Impact Strength of Adhesive Joints of Pre-Impregnated Composite Elements

Abstract

1. Introduction

2. Methodology of Research

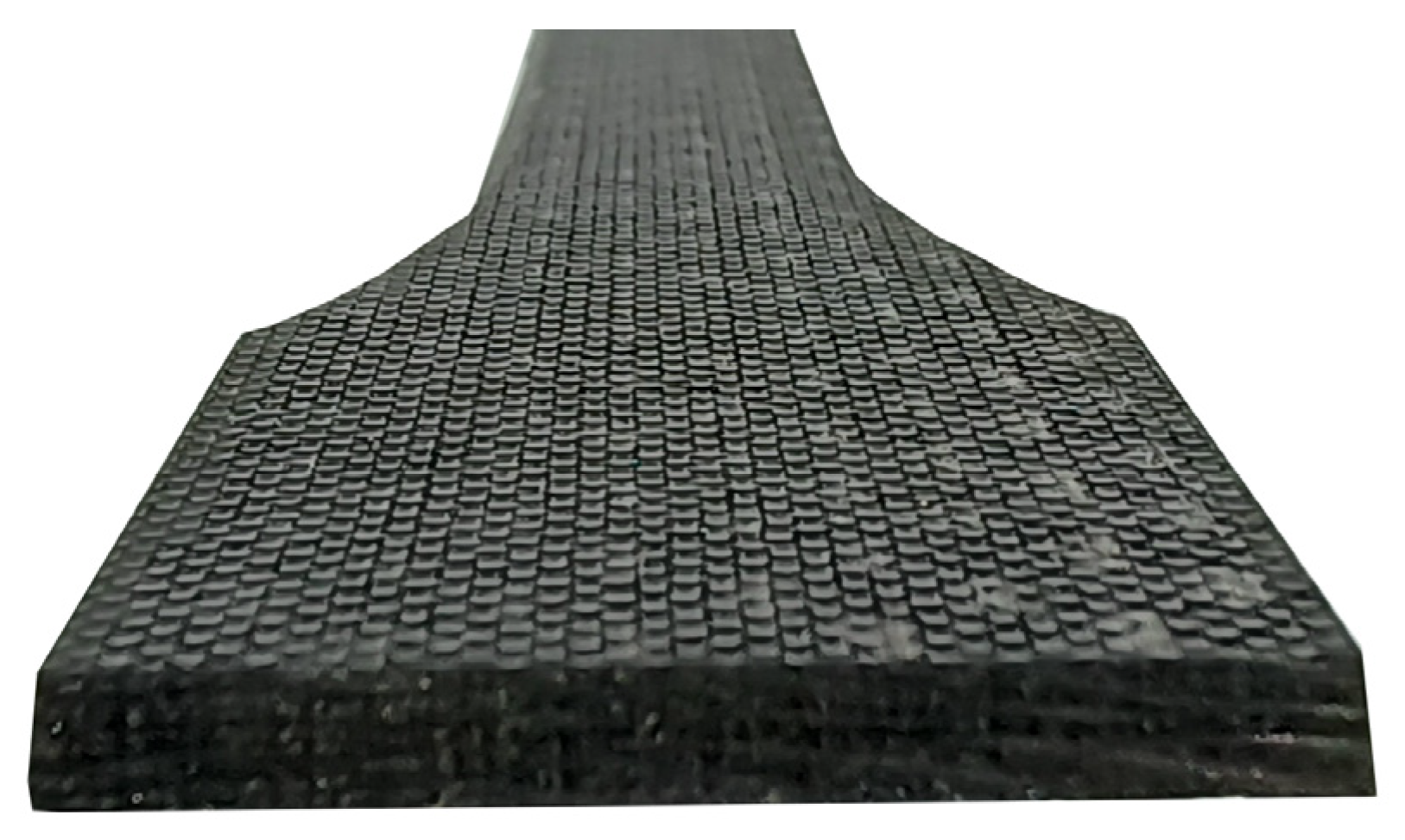

Preparation of Samples for Joint Strength Testing

- -

- Teroson PU9225 (Henkel AG & Co. KGaA, Dusseldorf, Germany) (two-component polyurethane-based adhesive);

- -

- Henkel HY4080 (Henkel AG & Co. KGaA, Dusseldorf, Germany) (cyanoacrylate/acrylic hybrid structural adhesive);

- -

- Henkel EA9497 (Henkel AG & Co. KGaA, Dusseldorf, Germany) (two-component epoxy adhesive);

- -

- Henkel EA9464 (Henkel AG & Co. KGaA, Dusseldorf, Germany) (two-component epoxy adhesive);

- -

- 3M DP420 (3M, Saint Paul, MN, USA) (epoxy structural adhesive recommended for bonding parts made with carbon fibre);

- -

- Epidian 57 + hardener Z1 (Sarzyna Chemical Sp.z.o., Sarzyna, Poland) (epoxy composition mixed 10:1 by weight).

3. Testing of Adhesive Joints

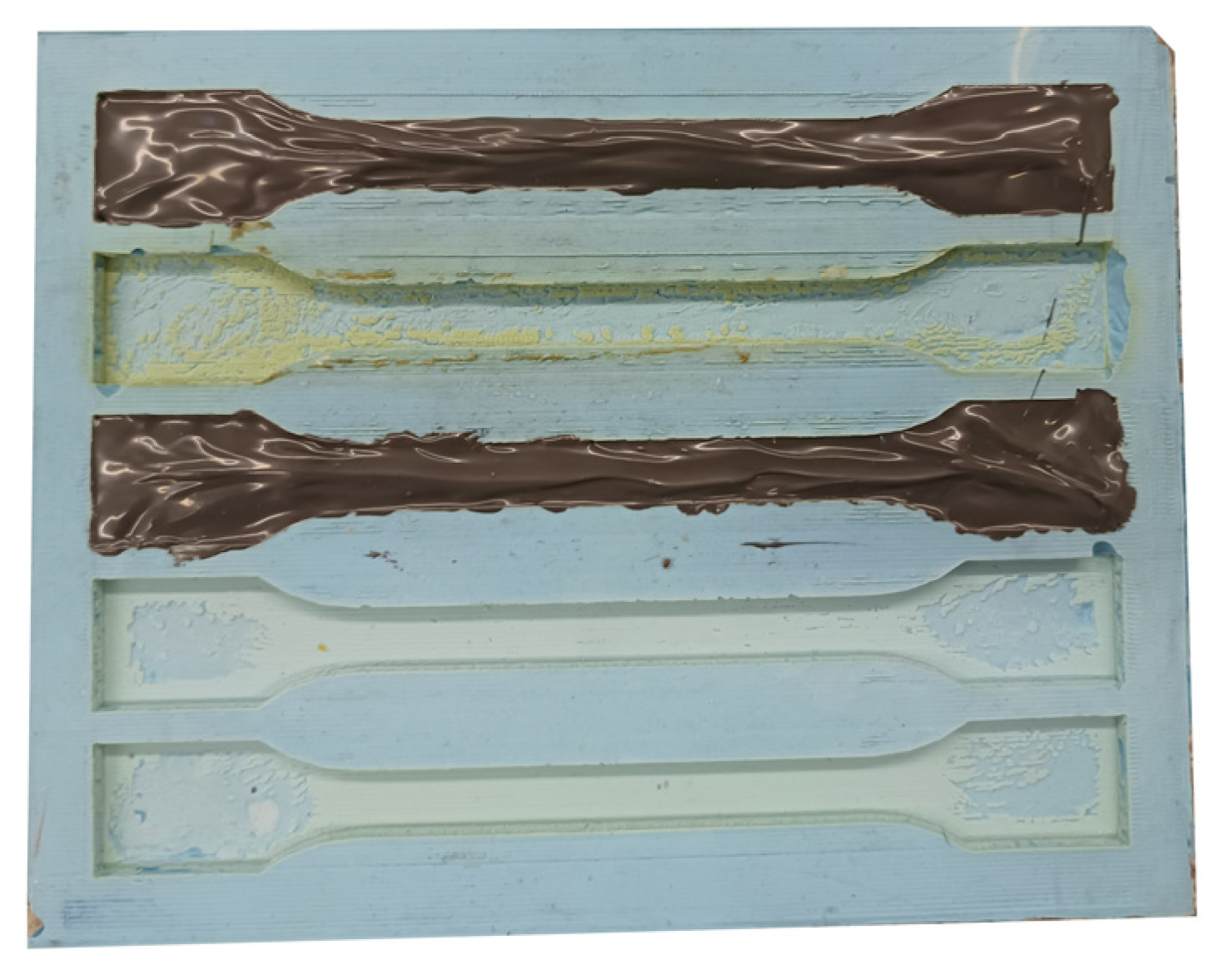

3.1. Sample Preparation

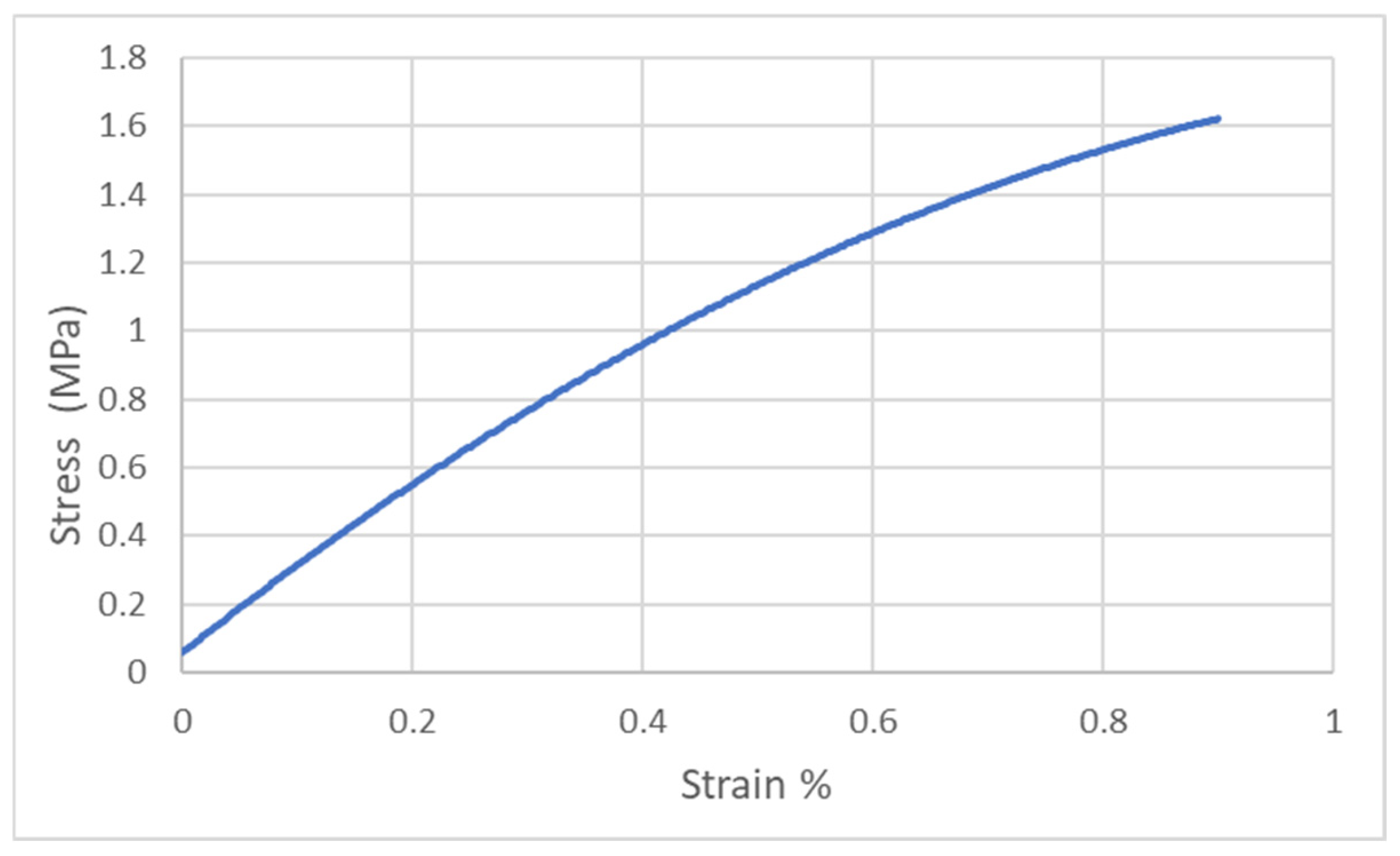

3.2. Tensile Strength Test

3.3. Investigation of Impact Strength

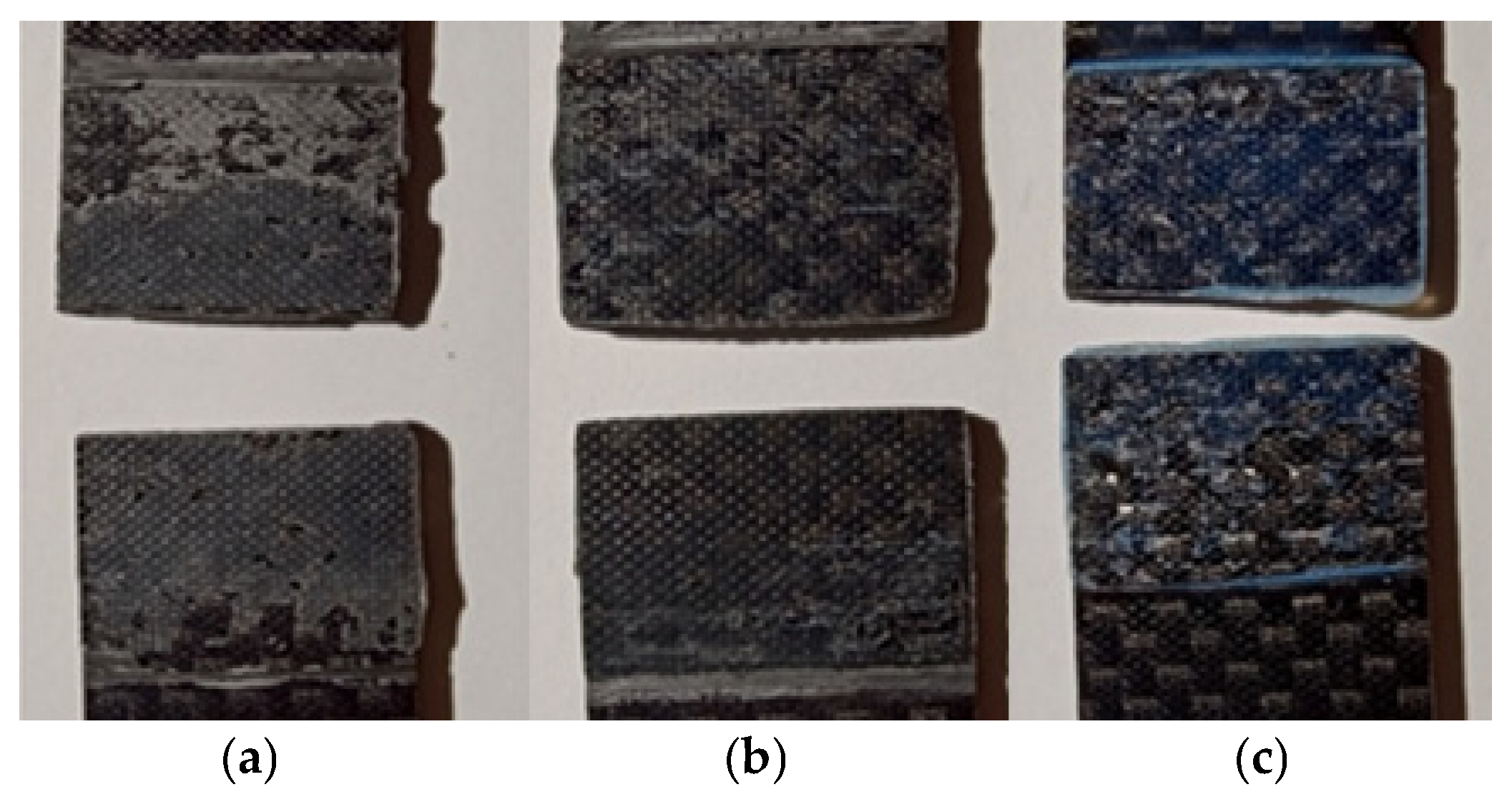

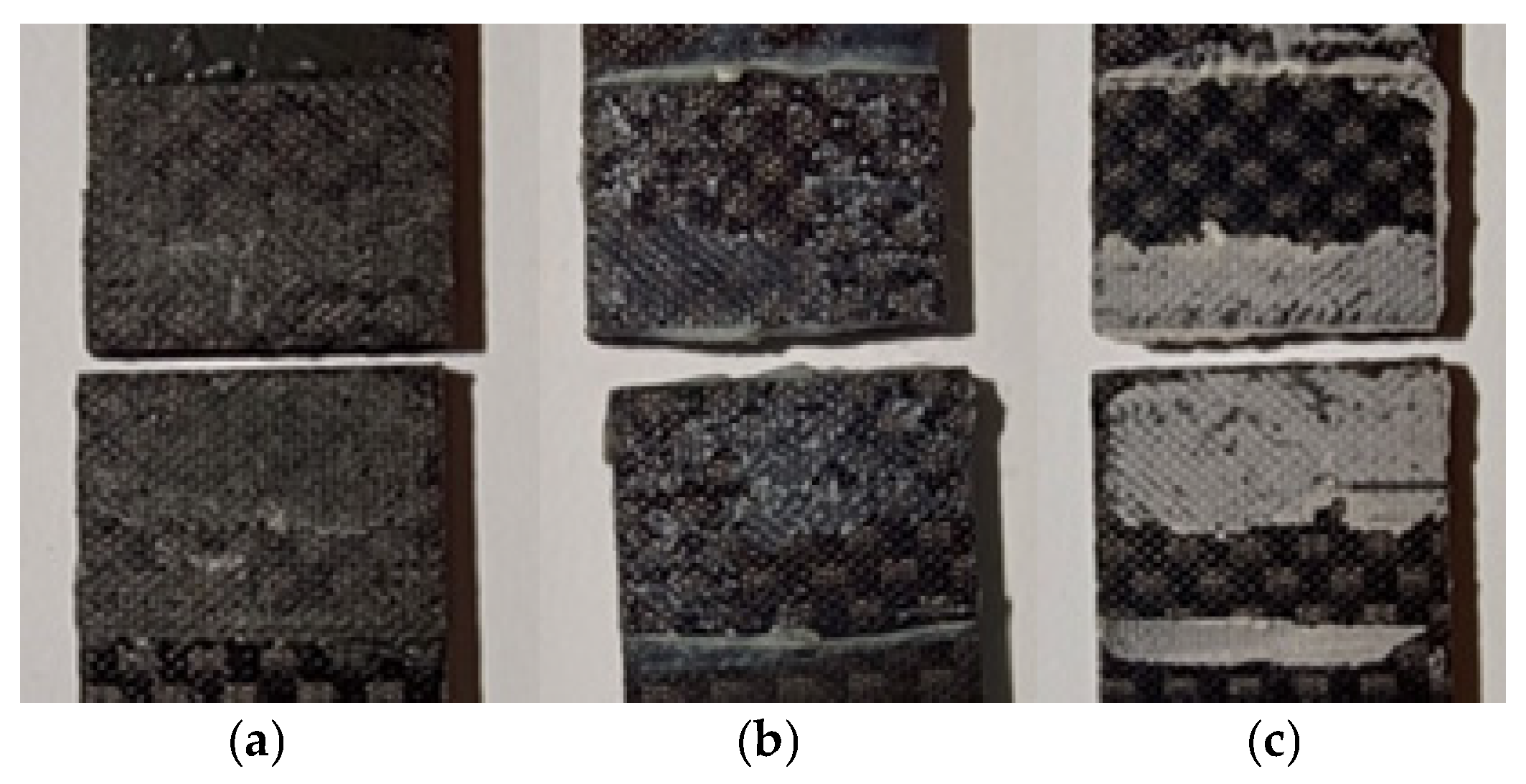

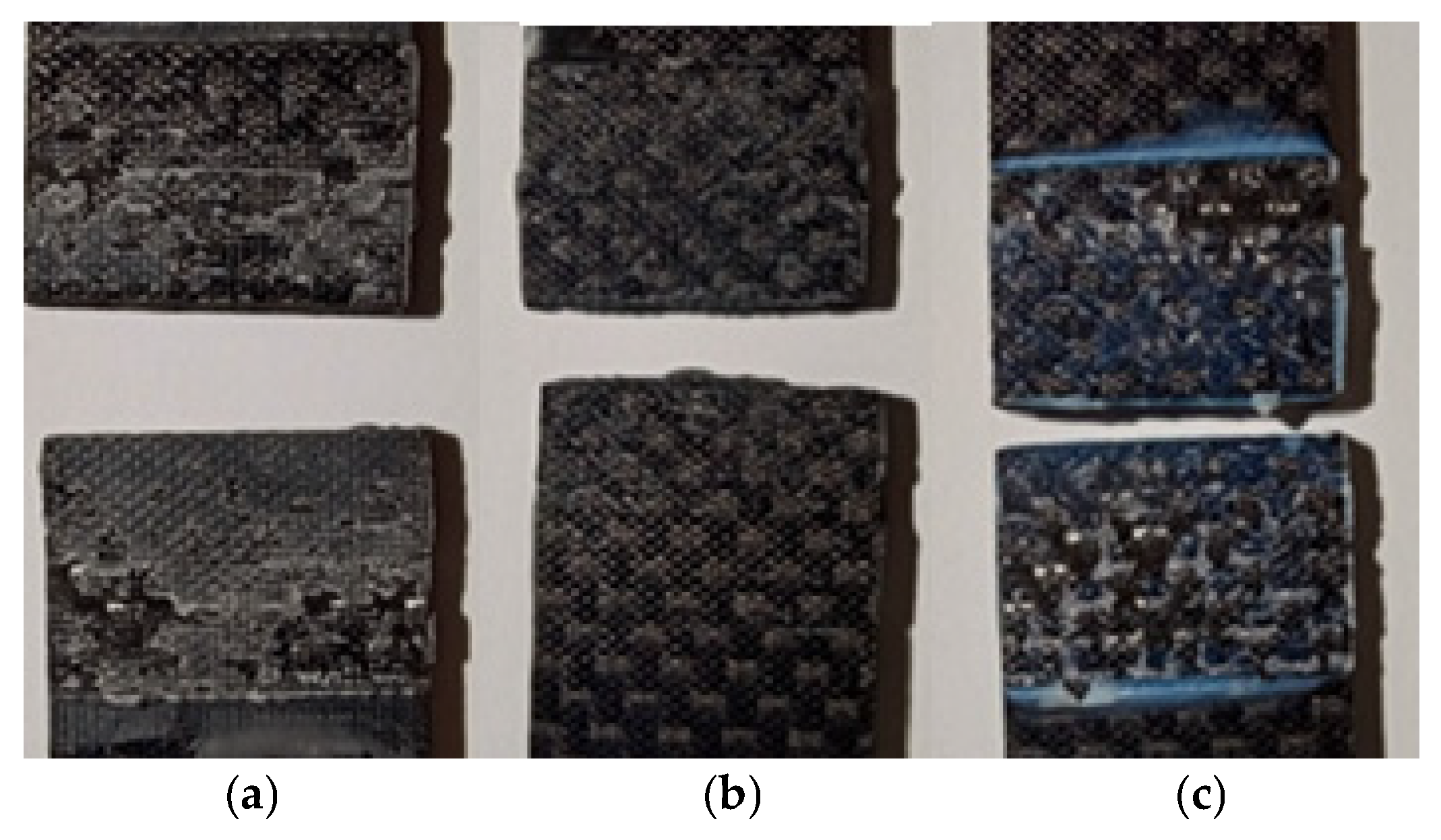

3.4. Visual Inspection of the Nature of the Damage

4. Conclusions

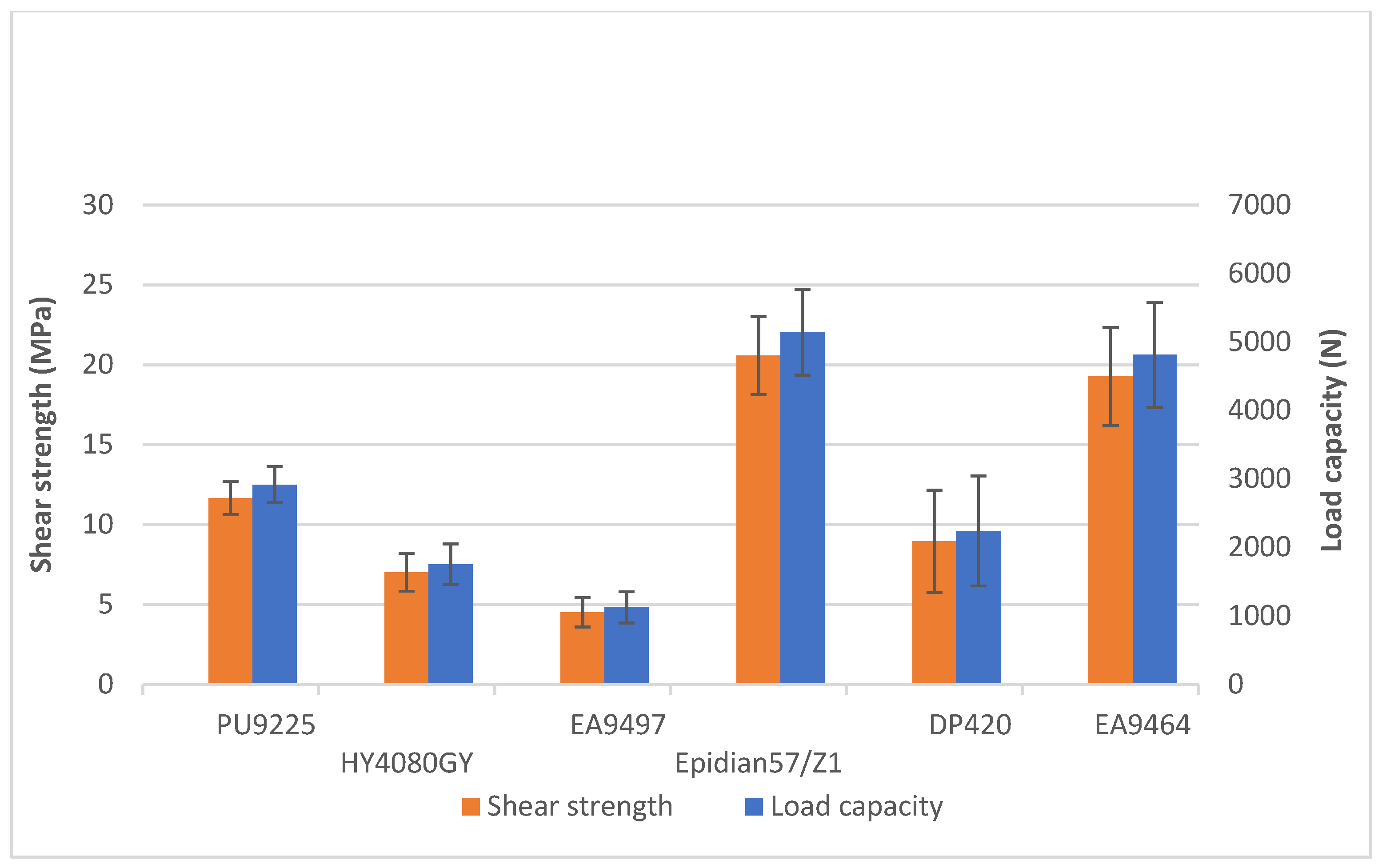

- (1)

- When selecting an adhesive for a joint that may be subjected to impact loads, it is essential to know the dynamic properties of such a joint. The impact strength of adhesive joints should not be predicted based on their static properties, because there is no clear relationship between these properties;

- (2)

- Among the adhesives used in the study, composite samples joined with Epidian 57/Z1 had not only the highest impact strength but also the highest static strength. Furthermore, cracks in samples joined with Epidian 57/Z1 after both static and impact tests were characterized by adhesive and cohesive damage in equal proportions, which indicates the good quality of the connection regardless of the nature of the applied loads;

- (3)

- Lap joints of composite components have a higher impact strength than those of aluminum alloy components;

- (4)

- Joints made with EA9464 adhesive, despite having a slightly lower static and impact strength than Epidian 57/Z1 adhesive (but with a similar Young’s modulus value), have a significantly lower standard deviation, which allows a more reliable prediction of the behaviour of adhesive joints under loads;

- (5)

- The lowest impact strength and shear strength occurred for adhesive joints made with epoxy glue with the highest value of Young’s modulus, similar to the impact testing of aluminum alloy component joints;

- (6)

- Poor adhesion of adhesives to bonded surfaces can result from not subjecting the joined surface to additional blasting or abrasive treatment and also because of possible residues of the delamination fabric.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baker, A.A.; Scott, M.L. Composite Materials for Aircraft Structures, 3rd ed.; AIAA/American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar]

- Ye, L.; Lu, Y.; Su, Z.; Meng, G. Functionalized composite structures for new generation airframes: A review. Compos. Sci. Technol. 2005, 65, 1436–1446. [Google Scholar] [CrossRef]

- Jawaid, M.; Thariq, M. Sustainable Composites for Aerospace Applications; Woodhead Publishing: Philadelphia, PA, USA, 2018. [Google Scholar]

- Dhas, J.E.R.; Arun, M. A review on development of hybrid composites for aerospace applications. Mater. Today Proc. 2022, 64, 267–273. [Google Scholar] [CrossRef]

- Volker, M. The composites industry: Plenty of opportunities in heterogeneous market. J. Reinf. Plast. 2018, 62, 44–51. [Google Scholar] [CrossRef]

- Doo-Yeol, Y.; Nemkumar, B.; Rishi, G.; Young, H.K.; Aamer, B. Polymer-Based Construction Materials for Civil Engineering. Int. J. Polym. Sci. 2019, 8914073. [Google Scholar] [CrossRef]

- Surowska, B. Functional And Hybrid Materials in Air Transport. Eksploat. Niezawodn.-Maint. Reliab. 2008, 3, 30–40. [Google Scholar]

- Uddin, N. (Ed.) Developments in Fiber-Reinforced Polymer (FRP) Composites for Civil Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Bieniaś, J.; Jakubczak, P.; Majerski, K.; Ostapiuk, M.; Surowska, B. Methods of ultrasonic testing, as an effective way of estimating durability and diagnosing operational capability of composite laminates used in aerospace industry. Eksploat. Niezawodn. 2013, 15, 284–289. [Google Scholar]

- Cagle, C.V. Kleje i Klejenie; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1977. [Google Scholar]

- Adams, R.D.; Comyn, J.; Wake, W.C. Structural Adhesive Joint in Engineering; Springer Science & Business Media: London, UK, 1997. [Google Scholar]

- Staszewski, W.; Boller, C.; Tomlinson, G. Health Monitoring of Aerospace Structures; John Willey & Sons, Ltd.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Basak, A.K.; Bajwa, D.S.; Pramanik, A. Fatigue Behaviour of Mechanical Joints: A Review. Metals 2025, 15, 25. [Google Scholar] [CrossRef]

- Camanho, P.; Tong, L. Composite Joints and Connections: Principles, Modeling and Testing; Woodhead Publishing Ltd.: Cambridge, UK, 2011. [Google Scholar]

- Wahab, M.A. (Ed.) Joining Composites with Adhesives; DESTech Publications Inc.: Lancaster, PA, USA, 2016. [Google Scholar]

- Higgins, A. Adhesive bonding of aircraft structures. Int. J. Adhes. Adhes. 2009, 20, 367–376. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. (Eds.) Handbook of Adhesion Technology; Springer: Heidelberg, Germany, 2011. [Google Scholar]

- Malekinejad, H.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Performance of Hybrid Reinforced Composite Substrates in Adhesively Bonded Joints Under Varied Loading Rates. Polymers 2025, 17, 469. [Google Scholar] [CrossRef]

- Tasdemir, H.A.; Mirza, B.A.; Erkendirci, Y.H. Investigation of Skin–Stringer Assembly Made with Adhesive and Mechanical Methods on Aircraft. Aerospace 2025, 12, 383. [Google Scholar] [CrossRef]

- Falzon, B.G. Impact damage and repair of composite structures. Aeronaut. J. 2009, 113, 431–445. [Google Scholar] [CrossRef]

- Savage, G.; Oxley, M. Repair of composite structures on Formula 1 race cars. Eng. Fail. Anal. 2010, 17, 70–82. [Google Scholar] [CrossRef]

- Katnam, K.; da Silva, L.F.M.; Young, T. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities. Prog. Aerosp. Sci. 2013, 61, 26–42. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Dillard, D.A.; Blackman, B.; Adams, R.D. Testing Adhesive Joints: Best Practices; Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Kuczmaszewski, J. Badania pełzania połączeń klejowych. Eksploat. Niezawodn. 2000, 6, 4–10. [Google Scholar]

- Sato, C. Impact behavior of adhesively bonded joints. In Adhesive Bonding Science, Technology and Applications; Adams, R.D., Ed.; WPL.: Cambridge, UK, 2005; pp. 165–187. [Google Scholar]

- Godzimirski, J.; Komorek, A. The Influence of Selected Test Conditions on the Impact Strength of Adhesively Bonded Connections. Materials 2020, 13, 1320. [Google Scholar] [CrossRef]

- Adamvalli, M.; Parameswaran, V. Dynamic strength of adhesive single lap joints at high temperature. Int. J. Adhes. Adhes. 2008, 28, 321–327. [Google Scholar] [CrossRef]

- Raykhere, S.L.; Kumar, P.; Singh, R.K.; Parameswaran, V. Dynamic shear strength of adhesive joints made of metallic and composite adherents. Mater. Des. 2010, 31, 2102–2109. [Google Scholar] [CrossRef]

- Galliot, C.; Rousseau, J.; Verchery, G. Drop weight tensile impact testing of adhesively bonded carbon/epoxy laminate joints. Int. J. Adhes. Adhes. 2012, 35, 68–75. [Google Scholar] [CrossRef]

- Komorek, A.; Godzimirski, J.; Pietras, A. Numerical Analysis of Impact Loading of Adhesive Joints. Advan. Mater. Sci. Eng. 2017, 2017, 5941086. [Google Scholar] [CrossRef]

- Adams, R.D.; Harris, J.A. A critical assessment of the block impact test for measuring the impact strength of adhesive bonds. Int. J. Adhes. Adhes. 1996, 16, 61–71. [Google Scholar] [CrossRef]

- Komorek, A.; Godzimirski, J.; Rośkowicz, M. Analysis of a New Shape of Test Specimen for Block Shear Impact Test. Materials 2020, 13, 1693. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Halpin, J.C.; DeFrancisci, G.K. Impact Damage of Composite Structures. In Long-Term Durability of Polymeric Matrix Composites; Pochiraju, K., Tandon, G., Schoeppner, G., Eds.; Springer: Boston, MA, USA, 2012. [Google Scholar] [CrossRef]

- Bieniaś, J.; Surowska, B.; Jakubczak, P. Influence of repeated impact on damage growth in fibre reinforced polymer composites. Eksploat. Niezawodn. 2015, 17, 194–198. [Google Scholar] [CrossRef]

- Godzimirski, J.; Rośkowicz, M.; Komorek, A. Investigation of ballistic resistance of adhesive bonded multi-layer structures. Eksploat. Niezawodn. 2017, 19, 324–330. [Google Scholar] [CrossRef]

- Szymczak, T.; Kowalewski, Z.L. Strength tests of polymer-glass composite to evaluate its operational suitability for ballistic shield plates. Eksploat. Niezawodn. 2021, 22, 592–600. [Google Scholar] [CrossRef]

- Upadhya, A.R.; Dayananda, G.N.; Kamalakannan, G.M.; Ramaswamy Setty, J.; Christopher Daniel, J. Autoclaves for Aerospace Applications: Issues and Challenges. Int. J. Aerosp. Eng. 2011, 2011, 285–295. [Google Scholar] [CrossRef]

- DIN EN 2562:1997-05; Aerospace Series—Carbon Fibre Reinforced Plastics—Unidirectional Laminates. Flexural Test Parallel to the Fibre Direction; DIN Media GmbH: Berlin, Germany, 1997.

- ISO 527-3:2018; Plastics—Determination of Tensile Properties Part 3: Test Conditions for Films and Sheets. ISO: Geneva, Switzerland, 2018.

- Komorek, A.; Godzimirski, J.; Kucharczyk, W. The Influence of the Joint Thickness Upon the Impact Strength of Block Adhesive Joints. Transp. Res. Proc. 2018, 35, 80–89. [Google Scholar] [CrossRef]

- Komorek, A.; Godzimirski, J.; Rośkowicz, M.; Gąsior, J. Influence of Young’s adhesive modulus on impact strength of block adhesive joints. Technol. Autom. Montażu (Assem. Tech. Technol.) 2018, 101, 53–58. [Google Scholar]

| Symbol | Unit Weight (g/m) | Weave | Fibre/Bundle | Thickness (mm) | |

|---|---|---|---|---|---|

| Matrix | Thread | ||||

| 204T | 204 | Twill 2 × 2 | Carbon 200 tex | Carbon 200 tex | 0.20 |

| Mechanical Property | Test Standard | Value |

|---|---|---|

| Bending strength (MPa) | DIN EN 2562:1997-05 [39] | 850 |

| Modulus of elasticity in bending (GPa) | DIN EN 2562:1997-05 [39] | 54 |

| Tensile strength (MPa) | EN ISO 527-3:2018 [40] | 550 |

| Young’s modulus (GPa) | EN ISO 527-3:2018 [40] | 60 |

| Curing Temperature | Curing Time | TG (°C) |

|---|---|---|

| 100 °C | 4 h | 95–105 |

| 120 °C | 1.5 h | 110–115 |

| 130 °C | 1.5 h | 120–130 |

| Parameter | Sample | Average | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Young’s modulus (MPa) | 83,600 | 82,400 | 81,100 | 80,700 | 80,800 | 81,700 ± 1260 |

| Tensile strength (MPa) | 537 | 569 | 526 | 536 | 513 | 536 ± 21 |

| Elongation (%) | 0.988 | 1.100 | 0.976 | 0.927 | 0.849 | 0.969 ± 0.093 |

| Adhesive | Young’s Modulus (MPA) |

|---|---|

| PU9225 | 290 |

| EA9497 | 5430 |

| HY4080GY | 2350 |

| Epidian 57/Z1 | 1830 |

| 3M DP420 | 3210 |

| EA9464 | 2400 |

| Adhesive | Static Tests | Dynamic Tests |

|---|---|---|

| PU9225 | adhesive | adhesive, 10% cohesive |

| HY4080GY | adhesive–cohesive | cohesive |

| EA9497 | adhesive | adhesive |

| EA9464 | adhesive–cohesive | cohesive/adhesive |

| 3M DP420 | adhesive (10% cohesive) | cohesive |

| Epidian 57/Z1 | adhesive–cohesive | adhesive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Komorek, A.; Żeglarski, P.; Godzimirski, J. Impact Strength of Adhesive Joints of Pre-Impregnated Composite Elements. Materials 2025, 18, 2887. https://doi.org/10.3390/ma18122887

Komorek A, Żeglarski P, Godzimirski J. Impact Strength of Adhesive Joints of Pre-Impregnated Composite Elements. Materials. 2025; 18(12):2887. https://doi.org/10.3390/ma18122887

Chicago/Turabian StyleKomorek, Andrzej, Paweł Żeglarski, and Jan Godzimirski. 2025. "Impact Strength of Adhesive Joints of Pre-Impregnated Composite Elements" Materials 18, no. 12: 2887. https://doi.org/10.3390/ma18122887

APA StyleKomorek, A., Żeglarski, P., & Godzimirski, J. (2025). Impact Strength of Adhesive Joints of Pre-Impregnated Composite Elements. Materials, 18(12), 2887. https://doi.org/10.3390/ma18122887