Review on Design, Characterization, and Prediction of Performance for Asphalt Materials and Asphalt Pavement Using Multi-Scale Numerical Simulation

Abstract

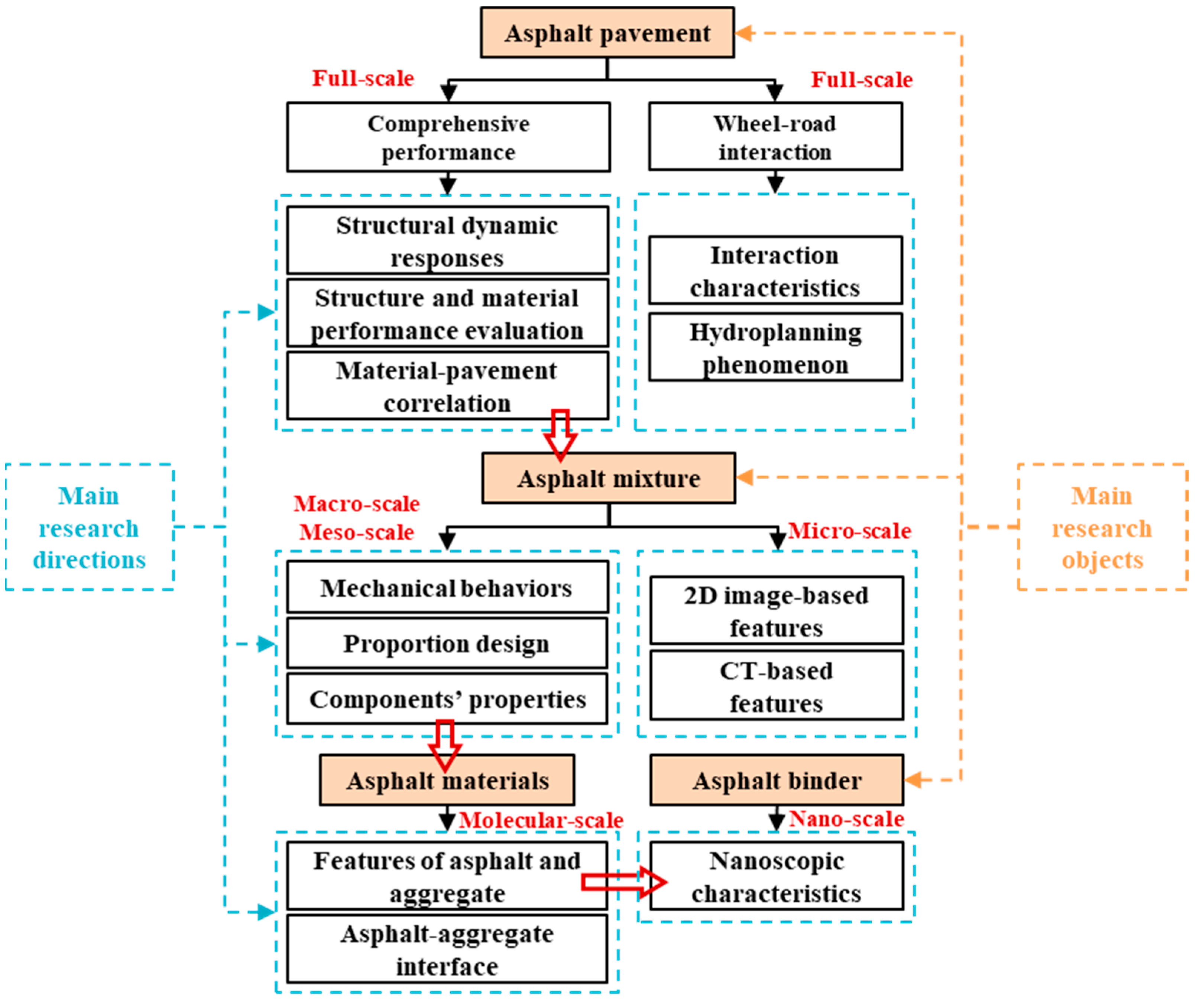

1. Introduction

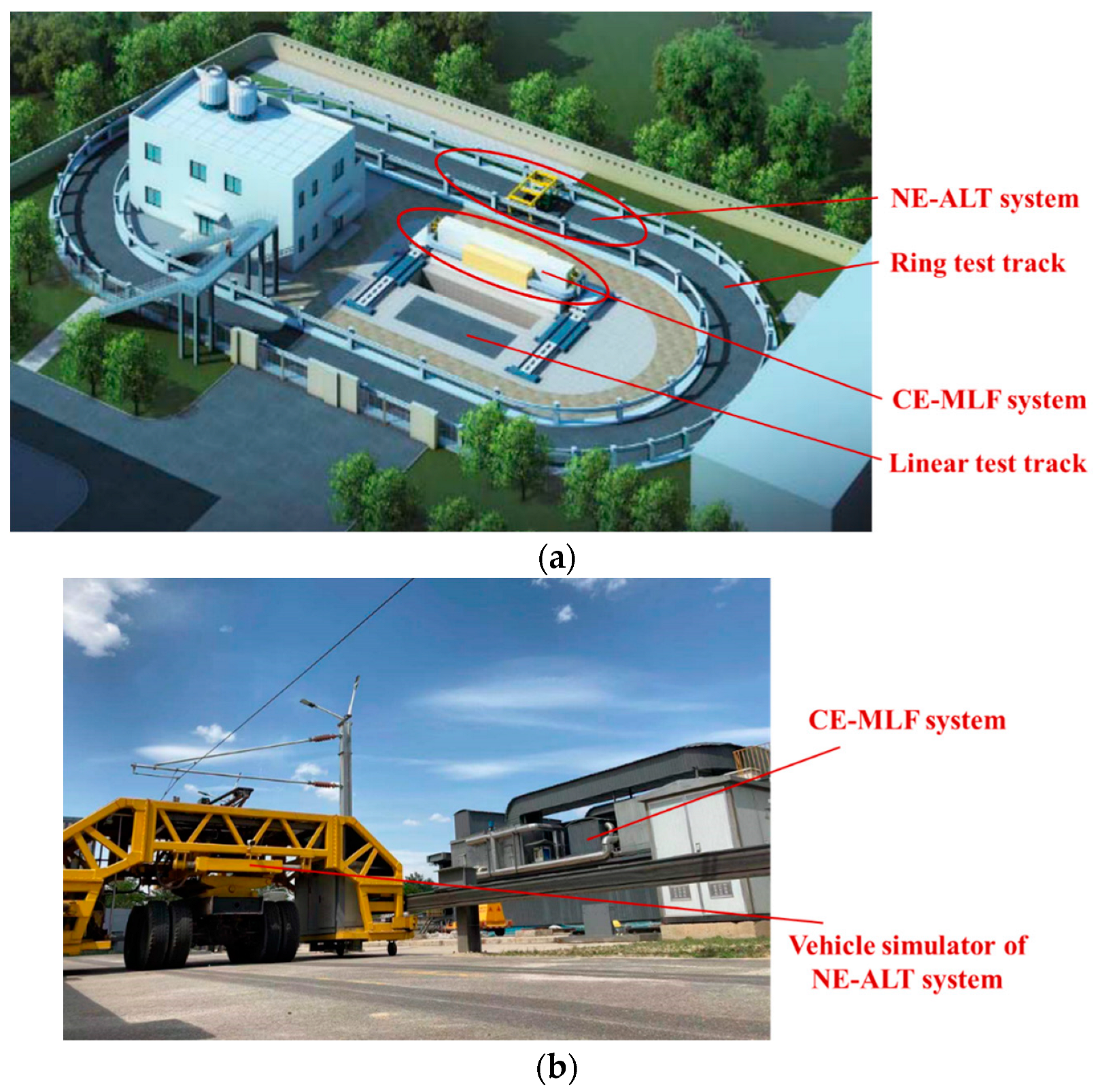

2. Full-Scale Performance Modeling on Asphalt Pavement

2.1. Comprehensive Performance of Asphalt Pavement

2.1.1. Structural Dynamic Response Analysis

2.1.2. Pavement Structure and Material Evaluation

2.1.3. Correlating Asphalt Materials’ Properties to Pavement Performance

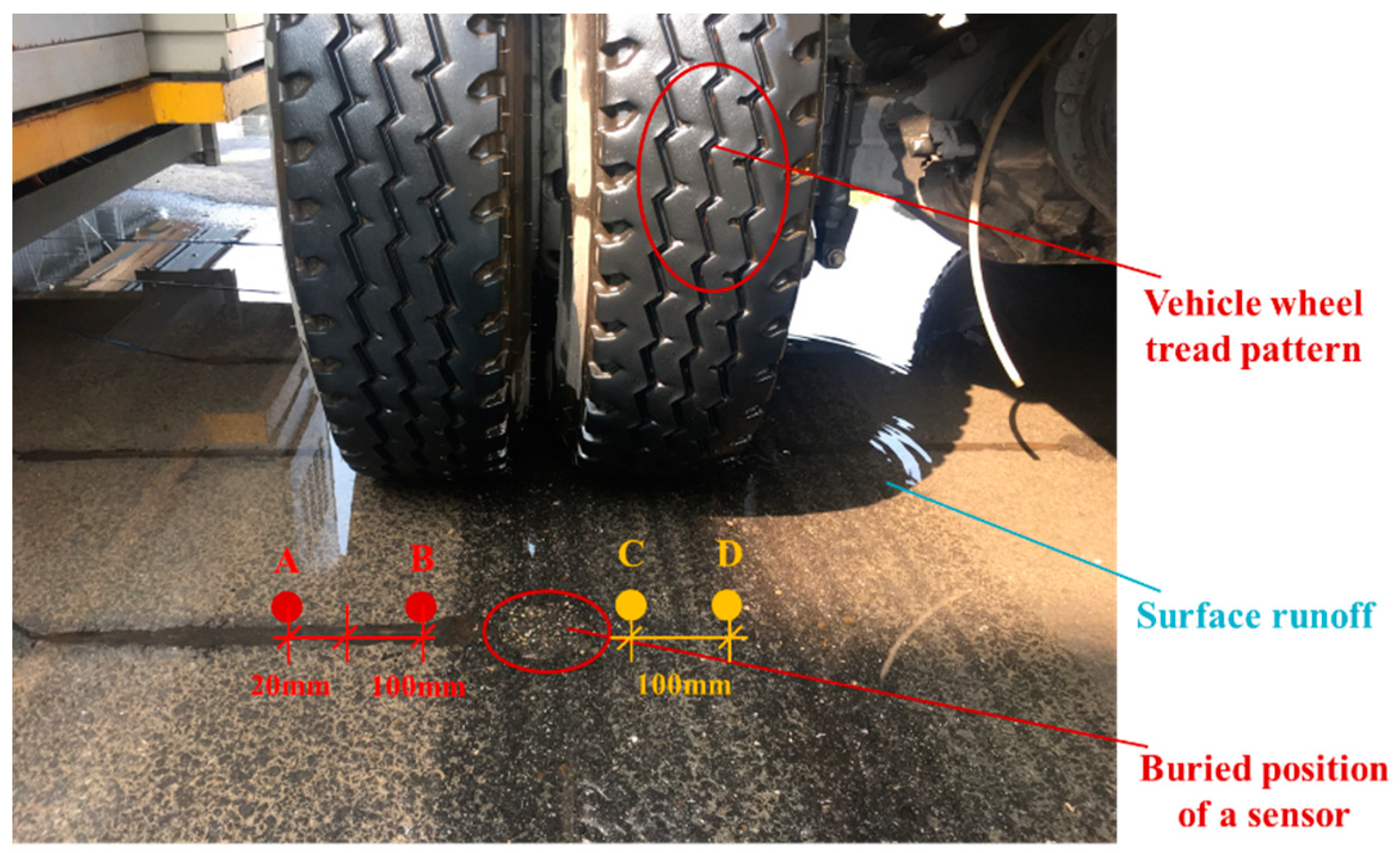

2.2. Interaction between Vehicle Wheel and Road Surface

2.2.1. Wheel–Pavement Interaction

2.2.2. Hydroplaning Phenomenon

3. Macro- and Mesoscale Properties Modeling on the Asphalt Mixture and Its Design

3.1. Mechanical Behaviors Evaluation on the Asphalt Mixture

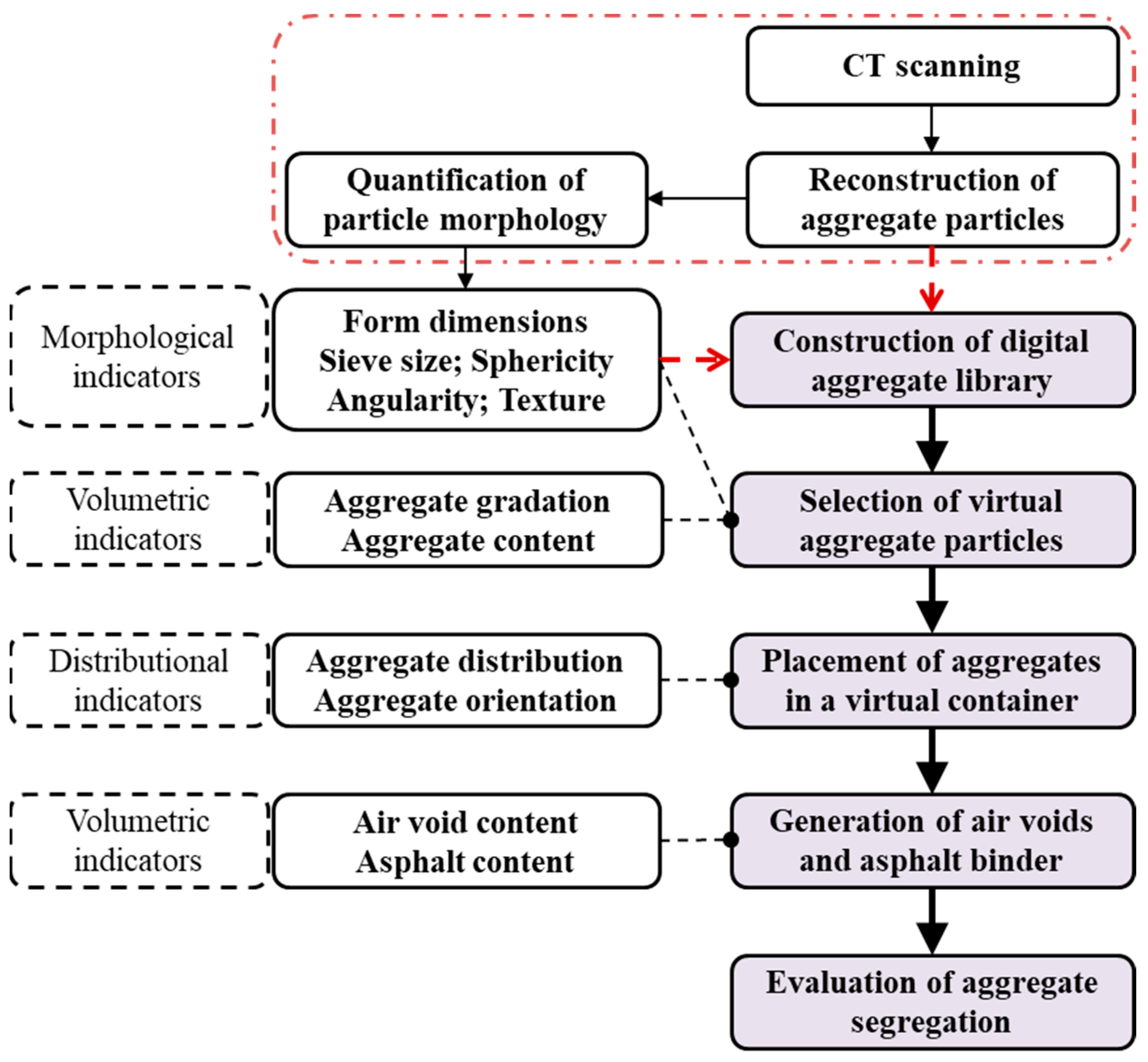

3.2. Proportion Design of the Asphalt Mixture

3.3. Components’ Properties of the Asphalt Mixture

4. Microscale Features Modeling on the Asphalt Mixture

4.1. Performance Modeling Based on a Two-Dimensional Cross-Section of the Asphalt Mixture

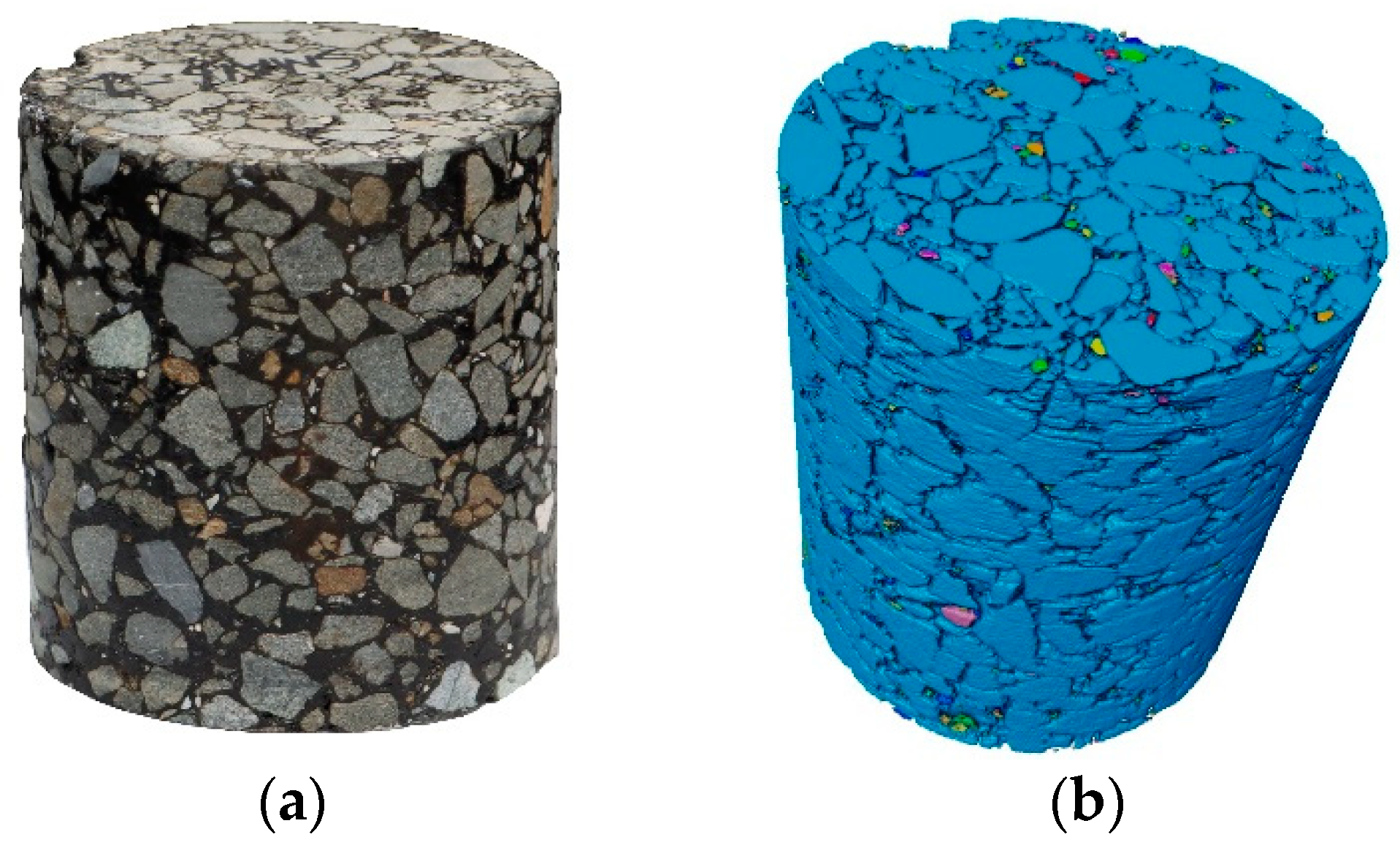

4.2. Performance Modeling of the Asphalt Mixture Based on X-ray Computed Tomography Technology

5. Molecular-Scale Behavior Modeling on Asphalt Materials

5.1. MD Simulation on the Asphalt Binder and Mineral Aggregate

5.2. MD Simulation on Features of the Asphalt–Aggregate Interface

6. Nanoscale Characteristics Modeling on the Asphalt Binder

7. Discussion

8. Conclusions and Outlook

- (a)

- Investigating a certain failure mechanism of asphalt materials using multi-scale numerical simulation systematically.

- (b)

- Taking multiple damage mechanisms such as aging, rutting, and moisture damage into account simultaneously to simulate the complex deterioration of asphalt material properties.

- (c)

- Conducting more field tests to support the research on numerical simulation of the wheel–pavement–water interaction.

- (d)

- Constructing databases concerning asphalt material properties and pavement structural behaviors for the purpose of numerically analyzing material design and performance prediction from the concept of material genome.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shanbara, H.; Ruddock, F.; Atherton, W. Predicting the rutting behaviour of natural fibre-reinforced cold mix asphalt using the finite element method. Constr. Build. Mater. 2018, 167, 907–917. [Google Scholar] [CrossRef]

- Bratu, C.; Ciobanu, V.; Derczeni, R.; Salca, E. Study on the forest road pavements reinforced with geogrids by using the 2D FEM method. Road Mater. Pavement Des. 2020, 21, 1738–1752. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, R.; Gao, L.; Wang, J.; Wang, X.; Yuan, X. Study on dynamic response characteristics of saturated asphalt pavement under multi-field coupling. Materials 2019, 12, 959. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, A.; Mora, J.; Espinosa, L. Quantification of stone-on-stone contact in permeable friction course mixtures based on image analysis. Constr. Build. Mater. 2018, 165, 462–471. [Google Scholar] [CrossRef]

- Zadshir, M.; Oldham, D.; Hosseinnezhad, S.; Fini, E. Investigating bio-rejuvenation mechanisms in asphalt binder via laboratory experiments and molecular dynamics simulation. Constr. Build. Mater. 2018, 190, 392–402. [Google Scholar] [CrossRef]

- Kazmee, H.; Tutumluer, E.; Beshears, S. Using accelerated pavement testing to evaluate reclaimed asphalt pavement materials for pavement unbound granular layers. J. Mater. Civ. Eng. 2017, 29, 04016205. [Google Scholar] [CrossRef]

- Król, J.; Khan, R.; Collop, A. The study of the effect of internal structure on permeability of porous asphalt. Road Mater. Pavement Des. 2017, 19, 935–951. [Google Scholar] [CrossRef]

- Yaphary, Y.; He, M.; Lu, G.; Zou, F.; Liu, P.; Tsang, D.; Leng, Z. Experiment and multiscale molecular simulations on the Cu absorption by biochar-modified asphalt: An insight into removal capability and mechanism of heavy metals from stormwater runoff. Chem. Eng. J. 2023, 462, 142205. [Google Scholar] [CrossRef]

- Leon, L.; Gay, D. Gene expression programming for evaluation of aggregate angularity effects on permanent deformation of asphalt mixtures. Constr. Build. Mater. 2019, 211, 470–478. [Google Scholar] [CrossRef]

- Maia, R.; Costa, S.; Cunto, F.; Branco, V. Relating weather conditions, drivers′ behavior, and tire-pavement friction to the analysis of microscopic simulated vehicular conflicts. J. Transp. Eng. Part B Pavements 2021, 147, 04021037. [Google Scholar] [CrossRef]

- Fang, M.; Park, D.; Singuranayo, J.; Chen, H.; Li, Y. Aggregate gradation theory, design and its impact on asphalt pavement performance: A review. Int. J. Pavement Eng. 2019, 20, 1408–1424. [Google Scholar] [CrossRef]

- Schuck, B.; Teutsch, T.; Alber, S.; Ressel, W.; Steeb, H.; Ruf, M. Study of air void topology of asphalt with focus on air void constrictions—A review and research approach. Road Mater. Pavement Des. 2021, 22 (Suppl. S1), S425–S443. [Google Scholar] [CrossRef]

- Plessis, A.; Boshoff, W. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Wang, H.; Ding, H.; Feng, B.; Shao, L.; Qu, X.; You, Z. Advances on molecular simulation technique in asphalt mixture. J. Traffic Transp. Eng. 2020, 20, 1–14. [Google Scholar]

- Chen, Z.; Pei, J.; Li, R.; Xiao, F. Performance characteristics of asphalt materials based on molecular dynamics simulation—A review. Constr. Build. Mater. 2018, 189, 695–710. [Google Scholar] [CrossRef]

- Tan, Y.; Li, G.; Shan, L.; Lv, H.; Meng, A. Research progress of bitumen microstructures and components. J. Traffic Transp. Eng. 2020, 20, 1–17. [Google Scholar]

- Han, Z.; Cong, P.; Qu, J. Microscopic experimental and numerical research on rejuvenators: A review. J. Traffic Transp. Eng. (Eng. Ed.) 2022, 9, 180–207. [Google Scholar] [CrossRef]

- Dhakal, N.; Elseifi, M.; Al-Qadi, I.; Rupnow, T. Effect of pavement responses on fatigue cracking and cement-treated reflective cracking failure mechanisms. J. Transp. Eng. Part B Pavements 2021, 147, 04021056. [Google Scholar] [CrossRef]

- Assogba, O.; Tan, Y.; Zhou, X.; Zhang, C.; Anato, J. Numerical investigation of the mechanical response of semi-rigid base asphalt pavement under traffic load and nonlinear temperature gradient effect. Constr. Build. Mater. 2020, 235, 117406. [Google Scholar] [CrossRef]

- Estaji, M.; Coleri, E.; Harvey, J.; Butt, A. Predicting excess vehicle fuel use due to pavement structural response using field test results and finite element modelling. Int. J. Pavement Eng. 2021, 22, 973–983. [Google Scholar] [CrossRef]

- Saliko, D.; Erlingsson, S. Damage investigation of thin flexible pavements to Longer Heavier Vehicle loading through instrumented road sections and numerical calculations. Road Mater. Pavement Des. 2021, 22 (Suppl. S1), S575–S591. [Google Scholar] [CrossRef]

- Sok, T.; Kim, Y.; Lee, S. Numerical evaluation of built-in temperature distribution effects on stress development in concrete pavements. Road Mater. Pavement Des. 2021, 22, 871–893. [Google Scholar] [CrossRef]

- Okte, E.; Al-Qadi, I. Prediction of flexible pavement 3-D finite element responses using Bayesian neural networks. Int. J. Pavement Eng. 2022, 23, 5066–5076. [Google Scholar] [CrossRef]

- Onur, O.; Hasan, Y.; Nilufer, O.; Turan, O. Evaluation of mechanical properties and structural behaviour of concrete pavements produced with virgin and recycled aggregates: An experimental and numerical study. Int. J. Pavement Eng. 2022, 23, 5239–5253. [Google Scholar]

- Kabir, R.; Hiller, J. Numerical analyses of rigid and flexible pavements responses under heavy vehicles’ loading. Road Mater. Pavement Des. 2021, 22, 333–356. [Google Scholar] [CrossRef]

- Gabriel, B.; Mansour, E.; Sebaaly, P.; Ji, R.; Garg, N. Instrumented flexible pavement responses under aircraft loading. Int. J. Pavement Eng. 2021, 22, 1213–1225. [Google Scholar]

- Yang, Z.; Wang, Z.; Chen, E.; Si, C.; Wang, X. Dynamic response analysis of vehicle-load on asphalt pavement based on discrete element method. China J. Highw. Transp. 2019, 32, 51–60. [Google Scholar]

- Neves, J.; Freire, A.; Qamhia, I.; Al-Qadi, I.; Tutumluer, E. Full-scale accelerated pavement testing and instrumentation. In Advances on Testing and Experimentation in Civil Engineering; Chastre, C., Neves, J., Ribeiro, D., Neves, M.G., Faria, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2023; pp. 163–186. [Google Scholar]

- Plessis, L.; Ullo, A.; Harvey, J.; Coetzee, N. Accelerated pavement testing efforts using the heavy vehicle simulator. Int. J. Pavement Res. Technol. 2018, 11, 327–338. [Google Scholar] [CrossRef]

- National Center for Materials Service Safety, University of Science and Technology Beijing. Special-Regional Environment Test Facility. 2023. Available online: http://en.ncms.ustb.edu.cn/Plantconstruction/samtffse/ (accessed on 16 January 2023).

- Wang, W.; Yan, G.; Zhao, K.; Wang, L. Numerical simulation and experimental measurements of dynamic responses of asphalt pavement in dry and saturated conditions under full-scale accelerated loading. Appl. Sci. 2022, 12, 12291. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, K.; Li, J.; Luo, R.; Wang, L. Characterization of dynamic response of asphalt pavement in dry and saturated conditions using the full-scale accelerated loading test. Constr. Build. Mater. 2021, 312, 125355. [Google Scholar] [CrossRef]

- Peng, Y.; Xia, S.; Xu, Y.; Lu, X.; Li, Y. Mechanical response of asphalt surfaces under moving traffic loads using 3D discrete element method. J. Transp. Eng. Part B Pavements 2022, 148, 04022006. [Google Scholar] [CrossRef]

- Xie, S.; Yi, J.; Wang, H.; Yang, S.; Xu, M.; Feng, D. Mechanical response analysis of transverse crack treatment of asphalt pavement based on DEM. Int. J. Pavement Eng. 2022, 23, 2206–2226. [Google Scholar] [CrossRef]

- Montoya, A.; Jagtap, P.; Papagiannakis, A.; Dessouky, S.; Walubita, L. Numerical study on design and installation of energy-harvesting modules embedded within a flexible pavement structure. J. Transp. Eng. Part B Pavements 2020, 146, 04020066. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L.; Hou, Y.; Zhang, W.; Zhang, Y. A prototype IOT based wireless sensor network for traffic information monitoring. Int. J. Pavement Res. Technol. 2018, 11, 146–152. [Google Scholar] [CrossRef]

- Zhao, H.; Qin, L.; Ling, J. Synergistic performance of piezoelectric transducers and asphalt pavement. Int. J. Pavement Res. Technol. 2018, 11, 381–387. [Google Scholar] [CrossRef]

- Shi, B.; Shen, S.; Liu, L.; Wang, X. Estimation of vehicle speed from pavement stress responses using wireless sensors. J. Transp. Eng. Part B Pavements 2021, 147, 04021028. [Google Scholar] [CrossRef]

- Mabrouk, G.; Elbagalati, O.; Dessouky, S.; Fuentes, L.; Walubita, L. 3D-finite element pavement structural model for using with traffic speed deflectometers. Int. J. Pavement Eng. 2022, 23, 4065–4079. [Google Scholar] [CrossRef]

- Yan, G.; Wang, L.; Ye, Z.; Wang, W. Effects of crack damage on acceleration response of asphalt pavement via numerical analysis. J. Mater. Civ. Eng. 2020, 32, 04020163. [Google Scholar] [CrossRef]

- Thulasibai, A.; Velayudhan, S. Numerical modeling and optimization of the geometric properties influencing the deflection behavior of interlocking concrete block pavement. J. Transp. Eng. Part B Pavements 2022, 148, 04022036. [Google Scholar] [CrossRef]

- Thulasibai, A.; Velayudhan, S.; Pathath, M.; Lekshmipathy, J.; Visvanathan, A. Experimental and numerical evaluation of the parameters influencing the shear-stress behavior of interlocking paver blocks-bedding sand interface using large-scale direct shear test. J. Mater. Civ. Eng. 2021, 33, 04021104. [Google Scholar] [CrossRef]

- Matini, N.; Qiao, Y.; Sias, J. Development of Time-Depth-Damage Functions for Flooded Flexible Pavements. J. Transp. Eng. Part B Pavements 2022, 148, 04022011. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; White, G.; Nishizawa, T.; Igarashi, T.; Nawa, T.; Mao, J. State-of-the-art of interlocking concrete block pavement technology in Japan as a post-modern pavement. Constr. Build. Mater. 2019, 200, 713–755. [Google Scholar] [CrossRef]

- Sun, L.; Wang, G.; Zhang, H.; Liu, L. Initiation and propagation of top-down cracking in asphalt pavement. Appl. Sci. 2018, 8, 774. [Google Scholar] [CrossRef]

- Lu, G.; Liu, P.; Törzs, T.; Wang, D.; Osser, M.; Grabe, J. Numerical analysis for the influence of saturation on the base course of permeable pavement with a novel polyurethane binder. Constr. Build. Mater. 2020, 240, 117930. [Google Scholar] [CrossRef]

- Lu, G.; Wang, H.; Zhang, Y.; Liu, P.; Wang, D.; Oeser, M.; Grabe, J. The hydro-mechanical interaction in novel polyurethane-bound pervious pavement by considering the saturation states in unbound granular base course. Int. J. Pavement Eng. 2022, 23, 3677–3690. [Google Scholar] [CrossRef]

- Caro, S.; Manrique-Sanchez, L.; Kim, Y. Computational evaluation of long-term raveling susceptibility of Permeable Friction Courses (PFC). Constr. Build. Mater. 2021, 291, 123306. [Google Scholar] [CrossRef]

- Walubita, L.; Ling, M.; Pianeta, L.; Fuentes, L.; Komba, J.; Mabrouk, G. Correlating the asphalt-binder MSCR test results to the HMA HWTT and field rutting performance. J. Transp. Eng. Part B Pavements 2022, 148, 04022047. [Google Scholar] [CrossRef]

- Walubita, L.; Fuentes, L.; Prakoso, A.; Pianeta, L.; Komba, J.; Naik, B. Correlating the HWTT laboratory test data to field rutting performance of in-service highway sections. Constr. Build. Mater. 2020, 236, 117552. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, X.; Shen, S.; Mohammad, L.; Cui, B.; Wu, S.; Khan, A. Investigation of field rut depth of asphalt pavements using hamburg wheel tracking test. J. Transp. Eng. Part B Pavements 2021, 147, 04020091. [Google Scholar] [CrossRef]

- Loizos, A.; Gkyrtis, K.; Plati, C. Modelling Asphalt Pavement Responses Based on Field and Laboratory Data. In Accelerated Pavement Testing to Transport Infrastructure Innovation. Lecture Notes in Civil Engineering; Chabot, A., Hornych, P., Harvey, J., Loria-Salazar, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 96, pp. 438–447. [Google Scholar]

- Islam, M.; Vallejo, M.; Tarefder, R. Crack propagation in hot mix asphalt overlay using extended finite-element model. J. Mater. Civ. Eng. 2017, 29, 04016296. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Z.; Gong, H.; Zhou, C.; Chen, J.; Huang, B. 3D multiscale modeling of asphalt pavement responses under coupled temperature–stress fields. J. Eng. Mech. 2022, 148, 04022010. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Maupin, G. An inverse approach for evaluating the properties of asphalt concrete using the APA test. Road Mater. Pavement Des. 2008, 9 (Suppl. S1), 201–218. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L.; Xiong, H. Evaluation of pavement response and performance under different scales of APT facilities. Road Mater. Pavement Des. 2017, 18 (Suppl. S3), 159–169. [Google Scholar] [CrossRef]

- Khan, Z.; Tarefder, R. A procedure to convert field sensor data for finite element model inputs and its validation. Constr. Build. Mater. 2019, 212, 442–455. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, H.; Qian, J.; Zhou, H. Evaluation of tire rolling resistance from tire-deformable pavement interaction modeling. J. Transp. Eng. Part B Pavements 2021, 147, 04021041. [Google Scholar] [CrossRef]

- Bai, T.; Cheng, Z.; Hu, X.; Fuentes, L.; Walubita, L. Viscoelastic modelling of an asphalt pavement based on actual tire-pavement contact pressure. Road Mater. Pavement Des. 2021, 22, 2458–2477. [Google Scholar] [CrossRef]

- Stache, J.; Robinson, W. Effects of nonuniform tire contact pressures on near-surface pavement response. J. Transp. Eng. Part B Pavements 2022, 148, 04021077. [Google Scholar] [CrossRef]

- Zheng, B.; Chen, J.; Zhao, R.; Tang, J.; Tian, R.; Zhu, S.; Huang, X. Analysis of contact behaviour on patterned tire-asphalt pavement with 3-D FEM contact model. Int. J. Pavement Eng. 2022, 23, 171–186. [Google Scholar] [CrossRef]

- Wang, T.; Dong, Z.; Xu, K.; Ullah, S.; Wang, D.; Li, Y. Numerical simulation of mechanical response analysis of asphalt pavement under dynamic loads with non-uniform tire-pavement contact stresses. Constr. Build. Mater. 2022, 361, 129711. [Google Scholar] [CrossRef]

- Liu, X.; Al-Qadi, I. Three-dimensional tire-pavement contact stresses prediction by deep learning approach. Int. J. Pavement Eng. 2022, 23, 4991–5002. [Google Scholar] [CrossRef]

- Behroozinia, P.; Khaleghian, S.; Taheri, S.; Mirzaeifar, R. An investigation towards intelligent tyres using finite element analysis. Int. J. Pavement Eng. 2020, 21, 311–321. [Google Scholar] [CrossRef]

- Said, I.; Hernandez, J.; Kang, S.; Al-Qadi, I. Structural and environmental impact of new-generation wide-base tires in New Brunswick, Canada. Road Mater. Pavement Des. 2020, 21, 1968–1984. [Google Scholar] [CrossRef]

- Peng, J.; Chu, L.; Fwa, T. Determination of safe vehicle speeds on wet horizontal pavement curves. Road Mater. Pavement Des. 2021, 22, 2641–2653. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, H. Computational investigation of hydroplaning risk of wide-base truck tyres on roadway. Int. J. Pavement Eng. 2020, 21, 122–133. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, M.; Bai, S.; Zhao, H. A 3D virtual prototype-finite element co-simulation of aircraft hydroplaning on a wet rough runway. Int. J. Pavement Eng. 2022, 23, 2577–2592. [Google Scholar] [CrossRef]

- Gerthoffert, J.; Cerezo, V.; Thiery, M.; Bouteldja, M.; Do, M. A brush-based approach for modelling runway friction assessment device. Int. J. Pavement Eng. 2020, 21, 1694–1702. [Google Scholar] [CrossRef]

- Schulz, H.; Curry, J.; Simões, A. Water films and hydroplaning on highways: Hydrodynamic aspects. J. Transp. Eng. Part B Pavements 2021, 147, 04021053. [Google Scholar] [CrossRef]

- Luo, J.; Liu, J.; Wang, Y. Validation test on pavement water film depth prediction model. China J. Highw. Transp. 2015, 28, 57–63. [Google Scholar]

- Luo, W.; Li, L.; Wang, K.; Wei, C. Surface drainage evaluation of asphalt pavement using a new analytical water film depth model. Road Mater. Pavement Des. 2020, 21, 1985–2004. [Google Scholar] [CrossRef]

- Luo, W.; Li, L. Estimation of water film depth for rutting pavement using IMU and 3D laser imaging data. Int. J. Pavement Eng. 2021, 22, 1334–1349. [Google Scholar] [CrossRef]

- Geng, Y.; Chen, X.; Chen, Y.; Ma, Y.; Huang, X. Runoff characteristics for straightline segment asphalt pavement based on two-dimensional shallow water equations. J. Traffic Transp. Eng. 2019, 19, 9–16. [Google Scholar]

- Poshtmesari, A.; Nejad, F. Analyzing moisture susceptibility of hot-mix asphalt based on tensile strength ratio, coating ratio, and thermodynamic parameters. J. Mater. Civ. Eng. 2022, 34, 04022247. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, J.; Zhou, L.; Ni, F. Improving the calculation accuracy of FEM for asphalt mixtures in simulation of SCB test considering the mesostructure characteristics. Int. J. Pavement Eng. 2022, 23, 80–94. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, L.; Jiang, J.; Ni, F. Accuracy improvement for two-dimensional finite-element modeling while considering asphalt mixture meso-structure characteristics in indirect tensile test simulation. J. Mater. Civ. Eng. 2020, 32, 04020275. [Google Scholar] [CrossRef]

- Song, W.; Deng, Z.; Wu, H.; Zhan, Y. Extended finite element modeling of hot mix asphalt based on the semi-circular bending test. Constr. Build. Mater. 2022, 340, 127462. [Google Scholar] [CrossRef]

- Chang, M.; Liu, Z.; Zhang, J.; Zhang, Y.; Yang, B. Distribution characteristics of force chains in asphalt mixtures based on indirect tensile pattern. China J. Highw. Transp. 2022, 35, 224–234. [Google Scholar]

- Liu, P.; Lu, G.; Yang, X.; Jin, C.; Leischner, S.; Oeser, M. Influence of different fillers on mechanical properties of porous asphalt mixtures using microstructural finite-element analysis. J. Transp. Eng. Part B Pavements 2021, 147, 04021004. [Google Scholar] [CrossRef]

- Bai, X.; Wang, L. Study on mesoscopic model of low-temperature cracking of steel slag asphalt mixture based on random aggregate. Constr. Build. Mater. 2023, 364, 129974. [Google Scholar] [CrossRef]

- Nian, T.; Ge, J.; Li, P.; Wang, M.; Mao, Y. Improved discrete element numerical simulation and experiment on low-temperature anti-cracking performance of asphalt mixture based on PFC2D. Constr. Build. Mater. 2021, 283, 122792. [Google Scholar] [CrossRef]

- Teng, G.; Zheng, C.; Chen, X.; Lan, X.; Zhu, Y.; Shan, C. Numerical fracture investigation of single-edge notched asphalt concrete beam based on random heterogeneous FEM model. Constr. Build. Mater. 2021, 304, 124581. [Google Scholar] [CrossRef]

- Juliana, M.; Nilthson, N.; Carlos, M.; Celso, R. Modeling of asphalt concrete fracture tests with the discrete-element method. J. Mater. Civ. Eng. 2020, 32, 04020228. [Google Scholar]

- Cezary, S.; Łukasz, S.; Marcin, S.; Jarosław, G. The use of a two-phase Monte Carlo material model to reflect the dispersion of asphalt concrete fracture parameters. Theor. Appl. Fract. Mech. 2022, 119, 103326. [Google Scholar]

- Sanfilippo, D.; Garcia-Hernández, A.; Alexiadis, A.; Ghiassi, B. Effect of freeze–thaw cycles on the void topologies and mechanical properties of asphalt. Constr. Build. Mater. 2022, 344, 128085. [Google Scholar] [CrossRef]

- Erarslan, N. Investigation of the tensile-shear failure of asphalt concrete base (ACB) construction materials using a non-linear cohesive crack model and critical crack threshold analysis. Constr. Build. Mater. 2023, 364, 129901. [Google Scholar] [CrossRef]

- Quezada, J.; Chazallon, C. Discrete element modelling of hot mix asphalt complex modulus using realistic aggregate shapes. Road Mater. Pavement Des. 2022, 23 (Suppl. S1), 178–195. [Google Scholar] [CrossRef]

- Behnia, B.; Buttlar, W.; Reis, H. Evaluation of low-temperature cracking performance of asphalt pavements using acoustic emission: A review. Appl. Sci. 2018, 8, 306. [Google Scholar] [CrossRef]

- Sudarsanan, N.; Kim, Y. A critical review of the fatigue life prediction of asphalt mixtures and pavements. J. Traffic Transp. Eng. (Eng. Ed.) 2022, 9, 808–835. [Google Scholar] [CrossRef]

- Benaboud, S.; Takarli, M.; Pouteau, B.; Allou, F.; Dubois, F.; Hornych, P.; Nguyen, M. Fatigue damage monitoring and analysis of aged asphalt concrete using acoustic emission technique. Road Mater. Pavement Des. 2021, 22 (Suppl. S1), S592–S603. [Google Scholar] [CrossRef]

- Syrine, C.; Mondher, N.; Daniel, P.; Lotfi, J. Numerical investigation to predict fatigue damage response in high-modulus asphalt mixture: A coupled damage-visco-elastoplastic approach. Int. J. Pavement Eng. 2022, 23, 4344–4356. [Google Scholar] [CrossRef]

- Bertoldo, C.; Gorski, R.; Gonçalves, R. Evaluation of elastic anisotropy of concrete using ultrasound wave propagation. J. Mater. Civ. Eng. 2020, 32, 04020056. [Google Scholar] [CrossRef]

- Taghipoor, M.; Tahami, A.; Forsat, M. Numerical and laboratory investigation of fatigue prediction models of asphalt containing glass wastes. Int. Fatigue 2020, 140, 105819. [Google Scholar] [CrossRef]

- Papagiannakis, A.; Zelelew, H.; Mahmoud, E. Simulation of asphalt concrete plastic deformation behavior. J. Mater. Civ. Eng. 2018, 30, 04018025. [Google Scholar] [CrossRef]

- Peng, Y.; Gao, H.; Lu, X.; Sun, L. Micromechanical discrete element modeling of asphalt mixture shear fatigue performance. J. Mater. Civ. Eng. 2020, 32, 04020183. [Google Scholar] [CrossRef]

- Ge, H.; Quezada, J.; Houerou, V.; Chazallon, C. Three-dimensional simulation of asphalt mixture incorporating aggregate size and morphology distribution based on contact dynamics method. Constr. Build. Mater. 2021, 302, 124124. [Google Scholar] [CrossRef]

- Yuan, G.; Li, X.; Hao, P.; Li, D.; Pan, J.; Li, A. Application of flat-joint contact model for uniaxial compression simulation of large stone porous asphalt mixes. Constr. Build. Mater. 2020, 238, 117695. [Google Scholar] [CrossRef]

- Ji, J.; Wang, Z.; Yao, H.; Wang, D.; Zhang, R.; Diab, A.; Dai, Q. A numerical study on rutting behaviour of direct coal liquefaction residue modified asphalt mixture. Road Mater. Pavement Des. 2021, 22, 1454–1468. [Google Scholar] [CrossRef]

- Sadeghnejad, M.; Arabani, M.; Taghipoor, M. Predicting the impact of temperature and stress on the glasphalt mixtures’ rutting behavior. Int. J. Pavement Res. Technol. 2018, 11, 300–310. [Google Scholar] [CrossRef]

- Behera, R.; Das, N.; Nanthagopalan, P. Development of simple and structured model for packing-density assessment of gap-graded coarse aggregates in concrete. J. Mater. Civ. Eng. 2022, 34, 04022182. [Google Scholar] [CrossRef]

- Thilakarathna, P.; Baduge, S.; Mendis, P.; Chandrathilaka, E.; Vimonsatit, V.; Lee, H. Aggregate geometry generation method using a structured light 3D scanner, spherical harmonics-based geometry reconstruction, and placing algorithms for mesoscale modeling of concrete. J. Mater. Civ. Eng. 2021, 33, 04021198. [Google Scholar] [CrossRef]

- Kusumawardani, D.; Yiik, W. Evaluation of aggregate gradation on aggregate packing in porous asphalt mixture (PAM) by 3D numerical modelling and laboratory measurements. Constr. Build. Mater. 2020, 246, 118414. [Google Scholar] [CrossRef]

- Pouranian, M.; Haddock, J. A new framework for understanding aggregate structure in asphalt mixtures. Int. J. Pavement Eng. 2021, 22, 1090–1106. [Google Scholar] [CrossRef]

- Jin, C.; Zou, F.; Yang, X.; Liu, K. 3-D virtual design and microstructural modeling of asphalt mixture based on a digital aggregate library. Comput. Struct. 2021, 242, 106378. [Google Scholar] [CrossRef]

- Manrique-Sanchez, L.; Caro, S.; Estrada, N.; Castillo, D.; Alvarez, A. Random generation of 2D PFC microstructures through DEM gravimetric methods. Road Mater. Pavement Des. 2022, 23, 925–941. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L. Computer-aided procedure for analysis of effect of gradation and compaction temperature in asphalt mix design by using DEM. J. Transp. Eng. Part B Pavements 2020, 146, 04020010. [Google Scholar] [CrossRef]

- Ren, J.; Xu, Y.; Huang, J.; Wang, Y.; Jia, Z. Gradation optimization and strength mechanism of aggregate structure considering macroscopic and mesoscopic aggregate mechanical behaviour in porous asphalt mixture. Constr. Build. Mater. 2021, 300, 124262. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Yang, Y.; Huang, Q.; Zhang, X. Effect of curing reaction behaviors of warm mix epoxy asphalt concrete on its field compaction characteristics using discrete-element method. J. Mater. Civ. Eng. 2022, 34, 04022092. [Google Scholar] [CrossRef]

- Chang, J.; Li, J.; Hu, H.; Qian, J.; Yu, M. Numerical investigation of aggregate segregation of Superpave gyratory compaction and its influence on mechanical properties of asphalt mixtures. J. Mater. Civ. Eng. 2023, 35, 04022453. [Google Scholar] [CrossRef]

- Elio, Z.; Fakhari Tehrani, F.; Beghin, A.; Petit, C.; Absi, J.; Millien, A.; Reynaud, P. Experimental and numerical investigation on the rheological behaviour of bituminous composites via DSR testing. Road Mater. Pavement Des. 2021, 22 (Suppl. S1), S328–S344. [Google Scholar]

- Giancontieri, G.; Hargreaves, D.; Presti, D. Are we correctly measuring the rotational viscosity of heterogeneous bituminous binders? Road Mater. Pavement Des. 2020, 21 (Suppl. S1), S37–S56. [Google Scholar] [CrossRef]

- Ye, Z.; Ren, W.; Yang, H.; Miao, Y.; Sun, F.; Wang, L. An improved asphalt penetration test method. Materials 2021, 14, 147. [Google Scholar] [CrossRef]

- Wu, J.; Wang, L.; Hou, Y.; Qian, Z.; Meng, L.; Zhao, Q. Simulation on the micro-deval test for the aggregate wear properties measurement. Constr. Build. Mater. 2018, 180, 445–454. [Google Scholar] [CrossRef]

- Tan, Z.; Leng, Z.; Jiang, J.; Cao, P.; Jelagin, D.; Li, G.; Sreeram, A. Numerical study of the aggregate contact effect on the complex modulus of asphalt concrete. Mater. Des. 2022, 213, 110342. [Google Scholar] [CrossRef]

- Cheng, P.; Yi, J.; Guo, S.; Pei, Z.; Feng, D. Influence of fiber dispersion and distribution on flexural tensile properties of asphalt mixture Based on finite element simulation. Constr. Build. Mater. 2022, 352, 128939. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Jarrar, Z.; Jiang, X.; Xiao, R.; Huang, B. Quantification of asphalt mixture interlocking utilizing 2D and 3D image processing. J. Mater. Civ. Eng. 2023, 35, 04022382. [Google Scholar] [CrossRef]

- Hajikarimi, P.; Tehrani, F.; Nejad, F.; Absi, J.; Khodaii, A.; Rahi, M.; Petit, C. Mechanical behavior of polymer-modified bituminous mastics. II: Numerical approach. J. Mater. Civ. Eng. 2019, 31, 04018338. [Google Scholar] [CrossRef]

- Najmeddine, A.; Shakiba, M. Impact of void morphology on the mechanical response of time-dependent heterogeneous media: A numerical investigation. J. Mater. Civ. Eng. 2020, 32, 04020191. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, Q.; Yan, Z. Research on asphalt mixture bending test and micromechanical evolution based on 2D discrete-element method. J. Mater. Civ. Eng. 2021, 33, 04021179. [Google Scholar] [CrossRef]

- Zhang, K.; Shen, S.; Lim, J.; Muhunthan, B. Development of dynamic modulus-based mixture blending chart for asphalt mixtures with reclaimed asphalt pavement. J. Mater. Civ. Eng. 2019, 31, 04018382. [Google Scholar] [CrossRef]

- Liu, P.; Xu, H.; Wang, D.; Wang, C.; Schulze, C.; Oeser, M. Comparison of mechanical responses of asphalt mixtures manufactured by different compaction methods. Constr. Build. Mater. 2018, 162, 765–780. [Google Scholar] [CrossRef]

- Tielmann, M.; Hill, T. Air void analyses on asphalt specimens using plane section preparation and image analysis. J. Mater. Civ. Eng. 2018, 30, 04018189. [Google Scholar] [CrossRef]

- Sahdeo, S.; Ransinchung, G.; Singh, A. Microstructural and pore skeleton characteristics of pervious concrete containing RAP aggregates using X-ray microcomputed tomography and scanning electron microscope. J. Transp. Eng. Part B Pavements 2021, 147, 04021064. [Google Scholar] [CrossRef]

- Chandrappa, A.; Biligiri, K. Pore structure characterization of pervious concrete using X-ray microcomputed tomography. J. Mater. Civ. Eng. 2018, 30, 04018108. [Google Scholar] [CrossRef]

- Alexis, E.; Souza, T.; Aragão, F.; Braz, D.; Pereira, A.; Nogueira, L. Determination of the air void content of asphalt concrete mixtures using artificial intelligence techniques to segment micro-CT images. Int. J. Pavement Eng. 2022, 23, 3973–3982. [Google Scholar]

- Yassine, E.; Fakhari, F.; Absi, J.; Courreges, F.; El, M.; Fatima, A.; Petit, C. Modelling of asphalt mixes based on X-ray computed tomography and random heterogeneous generation. Int. J. Pavement Eng. 2020, 21, 1626–1637. [Google Scholar]

- Shakiba, M.; Darabi, M.; Rashid, K.; You, T.; Little, D.; Masad, E. Three-dimensional microstructural modelling of coupled moisture–mechanical response of asphalt concrete. Int. J. Pavement Eng. 2015, 16, 445–466. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Wang, H.; Xie, P.; Guo, L. Analysis of pore characteristics and flow pattern of open-graded asphalt mixture in different directions. J. Mater. Civ. Eng. 2020, 32, 04020256. [Google Scholar] [CrossRef]

- Meng, A.; Tan, Y.; Xing, C.; Lv, H.; Xiao, S. Investigation on preferential path of fluid flow by using topological network model of permeable asphalt mixture. Constr. Build. Mater. 2020, 242, 118163. [Google Scholar] [CrossRef]

- Ghauch, Z.; Ozer, H.; Al-Qadi, I. Micromechanical finite element modeling of moisture damage in bituminous composite materials. Constr. Build. Mater. 2015, 80, 9–17. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Bahia, H.; Tang, N.; Zhu, T. Three-stage damage evolution of asphalt mixture in the wet Hamburg wheel tracking device test using X-ray computed tomography. J. Mater. Civ. Eng. 2018, 30, 04018138. [Google Scholar] [CrossRef]

- Lövqvist, L.; Balieu, R.; Kringos, N. A micromechanical model of freeze-thaw damage in asphalt mixtures. Int. J. Pavement Eng. 2021, 22, 1017–1029. [Google Scholar] [CrossRef]

- You, T.; Abu Al-Rub, R.; Darabi, M.; Masad, E.; Little, D. Three-dimensional microstructural modeling of asphalt concrete using a unified viscoelastic–viscoplastic–viscodamage mode. Constr. Build. Mater. 2012, 28, 531–548. [Google Scholar] [CrossRef]

- Zadshir, M.; Hosseinnezhad, S.; Fini, E. Deagglomeration of oxidized asphaltenes as a measure of true rejuvenation for severely aged asphalt binder. Constr. Build. Mater. 2019, 209, 416–424. [Google Scholar] [CrossRef]

- Du, Z.; Zhu, X.; Zhang, Y. Diffusive dynamics and structural organization of moisture in asphaltic materials based on molecular dynamics simulation. J. Mater. Civ. Eng. 2021, 33, 04020403. [Google Scholar] [CrossRef]

- Qu, X.; Wang, D.; Hou, Y.; Oeser, M.; Wang, L. Influence of paraffin on the microproperties of asphalt binder using MD simulation. J. Mater. Civ. Eng. 2018, 30, 04018191. [Google Scholar] [CrossRef]

- Qu, X.; Wang, D.; Hou, Y.; Liu, Q.; Oeser, M.; Wang, L. Investigation on self-healing behavior of asphalt binder using a six-fraction molecular model. J. Mater. Civ. Eng. 2019, 31, 04019046. [Google Scholar] [CrossRef]

- Peng, C.; Lu, L.; You, Z.; Xu, F.; Zhou, L.; Ma, H.; Hu, X.; Liu, Y. Influence of waste polyethylene on the performances of asphalt before and after oxidative aging based on the molecular dynamics simulation. J. Mater. Civ. Eng. 2022, 34, 04022274. [Google Scholar] [CrossRef]

- Cao, X.; Deng, M.; Ding, Y.; Tang, B.; Yang, X.; Shan, B.; Su, Y. Effect of photocatalysts modification on asphalt: Investigations by experiments and theoretical calculation. J. Mater. Civ. Eng. 2021, 33, 04021083. [Google Scholar] [CrossRef]

- Zhu, X.; Du, Z.; Ling, H.; Chen, L.; Wang, Y. Effect of filler on thermodynamic and mechanical behaviour of asphalt mastic: A MD simulation study. Int. J. Pavement Eng. 2020, 21, 1248–1262. [Google Scholar] [CrossRef]

- Khan, Z.; Faisal, H.; Tarefder, R. Evaluation of nanomechanical properties of nonaggregate phase of asphalt concrete using finite-element method. J. Mater. Civ. Eng. 2018, 20, 04018331. [Google Scholar] [CrossRef]

- Apostolidis, P.; Scarpas, A. Numerical study of sorption of asphalt binders on minerals. Constr. Build. Mater. 2020, 259, 120392. [Google Scholar] [CrossRef]

- Yaphary, Y.; Leng, Z.; Wang, H.; Ren, S.; Lu, G. Characterization of nanoscale cracking at the interface between virgin and aged asphalt binders based on molecular dynamics simulations. Constr. Build. Mater. 2022, 335, 127475. [Google Scholar] [CrossRef]

- Andres, C.; Caro, S.; Lleras, M.; Rojas, Y. Impact of the chemical composition of aggregates on the adhesion quality and durability of asphalt-aggregate systems. Constr. Build. Mater. 2019, 216, 661–672. [Google Scholar]

- Zhai, M.; Li, J.; Wang, R.; Yue, J.; Wang, X. Revealing mechanisms of aging and moisture on thermodynamic properties and failure patterns of asphalt-aggregate interface from the molecular scale. J. Mater. Civ. Eng. 2023, 35, 04022486. [Google Scholar] [CrossRef]

- Wang, W.; Luo, R.; Yang, H.; Wang, L. Analysis of water erosion on asphalt binder using multi-scale experimental methods. Int. J. Pavement Res. Technol. 2022, 15, 485–495. [Google Scholar] [CrossRef]

- Du, Z.; Zhu, X.; Li, F.; Zhou, S.; Dai, Z. Failure of the asphalt-aggregate interface under tensile stress: Insight from molecular dynamics. J. Mater. Civ. Eng. 2021, 33, 04021008. [Google Scholar] [CrossRef]

- Du, Z.; Zhu, X. Surface-roughness-induced control of the interfacial failure mode and bonding strength: Atomistic case study in an asphalt-aggregate system. J. Mater. Civ. Eng. 2022, 34, 04022334. [Google Scholar] [CrossRef]

- Zhang, L.; Long, N.; Liu, Y.; Wang, L. Cross-scale study on the influence of moisture-temperature coupling conditions on adhesive properties of rubberized asphalt and steel slag. Constr. Build. Mater. 2022, 332, 127401. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Liu, Y. Molecular dynamics study on the effect of mineral composition on the interface interaction between rubberized asphalt and aggregate. J. Mater. Civ. Eng. 2022, 34, 04022032. [Google Scholar] [CrossRef]

- AbuQtaish, L.; Nazzal, M.; Kaya, S.; Kim, S.; Abbas, A.; Abu, H. AFM-based approach to study blending between RAP and virgin asphalt binders. J. Mater. Civ. Eng. 2018, 30, 04017300. [Google Scholar] [CrossRef]

- Nazzal, M.; Qtaish, L.; Al-Hosainat, A.; Talha, S.; Kaya, S.; Abbas, A. Evaluation of moisture damage in asphalt mixtures at macro- and nanoscales. J. Mater. Civ. Eng. 2021, 33, 04021369. [Google Scholar] [CrossRef]

- Tarefder, R.; Zaman, A. Nanoscale evaluation of moisture damage in polymer modified asphalts. J. Mater. Civ. Eng. 2010, 22, 714–725. [Google Scholar] [CrossRef]

- Macedo, T.; Badilla-Vargas, G.; Osmari, P. An experimental testing and analysis procedure to determine linear viscoelastic properties of asphalt binder microstructural components. Constr. Build. Mater. 2020, 230, 116999. [Google Scholar] [CrossRef]

- Shan, L.; Zhang, E.; Liu, S.; Xu, H.; Tan, Y. Analysis of microscopic damage mechanism of asphalt binder through atomic force microscopy (AFM). China J. Highw. Transp. 2020, 33, 171–177. [Google Scholar]

- Du, C.; Liu, P.; Ganchev, K.; Lu, G.; Oeser, M. Influence of microstructure evolution of bitumen on its micromechanical property by finite element simulation. Constr. Build. Mater. 2021, 293, 123522. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Wang, L. Review on Design, Characterization, and Prediction of Performance for Asphalt Materials and Asphalt Pavement Using Multi-Scale Numerical Simulation. Materials 2024, 17, 778. https://doi.org/10.3390/ma17040778

Wang W, Wang L. Review on Design, Characterization, and Prediction of Performance for Asphalt Materials and Asphalt Pavement Using Multi-Scale Numerical Simulation. Materials. 2024; 17(4):778. https://doi.org/10.3390/ma17040778

Chicago/Turabian StyleWang, Wentao, and Linbing Wang. 2024. "Review on Design, Characterization, and Prediction of Performance for Asphalt Materials and Asphalt Pavement Using Multi-Scale Numerical Simulation" Materials 17, no. 4: 778. https://doi.org/10.3390/ma17040778

APA StyleWang, W., & Wang, L. (2024). Review on Design, Characterization, and Prediction of Performance for Asphalt Materials and Asphalt Pavement Using Multi-Scale Numerical Simulation. Materials, 17(4), 778. https://doi.org/10.3390/ma17040778