Effect of Al7Cu2Fe Particles on the Anisotropic Mechanical Properties and Formability of Al-Zn-Mg-Cu-Based Alloy Sheets

Abstract

:1. Introduction

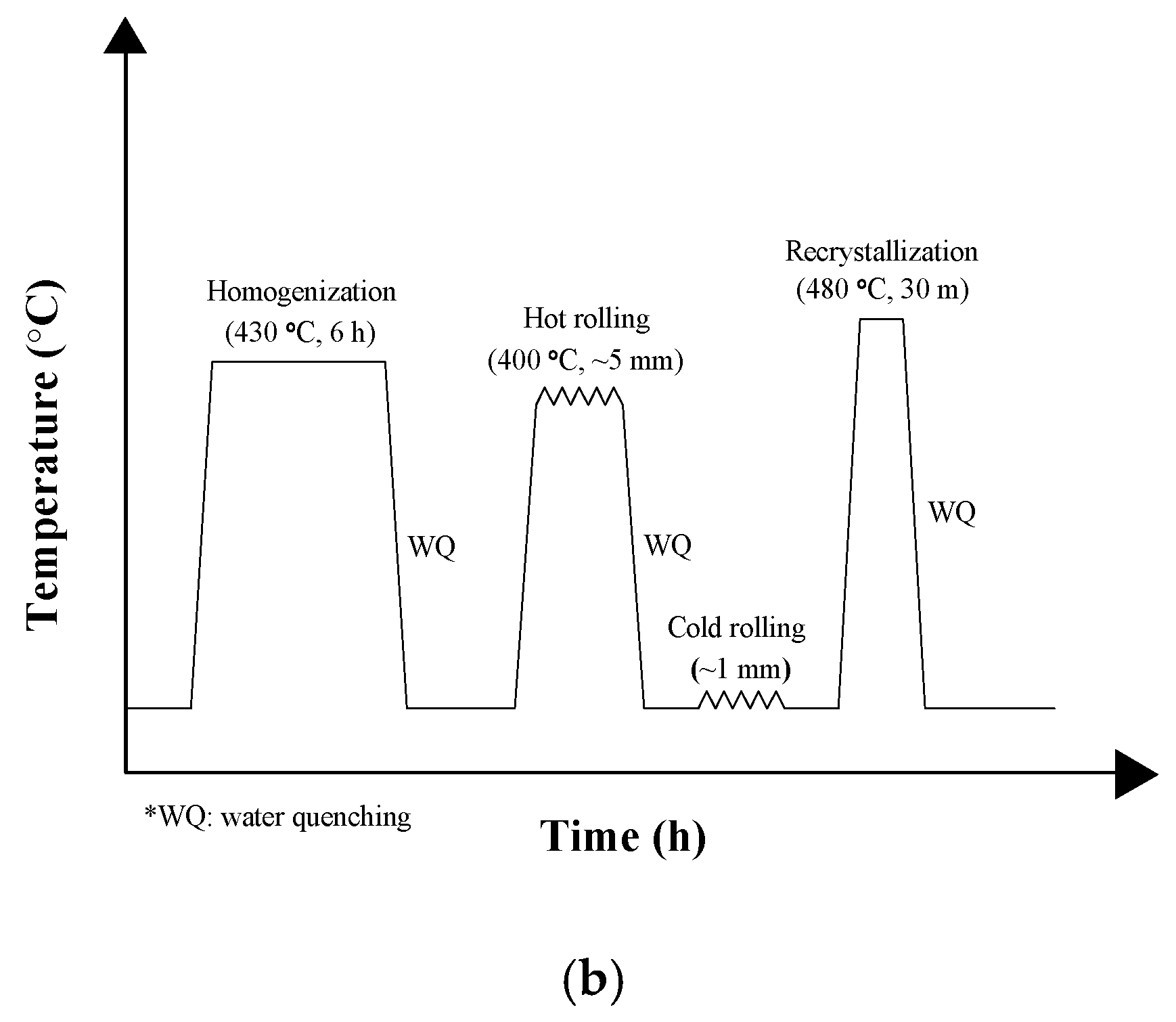

2. Experimental Procedures

3. Experimental Results

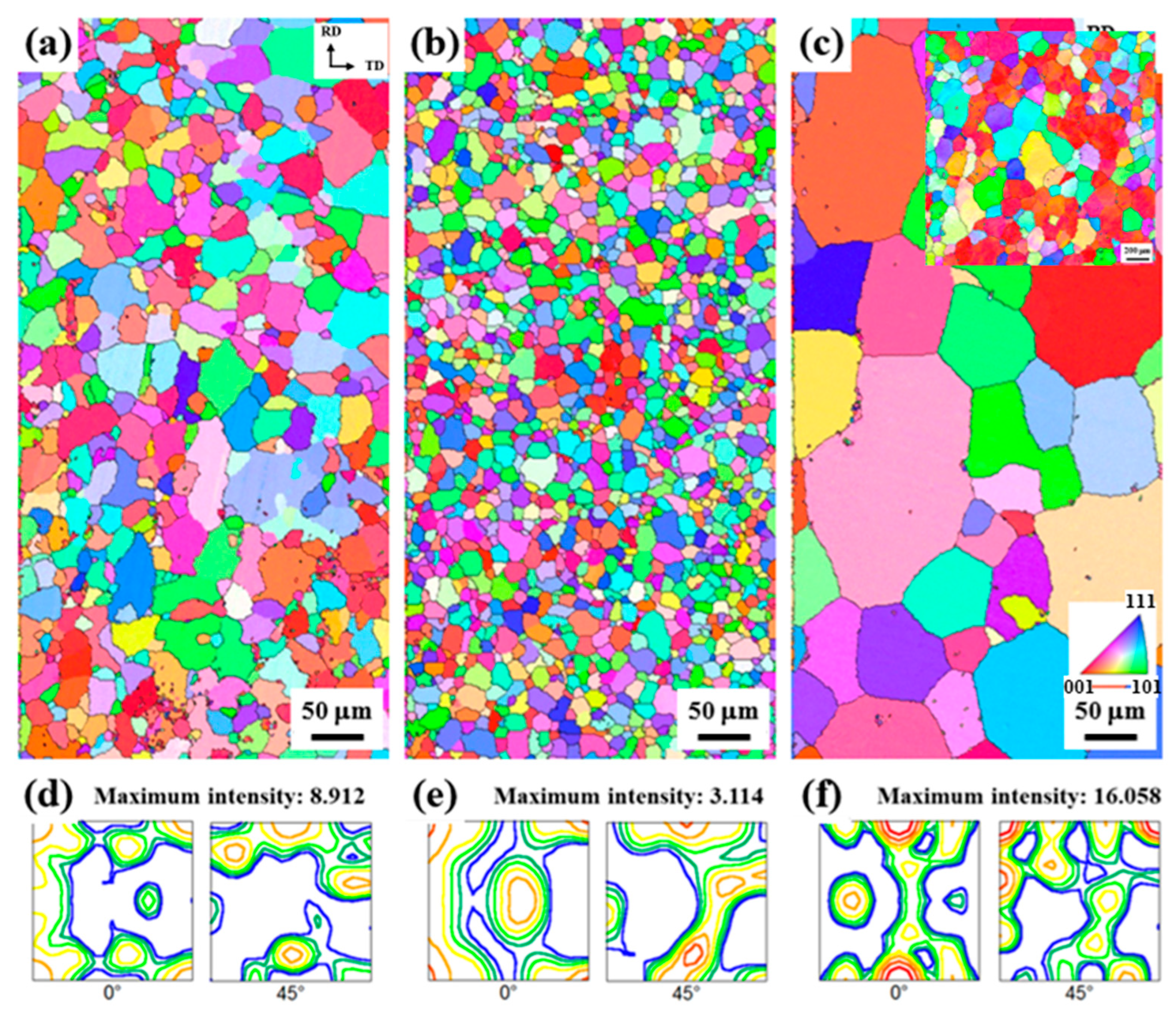

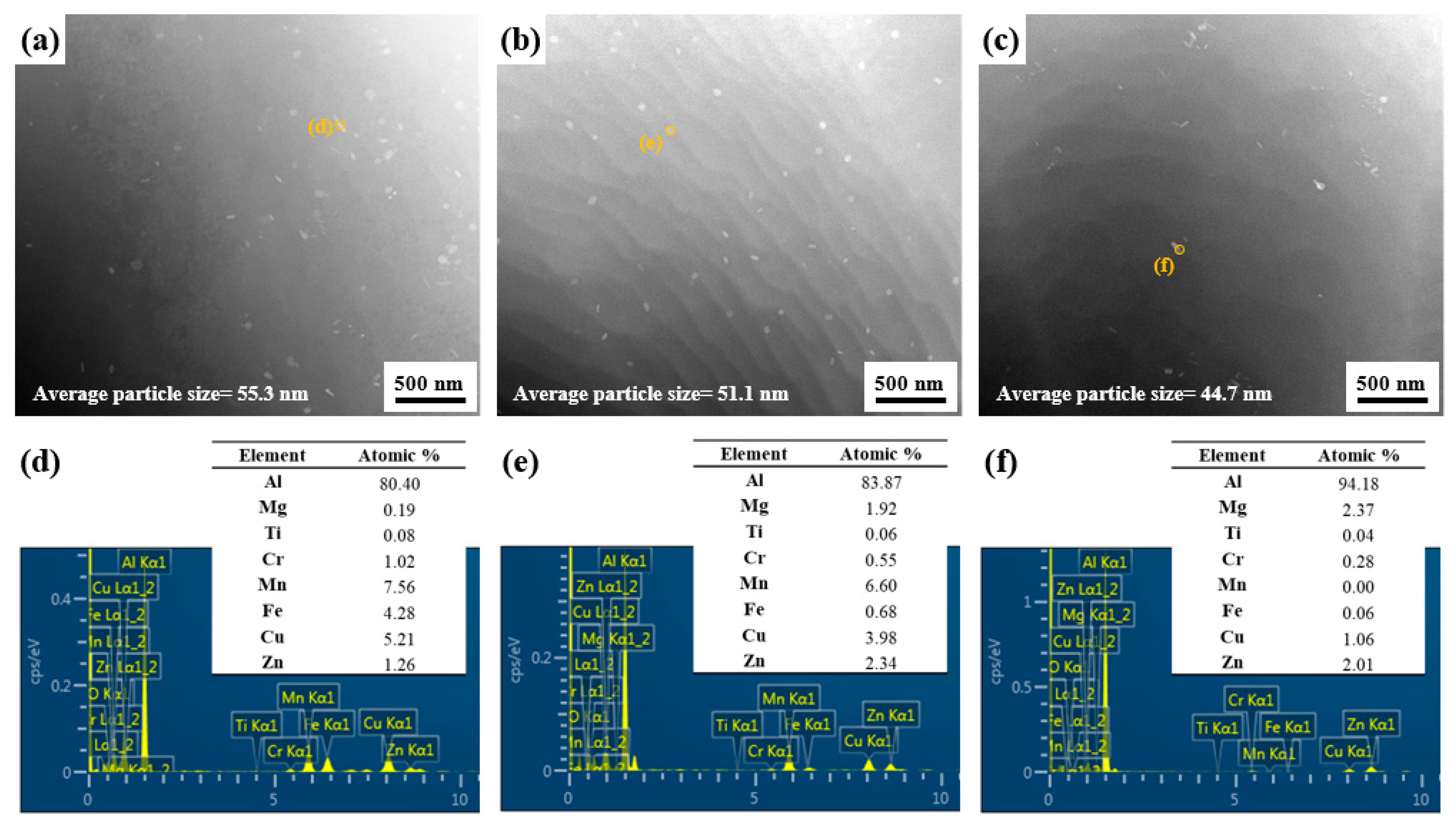

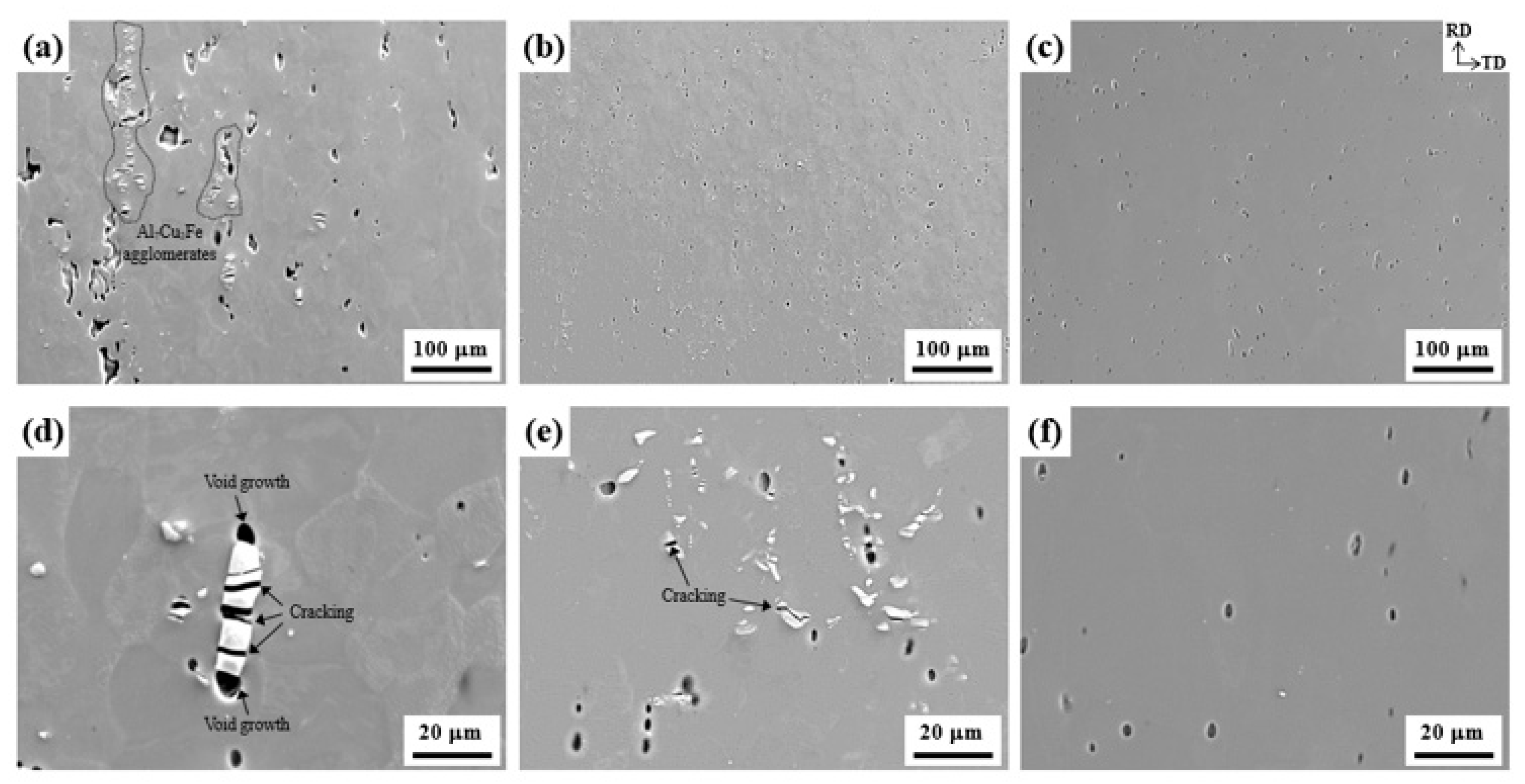

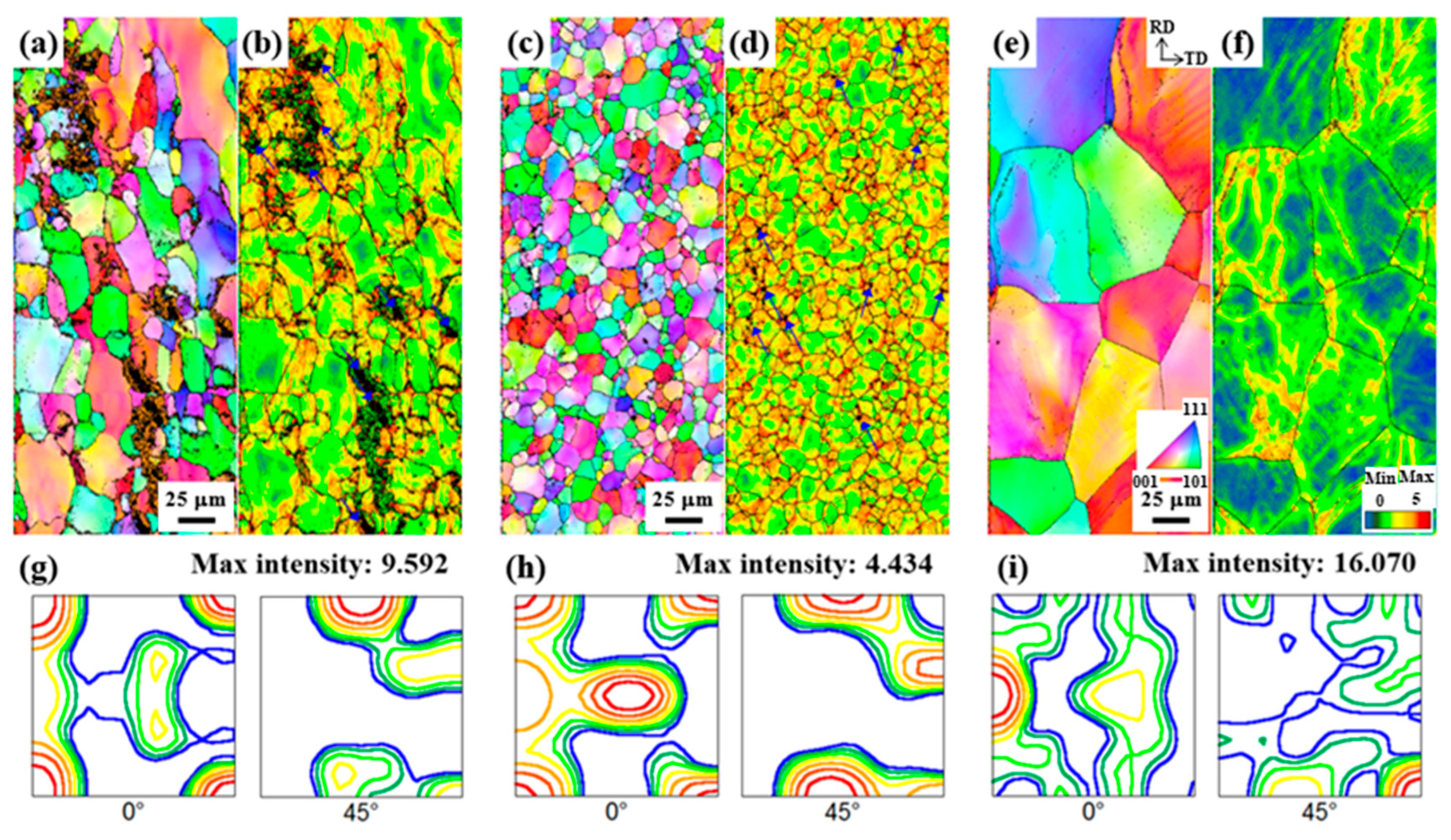

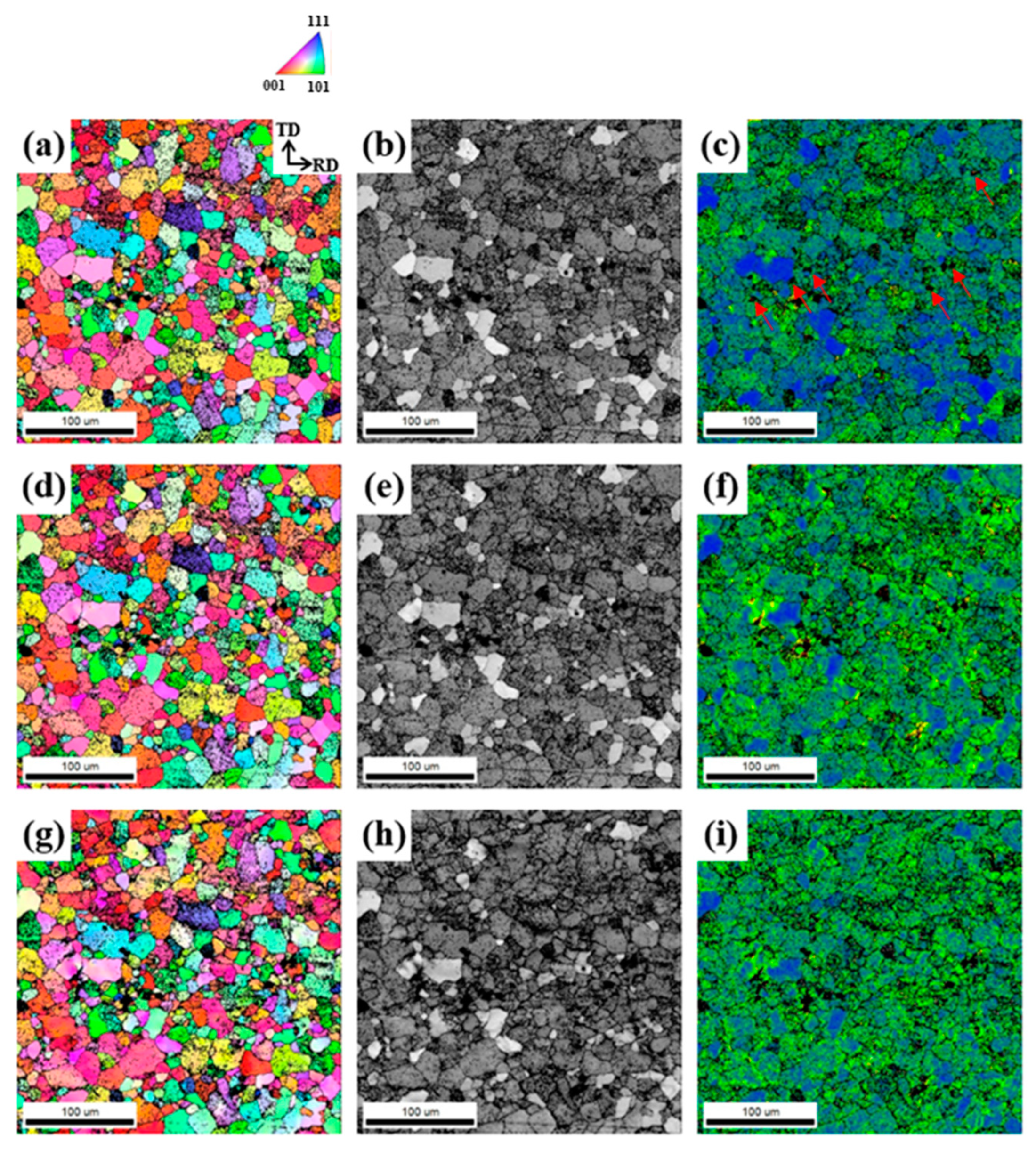

3.1. Microstructural Evolution During Thermo-Mechanical Treatment Processes

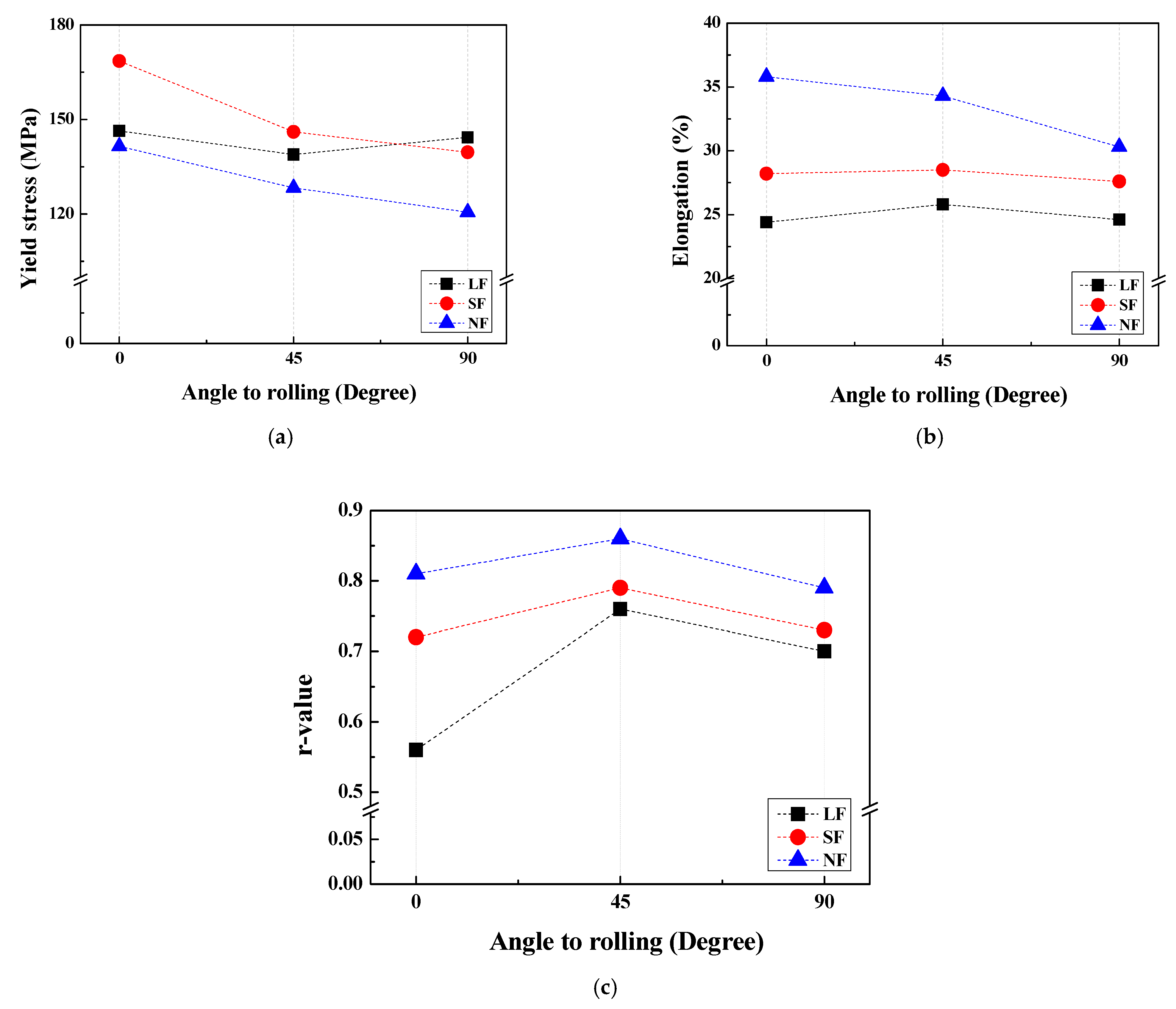

3.2. Mechanical Properties and Formability of Recrystallized Sheets

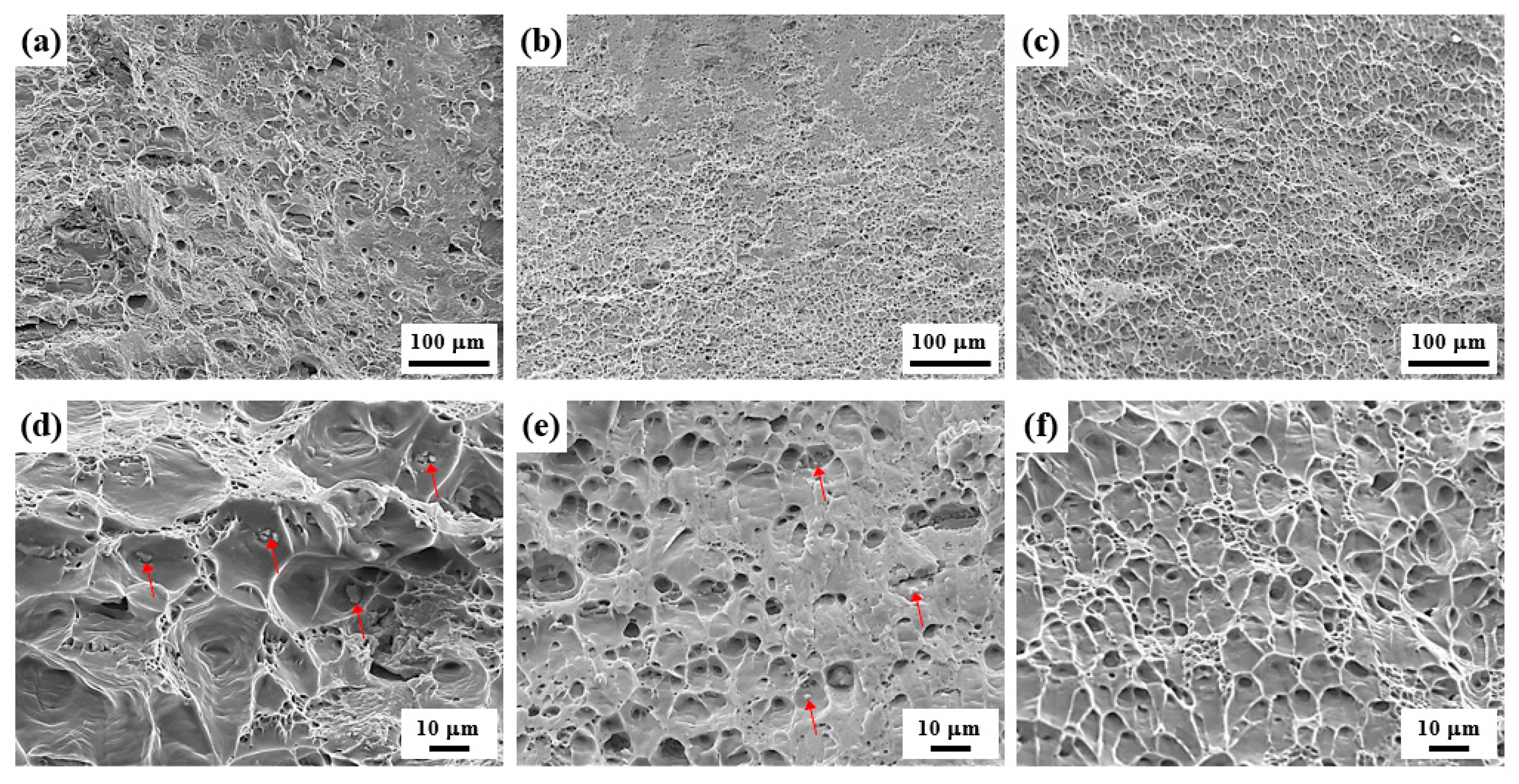

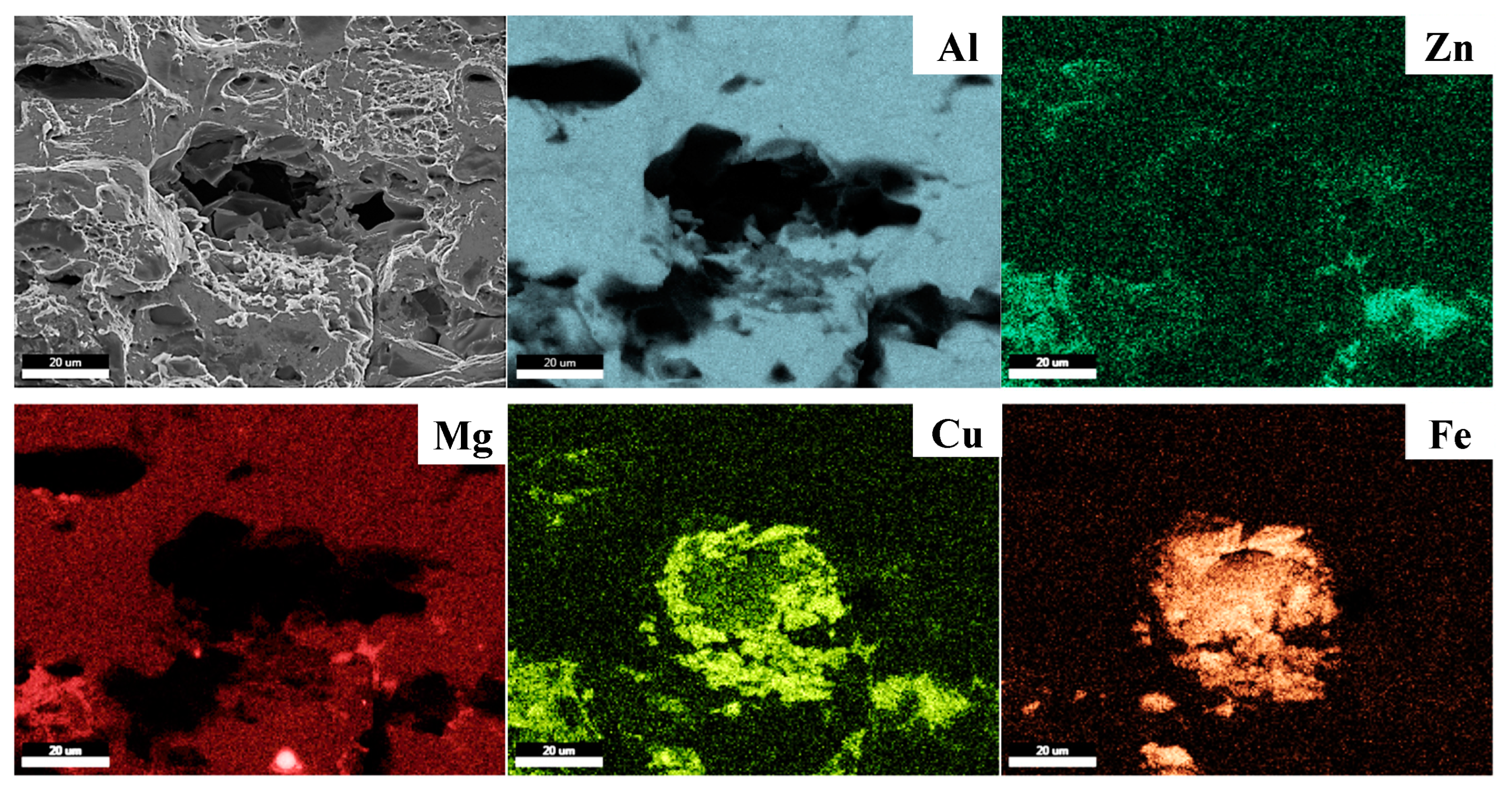

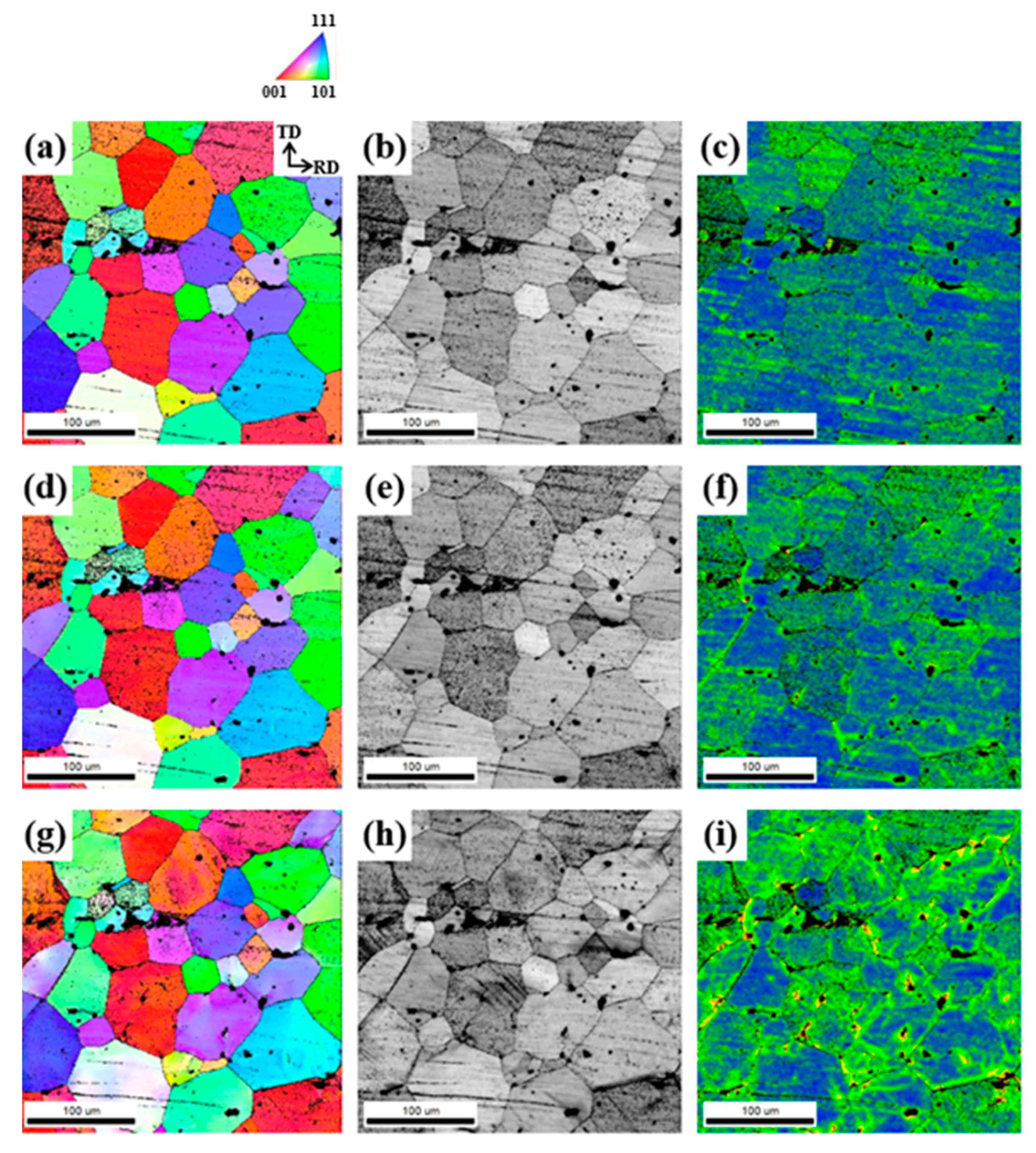

3.3. Microstructural Evolution During Deformation

3.4. Mechanical Properties of Naturally Aged Alloy Sheets

3.5. Microstructures of Naturally Aged Alloy Sheets

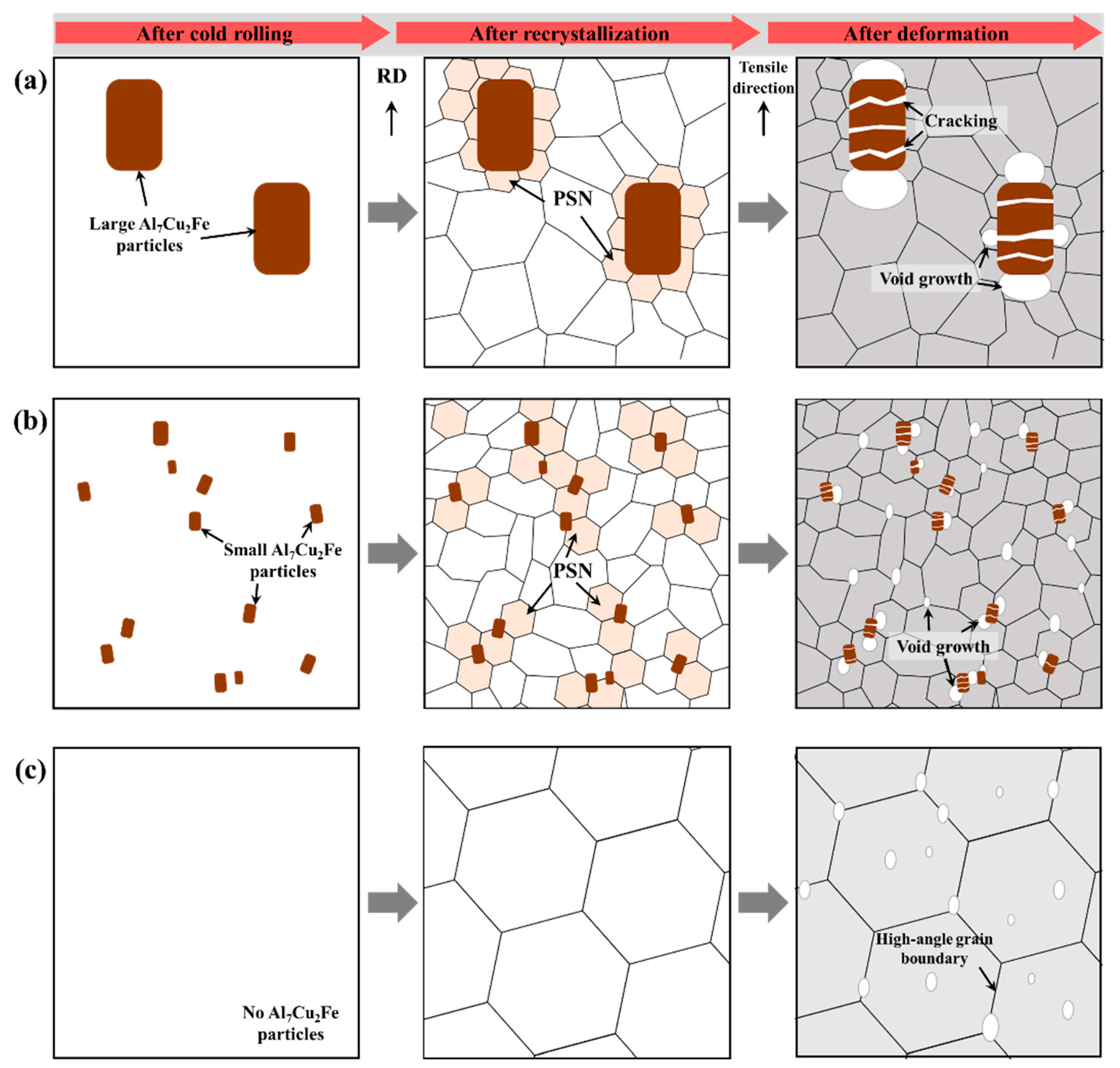

4. Discussion

4.1. Recrystallization Behavior

4.2. Mechanical Properties

4.3. Anisotropic Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ebrahimi, M.; Shaeri, M.; Naseri, R.; Gode, C. Equal channel angular extrusion for tube configuration of Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2018, 731, 569–576. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, Y.; Liu, X. Influence of trace Ti on the microstructure, age hardening behavior and mechanical properties of an Al–Zn–Mg–Cu–Zr alloy. Mater. Sci. Eng. A 2014, 598, 293–298. [Google Scholar] [CrossRef]

- Gupta, M.K.; Singhal, V. Review on materials for making lightweight vehicles. Mater. Today Proc. 2022, 56, 868–872. [Google Scholar] [CrossRef]

- Huo, W.; Hou, L.; Zhang, Y.; Zhang, J. Warm formability and post-forming microstructure/property of high-strength AA 7075-T6 Al alloy. Mater. Sci. Eng. A 2016, 675, 44–54. [Google Scholar] [CrossRef]

- Li, S.-S.; Yue, X.; Li, Q.-Y.; Peng, H.-L.; Dong, B.-X.; Liu, T.-S.; Yang, H.-Y.; Fan, J.; Shu, S.-L.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Wang, B.; Liu, X.; Wang, J.; Li, Q.; Liu, K.; Zhang, M. Uncovering the effects of Ce and superheat temperature on Fe-rich intermetallic and microporosity formation in aluminum alloy. Mater. Charact. 2022, 193, 112226. [Google Scholar] [CrossRef]

- Liu, T.; Karkkainen, M.; Nastac, L.; Arvikar, V.; Levin, I.; Brewer, L.N. Iron-rich intermetallics in high pressure die cast A383 aluminum alloys. Intermetallics 2020, 126, 106814. [Google Scholar] [CrossRef]

- Yuan, L.; Guo, M.; Yu, K.; Zhang, J.; Zhuang, L. Multi-scale iron-rich phases induce fine microstructures in Al-Zn-Mg-Cu-Fe alloys. Philos. Mag. 2021, 101, 1417–1442. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, H.; Weng, S.; Fu, D. Characterization of dynamic microstructural evolution of AA7150 aluminum alloy at high strain rate during hot deformation. Trans. Nonferrous Met. Soc. China 2016, 26, 51–62. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.; Cong, F. Intermetallic phase evolution of 7050 aluminum alloy during homogenization. Intermetallics 2012, 26, 114–121. [Google Scholar] [CrossRef]

- Morgeneyer, T.; Starink, M.; Sinclair, I. Evolution of voids during ductile crack propagation in an aluminium alloy sheet toughness test studied by synchrotron radiation computed tomography. Acta Mater. 2008, 56, 1671–1679. [Google Scholar] [CrossRef]

- Goto, I.; Shirai, K.; Ohyama, R.; Kurosawa, K. Dissolution Mechanism of Intermetallic Layer by Iron Erosion in Aluminum-Based Molten Binary Alloys. Mater. Trans. 2022, 63, 730–739. [Google Scholar] [CrossRef]

- Vratnica, M.; Pluvinage, G.; Jodin, P.; Cvijović, Z.; Rakin, M.; Burzić, Z. Influence of notch radius and microstructure on the fracture behavior of Al–Zn–Mg–Cu alloys of different purity. Mater. Des. 2010, 31, 1790–1798. [Google Scholar] [CrossRef]

- Ohira, T.; Kishi, T. Effect of iron content on fracture toughness and cracking processes in high strength Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. 1986, 78, 9–19. [Google Scholar] [CrossRef]

- Vratnica, M.; Cvijović, Z.; Gerić, K.; Burzić, Z. The role of intermetallic phases in fatigue crack propagation behavior of Al-Zn-Mg-Cu alloys. Mater. Sci. Forum 2007, 555, 553–558. [Google Scholar] [CrossRef]

- Hochhalter, J.; Littlewood, D.; Veilleux, M.; Bozek, J.; Maniatty, A.; Rollett, A.; Ingraffea, A. A geometric approach to modeling microstructurally small fatigue crack formation: III. Development of a semi-empirical model for nucleation. Model. Simul. Mater. Sci. Eng. 2011, 19, 035008. [Google Scholar] [CrossRef]

- Yasakau, K.; Zheludkevich, M.; Ferreira, M. Role of Intermetallics in Corrosion of Aluminum Alloys. Smart Corrosion Protection. In Intermetallic Matrix Composites; Woodhead Publishing: Cambridge, UK, 2018; pp. 425–462. [Google Scholar]

- Sun, Y.; Pan, Q.; Sun, Y.; Wang, W.; Huang, Z.; Wang, X.; Hu, Q. Localized corrosion behavior associated with Al7Cu2Fe intermetallic in Al-Zn-Mg-Cu-Zr alloy. J. Alloys Compd. 2019, 783, 329–340. [Google Scholar] [CrossRef]

- Zhong, G.; Wu, S.; Jiang, H.; An, P. Effects of ultrasonic vibration on the iron-containing intermetallic compounds of high silicon aluminum alloy with 2% Fe. J. Alloys Compd. 2010, 492, 482–487. [Google Scholar] [CrossRef]

- Samuel, F.; Samuel, A.; Doty, H.; Valtierra, S. Decomposition of Fe-intermetallics in Sr-modified cast 6XXX type aluminum alloys for automotive skin. Met. Mater. Trans. A 2001, 32, 2061–2075. [Google Scholar] [CrossRef]

- Hosseinifar, M.; Malakhov, D.V. Effect of Ce and La on microstructure and properties of a 6xxx series type aluminum alloy. J. Mater. Sci. 2008, 43, 7157–7164. [Google Scholar] [CrossRef]

- Khalifa, W.; Samuel, F.; Gruzleski, J.; Doty, H.; Valtierra, S. Nucleation of Fe-intermetallic phases in the Al-Si-Fe alloys. Metall. Mater. Trans. A 2005, 36, 1017–1032. [Google Scholar] [CrossRef]

- Dorin, T.; Stanford, N.; Birbilis, N.; Gupta, R. Influence of cooling rate on the microstructure and corrosion behavior of Al–Fe alloys. Corros. Sci. 2015, 100, 396–403. [Google Scholar] [CrossRef]

- Belov, N.A.; Eskin, D.G.; Aksenov, A.A. Multicomponent Phase Diagrams: Applications for Commercial Aluminum Alloys; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Verma, A.; Kumar, S.; Grant, P.; O’Reilly, K. Influence of cooling rate on the Fe intermetallic formation in an AA6063 Al alloy. J. Alloys Compd. 2013, 555, 274–282. [Google Scholar] [CrossRef]

- Khalifa, W.; Tsunekawa, Y.; Okumiya, M. Effect of ultrasonic treatment on the Fe-intermetallic phases in ADC12 die cast alloy. J. Mater. Process. Technol. 2010, 210, 2178–2187. [Google Scholar] [CrossRef]

- Sha, G.; Wang, Y.; Liao, X.; Duan, Z.; Ringer, S.; Langdon, T. Microstructural evolution of Fe-rich particles in an Al–Zn–Mg–Cu alloy during equal-channel angular pressing. Mater. Sci. Eng. A 2010, 527, 4742–4749. [Google Scholar] [CrossRef]

- She, H.; Shu, D.; Dong, A.; Wang, J.; Sun, B.; Lai, H. Relationship of particle stimulated nucleation, recrystallization and mechanical properties responding to Fe and Si contents in hot-extruded 7055 aluminum alloys. J. Mater. Sci. Technol. 2019, 35, 2570–2581. [Google Scholar] [CrossRef]

- Mondal, C.; Mukhopadhyay, A. On the nature of T(Al2Mg3Zn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater. Sci. Eng. A 2005, 391, 367–376. [Google Scholar] [CrossRef]

- Jeon, J.G.; Shin, J.H.; Shin, S.E.; Bae, D.H. Improvement in the anisotropic mechanical properties and formability of Al-Si-Mg-Cu-based alloy sheets. Mater. Sci. Eng. A 2021, 799, 140199. [Google Scholar] [CrossRef]

- Park, S.; Kim, W. Difference in the hot compressive behavior and processing maps between the as-cast and homogenized Al-Zn-Mg-Cu (7075) alloys. J. Mater. Sci. Technol. 2016, 32, 660–670. [Google Scholar] [CrossRef]

- Han, Y.; Ma, K.; Li, L.; Chen, W.; Nagaumi, H. Study on microstructure and mechanical properties of Al–Mg–Si–Cu alloy with high manganese content. Mater. Des. 2012, 39, 418–424. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, K.C.; Park, D.S.; Nam, S.W. Enhancement of the fatigue properties in a weldable high-strength Al-Zn-Mg-Mn alloy by means of Mn-dispersoids. Int. J. Fatigue 1999, 21, 383–391. [Google Scholar] [CrossRef]

- Jeon, J.G.; Lee, S.J.; Choi, K.M.; Kang, H.; Kim, W.C.; Jeon, J.H.; Bae, D.H. Influence of Cu and Mg Content on Recrystallization Behavior in Al–Zn–Mg–Cu-Based Alloy Sheets. Met. Mater. Int. 2023, 29, 1684–1698. [Google Scholar] [CrossRef]

- Yuan, L.; Guo, M.; Song, Y.; Miao, L.; Jiang, N.; Zhuang, L. The recrystallization-assisted reduction in mechanical anisotropy of Al–Zn–Mg–Cu–Zr–Mn alloys. Int. J. Mater. Res. 2022, 113, 712–729. [Google Scholar] [CrossRef]

- Ku, M.-H.; Hung, F.-Y.; Lui, T.-S. Examination of the High Tensile Ductility Improvement in an As-Solutionized AA7075 Alloy with the Aid of a Friction Stir Process. Metals 2019, 9, 196. [Google Scholar] [CrossRef]

- Oguocha, I.; Tiamiyu, A.; Rezaei, M.; Odeshi, A.; Szpunar, J. Experimental investigation of the dynamic impact responses of as-cast and homogenized A535 aluminum alloy. Mater. Sci. Eng. A 2020, 771, 138536. [Google Scholar] [CrossRef]

- Zavadil, K.R.; Ohlhausen, J.; Kotula, P. Nanoscale void nucleation and growth in the passive oxide on aluminum as a prepitting process. J. Electrochem. Soc. 2006, 153, B296–B303. [Google Scholar] [CrossRef]

- Ko, Y.G.; Shin, D.H.; Park, K.-T.; Lee, C.S. An analysis of the strain hardening behavior of ultra-fine grain pure titanium. Scr. Mater. 2006, 54, 1785–1789. [Google Scholar] [CrossRef]

- Hansen, V.; Gjønnes, J.; Skjervold, S. Effect of predeformation and preaging at room temperature in Al–Zn–Mg–(Cu, Zr) alloys. Mater. Sci. Eng. A 2001, 303, 226–233. [Google Scholar]

- Chen, Y.; Liu, C.Y.; Zhang, B.; Qin, F.C.; Hou, Y.F. Precipitation behavior and mechanical properties of Al-Zn-Mg alloy with high Zn concentration. J. Alloys Compd. 2020, 825, 154005. [Google Scholar] [CrossRef]

- Lee, S.H.; Jung, J.G.; Baik, S.I.; Seidman, D.N.; Kim, M.S.; Lee, Y.K.; Euh, K. Precipitation strengthening in naturally aged Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2021, 803, 140719. [Google Scholar] [CrossRef]

- Zhao, Y.; Wen, W.; Morris, J. The differences in particle structures and recrystallization behaviors between DC and CC AA5052 aluminum alloys. Mater. Sci. Eng. A 2004, 373, 167–174. [Google Scholar] [CrossRef]

- Zhang, G.W.; Nagaumi, H.; Han, Y.; Xu, Y.; Parish, C.M.; Zhai, T.G. Effects of Mn and Cr additions on the recrystallization behavior of Al-Mg-Si-Cu alloys. Mater. Sci. Forum 2017, 877, 172–179. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.; Ryazantseva, M.; Portnoy, V. Effect of eutectic particles on the grain size control and the superplasticity of aluminium alloys. Mater. Sci. Eng. A 2011, 528, 7306–7309. [Google Scholar] [CrossRef]

- Bhattacharya, V.; Chattopadhyay, K. Microstructure and wear behaviour of aluminium alloys containing embedded nanoscaled lead dispersoids. Acta Mater. 2004, 52, 2293–2304. [Google Scholar] [CrossRef]

- Huo, W.; Hou, L.; Lang, Y.; Cui, H.; Zhuang, L.; Zhang, J. Improved thermo-mechanical processing for effective grain refinement of high-strength AA 7050 Al alloy. Mater. Sci. Eng. A 2015, 626, 86–93. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Guo, W.; Zhang, Y. Effects of thermomechanical treatment on grain refinement, second-phase particle dissolution, and mechanical properties of 2219 Al alloy. J. Mater. Process. Technol. 2020, 278, 116506. [Google Scholar] [CrossRef]

- Humphreys, J.; Bate, P. Gradient plasticity and deformation structures around inclusions. Scr. Mater. 2003, 48, 173–178. [Google Scholar] [CrossRef]

- Engler, O.; Kong, X.; Lücke, K. Influence of precipitates on the microstructure and texture during the rolling of Al-Cu and Al-Mn single crystals with rolling texture orientations. Philos. Mag. A 2001, 81, 543–570. [Google Scholar] [CrossRef]

- Wert, J. Strength of Metal Alloys; Gifkins, R.C., Ed.; Pergamon Press: Oxford, UK, 1980. [Google Scholar]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Xiao, H.; Li, Y.; Geng, J.; Li, H.; Wang, M.; Dong, C.; Li, Z.; Wang, H. Effects of nano-sized TiB2 particles and Al3Zr dispersoids on microstructure and mechanical properties of Al–Zn–Mg–Cu based materials. Trans. Nonferrous Met. Soc. China 2021, 31, 2189–2207. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L.; Zhang, J. The mechanism of grain refinement and plasticity enhancement by an improved thermomechanical treatment of 7055 Al alloy. Mater. Sci. Eng. A 2017, 702, 42–52. [Google Scholar] [CrossRef]

- Xiang, Y. Effects of Grain Shape and Crystallographic Texture on Plastic Anisotropy of Aluminum Alloy Sheets. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2004. [Google Scholar]

- Cho, K.; Kwun, S.; Chung, Y.; Lee, C.; Shin, M. Effects of grain shape and texture on the yield strength anisotropy of Al-Li alloy sheet. Scr. Mater. 1999, 40, 651–657. [Google Scholar] [CrossRef]

- Li, Y.; Xu, G.; Liu, S.; Wang, B.; Peng, X. Study on anisotropy of Al-Zn-Mg-Sc-Zr alloy sheet. Mater. Charact. 2021, 172, 110904. [Google Scholar] [CrossRef]

- Yuan, L.; Guo, M.; Zhang, J.; Zhuang, L. Synergy in hybrid multi-scale particles for the improved formability of Al–Zn–Mg–Cu alloys. J. Mater. Res. Technol. 2021, 10, 1143–1157. [Google Scholar] [CrossRef]

- Moon, C.; Thuillier, S.; Lee, J.; Lee, M.-G. Mechanical properties of solution heat treated Al-Zn-Mg-Cu (7075) alloy under different cooling conditions: Analysis with full field measurement and finite element modeling. J. Alloys Compd. 2021, 856, 158180. [Google Scholar] [CrossRef]

- Wang, B.B.; Xie, G.M.; Wu, L.H.; Xue, P.; Ni, D.R.; Xiao, B.L.; Liu, Y.D.; Ma, Z.Y. Grain size effect on tensile deformation behaviors of pure aluminum. Mater. Sci. Eng. A 2021, 820, 141504. [Google Scholar] [CrossRef]

- Zong, C.; Zhu, G.; Mao, W. Effect of crystallographic texture on anisotropy of yield strength in X100 pipeline steel. J. Iron Steel Res. Int. 2013, 20, 66–71. [Google Scholar] [CrossRef]

- Chae, W.; Jeong, M.; Lee, D.; Lee, J.; Chun, D.W.; Lee, S.Y.; Hong, S.-K.; Kim, S.H.; Han, J.H. Effects of pre/post-aging treatment on the mechanical properties and texture of asymmetrically rolled 6061 aluminum alloy: Formability and planar anisotropy. J. Mater. Res. Technol. 2023, 24, 9476–9490. [Google Scholar] [CrossRef]

- Dhal, A.; Panigrahi, S.K.; Shunmugam, M.S. A comprehensive study on size-effect, plastic anisotropy and microformability of aluminum with varied alloy chemistry, crystallographic texture, and microstructure. Mater. Sci. Eng. A 2023, 876, 145111. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Luo, J.; Xie, C.; Wang, Y.; Zhang, J.; Zhuang, L. Effect of intermediate annealing time on microstructure, texture and mechanical properties of Al-Mg-Si-Cu alloy. Mater. Charact. 2018, 142, 309–320. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Chapuis, A.; Luo, J.; Zhang, J.; Zhuang, L. Effect of solution time on microstructure, texture and mechanical properties of Al–Mg–Si–Cu alloys. Mater. Sci. Eng. A 2015, 644, 137–151. [Google Scholar] [CrossRef]

- Gao, G.; Chen, H.; Yong, L.; Li, J.; Wang, Z.; Misra, R. Influence of different solution methods on microstructure, precipitation behavior and mechanical properties of Al–Mg–Si alloy. Trans. Nonferrous Met. Soc. China 2018, 28, 839–847. [Google Scholar] [CrossRef]

| Samples | Zn | Mg | Cu | Fe | Cr | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| LF | 6.34 | 2.43 | 1.56 | 0.13 | 0.05 | 0.05 | 0.09 | Bal. |

| SF | 6.23 | 2.58 | 1.53 | 0.12 | 0.06 | 0.04 | 0.08 | |

| NF | 6.19 | 2.53 | 1.52 | 0.03 | 0.02 | 0.05 | 0.10 |

| Samples | D (μm) | Direction (°) | YS (MPa) | UTS (MPa) | Elongation (%) | n | r | Δr | ||

|---|---|---|---|---|---|---|---|---|---|---|

| LF | 36.9 | 0 | 146.4 | 336.5 | 24.6 | 0.262 | 0.258 | 0.56 | 0.69 | −0.13 |

| 45 | 138.9 | 321.5 | 25.8 | 0.253 | 0.76 | |||||

| 90 | 144.4 | 326.5 | 24.4 | 0.259 | 0.70 | |||||

| SF | 16.5 | 0 | 168.6 | 361.2 | 28.2 | 0.303 | 0.288 | 0.72 | 0.76 | −0.07 |

| 45 | 146.1 | 324.1 | 28.5 | 0.278 | 0.79 | |||||

| 90 | 139.6 | 321.3 | 27.6 | 0.283 | 0.73 | |||||

| NF | 81.9 | 0 | 141.5 | 318.4 | 35.8 | 0.199 | 0.209 | 0.81 | 0.83 | −0.05 |

| 45 | 128.3 | 313.9 | 34.3 | 0.206 | 0.86 | |||||

| 90 | 120.6 | 309.6 | 30.3 | 0.222 | 0.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, J.; Lee, S.; Jeon, J.; Kang, M.; Kang, H. Effect of Al7Cu2Fe Particles on the Anisotropic Mechanical Properties and Formability of Al-Zn-Mg-Cu-Based Alloy Sheets. Materials 2024, 17, 5924. https://doi.org/10.3390/ma17235924

Jeon J, Lee S, Jeon J, Kang M, Kang H. Effect of Al7Cu2Fe Particles on the Anisotropic Mechanical Properties and Formability of Al-Zn-Mg-Cu-Based Alloy Sheets. Materials. 2024; 17(23):5924. https://doi.org/10.3390/ma17235924

Chicago/Turabian StyleJeon, Jonggyu, Sangjun Lee, Jeheon Jeon, Maru Kang, and Heon Kang. 2024. "Effect of Al7Cu2Fe Particles on the Anisotropic Mechanical Properties and Formability of Al-Zn-Mg-Cu-Based Alloy Sheets" Materials 17, no. 23: 5924. https://doi.org/10.3390/ma17235924

APA StyleJeon, J., Lee, S., Jeon, J., Kang, M., & Kang, H. (2024). Effect of Al7Cu2Fe Particles on the Anisotropic Mechanical Properties and Formability of Al-Zn-Mg-Cu-Based Alloy Sheets. Materials, 17(23), 5924. https://doi.org/10.3390/ma17235924