Abstract

Using metal additive manufacturing processes can make up for traditional forging technologies when forming complex-shaped parts. At the same time, metal additive manufacturing has a fast forming speed and excellent manufacturing flexibility, so it is widely used in the aerospace industry and other fields. The fatigue strength of metal additive manufacturing is related to the microstructure of the epitaxially grown columnar grains and crystallographic texture. The crystal plasticity finite element method is widely used in the numerical simulation of the microstructure and macro-mechanical response of materials, which provides a strengthening and toughening treatment and can reveal the inner rules of material deformation. This paper briefly introduces common metal additive manufacturing processes. In terms of additive manufacturing fatigue, crystal plasticity simulations are summarized and discussed with regard to several important influencing factors, such as the microstructure, defects, surface quality, and residual stress.

1. Introduction

Metal additive manufacturing is often used in the aerospace industry, medical equipment, weaponry, rail transit, and many other applications [1,2]. In the aerospace industry, the main load-bearing components, such as aircraft fuselage, frames, wing, landing gear, and key engine components, are manufactured by forging [3,4,5]. Forge pieces possess excellent comprehensive mechanical properties, but it is difficult to manufacture complex-shaped parts. Additive manufacturing using two-dimensional stacking to form three-dimensional entities of the processing principle can form complex-shaped mechanical parts [6,7]. This process makes up for traditional forging processes when manufacturing complex-shaped parts and is widely used. However, metal additive manufacturing still requires further improvement relative to the fatigue performance of forged components [8].

The key factors [9,10,11] affecting the fatigue performance of metal additive manufacturing mainly include the following. First is the effect of microstructures on the fatigue properties. Due to the influence of temperature gradients, the grain morphology of the primary phase in metal additive manufacturing is columnar grains that exhibit epitaxial growth. This inhomogeneous microstructure causes anisotropy in the macro-mechanical properties of the additive manufacturing. Second is manufacturing defects (pore, lack of fusion, etc.) that cause fatigue crack growth and reduce the service life of parts. Third is the problem of fatigue cracking induced by residual stress. Microscopic notches in rough surfaces can easily lead to fatigue crack initiation. From the essential relationship of “manufacturing process-material microstructure-fatigue performance,” the damage mechanism of fatigue in additive manufacturing is studied to establish a theoretical basis for optimizing process parameters and improving heat treatment schedules. Highly controllable fatigue performance is achieved by further improving the microstructure and reducing the defect level.

The crystal plasticity finite element method [12] is widely used in fields such as mechanics, material science, and mechanical research. Multi-scale numerical simulations based on crystal plasticity frameworks have gained widespread attention. The crystal plasticity finite element method can simulate various macroscopic mechanical responses of materials and characterize interactions between macroscopic boundary conditions and material microstructure evolution [13]. Crystal plasticity simulations show the strong advantage of multi-scale numerical simulations in exploring the more essential relationship between the “manufacturing process-material microstructure-fatigue performance” of metal additive manufacturing [14,15]. Many of the metal components in aerospace, weaponry, rail transit, etc., experience fatigue failure due to cyclic loading. In order to investigate the fatigue damage mechanism in metal additive manufacturing, this paper briefly reviews crystal plasticity simulations for the fatigue performance of metal additive manufacturing from crystal plasticity theory, with the aim of establishing a theoretical basis for improving the fatigue performance of metal additive manufacturing.

2. Metal Additive Manufacturing Formation Process

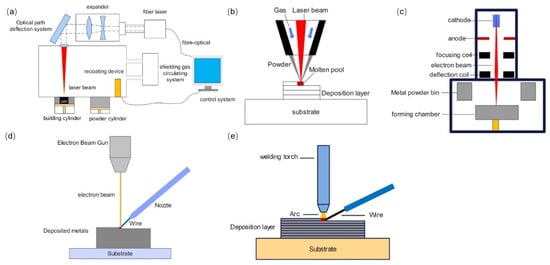

Additive manufacturing metal materials include titanium alloys [16,17], aluminum alloys [18,19], high-temperature alloys [20,21,22,23], steel [24,25,26], and magnesium alloys [27,28]. The raw material forms used in metal additive manufacturing include metal powders and wires [29], the most widely used of which is metal powder. The processing technology of metal additive manufacturing can be divided into two categories [30,31,32]: powder bed fusion (PBF) and direct energy deposition (DED). PBF featuring powder laying is an additive manufacturing process utilizing heat generated by lasers, electron beams, and infrared lamps to selectively melt/sinter raw materials in the area of the powder bed. The main representative technologies include selective laser melting (SLM) and electron selective beam melting (EBSM). DED featuring powder feeding is an additive manufacturing process that utilizes focused thermal energy to synchronously melt and deposit raw materials. Processing energy sources primarily include lasers, electron beams, and electric arcs. Common DED technologies include laser solid forming (LSF), electron beam free form fabrication (EBF3), and wire and arc additive manufacturing (WAAM). In addition, according to the different types of energy sources, metal additive manufacturing can be divided into laser additive manufacturing, electron beam additive manufacturing, and wire and arc additive manufacturing.

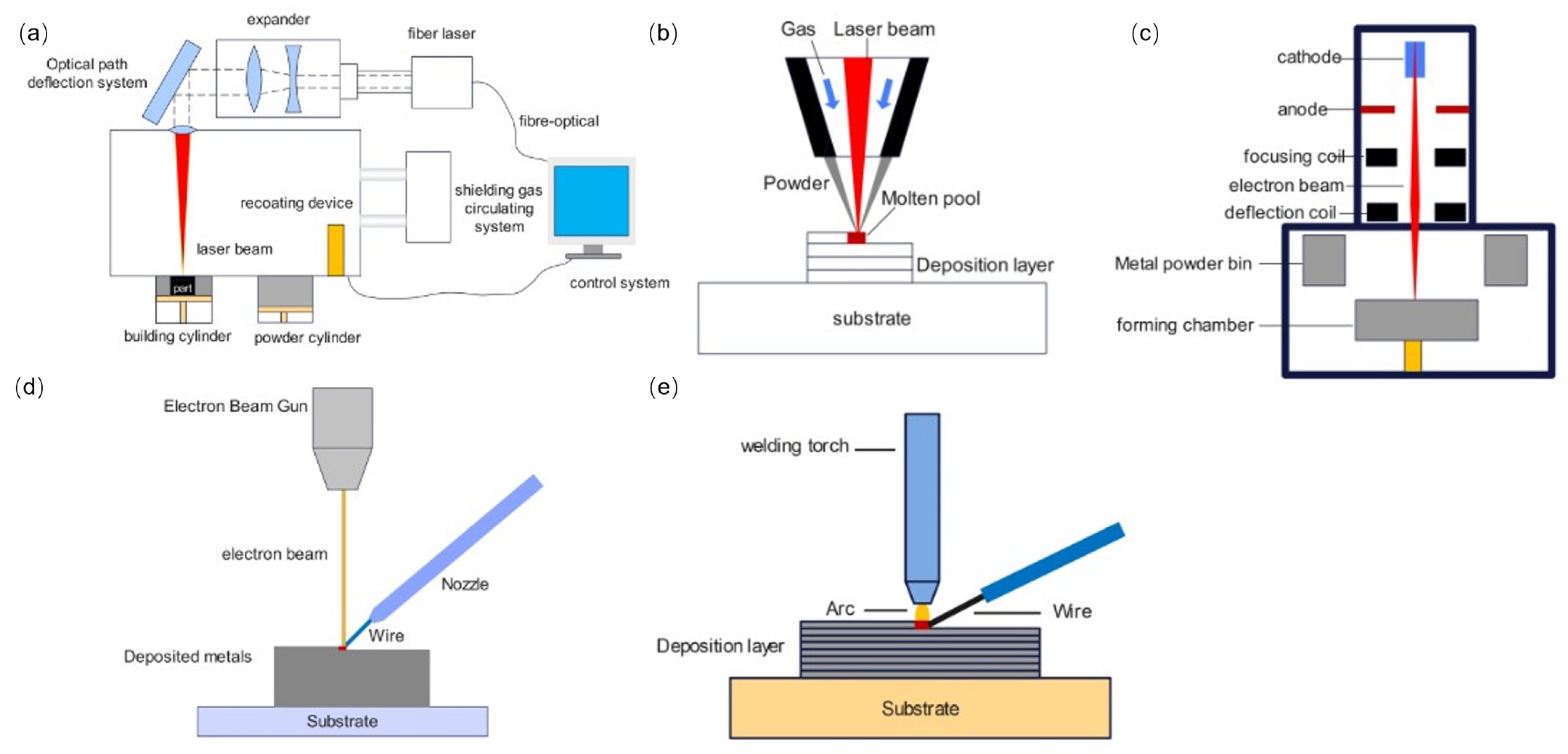

SLM [33,34,35,36] is a commonly used metal additive manufacturing process. Its principle is to use laser beams as the energy source to selectively melt/sinter metal powder layer-by-layer based on two-dimensional information obtained by layering the part modeling data using software and ultimately manufacture the required three-dimensional solid parts (Figure 1a). Firstly, a horizontal scraper lays a layer of metal powder evenly on the substrate of the processing chamber; the laser beams selectively melt/sinter the metal powder based on the current two-dimensional profile information. The lifting system adjusts the substrate to descend, the horizontal scraper lays powder on the machined surface, and the equipment melts/sinters the current layer of metal powder. This cycle is repeated layer-by-layer until the manufacturing of the part is completed. The processing parameters significantly impact the quality of parts formed by SLM, making selecting the appropriate processing parameters necessary. The main processing process parameters include the power bed depth, scanning speed, laser power, and scanning interval [37,38,39,40]. The advantages of SLM are high dimensional accuracy, high surface quality, and excellent mechanical properties of the formed parts.

Figure 1.

Schematic diagram of the working principle of metal additive manufacturing equipment. (a) SLM; (b) LSF; (c) EBSM; (d) EBF3; (e) WAAM.

LSF [41,42,43] uses laser beams to melt the metal powder sprayed by the powder feeding nozzle into a liquid state, which is then stacked and solidified through a planned motion path to achieve a near-net-shape of the metal parts (Figure 1b).

EBSM [44,45,46,47] works similarly to SLM, using electron beams as the energy source for the additive manufacturing process. In a vacuum environment, the high-energy electron beam is controlled by a deflection coil to selectively melt/sinter metal powders along a planned path (Figure 1c).

EBF3 [48,49,50] uses high-energy electron beams as the heat source to melt/sinter the metal wire fed by the wire-feeding device. In a vacuum environment, equipment builds up point-by-point, line-by-line, and surface-by-surface until the metal part is formed (Figure 1d). Metal materials have lower reflectivities to electron beams than lasers, giving significant advantages of high energy density and high energy utilization. Electron beam additive manufacturing has the characteristics of high power and high radiation and needs to be carried out in a vacuum environment [51,52]. Thus, the equipment cost is high. Radiation leakage occurring during production can cause environmental pollution. Additionally, electron beams can only be used for processing conductive materials.

WAAM [53,54] uses high-energy arcs as energy sources and metal wires as the processed raw materials (Figure 1e). WAAM has the advantages of high efficiency, mature technology, and low cost. In addition, this process is more suitable for processing aluminum alloys.

3. Review of the Development of Crystal Plasticity Theory

The combination of crystal plasticity theory, including dislocation slip and finite elements, called the crystal plasticity finite element method, establishes a bridge between the macroscopic mechanical response and microscopic slip and shear in mesoscopic scales to characterize the fatigue damage process of materials. The early work of crystal plasticity theory can be traced back to the 1920s. In 1934, Taylor [55] believed on the basis of shear deformation that the essence of single-crystal plastic deformation was crystal shear based on dislocation slip and quantitatively described it. Later, Hill and Rice [56,57] established a crystal plasticity theoretical framework for analyzing single-crystal rate-independent behaviors. Subsequently, crystal plasticity theories for rate-dependent [58,59] and containing deformation twins [60,61,62,63,64,65] have been proposed. These studies have improved the crystal plasticity constitutive theory, and the crystal plasticity constitutive theory for large deformation is now basically complete. Regarding the crystal plasticity constitutive theory, Asaro [66] and Roters et al. [13] gave systematic presentations.

Regarding the constitutive theory of polycrystalline plasticity, the polycrystalline plastic response can be regarded as the common action of all single-crystal plastic responses. The transition theory that relates the mechanical response of a single crystal to multiple crystals is the homogenization method, and the representative homogenization method includes the Sachs polycrystalline model, Taylor model [67,68,69,70,71,72], and self-consistent model [73,74,75,76,77,78]. In terms of plastic-deformation mechanisms, the crystal plasticity framework is currently mainly used to predict the mechanical response induced by dislocation slip [79,80,81,82,83] and deformation twins. Some studies have also considered other special deformation modes, such as martensitic phase transition [84], shear banding [85,86], dislocation high-temperature climb [87,88], and creep [89]. The crystal plasticity constitutive theory includes the phenomenological crystal plasticity theory and the crystal plasticity theory based on physical mechanisms. The phenomenological crystal plasticity model is established by describing experimental phenomena. The crystal plasticity model based on physical mechanisms can explain the physical essence of plastic deformation [90] by considering the microstructure evolution [91,92] (such as dislocation density), and the mathematical model of crystal plasticity is established in the form of state variables [93]. On the meso-scale, crystal plasticity theory has become a hot research topic in the field of materials science because it more accurately characterizes the plastic deformation of metallic materials by using the flow model, the hardening model, and the internal state variable model. The rate-dependent crystal plasticity theory [94,95] can describe the relationship between material plastic deformation and loading path well. In terms of the interaction of slip systems, the rate-dependent crystal plasticity constitutive model introduces the self-hardening and latent hardening rate [96,97], which can be applied to metal materials based on dislocation slip deformation mechanisms. The following briefly introduces the single-crystal plastic constitutive theory for rate-dependent materials.

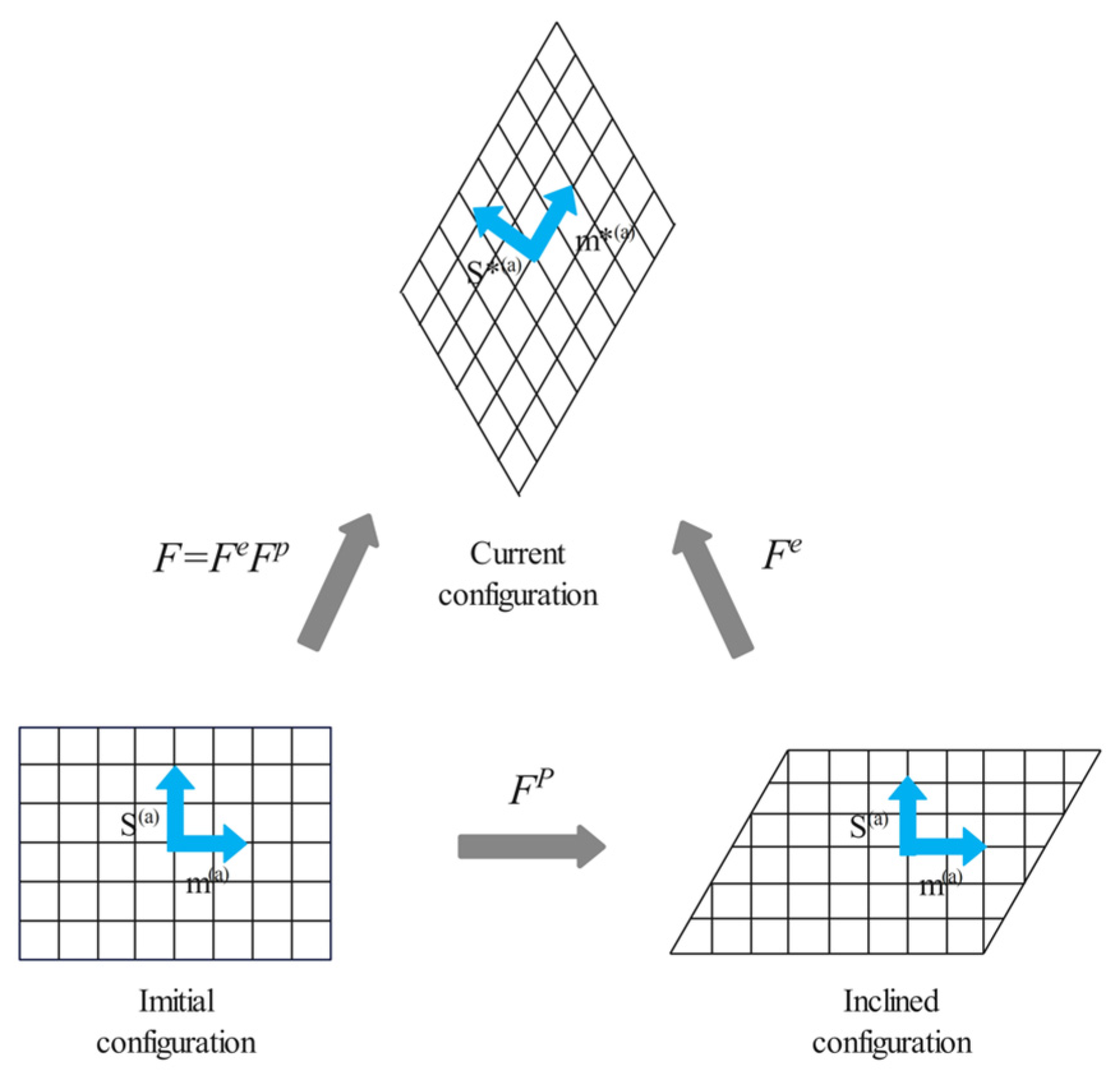

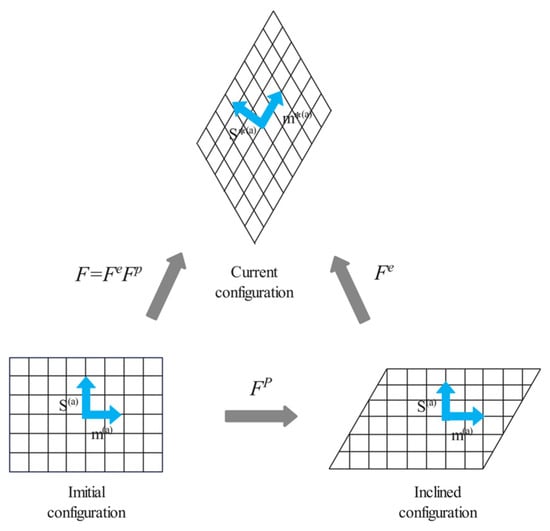

In continuum mechanics, the deformation gradient F represents the deformation of an object. The theory of crystal plasticity suggests that crystal deformation comes from the plastic deformation part Fp and the elastic deformation part Fe (Figure 2), and the total deformation gradient F can be written as

Figure 2.

Decomposition of deformation.

Introduce the velocity gradient, denoted by L:

where represents the particle position of the current configuration, and X represents the particle position of the initial configuration.

Substituting (2) into (1) obtains

where and .

Any n-order matrix can be expressed as the sum of a symmetric matrix and an antisymmetric matrix. Decompose the velocity gradient tensor into the deformation rate tensor D and the spin tensor W representing rotation:

In the αth slip system before deformation, the unit vector of the slip direction is denoted by S(α), and the unit normal vector of the slip surface is denoted by m(α). As shown in Figure 2, the plastic deformation experiences shear only in the direction of slip and does not change the direction of S(α) and m(α). Elastic deformation can cause the rotation and deformation of the crystal lattice, thus changing the magnitude and direction of S(α) and m(α). After deformation, the sliding direction and the normal direction of the sliding surface are, respectively, represented as

One work [98] demonstrates that the plastic deformation velocity gradient in the intermediate configuration can be expressed as

where denotes the shear strain rate caused by the αth slip system.

The plastic velocity gradient in the final configuration can be expressed as

The plastic velocity gradient can also be expressed as

Redefining the two formulas, the following emerge:

Then, there are

From the above basic formula of crystal deformation dynamics, the relationship between the shear stress rate and the shear strain rate on the crystal slip system, i.e., the crystal plastic constitutive relationship, can be established by further derivation. The single-crystal plastic constitutive relationship obtained from [57] is

where represents the Jaumann derivative of the Kirchhoff stress based on intermediate configurations, C represents the fourth-order elastic modulus tensor, and denotes the material derivative of the Kirchhoff stress tensor .

The Jaumann derivative of the Kirchhoff stress tensor based on W is expressed as

Therefore, there is

Due to Equation (15), there is

wherein

Simultaneously, Equations (5), (15), (16) and (18) can obtain the single-crystal constitutive equation:

According to Equation (21), solving the stress rate requires first solving the shear strain rate. The shear strain rates are usually calculated using rate-dependent plasticity models [59], expressed in the form of a power function as follows:

where denotes the component shear stress of the slip system α, denotes the reference shear strain rate, g(α) denotes the strain hardening state function, and m denotes the strain rate sensitive index. The hardening equation reflecting work-hardening behaviors adopts the Peirce–Asaro–Needleman hardening model [58]. g(α) is used to characterize the strain hardening state, assuming it is a function of the total deformation for slip γ,

When γ = 0, let the initial value of g(α) be τ0:

In the equation, hαβ represents the hardening modulus matrix:

where q denotes the coefficient describing the relative level of self-hardening and latent hardening, generally taken as 1 < q < 1.4; δαβ denotes the Kronecker symbol; h0 represents initial hardening rate; τ0 represents yield shear stress; and τs represents the saturation strength.

4. Additive Manufacturing Fatigue Simulation of Crystal Plasticity

Metal parts of additive manufacturing are often used as large integral main-load-bearing components in the aerospace field, and whether they meet the fatigue performance is the main technical indicator to measure their mechanical performance. Fatigue refers to the damage or fracture of a component under repeated action of alternating loads. The vast majority of equipment damage or failure during service is caused by fatigue.

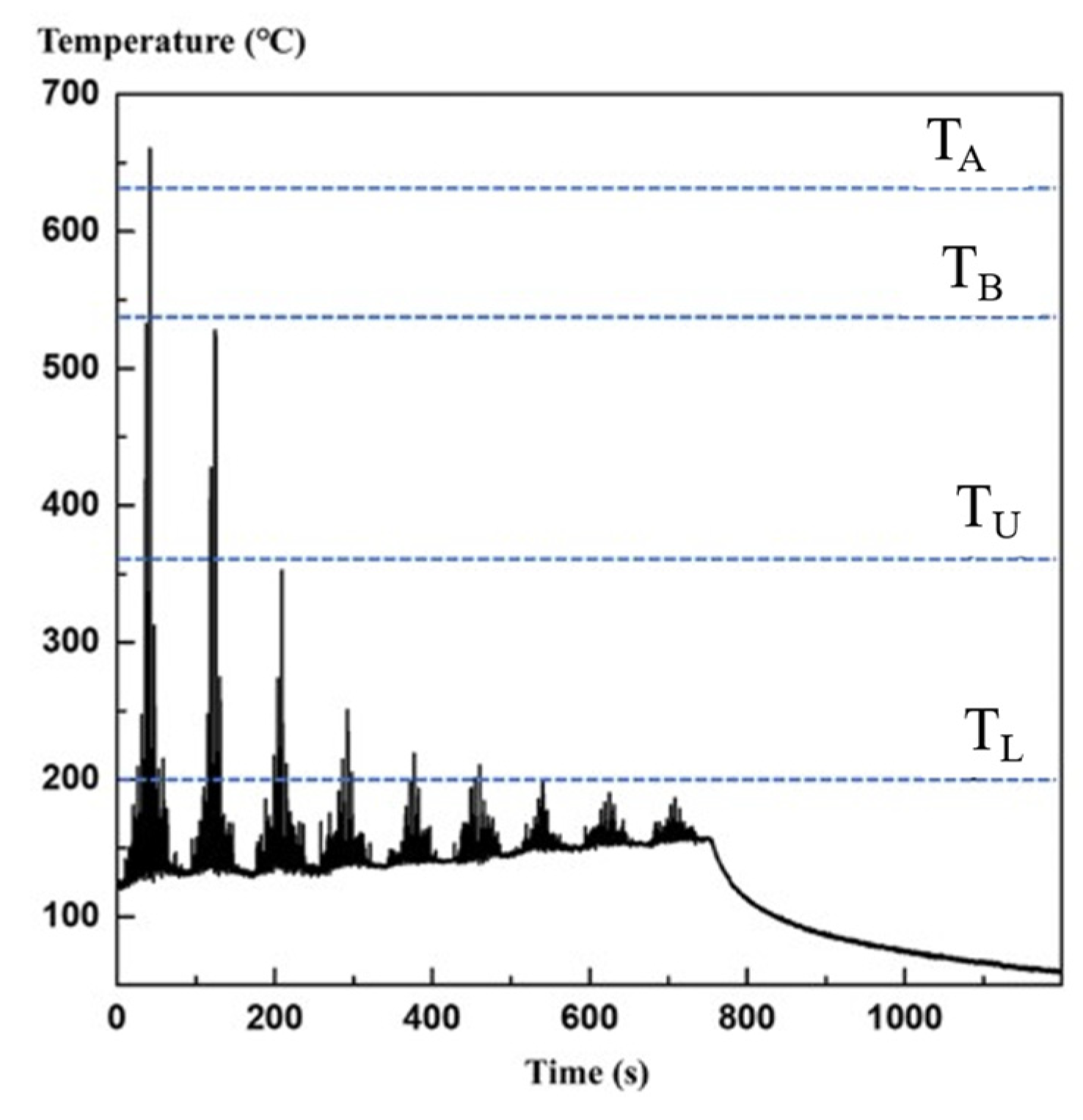

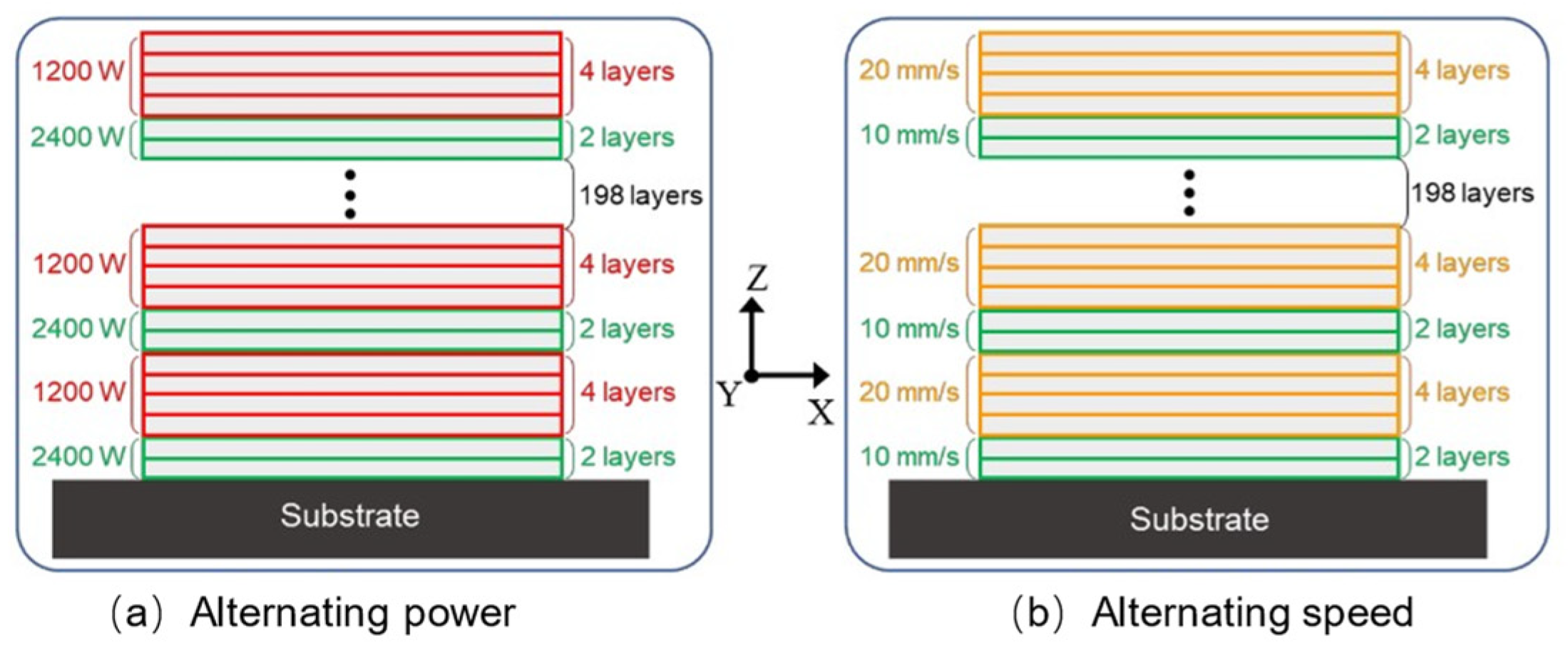

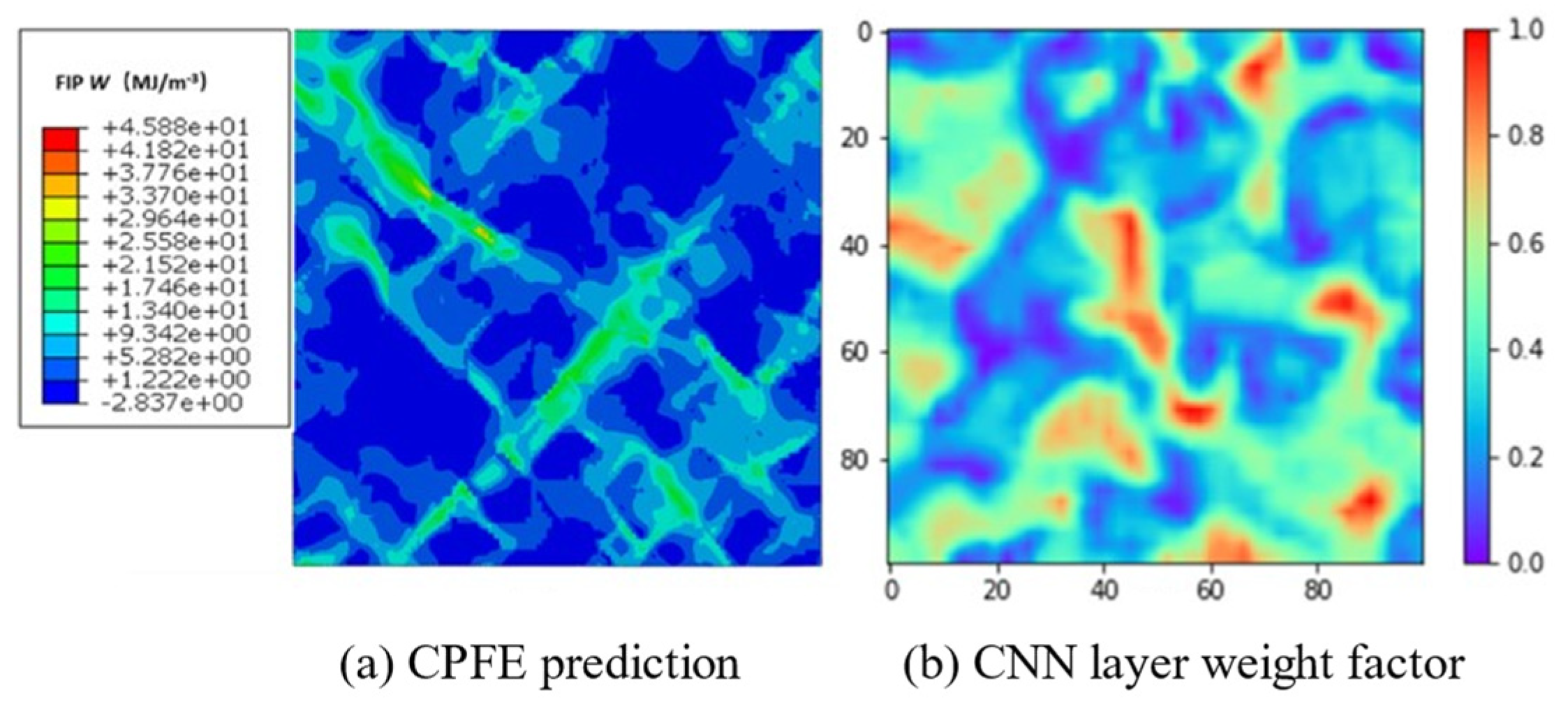

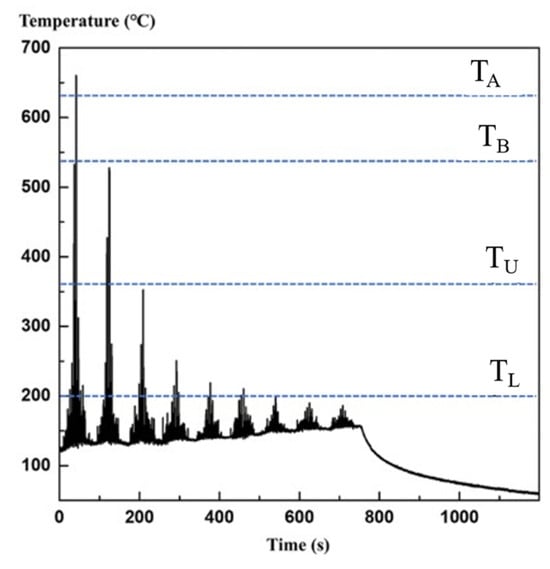

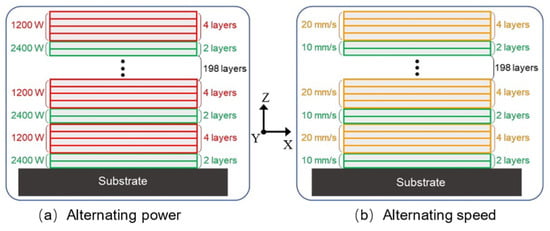

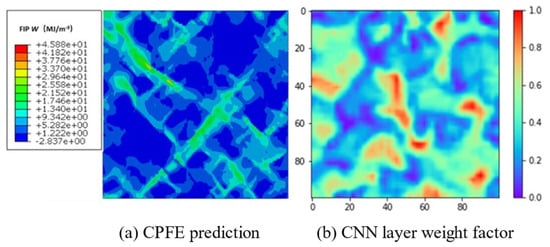

Additive manufacturing heats a metal wire or powder through an energy source for melting/sintering and solidifying point-by-point, line-by-line, and surface-by-surface to form three-dimensional solid parts. Hence, the interior of the melt pool undergoes repeated thermal cycles (Figure 3). As shown in Figure 3, TA represents liquidus temperature; TB represents the eutectic temperature; and TU and TL, respectively, represent the upper and lower limit temperatures that β′ precipitate. Affected by temperature gradients, columnar grains with epitaxial growth are formed through multiple cladding layers. Some scholars believe that this is the root cause of anisotropy in additive manufacturing metal materials, while others attribute it to anisotropy in the texture. The uneven microstructure causes anisotropy in the macroscopic mechanical response; therefore, the anisotropy of the microstructure is an important factor affecting the fatigue performance of additive manufacturing components. Regarding the anisotropic control strategy, from the perspective of additive manufacturing columnar grains with epitaxial growth, due to the phenomenon of columnar grains transitioning to equiaxed grains at the top of the additive manufacturing deposition layer, Zhang et al. [99] retained the equiaxed grains region (Figure 4) through the strategy of alternating the forming process parameters, blocking the growth of columnar grains, and achieved additive manufacturing of fully equiaxed grains for Ti-6Al-4V samples processed by DED. In addition, to achieve the additive manufacturing anisotropy regulation from the perspective of texture, Liu et al. [100] characterized the material texture information by EBSD, selected nine representative texture models of ODF, and simulated the Ti-6Al-4V sample produced by SLM by using the crystal plasticity finite element method, which showed that the nine textures have both positive anisotropic textures and negative anisotropic textures, and put forward the additive manufacturing metal materials anisotropy regulation strategy by combining the positive and negative anisotropic textures. Furthermore, regarding the impact of texture information on the mechanical properties of additive manufacturing, Tu et al. [101] proposed a deep learning model for strength prediction using input and output data from crystal plasticity simulations, which can accurately predict tensile properties, but the results in predicting FIP are not very reliable (Figure 5). As shown in Figure 5, compared with the crystal plasticity simulation results, the deep neural network model prediction results cannot identify the dominant grains contributed by FIP W. The use of data-driven and machine learning algorithms, as well as multi-scale and multi-physical field crystal plasticity simulations, are important research directions for achieving “structural design-fatigue performance prediction and evaluation” in additive manufacturing. Moreover, based on the advantages of crystal plasticity finite elements in micro simulations, crystal plasticity simulations of the effects of grain size and morphology [102], grain structure [103], precipitates [104], and microstructure evolution [105] on the fatigue properties of metal additive manufacturing have been reported in the literature.

Figure 3.

Temperature–time profile inside the molten pool during deposition process [106].

Figure 4.

Schematic diagram of alternating forming process parameters [99].

Figure 5.

FIP W prediction contour plot [101].

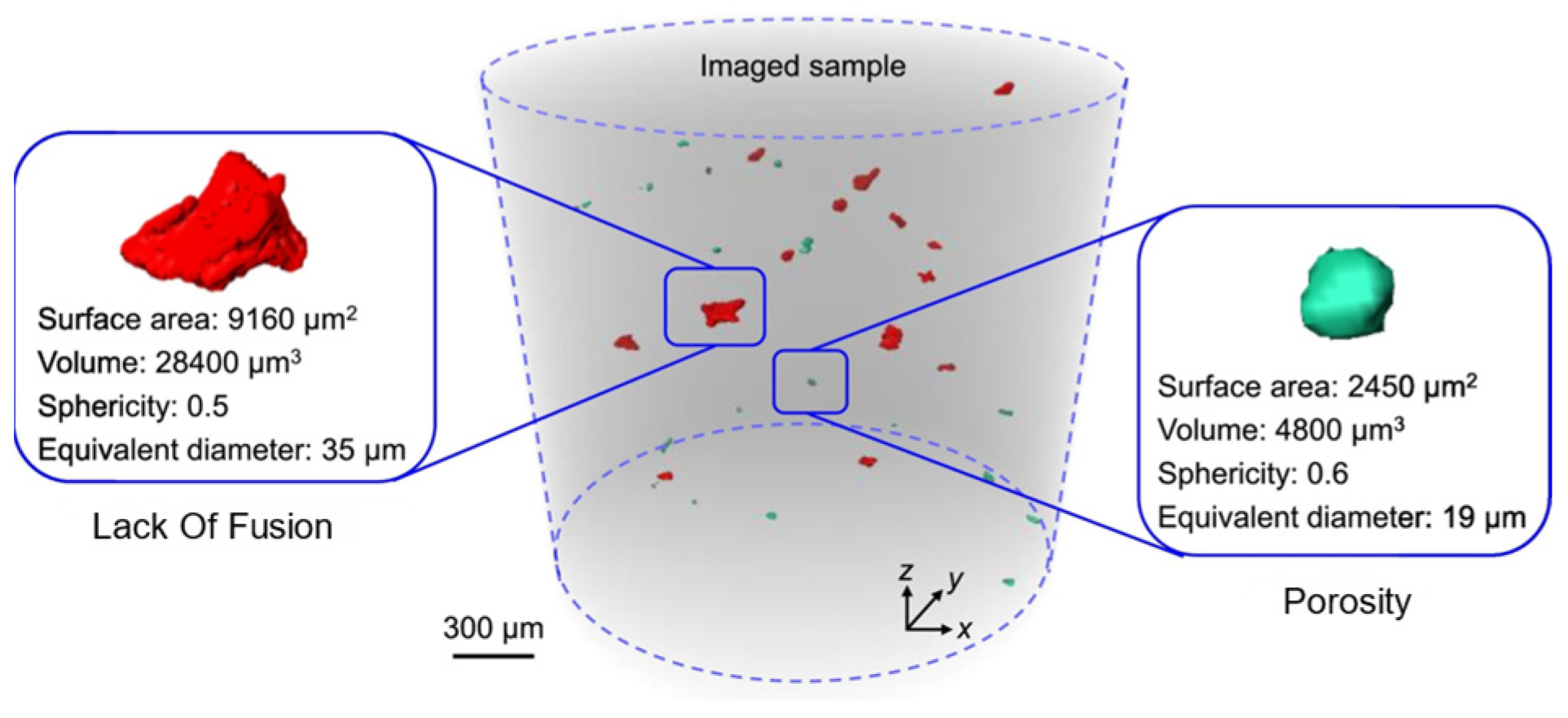

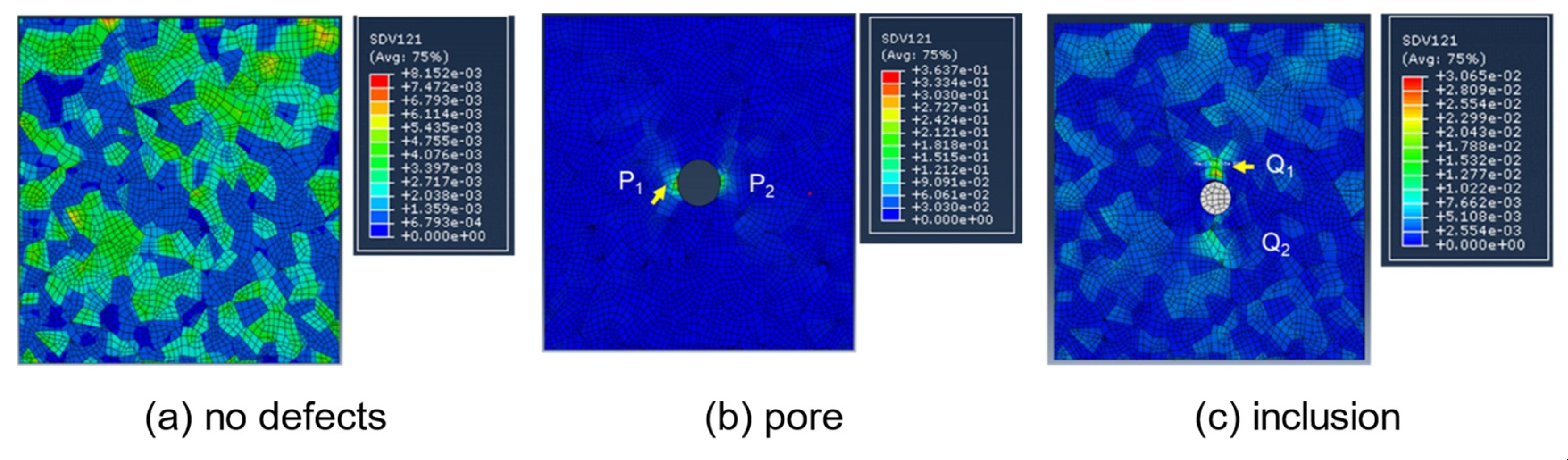

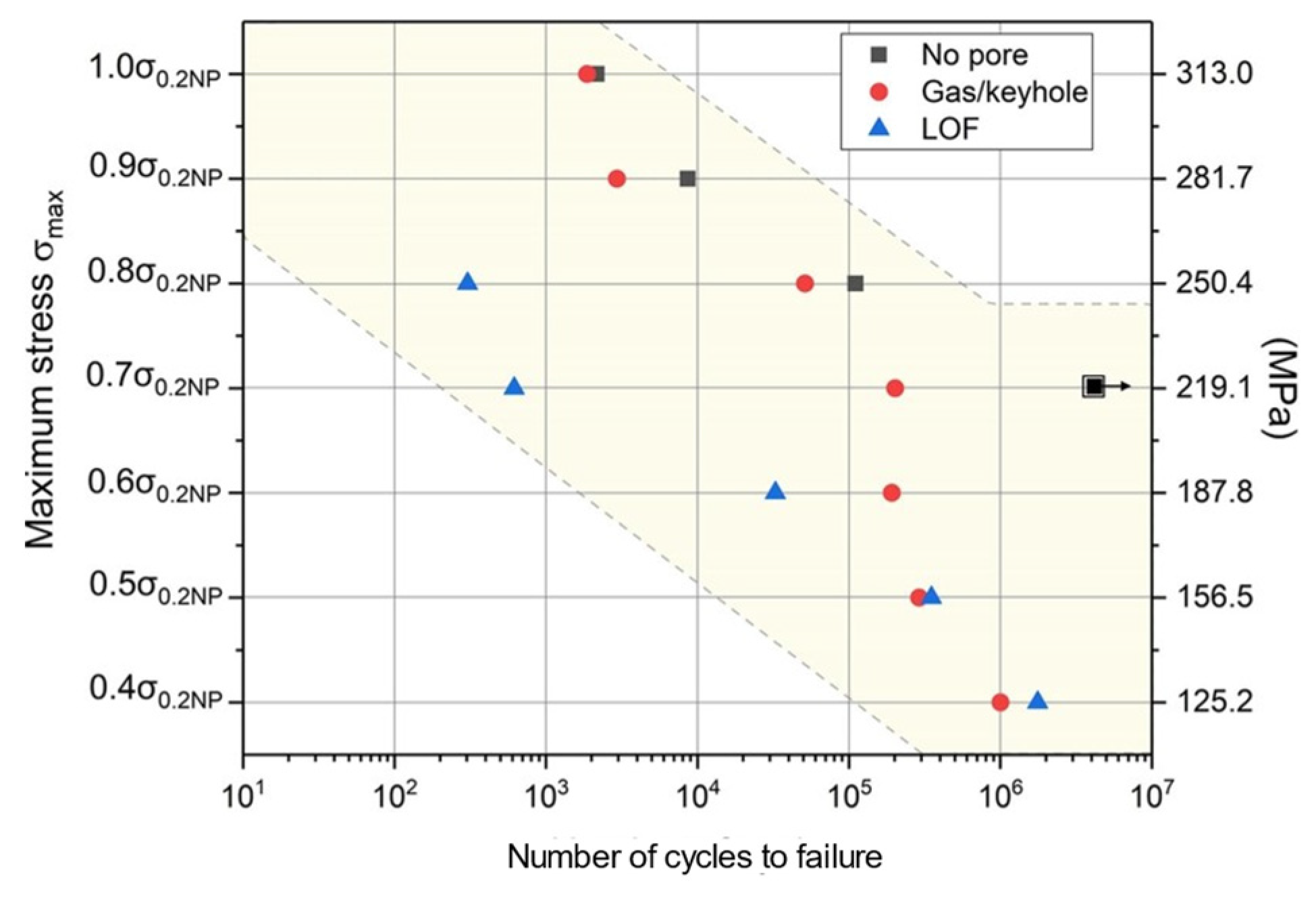

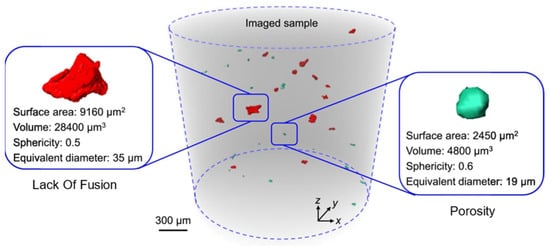

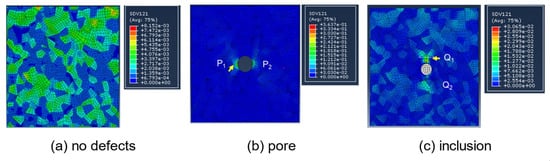

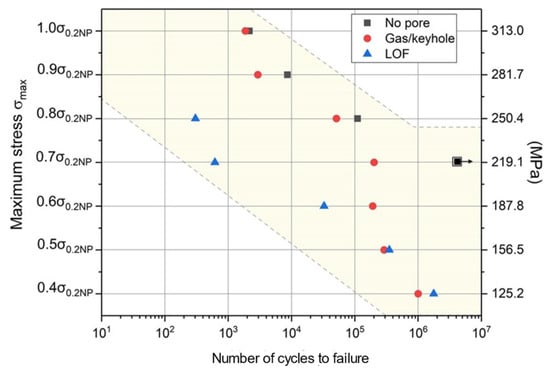

The defects in metal additive manufacturing mainly include pores and lack of fusion (Figure 6): the former is due to the pores formed during the rapid solidification process of gas in the molten pool, which is relatively regular in morphology and distributed inside the molten pool, which is one of the main factors leading to the high dispersion of fatigue life of additive manufacturing components. The latter is due to poor metallurgical bonding during the material stacking process, and the defect level of lack of fusion defects can be controlled by optimizing the additive manufacturing process parameters. Manufacturing defects are the preferred nucleation sites for fatigue cracks, inducing fatigue crack initiation and greatly affecting the service reliability of components. By optimizing process parameters, hot isostatic pressing, and post-heat treatment techniques, defects in components can be reduced to a certain extent, but they cannot be completely eliminated. Additive manufacturing defects are formed by complex mechanisms and come in a variety of morphology and sizes. The type, location, size, morphology, and orientation of defects all have a significant impact on the fatigue performance of additive manufacturing components. Therefore, exploring the laws of defect formation using the above aspects can help further improve the anti-fatigue technology of additive manufacturing components and establish a fatigue life prediction model for additive manufacturing caused by defects. Reference [107] reported that accumulated plastic shear strain is associated with fatigue crack initiation. Zhang et al. [108] simulated the very-high-cycle fatigue (VHCF) behaviors of SLM-ed AlSi10Mg alloy, and it was found that the accumulated plastic shear strain near the pores and inclusions was significantly increased and was even more severe near pores (Figure 7). Luo et al. [109] simulated the high-cycle fatigue response induced by SLM-ed AlSi10Mg alloy defects and found that lack of fusion defects has a greater impact on fatigue performance compared to pores. Cao et al. [110] comparatively simulated the fatigue behaviors of SLM-ed AlSi10Mg with different pores and provided S-N curves based on the storage energy density criterion (Figure 8) to quantitatively characterize the fatigue life, as shown in the S-N curves of Figure 8. The shaded area indicates the predicted fatigue failure range, and the fatigue life of the pore and lack of fusion defects is significantly reduced, with the latter decreasing even more under high applied stress conditions. The above research indicates that, at the same scale, different types of defects present different hazards to fatigue performance.

Figure 6.

Lack of fusion and pore in synchrotron radiation X-ray imaging [111].

Figure 7.

Contour of accumulated plastic shear strain [108].

Figure 8.

S-N data points predicted based on the storage energy density criterion [110].

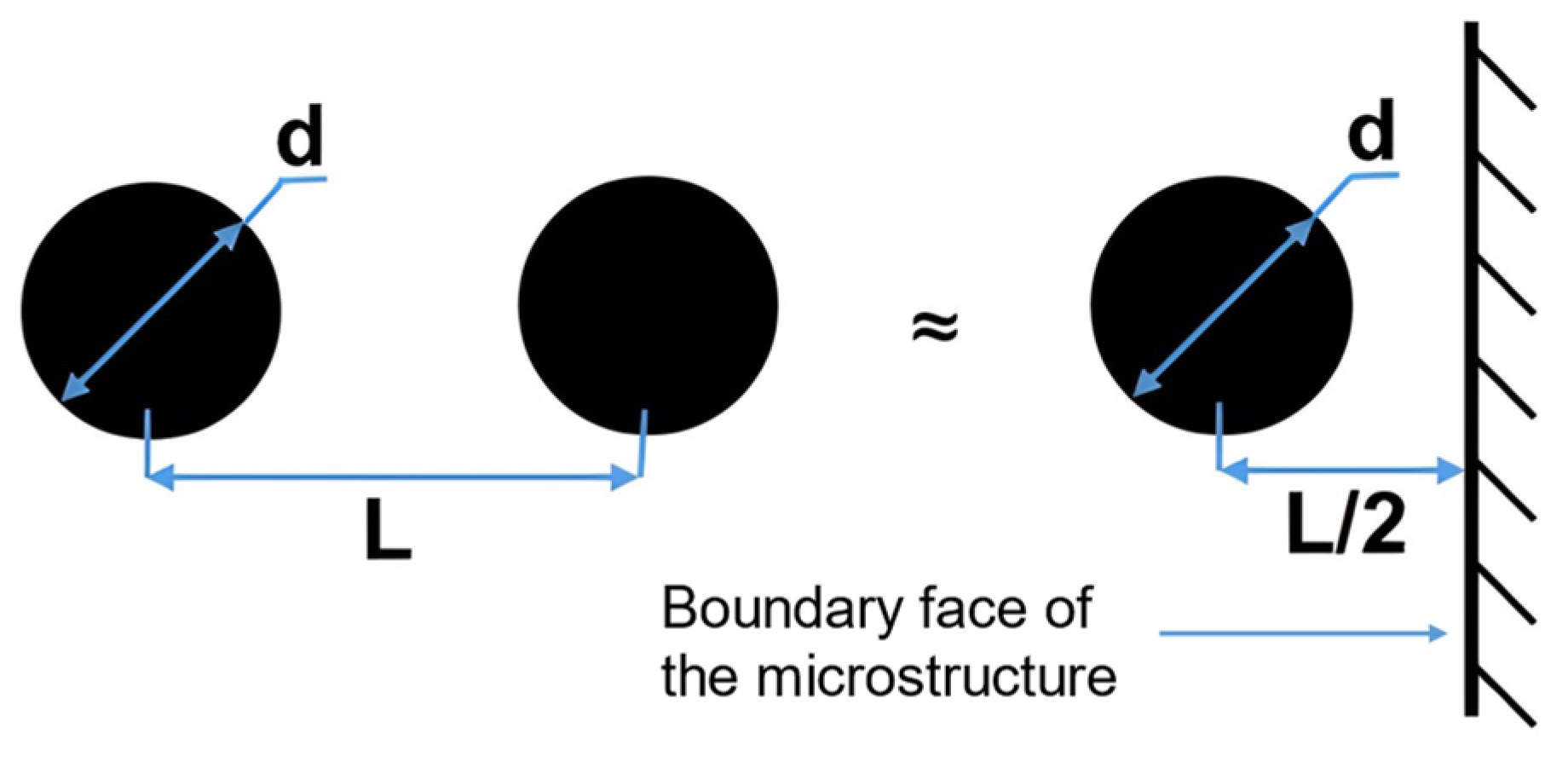

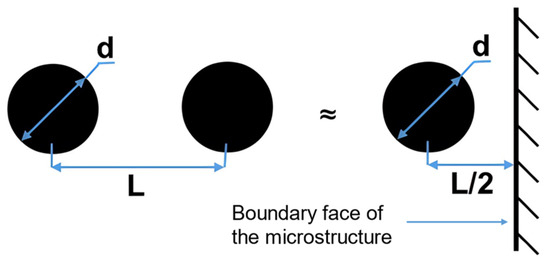

In addition, in terms of the influence of defect geometrical parameters (location, size, morphology, and orientation) on the fatigue performance of additive manufacturing components, Prithivirajan et al. [112] explored the critical porosity problem of additive manufacturing fatigue behaviors by taking SLM-ed IN718 as the object of study, characterizing the microstructure of SLM-ed IN718 based on EBSD. The critical porosity problem is defined in three aspects, i.e., the relative distance of pore from adjacent microstructures, the critical size of a single pore, and the distance of adjacent pores. Tthe critical porosity for fatigue failure of SLM-ed IN718 is quantitatively characterized by simulation prediction, and the pore-to-pore interaction problem is simplified and equated to the pore–boundary interaction (Figure 9). At present, the crystal plasticity simulations of geometric parameters of defects in additive manufacturing components are not yet perfect. The in-depth research on the fatigue damage mechanism of defect-induced additive manufacturing components can help to further optimize the additive manufacturing process parameters. Specifically, the additive manufacturing building direction (fatigue specimens of SLM-ed AlSi10Mg alloy with different building directions as shown in Figure 10) has a significant effect on the fatigue performance of the components. Zhang et al. [15] simulated the fatigue behaviors of SLM-ed AlSi10Mg and found that the fatigue performance of the 0° specimen was superior to that of the 90° specimen.

Figure 9.

The pore-to-pore interaction problem is equated to the pore–boundary interaction [112].

Figure 10.

Fatigue specimens of SLM-ed AlSi10Mg alloys [113].

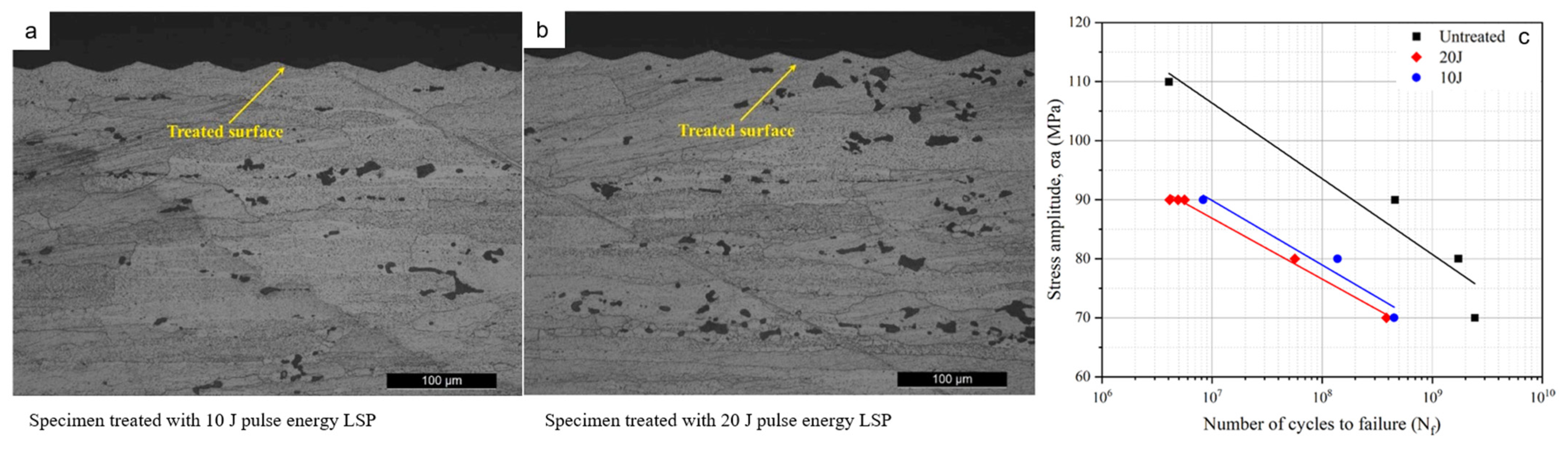

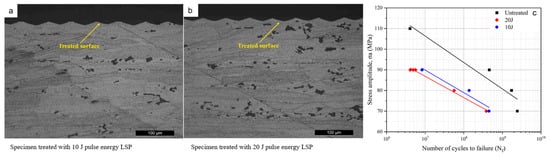

Surface quality is an important factor affecting the fatigue of additive manufacturing materials. Rough-surface parts are prone to fatigue crack nucleation due to stress concentration under cyclic loading conditions. Therefore, mechanical or chemical methods are usually used to improve the surface quality. In exploring the effect of laser shot peening strengthening on the fatigue performance of aluminum alloys, Qin et al. [114] and Li et al. [115] observed through experiments that the fatigue life of 2024—t351 aluminum alloy samples gradually decreased with the increase in pulse energy levels under laser shot peening strengthening treatment (Figure 11) and explained this phenomenon by modifying the crystal plasticity finite element method. Research has found that laser shot peening leads to a decrease in very high cycle fatigue performance when considering the combined effects of grain refinement and changes in the grain aspect ratio. In addition, rapid cooling during laser movement causes a complex residual stress field inside the components, which is prone to deformation and cracking due to the effect of internal stress. Kapoor et al. [116] incorporated residual stress into the CPFE framework to study Ti-6Al-4V prepared by selective laser melting and verified the reliability of the model but did not conduct research on fatigue performance. In summary, there have been fewer applied studies of the crystal plasticity finite element method with respect to the effects of surface quality and residual stress field on fatigue performance of additive manufacturing.

Figure 11.

Cross-section optical microscope image and S-N curve of the LSP-treated sample [114].

In conclusion, CPFEM, as a numerical simulation tool, has been widely used to simulate the microstructure and various macroscopic mechanical responses of materials. However, most research on the fatigue performance of additive manufacturing only stays in the application stage. At the theoretical level, in terms of the characteristics of the additive manufacturing process, the introduction of metallurgical and multi-scale, multi-physical field coupling of crystal plasticity constitutive theory can more accurately characterize the fatigue behaviors of additive manufacturing materials and improve the crystal plasticity constitutive theory. In the application of the crystal plasticity finite element method, establishing a fatigue model for crystal plasticity metal additive manufacturing using data-driven and machine learning algorithms for numerical simulation can more accurately reveal the strengthening and toughening mechanism of additive manufacturing. In addition, with the help of big data, machine learning, and crystal plasticity simulation, we can establish mathematical physics equations that take into account the coupling of microstructure, defects, surface quality, residual stress, and other factors. This can be used to predict the fatigue life of metal additive manufacturing, evaluate the fatigue performance of components, realize nondestructive testing, and simultaneously be directly applied to industrial production, which can significantly reduce production costs.

5. Development Trends and Forecasts

Fatigue of metal additive manufacturing is a multi-scale and multi-physical field coupling problem. Crystal plasticity simulations are an important means to explore the macro–micro intrinsic relationship. This paper discusses the application of crystal plasticity simulations in additive manufacturing fatigue research from four aspects: microstructure, defects, surface quality, and residual stress. In terms of the study of fatigue performance of metal additive manufacturing, the fatigue damage mechanism is a hot and difficult point of the current research. The mechanical properties of metal additive manufacturing components, especially fatigue performance, still require further improvement. With deepening research, the development of metal additive manufacturing has shifted from early process exploration to more systematic theoretical research. A deep understanding of the microstructure characteristics of additive manufacturing metal materials can help reveal the physical essence of material strengthening and toughening. This promotes the development of high-strength and high-toughness metal additive manufacturing formation processes. At present, the following research directions need to be further strengthened.

- (1)

- At the theoretical level, we can incorporate physical fields such as metallurgy and thermodynamics to reflect the characteristics of additive manufacturing and establish a constitutive theory of multi-physical field coupling.

- (2)

- When applying the crystal plasticity finite element method, we can strengthen research on crystal plasticity simulation in the fatigue performance of metal additive manufacturing and explore the more essential relationship of “manufacturing process—material microstructure—fatigue performance”. In terms of the process control of additive manufacturing, exploring the optimization of microstructures, characterization of textures, defect-induced fatigue damage mechanism of metal additive manufacturing components, and other issues need more in-depth research.

- (3)

- We can develop efficient CPFEM numerical implementation algorithms.

- (4)

- We can develop modeling techniques that better reflect the microstructure of real materials to more accurately characterize the deformation mechanism of materials.

Numerical simulation technology is widely used. The study of metal additive manufacturing processes using crystal plasticity frameworks is of great significance for improving the mechanical properties of additive manufacturing metal components. Further research is still needed at present.

Author Contributions

W.Z. performed the original draft preparation, data analysis, and drawing. A.W. and J.W. supervised the work and discussed the results with the other authors. Q.W. and K.L. provided some advice on the writing of the paper. F.L. performed the simulation investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This work is funded by the Natural Science Foundation of Anhui Province of China (2208085QE154) and the Research Initiation Fund Project of Anhui Polytechnic University (2021YQQ001).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors gratefully acknowledge the support of Update Industry (Wuhu) Co.

Conflicts of Interest

Author Kuai Lu was employed by the Update Industry (Wuhu) Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bandyopadhyay, A.; Zhang, Y.; Bose, S. Recent developments in metal additive manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 96–104. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Design 2021, 209, 110008. [Google Scholar] [CrossRef]

- Dziubińska, A.; Surdacki, P.; Majerski, K. The analysis of deformability, structure and properties of AZ61 cast magnesium alloy in a new hammer forging process for aircraft mounts. Materials 2021, 14, 2593. [Google Scholar] [CrossRef] [PubMed]

- Fernández, D.S.; Wynne, B.P.; Crawforth, P.; Fox, K.; Jackson, M. The effect of forging texture and machining parameters on the fatigue performance of titanium alloy disc components. Int. J. Fatigue 2021, 142, 105949. [Google Scholar] [CrossRef]

- Fernández, D.S.; Wynne, B.P.; Crawforth, P.; Jackson, M. Titanium alloy microstructure fingerprint plots from in-process machining. Mater. Sci. Eng. 2021, 811, 141074. [Google Scholar] [CrossRef]

- Tan, C.; Li, R.; Su, J.; Du, D.; Du, Y.; Attard, B.; Chew, Y.; Zhang, H.; Lavernia, E.J.; Fautrelle, Y.; et al. Review on field assisted metal additive manufacturing. Int. J. Mach. Tools Manuf. 2023, 189, 104032. [Google Scholar] [CrossRef]

- Keicher, D. Beyond rapid prototyping to direct fabrication: Forming metallic hardware directly from a CAD solid model. Mater. Technol. 1998, 13, 5–7. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- Gockel, J.; Sheridan, L.; Koerper, B.; Whip, B. The influence of additive manufacturing processing parameters on surface roughness and fatigue life. Int. J. Fatigue 2019, 124, 380–388. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; Yuan, T.; Kirka, M.M.; Dehoff, R.R.; Liaw, P.K.; Duty, C.E. A review on the fatigue behavior of Ti-6Al-4V fabricated by electron beam melting additive manufacturing. Int. J. Fatigue 2019, 119, 173–184. [Google Scholar] [CrossRef]

- Lewandowski, J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Bieler, T.R.; Raabe, D. Crystal Plasticity Finite Element Methods: In Materials Science and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.; Bieler, T.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Cong, T.; Li, R.; Zheng, Z.; Ma, X.; Wu, S.; Zhang, R.; Berto, F.; Sun, J.; Qian, G. Experimental and computational investigation of weathering steel Q450NQR1 under high cycle fatigue loading via crystal plasticity finite element method. Int. J. Fatigue 2022, 159, 106772. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Wu, S.; Zhang, W.; Sun, J.; Qian, G. High-cycle and very-high-cycle fatigue lifetime prediction of additively manufactured AlSi10Mg via crystal plasticity finite element method. Int. J. Fatigue 2022, 155, 106577. [Google Scholar] [CrossRef]

- Li, J.; Yuan, H.; Chandrakar, A.; Moroni, L.; Habibovic, P. 3D porous Ti6Al4V-beta-tricalcium phosphate scaffolds directly fabricated by additive manufacturing. Acta Biomater. 2021, 126, 496–510. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Design 2019, 164, 107552. [Google Scholar] [CrossRef]

- Mishra, R.S.; Thapliyal, S. Design approaches for printability-performance synergy in Al alloys for laser-powder bed additive manufacturing. Mater. Design 2021, 204, 109640. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Gibbons, G.; Das, A.; Howes, P.D. A review of Laser Powder Bed Fusion Additive Manufacturing of aluminium alloys: Microstructure and properties. Addit. Manuf. 2021, 46, 102155. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.-T.; Strayer, S.; Chang, K.-C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.-C.; Tin, S.; et al. Additive Manufacturing of Nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 101108. [Google Scholar] [CrossRef]

- Park, J.U.; Jun, S.Y.; Lee, B.H.; Jang, J.H.; Lee, B.S.; Lee, H.J.; Lee, J.H.; Hong, H.U. Alloy design of Ni-based superalloy with high γ′ volume fraction suitable for additive manufacturing and its deformation behavior. Addit. Manuf. 2022, 52, 102680. [Google Scholar] [CrossRef]

- Sarkar, R.; Chen, B.; Fitzpatrick, M.E.; Fabijanic, D.; Hilditch, T. Additive manufacturing-based repair of IN718 superalloy and high-cycle fatigue assessment of the joint. Addit. Manuf. 2022, 60, 103276. [Google Scholar]

- Sreeramagiri, P.; Bhagavatam, A.; Ramakrishnan, A.; Alrehaili, H.; Dinda, G.P. Design and development of a high-performance Ni-based superalloy WSU 150 for additive manufacturing. J. Mater. Sci. Technol. 2020, 47, 20–28. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Nanni, F. A simple route for additive manufacturing of 316L stainless steel via Fused Filament Fabrication. J. Manuf. Proc. 2021, 67, 141–150. [Google Scholar] [CrossRef]

- Kürnsteiner, P.; Wilms, M.B.; Weisheit, A.; Gault, B.; Jägle, E.A.; Raabe, D. High-strength Damascus steel by additive manufacturing. Nature 2020, 582, 515–519. [Google Scholar] [CrossRef] [PubMed]

- Fedina, T.; Sundqvist, J.; Powell, J.; Kaplan, A.F. A comparative study of water and gas atomized low alloy steel powders for additive manufacturing. Addit. Manuf. 2020, 36, 101675. [Google Scholar] [CrossRef]

- Karunakaran, R.; Ortgies, S.; Tamayol, A.; Bobaru, F.; Sealy, M.P. Additive manufacturing of magnesium alloys. Bioact. Mater. 2020, 5, 44–54. [Google Scholar] [CrossRef]

- Zeng, Z.; Salehi, M.; Kopp, A.; Xu, S.; Esmaily, M.; Birbilis, N. Recent progress and perspectives in additive manufacturing of magnesium alloys. J. Magnes. Alloys 2022, 10, 1511–1541. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A review of various materials for additive manufacturing: Recent trends and processing issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Obeidi, M.A. Metal additive manufacturing by laser-powder bed fusion: Guidelines for process optimisation. Results Eng. 2022, 15, 100473. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y. Laser powder bed fusion for metal additive manufacturing: Perspectives on recent developments. Virtual Phys. Prototyp. 2020, 15, 359–370. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Ahmadi, M.; Tabary, S.B.; Rahmatabadi, D.; Ebrahimi, M.; Abrinia, K.; Hashemi, R. Review of selective laser melting of magnesium alloys: Advantages, microstructure and mechanical characterizations, defects, challenges, and applications. J. Mater. Res. Technol. 2022, 19, 1537–1562. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Sutcliffe, C. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Sefene, E.M. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Singla, A.K.; Banerjee, M.; Sharma, A.; Singh, J.; Bansal, A.; Gupta, M.K.; Khanna, N.; Shahi, A.; Goyal, D.K. Selective laser melting of Ti6Al4V alloy: Process parameters, defects and post-treatments. J. Manuf. Process. 2021, 64, 161–187. [Google Scholar] [CrossRef]

- Zhao, C.; Bai, Y.; Zhang, Y.; Wang, X.; Xue, J.M.; Wang, H. Influence of scanning strategy and building direction on microstructure and corrosion behaviour of selective laser melted 316 L stainless steel. Mater. Design 2021, 209, 109999. [Google Scholar] [CrossRef]

- Li, X.; Yi, D.; Wu, X.; Zhang, J.; Yang, X.; Zhao, Z.; Feng, Y.; Wang, J.; Bai, P.; Liu, B.; et al. Effect of construction angles on microstructure and mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J. Alloys Compd. 2021, 881, 160459. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, F.; Huang, C.; Lin, X.; Xia, C.; Wang, Z.; You, Q.; Liu, L. Achieving superior burn resistant and mechanical properties of Ti40 alloy by laser solid forming. J. Manuf. Proc. 2023, 102, 406–415. [Google Scholar] [CrossRef]

- Liang, S.; Yan, W. Study on the micro-structure and the nano-indentation responses of laser solid formed epitaxial Ni-based superalloy. J. Alloys Compd. 2022, 921, 166091. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, P.; Yang, L.; Le, G.; He, S.; He, X.; Liu, X.; Wang, W. Microstructure and mechanical properties of Be–Al alloy fabricated by laser solid forming. Mater. Sci. Eng. 2021, 799, 140335. [Google Scholar] [CrossRef]

- Li, Y.; Kan, W.; Zhang, Y.; Li, M.; Liang, X.; Yu, Y.; Lin, F. Microstructure, mechanical properties and strengthening mechanisms of IN738LC alloy produced by Electron Beam Selective Melting. Addit. Manuf. 2021, 47, 102371. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Yu, Y.; Li, H.; Kan, W.; Lin, F. Microstructures and mechanical properties evolution of IN939 alloy during electron beam selective melting process. J. Alloys Compd. 2021, 883, 160934. [Google Scholar] [CrossRef]

- Yang, J.; Huang, Y.; Liu, B.; Guo, C.; Sun, J. Precipitation behavior in a Nb-5W-2Mo-1Zr niobium alloy fabricated by electron beam selective melting. Mater. Charact. 2021, 174, 111019. [Google Scholar] [CrossRef]

- Zhao, D.C.; Lin, F. Dual-detector electronic monitoring of electron beam selective melting. J. Mater. Process. Technol. 2021, 289, 116935. [Google Scholar] [CrossRef]

- Cui, R.; Wang, L.; Yao, L.; Li, B.; Su, Y.; Luo, L.; Chen, R.; Guo, J.; Fu, H. On the solidification behaviors of AlCu5MnCdVA alloy in electron beam freeform fabrication: Microstructural evolution, Cu segregation and cracking resistance. Addit. Manuf. 2022, 51, 102606. [Google Scholar] [CrossRef]

- Su, B.; Wang, B.; Luo, L.; Wang, L.; Li, B.; Liu, C.; Su, Y.; Xu, Y.; Huang, H.; Guo, J.; et al. Tuning microstructure and improving the corrosion resistance of Ti-6Al-3Nb-2Zr-1Mo alloy using the electron beam freeform fabrication. Chem. Eng. J. 2022, 444, 136524. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, L.; Wang, B.; Li, B.; Zhao, J.; Ding, B.; Cui, R.; Jiang, B.; Zhao, C.; Su, B.; et al. Multi-materials additive manufacturing of Ti64/Cu/316L by electron beam freeform fabrication. J. Mater. Res. Technol. 2023, 26, 8388–8405. [Google Scholar] [CrossRef]

- Osipovich, K.; Kalashnikov, K.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Vorontsov, A.; Zykova, A.; Utyaganova, V.; Panfilov, A.; Nikolaeva, A.; et al. Wire-Feed Electron Beam Additive Manufacturing: A Review. Metals 2023, 13, 279. [Google Scholar] [CrossRef]

- Gong, X.; Anderson, T.; Chou, K. Review on powder-based electron beam additive manufacturing technology. In Proceedings of the ASME/ISCIE 2012 International Symposium on Flexible Automation, St. Louis, MO, USA, 18–20 June 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 507–515. [Google Scholar]

- Jafari, D.; Vaneker, T.H.; Gibson, I. Wire and arc additive manufacturing: Opportunities and challenges to control the quality and accuracy of manufactured parts. Mater. Design 2021, 202, 109471. [Google Scholar] [CrossRef]

- Lin, Z.; Song, K.; Yu, X. A review on wire and arc additive manufacturing of titanium alloy. J. Manuf. Proc. 2021, 70, 24–45. [Google Scholar] [CrossRef]

- Taylor, G.I. The mechanism of plastic deformation of crystals. Part I.—Theoretical. Proc. R. Soc. Lond. Ser. A 1934, 145, 362–387. [Google Scholar]

- Hill, R. Generalized constitutive relations for incremental deformation of metal crystals by multislip. J. Mech. Phys. Solids 1966, 14, 95–102. [Google Scholar] [CrossRef]

- Hill, R.; Rice, J.R. Constitutive analysis of elastic-plastic crystals at arbitrary strain. J. Mech. Phys. Solids 1972, 20, 401–413. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. Material rate dependence and localized deformation in crystalline solids. Acta Metall. 1983, 31, 1951–1976. [Google Scholar] [CrossRef]

- Kalidindi, S.R. Incorporation of deformation twinning in crystal plasticity models. J. Mech. Phys. Solids 1998, 46, 267–290. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Tomé, C.N. A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: Application to zirconium alloys. Acta Metall. Mater. 1993, 41, 2611–2624. [Google Scholar] [CrossRef]

- Schlögl, S.M.; Fischer, F.D. The role of slip and twinning in the deformation behaviour of polysynthetically twinned crystals of TiAl: A micromechanical model. Philos. Mag. A 1997, 75, 621–636. [Google Scholar] [CrossRef]

- Tomé, C.N.; Lebensohn, R.A.; Kocks, U.F. A model for texture development dominated by deformation twinning: Application to zirconium alloys. Acta Metall. Mater. 1991, 39, 2667–2680. [Google Scholar] [CrossRef]

- Doquet, V. Twinning and multiaxial cyclic plasticity of a low stacking-fault-energy fcc alloy. Acta Metall. Mater. 1993, 41, 2451–2459. [Google Scholar] [CrossRef]

- Van Houtte, P. Simulation of the rolling and shear texture of brass by the Taylor theory adapted for mechanical twinning. Acta Metall. 1978, 26, 591–604. [Google Scholar] [CrossRef]

- Asaro, R.J. Crystal plasticity. J. Appl. Mech. 1983, 50, 921–934. [Google Scholar] [CrossRef]

- Becker, R.; Panchanadeeswaran, S. Effects of grain interactions on deformation and local texture in polycrystals. Acta Metall. Mater. 1995, 43, 2701–2719. [Google Scholar] [CrossRef]

- Van Houtte, P.; Delannay, L.; Kalidindi, S.R. Comparison of two grain interaction models for polycrystal plasticity and deformation texture prediction. Int. J. Plast. 2002, 18, 359–377. [Google Scholar] [CrossRef]

- Van Houtte, P. A comprehensive mathematical formulation of an extended Taylor–Bishop–Hill model featuring relaxed constraints, the Renouard–Wintenberger theory and a strain rate sensitivity model. Textures Microstruct. 1988, 8, 313–350. [Google Scholar] [CrossRef]

- Honneff, H.; Mecking, H. Analysis of the deformation texture at different rolling conditions. In Proceedings of the Sixth International Conference on Textures of Materials, Tokyo, Japan, 28 September–3 October 1981; pp. 347–355. [Google Scholar]

- Habraken, A.M. Modelling the plastic anisotropy of metals. Arch. Comput. Methods Eng. 2004, 11, 3–96. [Google Scholar] [CrossRef]

- Lin, T.H. Analysis of elastic and plastic strains of a face-centred cubic crystal. J. Mech. Phys. Solids 1957, 5, 143–149. [Google Scholar] [CrossRef]

- Berveiller, M.; Zaoui, A. An extension of the self-consistent scheme to plastically-flowing polycrystals. J. Mech. Phys. Solids 1978, 26, 325–344. [Google Scholar] [CrossRef]

- Hill, R. A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 1965, 13, 213–222. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Elastic-plastic behaviour of polycrystalline metals and composites. Proc. R. Soc. Lond. A Math. Phys. Sci. 1970, 319, 247–272. [Google Scholar]

- Iwakuma, T.; Nemat-Nasser, S. Finite elastic-plastic deformation of polycrystalline metals. Proc. R. Soc. Lond. A Math. Phys. Sci. 1984, 394, 87–119. [Google Scholar]

- Kröner, E. Zur plastischen verformung des vielkristalls. Acta Metall. 1961, 9, 155–161. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.D.; Tomé, C.N.; Huang, Y. A finite strain elastic–viscoplastic self-consistent model for polycrystalline materials. J. Mech. Phys. Solids 2010, 58, 594–612. [Google Scholar] [CrossRef]

- Kang, H.; Zhang, Y.; Nagaumi, H.; Yang, X. Roles of dislocation slip and twinning in the creep performance of a wrought Mg-Zn-Mn alloy sheet. J. Alloys Compd. 2023, 967, 171631. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Logan, R.W.; Hosford, W.F. Upper-bound anisotropic yield locus calculations assuming <111>-pencil glide. Int. J. Mech. Sci. 1980, 22, 419–430. [Google Scholar]

- Yang, Q.; Marvel, C.J.; Shen, Y.; He, M.-R.; Du, J.; Hwang, C.; Gronske, E.D.; Xie, K.Y.; Mercurio, S.R.; An, Q.; et al. Activating dislocation mediated plasticity in boron carbide through Al-doping. Acta Mater. 2022, 241, 118412. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Wang, L.; Jia, H.; Zeng, X. The role of grain boundary plane in slip transfer during deformation of magnesium alloys. Acta Mater. 2022, 227, 117662. [Google Scholar] [CrossRef]

- Petersmann, M.; Antretter, T.; Cailletaud, G.; Sannikov, A.; Ehlenbröker, U.; Fischer, F. Unification of the non-linear geometric transformation theory of martensite and crystal plasticity-Application to dislocated lath martensite in steels. Int. J. Plast. 2019, 119, 140–155. [Google Scholar] [CrossRef]

- Jia, N.; Roters, F.; Eisenlohr, P.; Raabe, D.; Zhao, X. Simulation of shear banding in heterophase co-deformation: Example of plane strain compressed Cu–Ag and Cu–Nb metal matrix composites. Acta Mater. 2013, 61, 4591–4606. [Google Scholar] [CrossRef]

- Jia, N.; Roters, F.; Eisenlohr, P.; Kords, C.; Raabe, D. Non-crystallographic shear banding in crystal plasticity FEM simulations: Example of texture evolution in α-brass. Acta Mater. 2012, 60, 1099–1115. [Google Scholar] [CrossRef]

- Yuan, S.; Huang, M.; Zhu, Y.; Li, Z. A dislocation climb/glide coupled crystal plasticity constitutive model and its finite element implementation. Mech. Mater. 2018, 118, 44–61. [Google Scholar] [CrossRef]

- Yuan, S.; Zhu, Y.; Liang, S.; Huang, M.; Li, Z. Dislocation-density based size-dependent crystal plasticity framework accounting for climb of piled up dislocations at elevated temperature. Mech. Mater. 2019, 134, 85–97. [Google Scholar] [CrossRef]

- Venkataramani, G.; Kirane, K.; Ghosh, S. Microstructural parameters affecting creep induced load shedding in Ti-6242 by a size dependent crystal plasticity FE model. Int. J. Plast. 2008, 24, 428–454. [Google Scholar] [CrossRef]

- Yu, C.; Kang, G.; Kan, Q.; Xu, X. Physical mechanism based crystal plasticity model of NiTi shape memory alloys addressing the thermo-mechanical cyclic degeneration of shape memory effect. Mech. Mater. 2017, 112, 1–17. [Google Scholar] [CrossRef]

- Jeong, J.; Voyiadjis, G.Z. A physics-based crystal plasticity model for the prediction of the dislocation densities in micropillar compression. J. Mech. Phys. Solids 2022, 167, 105006. [Google Scholar] [CrossRef]

- Patra, A.; Chaudhary, S.; Pai, N.; Ramgopal, T.; Khandelwal, S.; Rao, A.; McDowell, D.L. ρ-CP: Open source dislocation density based crystal plasticity framework for simulating temperature-and strain rate-dependent deformation. Comput. Mater. Sci. 2023, 224, 112182. [Google Scholar] [CrossRef]

- Potirniche, G.P.; Horstemeyer, M.F.; Ling, X.W. An internal state variable damage model in crystal plasticity. Mech. Mater. 2007, 39, 941–952. [Google Scholar] [CrossRef]

- Li, H.W.; Yang, H.; Sun, Z.C. A robust integration algorithm for implementing rate dependent crystal plasticity into explicit finite element method. Int. J. Plast. 2008, 24, 267–288. [Google Scholar] [CrossRef]

- Rashid, M.M.; Nemat-Nasser, S. A constitutive algorithm for rate-dependent crystal plasticity. Comput. Methods Appl. Mech. Eng. 1992, 94, 201–228. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.; Brochu, M.; Wang, X.; Harrison, N.M.; Leen, S.B.; Segurado, J. Understanding orientation-dependent plasticity in laser beam powder bed fusion stainless steel through crystal plasticity modelling. Mater. Sci. Eng. A 2022, 852, 143682. [Google Scholar] [CrossRef]

- Schilli, S.; Seifert, T.; Kreins, M.; Krupp, U. Bauschinger effect and latent hardening under cyclic micro-bending of Ni-base Alloy 718 single crystals: Part II. Single crystal plasticity modeling with latent kinematic hardening. Mater. Sci. Eng. A 2022, 830, 142030. [Google Scholar] [CrossRef]

- Rice, J.R. Inelastic constitutive relations for solids: An internal-variable theory and its application to metal plasticity. J. Mech. Phys. Solids 1971, 19, 433–455. [Google Scholar] [CrossRef]

- Zhang, G.; Lu, X.; Li, J.; Chen, J.; Lin, X.; Wang, M.; Tan, H.; Huang, W. In-situ grain structure control in directed energy deposition of Ti6Al4V. Addit. Manuf. 2022, 55, 102865. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, F.; Wang, Y. Mechanical Anisotropy of Selective Laser Melted Ti-6Al-4V Using a Reduced-order Crystal Plasticity Finite Element Model. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100062. [Google Scholar] [CrossRef]

- Tu, Y.; Liu, Z.; Carneiro, L.; Ryan, C.M.; Parnell, A.C.; Leen, S.B.; Harrison, N.M. Towards an instant structure-property prediction quality control tool for additive manufactured steel using a crystal plasticity trained deep learning surrogate. Mater. Design 2022, 213, 110345. [Google Scholar] [CrossRef]

- Lakshmanan, A.; Yaghoobi, M.; Stopka, K.S.; Sundararaghavan, V. Crystal plasticity finite element modeling of grain size and morphology effects on yield strength and extreme value fatigue response. J. Mater. Res. Technol. 2022, 19, 3337–3354. [Google Scholar] [CrossRef]

- Cheng, J.; Fernandez-Zelaia, P.; Hu, X.; Kirka, M. Effect of microstructure on fatigue crack propagation in additive manufactured nickel-based superalloy Haynes 282, an experiment and crystal plasticity study. J. Mater. Sci. 2022, 57, 9741–9768. [Google Scholar] [CrossRef]

- Eghtesad, A.; Knezevic, M. A full-field crystal plasticity model including the effects of precipitates: Application to monotonic, load reversal, and low-cycle fatigue behavior of Inconel 718. Mater. Sci. Eng. A 2021, 803, 140478. [Google Scholar] [CrossRef]

- Yi, M.; Chang, K.; Liang, C.; Zhou, L.; Yang, Y.; Yi, X.; Xu, B. Computational study of evolution and fatigue dispersity of microstructures by additive manufacturing. Chin. J. Theor. Appl. Mech. 2021, 53, 3263–3273. (In Chinese) [Google Scholar]

- Zheng, D.; Li, Z.; Jiang, Y.; Li, R.; Wu, Y.; Tu, Y.; Cheng, X.; Fu, P.; Peng, L.; Tang, H. Effect of multiple thermal cycles on the microstructure evolution of GA151K alloy fabricated by laser-directed energy deposition. Addit. Manuf. 2022, 57, 102957. [Google Scholar] [CrossRef]

- Manonukul, A.; Dunne, F. High–and low–cycle fatigue crack initiation using polycrystal plasticity. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2004, 460, 1881–1903. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, Y.; Ma, X.; Qian, G.; Zhang, J.; Yang, Z.; Berto, F. Very-high-cycle fatigue behavior of AlSi10Mg manufactured by selected laser melting: Crystal plasticity modeling. Int. J. Fatigue 2021, 145, 106109. [Google Scholar] [CrossRef]

- Luo, Z.; Li, D.; Ojha, A.; Lai, W.-J.; Engler-Pinto, C.; Li, Z.; Peng, Y. Prediction of high cycle fatigue strength for additive manufactured metals by defects incorporated crystal plasticity modeling. Mater. Sci. Eng. A 2023, 870, 144832. [Google Scholar] [CrossRef]

- Cao, M.; Liu, Y.; Dunne, F.P.E. A crystal plasticity approach to understand fatigue response with respect to pores in additive manufactured aluminium alloys. Int. J. Fatigue 2022, 161, 106917. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, S.; Withers, P.; Zhang, J.; Bao, H.; Fu, Y.; Kang, G. The effect of manufacturing defects on the fatigue life of selective laser melted Ti-6Al-4V structures. Mater. Design 2020, 192, 108708. [Google Scholar] [CrossRef]

- Prithivirajan, V.; Sangid, M.D. The role of defects and critical pore size analysis in the fatigue response of additively manufactured IN718 via crystal plasticity. Mater. Design 2018, 150, 139–153. [Google Scholar] [CrossRef]

- Xu, Z.W.; Wang, Q.; Wang, X.S.; Tan, C.H.; Guo, M.H.; Gao, P.B. High cycle fatigue performance of AlSi10mg alloy produced by selective laser melting. Mech. Mater. 2020, 148, 103499. [Google Scholar] [CrossRef]

- Qin, Z.; Li, B.; Huang, X.; Zhang, H.; Chen, R.; Adeel, M.; Xue, H. The effect of laser shock peening on surface integrity and high and very high cycle fatigue properties of 2024-T351 aluminum alloy. Opt. Laser Technol. 2022, 149, 107897. [Google Scholar] [CrossRef]

- Li, B.; Qin, Z.; Zhang, H.; Xue, H. The effects of laser peening treatment on the very high cycle fatigue properties for AA2024-T351 alloy using a crystal plasticity framework. Eng. Fract. Mech. 2022, 275, 108840. [Google Scholar] [CrossRef]

- Kapoor, K.; Yoo, Y.S.J.; Book, T.A.; Kacher, J.P.; Sangid, M.D. Incorporating grain-level residual stresses and validating a crystal plasticity model of a two-phase Ti-6Al-4 V alloy produced via additive manufacturing. J. Mech. Phys. Solids 2018, 121, 447–462. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).