A Performance Evaluation of Fly Ash–Plastic Aggregate in Hydraulic Backfilling: A Comparative Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Fly Ash–Plastic Aggregate Preparation

2.1.1. River Sand

2.1.2. Fly Ash

2.1.3. Plastic

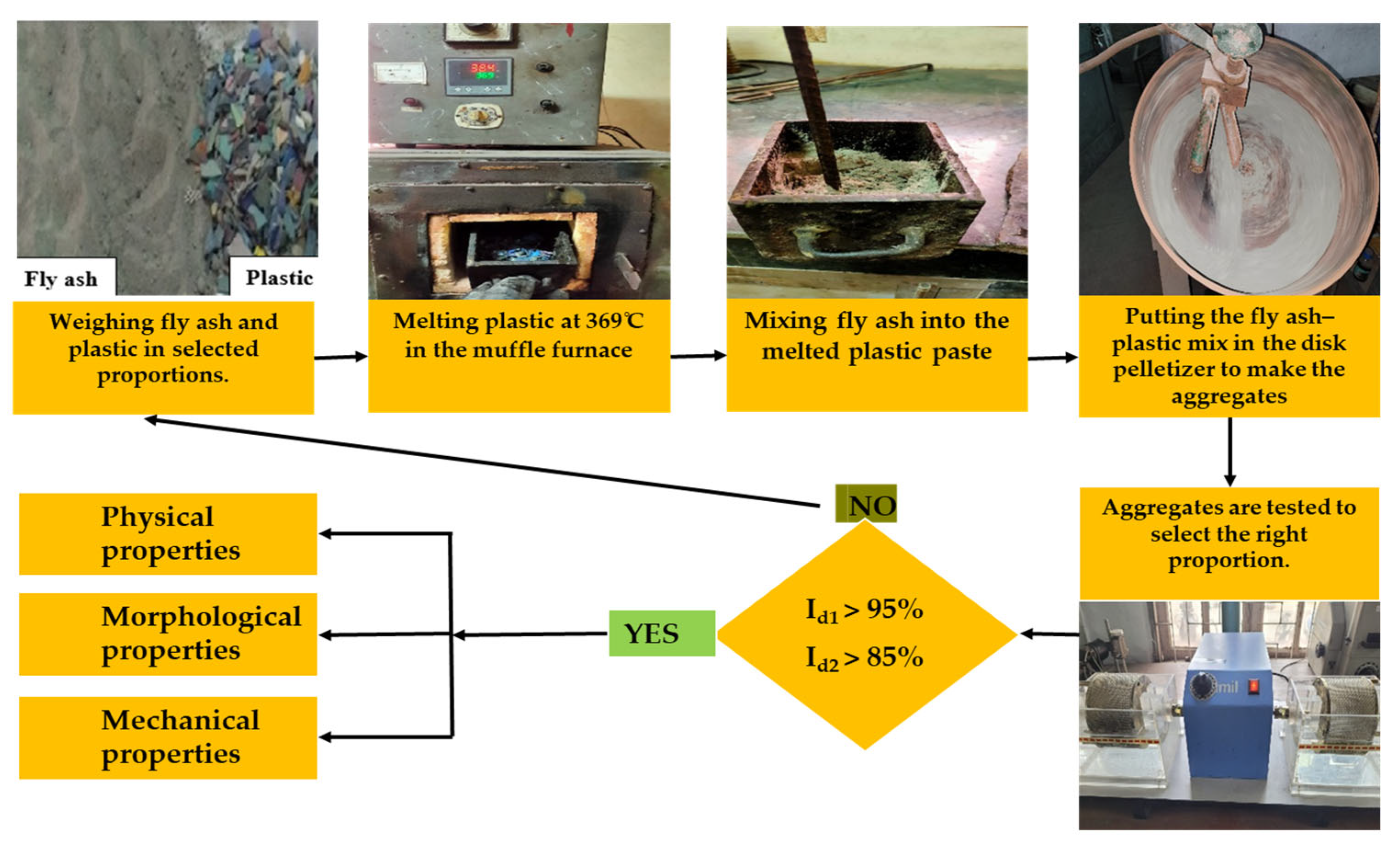

2.1.4. Preparation of Fly Ash–Plastic Aggregate

2.2. Methodology

3. Results and Discussion

3.1. Effect of Plastic Binding on Durability

Slake Durability

3.2. Effect of Plastic Binding on Physical Properties

3.2.1. Particle Size Analysis

3.2.2. Specific Gravity

3.2.3. Permeability

3.3. Effect of Plastic Binding on Morphology

Scanning Electron Micrograph Analysis

3.4. Effect of Plastic Binding on Mechanical Properties

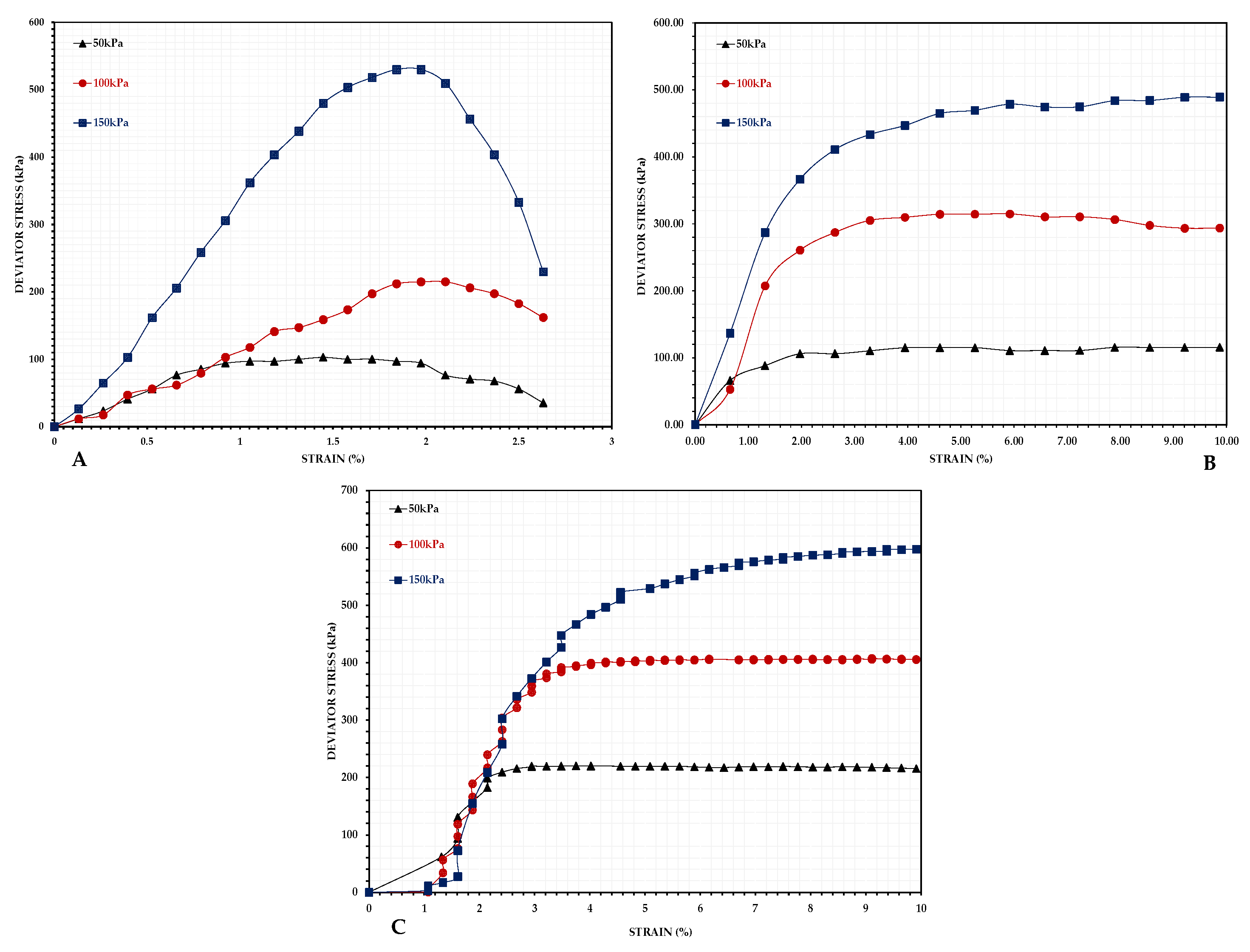

3.4.1. Stress–Strain Behavior

3.4.2. Shear Strength Parameters

4. Conclusions

- The slake durability index of FPA was recorded as Id1 = Id2 = 97.09, classifying it within the category of extremely high durability.

- Particle size distribution analysis showed that FPA contains an increased proportion of gravel- and sand-sized particles, with less than 10% silt-sized particles, and exhibits a well-graded distribution.

- The specific gravity of FPA was measured at 1.34, making it lighter than both FA and sand.

- The permeability of FPA was found to be 3.6 × 10−5 m/s, which is approximately 25 times greater than that of FA.

- FESEM analysis revealed that FPA exhibits sand-like, angular particle morphology with smooth edges and a rough surface texture.

- The stress–strain behavior indicated that FPA undergoes strain hardening without a distinct peak, similarly to sand and in contrast to the brittle or strain-softening behavior observed in FA.

- Shear strength analysis showed that FPA has an internal friction angle of 40°57′ and exhibits a small degree of cohesion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FA | Fly Ash |

| FPA | Fly Ash–Plastic Aggregate |

| HDPE | High-Density Polyethylene |

| MoEFCC | Ministry of Environment, Forest and Climate Change |

| MSW | Municipal Solid Waste |

| SCCL | Singareni Collieries Company Limited |

| ASTM | American Standards for Testing Materials |

| PSA | Particle Size Analysis |

| CU | Coefficient of Uniformity |

| CC | Coefficient of Curvature |

| XRF | X-Ray Fluorescence |

| OMC | Optimum Moisture Content |

| MDD | Maximum Dry Density |

| CTPS | Chandrapura Thermal Power Station |

| DVC | Damodar Valley Corporation |

| FESEM | Field Emission Scanning Electron Microscopy |

| SE | Secondary Electron |

| C | Cohesion |

| F | Angle of Internal Friction |

References

- Topuz, E.; Karfakis, M.G.; Bowman, C.H. Characterization of coal-mine refuse as backfilling material. Geotech. Geol. Eng. 1996, 14, 129–150. [Google Scholar] [CrossRef]

- Sivakugan, N.; Jayakodi, S.; To, P. Geotechnical Considerations of Mine Tailings Management Through Mine Backfilling; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–30. [Google Scholar] [CrossRef]

- Pacheco, M.; Sivakugan, N.; Rankine, R. Underground mining with backfills. Soils Rocks 2007, 30, 93–101. [Google Scholar] [CrossRef]

- Sivakugan, N.; To, P.; Thanayamwatte, P. Hydraulic Backfill Consolidation in Underground Mine Stopes. Int. J. Geosynth. Ground Eng. 2024, 10, 50. [Google Scholar] [CrossRef]

- Karanam, U.M.R.; Mishra, M.K. Geotechnical characterization of fly ash composites for backfilling mine voids. Geotech. Geol. Eng. 2006, 24, 1749–1765. [Google Scholar] [CrossRef]

- The Gazette of India. Ministry of Environment and Forests Notification. New Delhi. November 2009. Available online: https://cpcb.nic.in/fly-ash-management-and-utilization/ (accessed on 11 April 2025).

- Longarini, N.; Crespi, P.; Zucca, M.; Giordano, N.; Silvestro, G. The advantages of fly ash use in concrete structures. Inz. Miner. 2014, 15, 141–145. [Google Scholar]

- Mohapatra, S.; Singh, G.; Kumar, S. An assessment of the physical, mineral, and rheological properties of fly ash for stowing in coal mines. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 2955–2962. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, D.P. Evaluation of Some Parameters in Relation to Hydraulic Stowing of Pond Ash in Underground Coal Mines: A Prototype Study. J. Inst. Eng. India Ser. D 2015, 96, 37–42. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, D.P. Comprehensive characterization of pond ash and pond ash slurries for hydraulic stowing in underground coal mines. Part. Sci. Technol. 2014, 32, 456–465. [Google Scholar] [CrossRef]

- Mishra, D.P. Fly Ash Stowing in India—An Emerging Technology. 2007. Available online: https://www.researchgate.net/publication/290279068 (accessed on 26 February 2025).

- Khan, H.; Ahmad, W.; Khan, K.; Yousaf, S.; Ilyas, M.; Nazir, S. Plastic Waste as a Significant Threat to Environment—A Systematic Literature Review; De Gruyter: Berlin, Germany, 2018. [Google Scholar] [CrossRef]

- Ratnayake, A.S.; Pilapitiya, P.N.T. The World of Plastic Waste: A Review; Elsevier Ltd.: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Al Ansari, M.S. Improving solid waste management in Gulf Co-operation Council States: Developing Integrated Plans to Achieve Reduction in Greenhouse Gases. Mod. Appl. Sci. 2012, 6, 60–68. [Google Scholar] [CrossRef]

- Bansal, P.; Bose, B.; Mondal, M. Recycling waste thermoplastic for energy efficient construction materials: An experimental investigation. J. Environ. Manag. 2019, 240, 119–125. [Google Scholar] [CrossRef]

- Thakare, K.A.; Vishwakarma, H.G.; Bhave, A.G. Experimental Investigation of Possible Use of HDPE as Thermal Storage Material in Thermal Storage Type Solar Cookers. Int. J. Res. Eng. Technol. 2015, 4, 2321–7308. Available online: http://www.ijret.org (accessed on 26 February 2025).

- ASTM D4644; Standard Test Method for Slake Durability of Shales and Other Similar Weak Rocks. ASTM International: West Conshohocken, PA, USA, 2016.

- Chandra, R.; Franklin, J. The slake-durability test. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 1972, 9, 325–328. [Google Scholar] [CrossRef]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D550; Methods of Testing Glass Spool Insulators (Withdrawn 1957). ASTM International: West Conshohocken, PA, USA, 2014.

- Arora, K.R. Soil Mechanics and Foundation Engineering, 6th ed.; Standard Publishers Distributors: Delhi, India, 2004. [Google Scholar]

- Skrzypkowski, K. Compressibility of materials and backfilling mixtures with addition of solid wastes from flue-gas treatment and fly ashes. E3S Web Conf. 2018, 71, 00007. [Google Scholar] [CrossRef]

- ASTM D2434; Standard Test Methods for Measurement of Hydraulic Conductivity of Coarse-Grained Soils. ASTM International: West Conshohocken, PA, USA, 2022.

- Rao, B.H.; Sekhar, K. Assessment of fly ash based sand as a perspective alternate backfill material for stowing in mining activity. Discov. Geosci. 2024, 2, 79. [Google Scholar] [CrossRef]

- Mishra, D.P.; Das, S.K. Application of polymeric flocculant for enhancing settling of the pond ash particles and water drainage from hydraulically stowed pond ash. Int. J. Min. Sci. Technol. 2013, 23, 21–26. [Google Scholar] [CrossRef]

- Paul, B.; Gupta, A.K. Comparative analysis of different materials to be used for backfilling in underground mine voids with a particular reference to hydraulic stowing. Int. J. Oil Gas Coal Technol. 2017, 15, 425. [Google Scholar] [CrossRef]

- Daghistani, F.; Abuel-Naga, H. Evaluating the Influence of Sand Particle Morphology on Shear Strength: A Comparison of Experimental and Machine Learning Approaches. Appl. Sci. 2023, 13, 8160. [Google Scholar] [CrossRef]

- ASTM D2850; Standard Test Method for Unconsolidated-Undrained Triaxial Compression Test on Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2024.

- Guner, N.U.; Sari, M.; Kasap, T.; Yilmaz, E. Cementitious Backfill with Partial Replacement of Cu-Rich Mine Tailings by Sand: Rheological, Mechanical and Microstructural Properties. Minerals 2023, 13, 437. [Google Scholar] [CrossRef]

- Zhang, S.; Du, S.; Li, J.; Yang, S.; Che, C.; Liu, Y.; Zhao, C. Effect of Fly Ash and Steel Fiber Content on Workability and Mechanical Properties of Roadway Side Backfilling Materials in Deep Mine. Energies 2023, 16, 1505. [Google Scholar] [CrossRef]

- Ram, A.K.; Mohanty, S. State of the Art Review on Physiochemical and Engineering Characteristics of Fly Ash and Its Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Potvin, Y.; Thomas, E.; Fourie, A. Handbook on Mine Fill; Australian Centre for Geomechanics: Crawley, Australia, 2005. [Google Scholar]

| Property | River Sand | Fly Ash |

|---|---|---|

| Specific gravity | 2.66 | 2.00 |

| Grain size analysis | D10 = 0.26 | D10 = 0.032 |

| D30 = 0.41 | D30 = 0.044 | |

| D60 = 0.9 | D60 = 0.075 | |

| CU = 3.46 | CU = 3.46 | |

| CC = 0.72 | CC = 0.72 | |

| Poorly graded | Poorly graded | |

| Optimum moisture content | 5.16% | 35.3% |

| Maximum dry density | 1.66 g/cc | 1.15 g/cc |

| Coefficient of permeability | 1.29 × 10−4 m/s | 1.387 × 10−6 m/s |

| Material | Chemical Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | TiO2 | MnO | MgO | K2O | Na2O | P2O5 | LOI | |

| River sand | 63.03 | 11.11 | 5.50 | 13.11 | 1.62 | 0.10 | 1.27 | 2.77 | 1.31 | 0.17 | 0.00 |

| Fly ash | 55.82 | 31.57 | 4.66 | 0.65 | 2.36 | 0.04 | 0.37 | 1.51 | 0.06 | 0.45 | 2.50 |

| Material | Gravel (4.75 to 20 mm) | Coarse Sand (2 to 4.75 mm) | Medium Sand (0.425 to 2 mm) | Fine Sand (0.075 to 0.425 mm) | Silts (0.002 to 0.075 mm) |

|---|---|---|---|---|---|

| FA | 0 | 0 | 0 | 57.34 | 42.66 |

| Sand | 3.04 | 5.51 | 42.25 | 48.62 | 0.58 |

| FPA | 17.16 | 18.54 | 37.28 | 25.64 | 1.38 |

| Material | (σ3) kPa | (σ1) kPa | P (kPa) (σ1 + σ3)/2 | Q (kPa) (σ1 − σ3)/2 | Regression Equation of Failure Envelope | Cohesion (kPa) | Angle of Internal Friction (F) |

|---|---|---|---|---|---|---|---|

| Fly Ash | 50 | 153.00 | 101.50 | 51.50 | y = 0.6918x − 25.622 R2 = 0.9931 | 0 | 43°46′ |

| 100 | 314.98 | 207.49 | 107.49 | ||||

| 150 | 680.02 | 415.01 | 265.01 | ||||

| Sand | 50 | 187.36 | 118.67 | 68.67 | y = 0.6388x − 7.2133 R2 = 1 | 0 | 39°42′ |

| 100 | 412.95 | 256.47 | 156.47 | ||||

| 150 | 641.09 | 395.54 | 245.54 | ||||

| FPA | 50 | 270.39 | 160.19 | 110.19 | y = 0.6555x + 4.9995 R2 = 1 | 6.62 | 40°57′ |

| 100 | 507.28 | 303.64 | 203.64 | ||||

| 150 | 750.85 | 450.43 | 300.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manohar, M.; Choudhary, B.S.; Skrzypkowski, K.; Zagórski, K.; Zagórska, A. A Performance Evaluation of Fly Ash–Plastic Aggregate in Hydraulic Backfilling: A Comparative Study. Materials 2025, 18, 2751. https://doi.org/10.3390/ma18122751

Manohar M, Choudhary BS, Skrzypkowski K, Zagórski K, Zagórska A. A Performance Evaluation of Fly Ash–Plastic Aggregate in Hydraulic Backfilling: A Comparative Study. Materials. 2025; 18(12):2751. https://doi.org/10.3390/ma18122751

Chicago/Turabian StyleManohar, Munipala, Bhanwar Singh Choudhary, Krzysztof Skrzypkowski, Krzysztof Zagórski, and Anna Zagórska. 2025. "A Performance Evaluation of Fly Ash–Plastic Aggregate in Hydraulic Backfilling: A Comparative Study" Materials 18, no. 12: 2751. https://doi.org/10.3390/ma18122751

APA StyleManohar, M., Choudhary, B. S., Skrzypkowski, K., Zagórski, K., & Zagórska, A. (2025). A Performance Evaluation of Fly Ash–Plastic Aggregate in Hydraulic Backfilling: A Comparative Study. Materials, 18(12), 2751. https://doi.org/10.3390/ma18122751