Quality Characteristics of Sustainable High-Performance Concrete Formulated from Binary, Ternary, and Quaternary Supplementary Cementitious Materials Under Various Curing Conditions

Abstract

1. Introduction

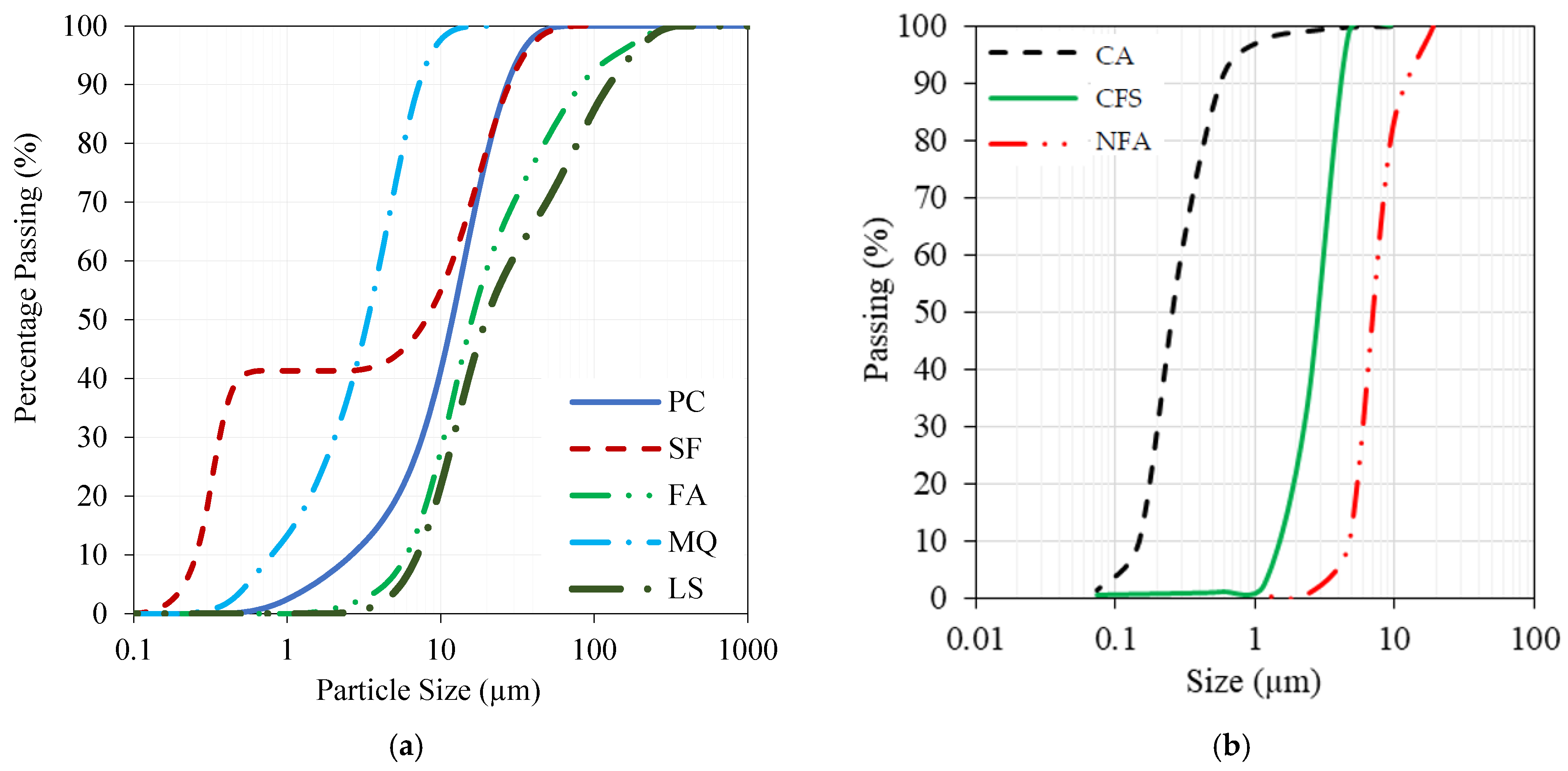

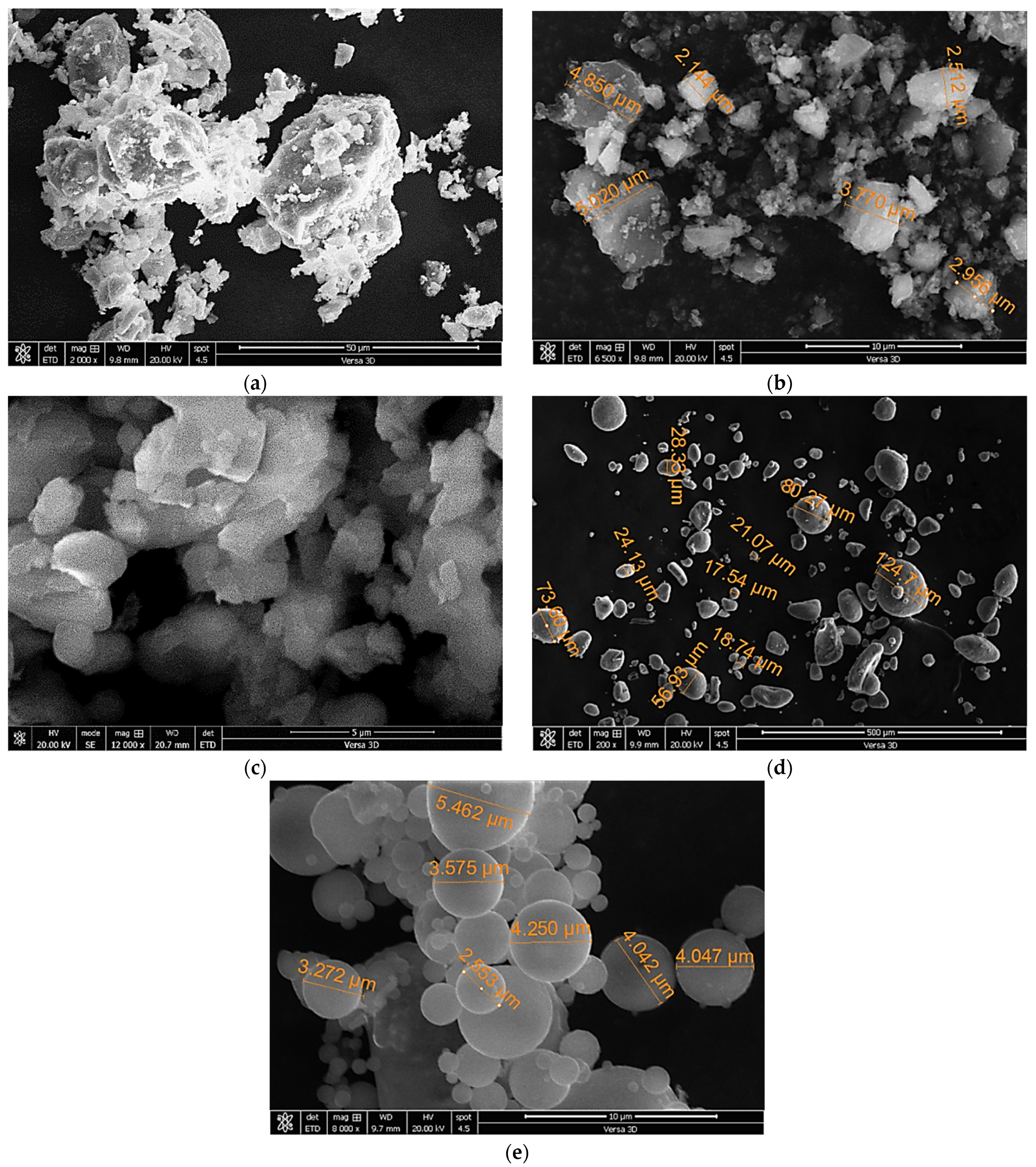

2. Materials

3. Methodology

3.1. Preparation Scheme

3.2. Detail of Mixtures

3.3. Testing Scheme

4. Results and Discussion

4.1. Compression Test Results

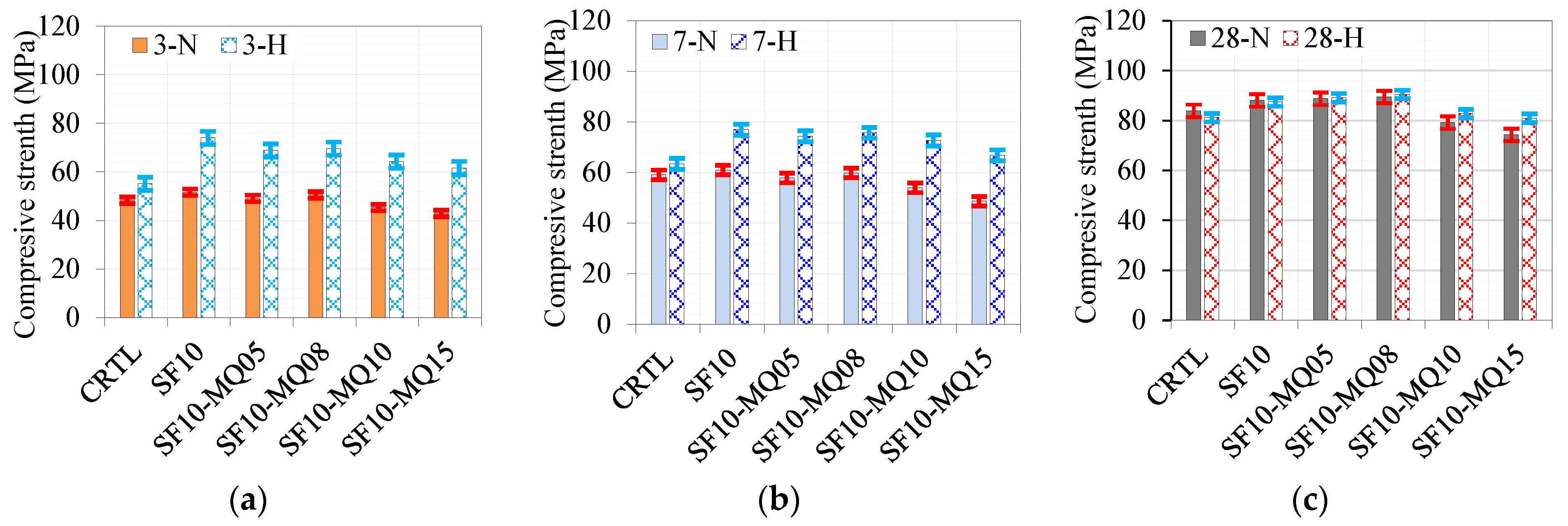

4.1.1. Compressive Strength of SF-MQ Ternary Concrete Mixtures

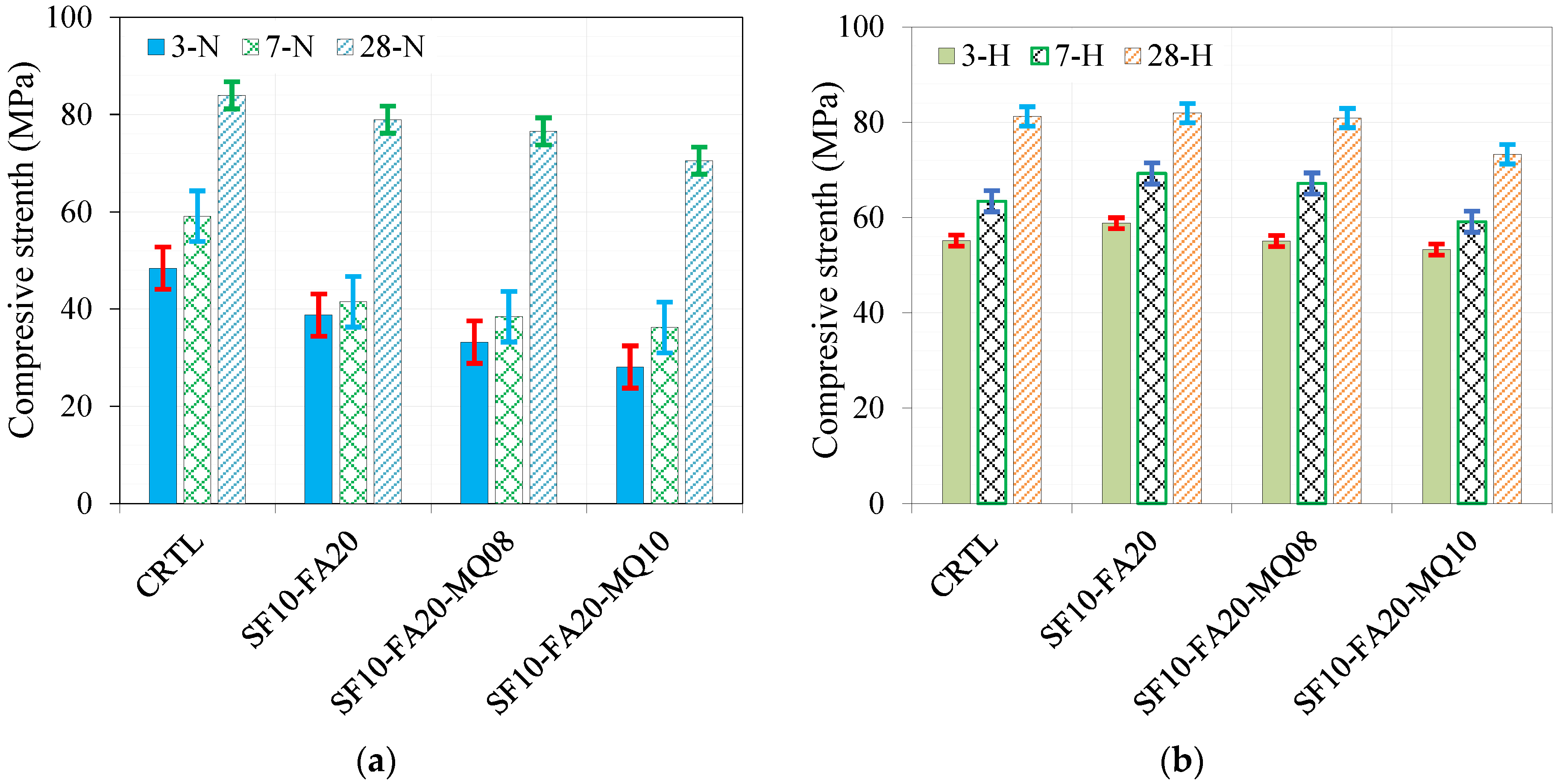

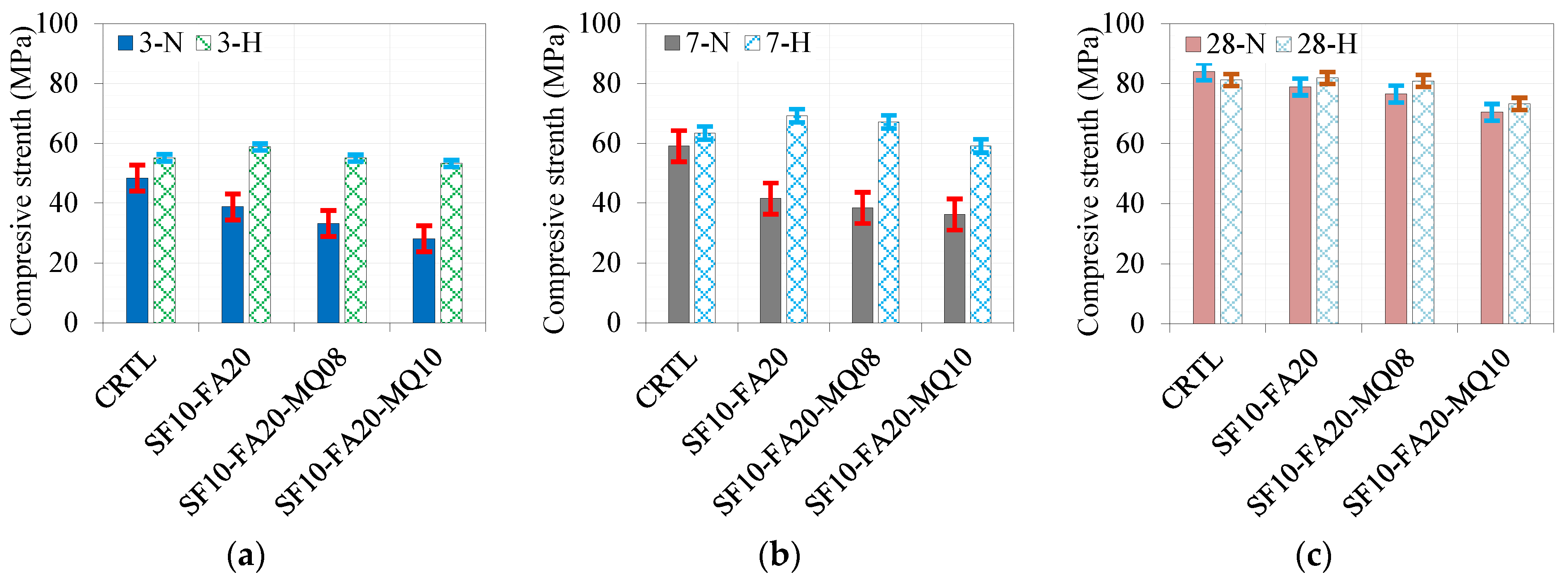

4.1.2. Compressive Strength of SF-MQ-FA Quaternary Concrete Mixtures

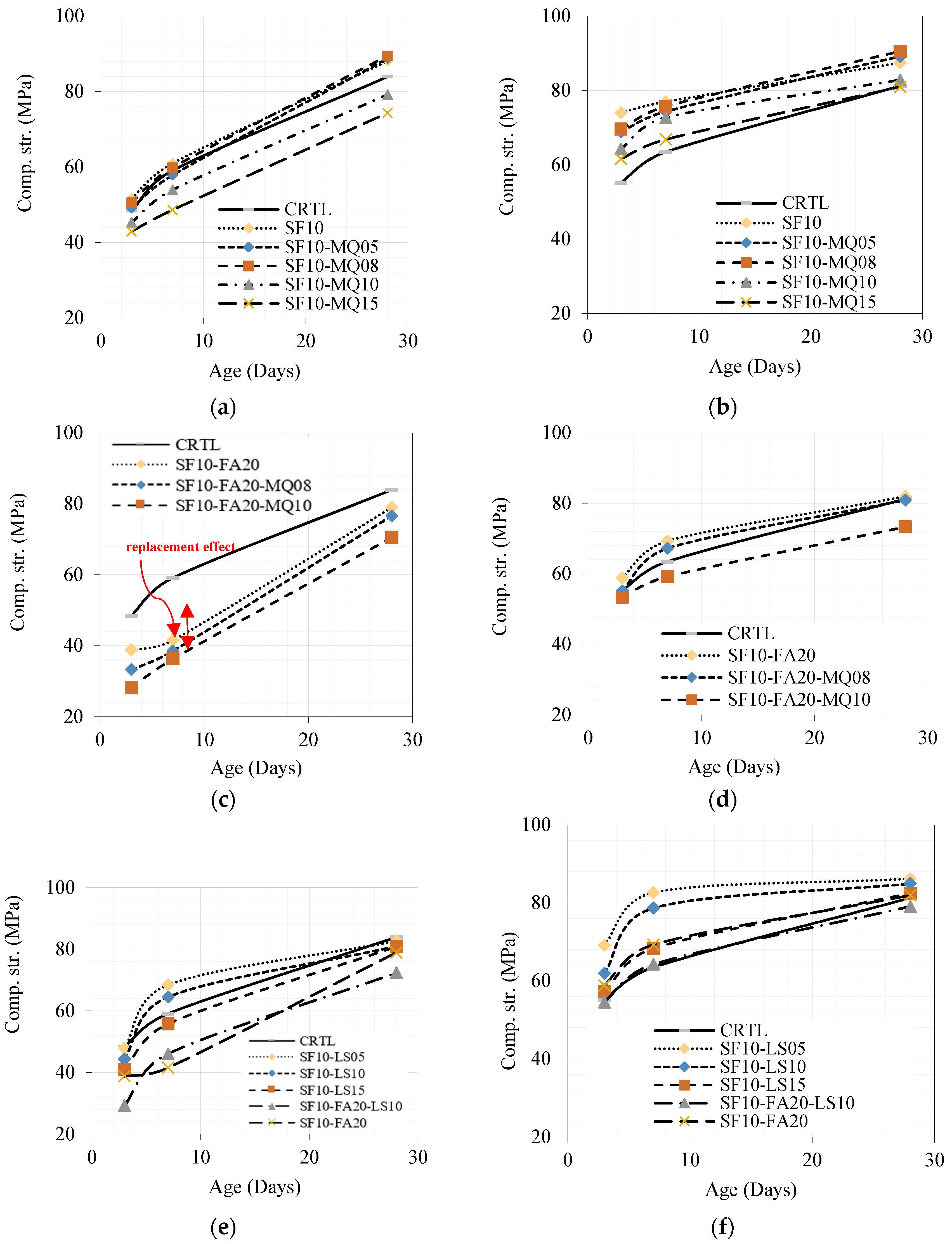

4.1.3. Development of Compressive Strength of Ternary and Quaternary Concrete Mixtures

4.1.4. Compressive Strength Variation with Time

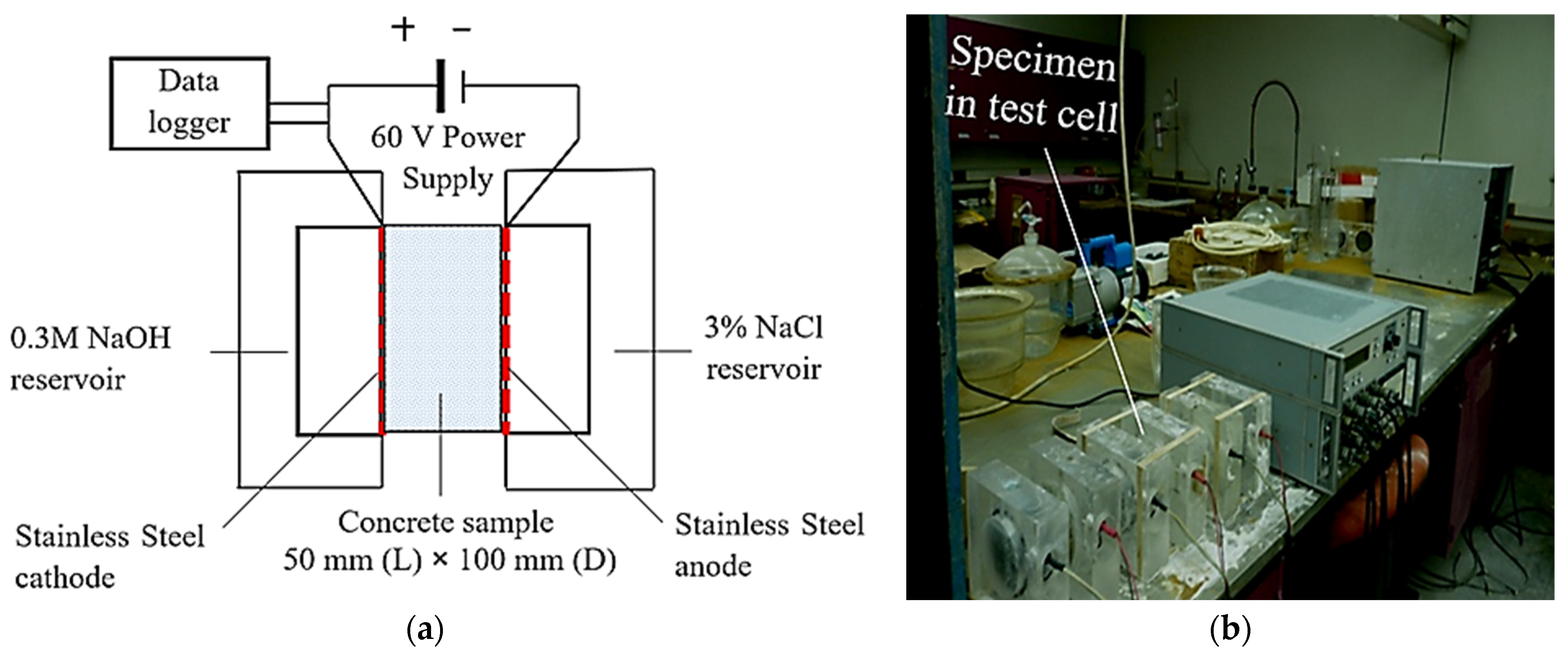

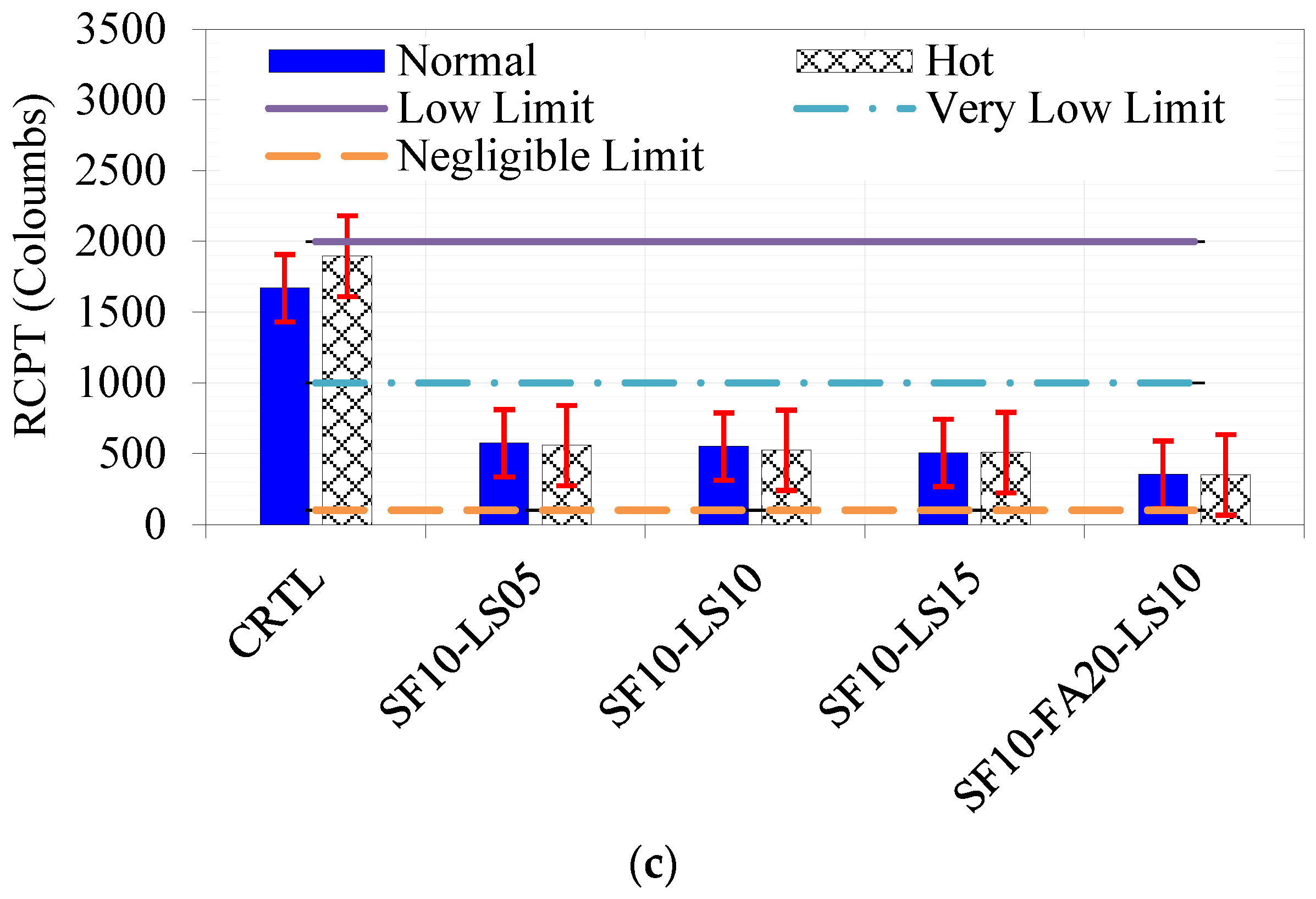

4.2. Rapid Chloride-Ion Permeability Test Results

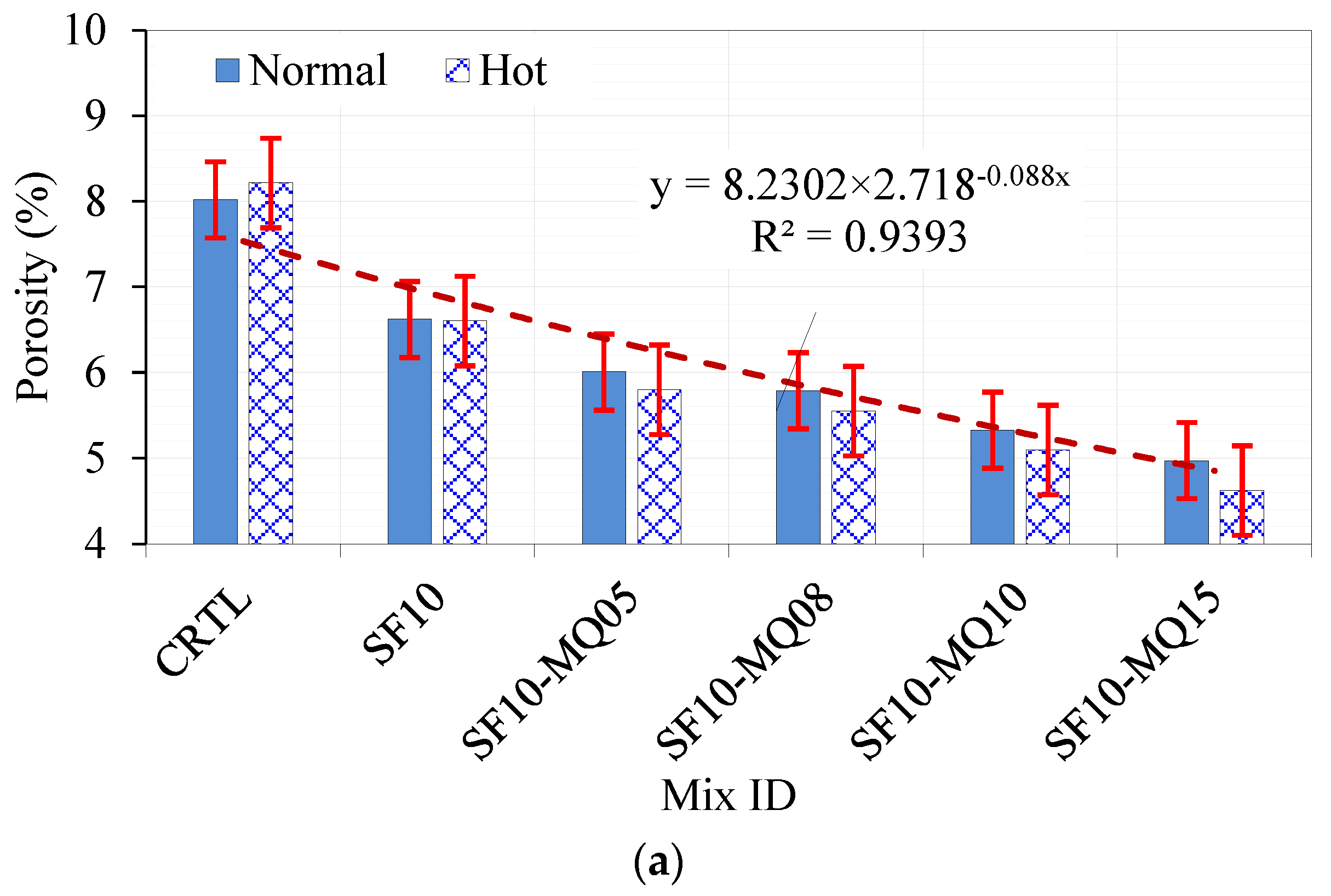

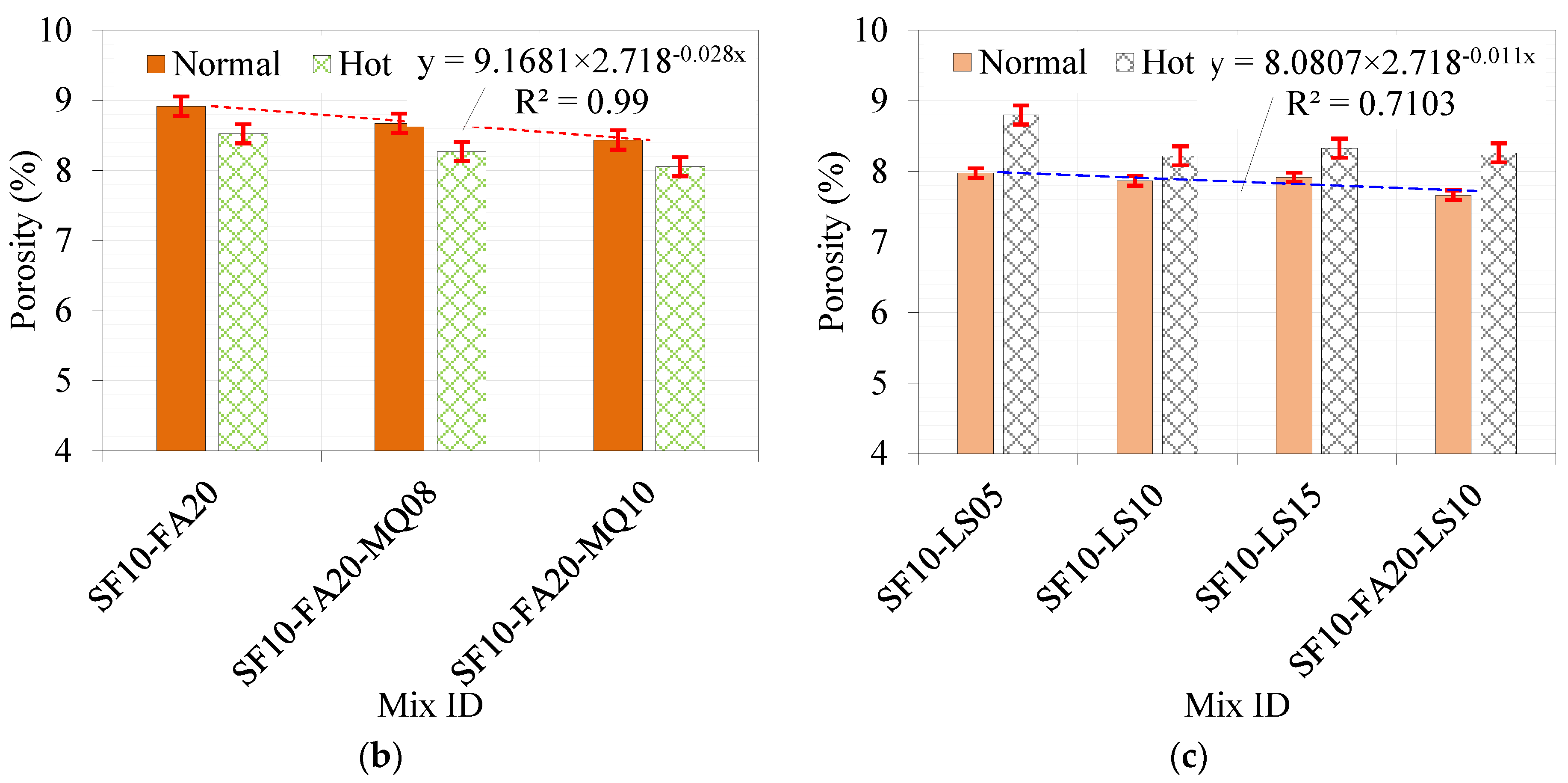

4.3. Porosity Test Results

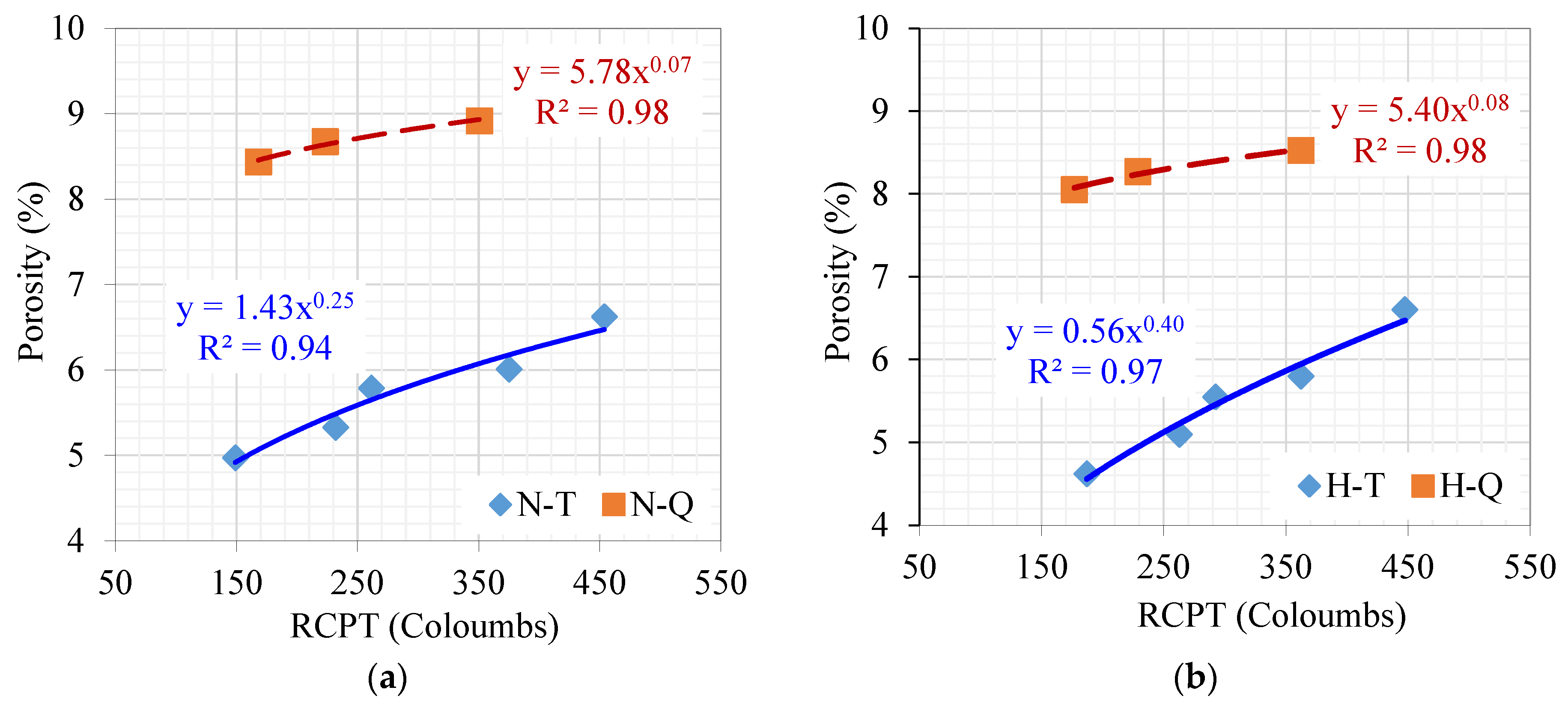

4.4. Permeability and Porosity Relations

5. Economic Feasibility Investigation

6. Conclusions, Limitations, and Future Studies

- (1)

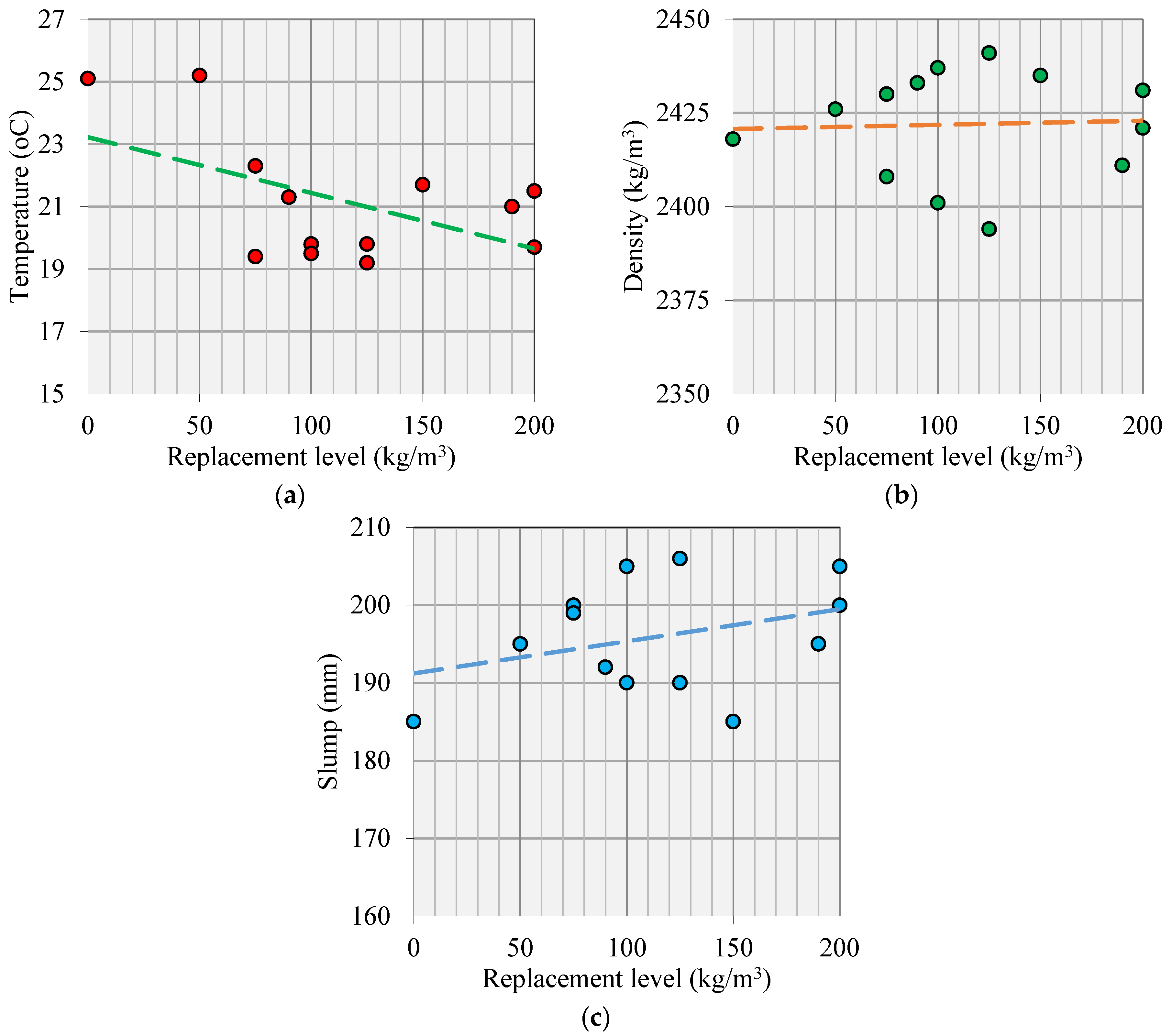

- The fresh properties are affected by the replacement levels of the SCMs. The temperature of the mixes decreases with an increase in the replacement level. The slump increases with an increase in the replacement level of SCMs. The effect on the concrete density is affected by many parameters, including the type, nature, and volume of SCM, in addition to the fine and coarse aggregate content.

- (2)

- Strength development is substantially affected by the replacement level of SCMs. The presence of MQ enhanced the strength until a replacement level of 8%. The incorporation of LS into compressive strength is noted to be slightly accompanied by a gradual reduction in strength that could be compensated using hot curing conditions. The quaternary cementitious systems led to a substantial reduction in strength that could be overcome using hot curing conditions.

- (3)

- The enhancing effect of SCMs on reducing chloride permeability is noted in all binary, ternary, and quaternary mixtures compared to the control mixture.

- (4)

- Porosity based on water absorption decreases with binary and ternary systems until the optimum replacement levels are reached, while it increases with quaternary systems due to reduced hydration reactions. Similarly, the effect of hot curing conditions increases water absorption due to the early accelerated hydration, which leads to an increased pore system.

- (5)

- The mixtures investigated demonstrated significantly improved impermeability and resistance against chloride ion penetration, which resulted in the enhanced durability of the structures. Therefore, the mixtures are recommended for structures susceptible to chloride and other chemical attacks.

- (6)

- The economic analysis revealed that optimized HPC mixtures incorporating SCMs and fillers significantly enhance cost-effectiveness and mechanical performance, with the optimum quaternary mix achieving the best balance of cost (EUR 75.6/m³) and efficiency (index: 1.047 under hot curing), while the binary and ternary mixes offered tailored improvements for specific conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ASTM | American society for testing and materials |

| CA | coarse aggregate |

| CFA | crushed fine aggregate, used in combination with NFA to achieve target gradation |

| CFS | crushed fine sand |

| CTRL | control mix without any SCMs or fillers |

| FA | fly ash |

| HPC | high-performance concrete |

| LS | limestone powder |

| MOE | modulus of elasticity |

| MQ | micro-quartz |

| NFA | natural fine aggregate |

| PC | Portland cement |

| QM | quartz micro-filler |

| RCPT | rapid chloride permeability test |

| SCMs | supplementary cementitious materials |

| SF | silica fume |

| SP | superplasticizer |

| W/B | water-to-binder ratio |

References

- Makul, N. Advanced Smart Concrete—A Review of Current Progress, Benefits and Challenges. J. Clean Prod. 2020, 274, 122899. [Google Scholar] [CrossRef]

- Azmee, N.; Abbas, Y.M.; Shafiq, N.; Fares, G.; Osman, M.; Iqbal Khan, M. Enhancing the Microstructure and Sustainability of Ultra-High-Performance Concrete Using Ultrafine Calcium Carbonate and High-Volume Fly Ash under Different Curing Regimes. Sustainability 2021, 13, 3900. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Khan, M.I. Optimization of Arabian-Shield-Based Natural Pozzolan and Silica Fume for High-Performance Concrete Using Statistical Design of Experiments. Adv. Civ. Eng. 2021, 2021, 5512666. [Google Scholar] [CrossRef]

- Aïtcin, P.C. The Durability Characteristics of High Performance Concrete: A Review. Cem. Concr. Compos. 2003, 25, 409–420. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Dai, Y.; Xu, C.; Yang, R.; Lu, J.; Peng, Y.; Wang, J.; Lv, Q.; Zeng, Q. Upcycling Waste Plastics to Fabricate Lightweight, Waterproof, and Carbonation Resistant Cementitious Materials with Polymer-Nano Silica Hybrids. Mater. Today Sustain. 2023, 21, 100325. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Kaptan, K.; Cunha, S.; Aguiar, J. A Review: Construction and Demolition Waste as a Novel Source for CO2 Reduction in Portland Cement Production for Concrete. Sustainability 2024, 16, 585. [Google Scholar] [CrossRef]

- Belaïd, F. How Does Concrete and Cement Industry Transformation Contribute to Mitigating Climate Change Challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Hache, E.; Simoën, M.; Seck, G.S.; Bonnet, C.; Jabberi, A.; Carcanague, S. The Impact of Future Power Generation on Cement Demand: An International and Regional Assessment Based on Climate Scenarios. Int. Econ. 2020, 163, 114–133. [Google Scholar] [CrossRef]

- Müller, H.S.; Haist, M.; Vogel, M. Assessment of the Sustainability Potential of Concrete and Concrete Structures Considering Their Environmental Impact, Performance and Lifetime. Constr. Build. Mater. 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Alexander, M.; Beushausen, H. Durability, Service Life Prediction, and Modelling for Reinforced Concrete Structures—Review and Critique. Cem. Concr. Res. 2019, 122, 17–29. [Google Scholar] [CrossRef]

- Larsen, I.L.; Thorstensen, R.T. The Influence of Steel Fibres on Compressive and Tensile Strength of Ultra High Performance Concrete: A Review. Constr. Build Mater 2020, 256, 119459. [Google Scholar] [CrossRef]

- Farooq, F.; Nasir Amin, M.; Khan, K.; Rehan Sadiq, M.; Faisal Javed, M.F.; Aslam, F.; Alyousef, R. A Comparative Study of Random Forest and Genetic Engineering Programming for the Prediction of Compressive Strength of High Strength Concrete (HSC). Appl. Sci. 2020, 10, 7330. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, T. Mixture-Proportioning of High-Performance Concrete. Cem Concr Res 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Maria da Silva, F.; Batista, L.S.; Gachet, L.A.; Lintz, R.C.C. The Effect of Tire-Rubber Pretreatment on the Physical–Mechanical Properties and Durability of High-Performance Concrete. J. Mater. Civ. Eng. 2022, 34, 04022354. [Google Scholar] [CrossRef]

- Khan, M.I.; Abbas, Y.M. Robust Extreme Gradient Boosting Regression Model for Compressive Strength Prediction of Blast Furnace Slag and Fly Ash Concrete. Mater. Today Commun. 2023, 35, 105793. [Google Scholar] [CrossRef]

- Ismail, F.I.; Shafiq, N.; Abbas, Y.M.; Ateya, E.S.; Zahid, M.; Bheel, N.; Benjeddou, O.; Abdulkadir, I. The Behavior of Graphene-Nanoplatelets-Based High-Performance Concrete under Ambient Curing. Structures 2023, 47, 694–708. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary Cementitious Materials: New Sources, Characterization, and Performance Insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; İnan Sezer, G.; Ramyar, K. Comparison of Fly Ash, Silica Fume and Metakaolin from Mechanical Properties and Durability Performance of Mortar Mixtures View Point. Constr. Build. Mater. 2014, 70, 17–25. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alsubari, B.; Alqedra, M.A.; Mo, K.H. Effect of Aggressive Chemicals on Durability and Microstructure Properties of Concrete Containing Crushed New Concrete Aggregate and Non-Traditional Supplementary Cementitious Materials. Constr. Build. Mater. 2018, 163, 482–495. [Google Scholar] [CrossRef]

- Fonseca, T.V.; dos Anjos, M.A.S.; Ferreira, R.L.S.; Branco, F.G.; Pereira, L. Evaluation of Self-Compacting Concretes Produced with Ternary and Quaternary Blends of Different SCM and Hydrated-Lime. Constr. Build. Mater. 2022, 320, 126235. [Google Scholar] [CrossRef]

- Kumar, R.; Shafiq, N.; Kumar, A.; Jhatial, A.A. Investigating Embodied Carbon, Mechanical Properties, and Durability of High-Performance Concrete Using Ternary and Quaternary Blends of Metakaolin, Nano-Silica, and Fly Ash. Environ. Sci. Pollut. Res. 2021, 28, 49074–49088. [Google Scholar] [CrossRef] [PubMed]

- Sojobi, A.O.; Awolusi, T.F.; Aina, G.B.; Oke, O.L.; Oladokun, M.; Oguntayo, D.O. Ternary and Quaternary Blends as Partial Replacement of Cement to Produce Hollow Sandcrete Blocks. Heliyon 2021, 7, e07227. [Google Scholar] [CrossRef] [PubMed]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and Durability Properties of Self Consolidating High Performance Concrete Incorporating Natural Zeolite, Silica Fume and Fly Ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Sumesh, M.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H.; Alnahhal, M.F. Incorporation of Nano-Materials in Cement Composite and Geopolymer Based Paste and Mortar—A Review. Constr. Build. Mater. 2017, 148, 62–84. [Google Scholar] [CrossRef]

- Kaish, A.B.M.A.; Odimegwu, T.C.; Zakaria, I.; Abood, M.M. Effects of Different Industrial Waste Materials as Partial Replacement of Fine Aggregate on Strength and Microstructure Properties of Concrete. J. Build. Eng. 2021, 35, 102092. [Google Scholar] [CrossRef]

- Larrard, F. de Ultrafine Particles for the Making of Very High Strength Concretes. Cem. Concr. Res. 1989, 19, 161–172. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Wong, H.H.C. Packing Density of Cementitious Materials: Part 2—Packing and Flow of OPC + PFA + CSF. Mater. Struct. 2008, 41, 773–784. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of Nano-SiO2 Addition on Properties of Hardened Cement Paste as Compared with Silica Fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Ma, B.; Li, H.; Li, X.; Mei, J.; Lv, Y. Influence of Nano-TiO2 on Physical and Hydration Characteristics of Fly Ash–Cement Systems. Constr. Build. Mater. 2016, 122, 242–253. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Zhao, X.; Xu, W.; Niu, D. Effect of Nano Calcium Carbonate on Hydration Characteristics and Microstructure of Cement-Based Materials: A Review. J. Build. Eng. 2022, 50, 104220. [Google Scholar] [CrossRef]

- Li, H.-W.; Wang, R.; Wei, M.-W.; Lei, N.-Z.; Sun, H.-X.; Fan, J.-J. Mechanical Properties and Hydration Mechanism of High-Volume Ultra-Fine Iron Ore Tailings Cementitious Materials. Constr. Build. Mater. 2022, 353, 129100. [Google Scholar] [CrossRef]

- John, V.M.; Damineli, B.L.; Quattrone, M.; Pileggi, R.G. Fillers in Cementitious Materials—Experience, Recent Advances and Future Potential. Cem. Concr. Res. 2018, 114, 65–78. [Google Scholar] [CrossRef]

- Al Martini, S.; Khartabil, A.; Sabouni, R. Evaluation of Thermal Conductivity of Sustainable Concrete Having Supplementary Cementitious Materials (SCMs) and Recycled Aggregate (RCA) Using Needle Probe Test. Sustainability 2022, 15, 109. [Google Scholar] [CrossRef]

- Du, Y.; Ge, Y. Multiphase Model for Predicting the Thermal Conductivity of Cement Paste and Its Applications. Materials 2021, 14, 4525. [Google Scholar] [CrossRef]

- Ramzi, S.; Hajiloo, H. The Effects of Supplementary Cementitious Materials (SCMs) on the Residual Mechanical Properties of Concrete after Exposure to High Temperatures—Review. Buildings 2022, 13, 103. [Google Scholar] [CrossRef]

- ASTM C150/C150M; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- Khan, M.I.; Abbas, Y.M.; Fares, G. Enhancing Cementitious Concrete Durability and Mechanical Properties through Sili-ca Fume and Micro-Quartz. Sustainability 2023, 15, 15913. [Google Scholar] [CrossRef]

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C 1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C1064/C1064M-17; Standard Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. American Society for Testing and Materials: Conshohocken, PA, USA, 2016.

- Khan, M.I.; Abbas, Y.M.; Fares, G.; Alqahtani, F.K. Flowability and Strength Characteristics of Binary Cementitious Systems Containing Silica Fume, Fly Ash, Metakaolin, and Glass Cullet Powder. Materials 2023, 16, 6436. [Google Scholar] [CrossRef]

- ASTM C469/C469M-22; Test Method for Static Modulus of Elasticity and Poissons Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2022.

- BS 1881-124:2015+A1:2021; Testing Concrete—Methods for Analysis of Hardened Concrete. British Standards Institution: London, UK, 2021.

- Akiije, I. Effects of Using 0.5, 0.55 and 0.6 Water Cement Ratio Separately with a Nigerian Grade 42.5 r Portland Cement. Int. J. Sci. Technol. Soc. 2016, 4, 80–88. [Google Scholar]

- Zagar, L. Methods of Determination of Pore Structure, Permeability and Diffusion. In Proceedings of the RILEM/IUPAC International Symposium on the Pore Structure and Properties of Materials, Prague, Czechoslovakia, 18–21 September 1973; pp. C249–C278. [Google Scholar]

- Abbas, Y.M. Simplex-Lattice Strength and Permeability Optimization of Concrete Incorporating Silica Fume and Natural Pozzolan. Constr. Build. Mater. 2018, 168, 199–208. [Google Scholar] [CrossRef]

- Liao, Y.; Lv, Y.; Huang, G.; Ren, S.; Wang, X.-Y.; Guo, R.; Tian, Y.; Deng, S.; Lin, R.-S. Strength and Microstructure Analysis of Subgrade Materials Containing Red Sandstone-Limestone-Cement Composites and Red Sandstone Gravel. Constr. Build. Mater. 2024, 416, 135190. [Google Scholar] [CrossRef]

- Du, Y.; Korjakins, A.; Sinka, M.; Pundienė, I. Lifecycle Assessment and Multi-Parameter Optimization of Lightweight Cement Mortar with Nano Additives. Materials 2024, 17, 4434. [Google Scholar] [CrossRef] [PubMed]

- Manufacturers, Suppliers, Exporters & Importers from the World’s Largest Online B2B Marketplace. Available online: https://www.alibaba.com (accessed on 24 September 2024).

- Amazon Publishing. Available online: https://www.amazon.com (accessed on 21 November 2024).

| Oxide Composition (%) | PC | SF | MQ | FA | LS |

|---|---|---|---|---|---|

| SiO2 | 20.2 | 93.2 | 99.5 | 53.20 | 1.80 |

| Al2O3 | 5.49 | 0.2 | 0.20 | 27.3 | 0.45 |

| Fe2O3 | 4.12 | 0.03 | 0.03 | 4.03 | 0.66 |

| CaO | 65.43 | 0.72 | 0.01 | 0.90 | 54.41 |

| MgO | 0.71 | 0.14 | - | 0.6 | 0.41 |

| Na2Oeq | 0.26 | 0.07 | - | 0.95 | 0.08 |

| SO3 | 2.61 | <0.01 | - | 0.2 | 0.46 |

| Loss on ignition (%) | 1.38 | 5.4 | - | 10.02 | 41.60 |

| Specific gravity | 3.14 | 2.27 | 2.65 | 2.45 | 2.7 |

| Mix | Fine Powders | Fine Aggregate | Slump | Temperature | Unit Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | Type | Fine Powders | Mix ID | PC | SF | MQ | LS | FA | CFS | NFS | mm | °C | kg/m3 |

| 1 | - | PC | CTRL | 500 | 0 | 0 | 0 | 0 | 251 | 467 | 185 | 25.1 | 2418 |

| 2 | Binary | PC-SF | SF10 | 450 | 50 | 0 | 0 | 0 | 245 | 455 | 195 | 25.2 | 2426 |

| 3 | Ternary | PC-SF-MQ | SF10-MQ05 | 425 | 50 | 25 | 0 | 0 | 242 | 449 | 200 | 22.3 | 2430 |

| 4 | SF10-MQ08 | 410 | 50 | 40 | 0 | 0 | 239 | 480 | 192 | 21.3 | 2433 | ||

| 5 | SF10-MQ10 | 400 | 50 | 50 | 0 | 0 | 239 | 444 | 205 | 19.8 | 2437 | ||

| 6 | SF10-MQ15 | 375 | 50 | 75 | 0 | 0 | 236 | 438 | 190 | 19.8 | 2441 | ||

| 7 | PC-SF-LS | SF10-LS05 | 425 | 50 | 0 | 25 | 0 | 242 | 449 | 199 | 19.4 | 2408 | |

| 8 | SF10-LS10 | 400 | 50 | 0 | 50 | 0 | 239 | 444 | 190 | 19.5 | 2401 | ||

| 9 | SF10-LS15 | 375 | 50 | 0 | 75 | 0 | 236 | 438 | 206 | 19.2 | 2394 | ||

| 10 | PC-SF-FA | SF10-FA20 | 350 | 50 | 0 | 0 | 100 | 232 | 432 | 185 | 21.7 | 2435 | |

| 11 | Quaternary | PC-SF-FA-MQ | SF10-FA20-MQ10 | 300 | 50 | 50 | 0 | 100 | 226 | 420 | 205 | 21.5 | 2421 |

| 12 | SF10-FA20-MQ08 | 310 | 50 | 40 | 0 | 100 | 227 | 491 | 195 | 21.0 | 2411 | ||

| 13 | PC-SF-FA-LS | SF10-FA20-LS10 | 300 | 50 | 0 | 50 | 100 | 226 | 420 | 200 | 19.7 | 2431 | |

| Material | Approximate Average Cost (EUR/kg) | Source |

|---|---|---|

| PC | 0.120 | [52] |

| SF | 0.410 | [53] |

| MQ | 0.230 | [53] |

| LS | 0.040 | [54] |

| FA | 0.030 | [53,54] |

| CFS | 0.025 | Local aggregate supplier |

| NFS | 0.020 | Local aggregate supplier |

| Mix ID | Strength Performance-Based Category | Cost (EUR/m3) | Normal Curing | Hot Curing | ||

|---|---|---|---|---|---|---|

| CS (MPa) | Cost-Normalized Index | CS (MPa) | Cost-Normalized Index | |||

| CTRL | –––– | 75.6 | 84.0 | 1.111 | 81.2 | 1.074 |

| SF10-MQ08 | Optimum ternary mix | 94.5 | 89.5 | 0.947 | 90.6 | 0.958 |

| SF10-FA20 | Optimum binary mix | 79.9 | 79.0 | 0.988 | 81.9 | 1.025 |

| SF10-FA20-LS10 | Optimum quaternary mix | 75.6 | 72.4 | 0.958 | 79.1 | 1.047 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.I.; Abbas, Y.M.; Fares, G. Quality Characteristics of Sustainable High-Performance Concrete Formulated from Binary, Ternary, and Quaternary Supplementary Cementitious Materials Under Various Curing Conditions. Materials 2024, 17, 5831. https://doi.org/10.3390/ma17235831

Khan MI, Abbas YM, Fares G. Quality Characteristics of Sustainable High-Performance Concrete Formulated from Binary, Ternary, and Quaternary Supplementary Cementitious Materials Under Various Curing Conditions. Materials. 2024; 17(23):5831. https://doi.org/10.3390/ma17235831

Chicago/Turabian StyleKhan, Mohammad Iqbal, Yassir M. Abbas, and Galal Fares. 2024. "Quality Characteristics of Sustainable High-Performance Concrete Formulated from Binary, Ternary, and Quaternary Supplementary Cementitious Materials Under Various Curing Conditions" Materials 17, no. 23: 5831. https://doi.org/10.3390/ma17235831

APA StyleKhan, M. I., Abbas, Y. M., & Fares, G. (2024). Quality Characteristics of Sustainable High-Performance Concrete Formulated from Binary, Ternary, and Quaternary Supplementary Cementitious Materials Under Various Curing Conditions. Materials, 17(23), 5831. https://doi.org/10.3390/ma17235831