A Novel Tensile Fracture Location of Friction Plug Welding (FPW) Joints

Abstract

1. Introduction

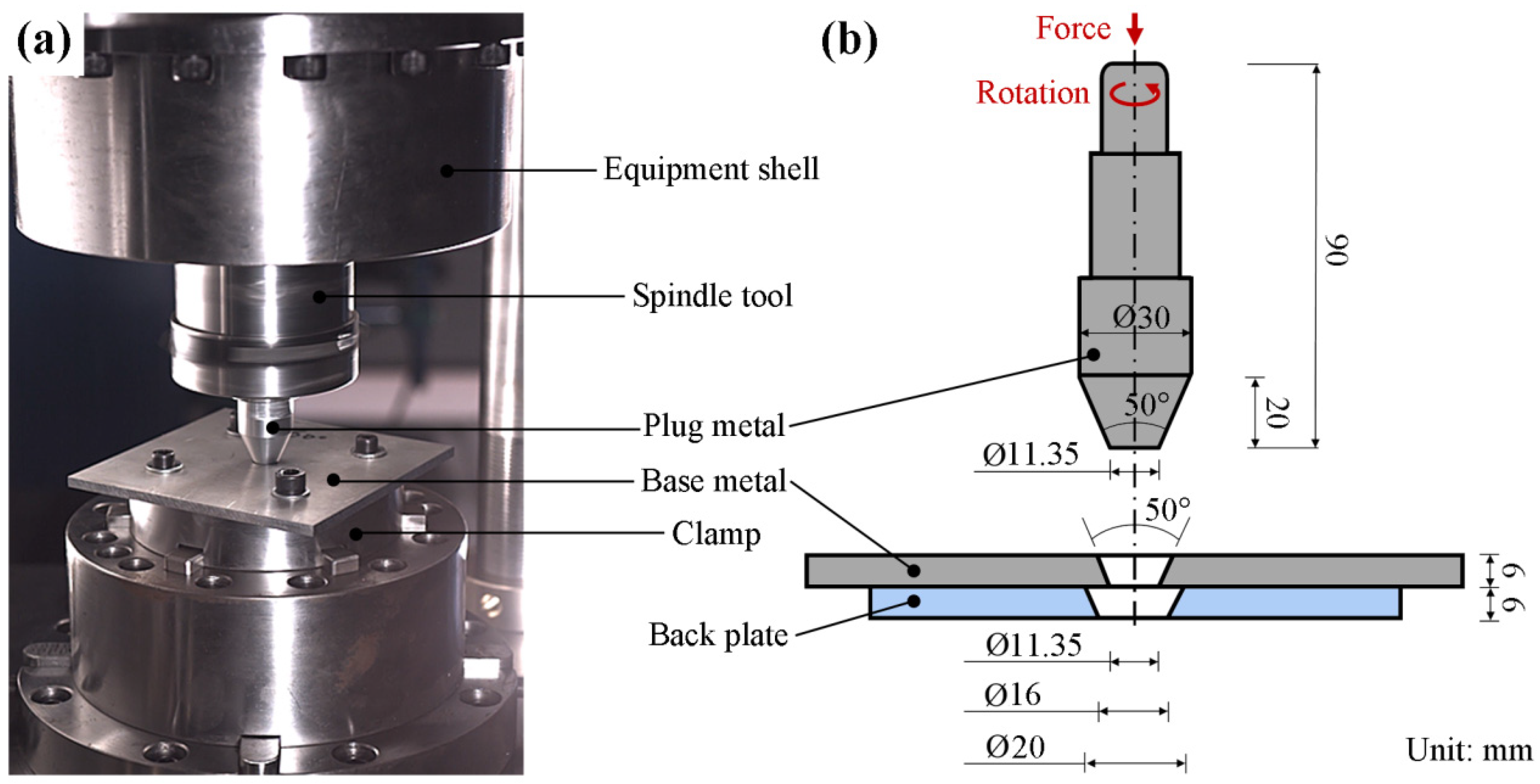

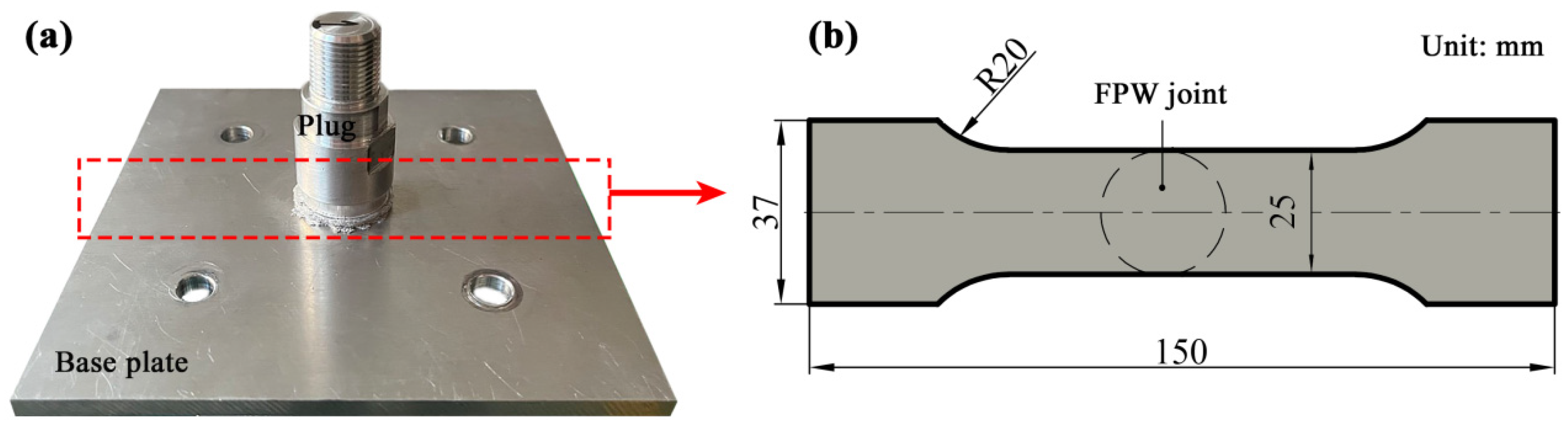

2. Experimental Materials and Methods

3. Results and Discussion

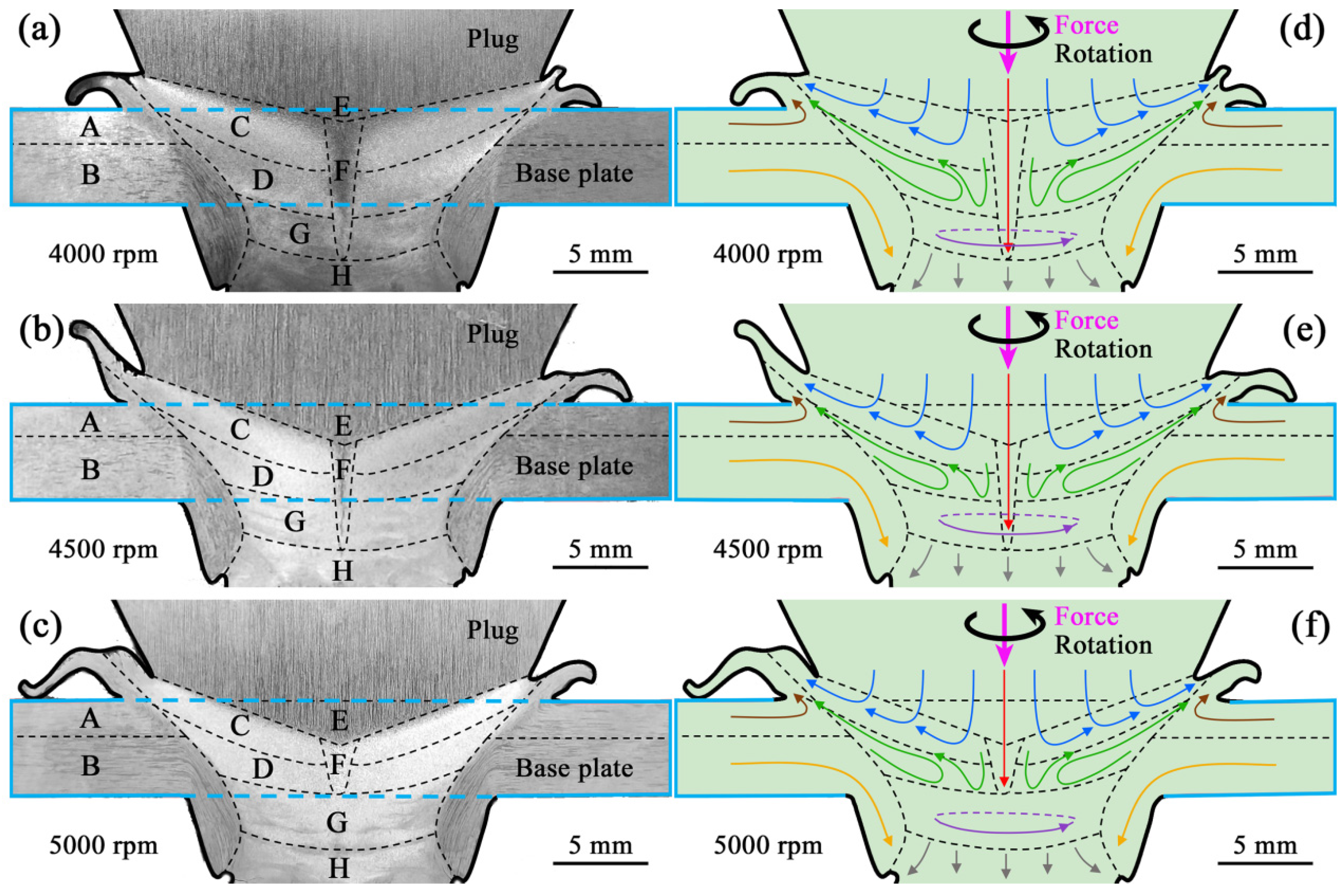

3.1. Macroscopic Forming and Material Flow

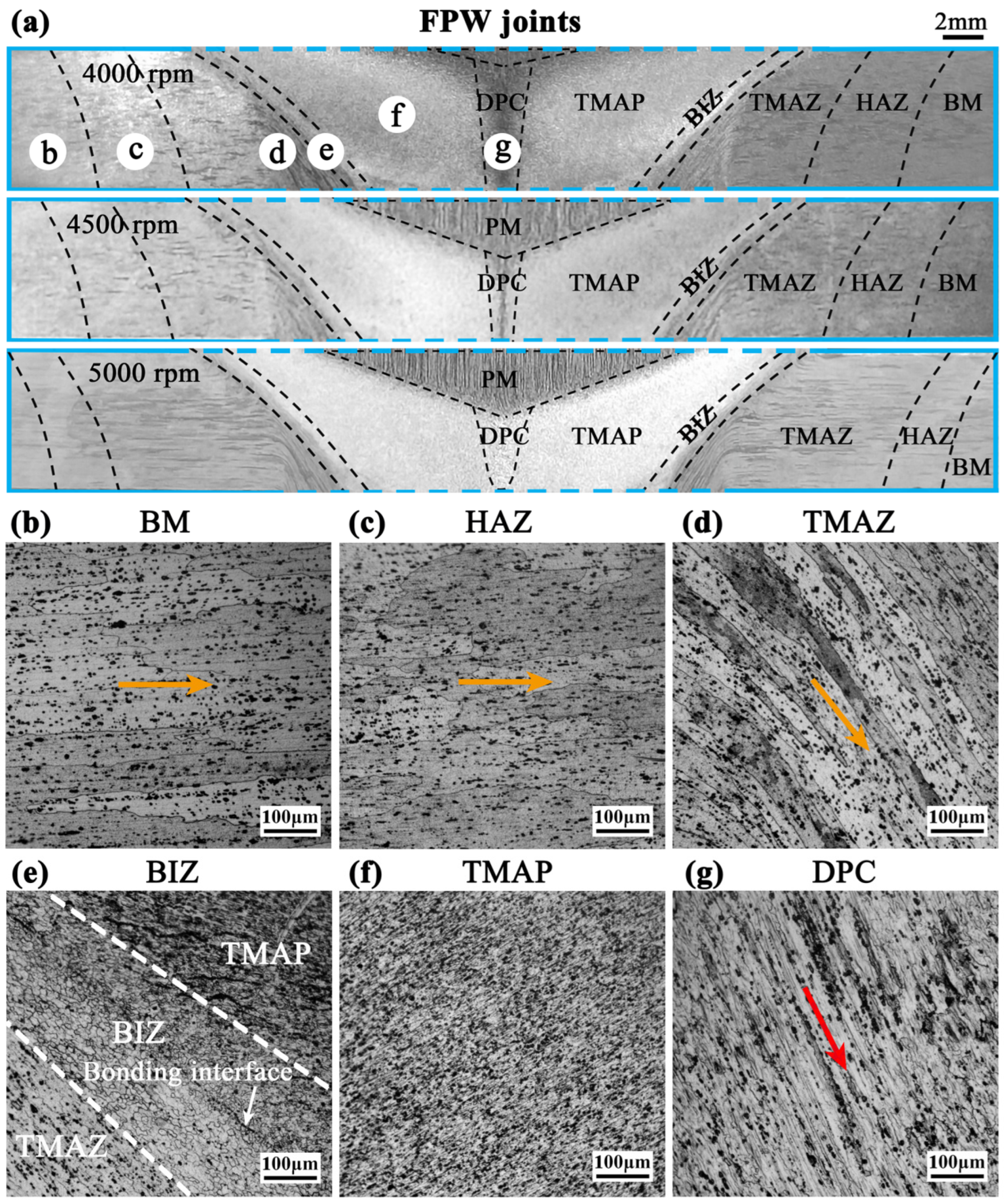

3.2. Microstructure

3.3. Mechanical Properties

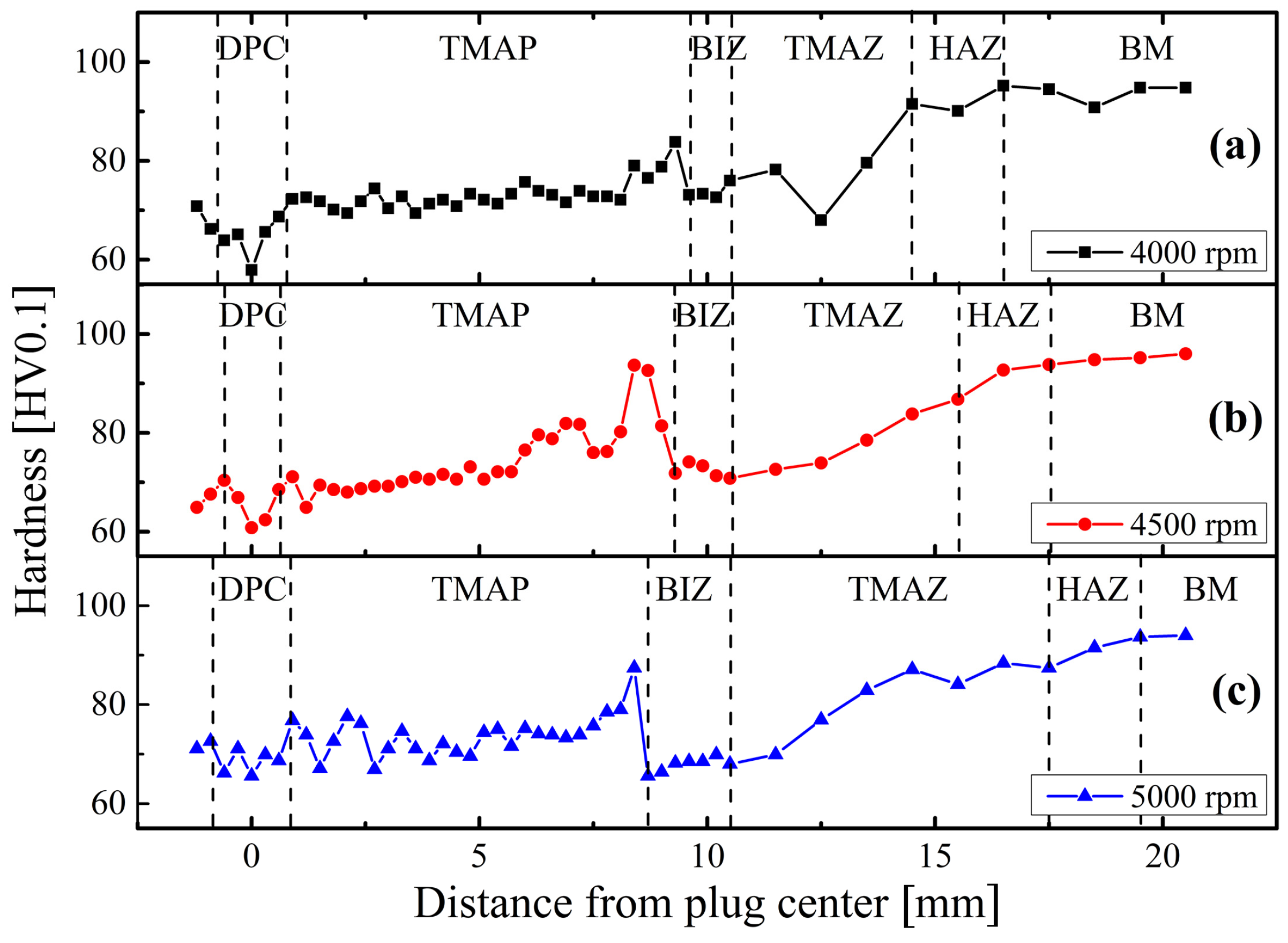

3.3.1. Hardness Distribution

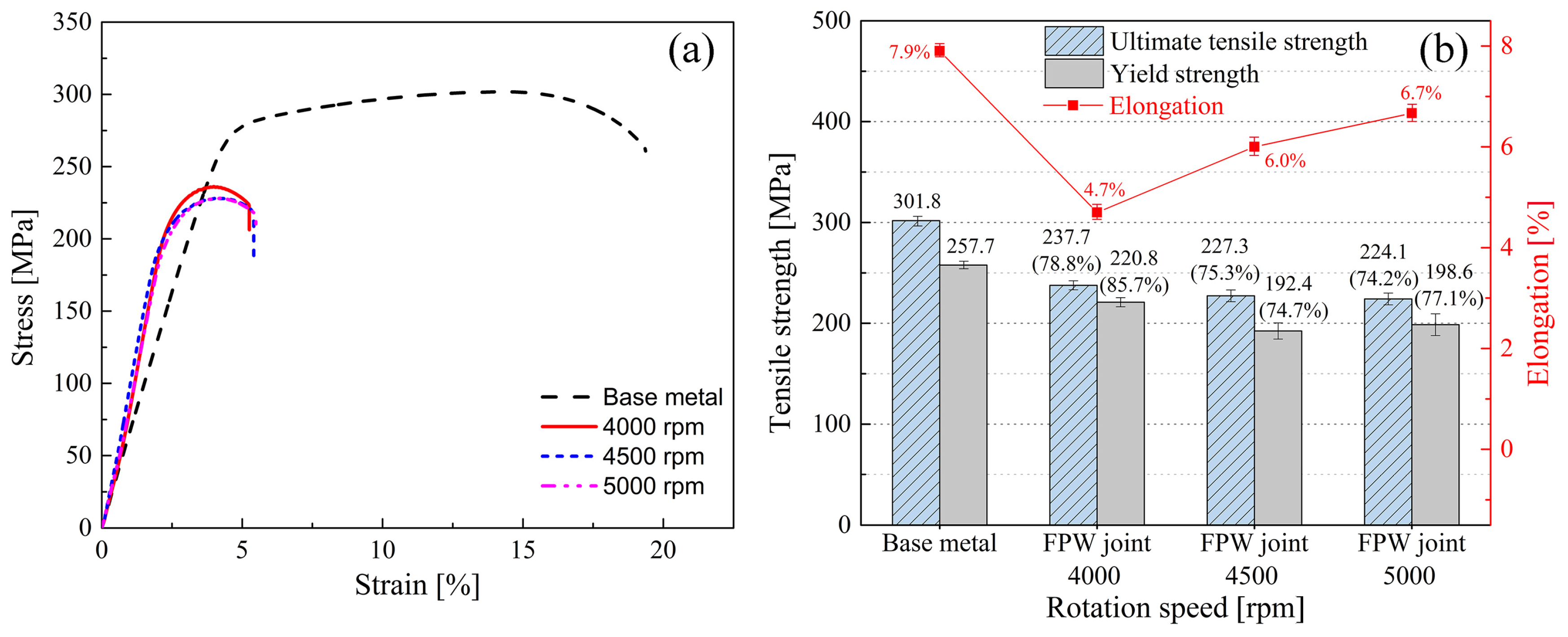

3.3.2. Tensile Property

4. Conclusions

- (1)

- 6061-T6 aluminum alloy can be effectively joined by the FPW technique, as indicated by the defect-free macrostructure, fracture positions of all joints at the plug center, and 78.8% (or 85.7%) of the ultimate tensile strength (or yield strength) of the base metal at 4000 rpm.

- (2)

- The marco- and micro-structures of the FPW joint are nonuniform. At the plug center, macrostructural inhomogeneity can be improved via increasing rotation speed, but microstructures at all of the selected rotation speeds are still uniform and consist of the upper plug metal (PM) zone and the lower deformed plug center (DPC) zone, leading to stress concentration and fractures at this region.

- (3)

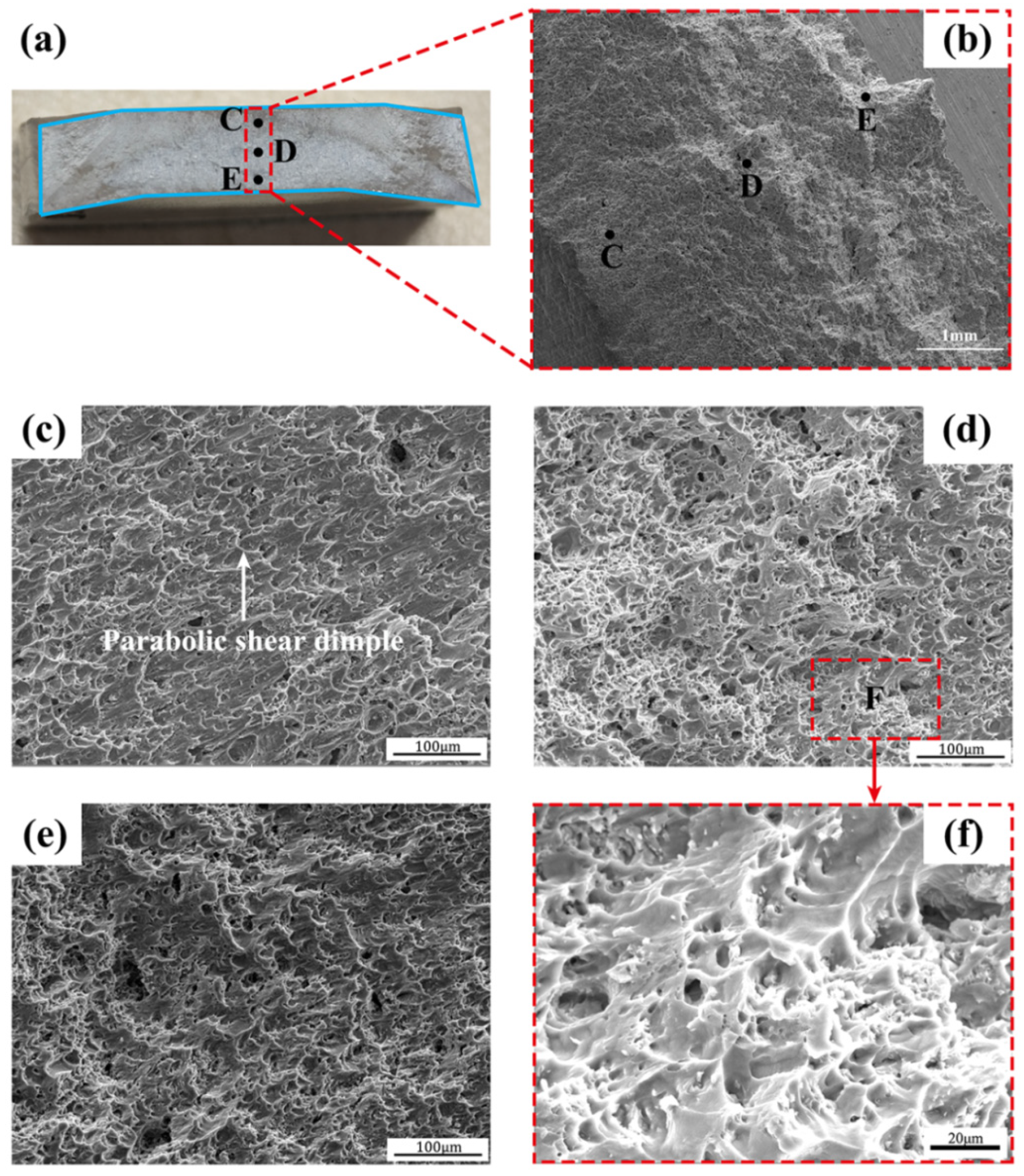

- Microcracks initiate at the DPC zone rather than the widely reported thermo-mechanically affected zone (TMAZ) or other zones, because the formation of the tilt fiber-like microstructure and the severe material softening in the DPC zone lead to the initiation of microcracks at this zone and facilitate the propagation of microcracks along 45° shear surfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, S.; Yue, X.; Li, Q.; Peng, H.; Dong, B.; Liu, T.; Yang, H.; Fan, J.; Shu, S.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Sumsion, D.C. Friction Taper Plug Welding as a Repair Method for Fatigue Damage Around Fastener Holes in Aerospace Structures. Theses and Dissertations, 2022, p. 10204. Available online: https://scholarsarchive.byu.edu/etd/10204 (accessed on 7 May 2024).

- Thorwald, G. Friction stir plug weld crack meshing for NASA. In Proceedings of the SIMULIA Customer Conference, Providence, RI, USA, 25–27 May 2010. [Google Scholar]

- Coletta, E.R.; Cantrell, M.A.; McCool, A. Friction plug weld repair geometric innovations. In Aerospace Materials; Lockheed Martin Michoud Space Systems: New Orleans, LA, USA, 2000. [Google Scholar]

- Zhang, Z.; Zhang, J.; Ji, S.; Gong, P.; Sun, Y.; Liu, H.; Ma, L. Microstructure, mechanical property and bonding mechanism of the repaired mechanical hole out of dimension tolerance of 2024 aluminum alloy by radial-additive friction stir repairing. J. Mater. Res. Technol. 2024, 29, 1565–1578. [Google Scholar] [CrossRef]

- Hartley, P.J.; McCool, A. Friction Plug Weld Repair for the Space Shuttle External Tank; Lockheed Martin Michoud Space Systems: New Orleans, LA, USA, 2000. [Google Scholar]

- Metz, D.F.; Barkey, M.E. Fatigue behavior of friction plug welds in 2195 Al-Li alloy. Int. J. Fatigue 2012, 43, 178–187. [Google Scholar] [CrossRef]

- Hynes, N.R.J.; Velu, P.S.; Nithin, A.M. Friction push plug welding in airframe structures using Ti-6Al-4V plug. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 158. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, X.; Zhao, Z.; Jiang, C.; Zhao, H. Process optimization and formation analysis of friction plug welding of 6082 aluminum alloy. Metals 2020, 10, 1454. [Google Scholar] [CrossRef]

- Li, D.F.; Wang, X.J.; Zhao, Z.L. Grain orientation and texture analysis of 6082 aluminum alloy friction plug welded joints. J. Mater. Res. Technol. 2022, 18, 1763–1771. [Google Scholar] [CrossRef]

- Li, D.; Wang, X. Influence of plug rotational speed on microstructure and texture of the recrystallized zone of a friction plug weld joint for AA6082-T6. Materials 2022, 15, 6011. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Wang, Z.; Cui, L.; Lin, Z.; Chen, Z.; Zhang, F.; Shao, Z.; Yang, L.; Chen, Y.; Huang, Y.; et al. High-quality friction pull plug welding of AA2219-T87 plate with a thickness of 18 mm: Experimental characterization on shaping, microstructure and mechanical properties. Mater. Charact. 2022, 194, 112448. [Google Scholar] [CrossRef]

- Gao, J.; Yang, L.; Cui, L.; Lu, P.; Yang, J.; Gao, Y. Improving the weld formation and mechanical properties of the AA-5A06 friction pull plug welds by axial force control. Acta Metall. Sin. 2020, 33, 828–838. [Google Scholar] [CrossRef]

- Shao, Z.; Cui, L.; Yang, L.; Lu, P.; Wang, H.; Sun, Z.; Song, J. Microstructure and mechanical properties of friction pull plug welding for 2219-T87 aluminum alloy with tungsten inert gas weld. Int. J. Miner. Metall. Mater. 2022, 29, 1216–1224. [Google Scholar] [CrossRef]

- Du, B.; Sun, Z.; Yang, X.; Cui, L.; Song, J.; Zhang, Z. Characteristics of friction plug welding to 10 mm thick AA2219-T87 sheet: Weld formation, microstructure and mechanical property. Mater. Sci. Eng. A 2016, 654, 21–29. [Google Scholar] [CrossRef]

- Du, B.; Cui, L.; Yang, X.; Wang, D.; Sun, Z. Weakening mechanism and tensile fracture behavior of AA 2219-T87 friction plug welds. Mater. Sci. Eng. A 2017, 693, 129–135. [Google Scholar] [CrossRef]

- Wu, J.N.; Huang, C.H.; Cheng, S.C.; Hsieh, W.F. Spontaneous emission from a two-level atom in anisotropic one-band photonic crystals: A fractional calculus approach. Phys. Rev. A At. Mol. Opt. Phys. 2010, 81, 023827. [Google Scholar] [CrossRef]

- Hernández-Acosta, M.A.; Martines-Arano, H.; Soto-Ruvalcaba, L.; Martínez-González, C.L.; Martínez-Gutiérrez, H.; Torres-Torres, C. Fractional thermal transport and twisted light induced by an optical two-wave mixing in single-wall carbon nanotubes. Int. J. Therm. Sci. 2020, 147, 106136. [Google Scholar] [CrossRef]

| Chemical Compositions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Element | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti | Al |

| Standard value [%] | 1.15 | 0.64 | 0.59 | 0.25 | 0.13 | 0.1 | 0.15 | 0.02 | Balance |

| Mechanical Properties | |||||||||

| Yield strength, Rp0.2 [MPa] | 257.7 | Elogation percentage [%] | 7.9 | ||||||

| Ultimate tensile strength [MPa] | 301.8 | Hardness [HV0.1] | 97 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-S.; Lv, X.-Q.; Xia, C.-M.; Li, X.-Y.; Yang, J.; Li, C.-G. A Novel Tensile Fracture Location of Friction Plug Welding (FPW) Joints. Materials 2024, 17, 5814. https://doi.org/10.3390/ma17235814

Wang Y-S, Lv X-Q, Xia C-M, Li X-Y, Yang J, Li C-G. A Novel Tensile Fracture Location of Friction Plug Welding (FPW) Joints. Materials. 2024; 17(23):5814. https://doi.org/10.3390/ma17235814

Chicago/Turabian StyleWang, Yu-Shu, Xue-Qi Lv, Chun-Ming Xia, Xiong-Ying Li, Jie Yang, and Chong-Gui Li. 2024. "A Novel Tensile Fracture Location of Friction Plug Welding (FPW) Joints" Materials 17, no. 23: 5814. https://doi.org/10.3390/ma17235814

APA StyleWang, Y.-S., Lv, X.-Q., Xia, C.-M., Li, X.-Y., Yang, J., & Li, C.-G. (2024). A Novel Tensile Fracture Location of Friction Plug Welding (FPW) Joints. Materials, 17(23), 5814. https://doi.org/10.3390/ma17235814