Effect of Laser Parameters on Through-Thickness Local Hardness of Polypropylene Plates

Abstract

1. Introduction

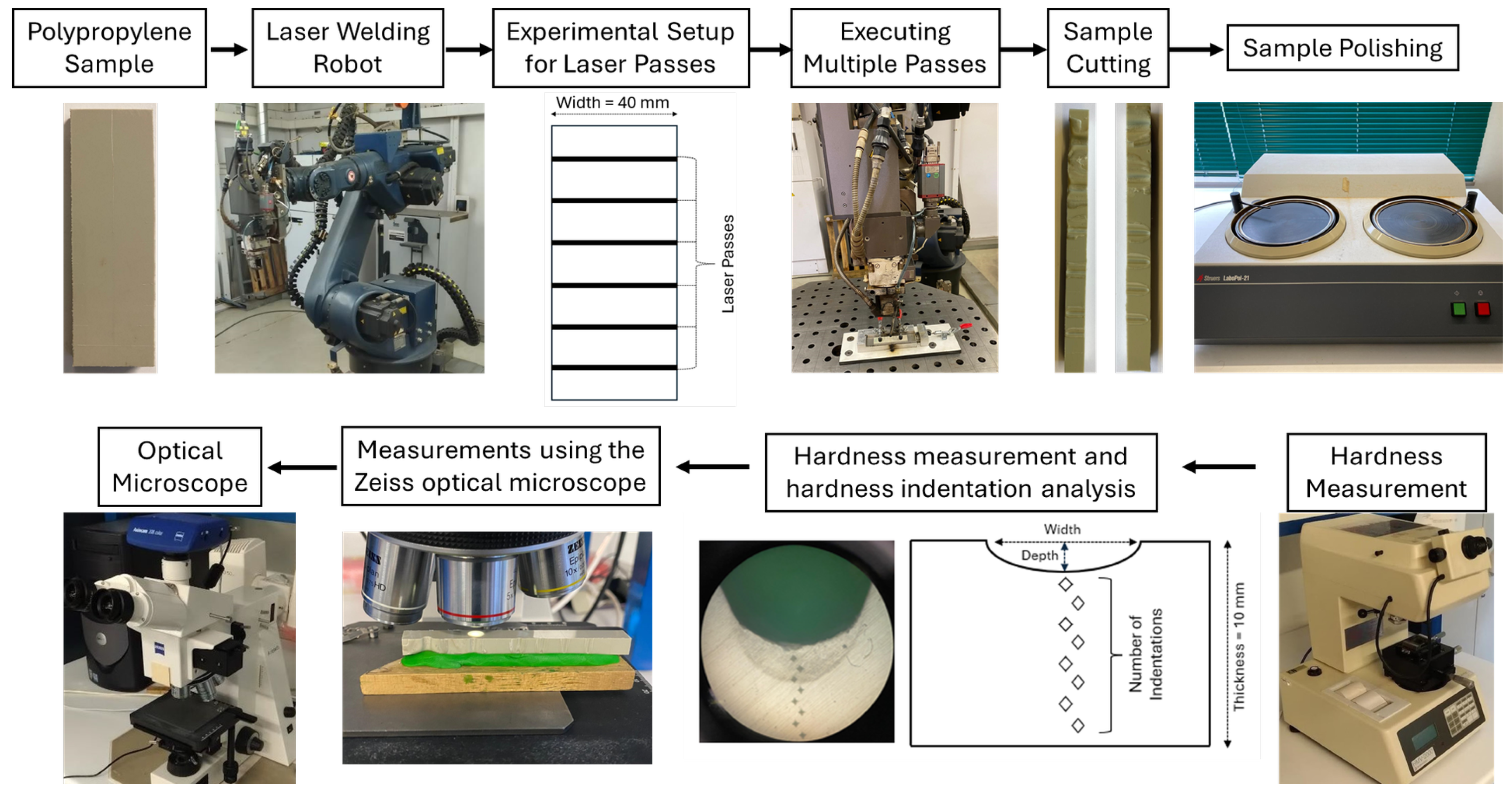

2. Materials and Methods

2.1. Materials and Specimens

2.2. Laser Assisted Welding Setup

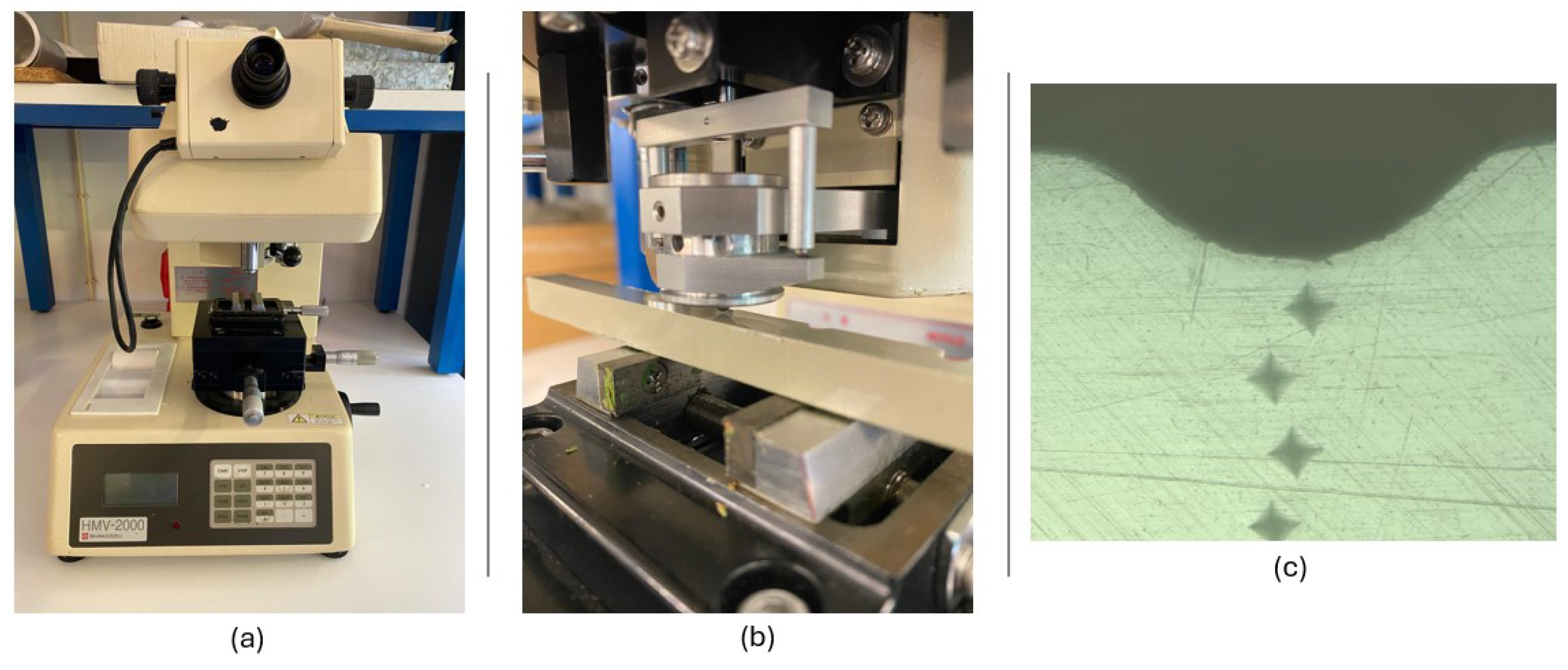

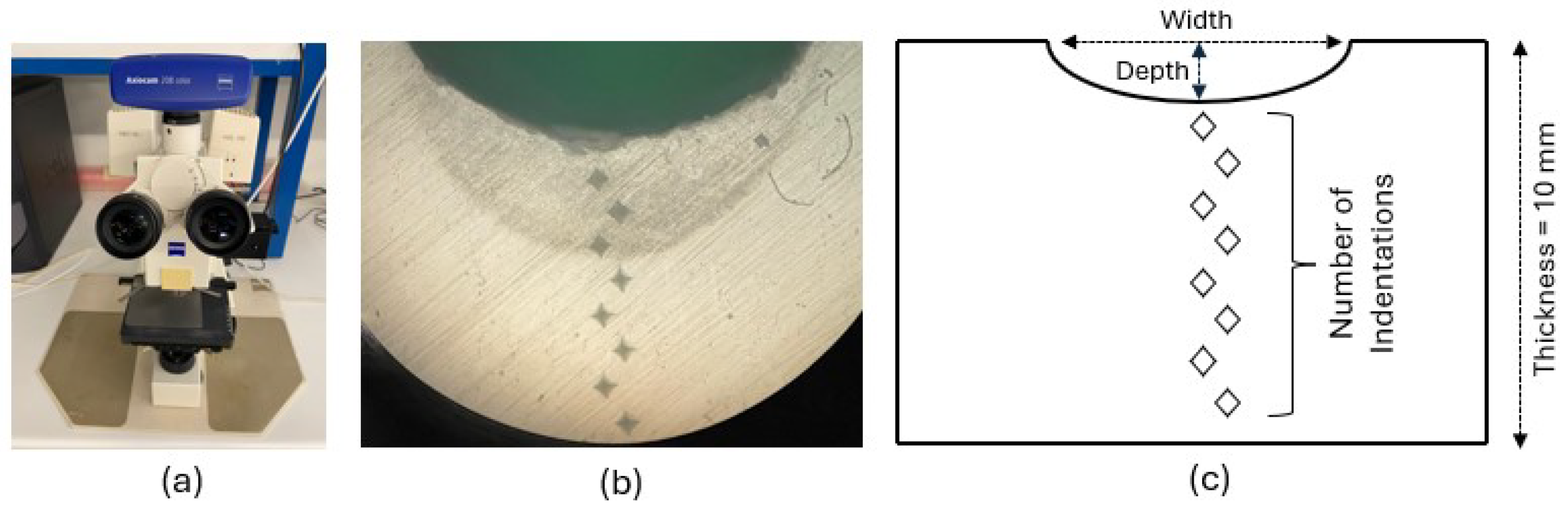

2.3. Hardness Testing

2.4. Data Processing

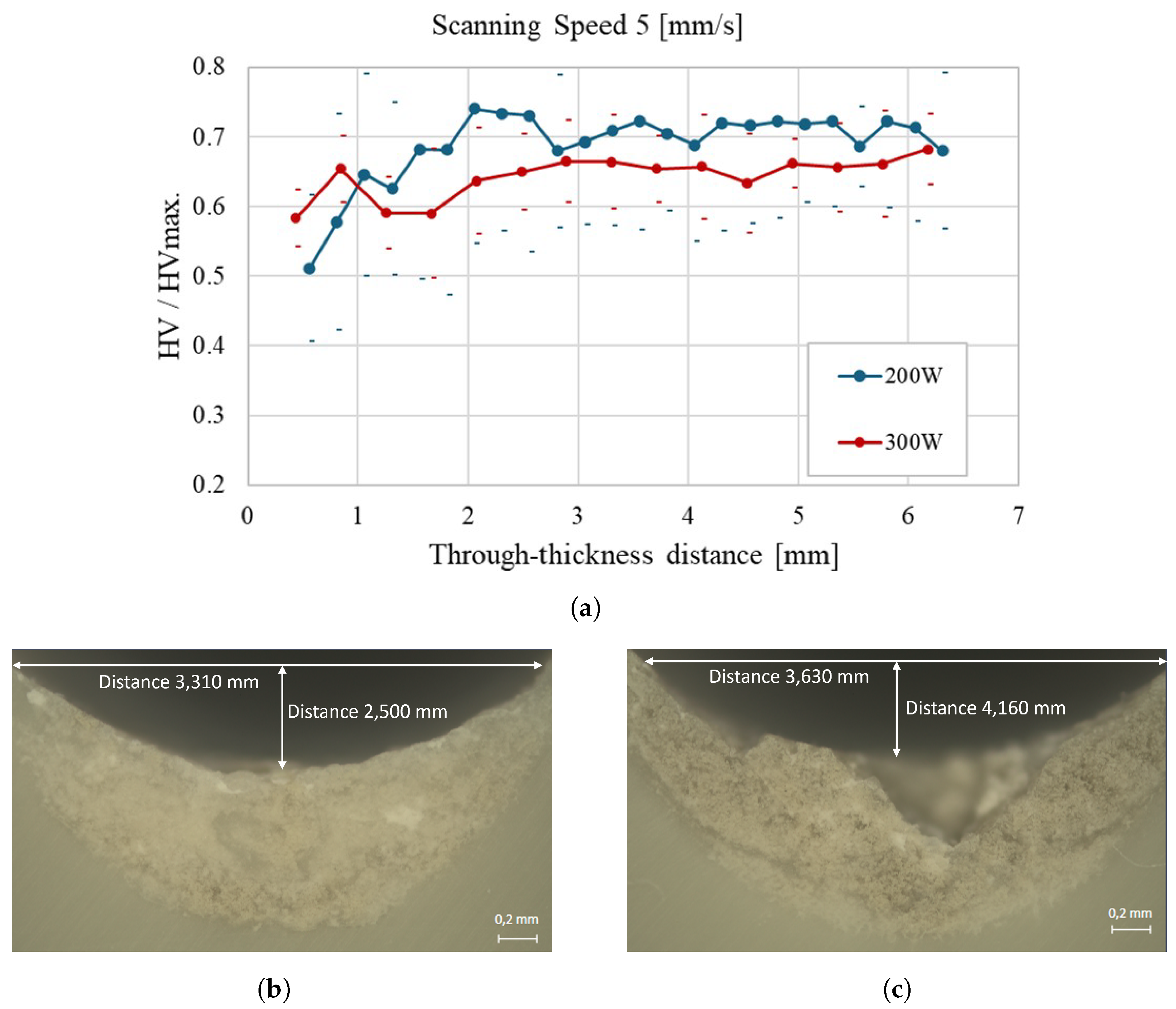

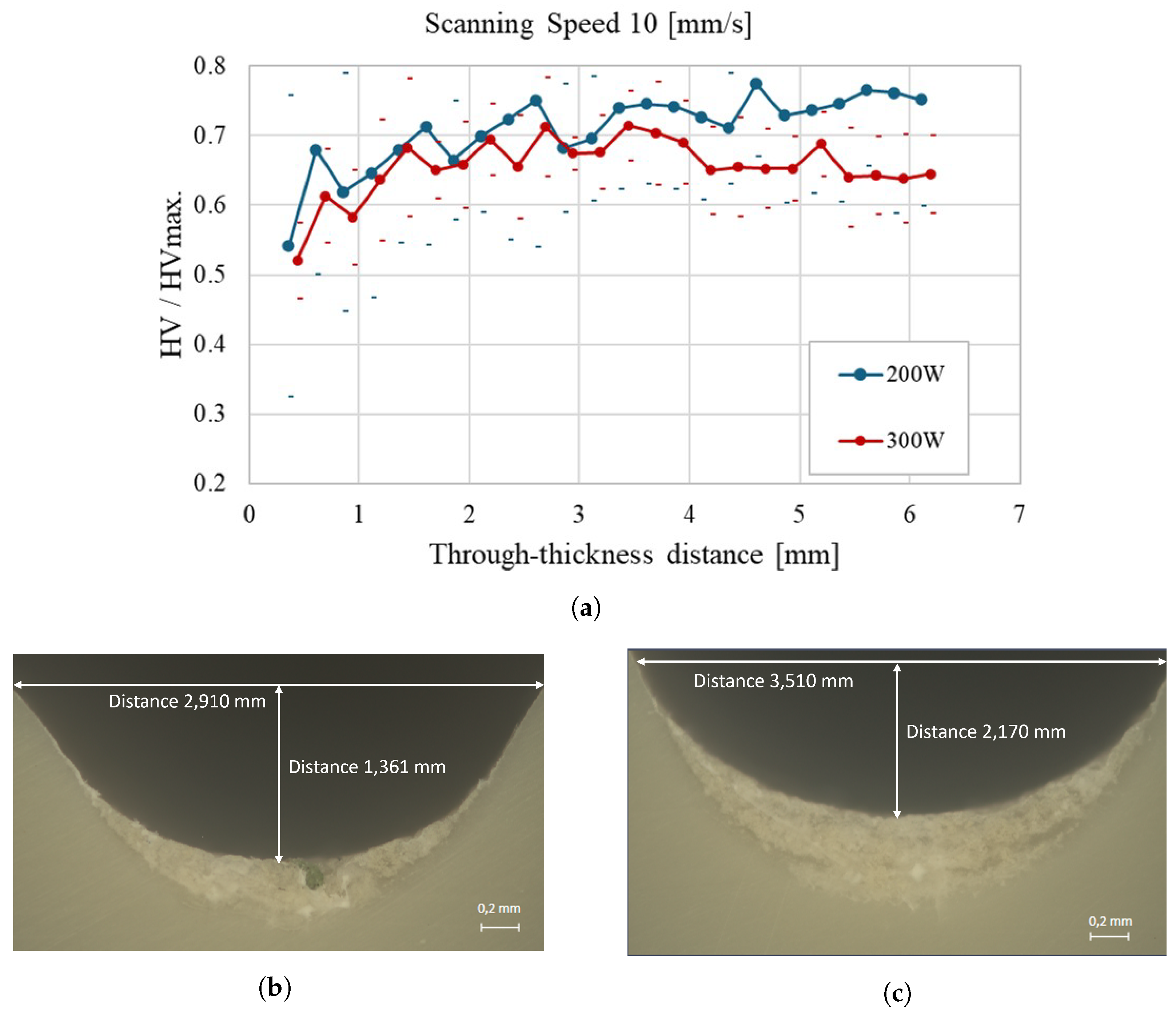

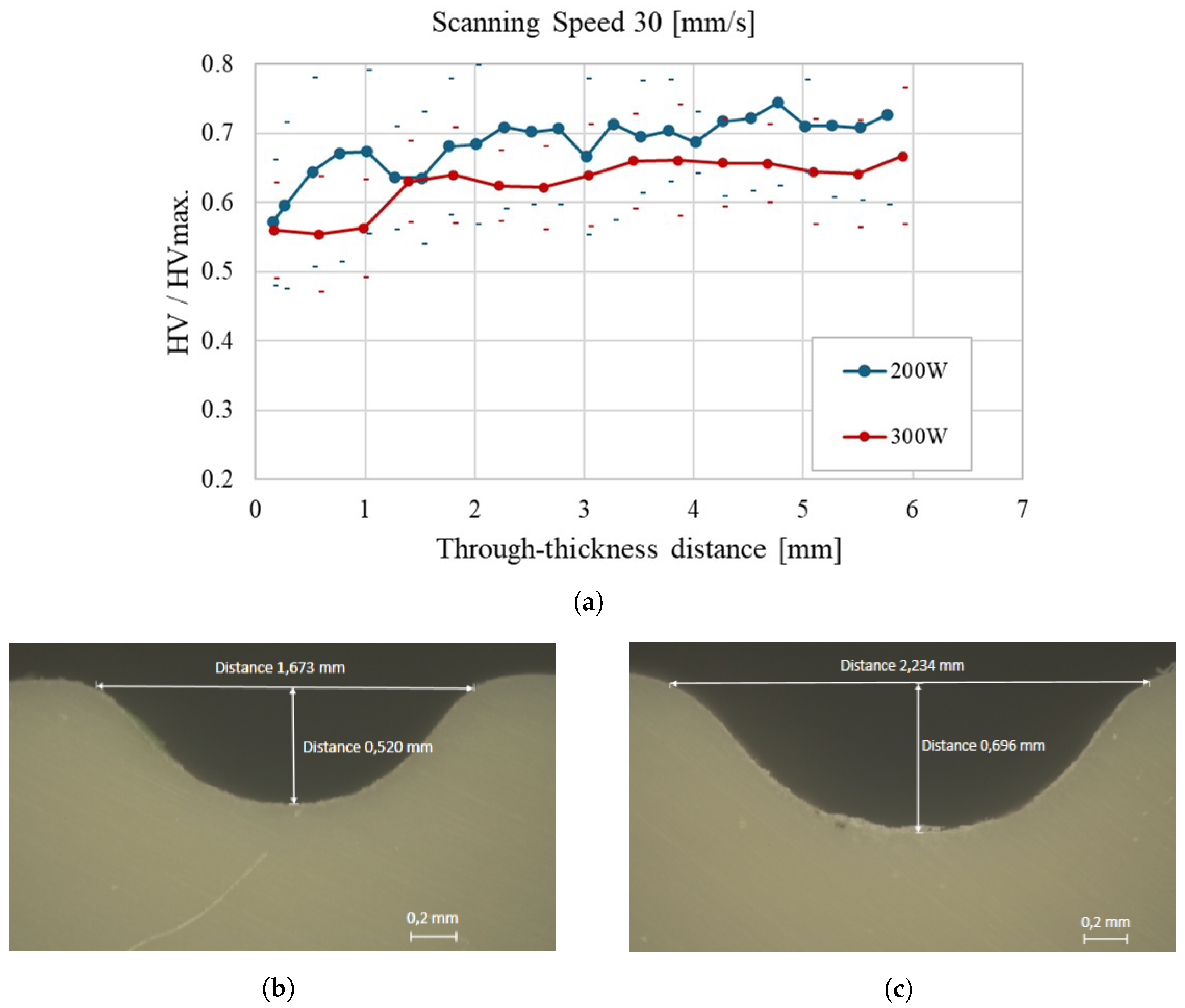

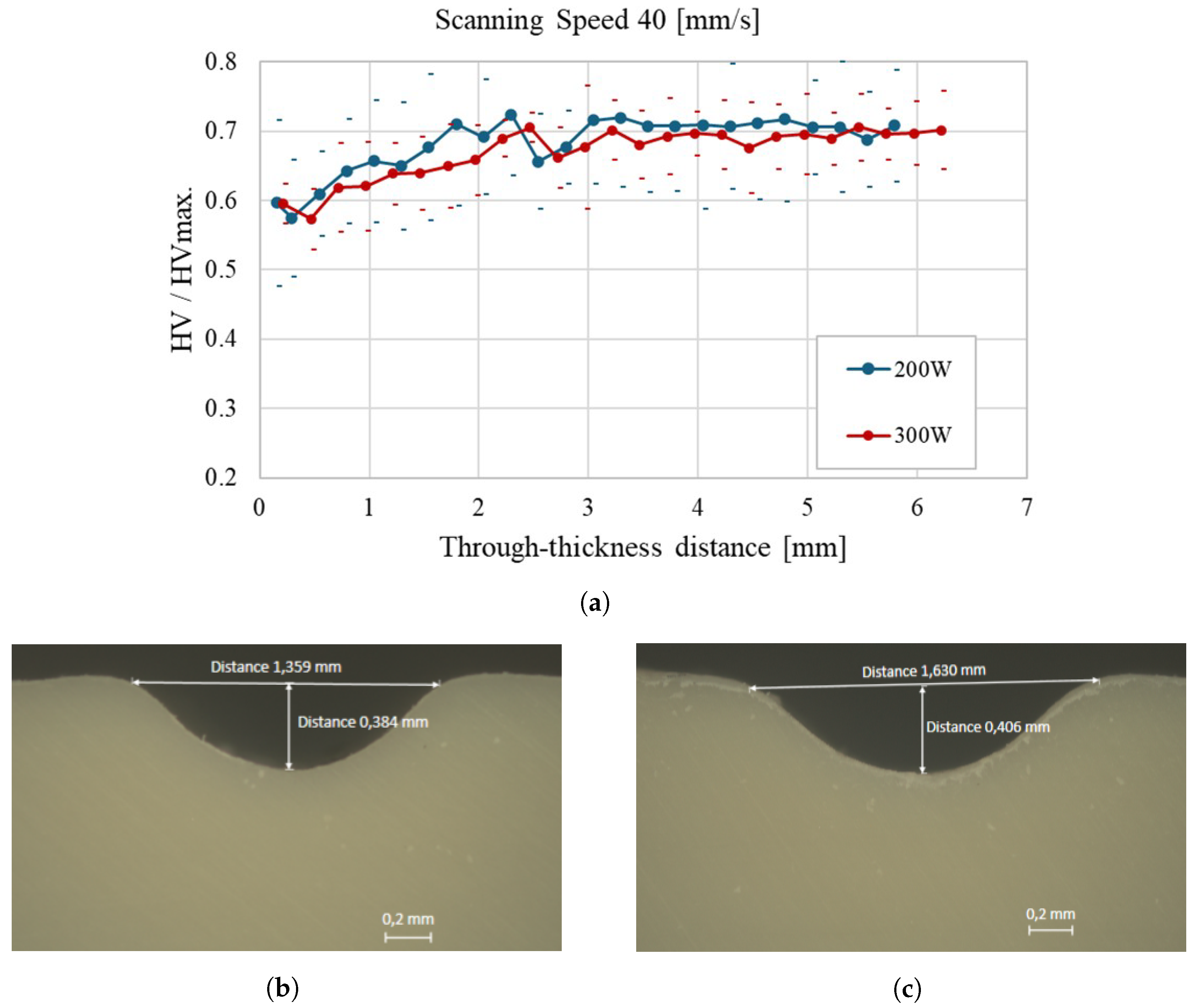

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Trindade, A.; Guimarães, A. Comparative Analysis of Welding Processes Using Different Thermoplastics. Int. J. Integr. Eng. 2024, 16, 126–139. [Google Scholar] [CrossRef]

- Lakemeyer, P.; Schöppner, V. Laser transmission welding of automotive headlamps without a clamping tool. Weld. World 2017, 61, 589–602. [Google Scholar] [CrossRef]

- Brodhun, J.; Blass, D.; Dilger, K. Laser transmission welding of thermoplastic fasteners: Influence of temperature distribution in a scanning based process. Procedia CIRP 2018, 74, 533–537. [Google Scholar] [CrossRef]

- Brosda, M.; Nguyen, P.; Olowinsky, A.; Gillner, A. Analysis of the interaction process during laser transmission welding of multilayer polymer films with adapted laser wavelength by numerical simulation and thermography. J. Laser Appl. 2020, 32. [Google Scholar] [CrossRef]

- Anwer, G.; Acherjee, B. Laser polymer welding process: Fundamentals and advancements. Mater. Today Proc. 2022, 61, 34–42. [Google Scholar] [CrossRef]

- Gisario, A.; Aversa, C.; Barletta, M.; Natali, S.; Veniali, F. Laser transmission welding of aluminum film coated with heat sealable co-polyester resin with polypropylene films for applications in food and drug packaging. Int. J. Adv. Manuf. Technol. 2022, 120, 2291–2309. [Google Scholar] [CrossRef]

- Zhang, L.; Ouyang, W.; Xu, Z.; Qin, X.; Yao, Y.; Wen, M.; Guo, C.; Zhang, W.; Sheng, L. Effect of asynchronized and synchronized laser shock peening on microstructure and mechanical properties of the Ti–6Al–4V laser joint. J. Mater. Res. Technol. 2023, 26, 9289–9314. [Google Scholar] [CrossRef]

- Mazumder, J. Laser welding: State of the art review. JOM 1982, 34, 16–24. [Google Scholar] [CrossRef]

- Amanat, N.; Chaminade, C.; Grace, J.; McKenzie, D.R.; James, N.L. Transmission laser welding of amorphous and semi-crystalline poly-ether–ether–ketone for applications in the medical device industry. Mater. Des. 2010, 31, 4823–4830. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A.; Rozanski, A. Cavitation during deformation of semicrystalline polymers. Prog. Polym. Sci. 2014, 39, 921–958. [Google Scholar] [CrossRef]

- Rozanski, A.; Krajenta, A.; Idczak, R.; Galeski, A. Physical state of the amorphous phase of polypropylene-influence on free volume and cavitation phenomenon. J. Polym. Sci. Part Polym. Phys. 2016, 54, 531–543. [Google Scholar] [CrossRef]

- Ghorbel, E.; Casalino, G.; Abed, S. Laser diode transmission welding of polypropylene: Geometrical and microstructure characterisation of weld. Mater. Des. 2009, 30, 2745–2751. [Google Scholar] [CrossRef]

- Hadriche, I.; Ghorbel, E.; Masmoudi, N.; Casalino, G. Investigation on the effects of laser power and scanning speed on polypropylene diode transmission welds. Int. J. Adv. Manuf. Technol. 2010, 50, 217–226. [Google Scholar] [CrossRef]

- Dave, F.; Ali, M.M.; Sherlock, R.; Kandasami, A.; Tormey, D. Laser transmission welding of semi-crystalline polymers and their composites: A critical review. Polymers 2021, 13, 675. [Google Scholar] [CrossRef]

- Kumar, N.; Bandyopadhyay, A. A state-of-the-art review of laser welding of polymers-part i: Welding parameters. Weld. J. 2021, 100, 221–228. [Google Scholar] [CrossRef]

- Xu, X.F.; Parkinson, A.; Bates, P.J.; Zak, G. Effect of part thickness, glass fiber and crystallinity on light scattering during laser transmission welding of thermoplastics. Opt. Laser Technol. 2015, 75, 123–131. [Google Scholar] [CrossRef]

- Hu, S.; Li, F.; Zuo, P. Numerical Simulation of Laser Transmission Welding—A Review on Temperature Field, Stress Field, Melt Flow Field, and Thermal Degradation. Polymers 2023, 15, 2125. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.; Yang, M.; Oliveira, J.P.; Song, D.; Peng, B. Laser welding of NiTi shape memory alloy wires and tubes for multi-functional design applications. Smart Mater. Struct. 2016, 25, 085001. [Google Scholar] [CrossRef]

- Teshome, F.B.; Peng, B.; Oliveira, J.; Shen, J.; Ao, S.; Li, H.; Chen, L.; Tan, C.; Song, X.; Zhou, N.; et al. Role of Pd interlayer on NiTi to Ti6Al4V laser welded joints: Microstructural evolution and strengthening mechanisms. Mater. Des. 2023, 228, 111845. [Google Scholar] [CrossRef]

- Kurosaki, Y.; Satoh, K. A fiber laser welding of plastics assisted by transparent solid heat sink to prevent the surface thermal damages. Phys. Procedia 2010, 5, 173–181. [Google Scholar] [CrossRef]

- Pawar, S.; Moholkar, A.; Kim, I.; Shin, S.; Moon, J.; Rhee, J.; Kim, J. Effect of laser incident energy on the structural, morphological and optical properties of Cu2ZnSnS4 (CZTS) thin films. Curr. Appl. Phys. 2010, 10, 565–569. [Google Scholar] [CrossRef]

- Casalino, G.; Ghorbel, E. Numerical model of CO2 laser welding of thermoplastic polymers. J. Mater. Process. Technol. 2008, 207, 63–71. [Google Scholar] [CrossRef]

- Katsiropoulos, C.V.; Moraitis, G.; Labeas, G.; Pantelakis, S.G. Optimisation of laser welding process for thermoplastic composite materials with regard to component quality and cost. Plast. Rubber Compos. 2009, 38, 153–161. [Google Scholar] [CrossRef]

- Ilie, M.; Cicala, E.; Grevey, D.; Mattei, S.; Stoica, V. Diode laser welding of ABS: Experiments and process modeling. Opt. Laser Technol. 2009, 41, 608–614. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.; Mitra, S.; Misra, D. Selection of process parameters for optimizing the weld strength in laser transmission welding of acrylics. Proc. Inst. Mech. Eng. Part J. Eng. Manuf. 2010, 224, 1529–1536. [Google Scholar] [CrossRef]

- Zoubeir, T.; Elhem, G. Numerical study of laser diode transmission welding of a polypropylene mini-tank: Temperature field and residual stresses distribution. Polym. Test. 2011, 30, 23–34. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, C.; Wang, K.; Li, P.; Hu, Y.; Liu, H. Multi-objective optimization of laser transmission joining of thermoplastics. Opt. Laser Technol. 2012, 44, 2393–2402. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Liu, H.; Li, P.; Yan, Z.; Huang, C.; Zhao, Z.; Gu, Y. Simulation and optimization of continuous laser transmission welding between PET and titanium through FEM, RSM, GA and experiments. Opt. Lasers Eng. 2013, 51, 1245–1254. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Liu, H. Investigation of the relationships of process parameters, molten pool geometry and shear strength in laser transmission welding of polyethylene terephthalate and polypropylene. Mater. Des. 2014, 55, 343–352. [Google Scholar] [CrossRef]

- Jiao, J.; Xu, Z.; Wang, Q.; Sheng, L.; Zhang, W. CFRTP and stainless steel laser joining: Thermal defects analysis and joining parameters optimization. Opt. Laser Technol. 2018, 103, 170–176. [Google Scholar] [CrossRef]

- Tao, W.; Su, X.; Chen, Y.; Tian, Z. Joint formation and fracture characteristics of laser welded CFRP/TC4 joints. J. Manuf. Processes 2019, 45, 1–8. [Google Scholar] [CrossRef]

- Ghasemi, H.; Zhang, Y.; Bates, P.J.; Zak, G.; DuQuesnay, D.L. Effect of processing parameters on meltdown in quasi-simultaneous laser transmission welding. Opt. Laser Technol. 2018, 107, 244–252. [Google Scholar] [CrossRef]

- Prabhakaran, R.; Kontopoulou, M.; Zak, G.; Bates, P.; Baylis, B. Contour laser–laser-transmission welding of glass reinforced nylon 6. J. Thermoplast. Compos. Mater. 2006, 19, 427–439. [Google Scholar] [CrossRef]

- Mamuschkin, V.; Roesner, A.; Aden, M. Laser transmission welding of white thermoplastics with adapted wavelengths. Phys. Procedia 2013, 41, 172–179. [Google Scholar] [CrossRef]

- Berger, S.; Oefele, F.; Schmidt, M. Laser transmission welding of carbon fiber reinforced thermoplastic using filler material—A fundamental study. J. Laser Appl. 2015, 27. [Google Scholar] [CrossRef]

- Xu, X.F.; Bates, P.J.; Zak, G. Effect of glass fiber and crystallinity on light transmission during laser transmission welding of thermoplastics. Opt. Laser Technol. 2015, 69, 133–139. [Google Scholar] [CrossRef]

- Klein, R. Laser Welding of Plastics: Materials, Processes and Industrial Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Shin, H.M.; Choi, H.W. Design of energy optimization for laser polymer joining process. Int. J. Adv. Manuf. Technol. 2014, 75, 1569–1576. [Google Scholar] [CrossRef]

- Zhan, X.; Zhang, D.; Wei, Y.; Wang, Y. Research on the microstructure and properties of laser-MIG hybrid welded joint of Invar alloy. Opt. Laser Technol. 2017, 97, 124–136. [Google Scholar] [CrossRef]

- Singare, S.K.; Chen, S.G.; Zou, J.J.; Lin, Y.Z. Laser transmission welding of thermoplastic: Effect of process parameters on weld strength. Adv. Mater. Res. 2014, 852, 463–466. [Google Scholar] [CrossRef]

- Kumar, N.; Sherlock, R.; Tormey, D. Prediction of weld interface depth and width at optimum laser welding temperature for polypropylene. Procedia CIRP 2019, 81, 1272–1277. [Google Scholar] [CrossRef]

- Yang, N.; Gong, Y.; He, P.; Zhou, C.; Zhou, R.; Shao, H.; Chen, G.; Lin, X.; Bie, H. Influence of Circular through Hole in Pt–Rh Bushing on Temperature Propagation at High Temperature. Materials 2022, 15, 7832. [Google Scholar] [CrossRef] [PubMed]

- Deng, X.; Li, J.; Xie, X. Effect of Preheating Temperature on Thermal–Mechanical Properties of Dry Vibrating MgO-Based Material Lining in the Tundish. Materials 2022, 15, 7699. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Chen, Q.; Hu, S.; Shi, Y.; He, Z.; Huang, Y.; Hui, C.; Chen, Y.; Wu, H.; Lu, G. Effect of Electro-Thermo-Mechanical Coupling Stress on Top-Cooled E-Mode AlGaN/GaN HEMT. Materials 2023, 16, 1484. [Google Scholar] [CrossRef] [PubMed]

- ASTM-E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Ouyang, W.; Zhang, L.; Wu, H.; Wu, D.; Zhang, S.; Qin, X.; Jiang, S.; Li, S.; Zhang, W.; Sheng, L. Optimized mechanical properties of the hot forged Ti–6Al–4V alloy by regulating multiscale microstructure via laser shock peening. Int. J. Mach. Tools Manuf. 2024, 201, 104192. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Density | 0.92 g/cm3 |

| Flammability | HB UL94 |

| Young’s Modulus | 1380 MPa |

| Yield Strength | 30 MPa |

| Tensile Strength | 33 MPa |

| Hardness (Shore D) | 73 Scale D |

| Coefficient of Thermal Expansion (CTE) | |

| Thermal Conductivity | |

| Continuous Service Temperature (CST) | 0–100 °C |

| Melting Temperature | 162–167 °C |

| Printing Parameters | Values |

|---|---|

| Wave length | 1030 ± 10 nm |

| Focal Distance | 10 mm |

| Collimation Distance | 150 mm |

| Beam Diameter | 0.4 mm |

| Laser Power | 200, 300 W |

| Speed | 5, 10, 20, 30, 40, 50 mm/s |

| Focal Length | 0 mm |

| 50 [mm/s] | 40 [mm/s] | 30 [mm/s] | 20 [mm/s] | 10 [mm/s] | 5 [mm/s] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV |

| [mm] | avg | std | [mm] | avg | std | [mm] | avg | std | [mm] | avg | std | [mm] | avg | std | [mm] | avg | std |

| 0.158 | 0.574 | 0.103 | 0.154 | 0.597 | 0.119 | 0.158 | 0.571 | 0.091 | 0.820 | 0.667 | 0.144 | 0.357 | 0.541 | 0.216 | 0.559 | 7.517 | 0.105 |

| 0.322 | 0.570 | 0.062 | 0.292 | 0.575 | 0.084 | 0.266 | 0.596 | 0.120 | 1.070 | 0.636 | 0.094 | 0.607 | 0.680 | 0.179 | 0.809 | 8.503 | 0.156 |

| 0.572 | 0.616 | 0.078 | 0.542 | 0.609 | 0.061 | 0.516 | 0.644 | 0.137 | 1.320 | 0.650 | 0.116 | 0.857 | 0.619 | 0.171 | 1.059 | 9.497 | 0.145 |

| 0.822 | 0.641 | 0.068 | 0.792 | 0.643 | 0.075 | 0.766 | 0.672 | 0.157 | 1.570 | 0.633 | 0.074 | 1.107 | 0.646 | 0.178 | 1.309 | 9.197 | 0.124 |

| 1.072 | 0.650 | 0.055 | 1.042 | 0.657 | 0.088 | 1.016 | 0.674 | 0.118 | 1.820 | 0.649 | 0.090 | 1.357 | 0.679 | 0.134 | 1.559 | 10.030 | 0.187 |

| 1.322 | 0.645 | 0.069 | 1.292 | 0.650 | 0.092 | 1.266 | 0.636 | 0.074 | 2.070 | 0.669 | 0.102 | 1.607 | 0.712 | 0.169 | 1.809 | 10.020 | 0.208 |

| 1.572 | 0.638 | 0.031 | 1.542 | 0.676 | 0.105 | 1.516 | 0.636 | 0.096 | 2.320 | 0.660 | 0.112 | 1.857 | 0.664 | 0.085 | 2.059 | 10.883 | 0.193 |

| 1.822 | 0.645 | 0.027 | 1.792 | 0.711 | 0.118 | 1.766 | 0.681 | 0.099 | 2.570 | 0.685 | 0.084 | 2.107 | 0.700 | 0.109 | 2.309 | 10.787 | 0.168 |

| 2.072 | 0.662 | 0.068 | 2.042 | 0.692 | 0.083 | 2.016 | 0.684 | 0.115 | 2.820 | 0.686 | 0.108 | 2.357 | 0.724 | 0.172 | 2.559 | 10.743 | 0.195 |

| 2.322 | 0.680 | 0.061 | 2.292 | 0.724 | 0.087 | 2.266 | 0.709 | 0.118 | 3.070 | 0.684 | 0.085 | 2.607 | 0.751 | 0.211 | 2.809 | 9.997 | 0.110 |

| 2.572 | 0.699 | 0.086 | 2.542 | 0.656 | 0.068 | 2.516 | 0.703 | 0.105 | 3.320 | 0.692 | 0.098 | 2.857 | 0.682 | 0.092 | 3.059 | 10.180 | 0.118 |

| 2.822 | 0.720 | 0.087 | 2.792 | 0.677 | 0.052 | 2.766 | 0.707 | 0.109 | 3.570 | 0.701 | 0.108 | 3.107 | 0.696 | 0.089 | 3.309 | 10.413 | 0.136 |

| 3.072 | 0.719 | 0.091 | 3.042 | 0.716 | 0.091 | 3.016 | 0.666 | 0.113 | 3.820 | 0.674 | 0.109 | 3.357 | 0.739 | 0.117 | 3.559 | 10.630 | 0.156 |

| 3.322 | 0.697 | 0.028 | 3.292 | 0.719 | 0.100 | 3.266 | 0.714 | 0.139 | 4.070 | 0.698 | 0.077 | 3.607 | 0.745 | 0.115 | 3.809 | 10.360 | 0.110 |

| 3.572 | 0.712 | 0.085 | 3.542 | 0.708 | 0.096 | 3.516 | 0.695 | 0.081 | 4.320 | 0.718 | 0.101 | 3.857 | 0.742 | 0.119 | 4.059 | 10.117 | 0.138 |

| 3.822 | 0.710 | 0.107 | 3.792 | 0.707 | 0.094 | 3.766 | 0.704 | 0.074 | 4.570 | 0.734 | 0.107 | 4.107 | 0.727 | 0.118 | 4.309 | 10.587 | 0.155 |

| 4.072 | 0.719 | 0.112 | 4.042 | 0.709 | 0.121 | 4.016 | 0.687 | 0.045 | 4.820 | 0.707 | 0.113 | 4.357 | 0.711 | 0.079 | 4.559 | 10.533 | 0.140 |

| 4.322 | 0.711 | 0.102 | 4.292 | 0.707 | 0.090 | 4.266 | 0.718 | 0.108 | 5.070 | 0.697 | 0.082 | 4.607 | 0.774 | 0.104 | 4.809 | 10.623 | 0.139 |

| 4.572 | 0.709 | 0.108 | 4.542 | 0.712 | 0.110 | 4.516 | 0.722 | 0.106 | 5.320 | 0.759 | 0.197 | 4.857 | 0.729 | 0.125 | 5.059 | 10.557 | 0.112 |

| 4.822 | 0.696 | 0.070 | 4.792 | 0.717 | 0.119 | 4.766 | 0.745 | 0.120 | 5.570 | 0.743 | 0.113 | 5.107 | 0.736 | 0.119 | 5.309 | 10.613 | 0.122 |

| 5.072 | 0.717 | 0.109 | 5.042 | 0.706 | 0.068 | 5.016 | 0.711 | 0.067 | 5.820 | 0.754 | 0.166 | 5.357 | 0.746 | 0.141 | 5.559 | 10.093 | 0.058 |

| 5.322 | 0.733 | 0.099 | 5.292 | 0.706 | 0.094 | 5.266 | 0.711 | 0.104 | 6.070 | 0.773 | 0.185 | 5.607 | 0.766 | 0.109 | 5.809 | 10.620 | 0.123 |

| 5.572 | 0.705 | 0.099 | 5.542 | 0.688 | 0.069 | 5.516 | 0.709 | 0.105 | 5.857 | 0.762 | 0.173 | 6.059 | 10.483 | 0.135 | |||

| 5.822 | 0.702 | 0.093 | 5.792 | 0.708 | 0.080 | 5.766 | 0.727 | 0.130 | 6.107 | 0.752 | 0.153 | 6.309 | 10.003 | 0.112 | |||

| 50 [mm/s] | 40 [mm/s] | 30 [mm/s] | 20 [mm/s] | 10 [mm/s] | 5 [mm/s] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV | Dist. | HV | HV |

| [mm] | avg | std | [mm] | avg | std | [mm] | avg | std | [mm] | avg | std | [mm] | avg | std | [mm] | avg | std |

| 0.170 | 0.572 | 0.019 | 0.216 | 0.595 | 0.028 | 0.167 | 0.560 | 0.069 | 0.123 | 0.646 | 0.093 | 0.441 | 0.521 | 0.054 | 0.434 | 0.584 | 0.040 |

| 0.420 | 0.590 | 0.075 | 0.466 | 0.573 | 0.044 | 0.577 | 0.554 | 0.084 | 0.533 | 0.574 | 0.065 | 0.691 | 0.613 | 0.068 | 0.844 | 0.654 | 0.047 |

| 0.670 | 0.612 | 0.098 | 0.716 | 0.619 | 0.064 | 0.987 | 0.563 | 0.070 | 0.943 | 0.607 | 0.045 | 0.941 | 0.583 | 0.069 | 1.254 | 0.591 | 0.051 |

| 0.920 | 0.655 | 0.048 | 0.966 | 0.621 | 0.064 | 1.397 | 0.630 | 0.059 | 1.353 | 0.644 | 0.070 | 1.191 | 0.636 | 0.087 | 1.664 | 0.590 | 0.093 |

| 1.170 | 0.644 | 0.058 | 1.216 | 0.639 | 0.045 | 1.807 | 0.640 | 0.069 | 1.763 | 0.655 | 0.065 | 1.441 | 0.683 | 0.100 | 2.074 | 0.637 | 0.076 |

| 1.420 | 0.639 | 0.055 | 1.466 | 0.639 | 0.052 | 2.217 | 0.624 | 0.051 | 2.173 | 0.632 | 0.044 | 1.691 | 0.650 | 0.041 | 2.484 | 0.650 | 0.055 |

| 1.670 | 0.650 | 0.075 | 1.716 | 0.650 | 0.061 | 2.627 | 0.622 | 0.060 | 2.583 | 0.634 | 0.043 | 1.941 | 0.658 | 0.062 | 2.894 | 0.665 | 0.059 |

| 1.920 | 0.673 | 0.062 | 1.966 | 0.659 | 0.050 | 3.037 | 0.639 | 0.074 | 2.993 | 0.657 | 0.056 | 2.191 | 0.695 | 0.051 | 3.304 | 0.665 | 0.068 |

| 2.170 | 0.681 | 0.063 | 2.216 | 0.690 | 0.026 | 3.447 | 0.660 | 0.068 | 3.403 | 0.661 | 0.056 | 2.441 | 0.655 | 0.074 | 3.714 | 0.654 | 0.048 |

| 2.420 | 0.681 | 0.100 | 2.466 | 0.705 | 0.022 | 3.857 | 0.661 | 0.080 | 3.813 | 0.661 | 0.049 | 2.691 | 0.712 | 0.071 | 4.124 | 0.657 | 0.075 |

| 2.670 | 0.669 | 0.033 | 2.716 | 0.662 | 0.044 | 4.267 | 0.657 | 0.063 | 4.223 | 0.658 | 0.039 | 2.941 | 0.674 | 0.023 | 4.534 | 0.634 | 0.071 |

| 2.920 | 0.695 | 0.049 | 2.966 | 0.677 | 0.089 | 4.677 | 0.657 | 0.056 | 4.633 | 0.666 | 0.046 | 3.191 | 0.676 | 0.053 | 4.944 | 0.662 | 0.035 |

| 3.170 | 0.682 | 0.058 | 3.216 | 0.701 | 0.043 | 5.087 | 0.645 | 0.076 | 5.043 | 0.673 | 0.038 | 3.441 | 0.714 | 0.050 | 5.354 | 0.656 | 0.063 |

| 3.420 | 0.698 | 0.065 | 3.466 | 0.680 | 0.049 | 5.497 | 0.642 | 0.078 | 5.453 | 0.685 | 0.050 | 3.691 | 0.704 | 0.074 | 5.764 | 0.661 | 0.077 |

| 3.670 | 0.696 | 0.047 | 3.716 | 0.692 | 0.055 | 5.907 | 0.667 | 0.098 | 5.863 | 0.685 | 0.051 | 3.941 | 0.691 | 0.060 | 6.174 | 0.683 | 0.051 |

| 3.920 | 0.708 | 0.044 | 3.966 | 0.697 | 0.032 | 6.317 | 0.637 | 0.078 | 6.273 | 0.680 | 0.059 | 4.191 | 0.650 | 0.062 | |||

| 4.170 | 0.704 | 0.073 | 4.216 | 0.695 | 0.049 | 6.727 | 0.639 | 0.080 | 6.683 | 0.684 | 0.034 | 4.441 | 0.655 | 0.071 | |||

| 4.420 | 0.707 | 0.085 | 4.466 | 0.676 | 0.065 | 7.137 | 0.620 | 0.093 | 7.093 | 0.663 | 0.069 | 4.691 | 0.653 | 0.056 | |||

| 4.670 | 0.716 | 0.068 | 4.716 | 0.692 | 0.047 | 7.547 | 0.660 | 0.069 | 7.503 | 0.664 | 0.064 | 4.941 | 0.653 | 0.046 | |||

| 4.920 | 0.732 | 0.089 | 4.966 | 0.695 | 0.058 | 7.957 | 0.648 | 0.087 | 5.191 | 0.688 | 0.046 | ||||||

| 5.170 | 0.685 | 0.084 | 5.216 | 0.689 | 0.038 | 8.367 | 0.617 | 0.097 | 5.441 | 0.640 | 0.072 | ||||||

| 5.420 | 0.687 | 0.092 | 5.466 | 0.705 | 0.048 | 8.777 | 0.617 | 0.110 | 5.691 | 0.643 | 0.056 | ||||||

| 5.670 | 0.693 | 0.092 | 5.716 | 0.696 | 0.037 | 9.187 | 0.607 | 0.113 | 5.941 | 0.638 | 0.064 | ||||||

| 5.920 | 0.682 | 0.086 | 5.966 | 0.697 | 0.046 | 6.191 | 0.645 | 0.056 | |||||||||

| 6.170 | 0.689 | 0.104 | 6.216 | 0.701 | 0.056 | 6.441 | 0.650 | 0.058 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guimarães, A.; Gomes, D.; Vieira, A.; Oliveira, S.M. Effect of Laser Parameters on Through-Thickness Local Hardness of Polypropylene Plates. Materials 2025, 18, 2638. https://doi.org/10.3390/ma18112638

Guimarães A, Gomes D, Vieira A, Oliveira SM. Effect of Laser Parameters on Through-Thickness Local Hardness of Polypropylene Plates. Materials. 2025; 18(11):2638. https://doi.org/10.3390/ma18112638

Chicago/Turabian StyleGuimarães, André, Daniel Gomes, André Vieira, and Serafim M. Oliveira. 2025. "Effect of Laser Parameters on Through-Thickness Local Hardness of Polypropylene Plates" Materials 18, no. 11: 2638. https://doi.org/10.3390/ma18112638

APA StyleGuimarães, A., Gomes, D., Vieira, A., & Oliveira, S. M. (2025). Effect of Laser Parameters on Through-Thickness Local Hardness of Polypropylene Plates. Materials, 18(11), 2638. https://doi.org/10.3390/ma18112638