Composite Filament Materials for 3D-Printed Drone Parts: Advancements in Mechanical Strength, Weight Optimization and Embedded Electronics

Abstract

1. Introduction

2. Overview of Composite Filaments in 3D Printing

2.1. Definition and Classification of Composite Filaments

2.2. Comparison of Carbon-Fiber-, Glass-Fiber-, and Kevlar-Infused Filaments for Drone Parts

2.3. Influence of Fiber Content, Dispersion, and Bonding on Mechanical Properties

3. Strength-to-Weight Optimization in Drone Components

3.1. Analysis of Mechanical Properties: Tensile Strength, Stiffness, and Impact Resistance

3.2. Case Studies of Carbon Fiber PLA, PETG, and Nylon in Drone Applications

3.3. Finite Element Analysis (FEA) and Experimental Testing for Optimizing Structures

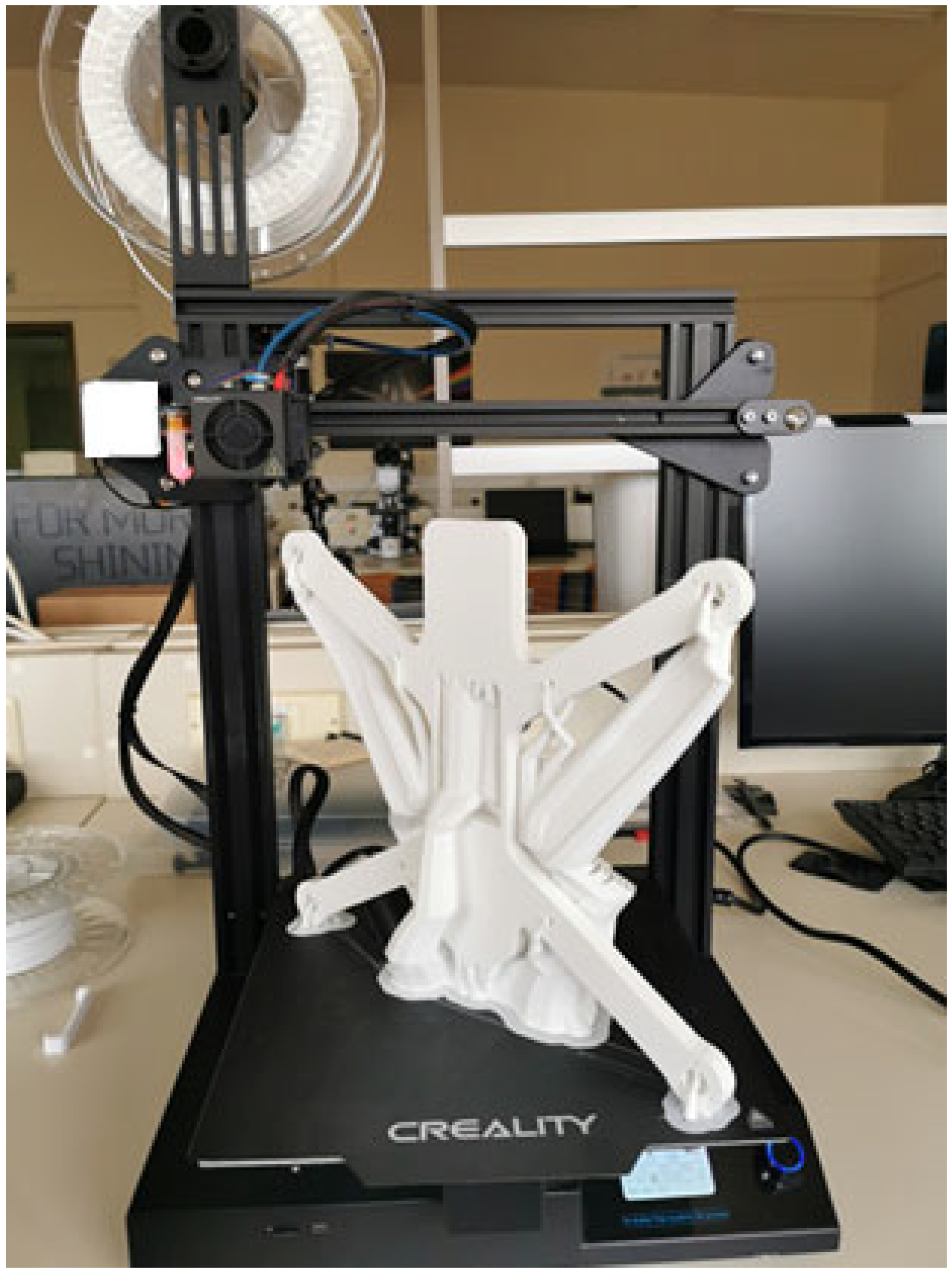

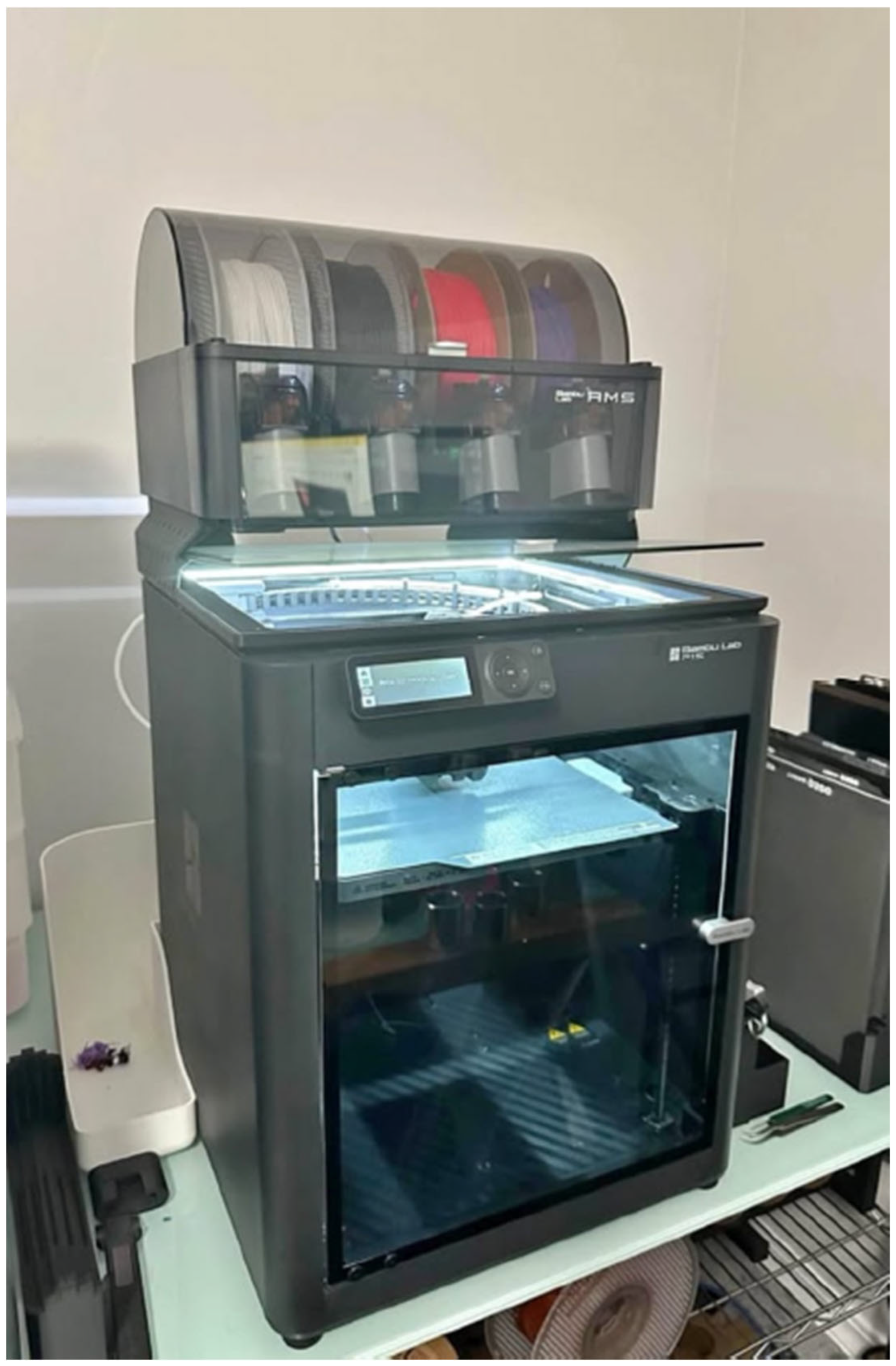

4. High-Speed FFF 3D Printing for Drone Fabrication

4.1. Evolution of High-Speed 3D Printing Technologies

4.2. Influence of Increased Speeds on Material Flow, Layer Adhesion, and Print Quality

4.3. Role of Heated Build Chambers and Advanced Extruder Designs in Maintaining Composite Filament Integrity

5. Embedded Electronics and Functional Integration

5.1. Soluble Support Materials for Complex Geometries

5.2. Techniques for Integrating Wiring Channels, Antennae, and Sensor Mounts Within Printed Drone Frames

6. Challenges and Limitations

6.1. Material Processing Difficulties: Nozzle Wear, Anisotropy, and Warping Issues

6.2. Cost and Scalability of High-Performance Composite Filaments

6.3. Reliability Concerns: Print Consistency, Delamination Risks, and Quality Control

7. Future Prospects and Research Directions

7.1. Innovations in Nanocomposite Filaments

7.2. AI-Driven Topology Optimization for Lightweight Drone Frames

7.3. Hybrid Manufacturing Approaches: 3D Printing and CNC Machining for Performance Enhancement

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| ABS | Acrylonitrile Butadiene Styrene |

| AI | Artificial Intelligence |

| AM | Additive Manufacturing |

| BVOH | Butenediol Vinyl Alcohol Copolymer |

| CAD | Computer-Aided Design |

| CFF | Continuous Fiber Fabrication |

| CFD | Computational Fluid Dynamics |

| CNT | Carbon Nanotube |

| CNC | Computer Numerical Control |

| EMI | Electromagnetic Interference |

| FFF | Fused Filament Fabrication |

| FGM | Functionally Graded Materials |

| FEA | Finite Element Analysis |

| FDM | Fused Deposition Modeling |

| GNP | Graphene Nanoplatelets |

| IMU | Inertial Measurement Unit |

| ML | Machine Learning |

| MIMO | Multiple-Input Multiple-Output |

| PA | Polyamide (Nylon) |

| PCA | Principal Component Analysis |

| PCL | Polycaprolactone |

| PCTG | Polycyclohexylenedimethylene Terephthalate Glycol |

| PEEK | Polyether Ether Ketone |

| PEI | Polyetherimide |

| PETG | Polyethylene Terephthalate Glycol |

| PLA | Polylactic Acid |

| PVA | Polyvinyl Alcohol |

| RF | Radio Frequency |

| SLA | Stereolithography |

| SLS | Selective Laser Sintering |

| TPU | Thermoplastic Polyurethane |

| UAV | Unmanned Aerial Vehicle |

| VPP | Vat Photopolymerization |

References

- MohamedZain, A.O.; Chua, H.; Yap, K.; Uthayasurian, P.; Jiehan, T. Novel Drone Design Using an Optimization Software with 3D Model, Simulation, and Fabrication in Drone Systems Research. Drones 2022, 6, 97. [Google Scholar] [CrossRef]

- Hairi, S.M.F.B.S.; Saleh, S.J.M.B.M.; Ariffin, A.H.; Omar, Z.B. A Review on Composite Aerostructure Development for UAV Application. In Green Hybrid Composites Science and Technology; Springer Nature: Singapore, 2023; pp. 137–157. ISBN 9789819915828. [Google Scholar]

- Šančić, T.; Brčić, M.; Kotarski, D.; Łukaszewicz, A. Experimental Characterization of Composite-Printed Materials for the Production of Multirotor UAV Airframe Parts. Materials 2023, 16, 5060. [Google Scholar] [CrossRef]

- Săftoiu, G.-V.; Constantin, C.; Nicoară, A.-I.; Pelin, G.; Ficai, D.; Ficai, A. Glass Fibre-Reinforced Composite Materials Used in the Aeronautical Transport Sector: A Critical Circular Economy Point of View. Sustainability 2024, 16, 4632. [Google Scholar] [CrossRef]

- Zaharia, S.-M.; Pascariu, I.S.; Chicos, L.-A.; Buican, G.R.; Pop, M.A.; Lancea, C.; Stamate, V.M. Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions. Drones 2023, 7, 602. [Google Scholar] [CrossRef]

- Liao, K.-C.; Liou, J.-L.; Hidayat, M.; Wen, H.-T.; Wu, H.-Y. Detection and Analysis of Aircraft Composite Material Structures Using UAV. Inventions 2024, 9, 47. [Google Scholar] [CrossRef]

- Brischetto, S.; Torre, R. Preliminary Finite Element Analysis and Flight Simulations of a Modular Drone Built through Fused Filament Fabrication. J. Compos. Sci. 2021, 5, 293. [Google Scholar] [CrossRef]

- Wang, Y.; Kumar, L.; Raja, V.; AL-bonsrulah, H.A.Z.; Kulandaiyappan, N.K.; Amirtharaj Tharmendra, A.; Marimuthu, N.; Al-Bahrani, M. Design and Innovative Integrated Engineering Approaches Based Investigation of Hybrid Renewable Energized Drone for Long Endurance Applications. Sustainability 2022, 14, 16173. [Google Scholar] [CrossRef]

- Castiblanco, J.M.; Garcia-Nieto, S.; Simarro, R.; Salcedo, J.V. Experimental Study on the Dynamic Behaviour of Drones Designed for Racing Competitions. Int. J. Micro Air Veh. 2021, 13, 17568293211005757. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2021, 12, 9. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Petrescu, F.I.T.; Ganetsos, T. Advanced Composite Materials Utilized in FDM/FFF 3D Printing Manufacturing Processes: The Case of Filled Filaments. Materials 2023, 16, 6210. [Google Scholar] [CrossRef]

- Huang, H.-Y.; Fan, F.-Y.; Lin, W.-C.; Huang, C.-F.; Shen, Y.-K.; Lin, Y.; Ruslin, M. Optimal Processing Parameters of Transmission Parts of a Flapping-Wing Micro-Aerial Vehicle Using Precision Injection Molding. Polymers 2022, 14, 1467. [Google Scholar] [CrossRef] [PubMed]

- Trzepieciński, T.; Najm, S.M.; Pepelnjak, T.; Bensaid, K.; Szpunar, M. Incremental Sheet Forming of Metal-Based Composites Used in Aviation and Automotive Applications. J. Compos. Sci. 2022, 6, 295. [Google Scholar] [CrossRef]

- Badea, G.P.; Frigioescu, T.F.; Dombrovschi, M.; Cican, G.; Dima, M.; Anghel, V.; Crunteanu, D.E. Innovative Hybrid UAV Design, Development, and Manufacture for Forest Preservation and Acoustic Surveillance. Inventions 2024, 9, 39. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive Manufactured Sandwich Composite/ABS Parts for Unmanned Aerial Vehicle Applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes 2023, 11, 1385. [Google Scholar] [CrossRef]

- Venegas, J.A.; Maulas, E.L.; Gomez, R.F.; Vinzon, M.G.V.; David, G.D. Development of 3D-Printed Agricultural Drone (Ardufarmer). Eng. Innov. 2022, 1, 39–51. [Google Scholar] [CrossRef]

- Biswas, P.; Heryudono, A.; Li, J.; Bi, J. Prediction of Printing Failure of a 3 D Printed Drone Propeller Using Fused Deposition Modeling. In Proceedings of the Science in the Age of Experience 2018, Bengaluru, India, 11 October 2018. [Google Scholar]

- Ferro, C.G.; Brischetto, S.; Torre, R.; Maggiore, P. Characterization of ABS Specimens Produced via the 3D Printing Technology for Drone Structural Components. Curved Layer. Struct. 2016, 3, 172–188. [Google Scholar] [CrossRef]

- Palmer, M.; Laliberte, J. Effects of Non-Planar Slicing Techniques and Carbon Fibre Material Additives on the Mechanical Properties of 3D-Printed Drone Propellers. Drone Syst. Appl. 2023, 11, 1–11. [Google Scholar] [CrossRef]

- Christodoulou, I.; Alexopoulou, V.; Markopoulos, A.P. Study and Development of a High-Speed Fused Filament Fabrication 3D Printer. In Proceedings of the 2023 8th South-East Europe Design Automation, Computer Engineering, Computer Networks and Social Media Conference (SEEDA-CECNSM), Piraeus, Greece, 10–12 November 2023; pp. 1–6. [Google Scholar]

- Ahmed, N.A.; Page, J.R. Manufacture of an Unmanned Aerial Vehicle (UAV) for Advanced Project Design Using 3D Printing Technology. Appl. Mech. Mater. 2013, 397, 970–980. [Google Scholar] [CrossRef]

- Goh, G.D.; Agarwala, S.; Goh, G.L.; Dikshit, V.; Sing, S.L.; Yeong, W.Y. Additive Manufacturing in Unmanned Aerial Vehicles (UAVs): Challenges and Potential. Aerosp. Sci. Technol. 2017, 63, 140–151. [Google Scholar] [CrossRef]

- Vakharia, V.S.; Leonard, H.; Singh, M.; Halbig, M.C. Multi-Material Additive Manufacturing of High Temperature Polyetherimide (PEI)–Based Polymer Systems for Lightweight Aerospace Applications. Polymers 2023, 15, 561. [Google Scholar] [CrossRef] [PubMed]

- Sanei, S.H.R.; Popescu, D. 3D-Printed Carbon Fiber Reinforced Polymer Composites: A Systematic Review. J. Compos. Sci. 2020, 4, 98. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Pop, M.A.; Chicos, L.-A.; Buican, G.R.; Lancea, C.; Pascariu, I.S.; Stamate, V.-M. Compression and Bending Properties of Short Carbon Fiber Reinforced Polymers Sandwich Structures Produced via Fused Filament Fabrication Process. Polymers 2022, 14, 2923. [Google Scholar] [CrossRef] [PubMed]

- Pappas, J.M.; Thakur, A.R.; Leu, M.C.; Dong, X. A Parametric Study and Characterization of Additively Manufactured Continuous Carbon Fiber Reinforced Composites for High-Speed 3D Printing. Int. J. Adv. Manuf. Technol. 2021, 113, 2137–2151. [Google Scholar] [CrossRef]

- Kuang, X.; Zhao, Z.; Chen, K.; Fang, D.; Kang, G.; Qi, H.J. High-speed 3D Printing of High-performance Thermosetting Polymers via Two-stage Curing. Macromol. Rapid Commun. 2018, 39, 1700809. [Google Scholar] [CrossRef]

- Hasan, M.M.B.; Abdkader, A.; Cherif, C.; Spennato, F. Fibre Hybrid Composites Consisting of Discontinuous Waste Carbon Fibre and Continuous Glass Filaments Developed for Load-Bearing Structures with Improved Impact Strength. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105610. [Google Scholar] [CrossRef]

- Overberg, M.; Badrul Hasan, M.M.; Abdkader, A.; Rehra, J.; Schmeer, S.; Cherif, C. Investigations on the Development of Impact-Resistant Thermoplastic Fibre Hybrid Composites from Glass and Steel Fibre. J. Compos. Mater. 2024, 58, 1675–1687. [Google Scholar] [CrossRef]

- Reddivari, B.R.; Vadapalli, S.; Sanduru, B.; Buddi, T.; Vafaeva, K.M.; Joshi, A. Fabrication and Mechanical Properties of Hybrid Fibre-Reinforced Polymer Hybrid Composite with Graphene Nanoplatelets and Multiwalled Carbon Nanotubes. Cogent Eng. 2024, 11, 2343586. [Google Scholar] [CrossRef]

- Li, J.; Wang, C.; Fu, Y.-T.; Xia, D.; Xu, P.-H.; Xiang, C.-T.; Wu, J.; Li, J.-Y.; Li, Y.-Q.; Li, F.; et al. Mechanical Characterization of 3D Printed Multiscale Carbon Nanofiller/Continuous Fiber Reinforced Polymer Hybrid Composites. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Bambu Lab. Available online: https://bambulab.com (accessed on 26 February 2025).

- Couți, N.; Porfire, A.; Iovanov, R.; Crișan, A.G.; Iurian, S.; Casian, T.; Tomuță, I. Polyvinyl Alcohol, a Versatile Excipient for Pharmaceutical 3D Printing. Polymers 2024, 16, 517. [Google Scholar] [CrossRef]

- Tarring, E.C.; Durance, I.; Harbottle, M.J.; Lucas, R.; Read, D.S.; Ward, B.D. Water-Soluble Polymers: Emerging Contaminants Detected, Separated and Quantified by a Novel GPC/MALDI-TOF Method. Environ. Pollut. 2024, 340, 122888. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.; Ungureanu, L.; Munteanu, I. Post-Production Finishing Processes Utilized in 3D Printing Technologies. Processes 2024, 12, 595. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Esposito Corcione, C. Bio-Composite Filaments Based on Poly(Lactic Acid) and Cocoa Bean Shell Waste for Fused Filament Fabrication (FFF): Production, Characterization and 3D Printing. Materials 2024, 17, 1260. [Google Scholar] [CrossRef]

- Dey, A.; Roan Eagle, I.N.; Yodo, N. A Review on Filament Materials for Fused Filament Fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments Production and Fused Deposition Modelling of ABS/Carbon Nanotubes Composites. Nanomaterials 2018, 8, 49. [Google Scholar] [CrossRef]

- Chicos, L.-A.; Pop, M.A.; Zaharia, S.-M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.-M. Fused Filament Fabrication of Short Glass Fiber-Reinforced Polylactic Acid Composites: Infill Density Influence on Mechanical and Thermal Properties. Polymers 2022, 14, 4988. [Google Scholar] [CrossRef]

- Shulga, E.; Karamov, R.; Sergeichev, I.S.; Konev, S.D.; I. Shurygina, L.; S. Akhatov, I.; D. Shandakov, S.; G. Nasibulin, A. Fused Filament Fabricated Polypropylene Composite Reinforced by Aligned Glass Fibers. Materials 2020, 13, 3442. [Google Scholar] [CrossRef] [PubMed]

- Pertuz-Comas, A.D.; Díaz, J.G.; Meneses-Duran, O.J.; Niño-Álvarez, N.Y.; León-Becerra, J. Flexural Fatigue in a Polymer Matrix Composite Material Reinforced with Continuous Kevlar Fibers Fabricated by Additive Manufacturing. Polymers 2022, 14, 3586. [Google Scholar] [CrossRef]

- Wang, K.; Li, S.; Rao, Y.; Wu, Y.; Peng, Y.; Yao, S.; Zhang, H.; Ahzi, S. Flexure Behaviors of ABS-Based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing. Polymers 2019, 11, 1878. [Google Scholar] [CrossRef]

- Rijckaert, S.; Daelemans, L.; Cardon, L.; Boone, M.; Van Paepegem, W.; De Clerck, K. Continuous Fiber-Reinforced Aramid/PETG 3D-Printed Composites with High Fiber Loading through Fused Filament Fabrication. Polymers 2022, 14, 298. [Google Scholar] [CrossRef]

- Buican, G.R.; Zaharia, S.-M.; Pop, M.A.; Chicos, L.-A.; Lancea, C.; Stamate, V.-M.; Pascariu, I.S. Fabrication and Characterization of Fiber-Reinforced Composite Sandwich Structures Obtained by Fused Filament Fabrication Process. Coatings 2021, 11, 601. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, Y.; Wang, K.; Gao, G.; Ahzi, S. Synergistic Reinforcement of Polyamide-Based Composites by Combination of Short and Continuous Carbon Fibers via Fused Filament Fabrication. Compos. Struct. 2019, 207, 232–239. [Google Scholar] [CrossRef]

- Pehlivan, M.; Özen, E.; Doğru, A. Unmanned Aerial Vehicle Propeller Design and Production by Fused Filament Fabrication. In Sustainable Aviation; Springer International Publishing: Cham, Switzerland, 2023; pp. 29–36. ISBN 9783031371592. [Google Scholar]

- Lancea, C.; Chicos, L.-A.; Zaharia, S.-M.; Pop, M.-A.; Pascariu, I.S.; Buican, G.-R.; Stamate, V.-M. Simulation, Fabrication and Testing of UAV Composite Landing Gear. Appl. Sci. 2022, 12, 8598. [Google Scholar] [CrossRef]

- Goh, G.D.; Toh, W.; Yap, Y.L.; Ng, T.Y.; Yeong, W.Y. Additively Manufactured Continuous Carbon Fiber-Reinforced Thermoplastic for Topology Optimized Unmanned Aerial Vehicle Structures. Compos. Part B Eng. 2021, 216, 108840. [Google Scholar] [CrossRef]

- Gupta, A.; Hasanov, S.; Fidan, I. Thermal Characterization of Short Carbon Fiber Reinforced High Temperature Polymer Material Produced Using the Fused Filament Fabrication Process. J. Manuf. Process. 2022, 80, 515–528. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A. Fracture Toughness of Additively Manufactured Carbon Fiber Reinforced Composites. Addit. Manuf. 2019, 26, 41–52. [Google Scholar] [CrossRef]

- Ahmed, H.; Hussain, G.; Gohar, S.; Ali, A.; Alkahtani, M. Impact Toughness of Hybrid Carbon Fiber-PLA/ABS Laminar Composite Produced through Fused Filament Fabrication. Polymers 2021, 13, 3057. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled Glass Fiber Composites from Wind Turbine Waste for 3D Printing Feedstock: Effects of Fiber Content and Interface on Mechanical Performance. Materials 2019, 12, 3929. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Ramadhoni, B.F.; Rizkyta, A.G.; Bintoro, A.; Nugroho, A. Effect of Glass Fibers and Aramid Fiber on Mechanical Properties of Composite Based Unmanned Aerial Vehicle (UAV) Skin. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2020; pp. 435–440. ISBN 9789811509490. [Google Scholar]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass Fiber-Reinforced Polymer Composites—A Review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Mechanical Properties of Continuous Kevlar Fiber Reinforced Composites Fabricated by Fused Deposition Modeling Process. Procedia Manuf. 2018, 26, 774–781. [Google Scholar] [CrossRef]

- Lin, M.-C.; Lou, C.-W.; Lin, J.-Y.; Lin, T.A.; Lin, J.-H. Mechanical Property Evaluations of Flexible Laminated Composites Reinforced by High-Performance Kevlar Filaments: Tensile Strength, Peel Load, and Static Puncture Resistance. Compos. Part B Eng. 2019, 166, 139–147. [Google Scholar] [CrossRef]

- Luke, S.S.; Soares, D.; Marshall, J.V.; Sheddden, J.; Keleş, Ö. Effect of Fiber Content and Fiber Orientation on Mechanical Behavior of Fused Filament Fabricated Continuous-Glass-Fiber-Reinforced Nylon. Rapid Prototyp. J. 2021, 27, 1346–1354. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Huang, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of Short CF/GF Reinforced PEEK Composite Filaments and Their Comprehensive Properties Evaluation for FDM-3D Printing. Compos. Part B Eng. 2020, 198, 108175. [Google Scholar] [CrossRef]

- Jiang, D.; Smith, D.E. Anisotropic Mechanical Properties of Oriented Carbon Fiber Filled Polymer Composites Produced with Fused Filament Fabrication. Addit. Manuf. 2017, 18, 84–94. [Google Scholar] [CrossRef]

- Cohen, D.; Mantell, S.C.; Zhao, L. The Effect of Fiber Volume Fraction on Filament Wound Composite Pressure Vessel Strength. Compos. Part B Eng. 2001, 32, 413–429. [Google Scholar] [CrossRef]

- Croom, B.P.; Abbott, A.; Kemp, J.W.; Rueschhoff, L.; Smieska, L.; Woll, A.; Stoupin, S.; Koerner, H. Mechanics of Nozzle Clogging during Direct Ink Writing of Fiber-Reinforced Composites. Addit. Manuf. 2021, 37, 101701. [Google Scholar] [CrossRef]

- Rimašauskas, M.; Kuncius, T.; Rimašauskienė, R. Processing of Carbon Fiber for 3D Printed Continuous Composite Structures. Mater. Manuf. Process. 2019, 34, 1528–1536. [Google Scholar] [CrossRef]

- Elderfield, N.; Cook, O.; Wong, J.C.H. Fiber Dispersion as a Quality Assessment Metric for Pultruded Thermoplastic Composites. Compos. Part B Eng. 2024, 275, 111321. [Google Scholar] [CrossRef]

- Balla, V.K.; Tadimeti, J.G.D.; Sudan, K.; Satyavolu, J.; Kate, K.H. First Report on Fabrication and Characterization of Soybean Hull Fiber: Polymer Composite Filaments for Fused Filament Fabrication. Prog. Addit. Manuf. 2021, 6, 39–52. [Google Scholar] [CrossRef]

- Angelopoulos, P.M.; Samouhos, M.; Taxiarchou, M. Functional Fillers in Composite Filaments for Fused Filament Fabrication; a Review. Mater. Today Proc. 2021, 37, 4031–4043. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Grasley, Z.; Tyson, B.M.; Al-Rub, R. Carbon Nano Filaments in Cementitious Materials: Some Issues on Dispersion and Interfacial Bond. ACI Spec. Publ. 2009, 267, 21–34. [Google Scholar] [CrossRef]

- Andrews, R.; Jacques, D.; Minot, M.; Rantell, T. Fabrication of Carbon Multiwall Nanotube/Polymer Composites by Shear Mixing. Macromol. Mater. Eng. 2002, 287, 395–403. [Google Scholar] [CrossRef]

- Bardin, M.; Knight, P.C.; Seville, J.P.K. On Control of Particle Size Distribution in Granulation Using High-Shear Mixers. Powder Technol. 2004, 140, 169–175. [Google Scholar] [CrossRef]

- Pizzorni, M.; Parmiggiani, A.; Prato, M. Adhesive Bonding of a Mixed Short and Continuous Carbon-Fiber-Reinforced Nylon-6 Composite Made via Fused Filament Fabrication. Int. J. Adhes. Adhes. 2021, 107, 102856. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of Processing Conditions on the Bonding Quality of FDM Polymer Filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Touchard, F.; Chocinski-Arnault, L.; Fournier, T.; Magro, C.; Lafitte, A.; Caradec, A. Interfacial Adhesion Quality in 3D Printed Continuous CF/PA6 Composites at Filament/Matrix and Interlaminar Scales. Compos. Part B Eng. 2021, 218, 108891. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar Bonding Performance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

- Pizzorni, M.; Lertora, E.; Parmiggiani, A. Adhesive Bonding of 3D-Printed Short- and Continuous-Carbon-Fiber Composites: An Experimental Analysis of Design Methods to Improve Joint Strength. Compos. Part B Eng. 2022, 230, 109539. [Google Scholar] [CrossRef]

- Gonabadi, H.; Hosseini, S.F.; Chen, Y.; Bull, S. Size Effects of Voids on the Mechanical Properties of 3D Printed Parts. Int. J. Adv. Manuf. Technol. 2024, 132, 5439–5456. [Google Scholar] [CrossRef]

- Gonabadi, H.; Chen, Y.; Bull, S. Investigation of the Effects of Volume Fraction, Aspect Ratio and Type of Fibres on the Mechanical Properties of Short Fibre Reinforced 3D Printed Composite Materials. Prog. Addit. Manuf. 2025, 10, 261–277. [Google Scholar] [CrossRef]

- Gonabadi, H.; Oila, A.; Yadav, A.; Bull, S. Investigation of the Effects of Environmental Fatigue on the Mechanical Properties of GFRP Composite Constituents Using Nanoindentation. Exp. Mech. 2022, 62, 585–602. [Google Scholar] [CrossRef]

- Chatzopoulos, A.; Xenakis, A.; Papoutsidakis, M.; Kalovrektis, K.; Kalogiannakis, M.; Psycharis, S. Proposing and Testing an Open—Source and Low—Cost Drone under the Engineering Design Process for Higher Education: The Mechatronics Course Use Case. In Proceedings of the 2024 IEEE Global Engineering Education Conference (EDUCON), Kos Island, Greece, 8–11 May 2024. [Google Scholar]

- Papoutsidakis, M.; Chatzopoulos, A.; Piromalis, D. Uav Flight Control Based on Arduino Board Implementations. Int. J. Eng. Appl. Sci. Technol. 2019, 4, 438–443. [Google Scholar] [CrossRef]

- Tsitses, I.; Zacharia, P.; Xidias, E.; Papoutsidakis, M. A Fuzzy-Based System for Autonomous Unmanned Aerial Vehicle Ship Deck Landing. Sensors 2024, 24, 680. [Google Scholar] [CrossRef] [PubMed]

- Sigalos, A.; Papoutsidakis, M.; Chatzopoulos, A.; Piromalis, D. Design of a Flight Controller and Peripherals for a Quadcopter. Int. J. Eng. Appl. Sci. Technol. 2019, 4, 463–470. [Google Scholar] [CrossRef]

- Soetanto, M.F.; Tritjahjono, R.I. Study the Strength of Material and Composite Structures of Belly-Landing Mini UAV. Appl. Mech. Mater. 2016, 842, 178–185. [Google Scholar] [CrossRef]

- Stiffness—an Unknown World of Mechanical Science? Injury 2000, 31, 14–84. [CrossRef]

- Hou, Y.; Li, Q.; Liu, Z. A Comprehensive Design Method for Load, Stiffness, and Strength of High Altitude Long Endurance UAV. In 2023 Asia-Pacific International Symposium on Aerospace Technology (APISAT 2023) Proceedings; Springer Nature: Singapore, 2024; pp. 1651–1659. ISBN 9789819739974. [Google Scholar]

- Barrett, E.; Reiling, M.; Barbieri, G.; Fumagalli, M.; Carloni, R. Mechatronic Design of a Variable Stiffness Robotic Arm. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017. [Google Scholar]

- Cantwell, W.J.; Morton, J. The Impact Resistance of Composite Materials—A Review. Composites 1991, 22, 347–362. [Google Scholar] [CrossRef]

- Liu, J.; Chen, C.; Yu, J.; Li, J.; Zhang, Z.; Wang, Y.; Li, Y. Unmanned Aerial Vehicle Strike on a Flat Plate: Tests and Numerical Simulations. Chin. J. Aeronaut. 2023, 36, 286–298. [Google Scholar] [CrossRef]

- Che Man, M.H.; Low, K.H. Damage Severity Prediction of Helicopter Windshields Caused by a Collision with a Small Unmanned Aerial Vehicle (sUAV). In Proceedings of the AIAA Aviation 2021 Forum, Virtual, 2–6 August 2021. [Google Scholar]

- Seyhan, A.; Irez, A.B.; Polat, Y. Development of a Polyamide 6-Based Composite Material for UAV Propellers. In Mechanics of Composite, Hybrid & Multi-functional Materials, Volume 5; Springer International Publishing: Cham, Switzerland, 2023; pp. 73–77. ISBN 9783031174445. [Google Scholar]

- Prado, R.; Luis, J. Economic Optimization of Drone Structure for Industrial Indoor Use by Additive Manufacturing. Master’s Thesis, Politecnico di Torino, Torino, Italy, 2022. [Google Scholar]

- Mihailescu, R.; Simion, I.; Enache, C.I.; Chivu, O.R.; Nitoi, D. Development of a prototype drone through carbon fiber composite structures and additive manufacturing techniques. Macromol. Symp. 2024, 413, 2300202. [Google Scholar] [CrossRef]

- Šostakaitė, L.; Šapranauskas, E.; Rudinskas, D.; Rimkus, A.; Gribniak, V. Investigating Additive Manufacturing Possibilities for an Unmanned Aerial Vehicle with Polymeric Materials. Polymers 2024, 16, 2600. [Google Scholar] [CrossRef] [PubMed]

- Kanesan, G.; Mansor, S.; Abdul-Latif, A. Validation of UAV Wing Structural Model for Finite Element Analysis. J. Teknol. 2014, 71, 1–5. [Google Scholar] [CrossRef][Green Version]

- Mazhar, F.; Khan, A. Structural Design of a UAV Wing Using Finite Element Method. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 18th AIAA/ASME/AHS Adaptive Structures Conference 12th, Orlando, FL, USA, 12–15 April 2010. [Google Scholar]

- Wang, B.; Ng, P.H.; Elhadidi, B.M.N.A.K.; Ang, H.S.; Moon, S.K. Failure Analysis and Finite Element Simulation for Structural Systems in an Unmanned Aerial Vehicle. In Proceedings of the 2019 16th International Conference on Ubiquitous Robots (UR), Jeju, Republic of Korea, 24–27 June 2019. [Google Scholar]

- Husaini; Putra, D.F.; Syahriza; Akhyar. Stress and Strain Analysis of UAV Hexacopter Frame Using Finite Element Method. In Proceedings of the AIP Conference Proceedings, Banda Aceh, Indonesia, 29–30 September 2021. [Google Scholar]

- Ahmad, F.; Kumar, P.; Patil, P.P.; Kumar, V. FEA Based Frequency Analysis of Unmanned Aerial Vehicle (UAV). Mater. Today Proc. 2021, 46, 10396–10403. [Google Scholar] [CrossRef]

- Gutierrez-Rivera, M.E.; Rumbo-Morales, J.Y.; Ortiz-Torres, G.; Gascon-Avalos, J.J.; Sorcia-Vázquez, F.D.J.; Torres-Cantero, C.A.; Buenabad-Arias, H.M.; Guillen-Escamilla, I.; López-Osorio, M.A.; Zurita-Gil, M.A.; et al. Design, Construction and Finite Element Analysis of a Hexacopter for Precision Agriculture Applications. Modelling 2024, 5, 1239–1267. [Google Scholar] [CrossRef]

- Holsten, J.; Ostermann, T.; Moormann, D. Design and Wind Tunnel Tests of a Tiltwing UAV. CEAS Aeronaut. J. 2011, 2, 69–79. [Google Scholar] [CrossRef]

- Jindeog, C.; Jangyeon, L.; Bongzoo, S.; Samok, K. Wind Tunnel Test of an Unmanned Aerial Vehicle (UAV). KSME Int. J. 2003, 17, 776–783. [Google Scholar] [CrossRef]

- Sui, L.; Sun, Y.; Kang, M. Analysis and Experimental Study for Fatigue Performance of Wing-Fuselage Connection Structure for Unmanned Aerial Vehicle. Aerospace 2024, 11, 826. [Google Scholar] [CrossRef]

- Uzun, M.; Çınar, H.; Kocamer, A.; Çoban, S. Structural and Fatigue Analysis of a UAV Wing. J. Aviat. 2024, 8, 80–87. [Google Scholar] [CrossRef]

- Nikolic, J.; Burri, M.; Rehder, J.; Leutenegger, S.; Huerzeler, C.; Siegwart, R. A UAV System for Inspection of Industrial Facilities. In Proceedings of the 2013 IEEE Aerospace Conference, Big Sky, MT, USA, 2–9 March 2013; pp. 1–8. [Google Scholar]

- Samad, A.M.; Kamarulzaman, N.; Hamdani, M.A.; Mastor, T.A.; Hashim, K.A. The Potential of Unmanned Aerial Vehicle (UAV) for Civilian and Mapping Application. In Proceedings of the 2013 IEEE 3rd International Conference on System Engineering and Technology, Shah Alam, Malaysia, 19–20 August 2013. [Google Scholar]

- Semsch, E.; Jakob, M.; Pavlicek, D.; Pechoucek, M. Autonomous UAV Surveillance in Complex Urban Environments. In Proceedings of the 2009 IEEE/WIC/ACM International Joint Conference on Web Intelligence and Intelligent Agent Technology, Milan, Italy, 15–18 September 2009. [Google Scholar]

- Lo, L.-Y.; Yiu, C.H.; Tang, Y.; Yang, A.-S.; Li, B.; Wen, C.-Y. Dynamic Object Tracking on Autonomous UAV System for Surveillance Applications. Sensors 2021, 21, 7888. [Google Scholar] [CrossRef]

- Serdeczny, M.P.; Comminal, R.; Pedersen, D.B.; Spangenberg, J. Experimental and Analytical Study of the Polymer Melt Flow through the Hot-End in Material Extrusion Additive Manufacturing. Addit. Manuf. 2020, 32, 100997. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.E.; Park, J.H.; Lee, N.K.; Lyu, M.-Y.; Park, K.; Koo, M.S.; Cho, S.H.; Son, Y.; Park, S.-H. Enhanced Solubility of the Support in an FDM-based 3D Printed Structure Using Hydrogen Peroxide under Ultrasonication. Adv. Mater. Sci. Eng. 2018, 2018, 3018761. [Google Scholar] [CrossRef]

- Zeller, A.-N.; Neuhaus, M.-T.; Fresenborg, S.; Zimmerer, R.M.; Jehn, P.; Spalthoff, S.; Gellrich, N.-C.; Dittmann, J.A. Accurate and Cost-Effective Mandibular Biomodels: A Standardized Evaluation of 3D-Printing via Fused Layer Deposition Modeling on Soluble Support Structures. J. Stomatol. Oral Maxillofac. Surg. 2021, 122, 355–360. [Google Scholar] [CrossRef] [PubMed]

- Paśnikowska-Łukaszuk, M.; Urzędowski, A.; Wlazło, M.; Mikušová, D.; Zaburko, J. Analysis of the Solubility of a Support Filament Made of a Copolymer of Vinyl Alcohol and Butanediol in Aqueous Solutions with Variable pH. J. Ecol. Eng. 2023, 24, 201–207. [Google Scholar] [CrossRef] [PubMed]

- Duran, C.; Subbian, V.; Giovanetti, M.T.; Simkins, J.R.; Beyette, F.R., Jr. Experimental Desktop 3D Printing Using Dual Extrusion and Water-Soluble Polyvinyl Alcohol. Rapid Prototyp. J. 2015, 21, 528–534. [Google Scholar] [CrossRef]

- About. Available online: https://orcaslicer.net/about/ (accessed on 19 March 2025).

- UltiMaker Cura. Available online: https://ultimaker.com/software/ultimaker-cura/ (accessed on 19 March 2025).

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological Behavior and Dynamic Mechanical Properties for Interpretation of Layer Adhesion in FDM 3D Printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Saleh, A.M.; Jaber, A.S.; Jabbar, M.S. Layer Adhesion Investigation of Three Dimension Printed Parts by Controlling the Environment Temperature. Adv. Sci. Technol. Res. J. 2025, 19, 74–83. [Google Scholar] [CrossRef]

- Kantaros, A.; Katsantoni, M.; Ganetsos, T.; Petrescu, N. The Evolution of Thermoplastic Raw Materials in High-Speed FFF/FDM 3D Printing Era: Challenges and Opportunities. Materials 2025, 18, 1220. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T. Integration of Cyber-Physical Systems, Digital Twins and 3D Printing in Advanced Manufacturing: A Synergistic Approach. Am. J. Eng. Appl. Sci. 2024, 17, 1–22. [Google Scholar] [CrossRef]

- Tadi, S.P.; Mamilla, R.S. Fabrication of SS 316L Particle-Infilled PLA Composite Filaments from Cast-off Bi-Material Extrudates for 3D Printing Applications. Waste Manag. 2025, 193, 386–397. [Google Scholar] [CrossRef]

- Nekin Joshua, R.; Sakthivel, A.R. Reinforced Polymer Composite Filaments in Fused Deposition Modeling of 3D Printing Technology: A Review. Adv. Eng. Mater. 2025, 27, 2402509. [Google Scholar] [CrossRef]

- Krapež, D.; Jusufagić, M.; Obućina, M.; Kitek Kuzman, M.; Kariž, M. Effect of Filament Material and Printing Temperature on 3D Printing Extrusion Force. Appl. Sci. 2025, 15, 2046. [Google Scholar] [CrossRef]

- Birkelid, A.H.; Eikevåg, S.W.; Elverum, C.W.; Steinert, M. High-Performance Polymer 3D Printing—Open-Source Liquid Cooled Scalable Printer Design. HardwareX 2022, 11, e00265. [Google Scholar] [CrossRef]

- Alarifi, I.M. A Performance Evaluation Study of 3d Printed Nylon/Glass Fiber and Nylon/Carbon Fiber Composite Materials. J. Mater. Res. Technol. 2022, 21, 884–892. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef]

- Huang, J.; Chen, Q.; Jiang, H.; Zou, B.; Li, L.; Liu, J.; Yu, H. A Survey of Design Methods for Material Extrusion Polymer 3D Printing. Virtual Phys. Prototyp. 2020, 15, 148–162. [Google Scholar] [CrossRef]

- Abilgaziyev, A.; Kulzhan, T.; Raissov, N.; Ali, M.H.; Match, W.L.K.O.; Mir-Nasiri, N. Design and Development of Multi-Nozzle Extrusion System for 3D Printer. In Proceedings of the 2015 International Conference on Informatics, Electronics & Vision (ICIEV), Fukuoka, Japan, 15–18 June 2015. [Google Scholar]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T. 3D Printing of PEEK and Its Composite to Increase Biointerfaces as a Biomedical Material—A Review. Colloids Surf. B Biointerfaces 2021, 203, 111726. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of Nozzle Temperature and Building Orientation on Mechanical Properties and Microstructure of PEEK and PEI Printed by 3D-FDM. Polym. Test. 2019, 78, 105948. [Google Scholar] [CrossRef]

- Tlegenov, Y.; Hong, G.S.; Lu, W.F. Nozzle Condition Monitoring in 3D Printing. Robot. Comput. Integr. Manuf. 2018, 54, 45–55. [Google Scholar] [CrossRef]

- Bauriedel, N.; Albuquerque, R.Q.; Utz, J.; Geis, N.; Ruckdäschel, H. Monitoring of Fused Filament Fabrication (FFF): An Infrared Imaging and Machine Learning Approach. J. Polym. Sci. 2024, 62, 5633–5641. [Google Scholar] [CrossRef]

- Li, J. Development of a Vision-Based Monitoring System for Quality Assessment of 3D Printing. Ph.D. Thesis, University of Central Lancashire, Preston, UK, 2024. [Google Scholar]

- Ng, N.Y.Z.; Abdul Haq, R.H.; Marwah, O.M.F.; Ho, F.H.; Adzila, S. Optimization of Polyvinyl Alcohol (PVA) Support Parameters for Fused Deposition Modelling (FDM) by Using Design of Experiments (DOE). Mater. Today Proc. 2022, 57, 1226–1234. [Google Scholar] [CrossRef]

- Nisser, M.; Zhu, J.; Chen, T.; Bulovic, K.; Punpongsanon, P.; Mueller, S. Sequential Support: 3D Printing Dissolvable Support Material for Time-Dependent Mechanisms. In Proceedings of the Thirteenth International Conference on Tangible, Embedded, and Embodied Interaction, Tempe, AZ, USA, 17–20 March 2019. [Google Scholar]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef]

- Xun, H.; Clarke, S.; Baker, N.; Shallal, C.; Lee, E.; Fadavi, D.; Wong, A.; Brandacher, G.; Kang, S.H.; Sacks, J.M. Method, Material, and Machine: A Review for the Surgeon Using Three-Dimensional Printing for Accelerated Device Production. J. Am. Coll. Surg. 2021, 232, 726–737. [Google Scholar] [CrossRef]

- Oh, H.-S.; Park, J.-B. Development of 3D-Printed Dual-Release Fixed-Dose Combination through Double-Melt Extrusion. Int. J. Pharm. 2024, 661, 124407. [Google Scholar] [CrossRef]

- Qureshi, I.; Tariq, R.; Habib, M.; Insha, S. Artificial Intelligence in Three-Dimensional (3D) Printing. In Artificial Intelligence in the Food Industry; CRC Press: Boca Raton, FL, USA, 2024; pp. 206–218. ISBN 9781032633602. [Google Scholar]

- Osmani, K.; Schulz, D. A Drone-Deployable Remote Current Sensor for Non-Invasive Overhead Transmission Lines Monitoring. IEEE Access 2025, 13, 62393–62411. [Google Scholar] [CrossRef]

- Singh, N.K.; Muthukrishnan, P.; Sanpini, S. Industrial System Engineering for Drones: A Guide with Best Practices for Designing, 1st ed.; APress: Berlin, Germany, 2019; ISBN 9781484235331. [Google Scholar]

- Mozaffari, M.; Saad, W.; Bennis, M.; Debbah, M. Communications and Control for Wireless Drone-Based Antenna Array. IEEE Trans. Commun. 2018, 67, 820–834. [Google Scholar] [CrossRef]

- Kandregula, V.R.; Zaharis, Z.D.; Ahmed, Q.Z.; Khan, F.A.; Loh, T.H.; Schreiber, J.; Serres, A.J.R.; Lazaridis, P.I. A Review of Unmanned Aerial Vehicle Based Antenna and Propagation Measurements. Sensors 2024, 24, 7395. [Google Scholar] [CrossRef] [PubMed]

- Raza, M.U.; Ren, H.; Yan, S. Dual-Band Monopole MIMO Antenna Array for UAV Communication Systems. Sensors 2024, 24, 5913. [Google Scholar] [CrossRef]

- Dudczyk, J.; Czyba, R.; Skrzypczyk, K. Multi-Sensory Data Fusion in Terms of UAV Detection in 3D Space. Sensors 2022, 22, 4323. [Google Scholar] [CrossRef]

- Meng, K.; Wu, Q.; Xu, J.; Chen, W.; Feng, Z.; Schober, R.; Swindlehurst, A.L. UAV-Enabled Integrated Sensing and Communication: Opportunities and Challenges. IEEE Wirel. Commun. 2023, 31, 97–104. [Google Scholar] [CrossRef]

- Andreou, A.; Mavromoustakis, C.X.; Batalla, J.M.; Markakis, E.; Mastorakis, G.; Pallis, E. Secure Two-Way Communications between UAVs and Control Center in IoV 5G Communication. In Proceedings of the 2022 IEEE 27th International Workshop on Computer Aided Modeling and Design of Communication Links and Networks (CAMAD), Paris, France, 2–3 November 2022. [Google Scholar]

- Khayat, G.; Mavromoustakis, C.X.; Mastorakis, G.; Pallis, E.; Markakis, E.K.; Bourdena, A. S-UAV Multiple Redundant Routing Scheme for Crisis Scenario. In Signals and Communication Technology; Springer Nature: Cham, Switzerland, 2024; pp. 81–91. ISBN 9783031585265. [Google Scholar]

- Bianchi, I.; Mancia, T.; Mignanelli, C.; Simoncini, M. Effect of Nozzle Wear on Mechanical Properties of 3D Printed Carbon Fiber-Reinforced Polymer Parts by Material Extrusion. Int. J. Adv. Manuf. Technol. 2024, 130, 4699–4712. [Google Scholar] [CrossRef]

- Pitayachaval, P.; Masnok, K. Feed Rate and Volume of Material Effects in Fused Deposition Modeling Nozzle Wear. In Proceedings of the 2017 4th International Conference on Industrial Engineering and Applications (ICIEA), Nagoya, Japan, 21–23 April 2017. [Google Scholar]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the Effect of Additives to ABS on the Mechanical Property Anisotropy of Specimens Fabricated by Material Extrusion 3D Printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Zohdi, N.; Yang, R.C. Material Anisotropy in Additively Manufactured Polymers and Polymer Composites: A Review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef] [PubMed]

- Lv, C.; Shen, H.; Liu, J.; Wu, D.; Qu, E.; Liu, S. Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy. Materials 2022, 15, 8032. [Google Scholar] [CrossRef] [PubMed]

- Dijkshoorn, A.; Schouten, M.; Stramigioli, S.; Krijnen, G. Modelling of Anisotropic Electrical Conduction in Layered Structures 3D-Printed with Fused Deposition Modelling. Sensors 2021, 21, 3710. [Google Scholar] [CrossRef]

- Rasheed, R.; Anwar, I.; Tahir, F.; Rizwan, A.; Javed, H.; Sharif, F. Techno-Economic and Environmental Sustainability Analysis of Filament-Winding versus Pultrusion Based Glass-Fiber Composite Technologies. Environ. Sci. Pollut. Res. 2023, 30, 36276–36293. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Esposito Corcione, C. Sustainable Polymer Composites Manufacturing through 3D Printing Technologies by Using Recycled Polymer and Filler. Polymers 2022, 14, 3756. [Google Scholar] [CrossRef]

- Veteška, P.; Hajdúchová, Z.; Feranc, J.; Tomanová, K.; Milde, J.; Kritikos, M.; Bača, Ľ.; Janek, M. Novel Composite Filament Usable in Low-Cost 3D Printers for Fabrication of Complex Ceramic Shapes. Appl. Mater. Today 2021, 22, 100949. [Google Scholar] [CrossRef]

- Díaz-García, Á.; Law, J.Y.; Cota, A.; Bellido-Correa, A.; Ramírez-Rico, J.; Schäfer, R.; Franco, V. Novel Procedure for Laboratory Scale Production of Composite Functional Filaments for Additive Manufacturing. Mater. Today Commun. 2020, 24, 101049. [Google Scholar] [CrossRef]

- Park, S.; Shi, B.; Islam, M.M.; He, J.; Sung, D.H.; Zhang, C.; Cao, Z.; Shang, Y.; Liu, L.; Fu, K. Universal Carbonizable Filaments for 3D Printing. Adv. Funct. Mater. 2024, 34, 2410164. [Google Scholar] [CrossRef]

- Sciti, D.; Galizia, P.; Reimer, T.; Schoberth, A.; Gutiérrez-Gonzalez, C.F.; Silvestroni, L.; Vinci, A.; Zoli, L. Properties of Large Scale Ultra-High Temperature Ceramic Matrix Composites Made by Filament Winding and Spark Plasma Sintering. Compos. Part B Eng. 2021, 216, 108839. [Google Scholar] [CrossRef]

- Bex, G.J.P.; Ingenhut, B.L.J.; Cate, T.; Sezen, M.; Ozkoc, G. Sustainable Approach to Produce 3D-printed Continuous Carbon Fiber Composites: “A Comparison of Virgin and Recycled PETG”. Polym. Compos. 2021, 42, 4253–4264. [Google Scholar] [CrossRef]

- Chen, J.V.; Dang, A.B.C.; Dang, A. Comparing Cost and Print Time Estimates for Six Commercially-Available 3D Printers Obtained through Slicing Software for Clinically Relevant Anatomical Models. 3D Print. Med. 2021, 7, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Jiang, D.; Zhao, Q.; Wang, L. Study on Printability of 3D Printing Carbon Fiber Reinforced Eco-Friendly Concrete: Characterized by Fluidity and Consistency. Case Stud. Constr. Mater. 2024, 21, e03589. [Google Scholar] [CrossRef]

- Ciocan, L.T.; Vasilescu, V.G.; Pantea, M.; Pițuru, S.M.; Imre, M.; Ripszky Totan, A.; Froimovici, F.O. The Evaluation of the Trueness of Dental Mastercasts Obtained through Different 3D Printing Technologies. J. Funct. Biomater. 2024, 15, 210. [Google Scholar] [CrossRef]

- Huang, T.; Bobyr, M. A Review of Delamination Damage of Composite Materials. J. Compos. Sci. 2023, 7, 468. [Google Scholar] [CrossRef]

- Suriani, M.J.; Rapi, H.Z.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M. Delamination and Manufacturing Defects in Natural Fiber-Reinforced Hybrid Composite: A Review. Polymers 2021, 13, 1323. [Google Scholar] [CrossRef] [PubMed]

- Polyzos, E.; Van Hemelrijck, D.; Pyl, L. An Open-Source ABAQUS Plug-in for Delamination Analysis of 3D Printed Composites. Polymers 2023, 15, 2171. [Google Scholar] [CrossRef]

- Gonabadi, H.; Oila, A.; Yadav, A.; Bull, S. Investigation of Anisotropy Effects in Glass Fibre Reinforced Polymer Composites on Tensile and Shear Properties Using Full Field Strain Measurement and Finite Element Multi-Scale Techniques. J. Compos. Mater. 2022, 56, 507–524. [Google Scholar] [CrossRef]

- Rădulescu, B.; Mihalache, A.M.; Hrițuc, A.; Rădulescu, M.; Slătineanu, L.; Munteanu, A.; Dodun, O.; Nagîț, G. Thermal Expansion of Plastics Used for 3D Printing. Polymers 2022, 14, 3061. [Google Scholar] [CrossRef]

- Mashayekhi, F.; Bardon, J.; Berthé, V.; Perrin, H.; Westermann, S.; Addiego, F. Fused Filament Fabrication of Polymers and Continuous Fiber-Reinforced Polymer Composites: Advances in Structure Optimization and Health Monitoring. Polymers 2021, 13, 789. [Google Scholar] [CrossRef] [PubMed]

- Anwajler, B.; Iwko, J.; Piwowar, A.; Wróblewski, R.; Szulc, P. Influence of Structural Optimization on the Physical Properties of an Innovative FDM 3D Printed Thermal Barrier. Materials 2024, 17, 6293. [Google Scholar] [CrossRef] [PubMed]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P.; Baryś, M. The Potential of 3D Printing in Thermal Insulating Composite Materials-Experimental Determination of the Impact of the Geometry on Thermal Resistance. Materials 2024, 17, 1202. [Google Scholar] [CrossRef]

- Przekop, R.E.; Kujawa, M.; Pawlak, W.; Dobrosielska, M.; Sztorch, B.; Wieleba, W. Graphite Modified Polylactide (PLA) for 3D Printed (FDM/FFF) Sliding Elements. Polymers 2020, 12, 1250. [Google Scholar] [CrossRef] [PubMed]

- Sztorch, B.; Pakuła, D.; Frydrych, M.; Romańczuk-Ruszuk, E.; Osiecki, T.; Sedlitz, H.; Przekop, R.E. SH-SSQ as a Modifier for Superior Mechanical Properties and Improved Plasticity of 3D Printed PLA. Sci. Rep. 2025, 15, 7779. [Google Scholar] [CrossRef]

- Hartung, D.; Seidlitz, H.; Osiecki, T.; Sztorch, B.; Przekop, R.E.; Kazimierczuk, M. Flax Fiber Reinforced PET-G Composites with Improved Interfacial Adhesion. Polimery 2025, 70, 113–123. [Google Scholar] [CrossRef]

- Kucia, Z.; Bik, M.; Jeleń, P.; Olejniczak, Z.; Mroczka, K.; Pakuła, D.; Przekop, R.; Urbanova, M.; Brus, J.; Motz, G.; et al. Tuning the Carbon Content of Silicon Carbonitride SiCN(O) Materials Obtained from Hydrosilylation-Derived Polysilazanes. J. Eur. Ceram. Soc. 2025, 45, 117177. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, H.-Y.; Cui, X.; Du, X.; Zhou, H.; Mai, Y.-W.; Jia, Y.-Y.; Yan, W. Tensile Properties of 3D-Printed CNT-SGF Reinforced PLA Composites. Compos. Sci. Technol. 2022, 230, 109333. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Brząkalski, D.; Kozera, P.; Martyła, A.; Gabriel, E.; Kurzydłowski, K.J.; Przekop, R.E. Polyamide 11 Composites Reinforced with Diatomite Biofiller-Mechanical, Rheological and Crystallization Properties. Polymers 2023, 15, 1563. [Google Scholar] [CrossRef]

- Dong, K.; Panahi-Sarmad, M.; Cui, Z.; Huang, X.; Xiao, X. Electro-Induced Shape Memory Effect of 4D Printed Auxetic Composite Using PLA/TPU/CNT Filament Embedded Synergistically with Continuous Carbon Fiber: A Theoretical & Experimental Analysis. Compos. Part B Eng. 2021, 220, 108994. [Google Scholar] [CrossRef]

- Liu, J.; Gao, Y.; Wang, H.; Poling-Skutvik, R.; Osuji, C.O.; Yang, S. Shaping and Locomotion of Soft Robots Using Filament Actuators Made from Liquid Crystal Elastomer–Carbon Nanotube Composites. Adv. Intell. Syst. 2020, 2, 1900163. [Google Scholar] [CrossRef]

- Umoga, U.J.; Sodiya, E.O.; Ugwuanyi, E.D.; Jacks, B.S.; Lottu, O.A.; Daraojimba, O.D.; Obaigbena, A. Exploring the Potential of AI-Driven Optimization in Enhancing Network Performance and Efficiency. Magna Sci. Adv. Res. Rev. 2024, 10, 368–378. [Google Scholar] [CrossRef]

- Patel, D. A Novel Computationally Efficient AI-Driven Generative Inverse Design Framework for Accelerating Topology Optimization and Designing Lattice-Infused Structures. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2022. [Google Scholar]

- Al Ali, M.; Shimoda, M.; Naguib, M. Toward Automated Structural Design for Controlled Vibration Characteristics Using Topology Optimization and Computer Vision in Space Missions. Appl. Sci. 2024, 14, 6786. [Google Scholar] [CrossRef]

- 183.Dharaneswaran, S.U.; Reddy, J.; Fusic, J.; Balamurali, M.; Hemraj, N.H. Optimizing Drone Construction: Topology Optimization and Generative Design. In Proceedings of the 2024 IEEE Students Conference on Engineering and Systems (SCES), Prayagraj, India, 21–23 June 2024; pp. 1–6. [Google Scholar]

- Karali, H.; Inalhan, G.; Tsourdos, A. AI-Driven Multidisciplinary Conceptual Design of Unmanned Aerial Vehicles. In Proceedings of the AIAA SCITECH 2024 Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar]

- Haider, S.K.; Ahmed, A.; Khan, N.M.; Nauman, A.; Kim, S.W. AI-Driven Energy Optimization in UAV-Assisted Routing for Enhanced Wireless Sensor Networks Performance. Comput. Mater. Contin. 2024, 80, 4085–4110. [Google Scholar] [CrossRef]

- Müller, M.; Wings, E. An Architecture for Hybrid Manufacturing Combining 3D Printing and CNC Machining. Int. J. Manuf. Eng. 2016, 2016, 8609108. [Google Scholar] [CrossRef]

- Pascu, S.; Pop, A.A.; Balc, N. Design and Development of SP Hybrid Manufacturing Prototype Combining 3D Printing and CNC Milling. In Proceedings of the 2023 10th International Conference on Modern Power Systems (MPS), Cluj-Napoca, Romania, 21–23 June 2023; pp. 1–6. [Google Scholar]

- Sebbe, N.P.V.; Fernandes, F.; Sousa, V.F.C.; Silva, F.J.G. Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals 2022, 12, 1874. [Google Scholar] [CrossRef]

- Djurović, S.; Lazarević, D.; Ćirković, B.; Mišić, M.; Ivković, M.; Stojčetović, B.; Petković, M.; Ašonja, A. Modeling and Prediction of Surface Roughness in Hybrid Manufacturing–Milling after FDM Using Artificial Neural Networks. Appl. Sci. 2024, 14, 5980. [Google Scholar] [CrossRef]

- Klippstein, H.; Diaz De Cerio Sanchez, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Fused Deposition Modeling for Unmanned Aerial Vehicles (UAVs): A Review. Adv. Eng. Mater. 2018, 20, 1700552. [Google Scholar] [CrossRef]

- Kosmal, T.; Beaumont, K.; Link, E.; Phillips, D.; Pulling, C.; Wotton, H.; Kudrna, C.; Kubalak, J.; Williams, C. Hybrid Additive Robotic Workcell for Autonomous Fabrication of Mechatronic Systems—A Case Study of Drone Fabrication. Addit. Manuf. Lett. 2022, 3, 100100. [Google Scholar] [CrossRef]

| Reinforcing Material | Base Polymer | Key Properties | General Applications |

|---|---|---|---|

| Carbon Fiber | PLA, PETG, Nylon | High strength-to-weight ratio, excellent rigidity, thermal stability | Aerospace, automotive components, structural parts, sports equipment |

| Glass Fiber | PLA, PETG, ABS | High impact resistance, increased stiffness, good durability | Automotive parts, construction materials, industrial applications, protective housings |

| Kevlar | PLA, Nylon, PETG | High abrasion resistance, flexibility, toughness, vibration damping | Protective gear, bulletproof vests, automotive parts, industrial belts |

| Hybrid (e.g., Carbon Fiber and Glass Fiber) | PLA, PETG, Nylon | Balanced strength, impact resistance, and thermal stability | Robotics, aerospace, automotive, structural components requiring multi-property optimization |

| Aramid Fiber | PLA, PETG | Lightweight, high strength, corrosion resistance, toughness | Military applications, protective wear, marine, and aerospace industries |

| Filament Type | Tensile Strength (MPa) | Young’s Modulus (GPa) | Impact Resistance (kJ/m2) | Density (g/cm3) | Key Applications in Drones |

|---|---|---|---|---|---|

| Carbon Fiber-PLA | 60–80 | 4.5–6.0 | 4–6 | 1.3–1.4 | Drone frames, motor mounts, structural parts |

| Carbon Fiber-PETG | 50–70 | 3.0–4.5 | 8–12 | 1.3–1.4 | Propellers, landing gear, aerodynamic components |

| Carbon Fiber-Nylon | 80–110 | 6.5–8.0 | 10–15 | 1.1–1.2 | High-stress drone arms, propeller guards |

| Glass Fiber-PETG | 40–60 | 3.0–5.0 | 12–16 | 1.4–1.5 | Protective covers, structural reinforcement |

| Kevlar-PLA | 45–65 | 3.5–5.0 | 15–18 | 1.2–1.3 | Impact-resistant housings, protective enclosures |

| Hybrid (Carbon and Glass Fiber-PLA) | 70–90 | 5.5–7.0 | 8–10 | 1.3–1.5 | Structural frames requiring high stiffness and toughness |

| Integration Method | Description | Advantages | Challenges | Applications in Drones |

|---|---|---|---|---|

| Embedded Wiring Channels | Pre-designed internal pathways for routing cables. | Protects wires from damage, reduces drag, improves aerodynamics. | Requires precise design and printing; limited flexibility for modifications. | Power distribution, motor wiring, ESC connections. |

| Printed Conductive Traces | Conductive inks or filaments used to print circuits directly into the frame. | Eliminates excess wiring, lightweight, allows for custom circuitry. | Limited conductivity, requires special materials and post-processing. | Signal routing, integrated power distribution. |

| Soluble Support-Based Conduits | Temporary support material is used to create hollow channels for wiring. | Enables complex internal structures, improves esthetics. | Requires dual extrusion printers, post-processing needed. | Sensor integration, embedded cabling. |

| RF-Transparent Antenna Housings | Specialized non-conductive enclosures to improve signal strength. | Reduces interference, protects delicate antenna structures. | Material selection critical for performance; positioning must be optimized. | GPS, telemetry, communication antennas. |

| Integrated Sensor Mounts | Custom-designed slots or enclosures for UAV sensors. | Secure sensor placement, minimizes vibrations. | Requires careful calibration to prevent misalignment. | Camera mounts, LiDAR, IMU, thermal imaging sensors. |

| Multi-Material Printing for Embedded Electronics | Uses conductive and insulating materials to embed electronics. | Allows functional parts to be directly printed with electronics. | High material costs, requires advanced multi-material printers. | Smart drone frames, real-time health m |

| Challenge | Description | Impact on Drone Components | Mitigation Strategies | Comments |

|---|---|---|---|---|

| Nozzle Wear | Abrasive fibers (e.g., carbon/glass) accelerate nozzle degradation. | Inconsistent extrusion, reduced print quality, increased downtime. | Use wear-resistant nozzles (hardened steel, ruby-tipped); regular maintenance. | Essential for maintaining consistent material flow. |

| Anisotropy | Layer-by-layer deposition causes directional dependency in mechanical properties. | Weakened interlayer bonds may lead to delamination under stress. | Optimize print orientation, adjust fiber alignment, use multi-directional printing strategies. | Critical for load-bearing parts where uniform strength is required. |

| Warping | Uneven cooling and thermal contraction lead to deformation. | Dimensional inaccuracies, poor adhesion to build platform, structural weaknesses. | Use heated build plates, controlled ambient temperature, rafts/brims for better adhesion. | Especially problematic for larger or intricate components. |

| Print Consistency | Variations in filament quality, extrusion temperature, or speed. | Inconsistent mechanical properties, surface imperfections, potential failure points. | Implement rigorous quality control, real-time monitoring systems, and standardize filament production. | Consistency is key to ensuring reliable drone performance. |

| Delamination Risks | Inadequate bonding between layers due to rapid cooling or poor adhesion. | Structural failure under dynamic loading conditions. | Fine-tune printing parameters (temperature, speed, cooling rates); use optimized bonding techniques. | Requires careful calibration, especially for high-stress parts. |

| Cost and Scalability | High-performance composite filaments and specialized equipment are expensive. | Increased production cost, limited accessibility for small-scale manufacturers. | Economies of scale, process optimization, hybrid manufacturing (3D printing and CNC machining). | Balancing performance with cost remains a significant challenge. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. Composite Filament Materials for 3D-Printed Drone Parts: Advancements in Mechanical Strength, Weight Optimization and Embedded Electronics. Materials 2025, 18, 2465. https://doi.org/10.3390/ma18112465

Kantaros A, Drosos C, Papoutsidakis M, Pallis E, Ganetsos T. Composite Filament Materials for 3D-Printed Drone Parts: Advancements in Mechanical Strength, Weight Optimization and Embedded Electronics. Materials. 2025; 18(11):2465. https://doi.org/10.3390/ma18112465

Chicago/Turabian StyleKantaros, Antreas, Christos Drosos, Michail Papoutsidakis, Evangelos Pallis, and Theodore Ganetsos. 2025. "Composite Filament Materials for 3D-Printed Drone Parts: Advancements in Mechanical Strength, Weight Optimization and Embedded Electronics" Materials 18, no. 11: 2465. https://doi.org/10.3390/ma18112465

APA StyleKantaros, A., Drosos, C., Papoutsidakis, M., Pallis, E., & Ganetsos, T. (2025). Composite Filament Materials for 3D-Printed Drone Parts: Advancements in Mechanical Strength, Weight Optimization and Embedded Electronics. Materials, 18(11), 2465. https://doi.org/10.3390/ma18112465