Effects of Induction Plasma Spheroidization on Properties of Yttria-Stabilized Zirconia Powders for Thermal Barrier Coating Applications

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

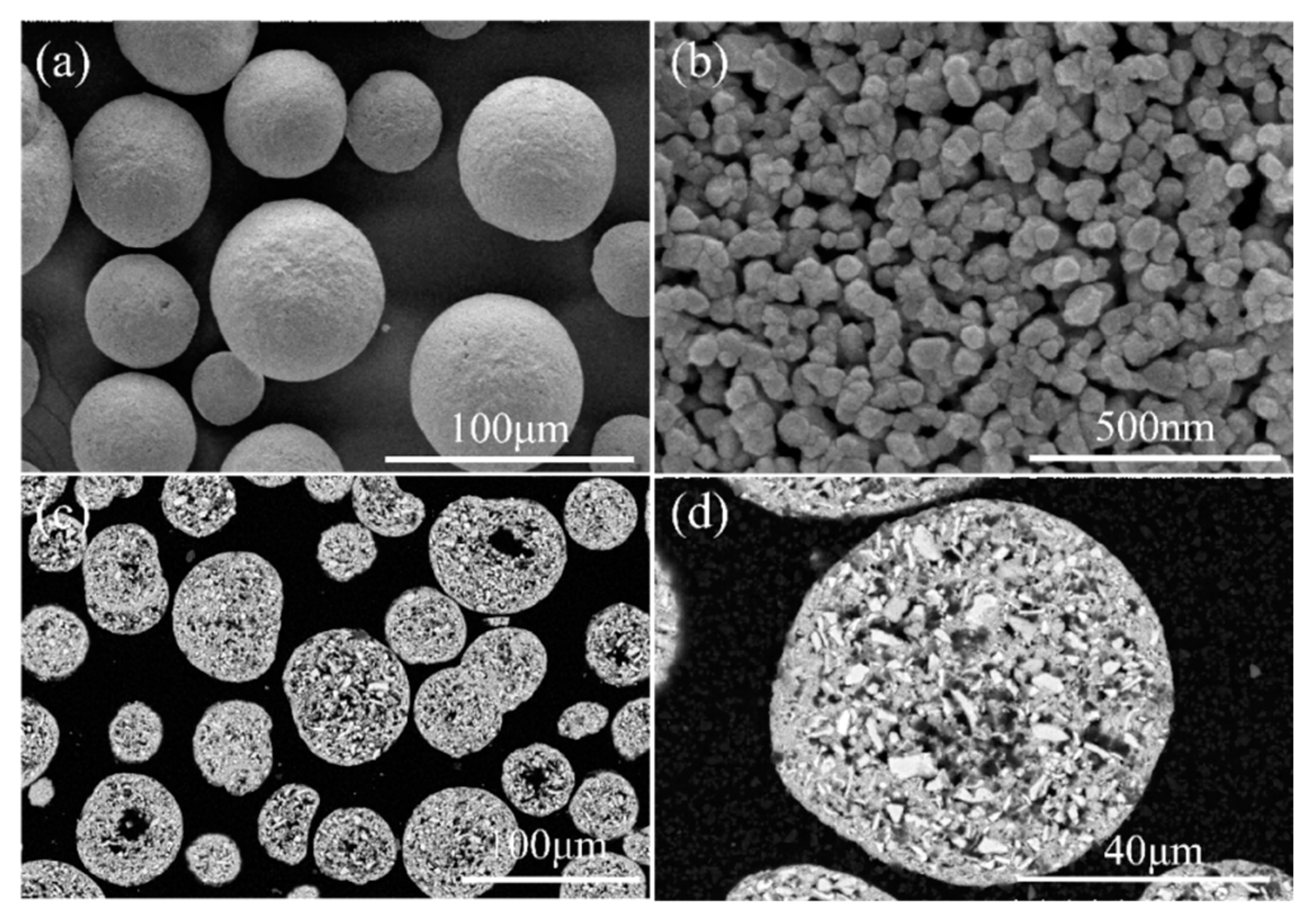

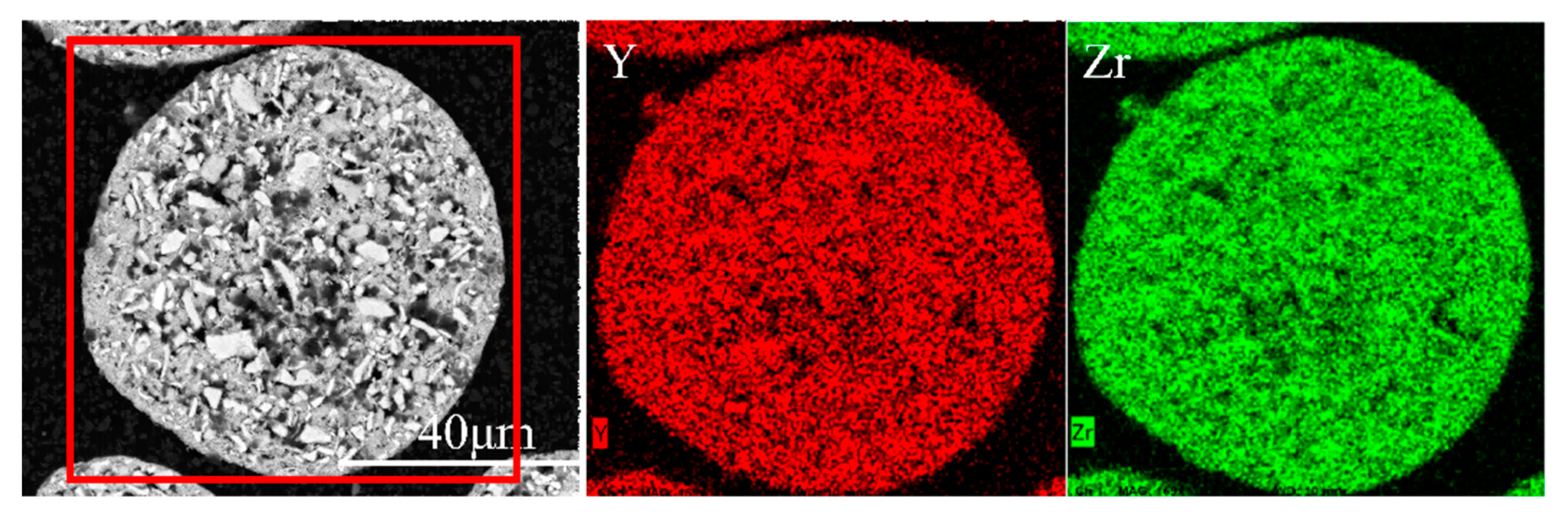

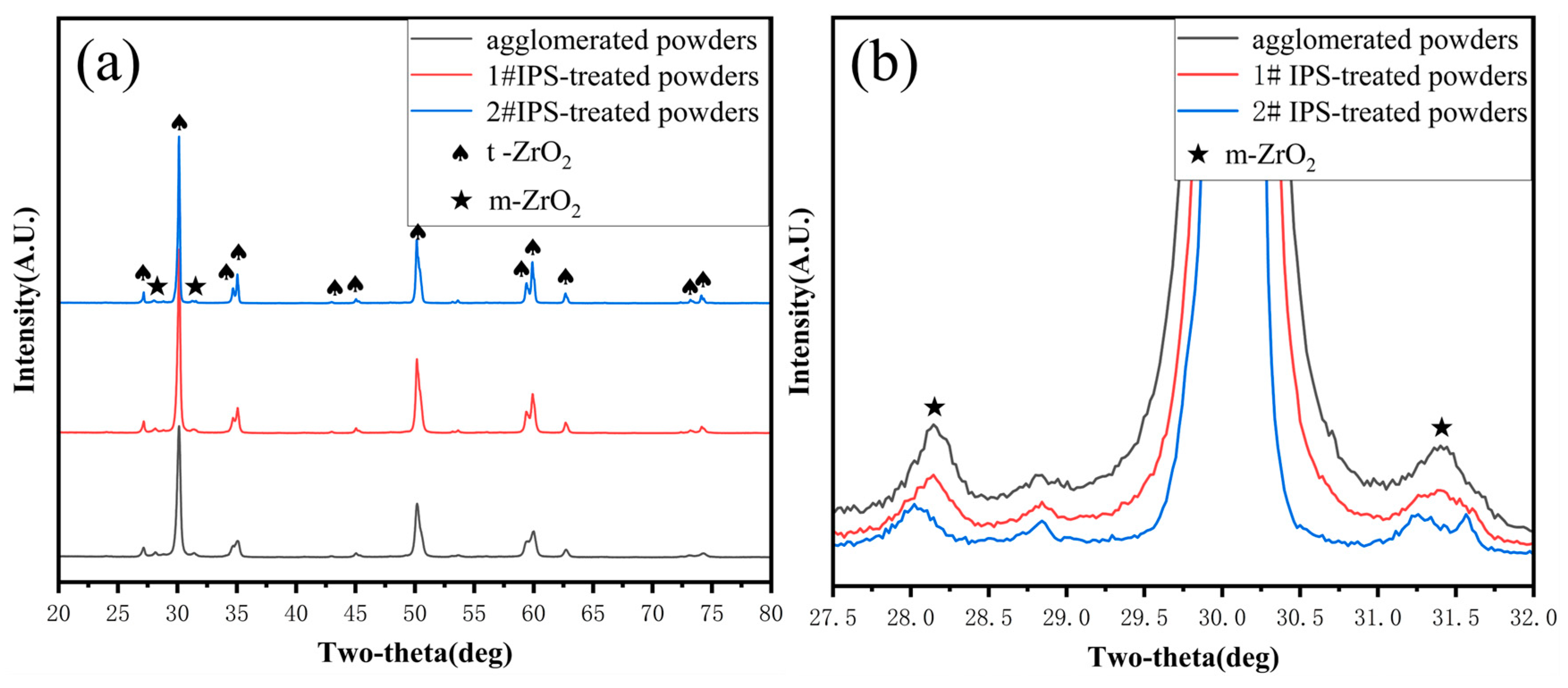

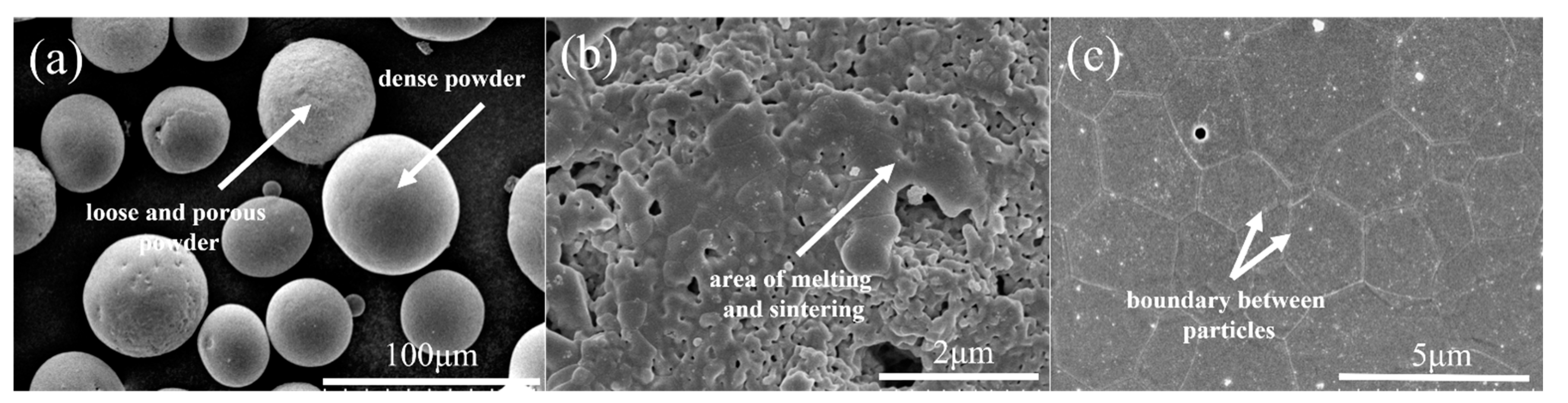

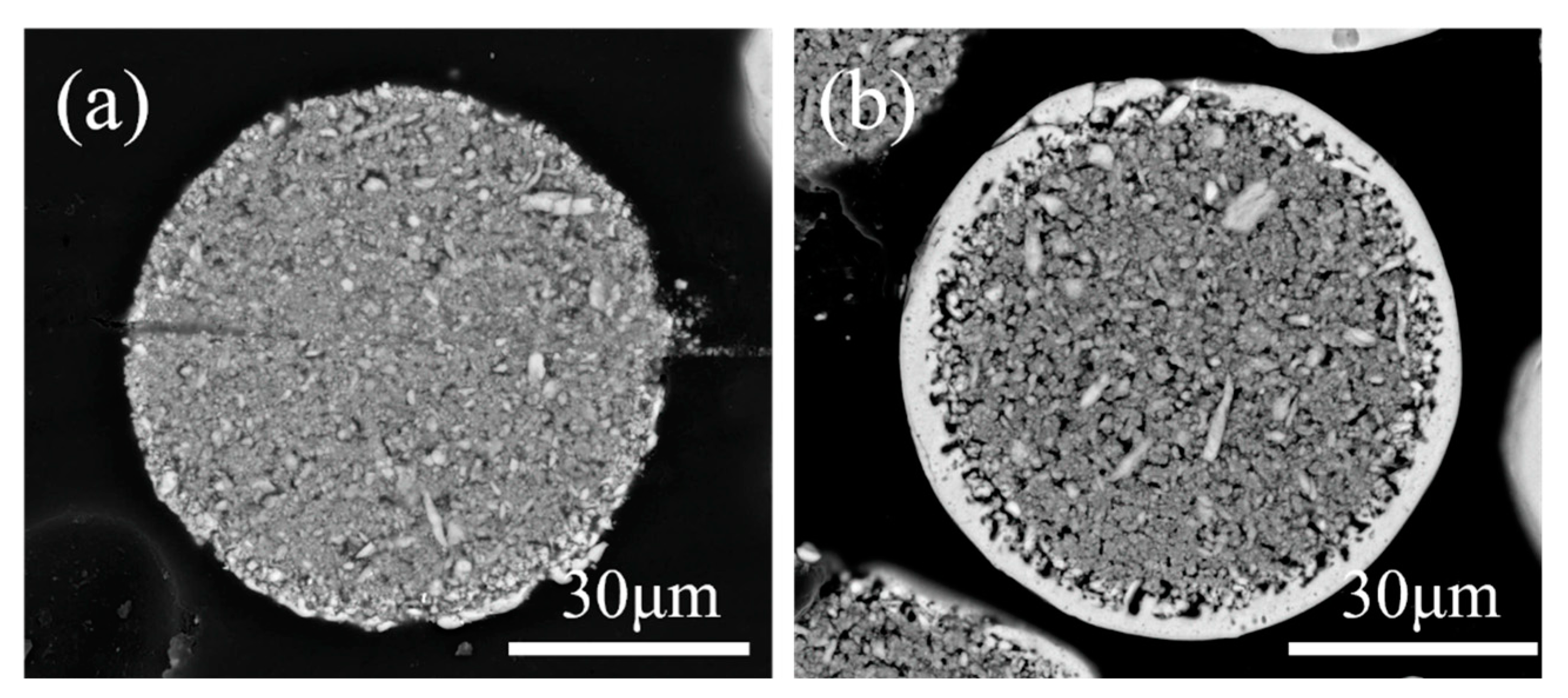

3.1. Characterization of the Agglomerated YSZ Powders

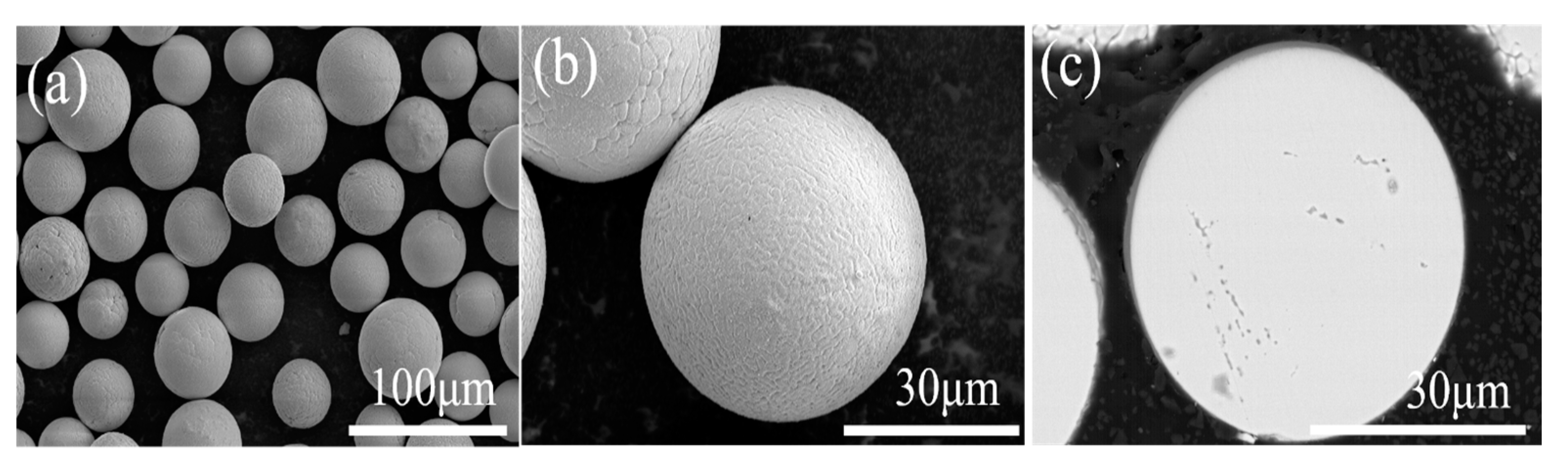

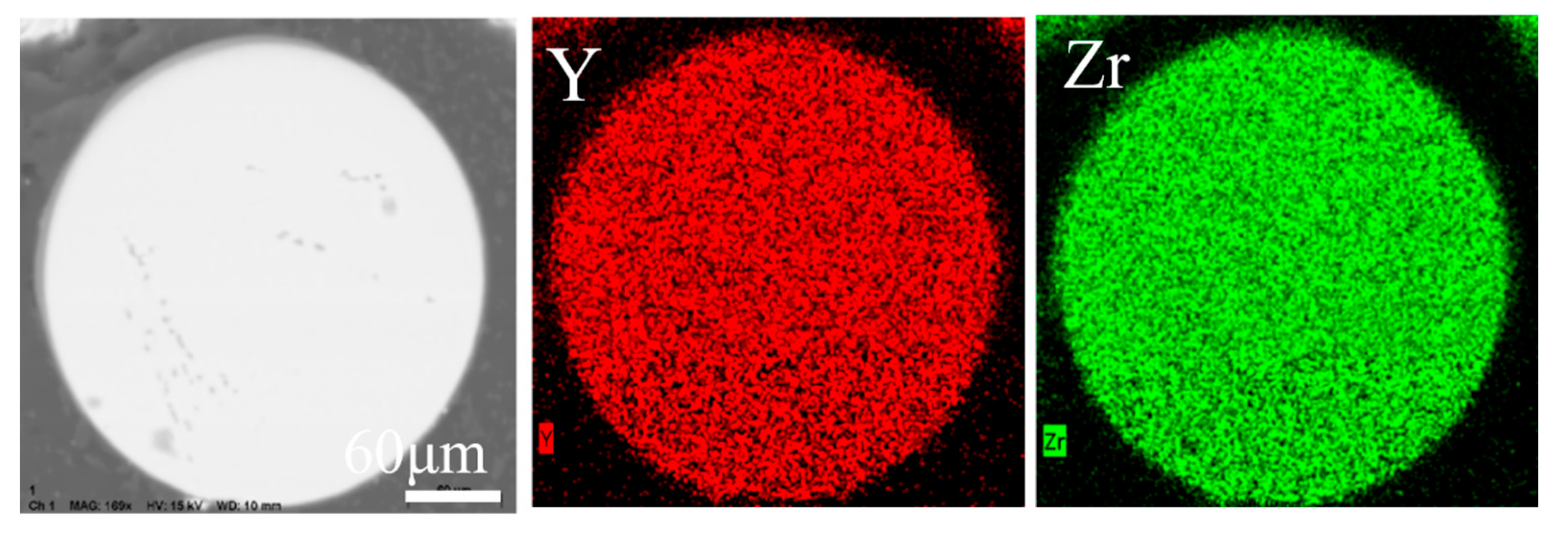

3.2. Characterization of the IPS-Treated YSZ Powders

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brindley, W.J.; Miller, R.A. TBCs for better engine efficiency. Adv. Mater. Process. 1989, 136, 29–33. [Google Scholar]

- Soechting, F.O. A design perspective on thermal barrier coatings. J. Therm. Spray Technol. 1999, 4, 505–511. [Google Scholar] [CrossRef]

- Volodymyr, K.; Zoia, D.; Andrii, K.; Bogdan, V.; Valentyna, V.; Olexandra, M. The Effect of Yttria Content on Microstructure, Strength, and Fracture Behavior of Yttria-Stabilized Zirconia. Materials 2022, 15, 5212. [Google Scholar] [CrossRef] [PubMed]

- Schulz, U.; Leyens, C.; Fritscher, K.; Peters, M. Some recent trends in research and technology of advanced thermal barrier coatings. Aerosp. Sci. Technol. 2003, 7, 73–80. [Google Scholar] [CrossRef]

- Thibblin, A.; Olofsson, U. A study of suspension plasma-sprayed insulated pistons evaluated in a heavy-duty diesel engine. Int. J. Engine Res. 2020, 21, 987–997. [Google Scholar] [CrossRef]

- Song, J.B.; Wang, L.S.; Dong, H.; Yao, J.T. Long lifespan thermal barrier coatings overview: Materials, manufacturing, failure mechanisms, and multiscale structural design. Ceram. Int. 2023, 49, 1–23. [Google Scholar] [CrossRef]

- Bakan, E.; Vaßen, R. Ceramic top coats of plasma-sprayed thermal barrier coatings: Materials, processes, and properties. J. Therm. Spray Technol. 2017, 26, 992–1010. [Google Scholar] [CrossRef]

- Rezanka, S.; Mack, D.E.; Mauer, G.; Sebold, D.; Guillon, O.; Vaßen, R. Investigation of the resistance of open-column-structured PS-PVD TBCs to erosive and high-temperature corrosive attack. Surf. Coat. Technol. 2017, 324, 222–235. [Google Scholar] [CrossRef]

- Hospach, A.; Mauer, G.; Vassen, R.; Stover, D. Collumnar-structured thermal barrier coatings (TBCs) by thin film low-pressure spraying (LPPS-TF). Therm. Spray Technol. 2011, 20, 116–120. [Google Scholar] [CrossRef]

- Ashofteh, A.; Seifollahpour, S. Role of nano-zones in enhancing the performance of YSZ coatings under thermal shock conditions. J. Am. Ceram. Soc. 2023, 107, 1201–1218. [Google Scholar] [CrossRef]

- Simone, B.; Stefania, M.; Giovanni, B.; Greta, C.; Edoardo, R.; Gerardo, M.F.; Salvatore, P.; Edoardo, B.; Luca, L. The effect of ceramic YSZ powder morphology on coating performance for industrial TBCs. Surf. Coat. Technol. 2024, 476, 130270. [Google Scholar]

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804–809. [Google Scholar] [CrossRef] [PubMed]

- Vassen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Yang, L.X.; Yang, F.; Long, Y.; Zhao, Y.; Xiong, X.; Zhao, X.F.; Xiao, P. Evolution of residual stress in air plasma sprayed yttria stabilised zirconia thermal barrier coatings after isothermal treatment. Surf. Coat. Technol. 2014, 251, 98–105. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coating14s for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Volodymyr, K.; Zoia, D.; Bogdan, V.; Valentyna, V.; Taras, K.; Pavlo, L.; Volodymyr, V. The Effect of Sintering Temperature on the Phase Composition, Microstructure, and Mechanical Properties of Yttria-Stabilized Zirconia. Materials 2022, 15, 2707. [Google Scholar] [CrossRef]

- Jang, B.K.; Kim, S.; Oh, Y.S. Effect of Gd2O3 on the thermal conductivity of ZrO2–4mol.% Y2O3 ceramics fabricated by spark plasma sintering. Scr. Mater. 2013, 69, 165–170. [Google Scholar] [CrossRef]

- Barad, C.; Shekel, G.; Shandalov, M.; Hayun, H.; Kimmel, G.; Shamir, D.; Gelbstein, Y. Internal Nano Voids in Yttria-Stabilised Zirconia (YSZ) Powder. Materials 2017, 10, 1440. [Google Scholar] [CrossRef]

- Liu, Z.G.; Ouyang, J.H.; Zhou, Y. Influence of ytterbium- and samarium-oxides codoping on structure and thermal conductivity of zirconate ceramics. J. Eur. Ceram. Soc. 2009, 29, 647–652. [Google Scholar] [CrossRef]

- Hossein, M.S.; Jackson, C.; Zane, Y. A review on ICP powder plasma spheroidization process parameters. Int. J. Refract. Met. Hard Mater. 2021, 103, 105764. [Google Scholar]

- Liu, L.; Wang, Y.; Ma, Z. Preparation and thermophysical properties of Yb-doped Ba2DyAlO5 ceramics. Mater. Lett. 2015, 144, 33–35. [Google Scholar] [CrossRef]

- Ko, S.; Koo, S.; Cho, W.; Hwnag, K.; Kim, J. Synthesis of SiC nano-powder from organic precursors using RF inductively coupled thermal plasma. Ceram. Int. 2012, 38, 1959–1963. [Google Scholar] [CrossRef]

- Saifutdinova, A.A.; Saifutdinov, A.I.; Gainullina, S.V.; Timerkaev, B.A. Modeling the parameters of an atmospheric pressure dielectric barrier discharge controlled by the shape of the applied voltage. IEEE Trans. Plasma Sci. 2022, 50, 1144–1156. [Google Scholar] [CrossRef]

- Christian, B.; Ilya, T.; Jörg, H.; Pierre, B.J. Numerical modeling of an inductively coupled plasma torch using OpenFOAM. Comput. Fluids 2021, 216, 104807. [Google Scholar]

- Kim, K.; Choi, S.; Kim, J.; Cho, W.; Hwang, K.; Han, K. Synthesis and characterization of high-purity aluminum nitride nanopowder by RF induction thermal plasma. Ceram. Int. 2014, 40, 8117–8123. [Google Scholar] [CrossRef]

- Wang, D.X.; Hao, Z.H.; Wang, P.; Ma, R.L.; Shu, Y.C.; He, J.L. Preparation of spherical tungsten powder with uniform distribution of lanthania by plasma spheroidization. Int. J. Refract. Met. Hard Mater. 2023, 117, 106400. [Google Scholar] [CrossRef]

- Shi, T.J.; Bai, B.T.; Peng, H.R.; Yuan, K.; Han, R.F.; Zhou, Q.; Pang, X.X.; Zhang, X.; Yan, Z. Improved thermal shock resistance of GYYZO-YSZ double ceramic layer TBCs induced by induction plasma spheroidization. Surf. Coat. Technol. 2024, 477, 130372. [Google Scholar] [CrossRef]

- Tong, J.B.; Lu, X.; Liu, C.C.; Wang, L.N.; Qu, X.H. Fabrication of micro-fine spherical high Nb containing TiAl alloy powder based on reaction synthesis and RF plasma spheroidization. Powder Technol. 2015, 283, 9–15. [Google Scholar] [CrossRef]

- Chivavibul, P.; Watanabe, M.; Kuroda, S.; Kawakita, J.; Komatsu, M.; Sato, K.; Kitamura, J. Effects of particle strength of feedstock powders on properties of warm-sprayed WC-Co coatings. Therm. Spray Technol. 2011, 20, 1098–1109. [Google Scholar] [CrossRef]

- Praveen, K.; Shanmugavelayutham, G.; Rao, D.S.; Sivakumar, G. Thermal cycling performance assessment of double-layered lanthanum titanium aluminate thermal barrier coatings developed using plasma spheroidized powders. Surf. Coat. Technol. 2023, 465, 129588. [Google Scholar] [CrossRef]

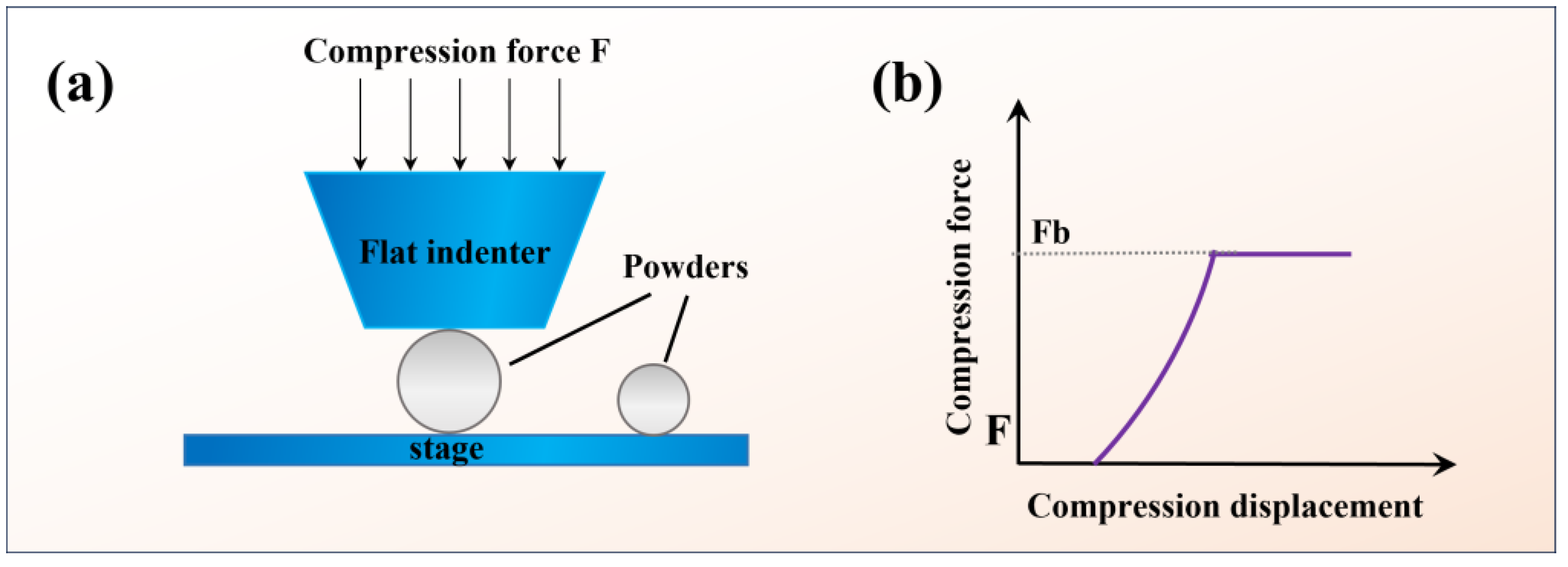

- SHIMADZU Micro Compression Tester MCT-211 Series Introduction Manual, 347–05375E. 2012. Available online: https://www.shimadzu.com/an/sites/shimadzu.com.an/files/pim/pim_document_file/brochures/10345/c227-e020.pdf (accessed on 27 February 2024).

- Kang, Y.; Jian Feng, W. Compression behavior of ceramic powders by inductive plasma sphero process. Ceram. Int. 2021, 47, 28566–28574. [Google Scholar]

- JIS R1639-5; Test Methods of Properties of Fine Ceramic Granules Part 5: Compressive Strength of a Single Granule. Japanese Industrial Standards: Tokyo, Japan, 2007.

| Parameters | Values |

|---|---|

| Inlet temperature | 300 °C |

| Outlet temperature | 120 °C |

| Atomizer rotary rate | 40 Hz |

| Feed Pump rate | 30 rpm |

| Series No. | Carrier Gas (Ar) (slpm) | H2 Flow (slpm) | Ar Flow (slpm) | Reactor Pressure (psia) | Powder Feed Rate (g/min) | Power (kW) |

|---|---|---|---|---|---|---|

| 1# | 95 | 15 | 30 | 15 | 100 | 80 |

| 2# | 95 | 15 | 30 | 15 | 40 | 80 |

| Content | Y2O3 (wt%) | Al2O3 (wt%) | SiO2 (wt%) | TiO2 (wt%) | Cl− (wt%) |

|---|---|---|---|---|---|

| Agglomerated YSZ powder | 7.32 | 0.042 | 0.038 | 0.012 | 0.036 |

| IPS-treated YSZ powder (2#) | 7.28 | 0.019 | 0.018 | 0.006 | 0.010 |

| Property | Apparent Density (g/cm3) | Flowability (s/50 g) | Particle Size Distribution (μm) | |

|---|---|---|---|---|

| Powder | ||||

| Agglomerated YSZ powder | 1.26 | 62.74 | D10 = 36.0 D50 = 56.0 D90 = 84.4 | |

| 1# IPS-treated YSZ powder | 1.92 | 39.68 | D10 = 35.9 D50 = 51.6 D90 = 72.4 | |

| 2# IPS-treated YSZ powder | 3.18 | 21.46 | D10 = 35.3 D50 = 43.9 D90 = 55.2 | |

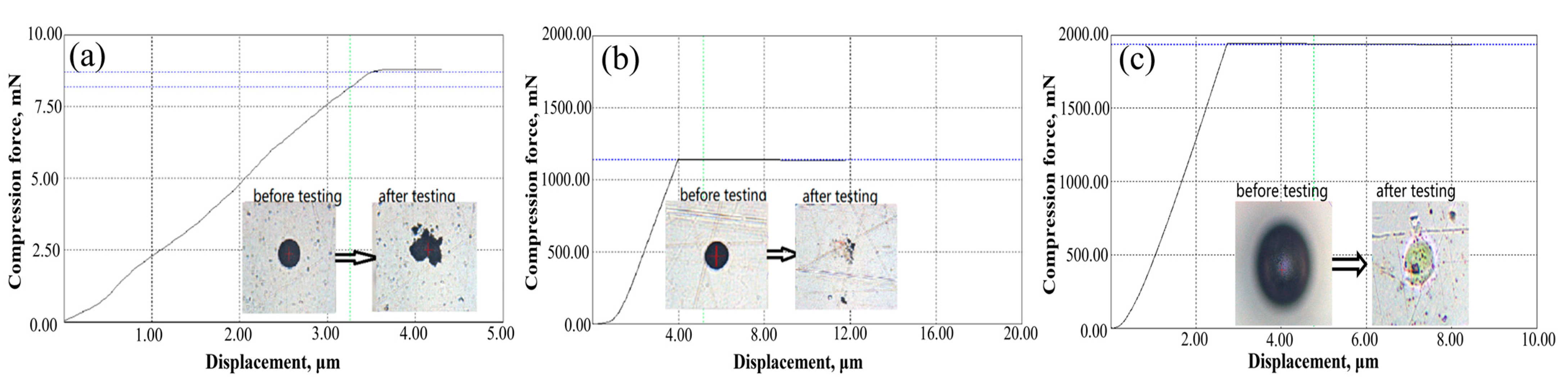

| Type of Powder | Strength Range (MPa) | Average Compressive Strength (MPa) |

|---|---|---|

| Agglomerated YSZ powders | 2~8 | 4.8 |

| 1# IPS-treated YSZ powders | 80~190 | 126.3 |

| 2# IPS-treated YSZ powders | 420~750 | 625.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, H.; Yu, Y.; Shi, T.; Bai, B.; Yan, Z.; Yuan, K. Effects of Induction Plasma Spheroidization on Properties of Yttria-Stabilized Zirconia Powders for Thermal Barrier Coating Applications. Materials 2024, 17, 1518. https://doi.org/10.3390/ma17071518

Peng H, Yu Y, Shi T, Bai B, Yan Z, Yuan K. Effects of Induction Plasma Spheroidization on Properties of Yttria-Stabilized Zirconia Powders for Thermal Barrier Coating Applications. Materials. 2024; 17(7):1518. https://doi.org/10.3390/ma17071518

Chicago/Turabian StylePeng, Haoran, Yueguang Yu, Tianjie Shi, Botian Bai, Zheng Yan, and Kang Yuan. 2024. "Effects of Induction Plasma Spheroidization on Properties of Yttria-Stabilized Zirconia Powders for Thermal Barrier Coating Applications" Materials 17, no. 7: 1518. https://doi.org/10.3390/ma17071518

APA StylePeng, H., Yu, Y., Shi, T., Bai, B., Yan, Z., & Yuan, K. (2024). Effects of Induction Plasma Spheroidization on Properties of Yttria-Stabilized Zirconia Powders for Thermal Barrier Coating Applications. Materials, 17(7), 1518. https://doi.org/10.3390/ma17071518