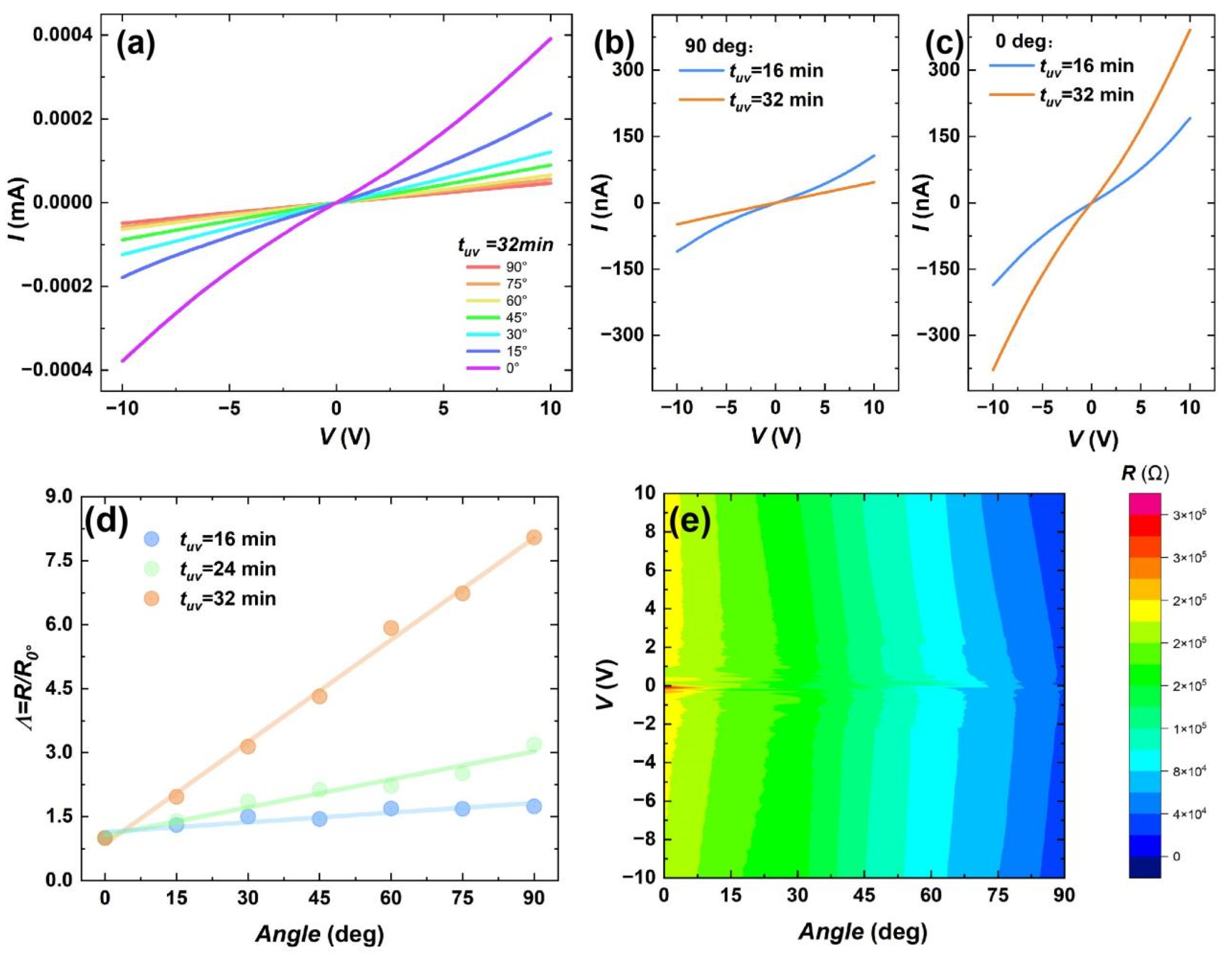

Anisotropic Photoelectric Properties of Aligned P3HT Nanowire Arrays Fabricated via Solution Blade Coating and UV-Induced Molecular Ordering

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Solution Preparation

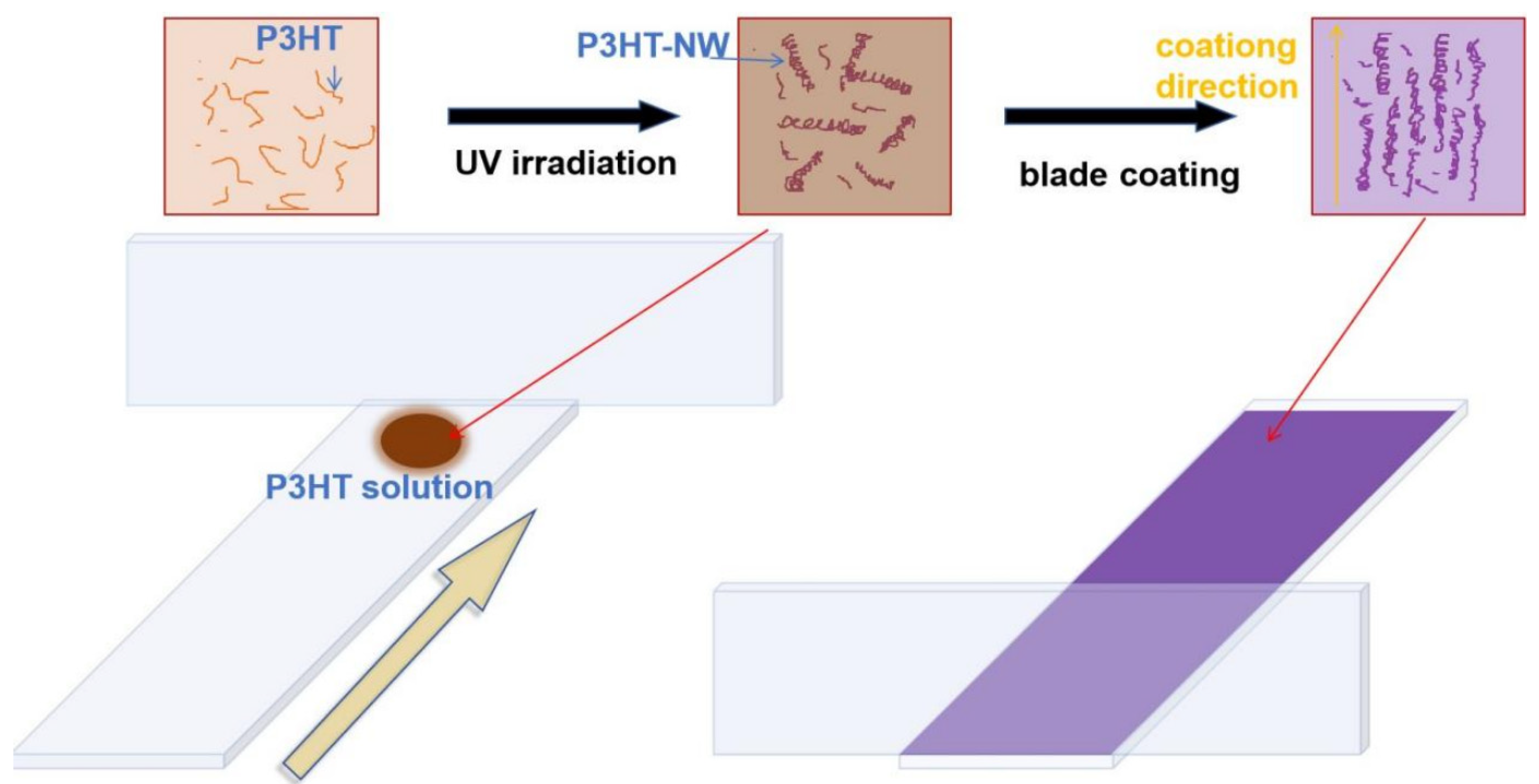

2.2. Fabricating the P3HT Films

2.3. Electrical Property Measurements

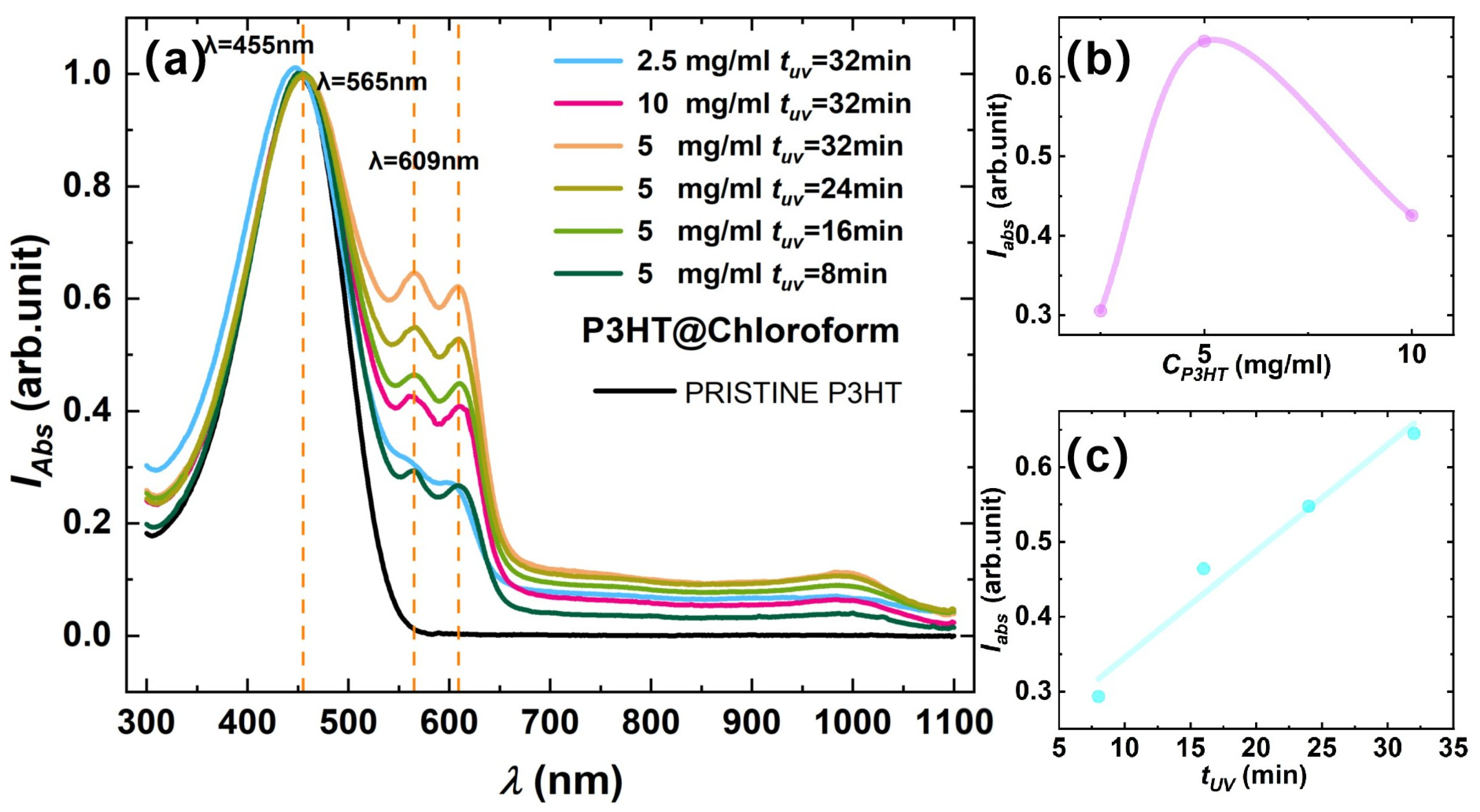

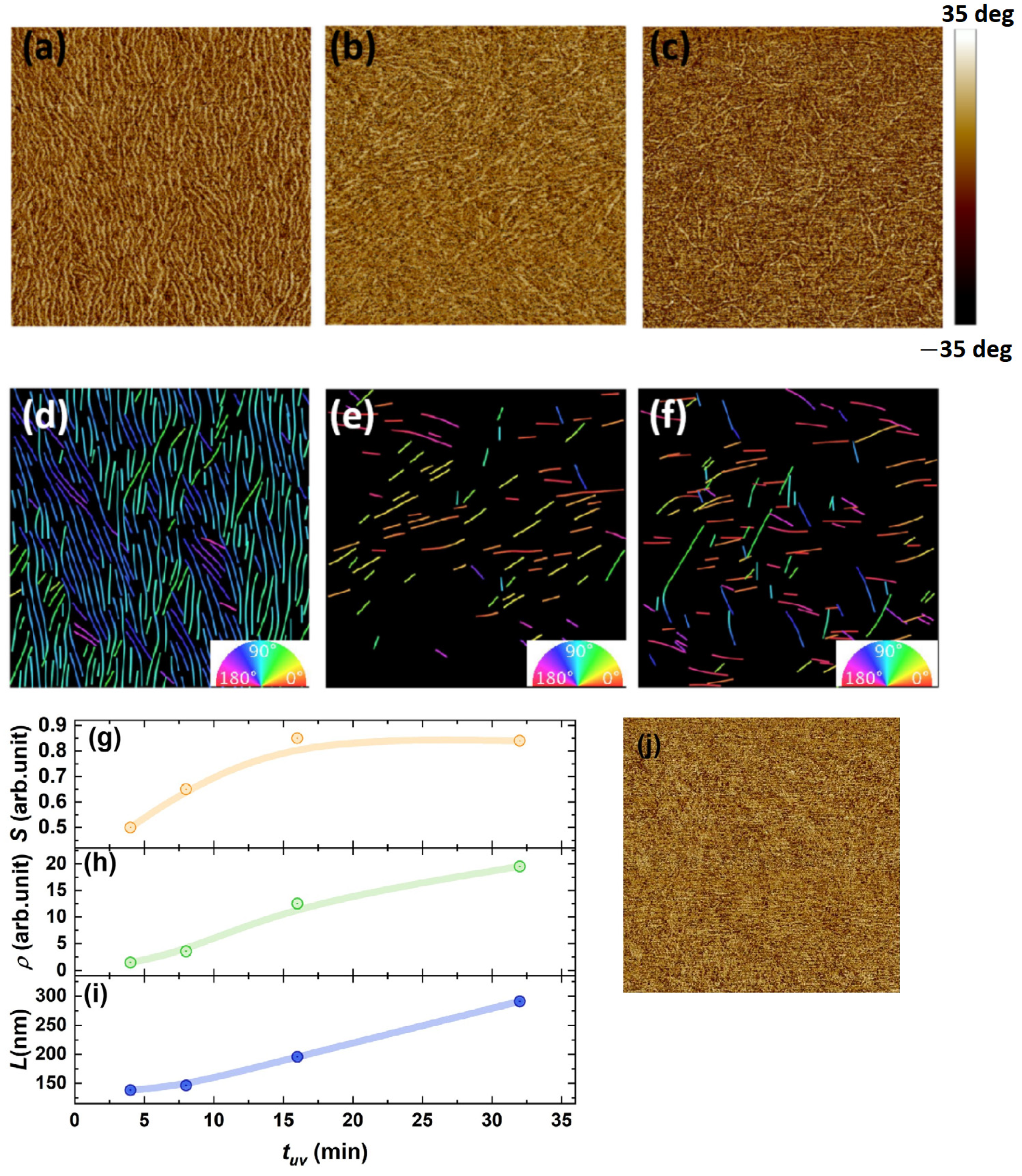

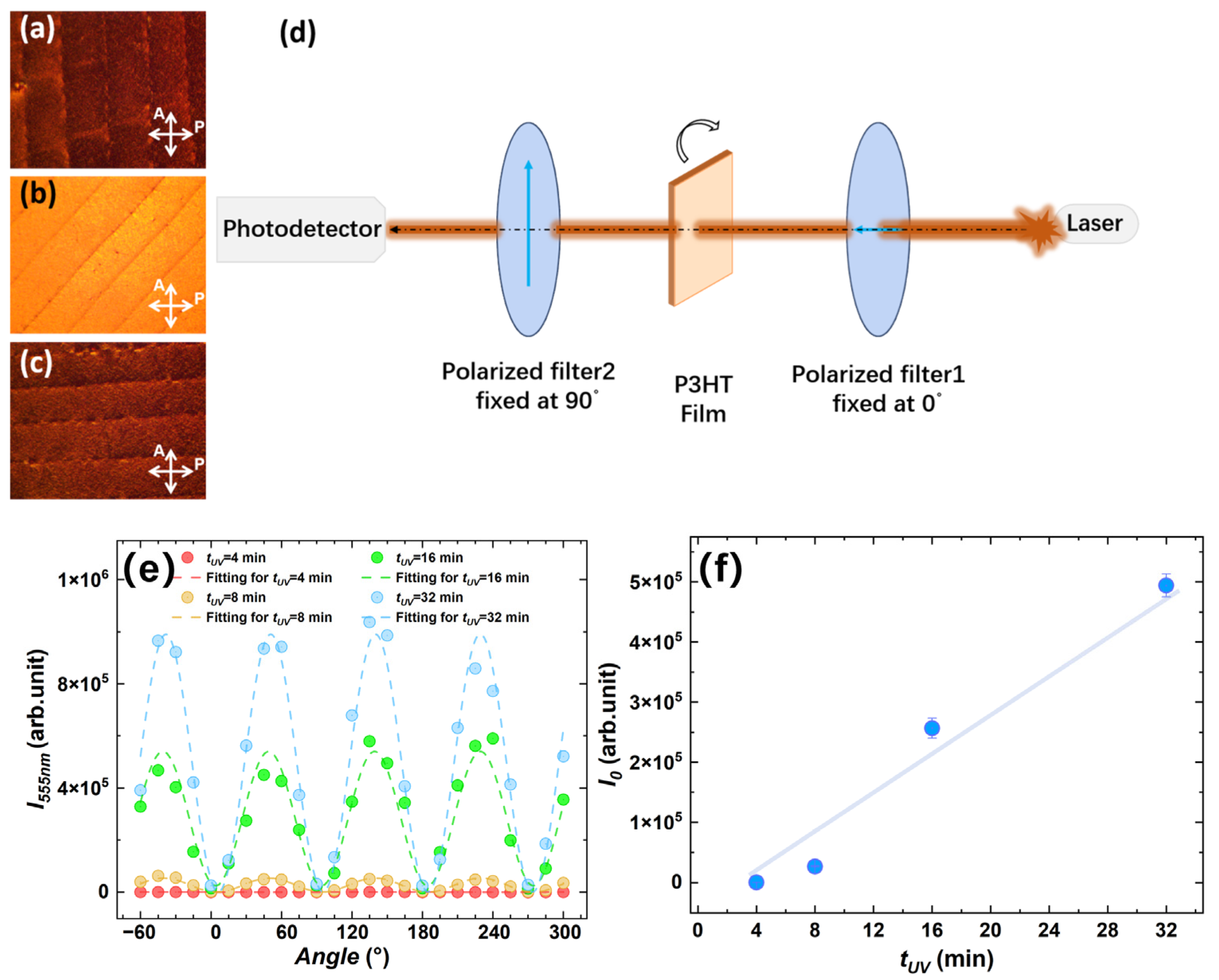

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| P3HT | Poly(3-hexylthiophene) |

| NW | Nanowire |

| NF | Nanofiber |

| OSC | Organic semiconductor |

| CPs | Conjugated polymers |

| AFM | Atomic force microscopy |

| POM | Polarized optical microscopy |

| UV | Ultraviolet |

| DC | Direct current |

References

- Kim, B.G.; Jeong, E.J.; Chung, J.W.; Seo, S.; Koo, B.; Kim, J.S. A Molecular Design Principle of Lyotropic Liquid-Crystaline Conjugated Polymers with Direct Alignment Capability for Plastic Electronics. Nat. Mater. 2013, 12, 659–664. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, V.; Pandey, R.K.; Prakash, R.; Kumar, N.; Singh, A.K. Highly aligned and crystalline poly(3-hexylthiophene) thin films by off-center spin coating for high performance organic field-effect transistors. Synth. Met. 2019, 258, 116221. [Google Scholar] [CrossRef]

- Li, J.H.; Sun, Z.H.; Yan, F. Solution Processable Low-Voltage Organic Thin Film Transistors with High-k Relaxor Ferroelectric Polymer as Gate Insulator. Adv. Mater. 2012, 24, 88–93. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, N.; Wang, J.Y.; Li, C.M.; Li, D.Y.; Fu, H.; Gu, D.E.; Jiang, X.D.; Liu, F.C.; Jiang, Y.D.; Li, W. Nanostructured Materials and Architectures for Advanced Optoelectronic Synaptic Devices. Adv. Funct. Mater. 2022, 32, 2110976. [Google Scholar] [CrossRef]

- Hua, Q.L.; Shen, G.Z. Low-dimensional nanostructures for monolithic 3D-integrated flexible and stretchable electronics. Chem. Soc. Rev. 2024, 53, 1316–1353. [Google Scholar] [CrossRef]

- Persson, N.E.; Rafshoon, J.; Naghshpour, K.; Fast, T.; Chu, P.H.; McBride, M.; Risteen, B.; Groyer, M.; Reichmanis, E. High-Throughput Image Analysis of Fibrillar Materials: A Case Study on Polymer Nanofiber Packing, Alignment, and Defects in Organic Field Effect Transistors. ACS Appl. Mater. Interfaces 2017, 9, 36090–36102. [Google Scholar] [CrossRef]

- Kline, R.J.; Mcgehee, M.D.; Toney, M.F. Highly oriented crystals at the buried interface in polythiophene thin-film transistors. Nat. Mater. 2006, 5, 222–228. [Google Scholar] [CrossRef]

- Ding, L.; Yu, Z.D.; Wang, X.Y.; Yao, Z.F.; Lu, Y.; Yang, C.Y.; Wang, J.Y.; Pei, J. Polymer Semiconductors: Synthesis, Processing, and Applications. Chem. Rev. 2023, 123, 7421–7497. [Google Scholar] [CrossRef]

- Berger, P.R.; Kim, M. Polymer solar cells: P3HT: PCBM and beyond. J. Renew. Sustain. Energy 2018, 10, 013508. [Google Scholar] [CrossRef]

- Agrahari, K.; Chi, M.H.; Priya, S.L.; Cheng, Y.H.; Wang, Y.W. Low voltage driven P3HT/PS phototransistor for ultra-high power efficiency UV sensing. Org. Electron. 2024, 128, 107033. [Google Scholar] [CrossRef]

- Yoon, H. Current Trends in Sensors Based on Conducting Polymer Nanomaterials. Nanomaterials 2013, 3, 524–549. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.A.; Kim, J.H.; Qiu, L.; Lee, W.H.; Lee, H.S.; Kwak, D.; Cho, K. Inkjet-Printed Single-Droplet Organic Transistors Based on Semiconductor Nanowires Embedded in Insulating Polymers. Adv. Funct. Mater. 2010, 20, 3292–3297. [Google Scholar] [CrossRef]

- Noriega, R.; Rivnay, J.; Vandewal, K.; Koch, F.P.V.; Stingelin, N.; Smith, P.; Toney, M.F.; Salleo, A. A general relationship between disorder, aggregation and charge transport in conjugated polymers. Nat. Mater. 2013, 12, 1038–1044. [Google Scholar] [CrossRef]

- Kleinhenz, N.; Persson, N.; Xue, Z.Z.; Chu, P.H.; Wang, G.; Yuan, Z.B.; McBride, M.A.; Choi, D.; Grover, M.A.; Reichmanis, E. Ordering of Poly(3-hexylthiophene) in Solutions and Films: Effects of Fiber Length and Grain Boundaries on Anisotropy and Mobility. Chem. Mater. 2016, 28, 3905–3913. [Google Scholar] [CrossRef]

- O’Connor, B.; Kline, R.J.; Conrad, B.R.; Richter, L.J.; Gundlach, D.; Toney, M.F.; DeLongchamp, D.M. Anisotropic Structure and Charge Transport in Highly Strain-Aligned Regioregular Poly(3-hexylthiophene). Adv. Funct. Mater. 2011, 21, 3697–3705. [Google Scholar] [CrossRef]

- Chang, M.; Choi, D.; Wang, G.; Kleinhenz, N.; Persson, N.; Park, B.; Reichmanis, E. Photoinduced Anisotropic Assembly of Conjugated Polymers in Insulating Polymer Blends. ACS Appl. Mater. Interfaces 2015, 7, 14095–14103. [Google Scholar] [CrossRef]

- Qiu, L.Z.; Lee, W.H.; Wang, X.H.; Kim, J.S.; Lim, J.A.; Kwak, D.; Lee, S.; Cho, K. Organic Thin-film Transistors Based on Polythiophene Nanowires Embedded in Insulating Polymer. Adv. Mater. 2009, 21, 1349–1353. [Google Scholar] [CrossRef]

- Cao, L.; Ren, C.X.; Wu, T. Recent advances in doped organic field-effect transistors: Mechanism, influencing factors, materials, and development directions. J. Mater. Chem. C 2023, 11, 3428–3447. [Google Scholar] [CrossRef]

- Kwon, E.H.; Kim, G.W.; Kim, M.; Park, Y.D. Effect of Alcohol Polarity on the Aggregation and Film-Forming Behaviors of Poly(3-hexylthiophene). ACS Appl. Polym. Mater. 2020, 2, 2980–2986. [Google Scholar] [CrossRef]

- Shabi, T.S.; Grigorian, S.; Brinkmann, M.; Pietsch, U.; Koenen, N.; Kayunkid, N.; Scherf, U. Enhancement in crystallinity of poly(3-hexylthiophene) thin films prepared by low-temperature drop casting. J. Appl. Polym. Sci. 2012, 125, 2335–2341. [Google Scholar] [CrossRef]

- Jang, G.N.; Hong, S.Y.; Park, H.; Lee, Y.H.; Park, H.; Lee, H.; Jeong, Y.R.; Jin, S.W.; Keum, K.; Ha, J.S. Highly sensitive pressure and temperature sensors fabricated with poly(3-hexylthiophene-2,5-diyl)-coated elastic carbon foam for bio-signal monitoring. Chem. Eng. J. 2021, 423, 130197. [Google Scholar] [CrossRef]

- Wales, D.J.; Keshavarz, M.; Howe, C.; Yeatman, E. 3D Printability Assessment of Poly(octamethylene maleate (anhydride) citrate) and Poly(ethylene glycol) Diacrylate Copolymers for Biomedical Applications. ACS Appl. Polym. Mater. 2022, 4, 5457–5470. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.Y.; Chen, J.Y.; Sun, Y.L.; Li, Q.Y.; Cai, Z.X.; Li, J.Y.; Guo, Y.L.; Hu, W.P.; Liu, Y.Q. Fast Deposition of Aligning Edge-On Polymers for High-Mobility Ambipolar Transistors. Adv. Mater. 2019, 31, 1805761. [Google Scholar] [CrossRef] [PubMed]

- Chang, M.; Su, Z.; Egap, E. Alignment and charge transport of one-dimensional conjugated polymer nanowires in insulating polymer blends. Macromolecules 2016, 49, 9449–9456. [Google Scholar] [CrossRef]

- Doerling, B.; Vohra, V.; Dao, T.T.; Garriga, M.; Murata, H.; Campoy-Quiles, M. Uniaxial macroscopic alignment of conjugated polymer systems by directional crystallization during blade coating. J. Mater. Chem. C 2014, 2, 3303–3310. [Google Scholar] [CrossRef]

- Reinspach, J.A.; Diao, Y.; Giri, G.; Sachse, T.; England, K.; Zhou, Y.; Tassone, C.; Worfolk, B.J.; Presselt, M.; Toney, M.F.; et al. Tuning the Morphology of Solution-Sheared P3HT:PCBM Films. ACS Appl. Mater. Interfaces 2016, 8, 1742–1751. [Google Scholar] [CrossRef]

- Diao, Y.; Tee, B.C.-K.; Giri, G.; Xu, J.; Kim, D.H.; Becerril, H.A.; Stoltenberg, R.M.; Lee, T.H.; Xue, G.; Mannsfeld, S.C.B.; et al. Solution Coating of Larger-Area Organic Semiconductor Thin Films with Aligned Single-Crystalline Domains. Nat. Mater. 2013, 12, 665–671. [Google Scholar] [CrossRef]

- Bastianini, F.; Pérez, G.E.; Hobson, A.R.; Rogers, S.E.; Parnell, A.J.; Grell, M.; Gutiérrez, A.F.; Dunbar, A.D.F. In-situ monitoring Poly(3-hexylthiophene) nanowire formation and shape evolution in solution via small angle neutron scattering. Sol. Energy Mater. Sol. Cells 2019, 202, 110128. [Google Scholar] [CrossRef]

- Jeong, G.; Choi, S.; Jang, M.; Chang, M. Thermal annealing effects on the morphology and charge transport of polymer semiconductor nanowires aligned in an insulating polymer matrix. D&P 2021, 185, 108962. [Google Scholar]

- Jordens, S.; Isa, L.; Usov, I.; Mezzenga, R. Non-equilibrium nature of two-dimensional isotropic and nematic coexistence in amyloid fibrils at liquid interfaces. Nat. Commun. 2013, 4, 1917. [Google Scholar] [CrossRef]

- Giri, G.; DeLongchamp, D.M.; Reinspach, J.; Fischer, D.A.; Richter, L.J.; Xu, J.; Benight, S.; Ayzner, A.; He, M.Q.; Fang, L.; et al. Effect of Solution Shearing Method on Packing and Disorder of Organic Semiconductor Polymers. Chem. Mater. 2015, 27, 2350–2359. [Google Scholar] [CrossRef]

- Jo, G.; Jung, J.; Chang, M. Controlled Self-Assembly of Conjugated Polymers via a Solvent Vapor Pre-Treatment for Use in Organic Field-Effect Transistors. Polymers 2019, 11, 332. [Google Scholar] [CrossRef] [PubMed]

- Li, J.L.; Xue, M.L.; Xue, N.; Li, H.H.; Zhang, L.; Ren, Z.J.; Yan, S.K.; Sun, X.L. Highly Anisotropic P3HT Film Fabricated via Epitaxy on an Oriented Polyethylene Film and Solvent Vapor Treatment. Langmuir 2019, 35, 7841–7847. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.L.; Xu, C.Y.; Wu, X.C.; Zhao, X.; Zhang, L.J.; Zhang, G.B.; Wang, X.H.; Qiu, L.Z. Deep ultraviolet light stimulated synaptic transistors based on poly(3-hexylthiophene) ultrathin films. ACS. Appl. Mater. Interfaces 2022, 14, 11718–11726. [Google Scholar] [CrossRef]

| Light Off | I0 (a.u.) | I1 (a.u.) | τ1 (s) | I2 (a.u.) | τ2 (s) |

|---|---|---|---|---|---|

| 0° | 0.821 | 0.124 | 351.2 | 0.054 | 18.7 |

| 90° | 0.686 | 0.226 | 339.1 | 0.089 | 27.8 |

| Light on | I0′ (a.u.) | A1 (a.u.) | τ3 (a.u.) | A2 (a.u.) | τ4 (a.u.) |

| 0° | 1.00 | 0.111 | 196.1 | 0.105 | 10.9 |

| 90° | 1.00 | 0.215 | 245.7 | 0.236 | 16.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, Q.; Luo, J.; Meng, C.; Xiong, Z.; Zhang, S.; Yu, T. Anisotropic Photoelectric Properties of Aligned P3HT Nanowire Arrays Fabricated via Solution Blade Coating and UV-Induced Molecular Ordering. Materials 2025, 18, 2649. https://doi.org/10.3390/ma18112649

Gong Q, Luo J, Meng C, Xiong Z, Zhang S, Yu T. Anisotropic Photoelectric Properties of Aligned P3HT Nanowire Arrays Fabricated via Solution Blade Coating and UV-Induced Molecular Ordering. Materials. 2025; 18(11):2649. https://doi.org/10.3390/ma18112649

Chicago/Turabian StyleGong, Qianxun, Jin Luo, Chen Meng, Zuhong Xiong, Sijie Zhang, and Tian Yu. 2025. "Anisotropic Photoelectric Properties of Aligned P3HT Nanowire Arrays Fabricated via Solution Blade Coating and UV-Induced Molecular Ordering" Materials 18, no. 11: 2649. https://doi.org/10.3390/ma18112649

APA StyleGong, Q., Luo, J., Meng, C., Xiong, Z., Zhang, S., & Yu, T. (2025). Anisotropic Photoelectric Properties of Aligned P3HT Nanowire Arrays Fabricated via Solution Blade Coating and UV-Induced Molecular Ordering. Materials, 18(11), 2649. https://doi.org/10.3390/ma18112649