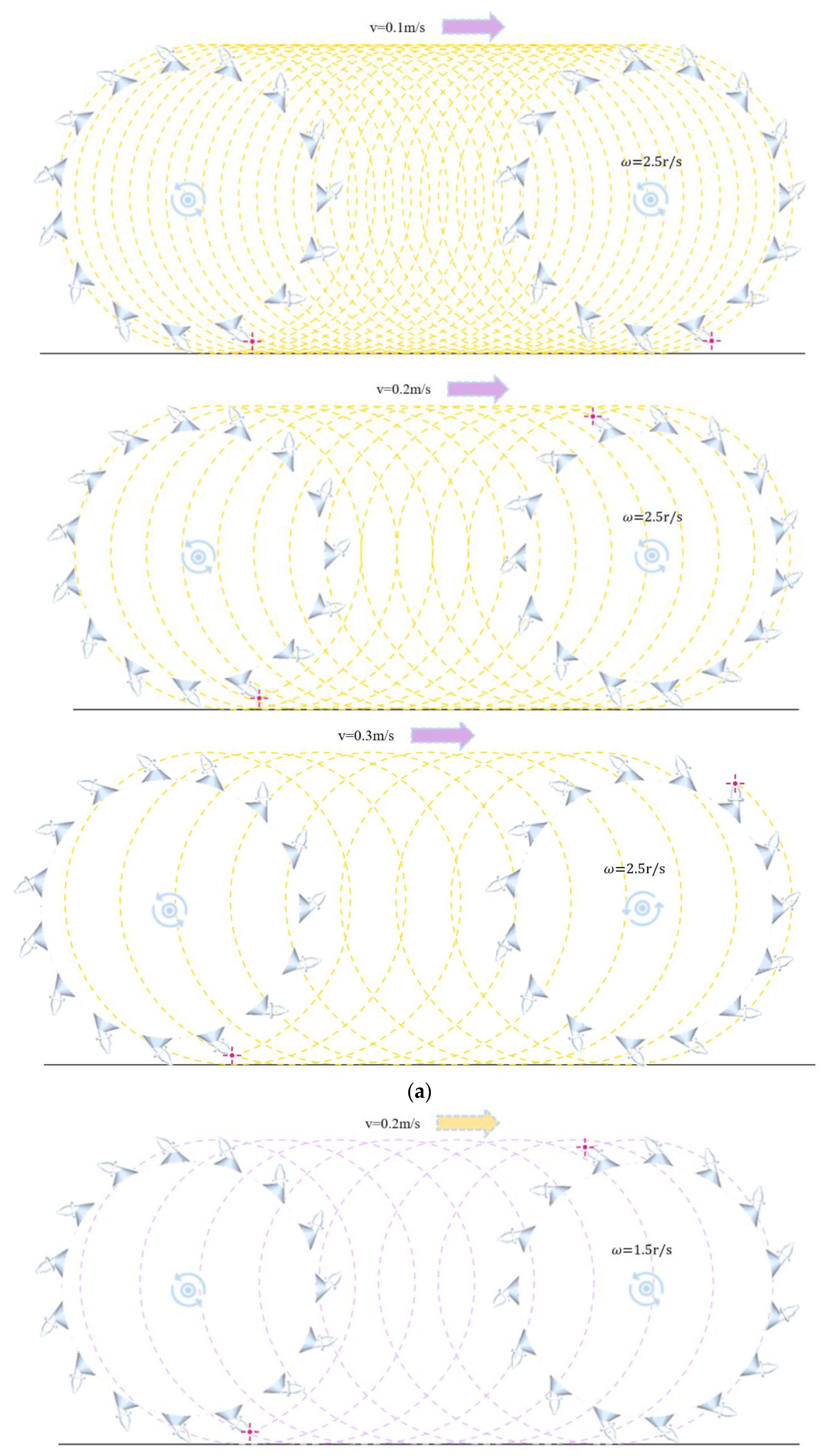

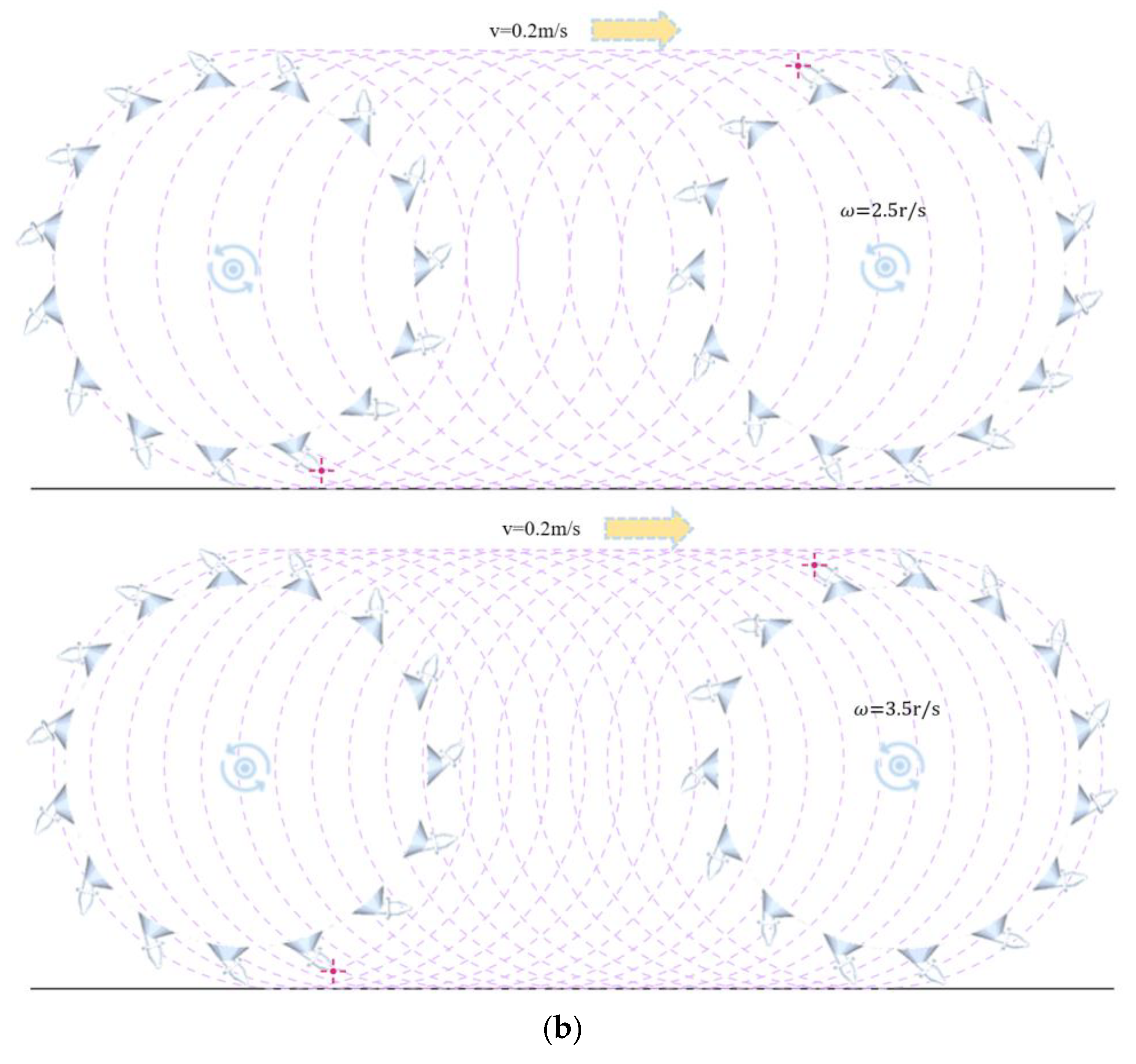

- With the constant rotating speed of the milling rotor controlled, the single milling path of the cutter tip becomes longer as the milling rotor moving speed increases, thereby increasing the milling area. Conversely, with a fixed milling rotor moving speed, as the rotating speed of the milling rotor increases, the cutter tip milling path becomes shorter, resulting in a reduced milling area.

- (2)

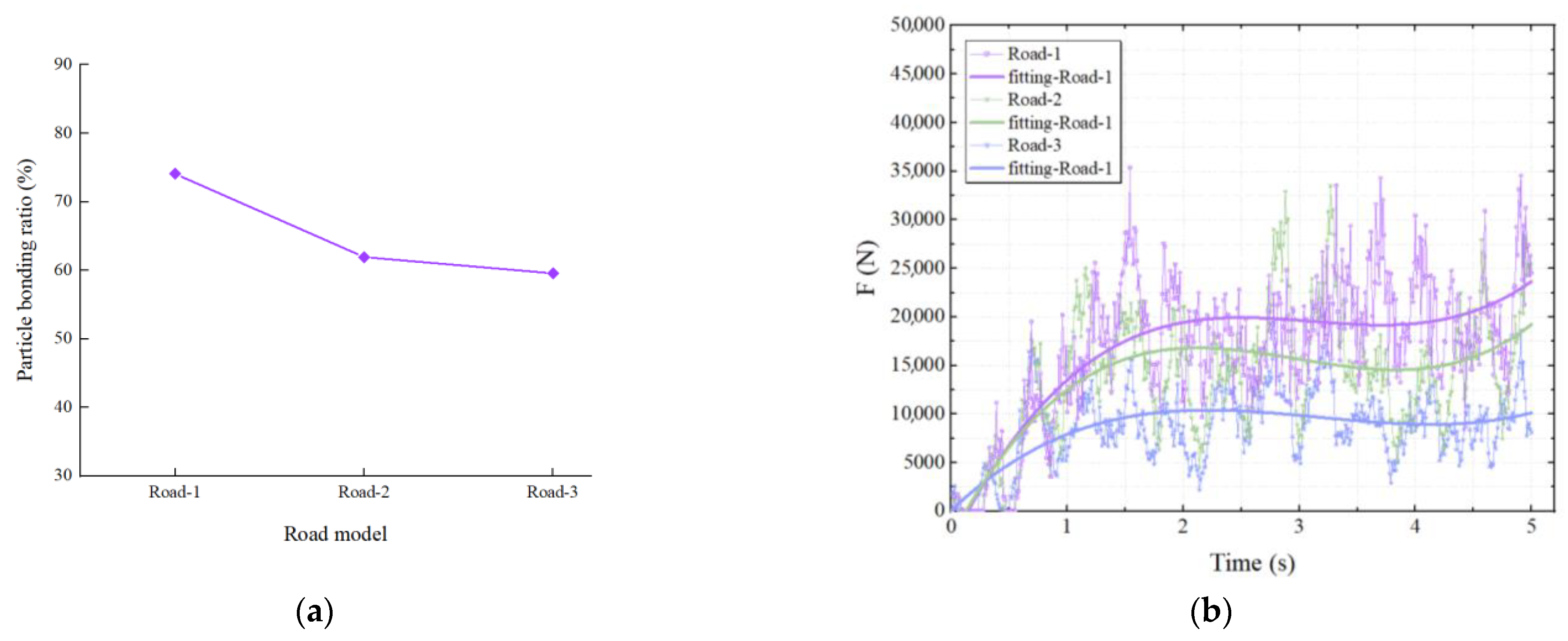

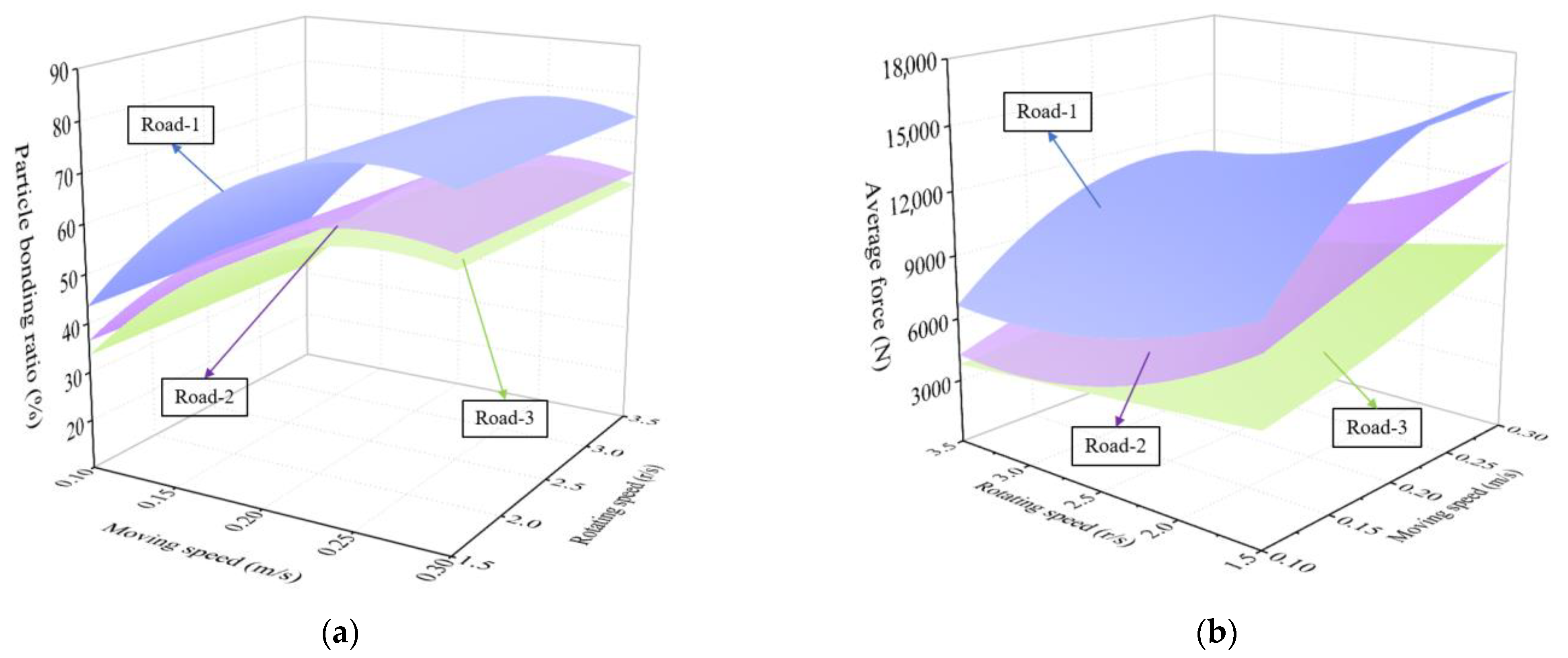

- As the moving speed of the milling rotor increased from 0.1 m/s to 0.3 m/s, longer milling paths and larger milling areas result in more RAP agglomeration along with greater resistance to the milling rotor. This is reflected in the simulation results by an increase of about 30% for the particle bonding rate and an increase of about 8388 N for the rotor average force. The degree of influence on the two test indexes is small as the milling rotor rotating speed increased from 1.5 r/s to 3.5 r/s because the amplitude of the changes in the milling path and the milling area is relatively small. The particle bonding ratio decreased by about 2.38% and the milling rotor average force decreased by about 4304 N.

- (3)

- The overall pattern of influence exerted by the milling rotor moving speed and rotating speed on the particle bonding ratio and rotor average force applied to the milling rotor remained consistent as the service years of the pavement increased. From 2~3 years pavements to 7~8 years pavements, the overall reduction in the particle bonding ratio index is about 12% and the milling rotor average force is about 24%; from 7~8 years pavements to 11~12 years pavements, the overall reduction in the particle bonding ratio index is about 3% and the milling rotor average force is about 15%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Yan, K.; Wang, M.; Shi, K.; Li, Y.; Zhang, Y. Performance evaluation of SBS-modified asphalt mixtures incorporating waste tire rubber and HDPE. Constr. Build. Mater. 2024, 430, 136423. [Google Scholar] [CrossRef]

- Zhao, F.; Liu, Q.; Peng, Z.; Wang, H.; Wan, P.; Ye, Q. A comparative study of the effects of calcium alginate capsules on self-healing properties of base and SBS modified asphalt mixtures. Constr. Build. Mater. 2023, 364, 129908. [Google Scholar] [CrossRef]

- Lu, J. Analysis of highway asphalt pavement disease and maintenance treatment. Intell. City 2021, 7, 93–94. [Google Scholar]

- Xu, D. Research on milling and paving construction technology in highway asphalt pavement construction. Transp. Bus. China 2023, 34, 22–24. [Google Scholar]

- Zhang, C.; Jia, X.; Wei, B. Research on Technical Index of recycled asphalt pavement (RAP) after Classiitcation and Standard Treatment. Fujian Constr. Sci. Technol. 2023, 02, 80–84. [Google Scholar]

- Diouri, K.; De, A.; Dave, E.V.; Sias, J.; Mallick, R.B. Effect of aging and temperature on milling-induced stresses and cracks in Hot Mix Asphalt (HMA) pavements. Constr. Build. Mater. 2021, 313, 125493. [Google Scholar] [CrossRef]

- Zaumanis, M.; Loetscher, D.; Mazor, S.; Stöckli, F.; Poulikakos, L. Impact of milling machine parameters on the properties of reclaimed asphalt pavement. Constr. Build. Mater. 2021, 307, 125114. [Google Scholar] [CrossRef]

- Song, C.; Cheng, H.; Fan, K.; Wu, W.; Wang, X.; Li, L. Influence of operating parameters of a multi-cutter milling rotor on particle size. Powder Technol. 2024, 438, 119651. [Google Scholar] [CrossRef]

- Yao, Y.; Yang, J.; Gao, J.; Zheng, M.; Song, L.; Xu, J.; Sun, C. RAP chunks produced in cold milling operation of asphalt pavement: Evaluation, mechanism, and engineering investigation in China. J. Traffic Transp. Eng. (Engl. Ed.) 2024, 11, 972–1000. [Google Scholar] [CrossRef]

- Petrescu, M.G.; Dumitru, T.; Laudacescu, E.; Tănase, M. Experimental Investigation and Numerical Analysis Regarding the Influence of Cutting Parameters on the Asphalt Milling Process. Materials 2024, 17, 3475. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. The Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Wen, Y.; Sun, L.; Wang, X.; Pei, J. Laboratory Simulation and Performance Evaluation of Long-Term Aging of Asphalt Mixtures at Service Temperatures. J. Tongji Univ. (Nat. Sci.) 2024, 52, 1331–1340. [Google Scholar]

- Wang, Y.; Li, B.; Ren, X.; Zhang, Z.; Chen, Z. Analysis of SBS Modified Asphalt with Different Aging Time by Regenerated Infrared Spectroscopy. J. Mater. Sci. Eng. 2020, 38, 643–647, 565. [Google Scholar]

- Zhang, D.; Zheng, Y.; Yuan, G.; Guo, H.; Zhou, Q.; Qian, G.; Liang, B. Comparative analysis of rheological and microscopic performance of SBS modified asphalt based on field aging and laboratory aging. Fuel 2023, 352, 128933. [Google Scholar] [CrossRef]

- Li, P. Research on the Aging Behavior and Mechanism of Road Asphalt. Master’s Thesis, Chang’an University, Xi’an, China, 2007. [Google Scholar]

- Lu, J. Research on the Aging Behavior and Recycling Technology of Asphalt Pavements. Ph.D. Thesis, Chang’an University, Xi’an, China, 2008. [Google Scholar]

- Li, D. Discrete Element Simulation of Milling Process of Old Pavement Based on Aging Characteristics of SBS Modified Asphalt Adhesive Mortar. Master’s Thesis, Chang’an University, Xi’an, China, 2017. [Google Scholar]

- Chen, J. Research on Aging Properties of Asphalt Mortar and Theimpact on road Milling Planer System Using DMA. Master’s Thesis, Chang’an University, Xi’an, China, 2016. [Google Scholar]

- Yao, X.; Wang, Y. Research on Aging Simulation Method of SBS Modified Asphalt. J. Huaiyin Inst. Technol. 2018, 27, 55–60. [Google Scholar]

- Wu, J.; Li, D.; Zhu, B.; Wu, C. Milling process simulation of old asphalt mixture by discrete element. Constr. Build. Mater. 2018, 186, 996–1004. [Google Scholar] [CrossRef]

- JTG 3432-2024; Test Methods of Aggregate for Highway Engineering. The Ministry of Transport of the People’s Republic of China: Beijing, China, 2024.

- Yi, X.; Chen, H.; Wang, H.; Tang, Z.; Yang, J.; Wang, H. Cross-Functional Test to Explore the Determination Method of Meso-Parameters in the Discrete Element Model of Asphalt Mixtures. Materials 2021, 14, 5786. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim Hassanin Mohamed, A.; Giraldo-Londoño, O.; Deng, B.; Chen, Z.; Rath, P.; Buttlar, W.G. Preliminary Study on Multi-Scale Modeling of Asphalt Materials: Evaluation of Material Behavior through an RVE-Based Approach. Materials 2024, 17, 5041. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

- Wang, S.; Ji, S. A unified level set method for simulating mixed granular flows involving multiple non-spherical DEM models in complex structures. Comput. Methods Appl. Mech. Eng. 2022, 393, 114802. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.; Zhao, L.; Zhang, H.; Shi, F. Research on the Calibration Method of the Bonding Parameters of the EDEM Simulation Model for Asphalt Mixtures. Coatings 2024, 14, 1553. [Google Scholar] [CrossRef]

- Wang, W.; Xu, Q.; Zhou, S.; Qin, Y.; Yan, Q. A Review on Evaluation Methods of Asphalt Aggregate Adhesion. Mater. Rep. 2019, 33, 2197–2205. [Google Scholar]

- Wang, S.; Miao, Y.; Wang, L. Investigation of the force evolution in aggregate blend compaction process and the effect of elongated and flat particles using DEM. Constr. Build. Mater. 2020, 258, 119674. [Google Scholar] [CrossRef]

- Stahl, M.; Konietzky, H. Discrete element simulation of ballast and gravel under special consideration of grain-shape, grain-size and relative density. Granul. Matter 2011, 13, 417–428. [Google Scholar] [CrossRef]

- Wu, C. A Micro-Mechanical Model of Asphalt Mixture on Old Asphalt Pavements and Simulation Study of Milling. Master’s Thesis, Chang’an University, Xi’an, China, 2019. [Google Scholar]

- Zhang, B. A Study on the Milling Process and Optimization of Milling Parameters for Asphalt Pavements Based on Discrete Elements. Master’s Thesis, Chang’an University, Xi’an, China, 2021. [Google Scholar]

- Wang, X. Research on the Dynamics of Milling Drum for Asphalt Concrete Pavement. Ph.D. Thesis, Chang’an University, Xi’an, China, 2017. [Google Scholar]

- Zheng, N.; Ji, X.; Hou, Y. Nonlinear Prediction of Attenuation of Asphalt Performance after Ultraviolet Aging. J. Highw. Transp. Res. Dev. 2009, 26, 33–36, 41. [Google Scholar]

- Cheng, G. Research on milling construction for maintenance of asphalt concrete pavement of high-grade highway and milling disposal method of special parts. Highway 2017, 62, 260–265. [Google Scholar]

- Zhong, X.; Si, Y. Contrastive Analysis of Economics of Highway Engineering Application with Large Ratio RAP Hot Recycling Mixture. Mod. Transp. Technol. 2020, 17, 1–5. [Google Scholar]

| Item | Unit | Test Value | Specification | Test Method |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 70.8 | 60~80 | T 0604 |

| Softening point | °C | 58.6 | ≥55 | T 0606 |

| Residual ductility at 5 °C | cm | 42.1 | ≥30 | T 0605 |

| RTFOT Aging Time (min) | Softening Point (°C) | Penetration (25 °C, 100 g, 5 s) | Residual Ductility at 5 °C (cm) |

|---|---|---|---|

| 180 | 61.3 | 41.1 | 22.9 |

| 360 | 72.5 | 29.2 | 7.1 |

| 600 | 77.8 | 26.8 | 5.8 |

| Material Type | Test Item | Unit | Standard Requirement | Test Result | Assess | Testing Method | |||

|---|---|---|---|---|---|---|---|---|---|

| Coarse Aggregate | Specifications | mm | 15~25 | 5~15 | 3~5 | ||||

| Apparent Relative Density | g/cm3 | ≥2.60 | 2.867 | 2.718 | 2.825 | Qualified | T 0304 | ||

| Bulk Relative Density | g/cm3 | Measured | 2.818 | 2.648 | 2.732 | Qualified | T 0304 | ||

| Water Absorption Rate | % | ≤2.0 | 0.62 | 0.97 | 1.2 | Qualified | T 0304 | ||

| Adhesion to Asphalt | Stage | ≥5 | 5 | Qualified | T 0616 | ||||

| Crushing Value | % | ≤28 | 16.2 | Qualified | T 0316 | ||||

| Elongated and Flaky Particle Content | % | ≤18 | 8.6 | Qualified | T 0312 | ||||

| Soft Stone Content | % | ≤3 | 2.3 | Qualified | T 0320 | ||||

| Sturdiness | % | ≤12 | 7 | Qualified | T 0314 | ||||

| Fine Aggregate | Apparent Density | g/cm3 | Measured | 2.701 | Qualified | T 0328 | |||

| Apparent Relative Density | — | ≥2.50 | 2.705 | — | T 0328 | ||||

| Robustness (>0.3 mm) | % | ≤12 | 8.8 | Qualified | T 0340 | ||||

| Sand Equivalent | % | ≥60 | 63 | Qualified | T 0334 | ||||

| Mineral Powder | Apparent Density | g/cm3 | Measured | 2.698 | Qualified | T 0352 | |||

| Water Content | % | ≤1 | 0.33 | Qualified | T 0103 Drying Method | ||||

| Particle Size Range | <0.6 mm | % | 100 | 100 | Qualified | T 0351 | |||

| <0.15 mm | % | 90~100 | 96.6 | Qualified | |||||

| <0.075 mm | % | 75~100 | 85.8 | Qualified | |||||

| Appearance | — | Free from Agglomeration and Caking | Free from Agglomeration and Caking | Qualified | — | ||||

| Hydrophilic Coefficient | — | <1.0 | 0.8 | Qualified | T 0353 | ||||

| RTFOT Aging Time (min) | Splitting Tensile Strength (RT/MPa) | Standard Error | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | ||

| 180 | 0.758 | 0.766 | 0.763 | 0.762 | 0.0040 |

| 360 | 0.527 | 0.536 | 0.530 | 0.531 | 0.0046 |

| 600 | 0.459 | 0.483 | 0.474 | 0.472 | 0.0120 |

| Average Splitting Tensile Strength (RT/MPa) | /(N∙m−3) | /(N∙m−3) | /Pa | /Pa |

|---|---|---|---|---|

| 0.762 | 1.31 × 1010 | 2.16 × 1010 | 4.12 × 109 | 1.94 × 109 |

| 0.531 | 1.31 × 1010 | 1.27 × 1010 | 2.83 × 109 | 5.53 × 109 |

| 0.472 | 1.31 × 1010 | 1.39 × 1010 | 2.58 × 109 | 1.25 × 109 |

| Test Number | Pavement Model | Test Factors | |

|---|---|---|---|

| Moving Speed (m/s) | Rotating Speed (r/s) | ||

| 1 | Road-1 | 0.1 | 1.5 |

| 2 | Road-1 | 0.1 | 2.5 |

| 3 | Road-1 | 0.1 | 3.5 |

| 4 | Road-1 | 0.2 | 1.5 |

| 5 | Road-1 | 0.2 | 2.5 |

| 6 | Road-1 | 0.2 | 3.5 |

| 7 | Road-1 | 0.3 | 1.5 |

| 8 | Road-1 | 0.3 | 2.5 |

| 9 | Road-1 | 0.3 | 3.5 |

| 10 | Road-2 | 0.1 | 1.5 |

| 11 | Road-2 | 0.1 | 2.5 |

| 12 | Road-2 | 0.1 | 3.5 |

| 13 | Road-2 | 0.2 | 1.5 |

| 14 | Road-2 | 0.2 | 2.5 |

| 15 | Road-2 | 0.2 | 3.5 |

| 16 | Road-2 | 0.3 | 1.5 |

| 17 | Road-2 | 0.3 | 2.5 |

| 18 | Road-2 | 0.3 | 3.5 |

| 19 | Road-3 | 0.1 | 1.5 |

| 20 | Road-3 | 0.1 | 2.5 |

| 21 | Road-3 | 0.1 | 3.5 |

| 22 | Road-3 | 0.2 | 1.5 |

| 23 | Road-3 | 0.2 | 2.5 |

| 24 | Road-3 | 0.2 | 3.5 |

| 25 | Road-3 | 0.3 | 1.5 |

| 26 | Road-3 | 0.3 | 2.5 |

| 27 | Road-3 | 0.3 | 3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhang, Z.; Liu, H.; Feng, H.; Zhang, H.; Shi, F.; Gou, Z. Research on the Milling Characteristics of SBS Modified Asphalt Pavement with Different Service Years Using the Discrete Element Method. Materials 2025, 18, 3226. https://doi.org/10.3390/ma18143226

Li X, Zhang Z, Liu H, Feng H, Zhang H, Shi F, Gou Z. Research on the Milling Characteristics of SBS Modified Asphalt Pavement with Different Service Years Using the Discrete Element Method. Materials. 2025; 18(14):3226. https://doi.org/10.3390/ma18143226

Chicago/Turabian StyleLi, Xiujun, Zhipeng Zhang, Hao Liu, Hao Feng, Heng Zhang, Fangzhi Shi, and Zhi Gou. 2025. "Research on the Milling Characteristics of SBS Modified Asphalt Pavement with Different Service Years Using the Discrete Element Method" Materials 18, no. 14: 3226. https://doi.org/10.3390/ma18143226

APA StyleLi, X., Zhang, Z., Liu, H., Feng, H., Zhang, H., Shi, F., & Gou, Z. (2025). Research on the Milling Characteristics of SBS Modified Asphalt Pavement with Different Service Years Using the Discrete Element Method. Materials, 18(14), 3226. https://doi.org/10.3390/ma18143226