High-Strength Ultrafine-Grained Al-Mg-Si Alloys Exposed to Mechanical Alloying and Press-Forming: A Comparison with Cast Alloys

Abstract

1. Introduction

2. Experimental

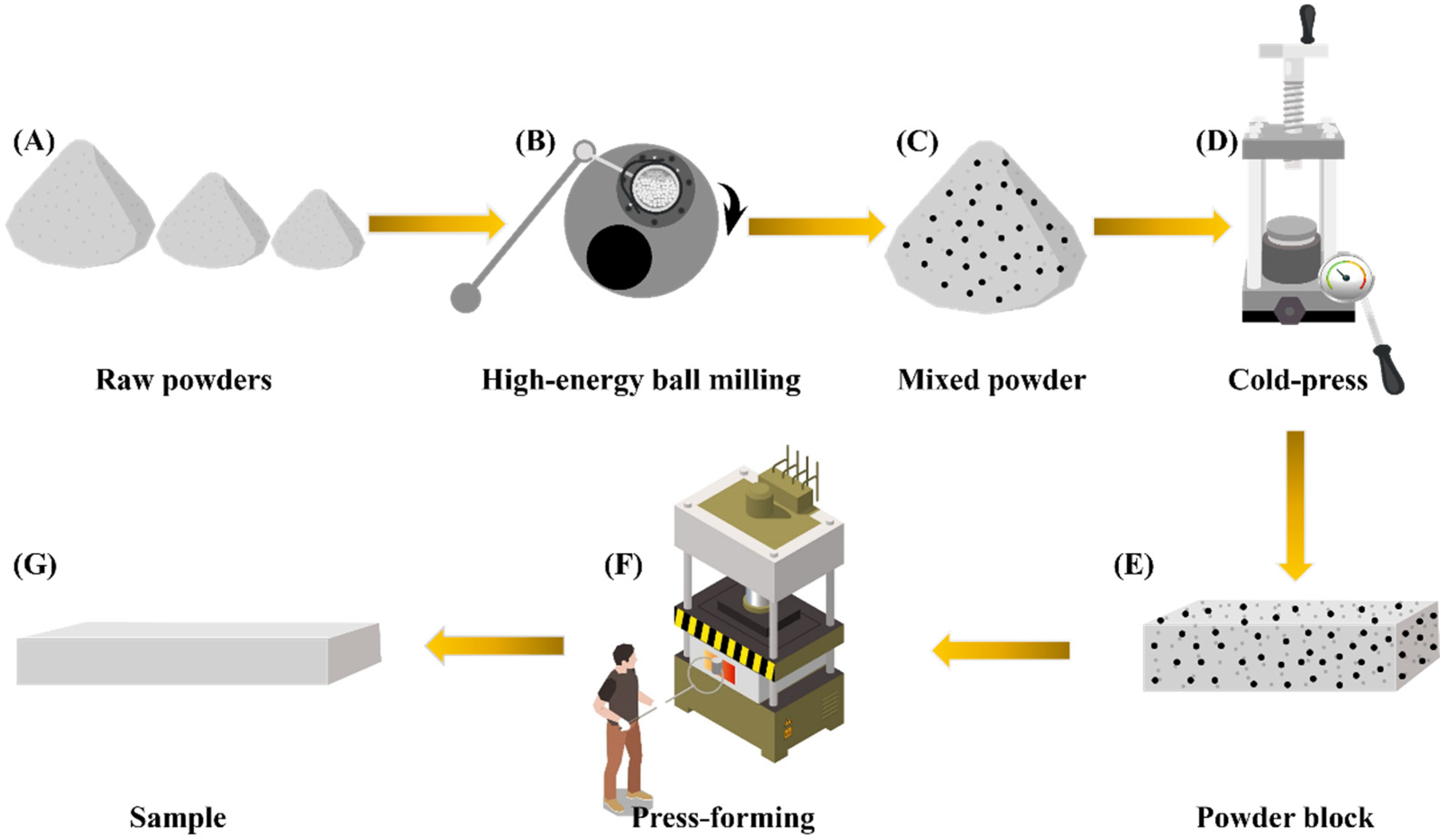

2.1. Material Fabrication

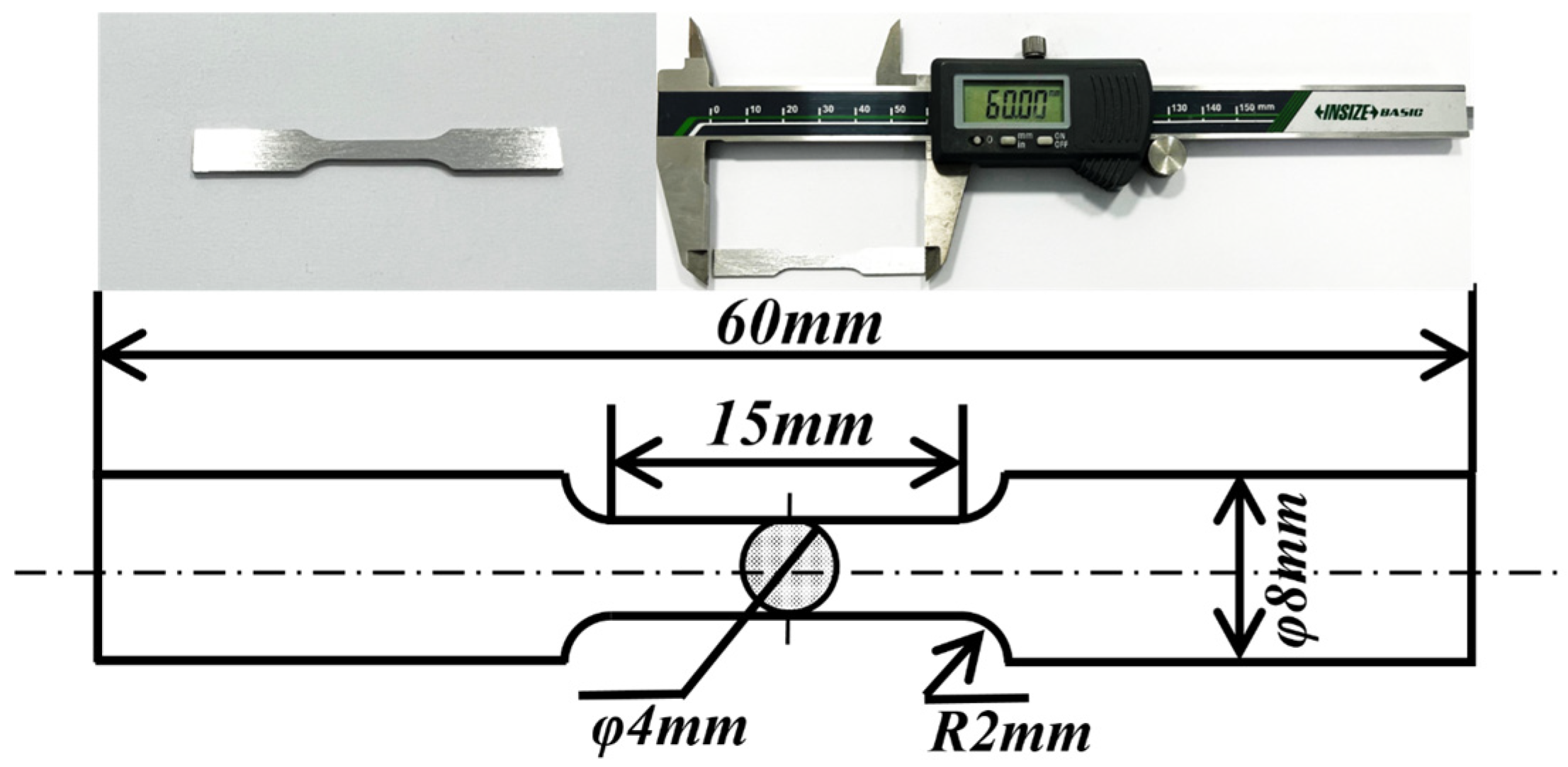

2.2. Microstructure Characterization and Mechanical Property Test

3. Results and Discussions

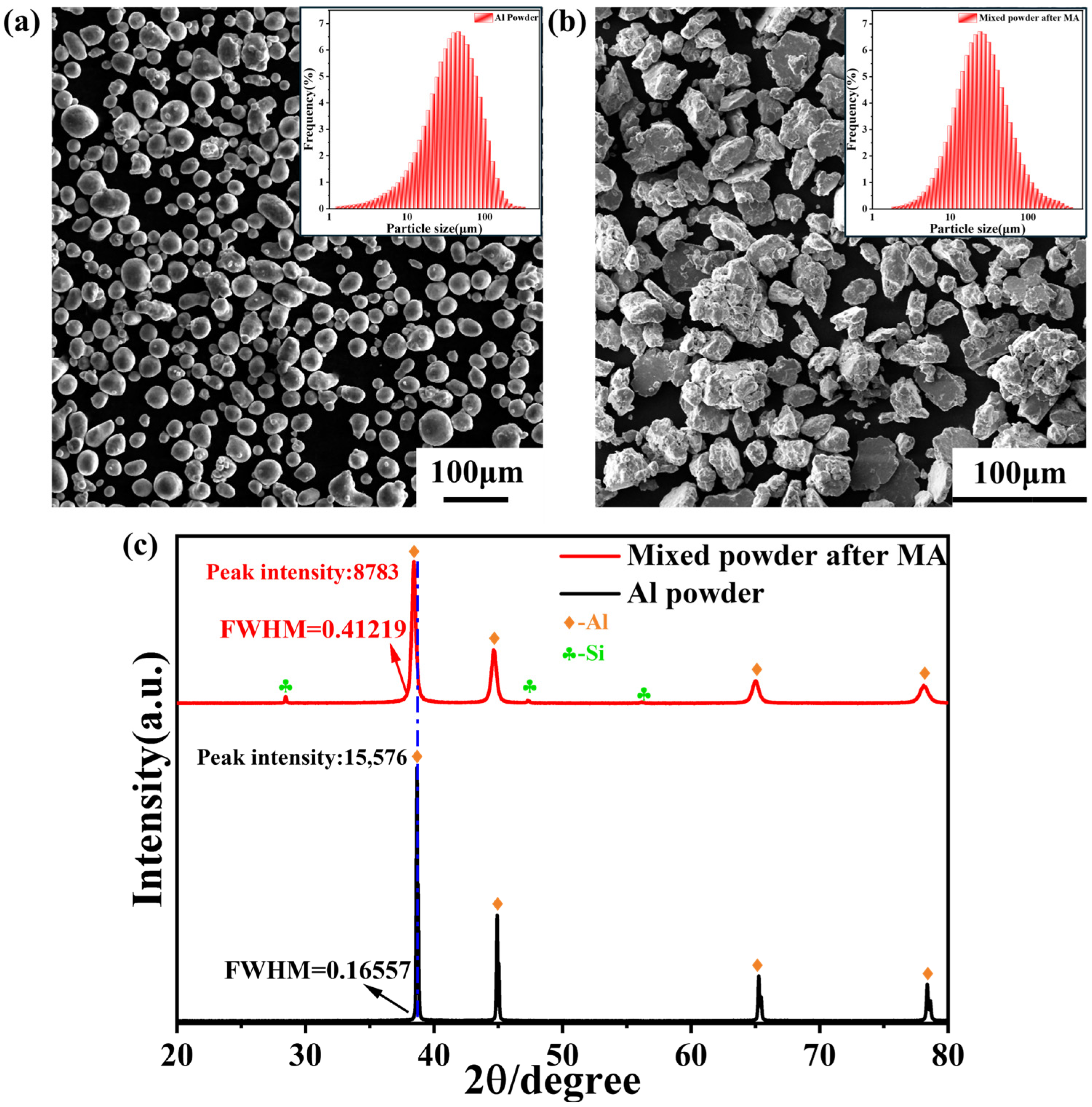

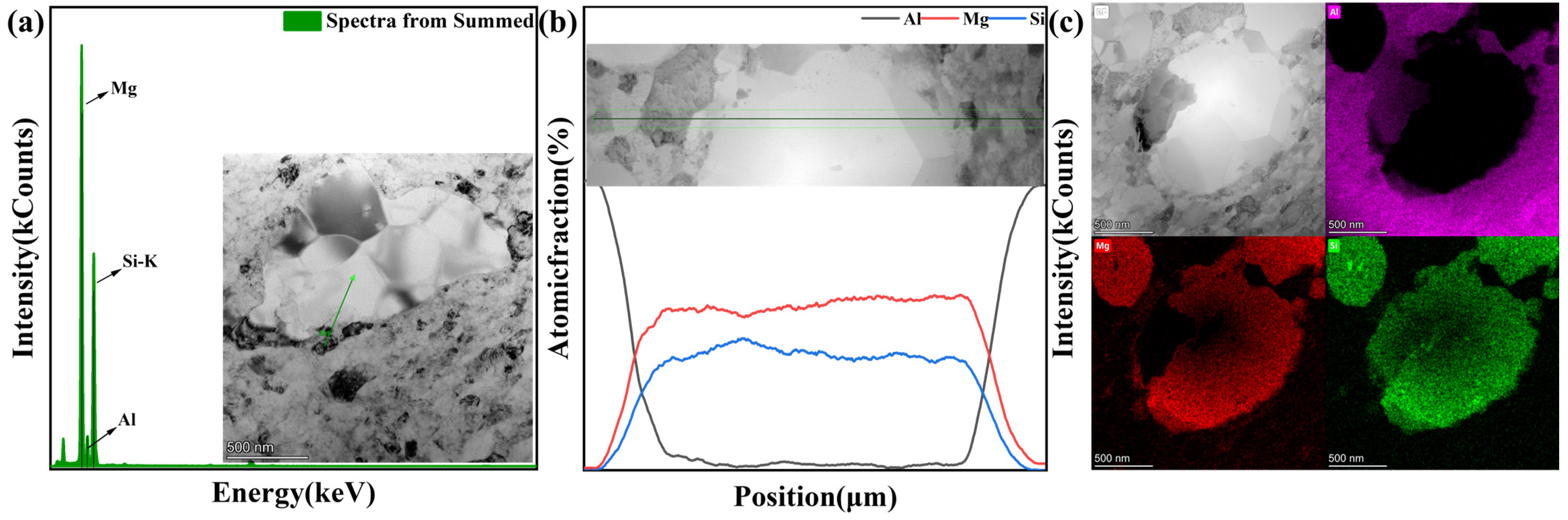

3.1. Powder Characterization

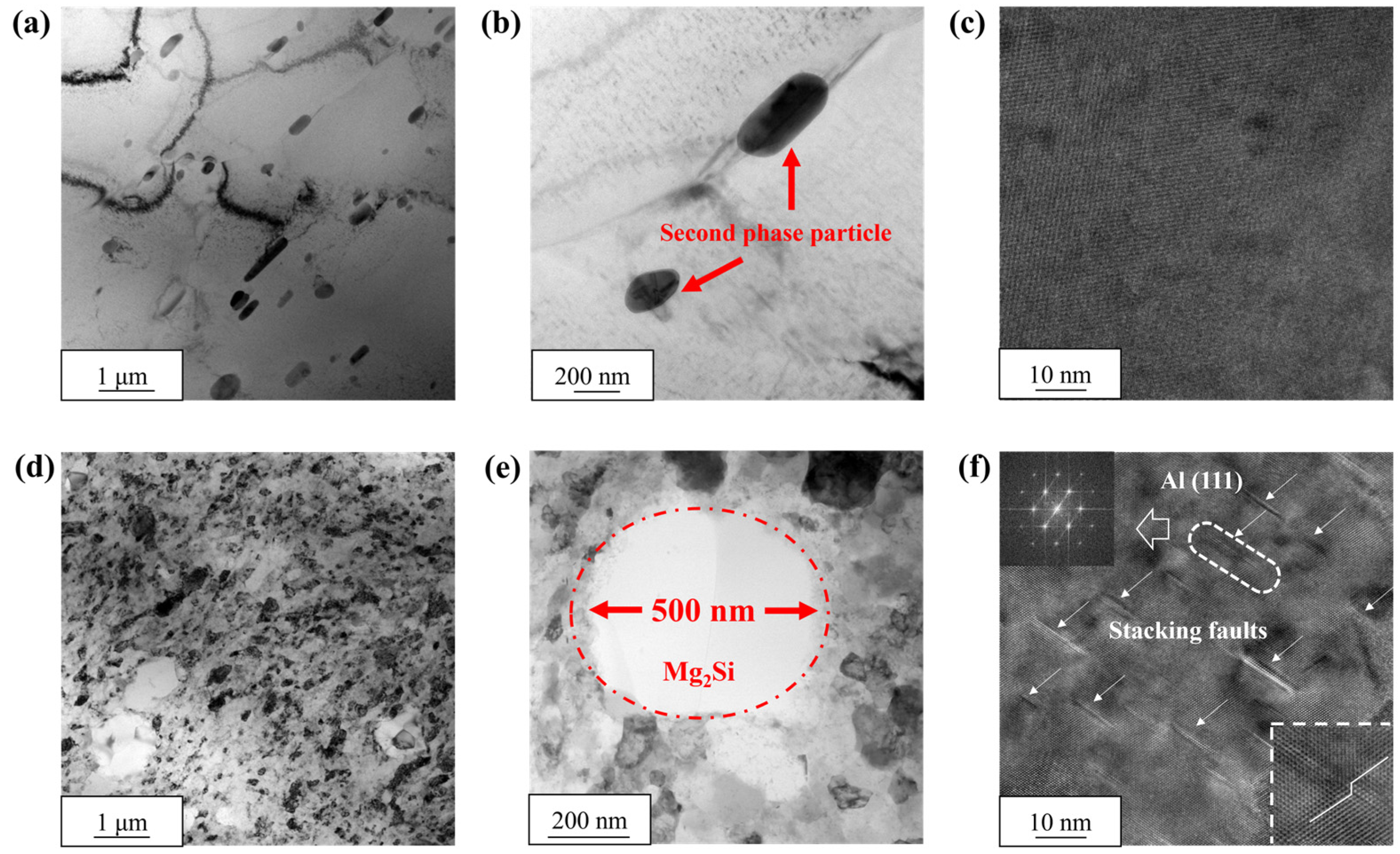

3.2. Microstructure Analysis

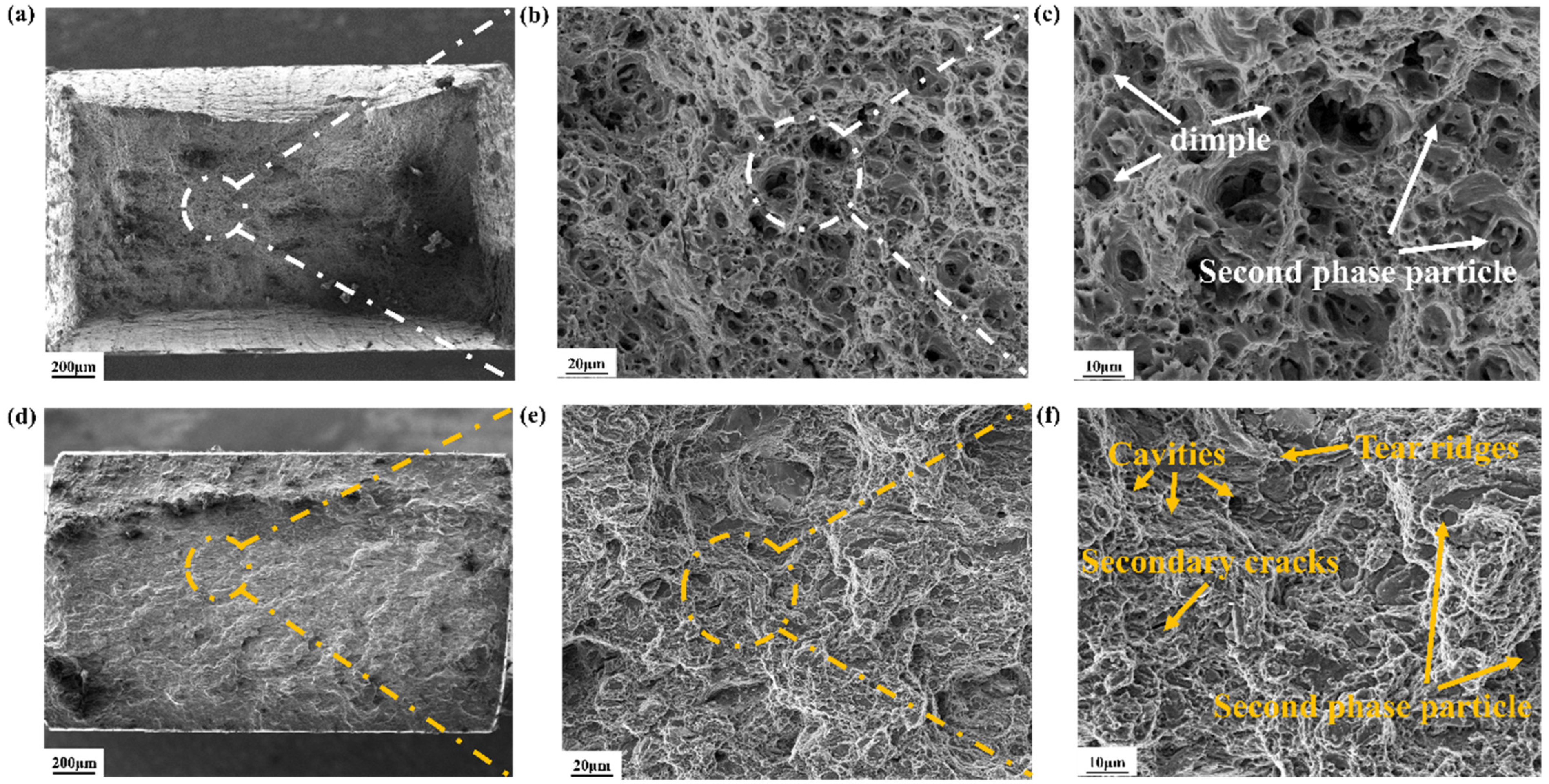

3.3. Mechanical Properties

4. Conclusions

- (1)

- The tensile strength of the CA sample was 324 MPa at room temperature, whereas the MPA sample exhibited superior performance with a tensile strength of 715 MPa.

- (2)

- XRD characterization confirmed the presence of the Mg2Si precipitate phase in both the CA and MPA samples. However, the MPA sample exhibited a higher Mg2Si content compared to the casting alloys. Additionally, Si monomers were identified as second-phase reinforcing particles in the MPA sample.

- (3)

- TKD analysis indicated that the grain size of the Al matrix in the CA sample was approximately 18.32 μm, whereas in the MPA sample, it was about 260 nm, signifying a substantial grain refinement compared to the CA sample.

- (4)

- TEM analysis revealed the absence of high-density SFs in the CA sample, whereas significant high-density SFs were observed in the MPA sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gupta, A.K.; Lloyd, D.J.; Court, S.A. Precipitation hardening in Al-Mg-Si alloys with and without excess Si. Mater. Sci. Eng. A 2001, 316, 11–17. [Google Scholar] [CrossRef]

- Miao, W.F.; Laughlin, D.E. Precipitation hardening in aluminum alloy 6022. Scr. Mater. 1999, 40, 873–878. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J.; Poole, W.J. Modeling of precipitation hardening for the naturally aged Al-Mg-Si-Cu alloy AA6111. Acta Mater. 2003, 51, 3467–3481. [Google Scholar] [CrossRef]

- Singh, P.; Ramacharyulu, D.A.; Kumar, N.; Saxena, K.K.; Eldin, S.M. Change in the structure and mechanical properties of Al-Mg-Si alloys caused by the addition of other elements: A comprehensive review. J. Mater. Res. Technol. 2023, 27, 1764–1796. [Google Scholar] [CrossRef]

- Xu, C.; Xiao, W.L.; Zheng, R.X.; Hanada, S.; Yamagata, H.; Ma, C.L. The synergic effects of Sc and Zr on the microstructure and mechanical properties of Al-Si-Mg alloy. Mater. Des. 2015, 88, 485–492. [Google Scholar] [CrossRef]

- Wang, S.B.; Pan, C.F.; Wei, B.; Zheng, X.; Lai, Y.X.; Chen, J.H. Nano-phase transformation of composite precipitates in multicomponent Al-Mg-Si(-Sc) alloys. J. Mater. Sci. Technol. 2022, 110, 216–226. [Google Scholar] [CrossRef]

- Bosio, F.; Fino, P.; Manfredi, D.; Lombardi, M. Strengthening strategies for an Al alloy processed by in-situ alloying during laser powder bed fusion. Mater. Des. 2021, 212, 110247. [Google Scholar] [CrossRef]

- Xu, C.; Xiao, W.L.; Hanada, S.; Yamagata, H.; Ma, C.L. The effect of scandium addition on microstructure and mechanical properties of Al-Si-Mg alloy: A multi-refinement modifier. Mater. Charact. 2015, 110, 160–169. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Zhang, M.-X.; Zhu, Q. Novel approach to additively manufacture high-strength Al alloys by laser powder bed fusion through addition of hybrid grain refiners. Addit. Manuf. 2021, 48, 102400. [Google Scholar] [CrossRef]

- Yan, Z.M.; Li, L.Y.; Zhu, J.X.; Ren, L.Y.; Xue, Y.; Wang, Q.; Zhang, Z.M. Deformation behavior of LPSO phases, grain refinement mechanism, and texture evolution of a Mg-Gd-Y-Zn-Zr alloy processed by forward extrusion combined with dual-directional angular deformation. J. Mater. Res. Technol. 2024, 28, 4131–4141. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T.; Ozaki, T.; Sugita, K.; Mizuno, M.; Araki, H. Microstructural formation and characterization mechanisms of selective laser melted Al-Si-Mg alloys with increasing magnesium content. Mater. Sci. Eng. A 2019, 754, 786–798. [Google Scholar] [CrossRef]

- Tang, H.G.; Cheng, Z.Q.; Liu, J.W.; Ma, X.F. Preparation of a high strength Al-Cu-Mg alloy by mechanical alloying and press-forming. Mater. Sci. Eng. A 2012, 550, 51–54. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L. Deformation twinning in nanocrystalline materials. Prog. Mater. Sci. 2012, 57, 1–62. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, X.; Tehranchi, A.; Hou, J.; Lu, W.; Hickel, T.; Ponge, D.; Raabe, D.; Zhang, D. Stacking faults in a mechanically strong Al(Mg)–Al3Mg2 composite. Compos. Part B Eng. 2022, 245, 110211. [Google Scholar] [CrossRef]

- Cao, Y.Z.; Zhao, X.S.; Tu, W.D.; Yan, Y.D.; Yu, F.L. Plastic deformation mechanisms in face-centered cubic materials with low stacking fault energy. Mater. Sci. Eng. A 2016, 676, 241–245. [Google Scholar] [CrossRef]

- Shi, S.; Dai, L.; Zhao, Y. Ternary relation among stacking fault energy, grain size and twin nucleation size in nanocrystalline and ultrafine grained CuAl alloys. J. Alloys Compd. 2022, 896, 162953. [Google Scholar] [CrossRef]

- He, M.; Zhang, Z.F.; Mao, W.M.; Li, B.; Bai, Y.L.; Xu, J. Numerical and Experimental Study on Melt Treatment for Large-Volume 7075 Alloy by a Modified Annular Electromagnetic Stirring. Materials 2019, 12, 820. [Google Scholar] [CrossRef]

- Qi, Q.W.; Li, M.; Duan, Y.H.; Bu, H.Y.; Li, M.N. Effect of Solution Heat Treatment on the Microstructure and Microhardness of 7050 Aluminum Alloy. Metals 2023, 13, 1819. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, D. Investigation of tensile behaviour of cryorolled and room temperature rolled 6082 Al alloy. Mater. Sci. Eng. A 2017, 691, 211–217. [Google Scholar] [CrossRef]

- Li, C.B.; Chen, D.D. Investigation on the Quench Sensitivity of 7085 Aluminum Alloy with Different Contents of Main Alloying Elements. Metals 2019, 9, 965. [Google Scholar] [CrossRef]

- Keerthipalli, T.; Aepuru, R.; Biswas, A. Review on precipitation, intermetallic and strengthening of aluminum alloys. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2023, 237, 833–850. [Google Scholar] [CrossRef]

- Deaquino-Lara, R.; Gutiérrez-Castañeda, E.; Estrada-Guel, I.; Hinojosa-Ruiz, G.; García-Sánchez, E.; Herrera-Ramírez, J.M.; Pérez-Bustamante, R.; Martínez-Sánchez, R. Structural characterization of aluminium alloy 7075-graphite composites fabricated by mechanical alloying and hot extrusion. Mater. Des. 2014, 53, 1104–1111. [Google Scholar] [CrossRef]

- Soltani, N.; Nodooshan, H.R.J.; Bahrami, A.; Pech-Canul, M.I.; Liu, W.C.; Wu, G.H. Effect of hot extrusion on wear properties of Al-15 wt.% Mg2Si in situ metal matrix composites. Mater. Des. 2014, 53, 774–781. [Google Scholar] [CrossRef]

- Guo, F.H.; Zhang, T.B.; Shi, L.M.; Chen, Y.; Song, L. Ameliorated microstructure and hydrogen absorption/desorption properties of novel Mg-Ni-La alloy doped with MWCNTs and Co nanoparticles. Int. J. Hydrogen Energy 2022, 47, 18044–18057. [Google Scholar] [CrossRef]

- Gandhi, P.M.; Valluri, S.K.; Schoenitz, M.; Dreizin, E. Effect of organic liquid process control agents on properties of ball-milled powders. Adv. Powder Technol. 2022, 33, 103332. [Google Scholar] [CrossRef]

- Jayasree, R.; Mane, R.B.; Vijay, R.; Chakravarty, D. Effect of process control agents on mechanically alloyed Al0.3CoCrFeNi. Mater. Lett. 2021, 292, 129618. [Google Scholar] [CrossRef]

- Kaykilarli, C.; Uzunsoy, D.; Yeprem, H.A. Role of process control agent in the production of Al2O3-reinforced titanium matrix composites. Ceram. Int. 2024, 50, 16452–16462. [Google Scholar] [CrossRef]

- Ruiz-Esparza-Rodríguez, M.A.; Garay-Reyes, C.G.; Estrada-Guel, I.; Hernández-Rivera, J.L.; Cruz-Rivera, J.J.; Gutiérrez-Castañeda, E.; Gómez-Esparza, C.D.; Martínez-Sánchez, R. Influence of process control agent and Al concentration on synthesis and phase stability of a mechanically alloyed AlxCoCrFeMnNi high-entropy alloy. J. Alloys Compd. 2021, 882, 160770. [Google Scholar] [CrossRef]

- Novelo-Peralta, O.; González, G.; Lara-Rodríguez, G.A. Characterization of precipitation in Al-Mg-Cu alloys by X-ray diffraction peak broadening analysis. Mater. Charact. 2008, 59, 773–780. [Google Scholar] [CrossRef]

- Korchef, A.; Champion, Y.; Njah, N. X-ray diffraction analysis of aluminium containing Al8Fe2Si processed by equal channel angular pressing. J. Alloys Compd. 2007, 427, 176–182. [Google Scholar] [CrossRef]

- Bayat, N.; Carlberg, T.; Cieslar, M. In-situ study of phase transformations during homogenization of 6005 and 6082 Al alloys. J. Alloys Compd. 2017, 725, 504–509. [Google Scholar] [CrossRef]

- Ma, L.H.; Tang, J.G.; Tu, W.B.; Ye, L.Y.; Jiang, H.C.; Zhan, X.; Zhao, J.H. Effect of a Trace Addition of Sn on the Aging Behavior of Al-Mg-Si Alloy with a Different Mg/Si Ratio. Materials 2020, 13, 913. [Google Scholar] [CrossRef]

- Zupanic, F.; Steinacher, M.; Zist, S.; Boncina, T. Microstructure and Properties of a Novel Al-Mg-Si Alloy AA 6086. Metals 2021, 11, 368. [Google Scholar] [CrossRef]

- Cui, Z.J.; Jiang, H.C.; Zhang, D.; Song, Y.Y.; Yan, D.S.; Rong, L.J. Effect of Natural Aging on Precipitation Strengthening Behaviors in Al-Mg-Si Alloy. Metals 2022, 12, 470. [Google Scholar] [CrossRef]

- Abd El-Aziz, K.; Ahmed, E.M.; Alghtani, A.H.; Felemban, B.F.; Ali, H.T.; Megahed, M.; Saber, D. Development of Al-Mg-Si alloy performance by addition of grain refiner Al-5Ti-1B alloy. Sci. Prog. 2021, 104, 00368504211029469. [Google Scholar] [CrossRef]

- Aster, P.; Dumitraschkewitz, P.; Uggowitzer, P.J.; Tunes, M.A.; Schmid, F.; Stemper, L.; Pogatscher, S. Unraveling the potential of Cu addition and cluster hardening in Al-Mg-Si alloys. Materialia 2024, 36, 102188. [Google Scholar] [CrossRef]

- Mandal, S.; Ali, S.I.; Ghosh, P.; Dutta, D.; Mandal, A.C. Micro-structural and opto-electronic correlation studies of sol-gel derived Zn1-xSmxS nanoparticles through the analysis of vacancy type defects. J. Mater. Sci. Mater. Electron. 2024, 35, 249. [Google Scholar] [CrossRef]

- Wang, D.; Bo, H.; Meng, H.W.; Li, H.L.; Zhuang, D.D.; Xu, N.; Shen, J.; Li, X.M.; Li, Q.; Shao, S.Y. , Ultrasonic vibration induced the improvement of mechanical properties and fracture behavior of Inconel 690 alloy joint during laser welding. J. Mater. Res. Technol. 2023, 24, 2064–2073. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, W.; Song, L.; Tang, H.; Wu, X.; Qiao, Z.; Liu, X. High-Strength Ultrafine-Grained Al-Mg-Si Alloys Exposed to Mechanical Alloying and Press-Forming: A Comparison with Cast Alloys. Materials 2025, 18, 99. https://doi.org/10.3390/ma18010099

Zhong W, Song L, Tang H, Wu X, Qiao Z, Liu X. High-Strength Ultrafine-Grained Al-Mg-Si Alloys Exposed to Mechanical Alloying and Press-Forming: A Comparison with Cast Alloys. Materials. 2025; 18(1):99. https://doi.org/10.3390/ma18010099

Chicago/Turabian StyleZhong, Wenjie, Lin Song, Huaguo Tang, Xu Wu, Zhuhui Qiao, and Xunyong Liu. 2025. "High-Strength Ultrafine-Grained Al-Mg-Si Alloys Exposed to Mechanical Alloying and Press-Forming: A Comparison with Cast Alloys" Materials 18, no. 1: 99. https://doi.org/10.3390/ma18010099

APA StyleZhong, W., Song, L., Tang, H., Wu, X., Qiao, Z., & Liu, X. (2025). High-Strength Ultrafine-Grained Al-Mg-Si Alloys Exposed to Mechanical Alloying and Press-Forming: A Comparison with Cast Alloys. Materials, 18(1), 99. https://doi.org/10.3390/ma18010099