Compressive Fracture Behavior of Zirconia/Resin Composites Prepared by Fused Deposition Modeling Combined with Vacuum Infiltration

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

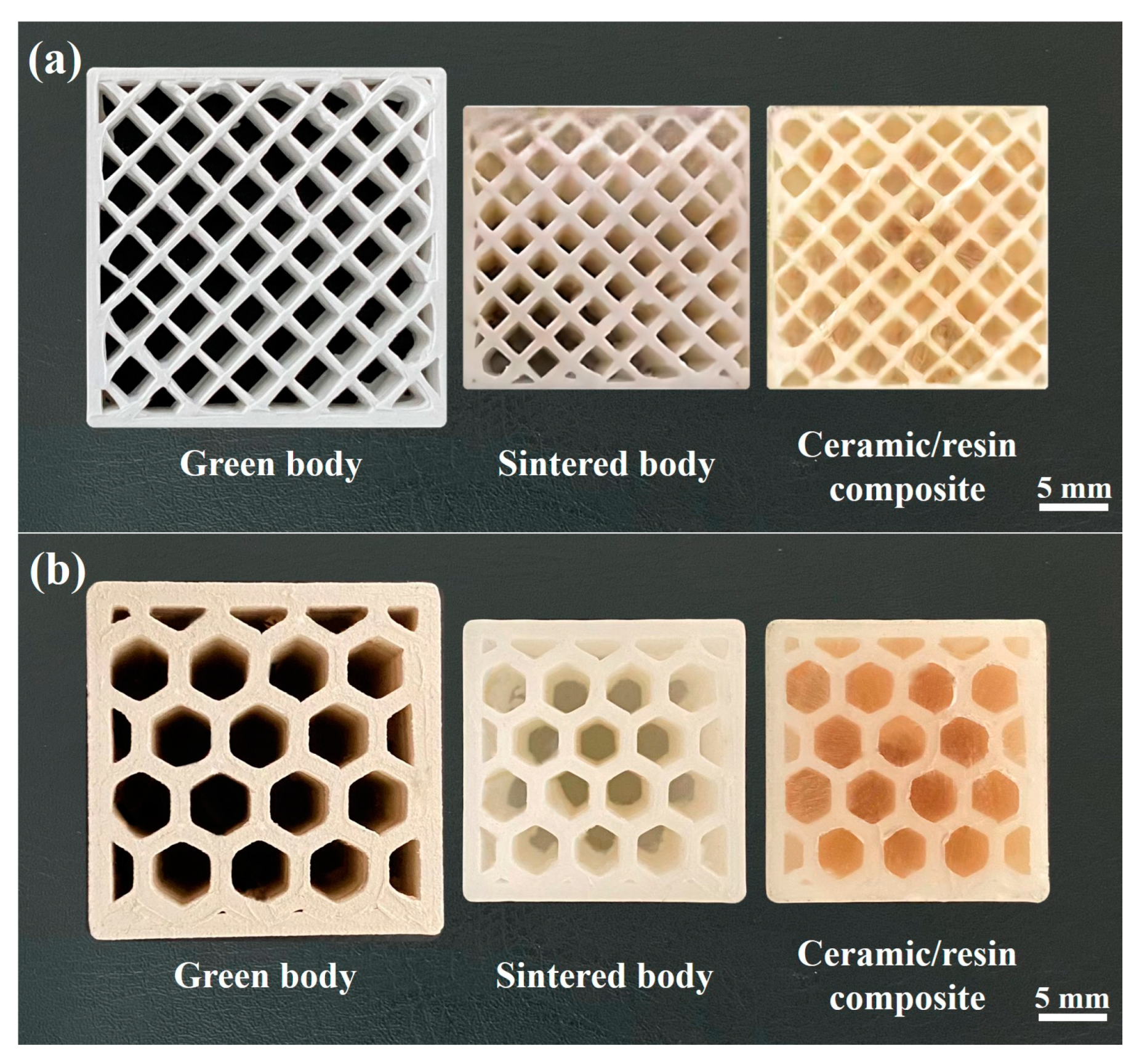

2.2. Preparation of the Porous Zirconia Ceramics

2.3. Preparation of the ZrO2/Resin Composites

2.4. Characterization of the Microstructures and Mechanical Properties

3. Results and Discussion

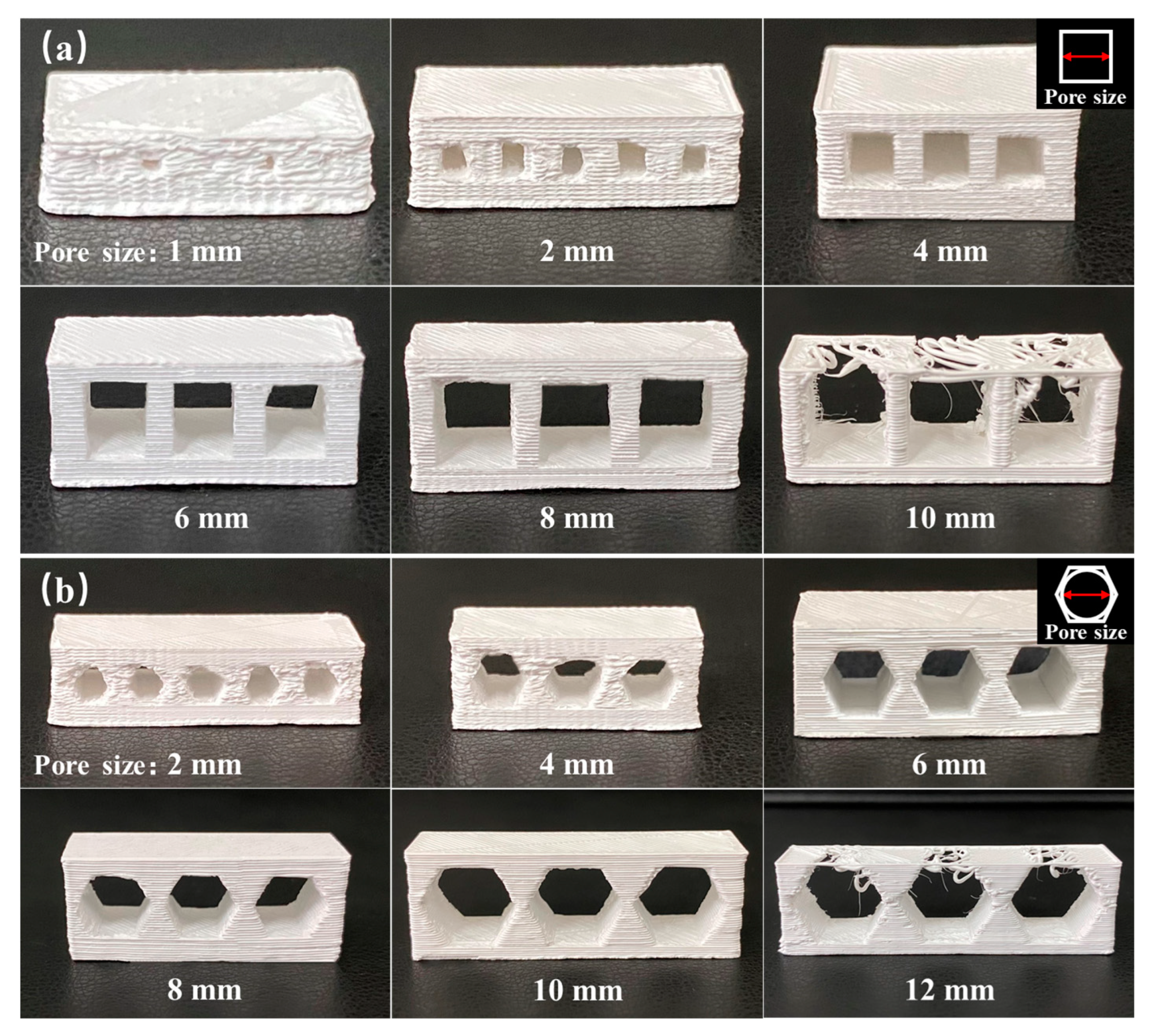

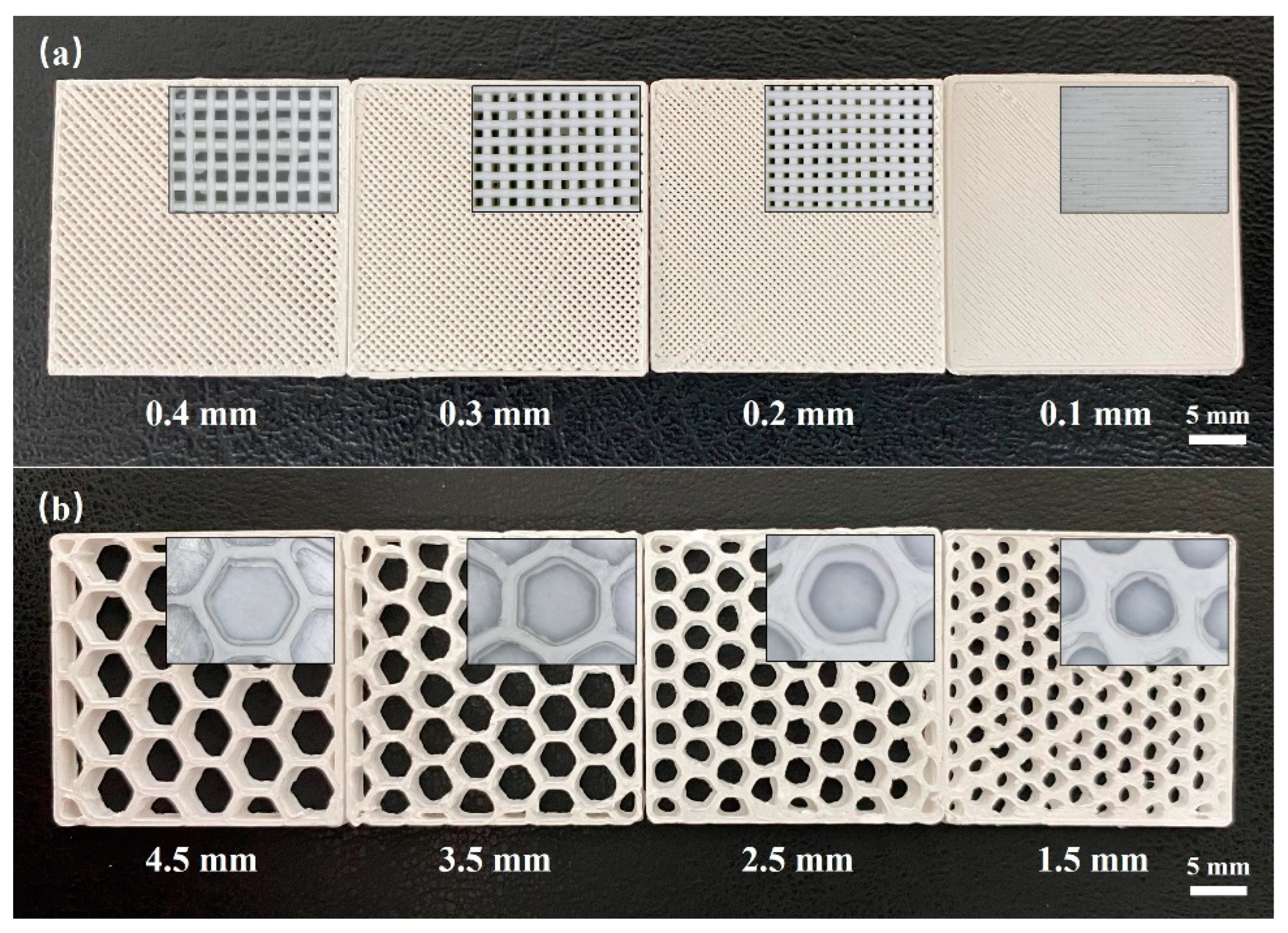

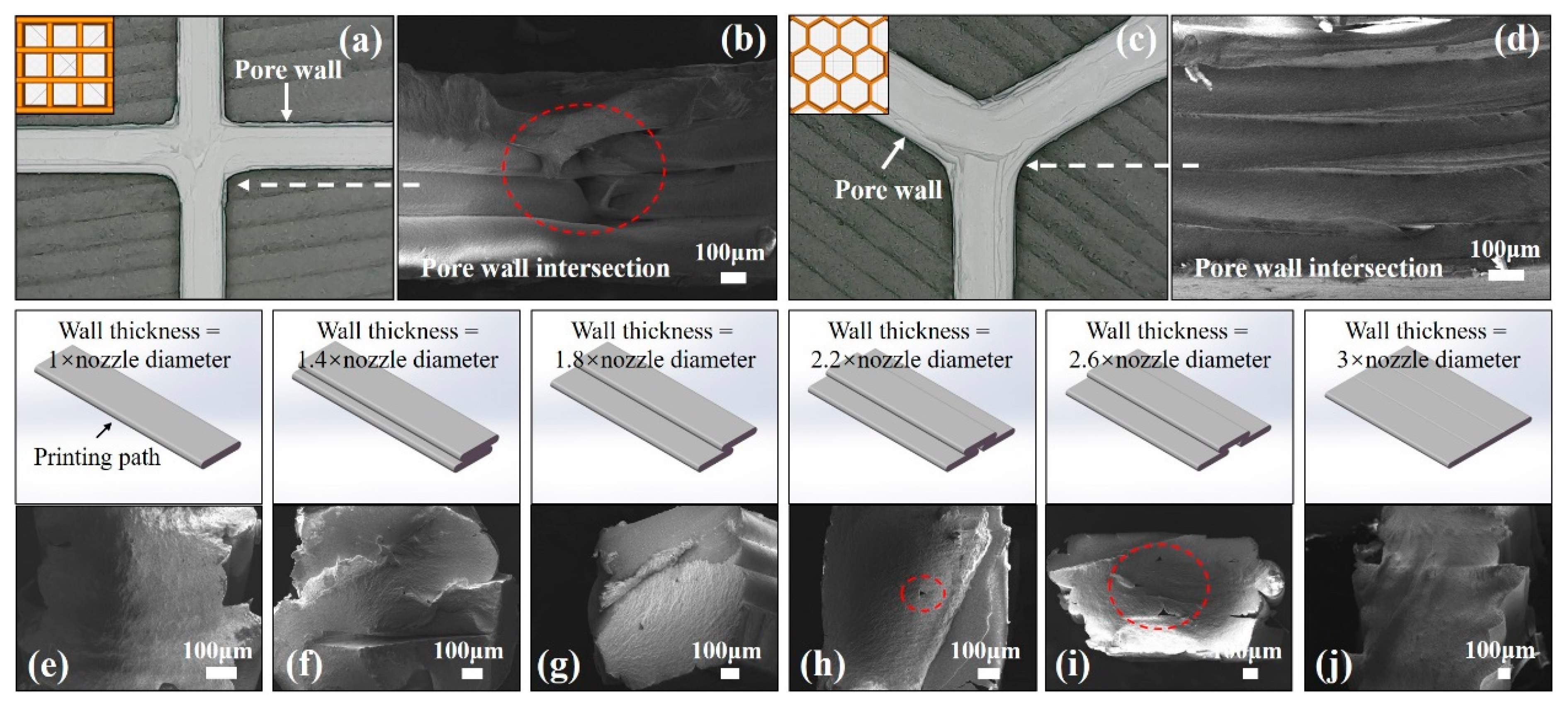

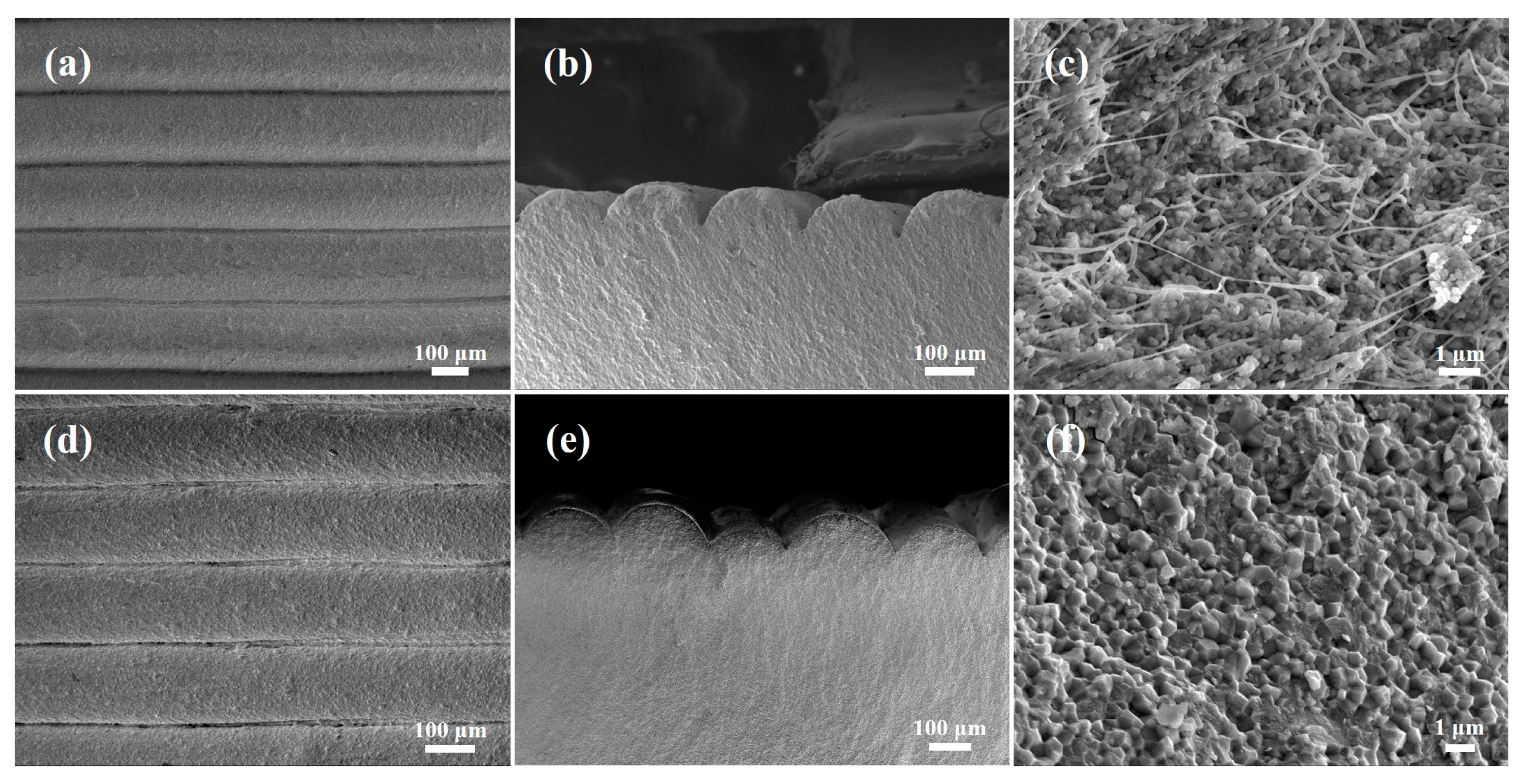

3.1. Printing of the Porous Structure and Evaluation of the Pore Wall Defects

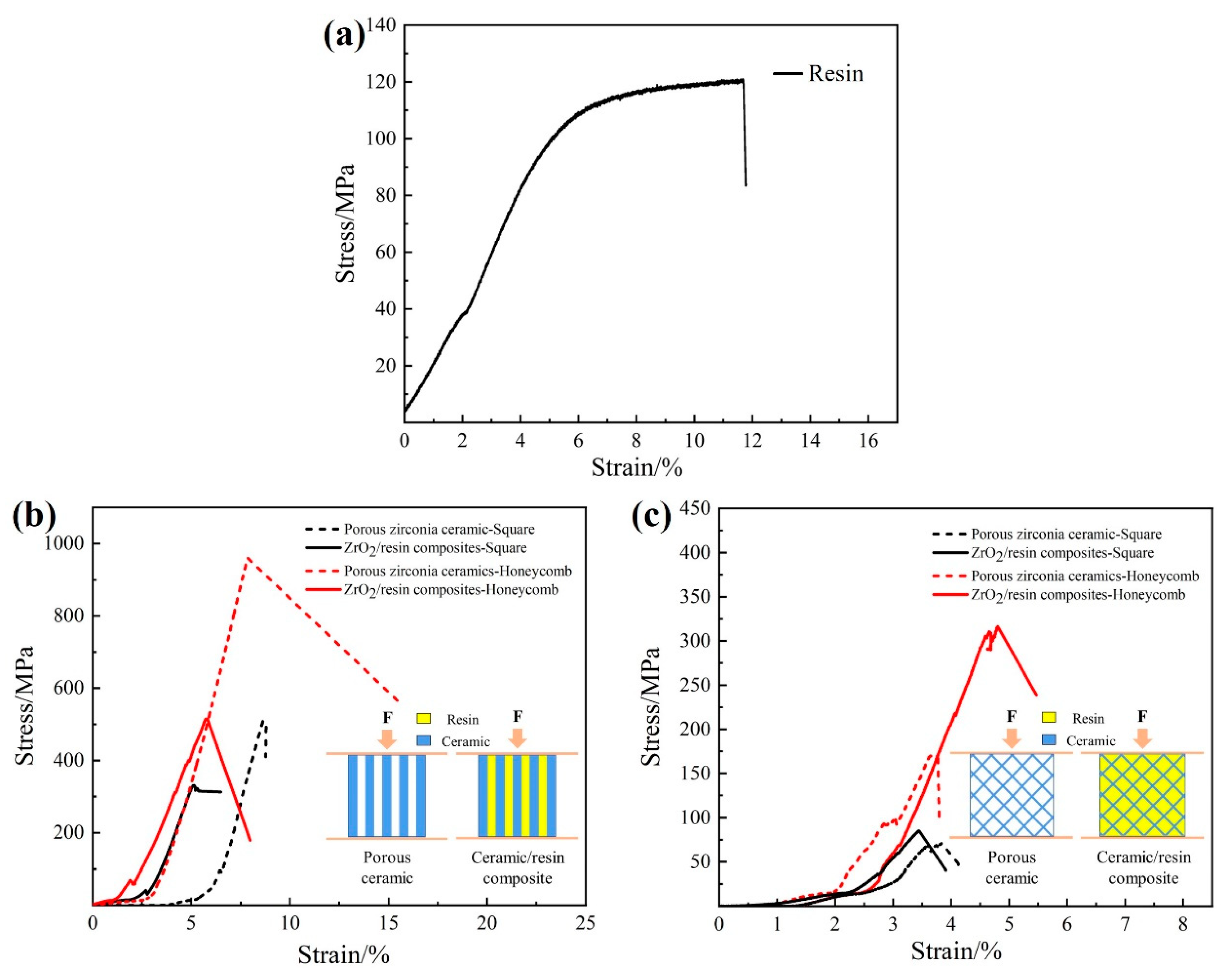

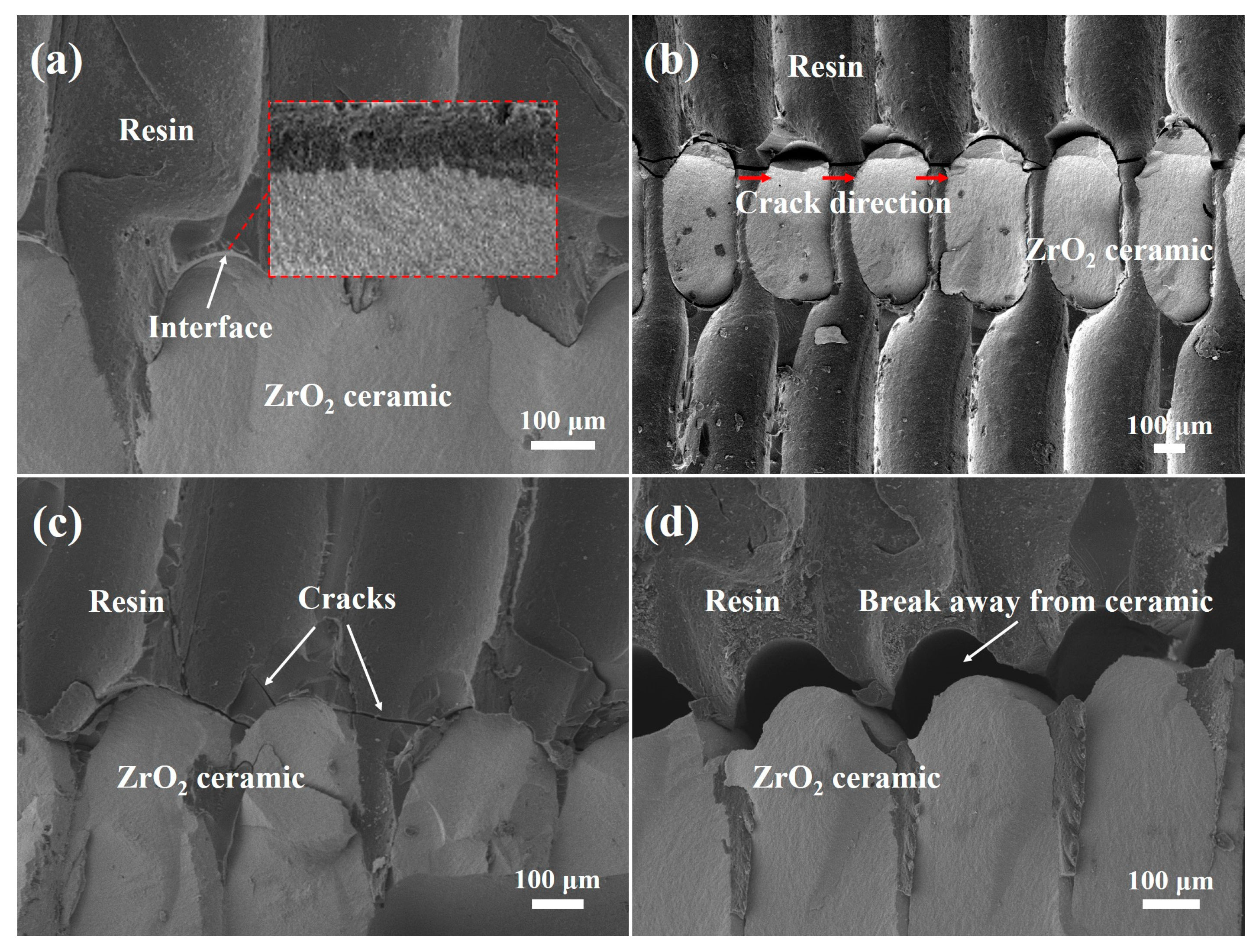

3.2. ZrO2/Resin Composites and Compressive Mechanical Behaviors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Carter, C.B.; Norton, M.G. Ceramic Materials; Springer: New York, NY, USA, 2013; pp. 659–676. [Google Scholar]

- Wood, J. Mother-of-pearl reveals her tough side. Mater. Today 2004, 9, 12. [Google Scholar] [CrossRef]

- Chen, B.; Peng, X.; Wang, J.G.; Wu, X. Laminated microstructure of Bivalva shell and research of biomimetic ceramic/polymer composite. Ceram. Int. 2004, 30, 2011–2014. [Google Scholar] [CrossRef]

- Sealy, C. Seashell provides blueprint for composites. Mater. Today 2006, 3, 10. [Google Scholar] [CrossRef]

- Katti, K.S.; Katti, D.R. Why is nacre so tough and strong? Mater. Sci. Eng. C 2006, 26, 1317–1324. [Google Scholar] [CrossRef]

- Seuba, J.; Maire, E.; Adrien, J.; Meille, S.; Deville, S. Mechanical properties of unidirectional, porous polymer/ceramic composites for biomedical applications. Open Ceram. 2021, 8, 100195. [Google Scholar] [CrossRef]

- Mohamad Yunos, D.; Bretcanu, O.; Boccaccini, A.R. Polymer-bioceramic composites for tissue engineering scaffolds. J. Mater. Sci. 2008, 43, 4433–4442. [Google Scholar] [CrossRef]

- Konopka, K.; Boczkowska, A.; Batorski, K.; Szafran, M.; Kurzydłowski, K.J. Microstructure and properties of novel ceramic–polymer composites. Mater. Lett. 2004, 58, 3857–3862. [Google Scholar] [CrossRef]

- Noh, K.T.; Lee, H.Y.; Shin, U.S.; Kim, H.W. Composite nanofiber of bioactive glass nanofiller incorporated poly (lactic acid) for bone regeneration. Mater. Lett. 2010, 64, 802–805. [Google Scholar] [CrossRef]

- Santana-Melo, G.F.; Rodrigues, B.V.; da Silva, E.; Ricci, R.; Marciano, F.R.; Webster, T.J.; Vasconcellos, L.M.; Lobo, A.O. Electrospun ultrathin PBAT/nHAp fibers influenced the in vitro and in vivo osteogenesis and improved the mechanical properties of neoformed bone. Colloids Surf. B Biointerfaces 2017, 155, 544–552. [Google Scholar] [CrossRef]

- Shankhwar, N.; Kumar, M.; Mandal, B.B.; Srinivasan, A. Novel polyvinyl alcohol-bioglass 45S5 based composite nanofibrous membranes as bone scaffolds. Mater. Sci. Eng. C 2016, 69, 1167–1174. [Google Scholar] [CrossRef]

- Mathieu, L.M.; Bourban, P.E.; Månson, J.A.E. Processing of homogeneous ceramic/polymer blends for bioresorbable composites. Compos. Sci. Technol. 2006, 66, 1606–1614. [Google Scholar] [CrossRef]

- Kravanja, G.; Primožič, M.; Knez, Ž.; Leitgeb, M. Transglutaminase release and activity from novel poly (ε-caprolactone)-based composites prepared by foaming with supercritical CO2. J. Supercrit. Fluids 2020, 166, 105031. [Google Scholar] [CrossRef]

- Prasad, A.; Sankar, M.R.; Katiyar, V. State of art on solvent casting particulate leaching method for orthopedic scaffoldsfabrication. Mater. Today Proc. 2017, 4, 898–907. [Google Scholar] [CrossRef]

- Singh, A.; Banerjee, S.L.; Dhiman, V.; Bhadada, S.K.; Sarkar, P.; Khamrai, M.; Kumari, K.; Kundu, P.P. Fabrication of calcium hydroxyapatite incorporated polyurethane-graphene oxide nanocomposite porous scaffolds from poly (ethylene terephthalate) waste: A green route toward bone tissue engineering. Polymer 2020, 195, 122436. [Google Scholar] [CrossRef]

- Blacher, S.; Maquet, V.; Jérôme, R.; Pirard, J.P.; Boccaccini, A.R. Study of the connectivity properties of Bioglass®-filled polylactide foam scaffolds by image analysis and impedance spectroscopy. Acta Biomater. 2005, 1, 565–574. [Google Scholar] [CrossRef] [PubMed]

- Maquet, V.; Boccaccini, A.R.; Pravata, L.; Notingher, I.; Jérôme, R. Porous poly (α-hydroxyacid)/Bioglass® composite scaffolds for bone tissue engineering. I: Preparation and in vitro characterisation. Biomaterials 2004, 25, 4185–4194. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Feng, Q. Improved mechanical properties of hydroxyapatite whisker-reinforced poly (L-lactic acid) scaffold by surface modification of hydroxyapatite. Mater. Sci. Eng. C 2014, 35, 190–194. [Google Scholar] [CrossRef]

- Alizadeh-Osgouei, M.; Li, Y.; Wen, C. A comprehensive review of biodegradable synthetic polymer-ceramic composites and their manufacture for biomedical applications. Bioact. Mater. 2019, 4, 22–36. [Google Scholar] [CrossRef] [PubMed]

- Cho, K.; Rajan, G.; Farrar, P.; Prentice, L.; Prusty, B.G. Dental resin composites: A review on materials to product realizations. Compos. Part B Eng. 2022, 230, 109495. [Google Scholar] [CrossRef]

- Rodríguez, H.A.; Kriven, W.M.; Casanova, H. Development of mechanical properties in dental resin composite: Effect of filler size and filler aggregation state. Mater. Sci. Eng. C 2019, 101, 274–282. [Google Scholar] [CrossRef]

- Li, B.; Tian, L.; Pan, L.; Li, J. Molecular dynamics investigation of structural and mechanical properties of silica nanorod reinforced dental resin composites. J. Mech. Behav. Biomed. Mater. 2021, 124, 104830. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhu, M.; Zhu, X.X. Functional fillers for dental resin composites. Acta Biomater. 2021, 122, 50–65. [Google Scholar] [CrossRef] [PubMed]

- Coldea, A.; Swain, M.V.; Thiel, N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent. Mater. 2013, 29, 419–426. [Google Scholar] [CrossRef] [PubMed]

- Cui, B.; Li, J.; Wang, H.; Lin, Y.; Shen, Y.; Li, M.; Deng, X.; Nan, C. Mechanical properties of polymer-infiltrated-ceramic (sodium aluminum silicate) composites for dental restoration. J. Dent. 2017, 62, 91–97. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Jiang, J.; Yang, X.; Zhang, L.; Zhou, Z.; Zhong, Y.; Shen, Z. Additive manufacturing of dense zirconia ceramics by fused deposition modeling via screw extrusion. J. Eur. Ceram. Soc. 2021, 41, 1033–1040. [Google Scholar] [CrossRef]

- Xie, H.; Yang, X.; Liu, P.; Xu, X.; Zhou, Z.; Zhao, W.; Shen, Z. 3D gel printing of alumina ceramics followed by efficient multi-step liquid desiccant drying. J. Eur. Ceram. Soc. 2021, 41, 6634–6640. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015. [Google Scholar]

- Hwa, L.C.; Rajoo, S.; Noor, A.M.; Ahmad, N.; Uday, M.B. Recent advances in 3D printing of porous ceramics: A review. Curr. Opin. Solid State Mater. Sci. 2017, 21, 323–347. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W. A Review on Laser Deposition-Additive Manufacturing of Ceramics and Ceramic Reinforced Metal Matrix Composites. Ceram. Int. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Chuan, L.T.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, X.; Shi, J. Additive manufacturing of zirconia ceramics: A state-of-the-art review. J. Mater. Res. Technol. 2020, 9, 9029–9048. [Google Scholar] [CrossRef]

- Galante, R.; Figueiredo-Pina, C.G.; Serro, A.P. Additive manufacturing of ceramics for dental applications: A review. Dent. Mater. 2019, 35, 825–846. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Jain, P.; Kuthe, A.M. Feasibility study of manufacturing using rapid prototyping: FDM approach. Procedia Eng. 2013, 63, 4–11. [Google Scholar] [CrossRef]

- Danforth, S. Fused deposition of ceramics: A new technique for the rapid fabrication of ceramic components. Mater. Technol. 1995, 10, 144–146. [Google Scholar] [CrossRef]

- Sarraf, F.; Abbatinali, E.; Gorjan, L.; Sebastian, T.; Colombo, P.; Churakov, S.V.; Clemens, F. Effect of MgO sintering additive on mullite structures manufactured by fused deposition modeling (FDM) technology. J. Eur. Ceram. Soc. 2021, 41, 6677–6686. [Google Scholar] [CrossRef]

- Shen, T.; Xiong, H.; Li, Z.; Zhang, L.; Zhou, K. Fused deposition fabrication of high-quality zirconia ceramics using granular feedstock. Ceram. Int. 2021, 47, 34352–34360. [Google Scholar] [CrossRef]

- Chen, J.; Wang, W.; Sun, X.; Sun, G.; Liang, Y. Microstructure and mechanical properties of zirconia toughened nacre-like alumina ceramics. Mater. Sci. Eng. A 2022, 855, 143908. [Google Scholar] [CrossRef]

- Ismail, H.; Mohamad, H. Effects of CaCO3 additive on the phase, physical, mechanical, and microstructural properties of zirconia-toughened alumina-CeO2-Nb2O5 ceramics. Ceram. Int. 2023, 49 Pt B, 36850–36856. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, X.; Xu, X.; Guo, J.; Zhou, Z.; Liu, P.; Xie, Z. 3D printed zirconia ceramics via fused deposit modeling and its mechanical properties. J. Inorg. Mater. 2021, 36, 436–442. [Google Scholar] [CrossRef]

- Duan, S.; Tao, Y.; Lei, H.; Wen, W.; Liang, J.; Fang, D. Enhanced out-of-plane compressive strength and energy absorption of 3D printed square and hexagonal honeycombs with variable-thickness cell edges. Extrem. Mech. Lett. 2018, 18, 9–18. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Y.; Wang, C.; Zhou, G.; Karamoozian, A.; Zhao, W. On the out-of-plane ballistic performances of hexagonal, reentrant, square, triangular and circular honeycomb panels. Int. J. Mech. Sci. 2020, 173, 105402. [Google Scholar] [CrossRef]

| ZrO2 Powder | PW | SA | EVA | PE |

|---|---|---|---|---|

| 87 wt.% | 7.5 wt.% | 0.7 wt.% | 2.2 wt.% | 2.6 wt.% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Guo, J.; Li, Y.; Yang, X. Compressive Fracture Behavior of Zirconia/Resin Composites Prepared by Fused Deposition Modeling Combined with Vacuum Infiltration. Materials 2024, 17, 1989. https://doi.org/10.3390/ma17091989

Yang X, Guo J, Li Y, Yang X. Compressive Fracture Behavior of Zirconia/Resin Composites Prepared by Fused Deposition Modeling Combined with Vacuum Infiltration. Materials. 2024; 17(9):1989. https://doi.org/10.3390/ma17091989

Chicago/Turabian StyleYang, Xiaole, Jinyu Guo, Yuanbing Li, and Xianfeng Yang. 2024. "Compressive Fracture Behavior of Zirconia/Resin Composites Prepared by Fused Deposition Modeling Combined with Vacuum Infiltration" Materials 17, no. 9: 1989. https://doi.org/10.3390/ma17091989

APA StyleYang, X., Guo, J., Li, Y., & Yang, X. (2024). Compressive Fracture Behavior of Zirconia/Resin Composites Prepared by Fused Deposition Modeling Combined with Vacuum Infiltration. Materials, 17(9), 1989. https://doi.org/10.3390/ma17091989