Enhanced Compressive Mechanical Properties of Bio-Inspired Lattice Metamaterials with Taper Struts

Abstract

1. Introduction

2. Materials and Methods

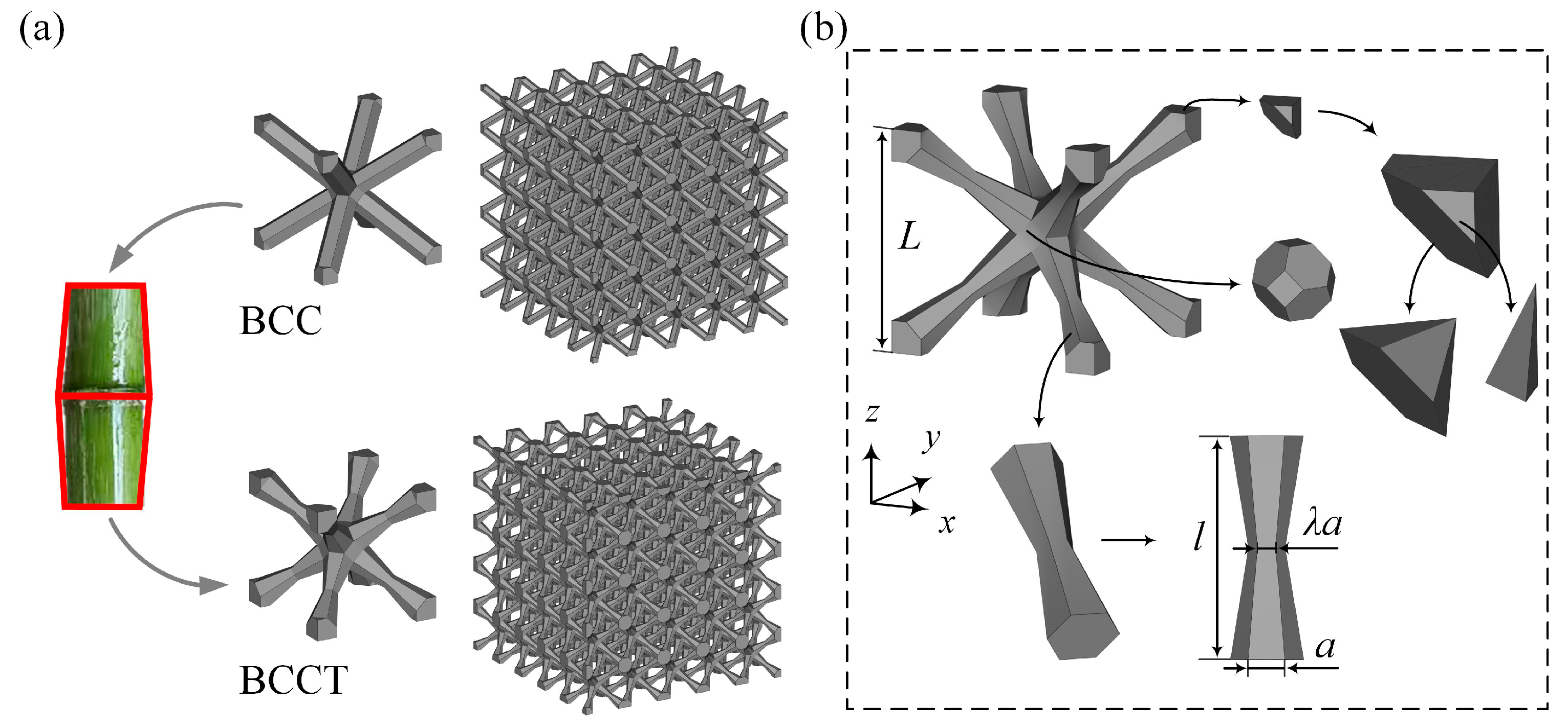

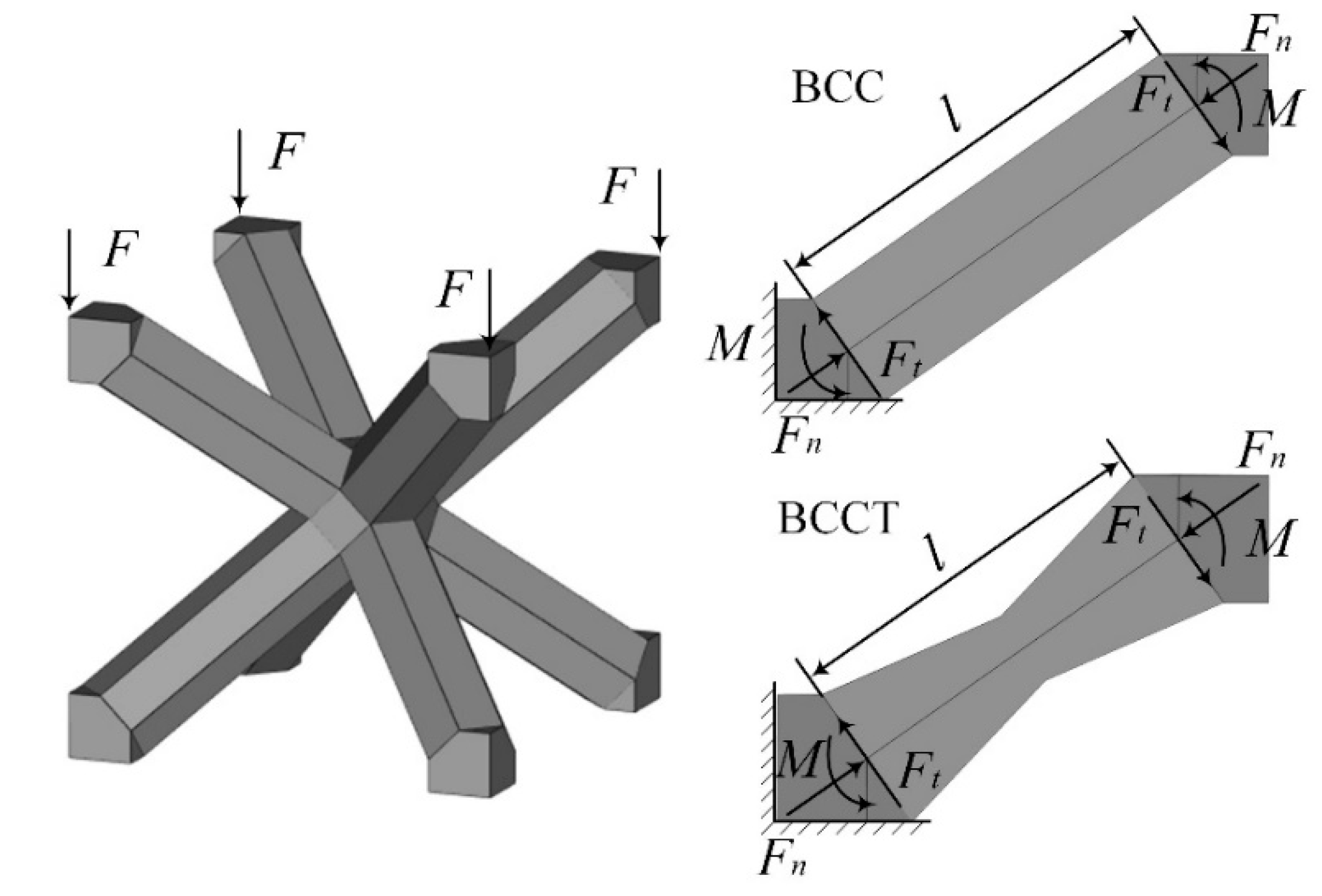

2.1. Design of BCCT Lattice Metamaterials

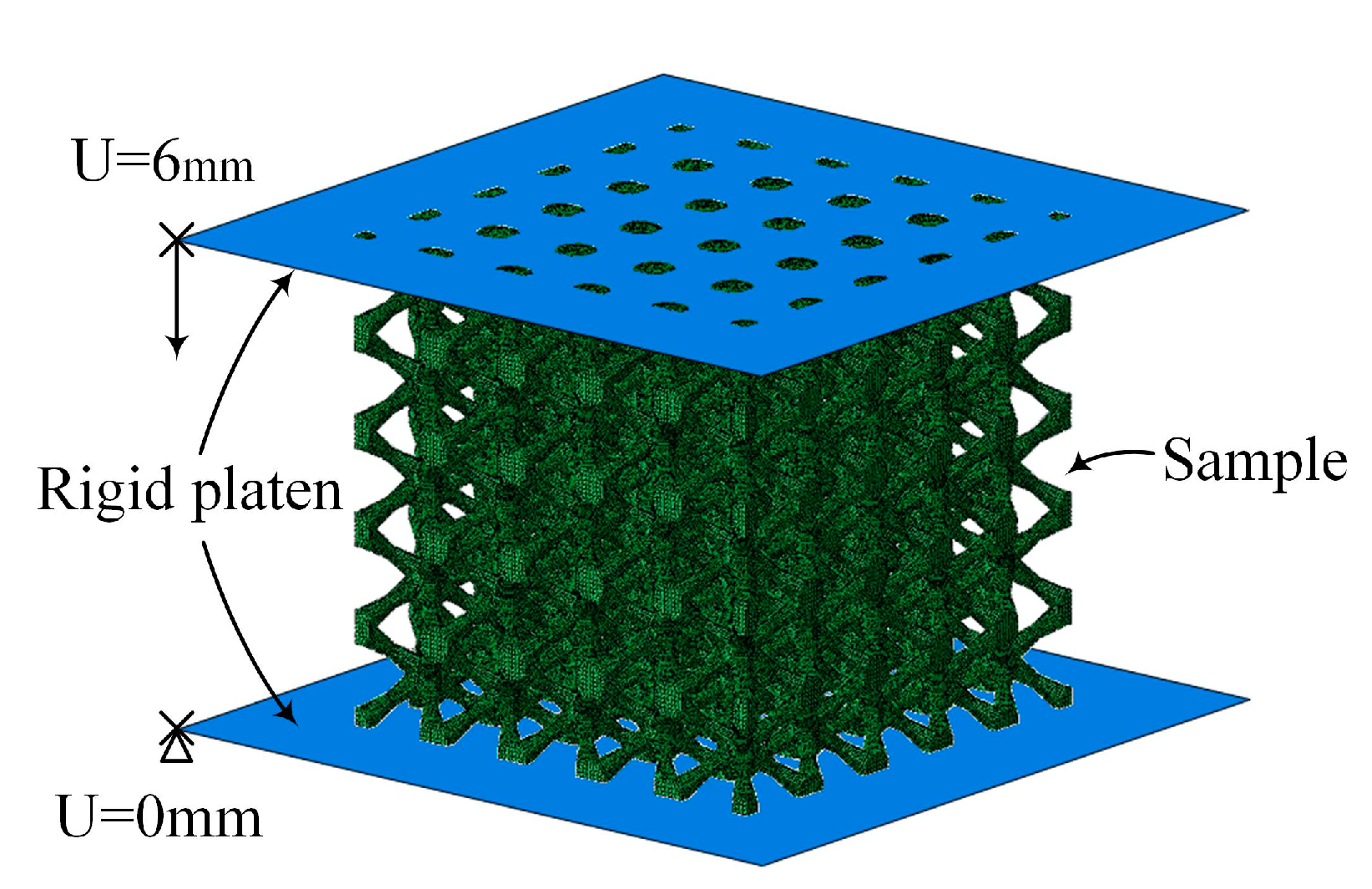

2.2. Finite Element Method

2.3. Sample Fabrication

2.4. Measurements

3. Results and Discussion

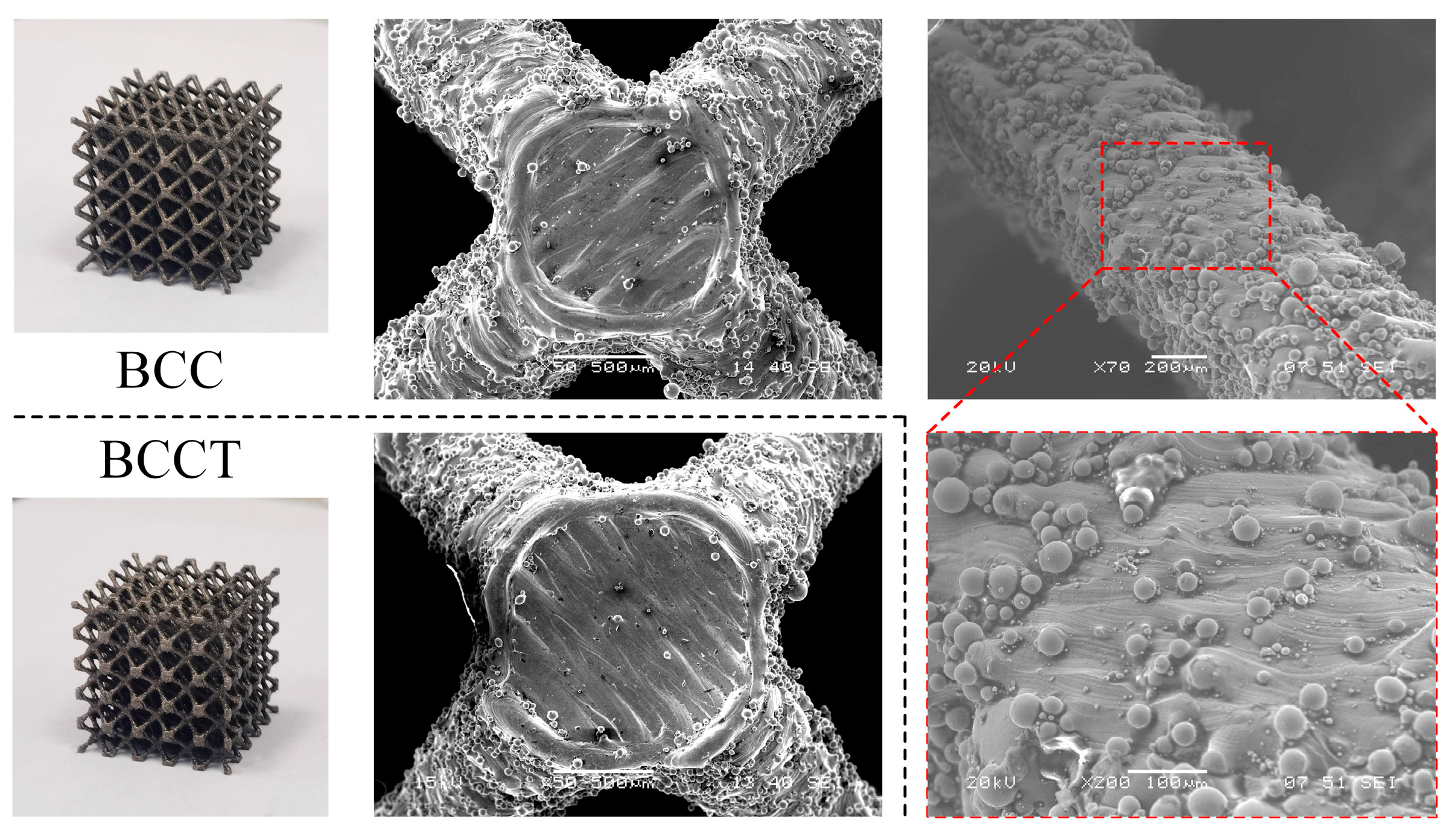

3.1. Validation of FEM

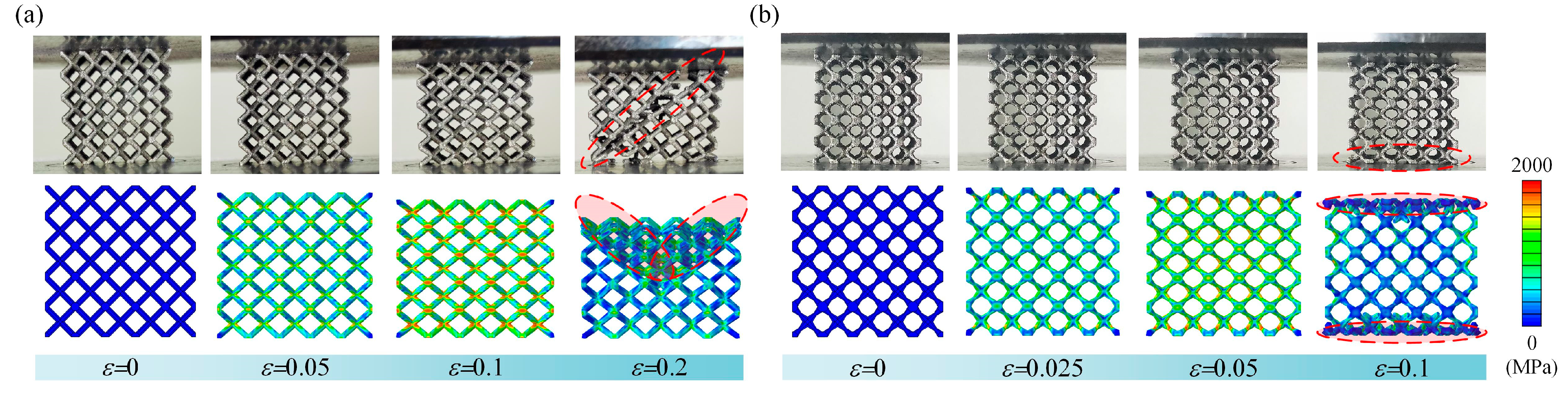

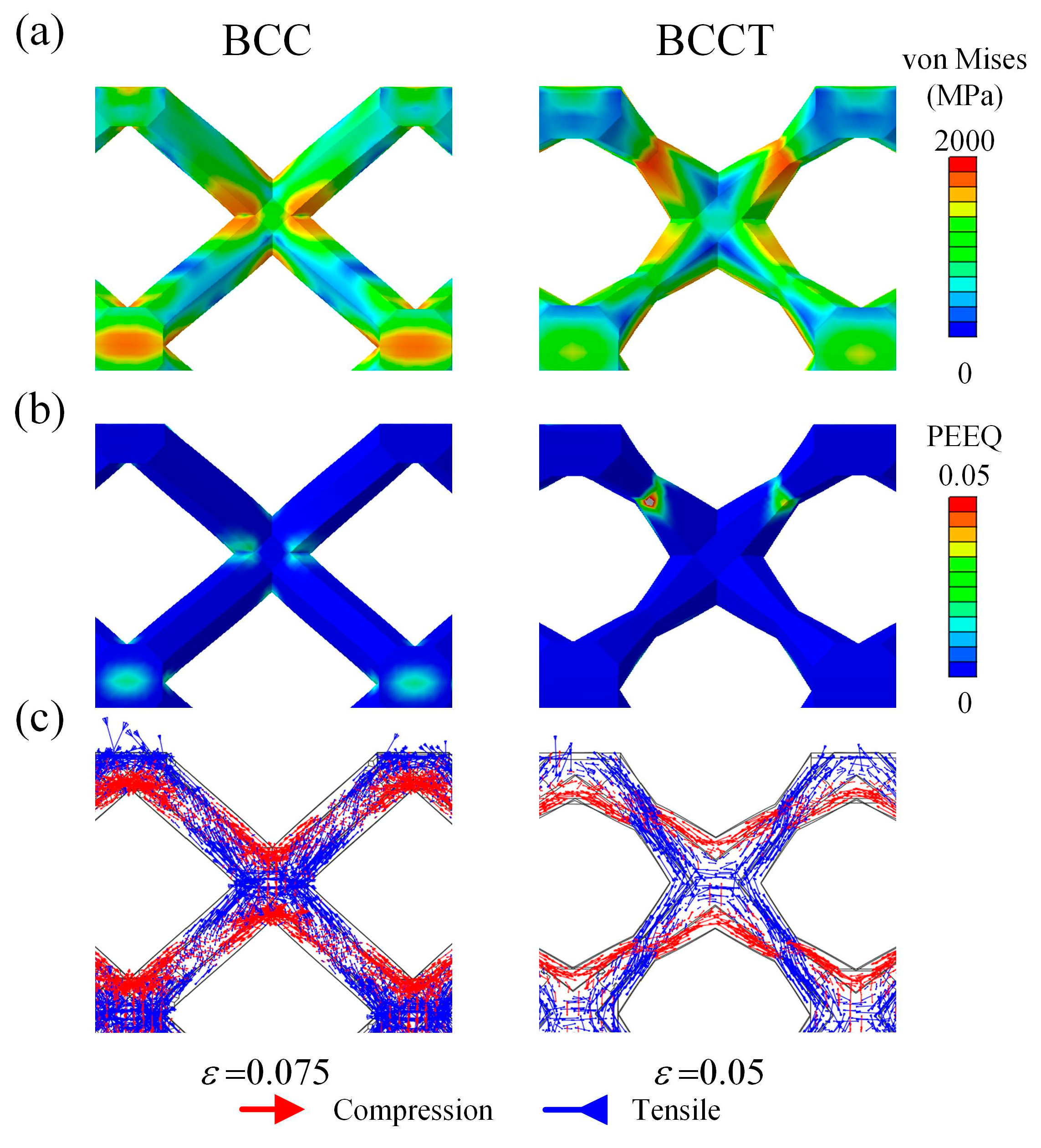

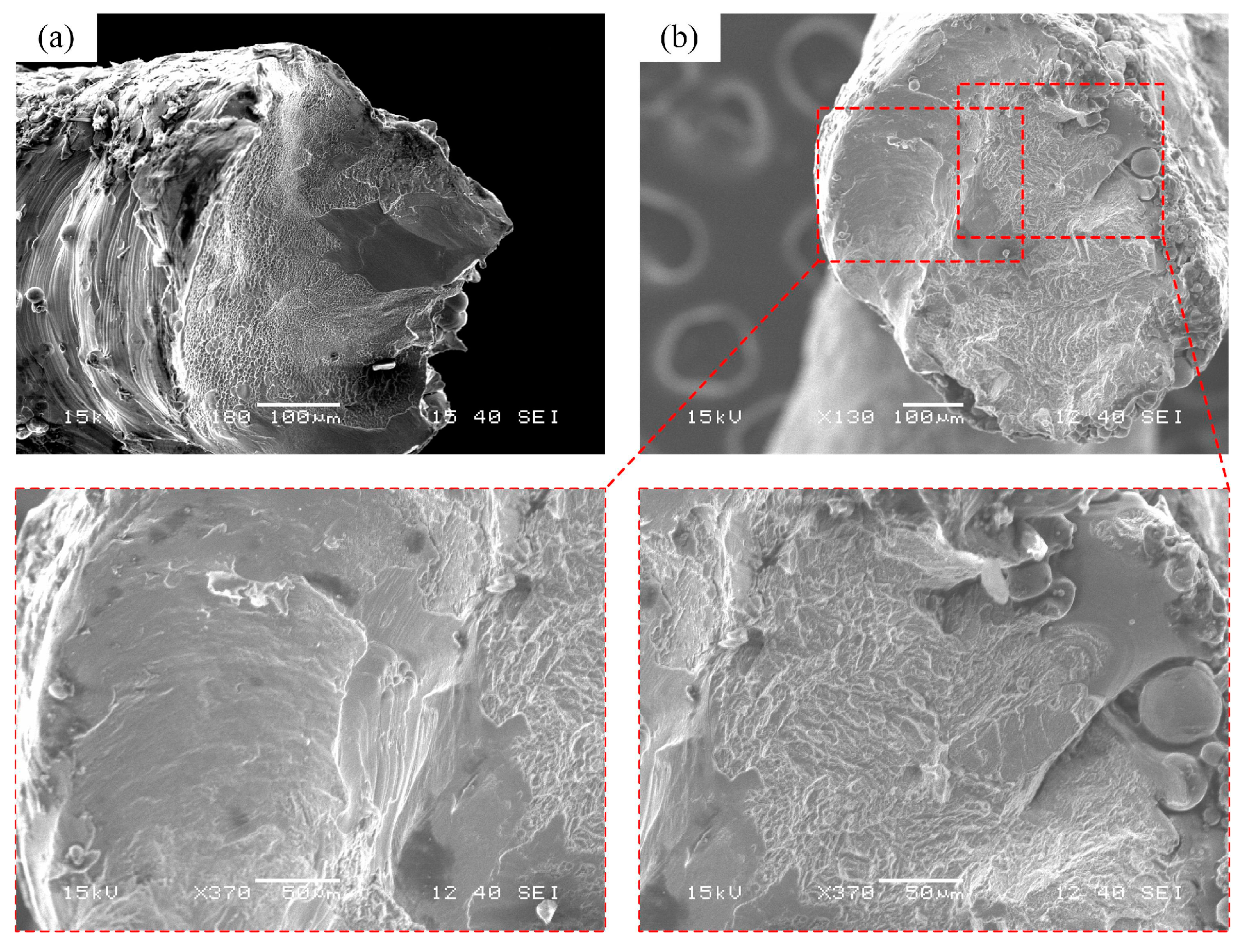

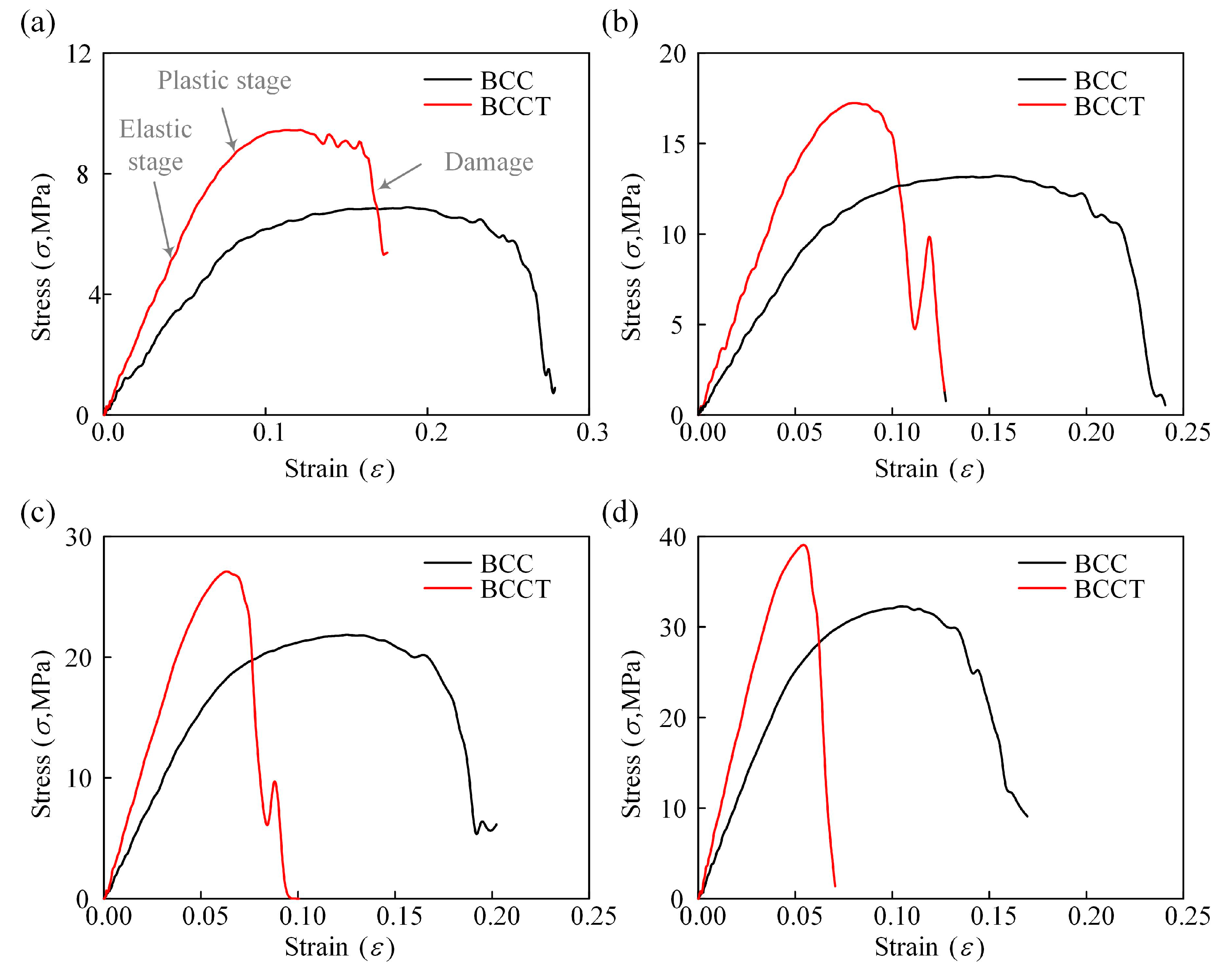

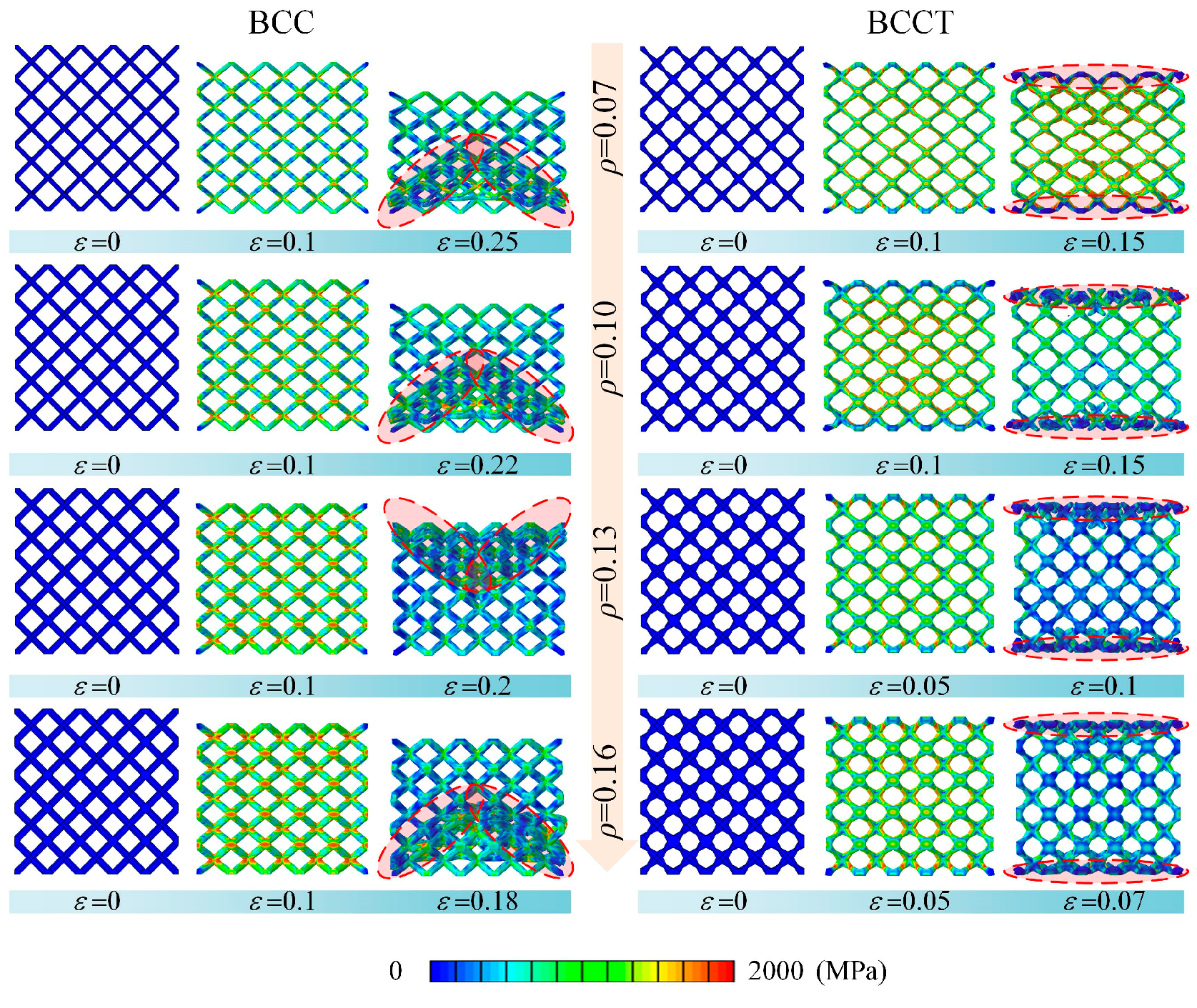

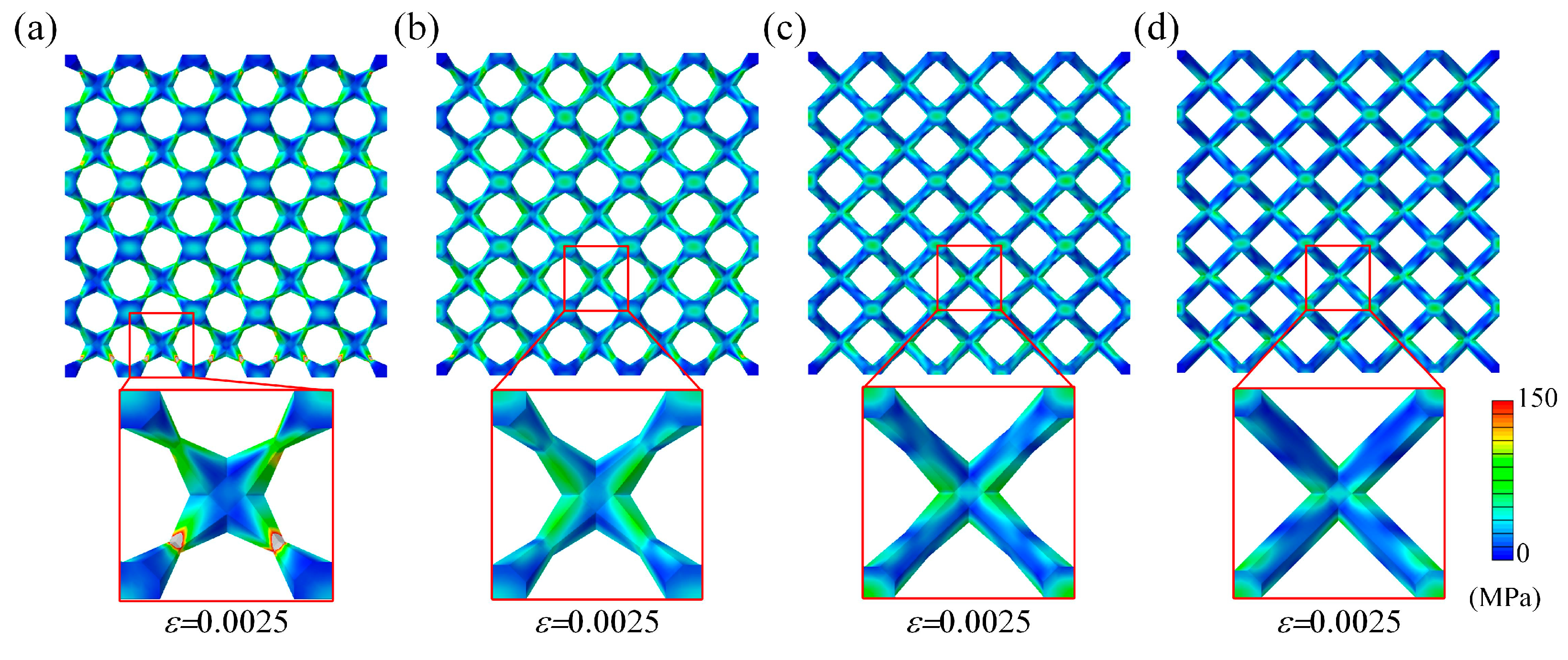

3.2. Deformation Behaviors

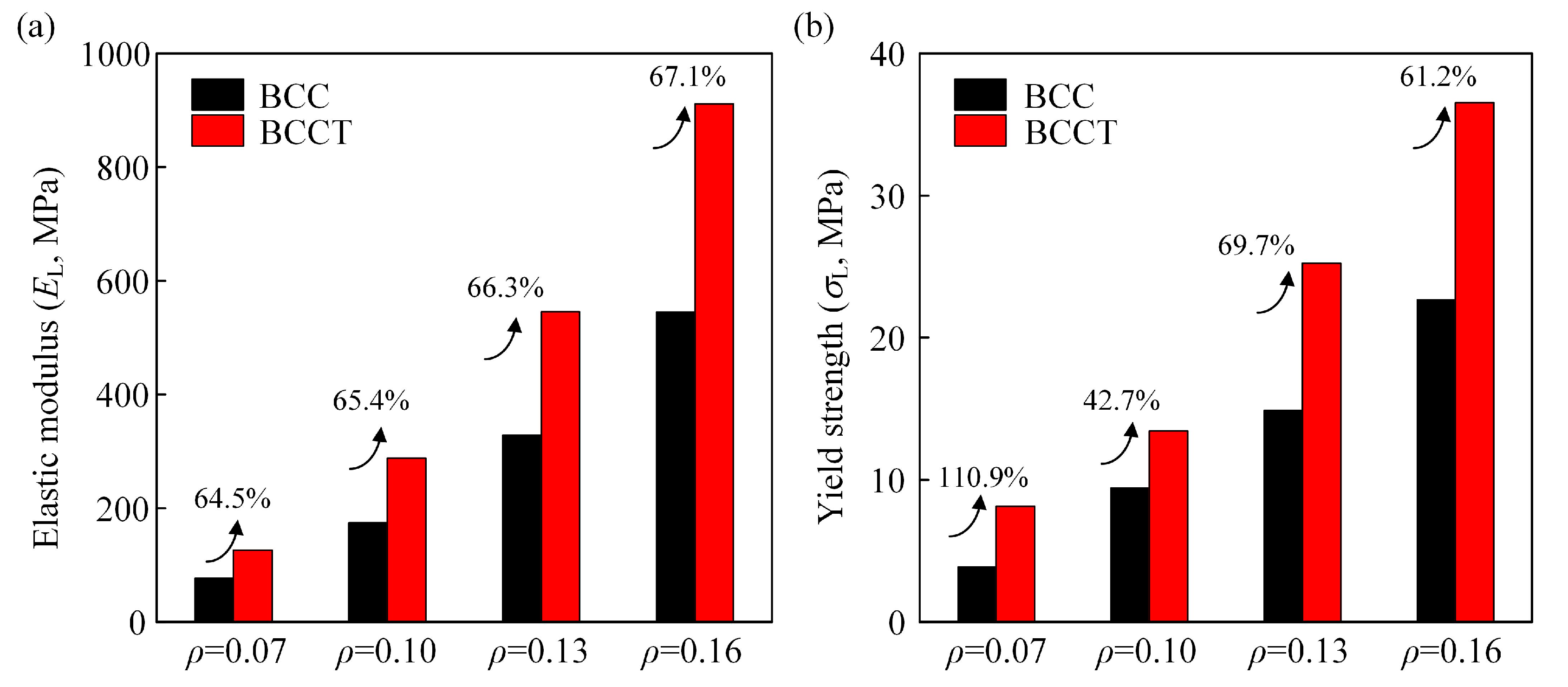

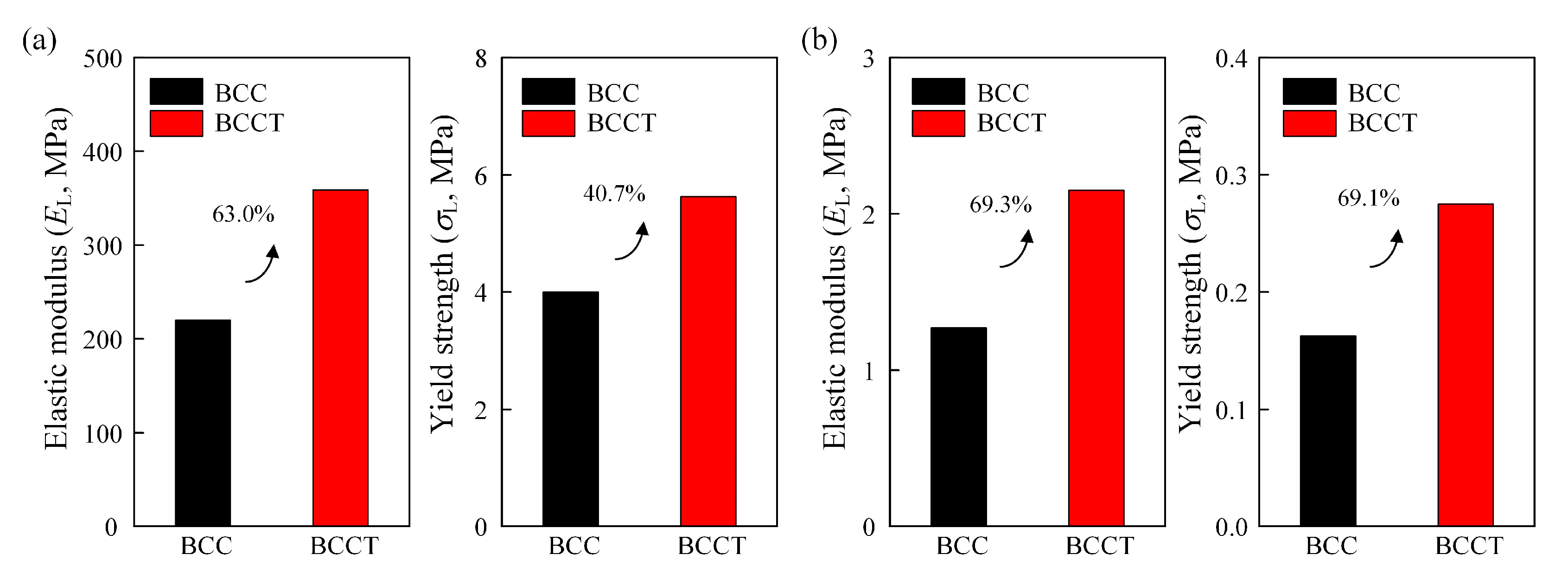

3.3. Mechanical Properties

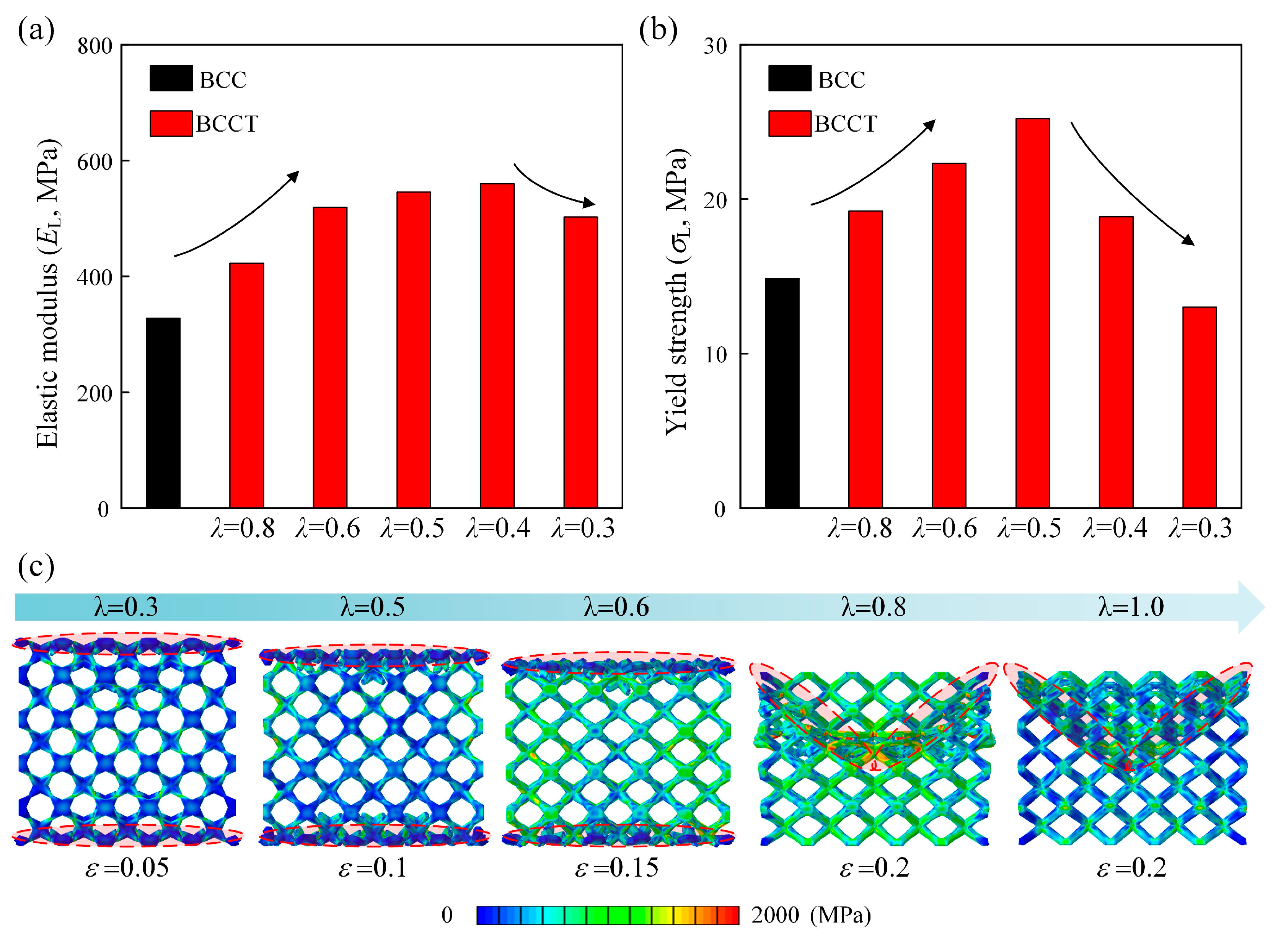

3.4. Parametric Study

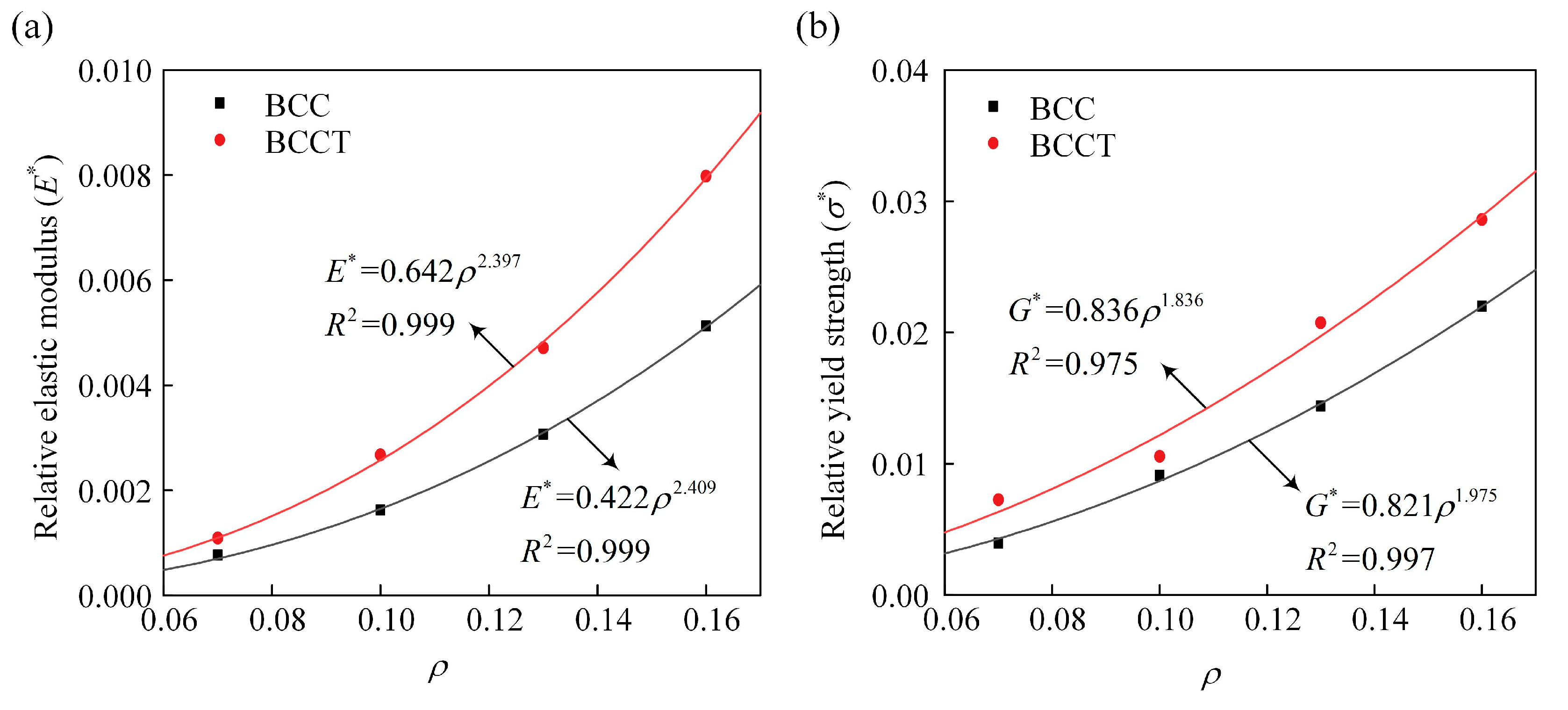

3.4.1. Effects of ρ

3.4.2. Effects of λ

3.4.3. Effects of Materials

4. Conclusions

- (1)

- BCCT lattice metamaterials eliminated stress concentration at nodes by redistributing stress to the center of the struts, resulting in a change in failure mode from shear band failure to layer collapse. Both BCC and BCCT lattice metamaterials exhibited a combination of brittle and ductile failure mechanisms.

- (2)

- Both BCC and BCCT lattice metamaterials underwent bending deformation during compression, with tensile and compressive stresses distributed symmetrically along the struts. According to the Gibson–Ashby model, the deformation mechanism of both structures was bending-dominated, and the tapered strut design minimally influenced the deformation mode of the lattice metamaterials.

- (3)

- The experimental results show that, compared to BCC lattice metamaterials, the elastic modulus and yield strength of the BCCT ones increased by 53.6% and 43.9%, respectively. The improved mechanical properties were attributed to the design of taper struts, which ensured more uniform stress distribution and reduced the bending moment.

- (4)

- The mechanical properties of BCCT lattice metamaterials were controlled by the shape factor λ. For BCCT lattice metamaterials made of Ti-6Al-4V with ρ = 0.13, the highest elastic modulus and yield strength was achieved at λ = 0.4 and λ = 0.5, respectively. Compared to BCC lattice metamaterials, the improvements in elastic modulus and yield strength were 70.7% and 69.7%, respectively.

- (5)

- The mechanical properties of BCCT lattice metamaterials with different volume fractions and materials were consistently superior to the BCC ones.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhong, H.; Das, R.; Gu, J.; Qian, M. Low-density, high-strength metal mechanical metamaterials beyond the Gibson-Ashby model. Mater. Today 2023, 68, 96–107. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Li, Z.; Wang, Z.; Zhai, W. Superior Strength, Toughness, and Damage-Tolerance Observed in Microlattices of Aperiodic Unit Cells. Small 2024, 20, e2307369. [Google Scholar] [CrossRef] [PubMed]

- Fu, T.; Rao, E.; Rabczuk, T. Sound transmission loss and energy absorbing performance of stiffened doubly-curved shells with corrugated-honeycomb hybrid cores. Eur. J. Mech.-A/Solids 2024, 107, 105386. [Google Scholar] [CrossRef]

- Sha, W.; Xiao, M.; Wang, Y.; Huang, M.; Li, Q.; Gao, L. Topology optimization methods for thermal metamaterials: A review. Int. J. Heat Mass Transf. 2024, 227, 125588. [Google Scholar] [CrossRef]

- Schneider, J.; Ebert, M.; Tipireddy, R.; Krishnamurthy, V.R.; Akleman, E.; Kumar, S. Concurrent geometrico-topological tuning of nanoengineered auxetic lattices fabricated by material extrusion for enhancing multifunctionality: Multiscale experiments, finite element modeling and data-driven prediction. Addit. Manuf. 2024, 88, 104213. [Google Scholar] [CrossRef]

- Fu, T.; Wang, X.; Rabczuk, T. Broadband low-frequency sound insulation of stiffened sandwich PFGM doubly-curved shells with positive, negative and zero Poisson′s ratio cellular cores. Aerosp. Sci. Technol. 2024, 147, 109049. [Google Scholar] [CrossRef]

- Qiu, N.; Zhang, J.; Yuan, F.; Jin, Z.; Zhang, Y.; Fang, J. Mechanical performance of triply periodic minimal surface structures with a novel hybrid gradient fabricated by selective laser melting. Eng. Struct. 2022, 263, 114377. [Google Scholar] [CrossRef]

- Xu, Y.; Pan, H.; Wang, R.; Du, Q.; Lu, L. New families of triply periodic minimal surface-like shell lattices. Addit. Manuf. 2023, 77, 103779. [Google Scholar] [CrossRef]

- Fusaro, G.; Barbaresi, L.; Cingolani, M.; Garai, M.; Ida, E.; Prato, A.; Schiavi, A. Investigation of the impact of additive manufacturing techniques on the acoustic performance of a coiled-up resonator. J. Acoust. Soc. Am. 2023, 153, 2921. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, N.; Chang, Y.; Tian, X. Multi-step deformation lattice structures from the rotation of unit cell. Int. J. Solids Struct. 2024, 288, 112599. [Google Scholar] [CrossRef]

- Guo, X.; Ding, J.; Li, X.; Qu, S.; Hsi Fuh, J.Y.; Lu, W.F.; Song, X.; Zhai, W. Interpenetrating phase composites with 3D printed triply periodic minimal surface (TPMS) lattice structures. Compos. Part B Eng. 2023, 248, 110351. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, M.; Zeng, Y.; Teshome, F.B.; Chen, L.; Zeng, Z. Evaluation of quasi-static and dynamic compressive properties of Ti-6Al-4 V functionally graded shell lattices with minimal surfaces. Mater. Today Commun. 2024, 40, 109792. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Z.; Wang, M.Y.; Feih, S. Hierarchical sheet triply periodic minimal surface lattices: Design, geometric and mechanical performance. Mater. Des. 2021, 209, 109931. [Google Scholar] [CrossRef]

- Kim, J.; Yoo, D.-J. 3D printed compact heat exchangers with mathematically defined core structures. J. Comput. Des. Eng. 2020, 7, 527–550. [Google Scholar] [CrossRef]

- Yang, N.; Song, Y.; Huang, J.; Chen, Y.; Maskery, I. Combinational design of heterogeneous lattices with hybrid region stiffness tuning for additive manufacturing. Mater. Des. 2021, 209, 109955. [Google Scholar] [CrossRef]

- Zhao, M.; Ji, B.; Zhang, D.Z.; Li, H.; Zhou, H. Design and mechanical performances of a novel functionally graded sheet-based lattice structure. Addit. Manuf. 2022, 52, 102676. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, D.Z.; Li, Z.; Zhang, T.; Zhou, H.; Ren, Z. Design, mechanical properties, and optimization of BCC lattice structures with taper struts. Compos. Struct. 2022, 295, 115830. [Google Scholar] [CrossRef]

- Liu, X.; Wada, T.; Suzuki, A.; Takata, N.; Kobashi, M.; Kato, M. Understanding and suppressing shear band formation in strut-based lattice structures manufactured by laser powder bed fusion. Mater. Des. 2021, 199, 109416. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Li, Z.; Wang, Z.; Zhai, W. A ribbed strategy disrupts conventional metamaterial deformation mechanisms for superior energy absorption. Virtual Phys. Prototyp. 2024, 19, e2337310. [Google Scholar] [CrossRef]

- Ren, X.; Xiao, L.; Hao, Z. Multi-property cellular material design approach based on the mechanical behaviour analysis of the reinforced lattice structure. Mater. Des. 2019, 174, 107785. [Google Scholar] [CrossRef]

- Li, Z.; Nie, Y.; Liu, B.; Kuai, Z.; Zhao, M.; Liu, F. Mechanical properties of AlSi10Mg lattice structures fabricated by selective laser melting. Mater. Des. 2020, 192, 108709. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, L.; Sun, L.; Li, N. Optimization of graded filleted lattice structures subject to yield and buckling constraints. Mater. Des. 2021, 206, 109746. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, F.; Fu, G.; Zhang, D.Z.; Zhang, T.; Zhou, H. Improved Mechanical Properties and Energy Absorption of BCC Lattice Structures with Triply Periodic Minimal Surfaces Fabricated by SLM. Materials 2018, 11, 2411. [Google Scholar] [CrossRef]

- Viswanath, A.; Khalil, M.; Al Maskari, F.; Cantwell, W.J.; Khan, K.A. Harnessing buckling response to design lattice structures with improved buckling strength. Mater. Des. 2023, 232, 112113. [Google Scholar] [CrossRef]

- Xiao, L.; Feng, G.; Li, S.; Mu, K.; Qin, Q.; Song, W. Mechanical characterization of additively-manufactured metallic lattice structures with hollow struts under static and dynamic loadings. Int. J. Impact Eng. 2022, 169, 104333. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, B.; Zhou, S.; Luo, M.; Han, F.; Chai, C.; Wang, J.; Yang, X. Superior energy absorption characteristics of additively-manufactured hollow-walled lattices. Int. J. Mech. Sci. 2024, 264, 108834. [Google Scholar] [CrossRef]

- Wang, P.; Yang, F.; Zheng, B.; Li, P.; Wang, R.; Li, Y.; Fan, H.; Li, X. Breaking the Tradeoffs between Different Mechanical Properties in Bioinspired Hierarchical Lattice Metamaterials. Adv. Funct. Mater. 2023, 33, 2305978. [Google Scholar] [CrossRef]

- Liu, X.; Kobir, M.H.; Yang, Y.; Jiang, F.; Kothari, T. Improving stiffness and strength of body-centered cubic lattices with an I-shape beam cross-section. Mech. Mater. 2023, 182, 104665. [Google Scholar] [CrossRef]

- Alomar, Z.; Concli, F. Compressive behavior assessment of a newly developed circular cell-based lattice structure. Mater. Des. 2021, 205, 109716. [Google Scholar] [CrossRef]

- Wang, P.; Yang, F.; Ru, D.; Zheng, B.; Fan, H. Additive-manufactured hierarchical multi-circular lattice structures for energy absorption application. Mater. Des. 2021, 210, 110116. [Google Scholar] [CrossRef]

- Li, Z.; Chen, C.; Mi, R.; Gan, W.; Dai, J.; Jiao, M.; Xie, H.; Yao, Y.; Xiao, S.; Hu, L. A Strong, Tough, and Scalable Structural Material from Fast-Growing Bamboo. Adv. Mater. 2020, 32, e1906308. [Google Scholar] [CrossRef] [PubMed]

- Ufodike, C.O.; Wang, H.; Ahmed, M.F.; Dolzyk, G.; Jung, S. Design and modeling of bamboo biomorphic structure for in-plane energy absorption improvement. Mater. Des. 2021, 205, 109736. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Parry, L.; Wildman, R.D.; Tuck, C.J.; Ashcroft, I.A. Effective design and simulation of surface-based lattice structures featuring volume fraction and cell type grading. Mater. Des. 2018, 155, 220–232. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P. Characterisation and constitutive model of tensile properties of selective laser melted Ti-6Al-4V struts for microlattice structures. Mater. Sci. Eng. A 2018, 725, 350–358. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Yang, L.; Yan, C.; Han, C.; Chen, P.; Yang, S.; Shi, Y. Mechanical response of a triply periodic minimal surface cellular structures manufactured by selective laser melting. Int. J. Mech. Sci. 2018, 148, 149–157. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, H.; Wang, J.; Jia, L.; Fan, Y.; Leary, M.; Qian, M. Additive manufacturing of intricate lattice materials: Ensuring robust strut additive continuity to realize the design potential. Addit. Manuf. 2022, 58, 103022. [Google Scholar] [CrossRef]

- Yang, L.; Wu, S.; Yan, C.; Chen, P.; Zhang, L.; Han, C.; Cai, C.; Wen, S.; Zhou, Y.; Shi, Y. Fatigue properties of Ti-6Al-4V Gyroid graded lattice structures fabricated by laser powder bed fusion with lateral loading. Addit. Manuf. 2021, 46, 102214. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Cai, X.; Pan, C.; Wang, J.; Zhang, W.; Fan, Z.; Gao, Y.; Xu, P.; Sun, H.; Li, J.; Yang, W. Mechanical behavior, damage mode and mechanism of AlSi10Mg porous structure manufactured by selective laser melting. J. Alloys Compd. 2022, 897, 162933. [Google Scholar] [CrossRef]

- Zhao, M.; Li, Z.; Chua, J.W.; Lim, C.H.; Li, X. Enhanced energy-absorbing and sound-absorbing capability of functionally graded and helicoidal lattice structures with triply periodic minimal surfaces. Int. J. Miner. Metall. Mater. 2023, 30, 1973–1985. [Google Scholar] [CrossRef]

| Laser Powder (W) | Hach Space (mm) | Layer Thickness (µm) | Scan Speed (mm/s) | Oxygen |

|---|---|---|---|---|

| 175 | 0.1 | 30 | 1250 | <0.1% |

| Sample | Elastic Modulus (EL, MPa) | Error (%) | Yield Strength (σL, MPa) | Error (%) | ||

|---|---|---|---|---|---|---|

| Experiment | Simulation | Experiment | Simulation | |||

| BCC | 328.16 ± 30.18 | 327.82 | −0.10 | 14.36 ± 0.75 | 14.86 | 3.48 |

| BCCT | 504.08 ± 25.87 | 545.28 | 8.17 | 20.67 ± 0.98 | 25.22 | 22.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, S.; Song, B.; Liu, G.; Yang, B.; Dai, M.; Gao, Z.; Cao, S.; Zhao, M. Enhanced Compressive Mechanical Properties of Bio-Inspired Lattice Metamaterials with Taper Struts. Materials 2025, 18, 29. https://doi.org/10.3390/ma18010029

Yuan S, Song B, Liu G, Yang B, Dai M, Gao Z, Cao S, Zhao M. Enhanced Compressive Mechanical Properties of Bio-Inspired Lattice Metamaterials with Taper Struts. Materials. 2025; 18(1):29. https://doi.org/10.3390/ma18010029

Chicago/Turabian StyleYuan, Shuangyin, Bingke Song, Gang Liu, Biqi Yang, Mingqiu Dai, Zetian Gao, Shan Cao, and Miao Zhao. 2025. "Enhanced Compressive Mechanical Properties of Bio-Inspired Lattice Metamaterials with Taper Struts" Materials 18, no. 1: 29. https://doi.org/10.3390/ma18010029

APA StyleYuan, S., Song, B., Liu, G., Yang, B., Dai, M., Gao, Z., Cao, S., & Zhao, M. (2025). Enhanced Compressive Mechanical Properties of Bio-Inspired Lattice Metamaterials with Taper Struts. Materials, 18(1), 29. https://doi.org/10.3390/ma18010029