Development and Characterization of AZ91 Magnesium Alloy Reinforced with Ti Wires

Abstract

1. Introduction

- Development of functionalized Mg-bone implants, which can have additional purpose. For instance, the delivery of medicament at a specific site of an organ [22].

- Hybrid coatings are developed by combining both organic and inorganic components. For instance, in the work [25], Singh et al. realized a TiO2 –HAp-PCL (polycaprolactone) based hybrid coating, where TiO2 –HAp was the inorganic part responsible for high adhesion strength and improving osteogenesis. PCL was an organic part responsible for improving corrosion resistance.

- Advancement of additive manufacturing technology for implant production. For instance, laser-based additive manufacturing can fabricate customized implants with effective efficiency and offer process flexibility [26].

2. Materials and Methods

2.1. Materials

2.2. Accelerated Aging Tests

2.3. Material Characteristics and Mechanical Tests

3. Results

3.1. Bending Strength Properties with Fracture Analysis

3.2. Aging Tests

3.3. Microtomographic Analysis

4. Conclusions

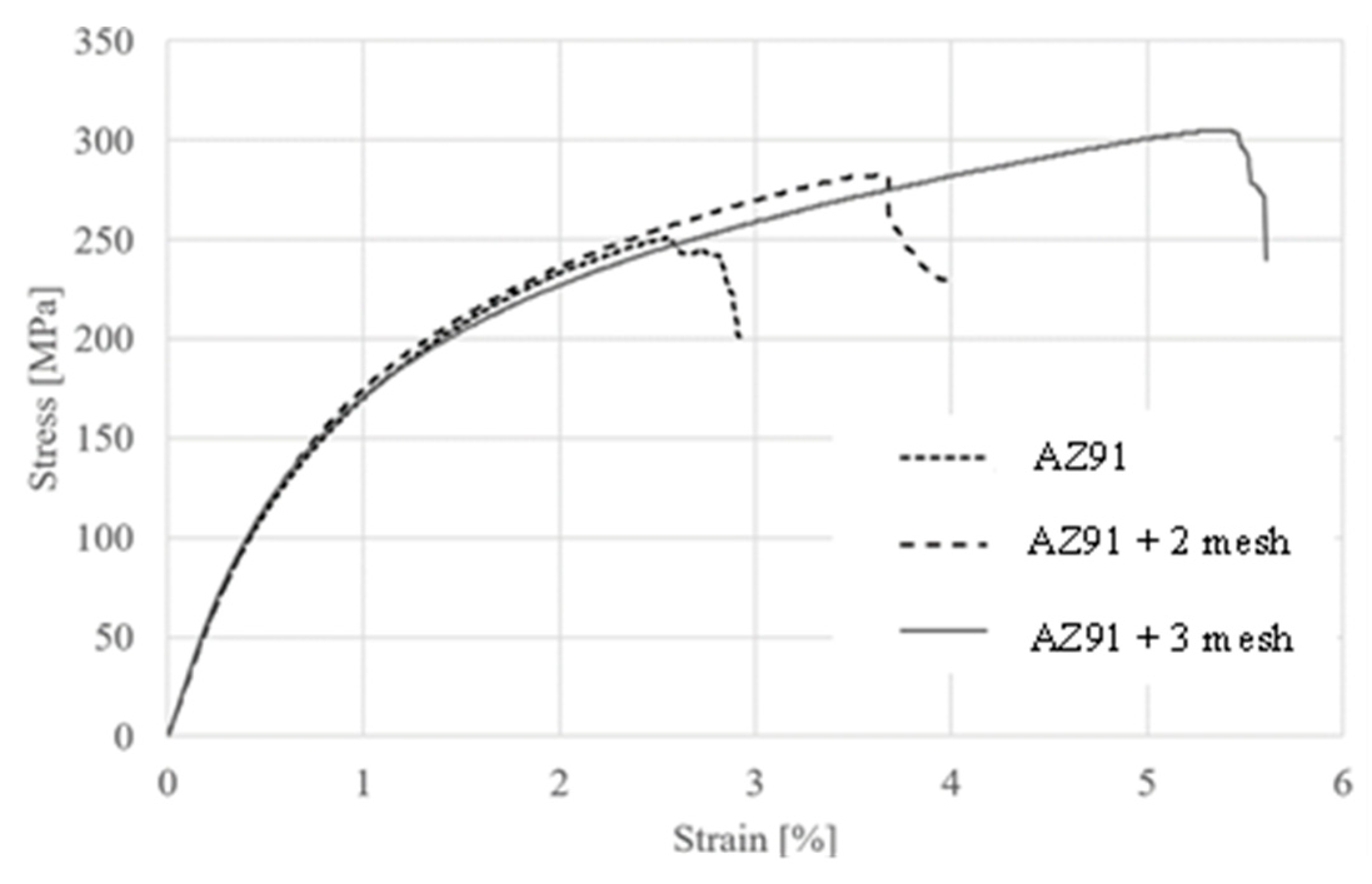

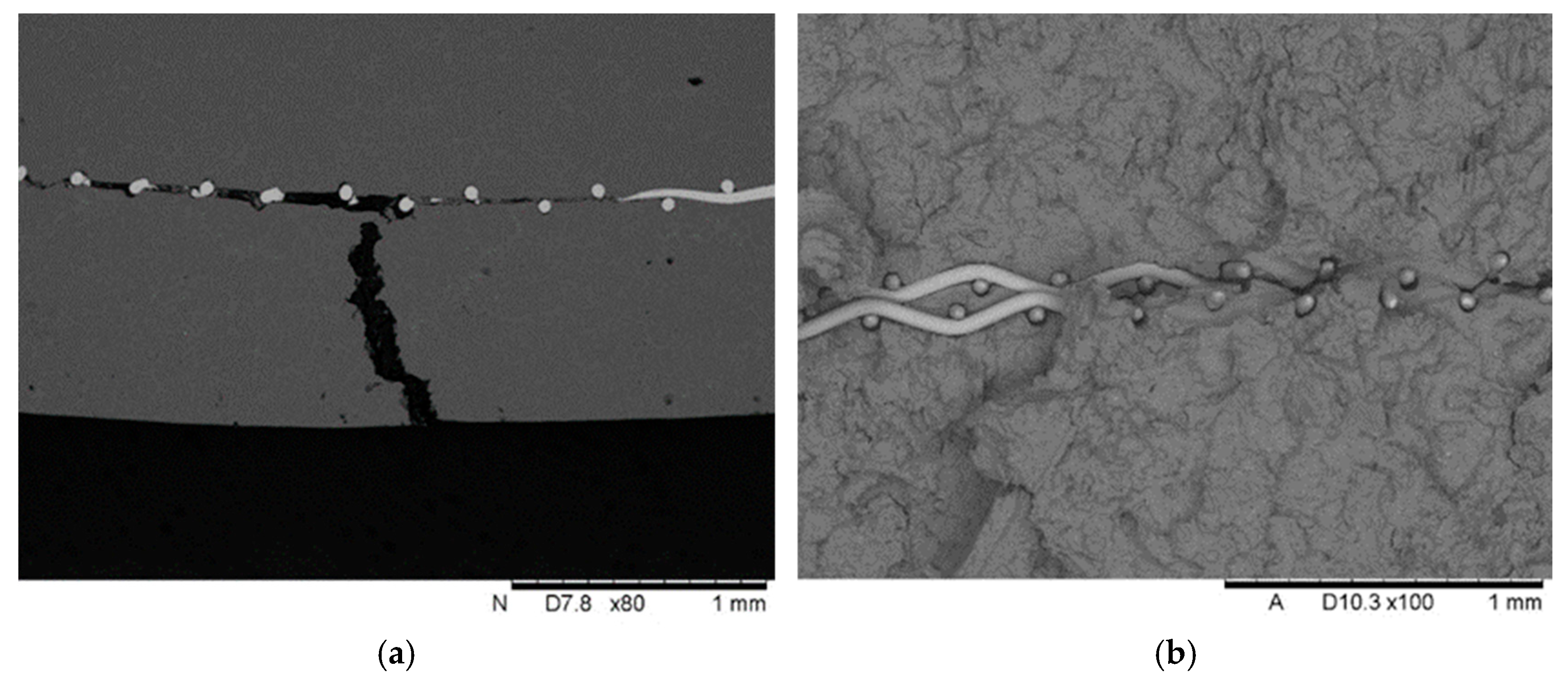

- Three-point bending tests showed that with an increased amount of titanium mesh in the composite, the bending strength increased. However, for Young’s modulus, a decrease in its value was observed for three layers of titanium mesh.

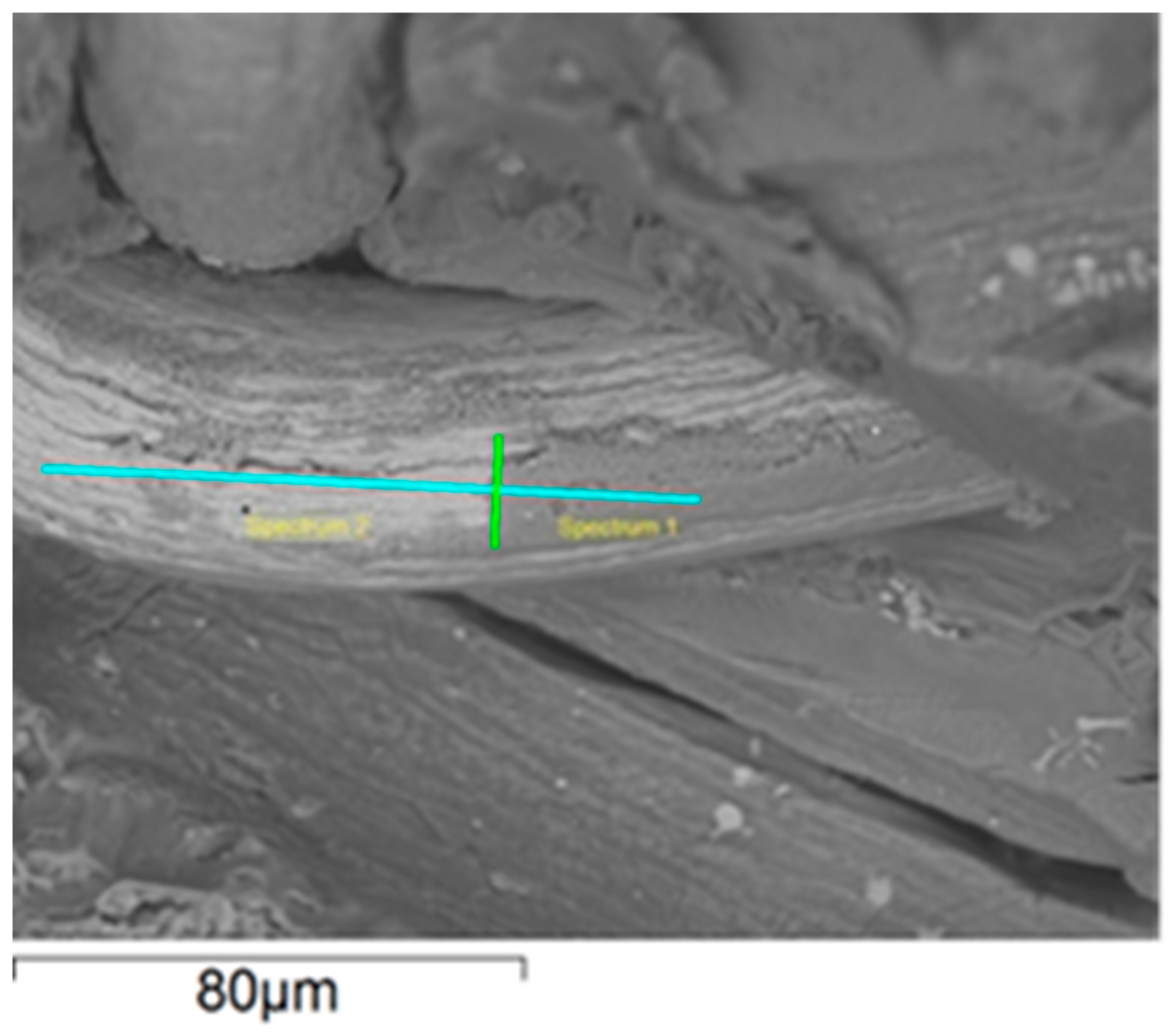

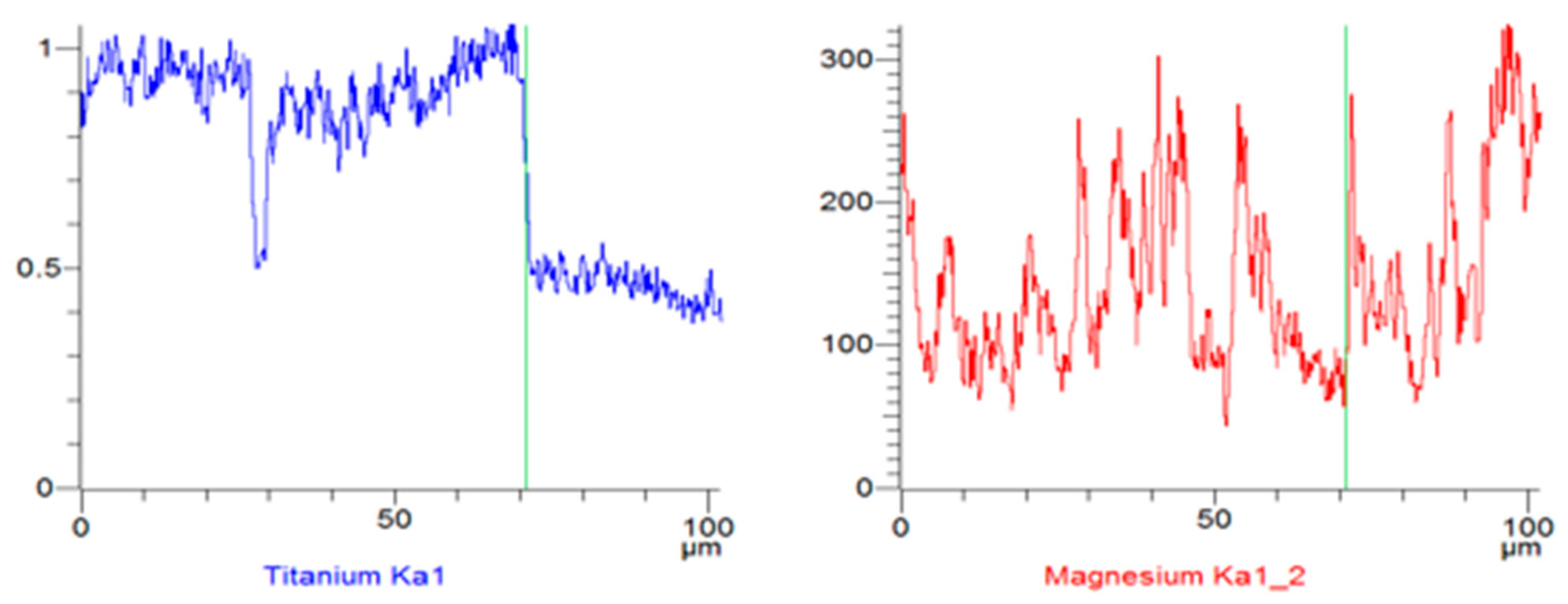

- SEM observations showed that, as a result of strength tests, titanium fibres detach from the magnesium matrix. Cracks that appear during three-point bending propagate from the edge of the sample and then along the placed reinforcement.

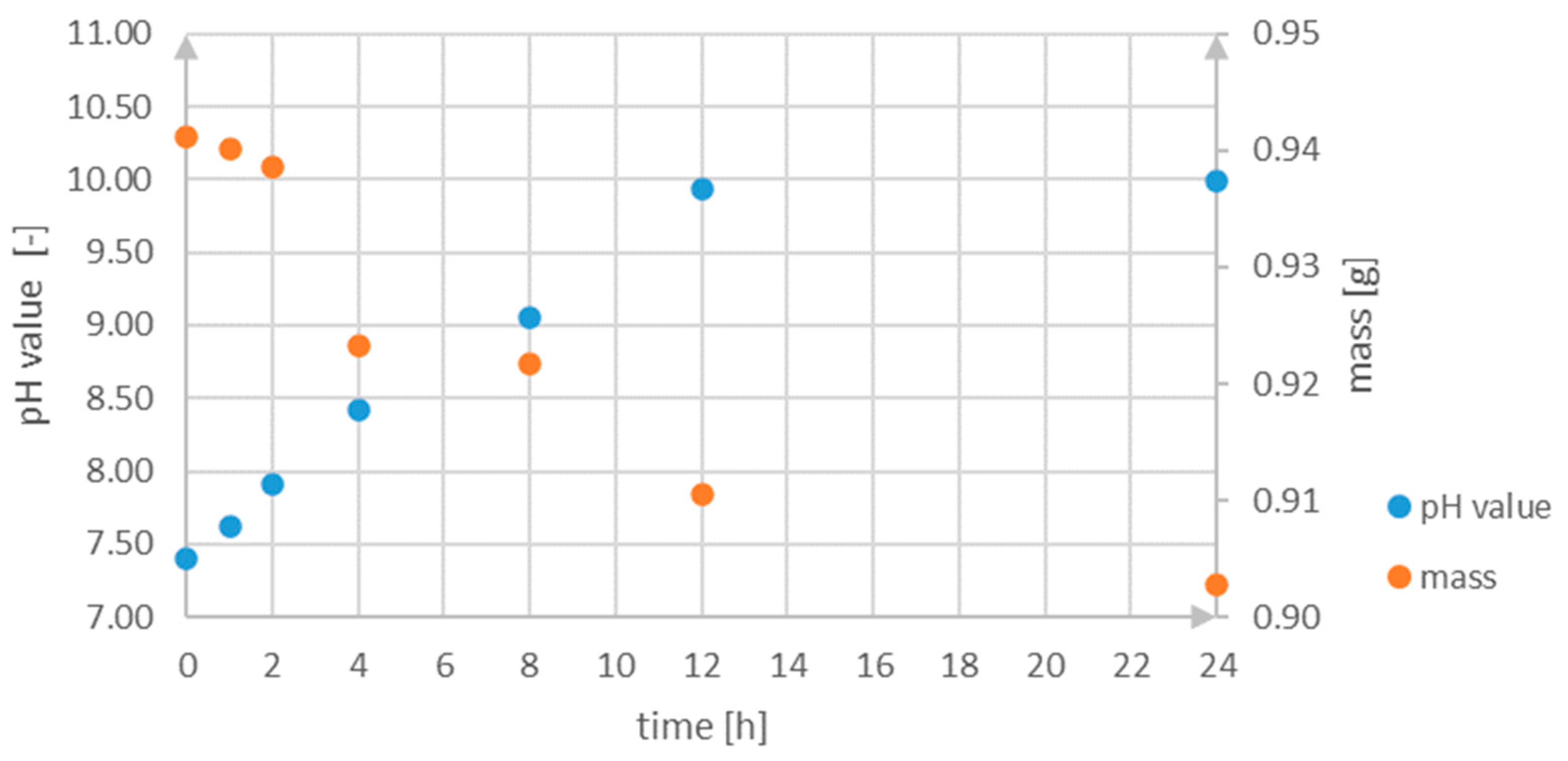

- Accelerated ageing tests showed that the pH of the SBF increases approximately linearly to a value around 10.00, which investigates the formation of . Afterward, this value stabilised, which implies the formation of an oxide layer on the sample and a state of dynamic equilibrium. Amidst corrosion products, there are ions of , hydrogen gas and compounds containing magnesium, oxygen, calcium and phosphorus.

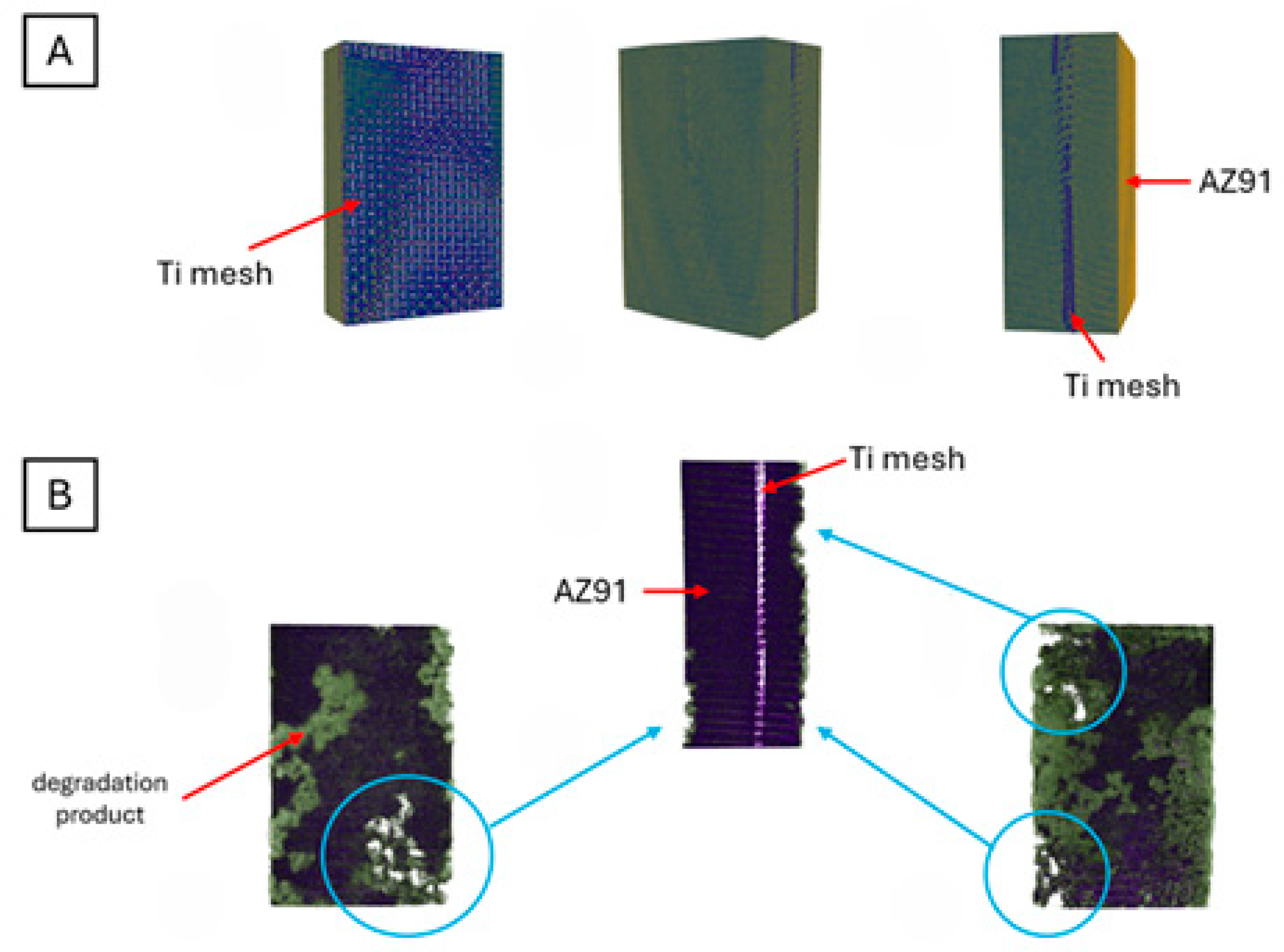

- Microtomography is a process that enables us to determine the internal structure of the samples without damaging them. In the presented 3D reconstructions of the samples following immersion in SBF, darker areas can be observed, which indicates the formation of degradation products in the sample. However, by using a 3D reconstruction processing program, it was possible to look inside the sample to check whether the SBF also affected the titanium mesh. Therefore, it is recommended that this method be used for further research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pu, D.; Wu, S.; Yang, H.; Chen, X.; Li, J.; Feng, X.; Zheng, K.; Pan, F. Effect of Ti particles on microstructure and mechanical properties of TiP/AZ91 composites. J. Mater. Res. Technol. 2023, 22, 1362–1374. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, H.; Sun, Y.; Ren, L.; Wan, Z.; Hu, L. Microstructures and mechanical properties of ultrafine-grained Ti/AZ31 magnesium matrix composite prepared by powder metallurgy. Adv. Powder Technol. 2018, 29, 3241–3249. [Google Scholar] [CrossRef]

- Yu, H.; Sun, Y.; Hu, L.; Zhou, H.; Wan, Z. Microstructural evolution of AZ61-10 at.% Ti composite powders during mechanical milling. Mater. Des. 2016, 104, 265–275. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Przełożyńska, E. The influence of Ti particles on microstructure and mechanical properties of Mg-5Al-5RE matrix alloy composite. J. Alloys Compd. 2017, 728, 600–606. [Google Scholar] [CrossRef]

- Yu, H.; Sun, Y.; Hu, L.; Wan, Z.; Zhou, H. Microstructure and properties of mechanically milled AZ61 powders dispersed with submicron/nanometer Ti particulates. Mater. Charact. 2017, 127, 272–278. [Google Scholar] [CrossRef]

- Yang, H.; Chen, X.; Huang, G.; Song, J.; She, J.; Tan, J.; Zheng, K.; Jin, Y.; Jiang, B.; Pan, F. Microstructures and mechanical properties of titanium-reinforced magnesium matrix composites: Review and perspective. J. Magnes. Alloys 2022, 10, 2311–2333. [Google Scholar] [CrossRef]

- Ye, J.; Li, J.; Luo, H.; Tan, J.; Chen, X.; Feng, B.; Zheng, K.; Pan, F. Effect of micron-Ti particles on microstructure and mechanical properties of Mge3Ale1Zn based composites. Mater. Sci. Eng. A 2022, 833, 142526. [Google Scholar] [CrossRef]

- Pu, D.; Chen, X.; Ding, Y.; Sun, Y.; Feng, B.; Zheng, K.; Pan, F. Effect of Ti particles size on the microstructure and mechanical properties of TiP/VW94 composites. Mater. Sci. Eng. A 2022, 858, 144140. [Google Scholar] [CrossRef]

- Kumar, N.; Bharti, A.; Chauhan, A.K. Effect of Ti reinforcement on the wear behaviour of AZ91/Ti composites fabricated by powder metallurgy. Mater. Phys. Mech. 2021, 47, 600–607. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K.; Luo, T.; Song, M.; Wu, H.; Xiao, J.; Tan, Y.; Cheng, M.; Chen, B.; Niu, X.; et al. Powder metallurgical low-modulus Ti-Mg alloys for biomedical applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 56, 241–250. [Google Scholar] [CrossRef]

- Chen, L.; Yao, Y. Processing, microstructures, and mechanical properties of magnesium matrix composites: A review. Acta Metall. Sin. 2014, 27, 762–774. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Przełożyńska, E. Analyses of AM50-Tip metal-metal composite microstructure. J. Alloys Compd. 2018, 731, 1181–1187. [Google Scholar] [CrossRef]

- Luo, H.; Li, J.; Ye, J.; Lu, Y.; Tan, J.; Song, J.; Chen, X.; Zheng, K.; Pan, F. Influence of Ti-6Al-4V particles on the interfacial microstructure and strength-ductility synergetic mechanism of AZ91 magnesium alloy. Mater. Charact. 2022, 191, 112154. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, S.J.; Zhang, B.; Tian, X.B.; Kan, Q.H.; Kang, G.Z. Dislocation–grain boundary interaction-based discrete dislocation dynamics modeling and its application to bicrystals with different misorientations. Acta Mater. 2021, 202, 88–98. [Google Scholar] [CrossRef]

- Xie, Y.; Li, S.; Zhang, T.; Wang, C.; Cai, X. Titanium mesh for bone augmentation in oral implantology current application and progress. Int. J. Oral. Sci. 2020, 12, 37. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Ji, P.; Li, X.; Gao, H.; Li, L.; Wang, C. Mechanical characterization of 3D-printed individualized Ti-Mesh (Membrane) for alveolar bone defects. J. Healthc. Eng. 2019, 2019, 4231872. [Google Scholar] [CrossRef] [PubMed]

- Joshi, C.; Rao, R.N.; Golla, C.B.; Özcan, M.; Prasad, P.S. Comprehensive review of Mg-based alloys: Mechanical, chemical and biological properties for prosthetic and orthopedic applications. J. Mater. Res. Technol. 2025, 35, 2487–2502. [Google Scholar] [CrossRef]

- Bairagi, D.; Mandal, S. A comprehensive review on biocompatible Mg-based alloys as temporary ortho-paedic implants: Current status, challenges, and future prospects. J. Magnes. Alloys 2022, 13, 627–669. [Google Scholar] [CrossRef]

- Wan, P.; Tan, L.; Yang, K. Surface Modification on Biodegradable Magnesium Alloys as Orthopedic Implant Materials to Improve the Bio-adaptability: A Review. J. Mater. Sci. Technol. 2016, 32, 827–834. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Kumar, S.; Nehra, M.; Kedia, D.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.H. Nanotechnology-based biomaterials for orthopaedic applications: Recent advances and future prospects. Mater. Sci. Eng. C 2020, 106, 110154. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Cui, X.T. Electrochemical deposition of conducting polymer coatings on magnesium surfaces in ionic liquid. Acta Biomater. 2011, 7, 441–446. [Google Scholar] [CrossRef] [PubMed]

- Riveiro, A.; Pou, P.; del Val, J.; Comesaña, R.; Arias-González, F.; Lusquiños, F.; Boutinguiza, M.; Quintero, F.; Badaoui, A.; Pou, J. Laser texturing to control the wettability of materials. Procedia CIRP 2020, 94, 879–884. [Google Scholar] [CrossRef]

- Xia, F.; Jiang, L. Bio-Inspired, Smart, Multiscale Interfacial Materials. Adv. Mater. 2008, 20, 2842–2858. [Google Scholar] [CrossRef]

- Singh, N.; Batra, U.; Kumar, K.; Mahapatro, A. Investigating TiO2–HA–PCL hybrid coating as an efficient corrosion resistant barrier of ZM21 Mg alloy. J. Magnes. Alloys 2021, 9, 627–646. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, J.; Pavanram, P.; Lee, M.A.; Fockaert, L.I.; Pouran, B.; Tümer, N.; Schröder, K.U.; Mol, J.M.C.; Weinans, H.; et al. Additively manufactured biodegradable porous magnesium. Acta Biomater. 2018, 67, 378–392. [Google Scholar] [CrossRef]

- Esen, Z.; Ocal, E.B.; Akkaya, A.; Gurcay, B.; Ozcan, C.; Ozgumus, B.A.; Duygulu, O.; Dericioglu, A.F. Corrosion behaviours of Ti6Al4V-Mg/Mg-alloy composites. Corros. Sci. 2020, 166, 108470. [Google Scholar] [CrossRef]

- Brooks, E.K.; Der, S.; Ehrensberger, M.T. Corrosion and mechanical performance of AZ91 exposed to simulated inflammatory conditions. Mater. Sci. Eng. C 2016, 60, 427–436. [Google Scholar] [CrossRef]

- Zhang, J.; Zare, P.; Jalili, T.; Hamidi, R. Fabrication of Cu/Al–Al2O3 laminar composites using squeeze casting and roll bonding techniques: Evaluation of microstructure, mechanical properties and wear characteristics. Vacuum 2024, 228, 113484. [Google Scholar] [CrossRef]

- Manu, K.S.; Raag, L.A.; Rajan, T.; Gupta, M.; Pai, B. Liquid metal infiltration processing of metallic composites: A critical review. Metall. Mater. Trans. B 2016, 47, 2799–2819. [Google Scholar] [CrossRef]

- Kridli, G.T.; Friedman, P.A.; Boileau, J.M. 7—Manufacturing processes for light alloys. In Materials, Design and Manufacturing for Lightweight Vehicles Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2010; pp. 235–274. [Google Scholar] [CrossRef]

- Girot, F.A.; Majidi, A.P.; Chou, T.W. Metal Matrix Composites Encyclopedia of Physical Science and Technology, 3rd ed.; Academic Press: Cambridge, MA, USA, 2003; pp. 485–493. [Google Scholar] [CrossRef]

- Latfpour, M.; Dehghanian, C.; Emamy, M.; Bahmani, A.; Malekan, M.; Saadati, A.; Taghizadeh, M.; Shokouhimehr, M. In-vitro corrosion behaviour of the cast and extruded biodegradable Mg-Zn-Cu alloys in simulated body fluid (SBF). J. Magnes. Alloys 2021, 9, 2078–2096. [Google Scholar] [CrossRef]

- Xin, Y.; Hu, T.; Chu, P.K. In vitro studies of biomedical magnesium alloys in a simulated physiological environment: A review. Acta Biomater. 2011, 7, 1452–1459. [Google Scholar] [CrossRef] [PubMed]

- Hassan, S.F.; Ho, K.F.; Gupta, M. Increasing elastic modulus, strength and CTE of AZ91 by reinforcing pure magnesium with elemental copper. Mater. Lett. 2004, 58, 2143–2146. [Google Scholar] [CrossRef]

- Gumuła, T.; Błażewicz, M.; Paluszkiewicz, C. Bioaktywne kompozyty włókno węglowe/pseudowolastonit dla zastosowań w chirurgii kostnej. Compos. Pol. Soc. Compos. Mater. 2008, 8, 41–46. [Google Scholar]

- Lee, G.M.; Lee, J.U.; Park, S.H. Effects of post-heat treatment on microstructure, tensile properties and bending properties of extruded AZ80 alloy. J. Mater. Res. Technol. 2021, 12, 1039–1050. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Guan, B. Microstructure and mechanical properties of hybrid Graphene nanoplatelets/titanium particles reinforced AZ91 laminated composite. Mater. Sci. Eng. 2022, 856, 144017. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, W.; Guo, J.; Jiang, S. Cracking behavior in a tensile and bending test of underwater explosive-welded AZ31/Cu laminated composite. Theoret. App. Fract. Mech. 2019, 103, 102256. [Google Scholar] [CrossRef]

- Silva Moreira, R.C.; Kovalenko, O.; Souza, D.; Reis, R.P. Metal matrix composite material reinforced with metal wire and produced with gas metal arc welding. J. Compd. Mater. 2019, 53, 4411–4426. [Google Scholar] [CrossRef]

- Deng, K.K.; Wu, K.; Wu, Y.W.; Nie, K.B.; Zheng, M.Y. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites. J. Alloys Compd. 2010, 504, 542–547. [Google Scholar] [CrossRef]

- Fathi, R.; Ma, A.; Saleh, B.; Xu, Q.; Jiang, J. Investigation on mechanical properties and wear performance of functionally graded AZ91–SiCp composites via centrifugal casting. Mater. Commun. 2020, 24, 101169. [Google Scholar] [CrossRef]

- Xin, Y.; Liu, C.; Zhang, X.; Tang, G.; Tian, X.; Chu, P. Corrosion behavior of biomedical AZ91 magnesium alloy in simulated body fluids. J. Mater. Res. 2007, 22, 2004–2011. [Google Scholar] [CrossRef]

- Li, L.; Gao, J.; Wang, Y. Evaluation of cyto-toxicity and corrosion behavior of alkali-heat-treated magnesium in simulated body fluid. Surf. Coat. Technol. 2004, 185, 92–98. [Google Scholar] [CrossRef]

- Song, G.L.; Atrens, A. Corrosion mechanisms of magnesium alloys. Adv. Eng. Mater. 1999, 1, 11–33. [Google Scholar] [CrossRef]

- Baril, G.; Pébère, N. The corrosion of pure magnesium in aerated and deaerated sodium sulphate solution. Corros. Sci. 2001, 43, 471. [Google Scholar] [CrossRef]

- Ocal, E.B.; Esen, Z.; Aydinol, K.; Dericioglu, A.F. Comparison of the short and long-term degradation behaviours of as-cast pure Mg, AZ91 and WE43 alloys. Mater. Chem. Phys. 2020, 241, 122350. [Google Scholar] [CrossRef]

- Zeng, R.C.; Zhang, J.; Huang, W.J.; Dietzel, W.; Kainer, K.; Blawert, C.; Wet, K. Review of studies on corrosion of magnesium alloys. Trans. Nonferrous Met. Soc. China 2006, 16, 763–771. [Google Scholar] [CrossRef]

| Element | Mg | Al | Zn | Mn | Si |

|---|---|---|---|---|---|

| wt.% | 89.8 | 9.00 | 1.00 | 0.13 | 0.05 |

| Element | C | Fe | H | N | O | Ti |

|---|---|---|---|---|---|---|

| wt.% | 0.008–0.016% | 0.03–0.04% | 0.002–0.003% | 0.004% | 0.048–0.05% | 99.897–99.898% |

| Ion | Simulated Body Fluid (SBF) [mM] | Blood Plasma [mM] |

|---|---|---|

| 142.0 | 142.0 | |

| 5.0 | 5.0 | |

| 1.5 | 1.5 | |

| 2.5 | 2.5 | |

| 147.8 | 103 | |

| 4.2 | 27.0 | |

| 1.0 | 1.0 | |

| 0.5 | 0.5 |

| Parameter | Parameter Value |

|---|---|

| rotation step | 0.2 deg |

| exposure time | 2100 ms |

| charging current | 112 µA |

| voltage | 89 kV |

| pixel size | 3 µm |

| filter | Al + Cu |

| Material | Flexural Strength [MPa] | E [GPa] | Break Strain [%] |

|---|---|---|---|

| AZ91 | 242.5 ± 7.5 | 25 ± 2 | 2.7 ± 0.2 |

| AZ91 + 2 mesh layers | 270 ± 13 | 27.5 ± 0.5 | 3.45 ± 0.35 |

| AZ91 + 3 mesh layers | 295 ± 10 | 23.5 ± 0.5 | 4.95 ± 0.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wyrwa, W.; Filipiak-Kaczmarek, A.; Nikodem, A. Development and Characterization of AZ91 Magnesium Alloy Reinforced with Ti Wires. Materials 2025, 18, 2517. https://doi.org/10.3390/ma18112517

Wyrwa W, Filipiak-Kaczmarek A, Nikodem A. Development and Characterization of AZ91 Magnesium Alloy Reinforced with Ti Wires. Materials. 2025; 18(11):2517. https://doi.org/10.3390/ma18112517

Chicago/Turabian StyleWyrwa, Wojciech, Adrianna Filipiak-Kaczmarek, and Anna Nikodem. 2025. "Development and Characterization of AZ91 Magnesium Alloy Reinforced with Ti Wires" Materials 18, no. 11: 2517. https://doi.org/10.3390/ma18112517

APA StyleWyrwa, W., Filipiak-Kaczmarek, A., & Nikodem, A. (2025). Development and Characterization of AZ91 Magnesium Alloy Reinforced with Ti Wires. Materials, 18(11), 2517. https://doi.org/10.3390/ma18112517