Heterogeneous Microstructure and Tensile Properties of Fe50Mn30Co10Cr10 Metastable High-Entropy Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

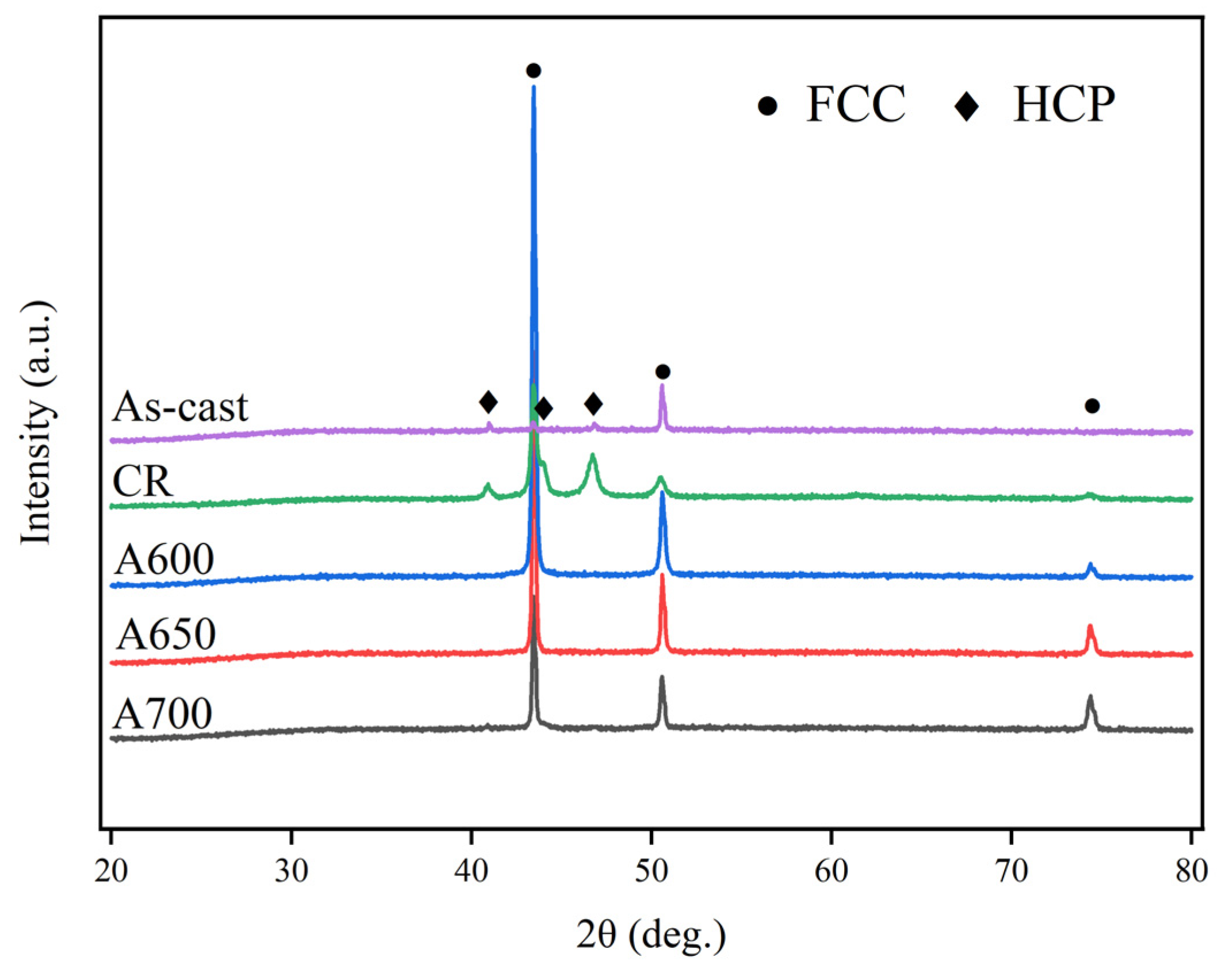

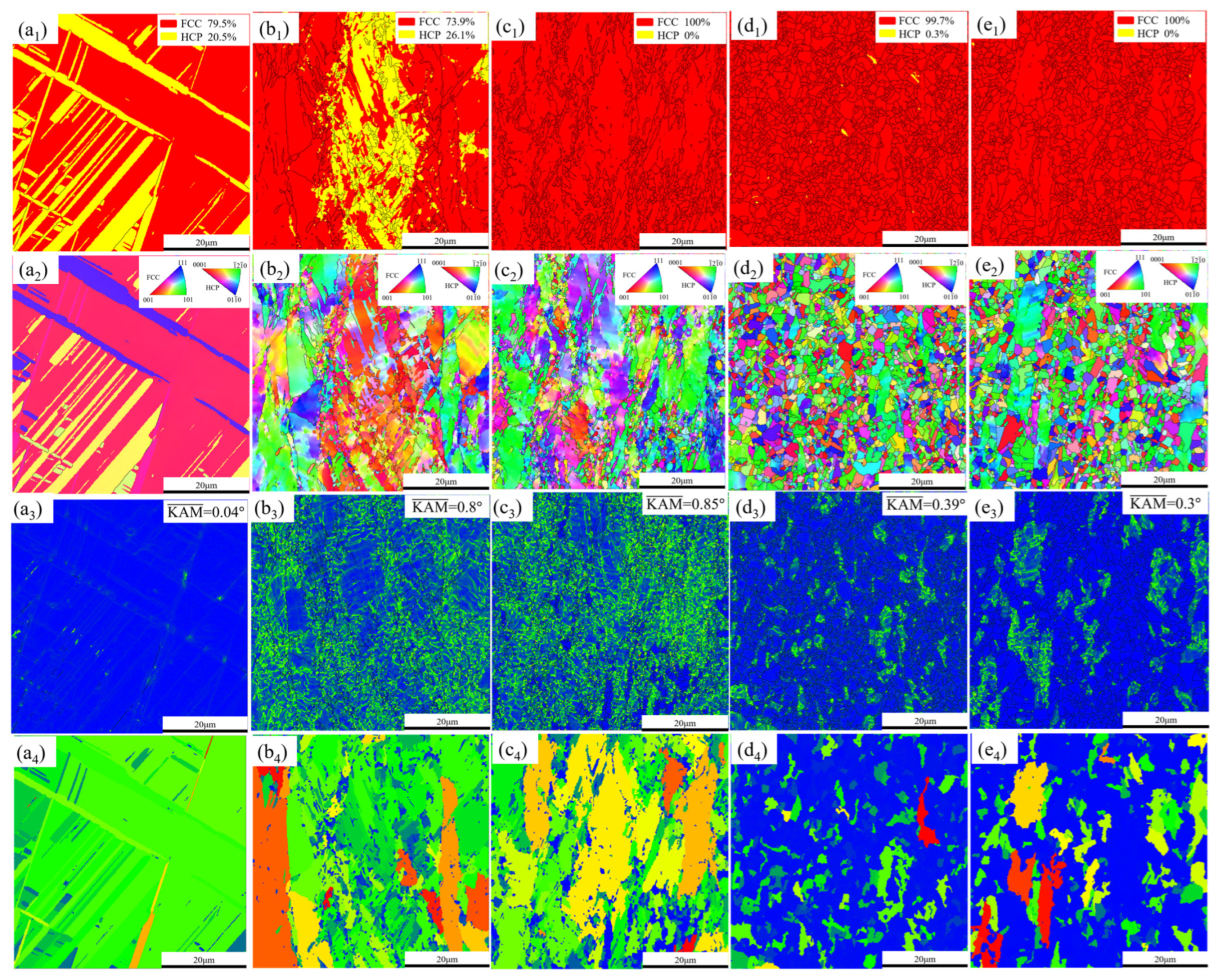

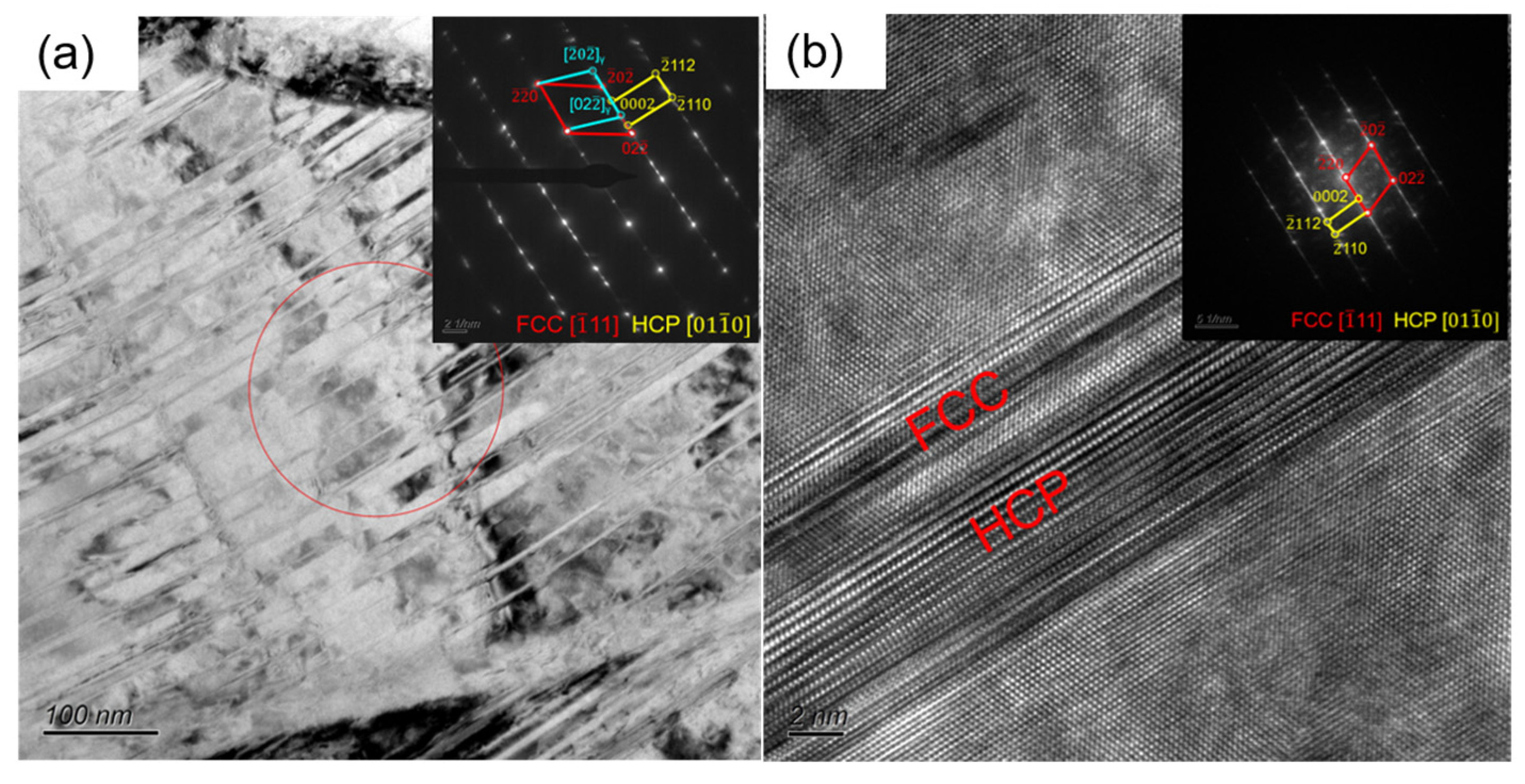

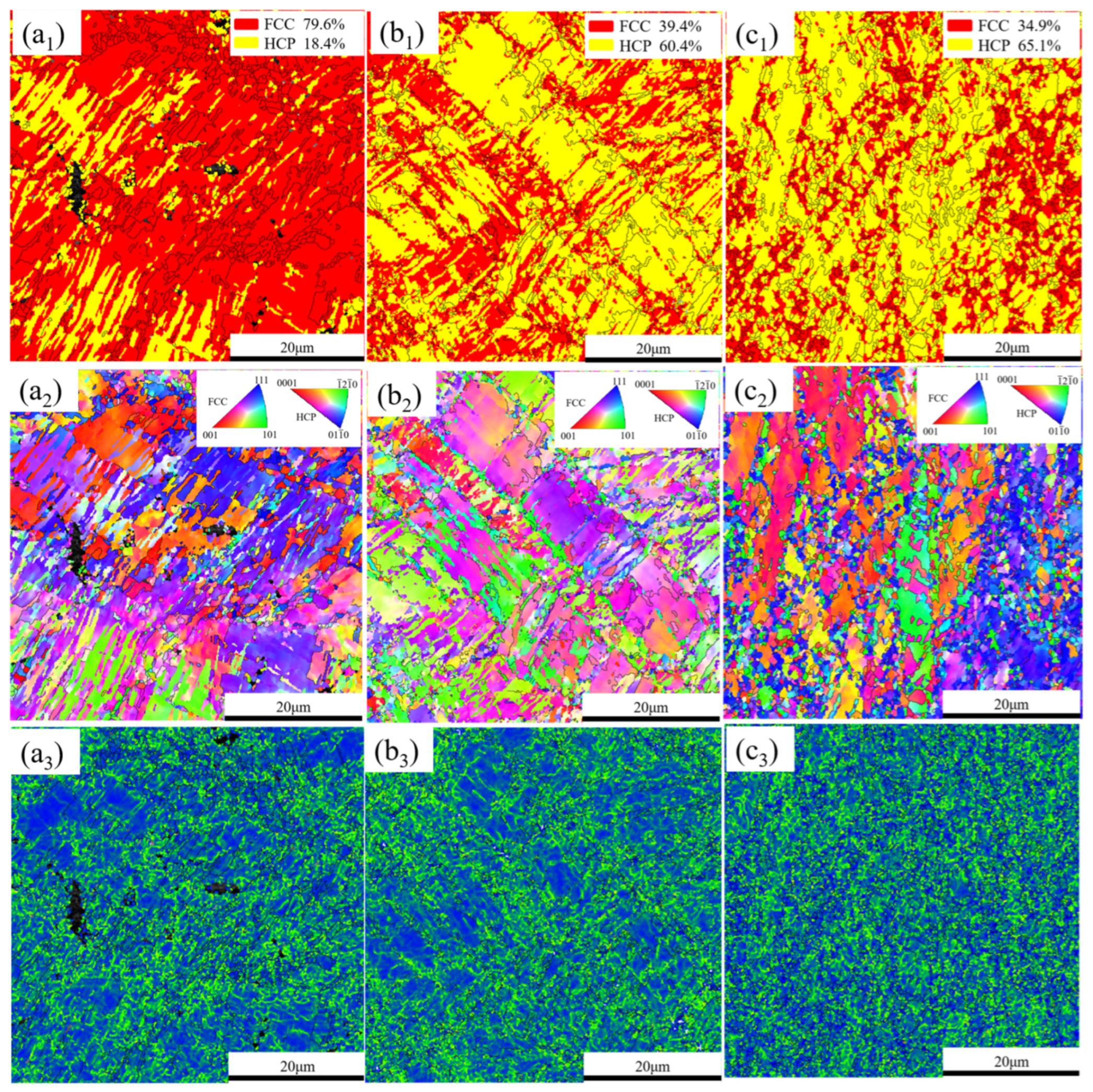

3.1. Microstructure After Annealing

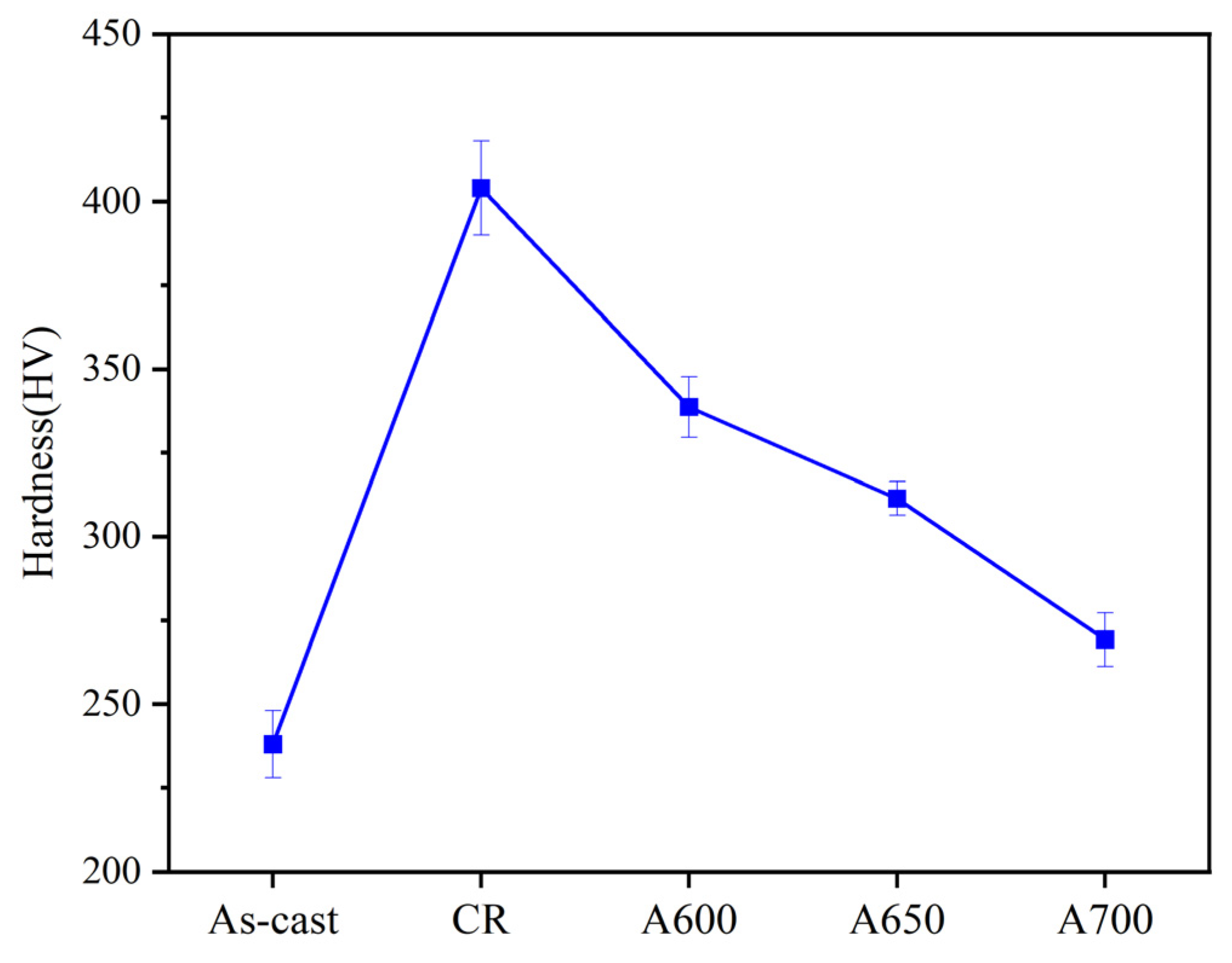

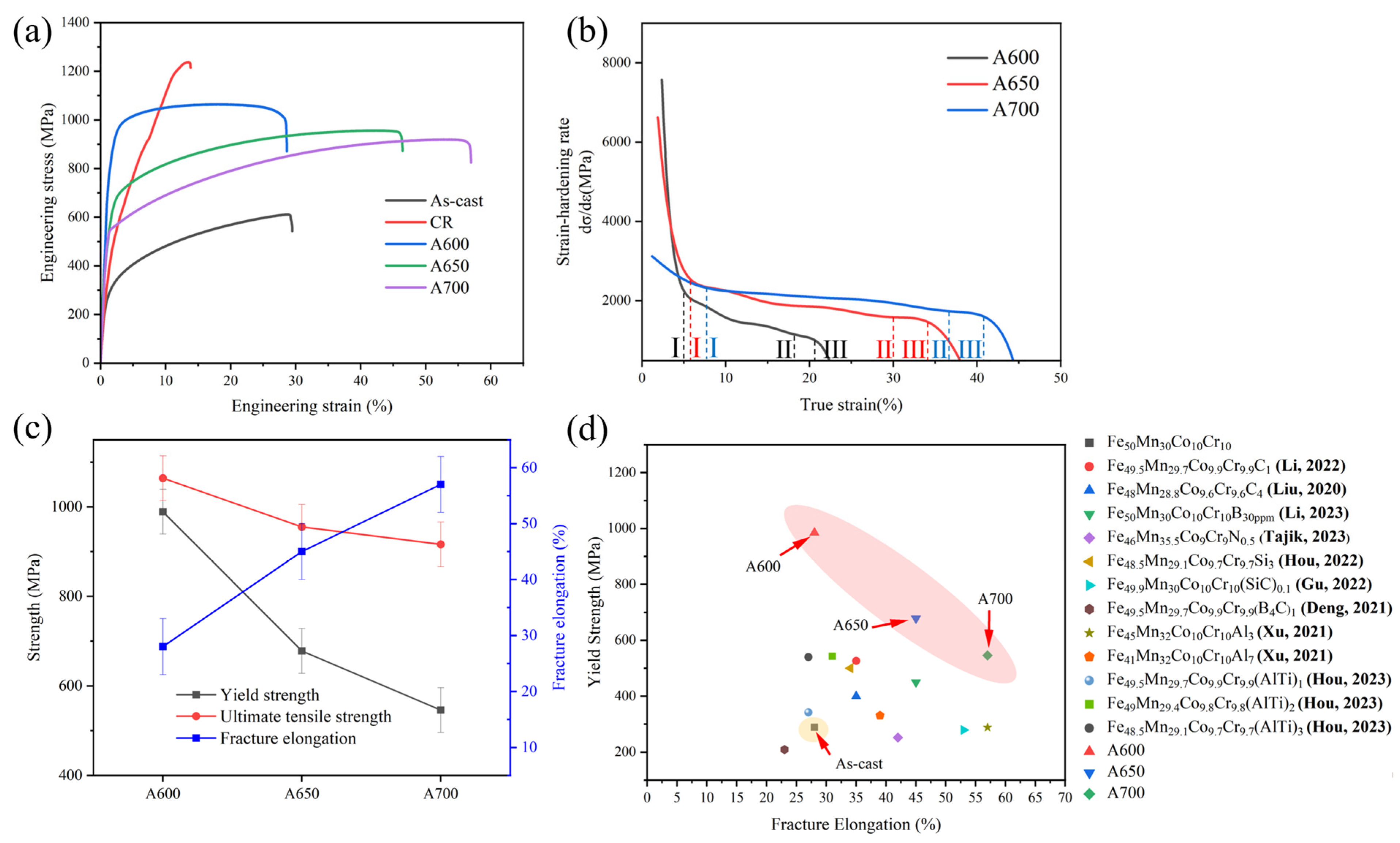

3.2. Mechanical Properties

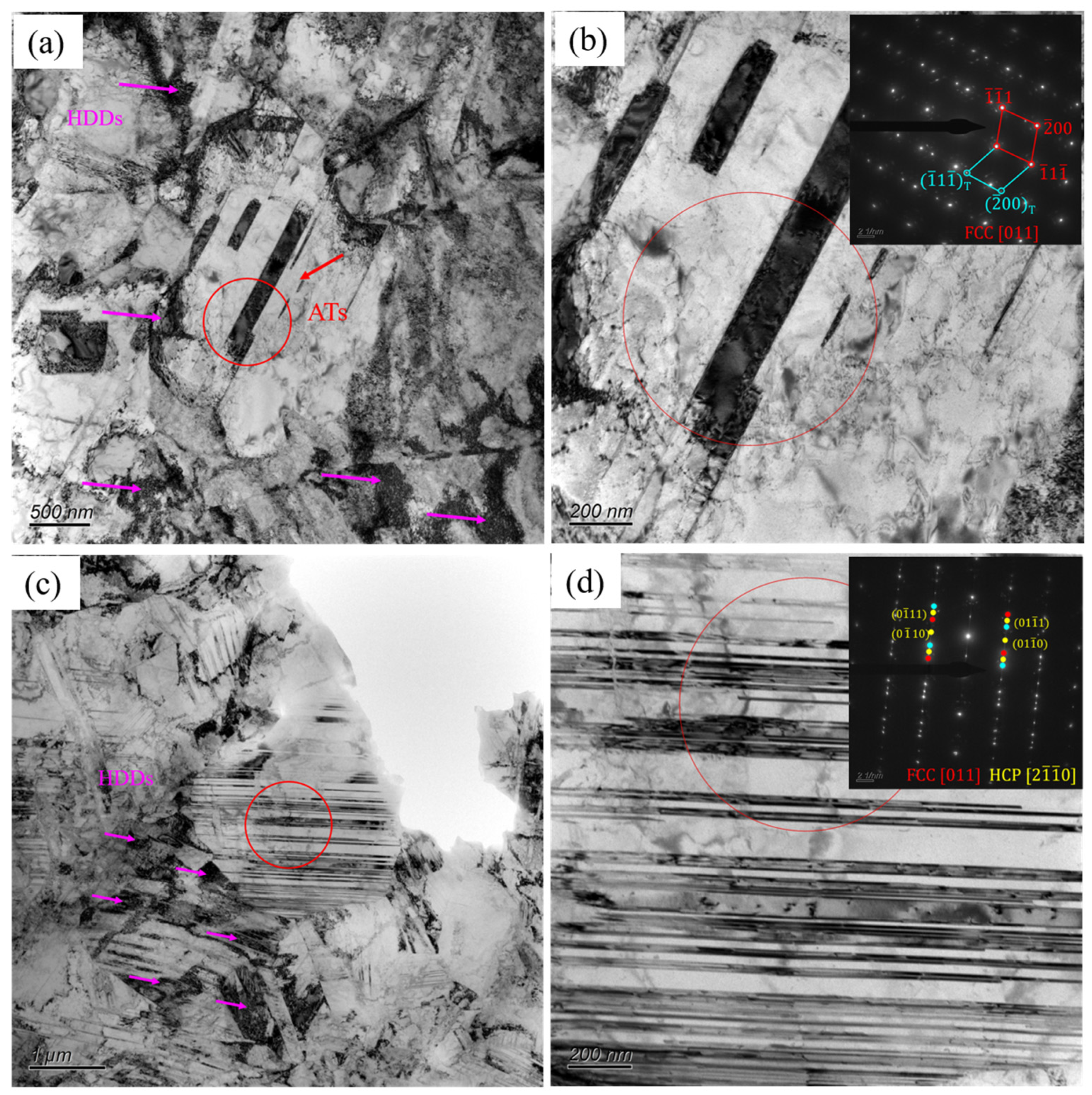

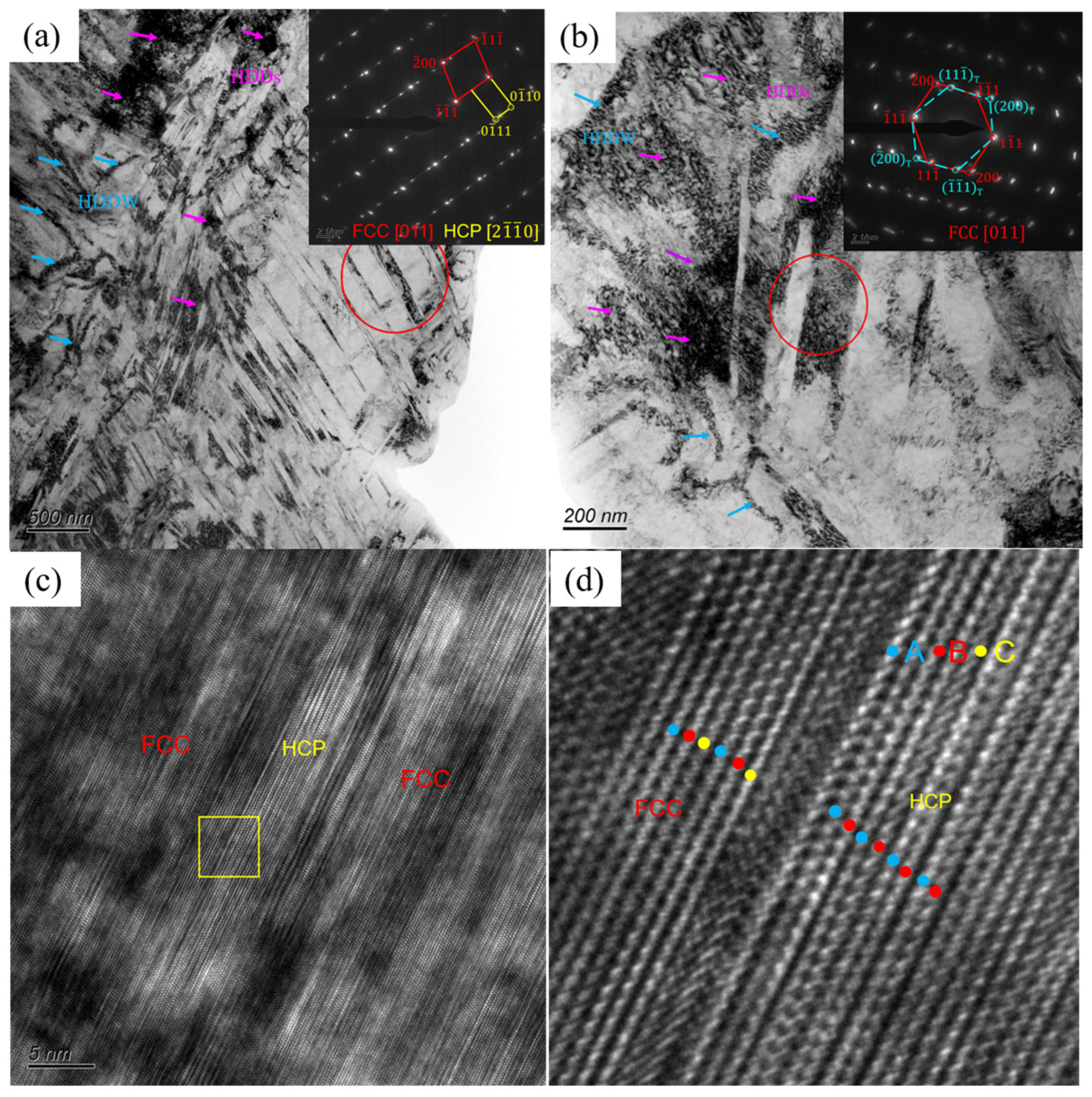

3.3. Microstructure After Deformation

4. Discussion

4.1. Strengthening Mechanism

4.2. Deformation Mechanism

5. Conclusions

- In the cold rolling process, in addition to some deformed FCC grains, there were some grains which occured the stress–induced FCC → HCP phase transformation. Subsequently, in the annealing process, some grains induced the HCP → FCC reverse phase transformation, and the remaining grains formed a heterogeneous microstructure characterized via the formation of deformed FCC grains with dense dislocations and the recrystallization of fine FCC grains.

- The combined effect of multiple strengthening mechanisms, including dislocation strengthening, grain boundary strengthening, and heterogeneous deformation-induced strengthening, resulted in a high yield strength of 989 MPa for the A600 sample with a heterogeneous microstructure.

- The TWIP effect activated by the deformation twins could continuously provide a source of strain-hardening and improve ductility while maintaining high strength. At the same time, the TRIP effect activated by stress induced FCC → HCP phase transformation combined with heterogeneous deformation-induced strain-hardening further improved the ductility. The combined effect of multiple deformation mechanisms realized a good combination of strength and ductility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Su, J.; Wu, X.X.; Raabe, D.; Li, Z.M. Deformation-driven bidirectional transformation promotes bulk nanostructure formation in a metastable interstitial high entropy alloy. Acta Mater. 2019, 167, 23–39. [Google Scholar] [CrossRef]

- Ikeda, Y.; Grabowski, B.; Körmann, F. Ab initio phase stabilities and mechanical properties of multicomponent alloys: A comprehensive review for high entropy alloys and compositionally complex alloys. Mater. Charact. 2019, 147, 464–511. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Ma, K.H.; Wang, Q.; Shek, C.H. Compositional dependence of phase formation and mechanical properties in three CoCrFeNi-(Mn/Al/Cu) high entropy alloys. Intermetallics 2016, 79, 1–11. [Google Scholar] [CrossRef]

- Mohammad-Ebrahimi, M.H.; Zarei-Hanzaki, A.; Abedi, H.R.; Vakili, S.M.; Soundararajan, C.K. The enhanced static recrystallization kinetics of a non-equiatomic high entropy alloy through the reverse transformation of strain induced martensite. J. Alloys Compd. 2019, 806, 1550–1563. [Google Scholar] [CrossRef]

- Ganji, R.S.; Karthik, P.S.; Rao, K.B.S.; Rajulapati, K.V. Strengthening mechanisms in equiatomic ultrafine grained AlCoCrCuFeNi high-entropy alloy studied by micro- and nanoindentation methods. Acta Mater. 2017, 125, 58–68. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Yang, T.; Tong, Y.; Wang, J.; Luan, J.H.; Jiao, Z.B.; Chen, D.; Yang, Y.; Hu, A.; Liu, C.T.; et al. Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater. 2017, 138, 72–82. [Google Scholar] [CrossRef]

- High Entropy Alloys Market Report Overview. Available online: https://www.businessresearchinsights.com/zh/market-reports/high-entropy-alloy-market-110243 (accessed on 4 November 2024).

- Otto, F.; Dlouhy, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Gu, L.; Hou, R.; Liu, Y.; Chen, G.; Liu, J.H.; Zheng, G.; Zhang, R.S.; Zhao, Y.H. Strengthening and toughening bulk Ni2CoFeV0.5 medium-entropy alloy via thermo-mechanical treatment. J. Mater. Sci. Technol. 2023, 151, 19–29. [Google Scholar] [CrossRef]

- Hu, J.J.; Zhong, W.; Liu, Q.Y. Study on the Performance of High-Speed Rail Damage of Four Different Materials. Adv. Mater. Sci. Eng. 2018, 2018, 5016414. [Google Scholar] [CrossRef]

- He, B.B.; Hu, B.; Yen, H.W.; Cheng, G.J.; Wang, Z.K.; Luo, H.W.; Huang, M.X. High dislocation density-induced large ductility in deformed and partitioned steels. Science 2017, 357, 1029–1032. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Cao, Y.; Jiang, Y.D.; Liu, Y.F.; Mao, Q.Z.; Zhou, H.; Liao, X.Z.; Zhao, Y.H. Effects of nanostructural hierarchy on the hardness and thermal stability of an austenitic stainless steel. J. Mater. Res. Technol.-JmrT 2021, 12, 376–384. [Google Scholar] [CrossRef]

- Zhang, L.J.; Yu, P.F.; Fan, J.T.; Zhang, M.D.; Zhang, C.Z.; Cui, H.Z.; Li, G. Investigating the micro and nanomechanical properties of CoCrFeNi-Cx high-entropy alloys containing eutectic carbides. Mater. Sci. Eng. a-Struct. Mater. Prop. Microstruct. Process. 2020, 796, 140065. [Google Scholar] [CrossRef]

- Xie, Y.C.; Cheng, H.; Tang, Q.H.; Chen, W.; Chen, W.K.; Dai, P.Q. Effects of N addition on microstructure and mechanical properties of CoCrFeNiMn high entropy alloy produced by mechanical alloying and vacuum hot pressing sintering. Intermetallics 2018, 93, 228–234. [Google Scholar] [CrossRef]

- Choi, M.; Ondicho, I.; Park, N.; Tsuji, N. Strength-ductility balance in an ultrafine-grained non-equiatomic Fe50(CoCrMnNi)50medium-entropy alloy with a fully recrystallized microstructure. J. Alloys Compd. 2019, 780, 959–966. [Google Scholar] [CrossRef]

- Ji, P.C.; Jia, Y.D.; Ma, P.; Mu, Y.K.; Sun, K.; Wang, G. Exceptional strength-ductility combination of CoCrFeMnNi high-entropy alloy with fully recrystallized structure by selective laser melting after post-deformation annealing. J. Mater. Res. Technol.-JmrT 2023, 23, 3166–3176. [Google Scholar] [CrossRef]

- Miao, X.L.; Liu, G.; Xu, C.C.; Wang, D.Y.; Han, Z.H.; Zhang, G.J. Achieving strength and ductility synergy in (CoCrFeNi)94Ti2Al4 high entropy alloy with multi-scale heterogeneous microstructure. Intermetallics 2024, 164, 108107. [Google Scholar] [CrossRef]

- Ma, E.; Zhu, T. Towards strength-ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today 2017, 20, 323–331. [Google Scholar] [CrossRef]

- Wu, X.L.; Yang, M.X.; Yuan, F.P.; Wu, G.L.; Wei, Y.J.; Huang, X.X.; Zhu, Y.T. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef]

- Wei, Y.J.; Li, Y.Q.; Zhu, L.C.; Liu, Y.; Lei, X.Q.; Wang, G.; Wu, Y.X.; Mi, Z.L.; Liu, J.B.; Wang, H.T.; et al. Evading the strength- ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 2014, 5, 3580. [Google Scholar] [CrossRef]

- Li, Z.M.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Jain, R.; Kumar, M.; Biswas, K.; Gurao, N.P. Deformation behaviour of the silicon doped metastable Fe50-xMn30Co10Cr10Six complex concentrated alloy using experiments and crystal plasticity simulations. Mater. Sci. Eng. a-Struct. Mater. Prop. Microstruct. Process. 2023, 885, 145620. [Google Scholar] [CrossRef]

- Li, X.L.; Hao, X.X.; Jin, C.; Wang, Q.; Deng, X.T.; Wang, H.F.; Wang, Z.D. The determining role of carbon addition on mechanical performance of a non-equiatomic high-entropy alloy. J. Mater. Sci. Technol. 2022, 110, 167–177. [Google Scholar] [CrossRef]

- Liu, X.L.; Zhao, X.R.; Chen, J.; Lv, Y.K.; Wang, X.H.; Liu, B.; Liu, Y. Effect of C addition on microstructure and mechanical properties of as-cast HEAs (Fe50Mn30Co10Cr10)100-x Cx. Mater. Chem. Phys. 2020, 254, 123501. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.L.; Jin, C.; Li, H.Z.; Hua, K.; Deng, X.T.; Wang, H.F. Trace B doping Fe50Mn30Co10Cr10 high entropy alloy: Mechanical response and multi-microstructure evolution under TWIP and TRIP effects. Mater. Sci. Eng. A 2023, 873, 145037. [Google Scholar] [CrossRef]

- Tajik, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Moshiri, A.; Lee, G.; Sohn, S.S. Substructure development, martensitic transformation and rapid work-hardening in an as-cast interstitial substituted N atom in FeMnCoCr high-entropy alloy. J. Alloys Compd. 2023, 960, 170705. [Google Scholar] [CrossRef]

- Hou, Y.X.; Liu, T.; He, D.D.; Li, Z.J.; Chen, L.; Su, H.H.; Fu, P.X.; Dai, P.Q.; Huang, W.D. Sustaining strength-ductility synergy of SLM Fe50Mn30Co10Cr10 metastable high-entropy alloy by Si addition. Intermetallics 2022, 145, 107565. [Google Scholar] [CrossRef]

- Gu, Y.L.; Yi, M.L.; Chen, Y.; Tu, J.; Zhou, Z.M.; Luo, J.R. Effect of the amount of SiC particles on the microstructure, mechanical and wear properties of FeMnCoCr high entropy alloy composites. Mater. Charact. 2022, 193, 112300. [Google Scholar] [CrossRef]

- Deng, L.; Bai, C.Y.; Jiang, Z.T.; Luo, J.R.; Tu, J.; Xu, H.Y.; Huang, H.; Tan, L.; Ding, L.P. Effect of B4C particles addition on microstructure and mechanical properties of Fe50Mn30Co10Cr10 high-entropy alloy. Mater. Sci. Eng. a-Struct. Mater. Prop. Microstruct. Process. 2021, 822, 141642. [Google Scholar] [CrossRef]

- Xu, N.; Yang, Z.M.; Mu, X.; Huang, Y.B.; Li, S.L.; Wang, Y.D. Effect of Al addition on the microstructures and deformation behaviors of non-equiatomic FeMnCoCr metastable high entropy alloys. Appl. Phys. Lett. 2021, 119, 261902. [Google Scholar] [CrossRef]

- Hou, Y.X.; Li, Z.J.; Chen, L.; Xiang, Z.N.; Dai, P.Q.; Chen, J.F. SLM Fe50Mn30Co10Cr10 metastable high entropy alloy with Al-Ti addition: Synergizing strength and ductility. J. Alloys Compd. 2023, 941, 168830. [Google Scholar] [CrossRef]

- Wang, Z.; Baker, I.; Cai, Z.; Chen, S.; Poplawsky, J.D.; Guo, W. The effect of interstitial carbon on the mechanical properties and dislocation substructure evolution in Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys. Acta Mater. 2016, 120, 228–239. [Google Scholar] [CrossRef]

- Chandan, A.K.; Tripathy, S.; Sen, B.; Ghosh, M.; Chowdhury, S.G. Temperature dependent deformation behavior and stacking fault energy of Fe40Mn40Co1Cr10alloy. Scr. Mater. 2021, 199, 113891. [Google Scholar] [CrossRef]

- Chen, W.T.; An, X.L.; Wang, Z.W.; Li, Y.; Gu, J.; Song, M. Grain size dependent deformation behavior of a metastable Fe40Co20Cr20Mn10Ni10 high-entropy alloy. J. Alloys Compd. 2021, 883, 160876. [Google Scholar] [CrossRef]

- Li, J.H.; Lu, K.J.; Zhao, X.J.; Ma, X.K.; Li, F.G.; Pan, H.B.; Chen, J.M. A superior strength-ductility synergy of Al0.1CrFeCoNi high-entropy alloy with fully recrystallized ultrafine grains and annealing twins. J. Mater. Sci. Technol. 2022, 131, 185–194. [Google Scholar] [CrossRef]

- Dini, G.; Ueji, R.; Najafizadeh, A.; Monir-Vaghefi, S.M. Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 2010, 527, 2759–2763. [Google Scholar] [CrossRef]

- Su, J.; Raabe, D.; Li, Z.M. Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy. Acta Mater. 2019, 163, 40–54. [Google Scholar] [CrossRef]

- Liu, W.; Tu, H.L.; Gao, M.; Su, X.P.; Zhang, S.Y.; Huo, C.S.; Yang, H. High performance DLC/BP and ZnS/YbF3 double-layer protective and antireflective coatings. J. Alloys Compd. 2013, 581, 526–529. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Min, P.J.; Jongun, M.; Wung, B.J.; Asghari-Rad, P.; Zargaran, A.; Hyoung, S.K. Achieving high strength and high ductility in Al0.3CoCrNi medium-entropy alloy through multi-phase hierarchical microstructure. Materialia 2019, 8, 100442. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.Y.; Harrington, T.; Vecchio, K. Design of non-equiatomic high entropy alloys with heterogeneous lamella structure towards strength-ductility synergy. Scr. Mater. 2018, 154, 78–82. [Google Scholar] [CrossRef]

- Gao, P.; Ma, Z.H.; Gu, J.; Ni, S.; Suo, T.; Li, Y.L.; Song, M.; Mai, Y.W.; Liao, X.Z. Exceptional high-strain-rate tensile mechanical properties in a CrCoNi medium-entropy alloy. Sci. China-Mater. 2022, 65, 811–819. [Google Scholar] [CrossRef]

- Wu, S.W.; Wang, G.; Wang, Q.; Jia, Y.D.; Yi, J.; Zhai, Q.J.; Liu, J.B.; Sun, B.A.; Chu, H.J.; Shen, J.; et al. Enhancement of strength-ductility trade-off in a high-entropy alloy through a heterogeneous structure. Acta Mater. 2019, 165, 444–458. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Lv, Y.K.; Song, P.T.; Wang, Y.Z.; Zhao, X.R.; Gao, W.; Zhang, J.; Lei, Y.T.; Chen, J. Improving Mechanical Properties of FeMnCoCr High-Entropy Alloy via Annealing after Cold Rolling. Materials 2024, 17, 676. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.L.; Jiang, P.; Chen, L.; Yuan, F.P.; Zhu, Y.T.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.L.; Zhu, Y.T. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

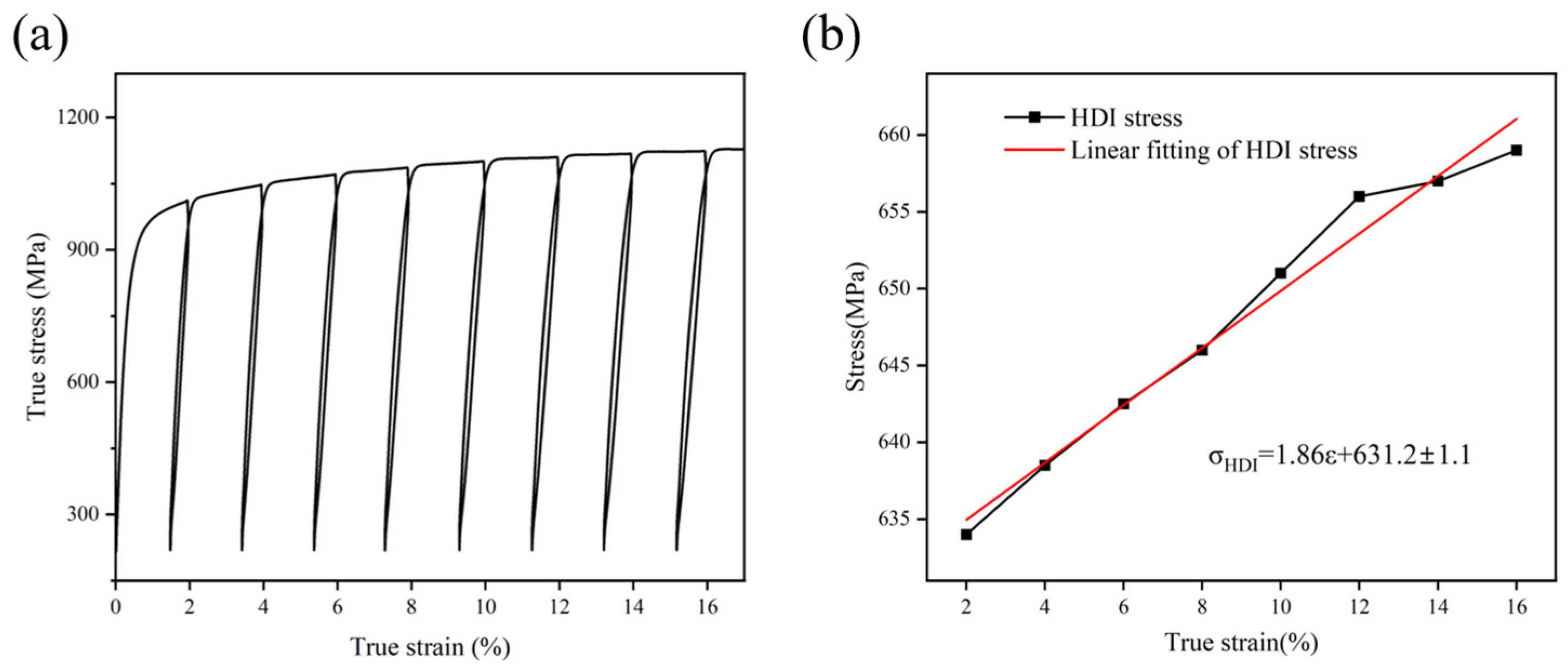

- Zhu, Y.T.; Wu, X.L. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef]

- Liu, Y.F.; Cao, Y.; Mao, Q.Z.; Zhou, H.; Zhao, Y.H.; Jiang, W.; Liu, Y.; Wang, J.T.; You, Z.S.; Zhu, Y.T. Critical microstructures and defects in heterostructured materials and their effects on mechanical properties. Acta Mater. 2020, 189, 129–144. [Google Scholar] [CrossRef]

| Sample Name | YS (MPa) | UTS (MPa) | FE (%) |

|---|---|---|---|

| As-cast | 300 ± 5 | 610 ± 7 | 29 ± 2 |

| CR | 1214 ± 5 | 1237 ± 7 | 13 ± 1 |

| A600 | 989 ± 8 | 1064 ± 11 | 28 ± 3 |

| A650 | 678 ± 9 | 955 ± 12 | 45 ± 2 |

| A700 | 546 ± 7 | 916 ± 9 | 57 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Zhou, W.; Li, Z.; Hong, C.; Chang, F.; Tian, J.; Dai, P. Heterogeneous Microstructure and Tensile Properties of Fe50Mn30Co10Cr10 Metastable High-Entropy Alloy. Materials 2024, 17, 5893. https://doi.org/10.3390/ma17235893

Sun X, Zhou W, Li Z, Hong C, Chang F, Tian J, Dai P. Heterogeneous Microstructure and Tensile Properties of Fe50Mn30Co10Cr10 Metastable High-Entropy Alloy. Materials. 2024; 17(23):5893. https://doi.org/10.3390/ma17235893

Chicago/Turabian StyleSun, Xiuying, Wei Zhou, Zhanjiang Li, Chunfu Hong, Fa Chang, Jun Tian, and Pinqiang Dai. 2024. "Heterogeneous Microstructure and Tensile Properties of Fe50Mn30Co10Cr10 Metastable High-Entropy Alloy" Materials 17, no. 23: 5893. https://doi.org/10.3390/ma17235893

APA StyleSun, X., Zhou, W., Li, Z., Hong, C., Chang, F., Tian, J., & Dai, P. (2024). Heterogeneous Microstructure and Tensile Properties of Fe50Mn30Co10Cr10 Metastable High-Entropy Alloy. Materials, 17(23), 5893. https://doi.org/10.3390/ma17235893