Study of the Straw Compaction Degree as a Function of Moisture Content, Particle Size and Process Temperature

Highlights

- ANOVA analysis of influence of process settings on the densification process results.

- The particle size has the most significant influence on densification degree.

- The temperature has the most significant influence on densification degree.

- The densification degree after unloading indicates better stability of the biofuel.

- The densification degree after unloading is more significant in terms of storage.

Abstract

1. Introduction

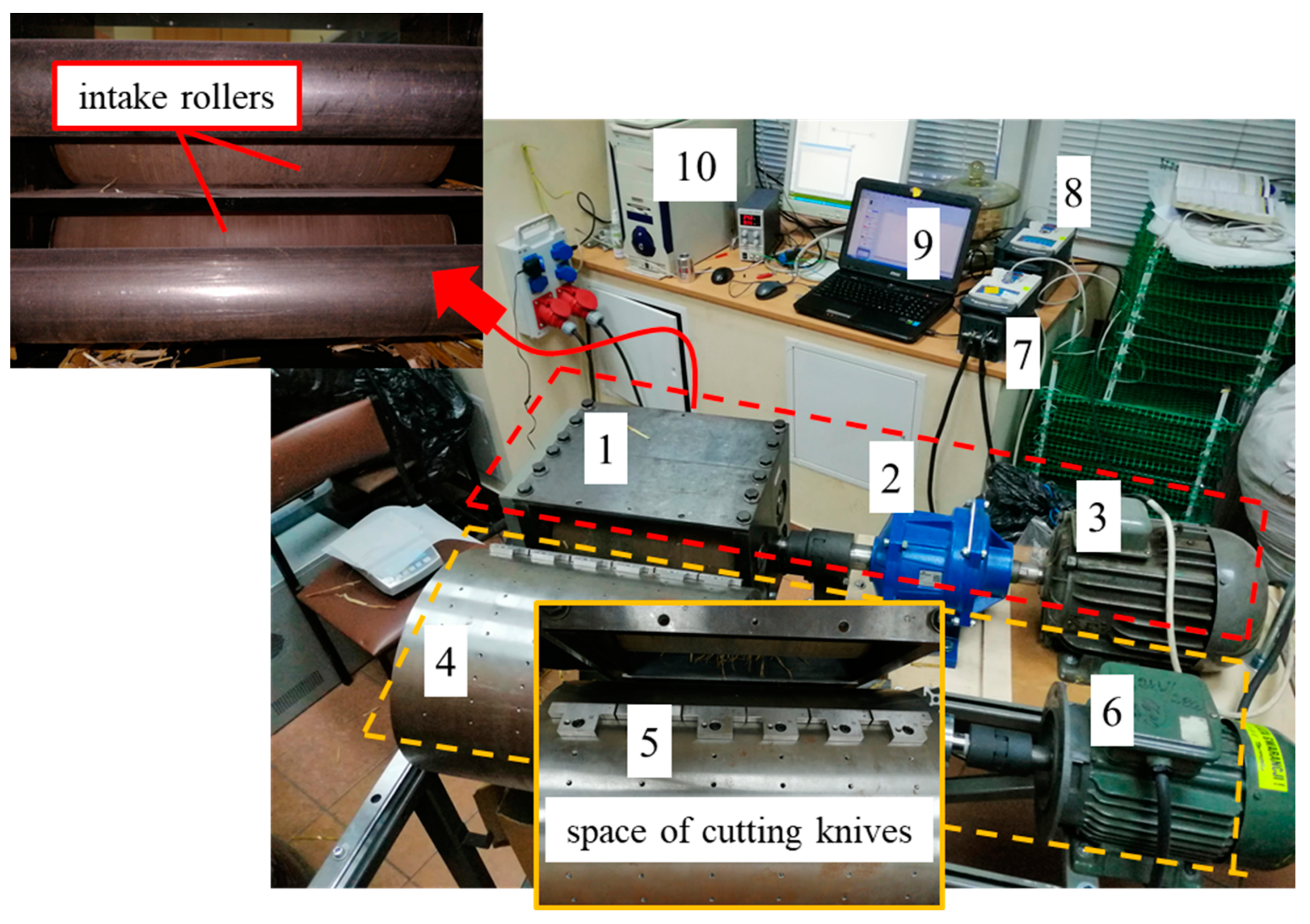

2. Materials and Methods

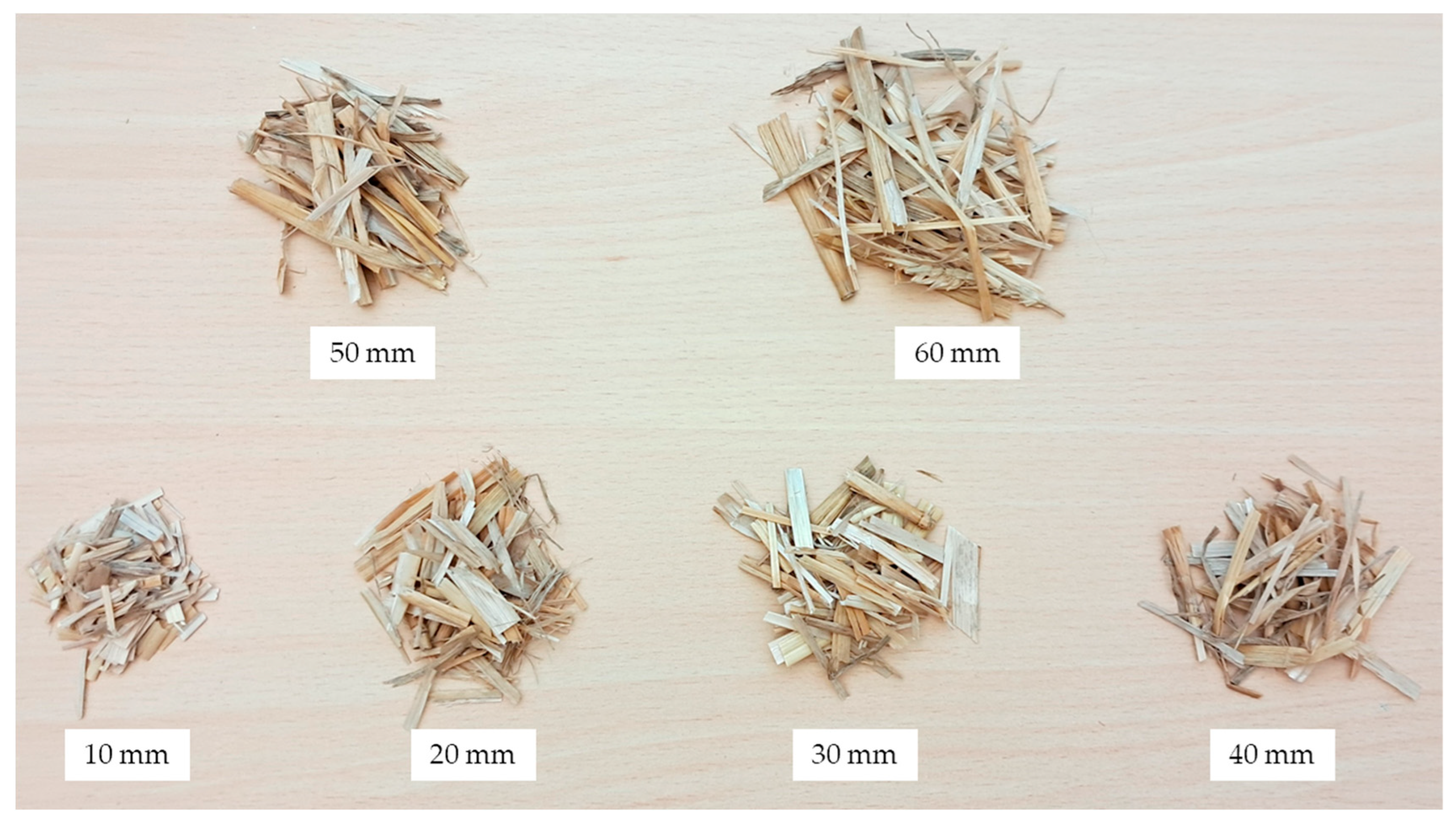

Material Preparation

3. Results and Discussion

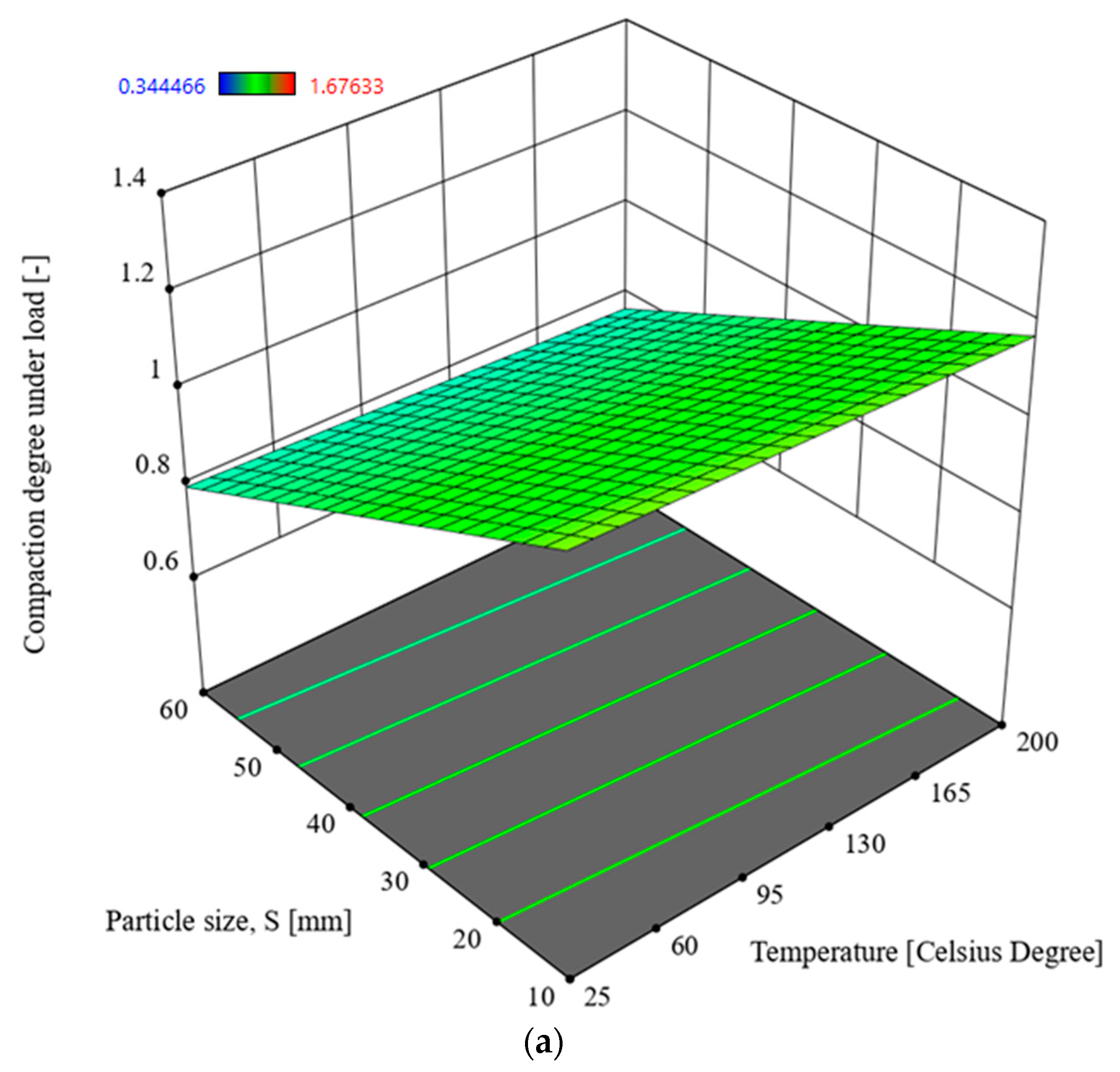

3.1. Multivariate Analysis of Compaction Degree Under Load x1

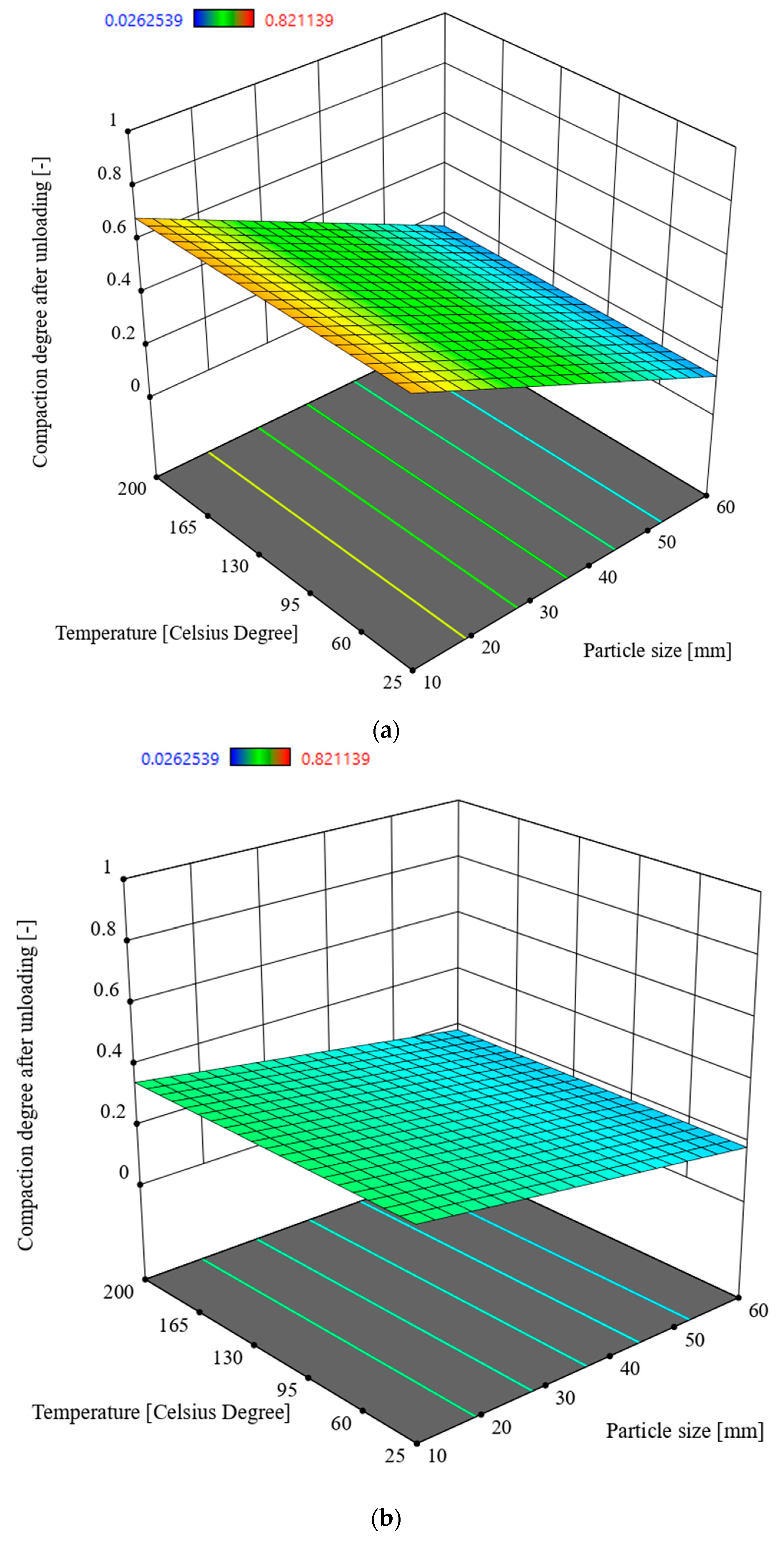

3.2. Multivariate Analysis of Compaction Degree After Unloading x2

3.3. Selection of Densification Process Parameters for Straw Using Recorded Experimental Results

4. Conclusions

- Based on the experimental studies, two values of densification degree were determined: x1, the densification degree under load, and x2, the densification degree after unloading. The densification degree x2 is considered more significant in terms of storage and transport. This is because, for materials like biomass, the ability of the densified material to maintain its shape and structural integrity after unloading is crucial for practical applications such as transportation and storage. A higher x2 value indicates better stability of the agglomerate after compression, which is desirable for ease of handling and minimising the risk of re-expansion or degradation during storage and transport.

- The Analysis of Variance (ANOVA) of the obtained results showed that the particle size S and the process temperature T had the greatest influence on the value of x1 (the densification degree under load). Higher values of x1 were achieved for straw with a moisture content of 30% (see Figure 6 and Table 3 and Table 5).

- The Analysis of Variance (ANOVA) regarding the densification degree after unloading x2 showed that higher values of x2 were obtained for straw with a moisture content of 10% and the smallest particle size of S = 10 mm. The greatest influence on the x2 value was exerted by the particle size and moisture content (see Table 5 and Figure 7).

- The conducted studies on the coefficient of friction of straw against the components of the densifying device indicated that the optimal process temperature is T = 150 °C. This temperature allows for maintaining lower energy consumption in the process, even though the friction coefficient of the straw increases at this temperature. The lowest value of the friction coefficient was recorded at a densification temperature of 200 °C.

- To extend the conducted research and obtain more detailed information, the authors believe that the study could be expanded by investigating the densification of straw at moisture content levels lower than 10%. Additionally, the influence of compaction stress could be explored by densifying straw at stress levels lower than 15 MPa, such as 10 MPa, and higher stress levels, for example, 20, 25 MPa, or even higher. Furthermore, to achieve lower energy consumption in the process while maintaining good mechanical properties of the resulting agglomerate, different types of binders could be used in the study to determine their impact on the mechanical properties of the agglomerate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zamiri, M.A.; Dafchahi, M.N.; Ebadian, M.; Acharya, B. Optimizing production conditions of innovative bio-pellets developed from flax straw. Ind. Crops Prod. 2024, 218, 118950. [Google Scholar] [CrossRef]

- Demirbas, M.F.; Balat, M.; Balat, H. Potential contribution of biomass to the sustainable energy development. Energy Convers. Manag. 2009, 50, 1746–1760. [Google Scholar] [CrossRef]

- Garrido, M.A.; Conesa, J.A.; Garcia, M.D. Characterization and Production of Fuel Briquettes Made from Biomass and Plastic Wastes. Energies 2017, 10, 850. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification system to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Fenton, J. Cost Benefit of Biomass Supply and Preprocessing: BIOCAP (Canada) Research Integration Program Synthesis Paper. Available online: https://www.cesarnet.ca/biocap-archive/rif/report/Sokhansanj_S.pdf (accessed on 6 November 2024).

- Mitchell, P.; Kiel, J.; Livingston, B.; Dupont-Roc, G. Torrefied biomass: A foresighting study into the business case for pellets from torrefied biomass as a new solid fuel. In All Energy; University of Aberdeen, ECN, Doosan Babcock, and ITI Energy: Aberdeen, UK, 2007. [Google Scholar]

- CAN, X.; Moset, V.; Wahid, R.; Moeller, H.B. The efficiency of shredded and briquetted wheat straw in anaerobic co-digestion with dairy cattle manure. Biosyst. Eng. 2015, 139, 16–24. [Google Scholar] [CrossRef]

- Liu, J.; Li, T.; Liu, T.; Cai, H. Parametric studies on energy utilization of the Chinese medicine residues: Preparation and properties of densified pellet. Heliyon 2024, 10, e36947. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Musiał, D.; Nabiałczyk, M. Computational and Experimental Studies on Combustion and Co-Combustion ofWood Pellets with Waste Glycerol. Materials 2023, 16, 7156. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Su, Z.; Jiang, T. Improving the Properties of Magnetite Green Pellets with a Novel Organic Composite Binder. Materials 2022, 15, 6999. [Google Scholar] [CrossRef]

- Laosena, R.; Palamanit, A.; Luengchavanon, M.; Kittijaruwattana, J.; Nakason, C.; Lee, S.H.; Chotikhun, A. Characterization of Mixed Pellets Made from Rubberwood (Hevea brasiliensis) and Refuse-Derived Fuel (RDF) Waste as Pellet Fuel. Materials 2022, 15, 3093. [Google Scholar] [CrossRef]

- Horabik, J.; Bańda, M.; Józefaciuk, G.; Adamczuk, A.; Polakowski, C.; Stasiak, M.; Parafiniuk, P.; Wiącek, J.; Kobyłka, R.; Molenda, M. Breakage Strength of Wood Sawdust Pellets: Measurements and Modelling. Materials 2021, 14, 3273. [Google Scholar] [CrossRef]

- Styks, J.; Knapczyk, A.; Łapczyńska-Kordon, B. Effect of Compaction Pressure and Moisture Content on Post-Agglomeration Elastic Springback of Pellets. Materials 2021, 14, 879. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Chandra, R.P.; Sokhansanj, S.; Saddler, J.N. The Role of Biomass Composition and Steam Treatment on Durability of Pellets. BioEnergy Res. 2018, 11, 341–350. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Stelte, W.; Dahl, J.; Ahrenfeldt, J.; Holm, J.K.; Puig Arnavat, M.; Bach, L.S.; Henriksen, U.B. Lab and Bench-Scale Pelletization of Torrefied Wood Chips—Process Optimization and Pellet Quality. Bioenerg. Res. 2014, 7, 87–94. [Google Scholar] [CrossRef]

- Colley, Z.; Fasina, O.O.; Bransby, D.; Lee, Y.Y. Moisture effect on the physical characteristics of switchgrass pellets. Am. Soc. Agric. Biol. Eng. 2006, 49, 1845–1851. [Google Scholar] [CrossRef]

- Adapa, P.K.; Tabil, L.G.; Schoenau, G.J. Compaction characteristics of barley, canola, oat, and wheat straw. Biosyst. Eng. 2009, 104, 335–344. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of process variables on density and durability of pellets made from high moisture corn stover. Biosyst. Eng. 2014, 119, 45–57. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Ojolo, S.J.; Ajiboye, J.S. Pressure buildup and wear analysis of tapered screw extruder biomass briquetting machines. Agric. Eng. Int. CIGR J. 2019, 21, 122–133. [Google Scholar]

- Orisaleye, J.I.; Ojolo, S.J.; Ajiboye, J.S. Mathematical modelling of die pressure of a screw briquetting machine. J. King Saud Univ. -Eng. Sci. 2019, 32, 555–560. [Google Scholar] [CrossRef]

- Kovacova, M.; Matúš, M.; Krizan, P.; Beniak, J. Design theory for the pressing chamber in the solid biofuel production process. Acta Polytech. 2014, 54, 28.e34. [Google Scholar] [CrossRef]

- Patta Granado, M.P.; Valentinovich, Y.; Suhogusoff, M.; Oliveira Santos, L.R.; Minoru Yamaji, F.; Cressoni De Conti, A. Effects of pressure densification on strength and properties of cassava waste briquettes. Renew. Energy 2021, 167, 306–312. [Google Scholar] [CrossRef]

- Höntsch, S.; Fehse, F.; Schröder, H.W.; Herdegen, V.; Braeuer, A.S. Influence of comminution and briquetting parameters on the agglomeration behaviour of wheat straw. Biomass Bioenergy 2024, 182, 107077. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Matkowski, P.; Lisowski, A.; Świętochowski, A. Effect of compacted dose of pure straw and blends of straw with calcium carbonate or cassava starch on pelletising process and pellet quality. J. Clean. Prod. 2020, 277, 124006. [Google Scholar] [CrossRef]

- Bai, X.; Wang, G.; Gong, C.; Yu, Y.; Liu, W.; Wang, D. Co-pelletizing characteristics of torrefied wheat straw with peanut shell. Bioresour. Technol. 2017, 233, 373–381. [Google Scholar] [CrossRef] [PubMed]

- Lisowski, A.; Matkowski, P.; Dąbrowska, M.; Piątek, M.; Świętochowski, A.; Klonowski, J.; Mieszkalski, L.; Reshetiuk, V. Particle Size Distribution and Physicochemical Properties of Pellets, Made of Straw, Hay, and Their Blends. Waste Biomass Valorization 2020, 11, 63–75. [Google Scholar] [CrossRef]

- Adam, R.; Yiyang, D.; Kruggel-Emden, H.; Zeng, T.; Lenz, V. Influence of pressure and retention time on briquette volume and raw density during biomass densification with an industrial stamp briquetting machine. Renew. Energy 2024, 229, 120773. [Google Scholar] [CrossRef]

- Chen, S.; Ding, H.; Tang, Z.; Hao, S.; Zhao, Y. Influence of rice straw forming factors on ring die wear and improved wear prediction model during briquetting. Biosyst. Eng. 2022, 214, 122–137. [Google Scholar] [CrossRef]

- Križan, P. The Densification Process of Wood Waste; De Gruyter Open Ltd.: Berlin, Germany, 2014; ISBN 978-3-11-044001-0. [Google Scholar]

- Tumuluru, J. Effect of Moisture Content and Hammer Mill Screen Size on the Briquetting Characteristics of Woody and Herbaceous Biomass. KONA Powder Part. J. 2019, 36, 241–251. Available online: https://www.jstage.jst.go.jp/article/kona/advpub/0/advpub_2019009/_article/-char/ja/ (accessed on 6 November 2024). [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability–A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Obidziński, S.; Szyszlak-Bargłowicz, J.; Zając, G.; Kowczyk-Sadowy, M.; Krasowska, M.; Sienkiewicz, A.; Cwalina, P.; Faszczewski, D.; Wasilewski, J. The effect of bakery waste addition on pine sawdust pelletization and pellet quality. Energies 2024, 17, 523. [Google Scholar] [CrossRef]

- Behjoee, M.; Zamiri, M.A.; Tabil, L.G.; Baik, O.D.; Niu, C.H. Equilibrium, thermodynamics, and regeneration and reuse of biosorbents developed from pelletized agricultural residues for gas dehydration. Energy Fuels 2023, 37, 1451–1463. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef] [PubMed]

- Rawal, T.B.; Zahran, M.; Dhital, B.; Akbilgic, O.; Petridis, L. The relation between lignin sequence and Its 3D structure. Biochim. Et. Biophys. Acta (BBA)-Gen. Subj. 2020, 1864, 129547. [Google Scholar] [CrossRef] [PubMed]

- Patel, R.; Dhar, P.; Babaei-Ghazvini, A.; Dafchahi, M.N.; Acharya, B. Transforming lignin into renewable fuels, chemicals, and materials: A review. Bioresour. Technol. Rep. 2023, 22, 101463. [Google Scholar] [CrossRef]

- Dos Santos Bernardes, M.A. (Ed.) Biofuel’s Engineering Process Technology; IntechOpen: Rijeka, Croatia, 2011; ISBN 978-953-307-480-1. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Constitutive model for densification of corn stover and switchgrass. Biosyst. Eng. 2009, 104, 47–63. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Densification characteristics of corn cobs. Fuel Process. Technol. 2010, 91, 559–565. [Google Scholar] [CrossRef]

- Sitzmann, W.; Buschhart, A. Pelleting as prerequisite for the energetic utilization of by-products of the wood-processing industry; Amandus Kahl GmBH & Co.: Oslo, Norway, 2009. [Google Scholar]

| Particle Size S [mm] | Temperature T [°C] | Moisture M [%] | Compaction Degree Under Load x1 [-] | Compaction Degree After Unloading x2 [-] |

|---|---|---|---|---|

| 10 | 25 | 10 | 1.12 | 0.82 |

| 10 | 50 | 10 | 1.16 | 0.67 |

| 10 | 100 | 10 | 1.15 | 0.61 |

| 10 | 150 | 10 | 1.39 | 0.74 |

| 10 | 200 | 10 | 1.19 | 0.76 |

| 20 | 25 | 10 | 0.98 | 0.48 |

| 20 | 50 | 10 | 1.03 | 0.49 |

| 20 | 100 | 10 | 1.15 | 0.52 |

| 20 | 150 | 10 | 1.02 | 0.43 |

| 20 | 200 | 10 | 1.09 | 0.62 |

| 30 | 25 | 10 | 1.14 | 0.59 |

| 30 | 50 | 10 | 1.06 | 0.59 |

| 30 | 100 | 10 | 1.05 | 0.44 |

| 30 | 150 | 10 | 0.99 | 0.38 |

| 30 | 200 | 10 | 1.14 | 0.60 |

| 40 | 25 | 10 | 1.19 | 0.63 |

| 40 | 50 | 10 | 0.99 | 0.44 |

| 40 | 100 | 10 | 0.78 | 0.25 |

| 40 | 150 | 10 | 0.87 | 0.26 |

| 40 | 200 | 10 | 0.91 | 0.32 |

| 50 | 25 | 10 | 0.95 | 0.36 |

| 50 | 50 | 10 | 0.78 | 0.27 |

| 50 | 100 | 10 | 0.88 | 0.21 |

| 50 | 150 | 10 | 0.76 | 0.08 |

| 50 | 200 | 10 | 0.81 | 0.19 |

| 60 | 25 | 10 | 0.84 | 0.29 |

| 60 | 50 | 10 | 0.82 | 0.29 |

| 60 | 100 | 10 | 0.77 | 0.15 |

| 60 | 150 | 10 | 0.82 | 0.05 |

| 60 | 200 | 10 | 0.78 | 0.09 |

| 10 | 25 | 30 | 1.68 | 0.66 |

| 10 | 50 | 30 | 1.13 | 0.19 |

| 10 | 100 | 30 | 0.52 | 0.26 |

| 10 | 150 | 30 | 0.79 | 0.02 |

| 10 | 200 | 30 | 1.24 | 0.69 |

| 20 | 25 | 30 | 1.49 | 0.41 |

| 20 | 50 | 30 | 0.99 | 0.42 |

| 20 | 100 | 30 | 0.48 | 0.34 |

| 20 | 150 | 30 | 0.68 | 0.15 |

| 20 | 200 | 30 | 0.78 | 0.13 |

| 30 | 25 | 30 | 1.58 | 0.61 |

| 30 | 50 | 30 | 0.99 | 0.17 |

| 30 | 100 | 30 | 0.60 | 0.23 |

| 30 | 150 | 30 | 0.54 | 0.18 |

| 30 | 200 | 30 | 0.95 | 0.19 |

| 40 | 25 | 30 | 1.29 | 0.31 |

| 40 | 50 | 30 | 1.02 | 0.03 |

| 40 | 100 | 30 | 0.76 | 0.21 |

| 40 | 150 | 30 | 0.52 | 0.34 |

| 40 | 200 | 30 | 0.53 | 0.22 |

| 50 | 25 | 30 | 1.13 | 0.22 |

| 50 | 50 | 30 | 0.92 | 0.05 |

| 50 | 100 | 30 | 0.62 | 0.25 |

| 50 | 150 | 30 | 0.49 | 0.35 |

| 50 | 200 | 30 | 0.40 | 0.38 |

| 60 | 25 | 30 | 0.97 | 0.15 |

| 60 | 50 | 30 | 0.79 | 0.04 |

| 60 | 100 | 30 | 0.54 | 0.18 |

| 60 | 150 | 30 | 0.42 | 0.24 |

| 60 | 200 | 30 | 0.34 | 0.26 |

| Name | Units | Type | Low | High |

|---|---|---|---|---|

| Particle size, S | [mm] | Factor | 10 | 60 |

| Temperature, T | [°C] | Factor | 25 | 200 |

| Moisture, M | [%] | Factor | 10 | 30 |

| Compaction degree under load, x1 | [-] | Response | 0.34 | 1.68 |

| Compaction degree after unloading, x2 | [-] | Response | 0.03 | 0.82 |

| Source | Sum of Squares | df a | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 3.08 | 4 | 0.7701 | 22.68 | <0.0001 | significant |

| S | 1.16 | 1 | 1.16 | 34.29 | <0.0001 | |

| T | 0.8549 | 1 | 0.8549 | 25.17 | <0.0001 | |

| M | 0.4625 | 1 | 0.4625 | 13.62 | 0.0005 | |

| T · M | 0.6998 | 1 | 0.6998 | 20.61 | <0.0001 |

| Source | Sum of Squares | df a | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 1.46 | 3 | 0.4876 | 25.56 | <0.0001 | significant |

| S | 0.8536 | 1 | 0.8536 | 44.74 | <0.0001 | |

| M | 0.3661 | 1 | 0.3661 | 19.19 | <0.0001 | |

| S . M | 0.2431 | 1 | 0.2431 | 12.74 | 0.0007 |

| Response | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| x1 | S | T | T · M | M | - |

| x2 | S | M | S · M | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilczyński, D.; Talaśka, K.; Wałęsa, K.; Wojtkowiak, D.; Kryszczyński, K.; Kołodziej, A.; Konecki, K.; Urbaniak, Ł. Study of the Straw Compaction Degree as a Function of Moisture Content, Particle Size and Process Temperature. Materials 2024, 17, 5869. https://doi.org/10.3390/ma17235869

Wilczyński D, Talaśka K, Wałęsa K, Wojtkowiak D, Kryszczyński K, Kołodziej A, Konecki K, Urbaniak Ł. Study of the Straw Compaction Degree as a Function of Moisture Content, Particle Size and Process Temperature. Materials. 2024; 17(23):5869. https://doi.org/10.3390/ma17235869

Chicago/Turabian StyleWilczyński, Dominik, Krzysztof Talaśka, Krzysztof Wałęsa, Dominik Wojtkowiak, Kuba Kryszczyński, Andrzej Kołodziej, Karol Konecki, and Łukasz Urbaniak. 2024. "Study of the Straw Compaction Degree as a Function of Moisture Content, Particle Size and Process Temperature" Materials 17, no. 23: 5869. https://doi.org/10.3390/ma17235869

APA StyleWilczyński, D., Talaśka, K., Wałęsa, K., Wojtkowiak, D., Kryszczyński, K., Kołodziej, A., Konecki, K., & Urbaniak, Ł. (2024). Study of the Straw Compaction Degree as a Function of Moisture Content, Particle Size and Process Temperature. Materials, 17(23), 5869. https://doi.org/10.3390/ma17235869