Research on Compression Failure Characteristics and Damage Constitutive Model of Steel Fiber-Reinforced Concrete with 2% Copper-Coated Fibers Under Impact Load

Abstract

1. Introduction

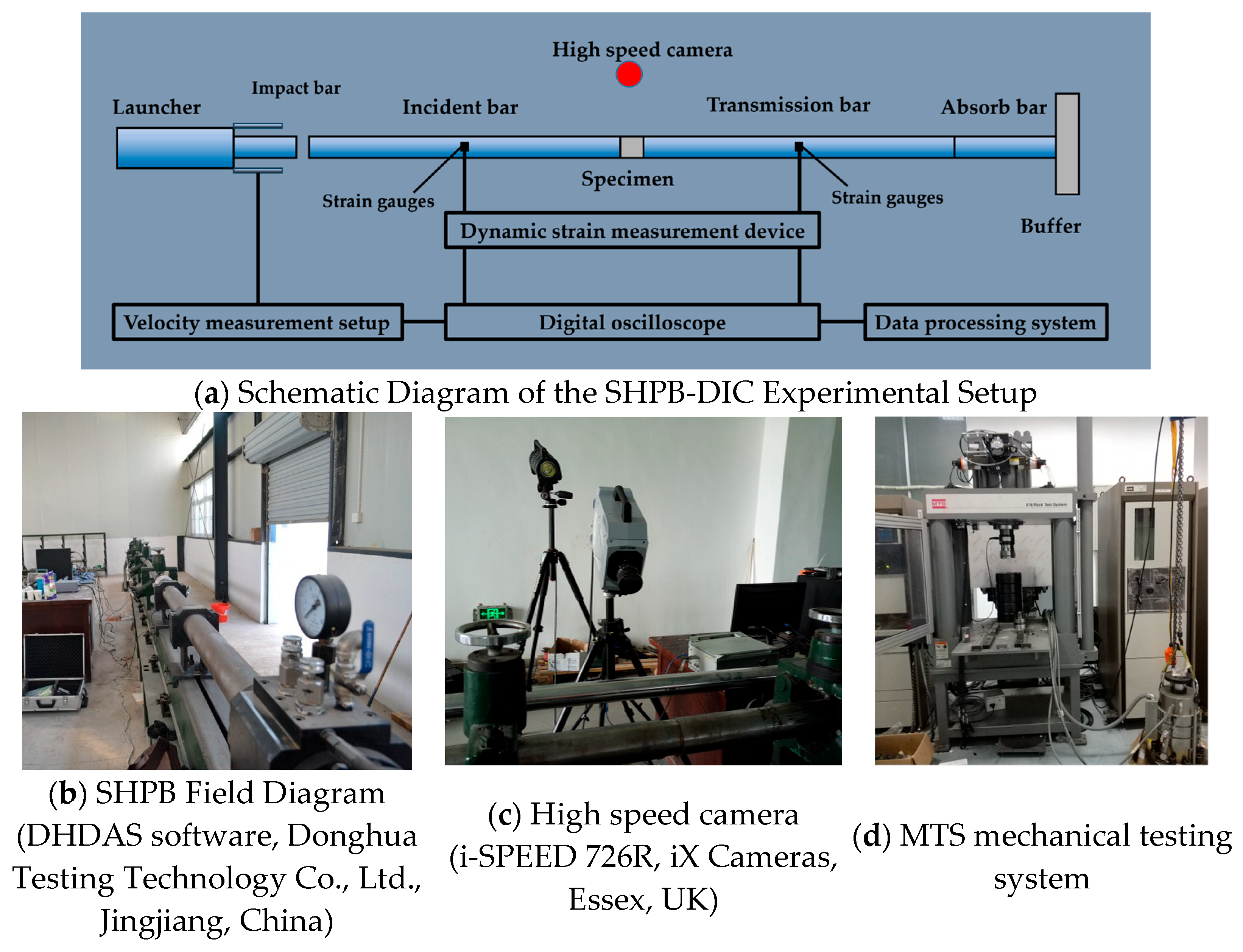

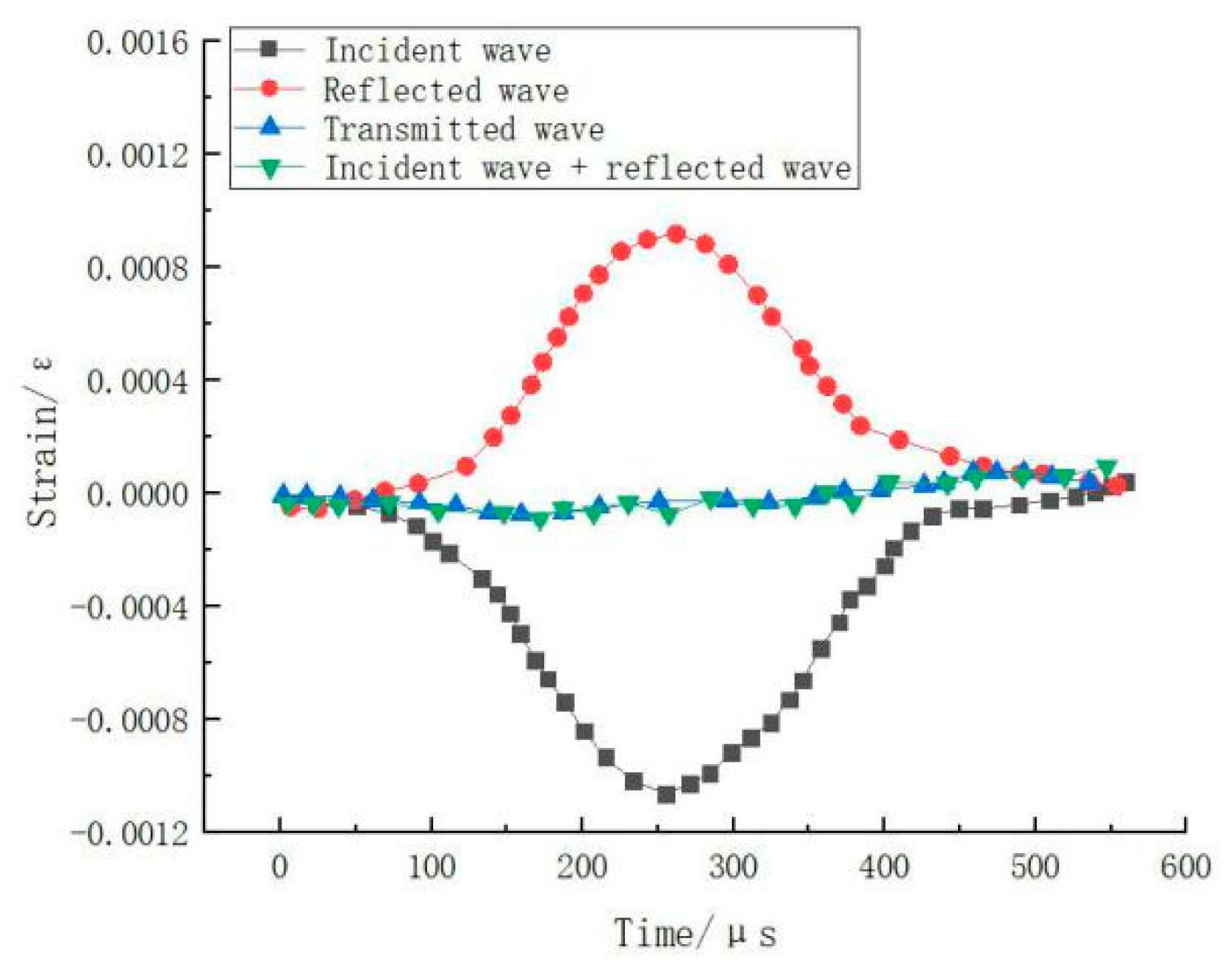

2. Experimental System and Testing Principles

2.1. Testing Equipment for the Experimental System

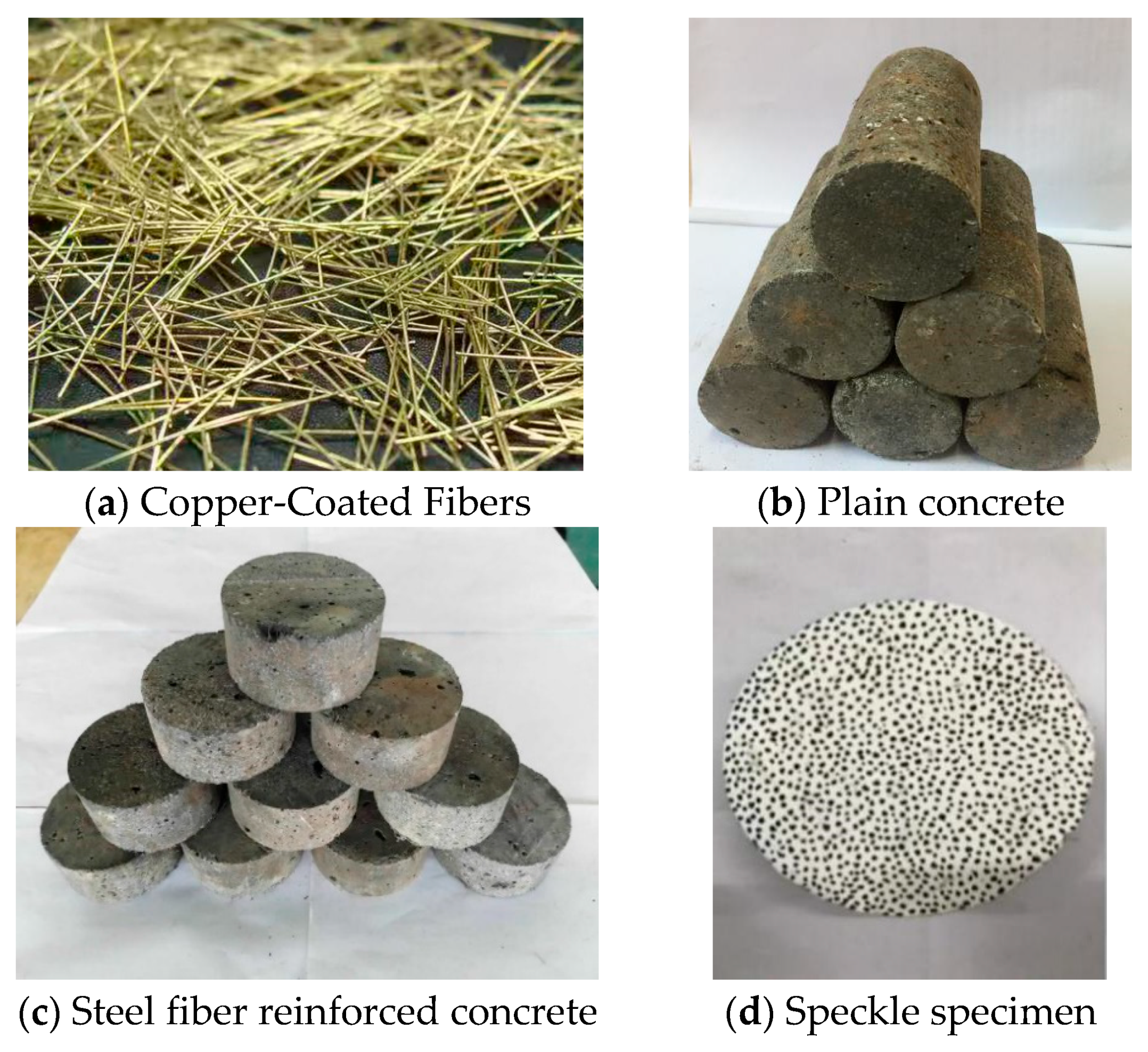

2.2. Preparation of Test Specimens

3. Test Results and Analysis

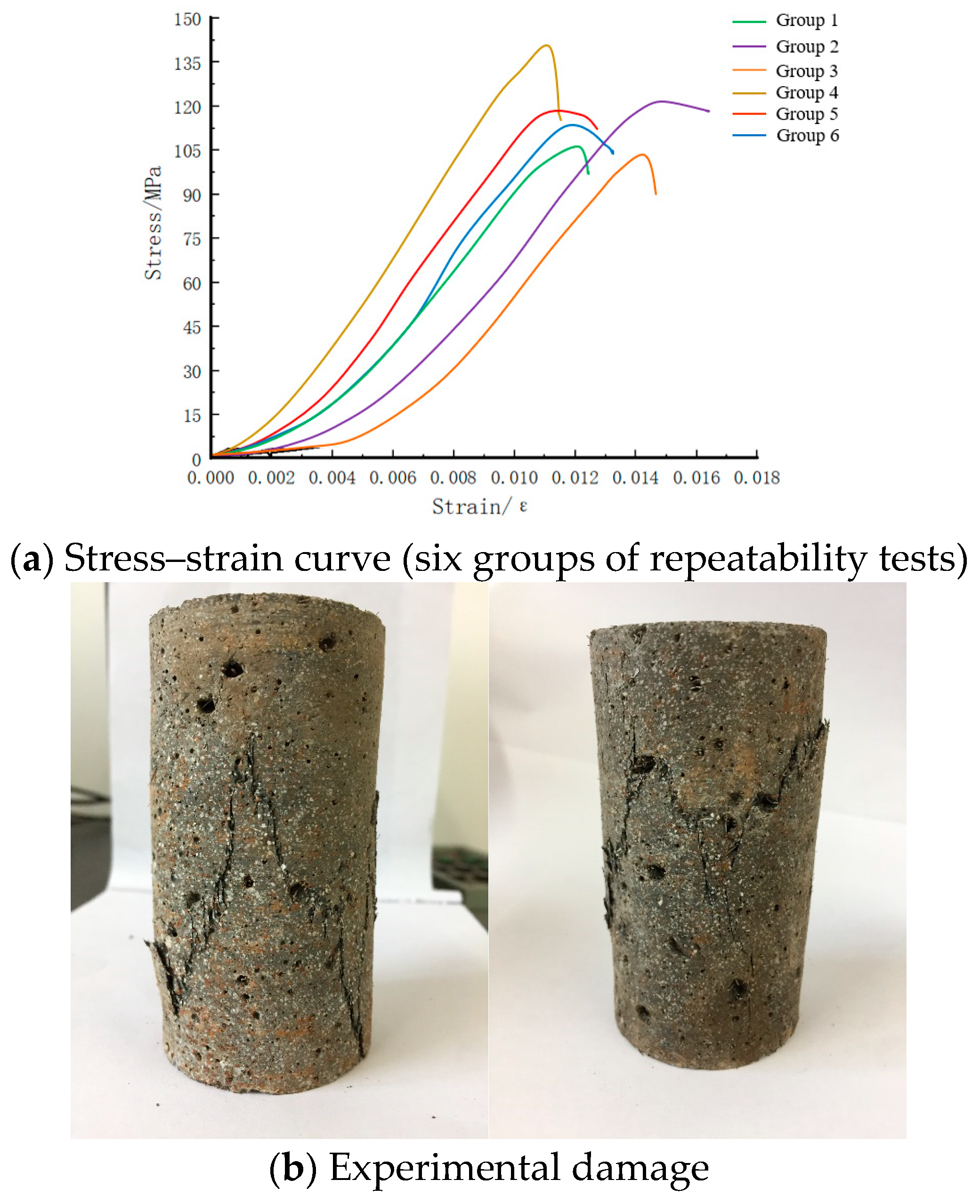

3.1. Static Mechanics Experimental Analysis

3.2. Analysis of Compression Failure Process and Damage Mode of Steel Fiber Concrete

3.3. Dynamic Mechanical Characterization

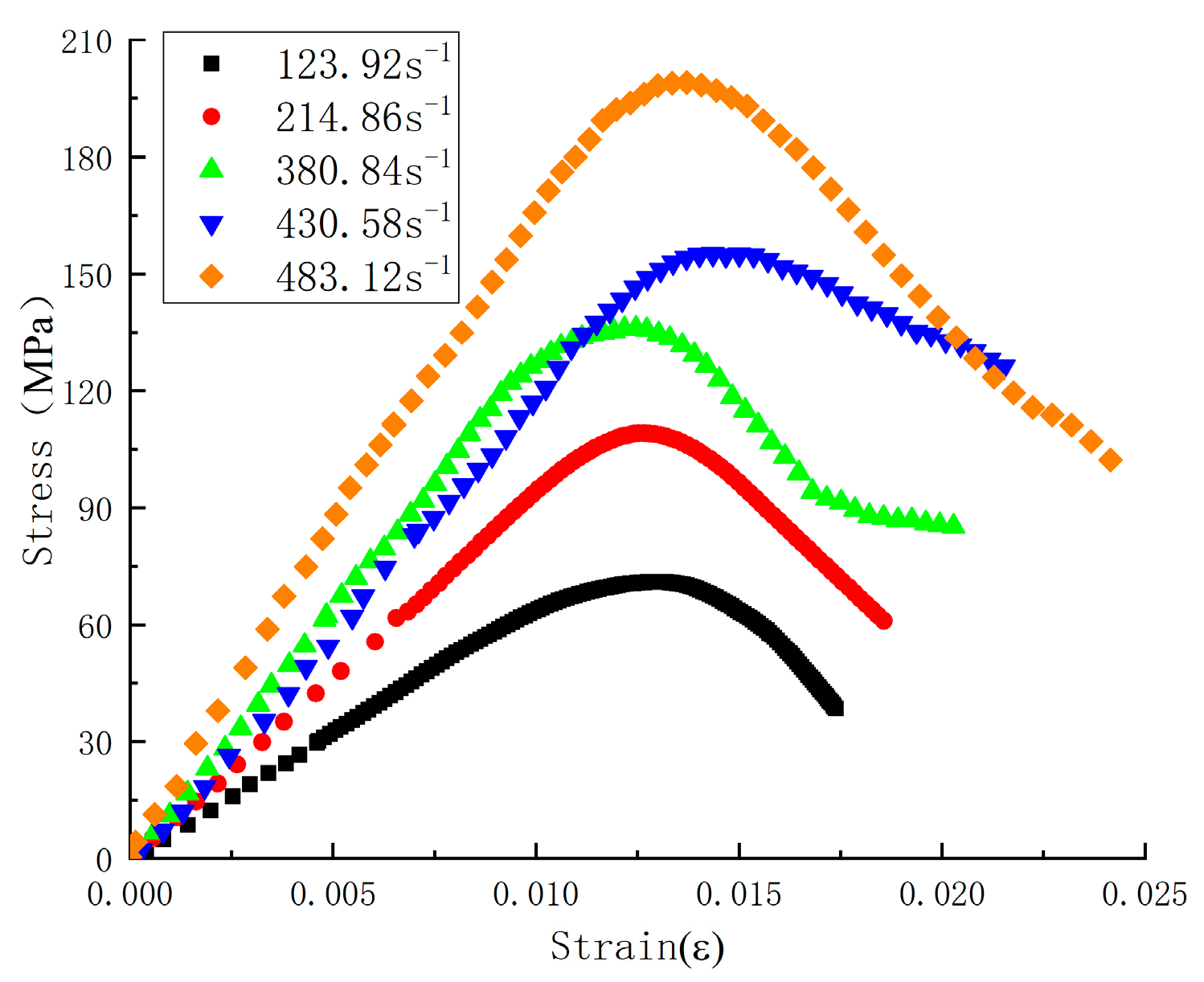

- (1)

- For concrete materials, the energy required to initiate internal cracks is significantly higher than that needed for crack propagation. As the strain rate increases, the number of cracks generated by the impact also increases, necessitating more incredible energy. In dynamic compression tests, the impact speed is extremely high, and the duration of the load application on the specimen is concise, leaving insufficient time for the material to absorb the shock. According to the impulse-momentum theorem, concrete can only release energy by increasing the stress path, which increases peak stress with rising strain rates.

- (2)

- The mechanical response generated during concrete transition from a uniaxial stress to a uniaxial strain state is similar. As the strain rate increases, the lateral deformation in the center is constrained by inertial effects; the higher the strain rate, the greater the constraint. This phenomenon is akin to applying confining pressure to the concrete, increasing compressive strength with elevated strain rates.

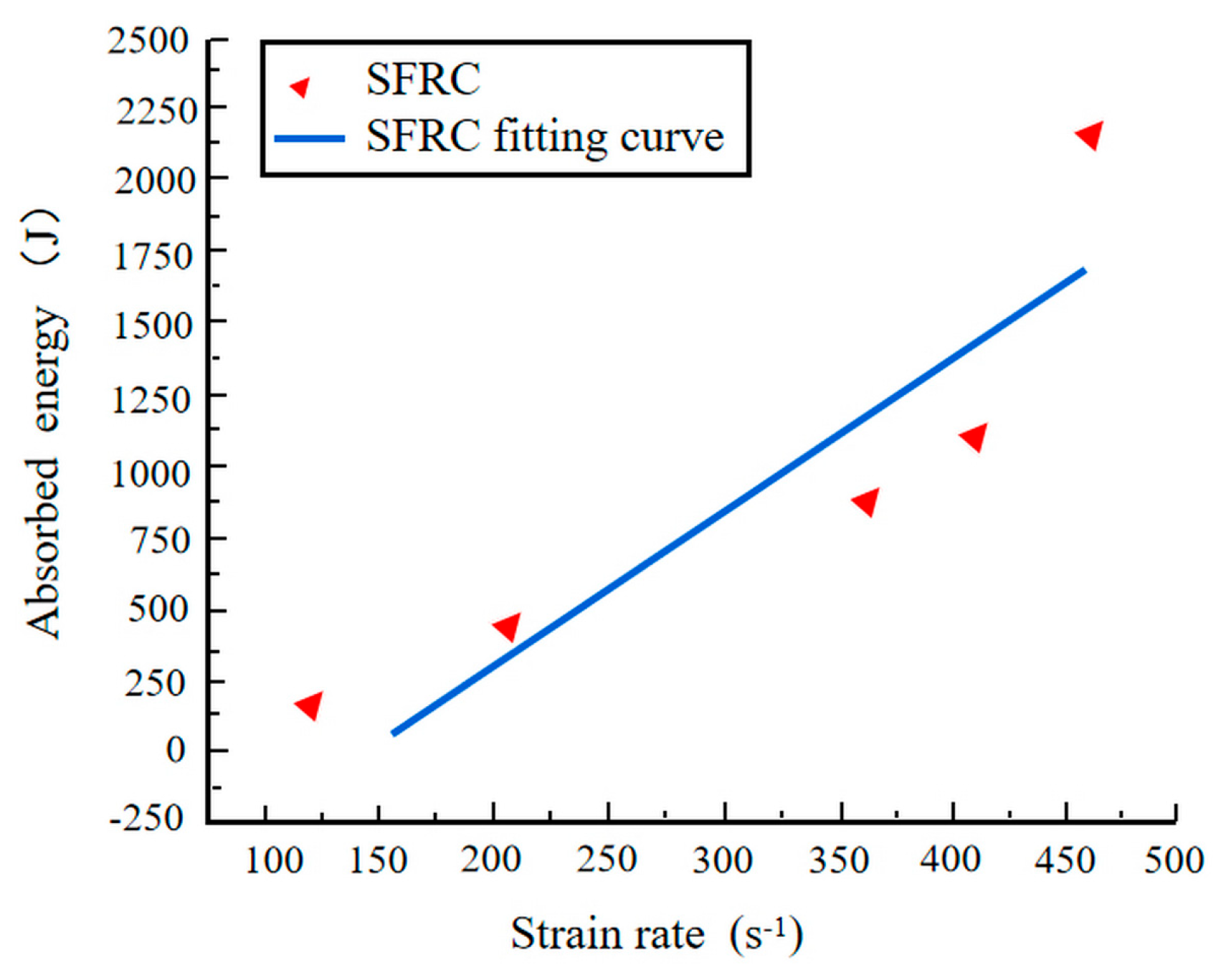

3.4. Analysis of Absorbed Energy of PC and Steel Fiber Concrete Under Impact Loading

4. Ontological Modeling

- (1)

- Regarding the first term of the equation, , its significance lies in representing the strain rate-independent equilibrium stress, which characterizes the material’s nonlinear elasticity. Based on the actual deformation observed in steel fiber-reinforced concrete during experiments, where the deformation is minimal, the elastic component can be treated as linear. Consequently, the trinomial of the first term can be simplified to a monomial, that is , transforming the nonlinear spring in the Zhu-Wang-Tang constitutive model into a linear spring. Thus, the simplified constitutive model yields the following expression for the Zhu-Wang-Tang model:

- (2)

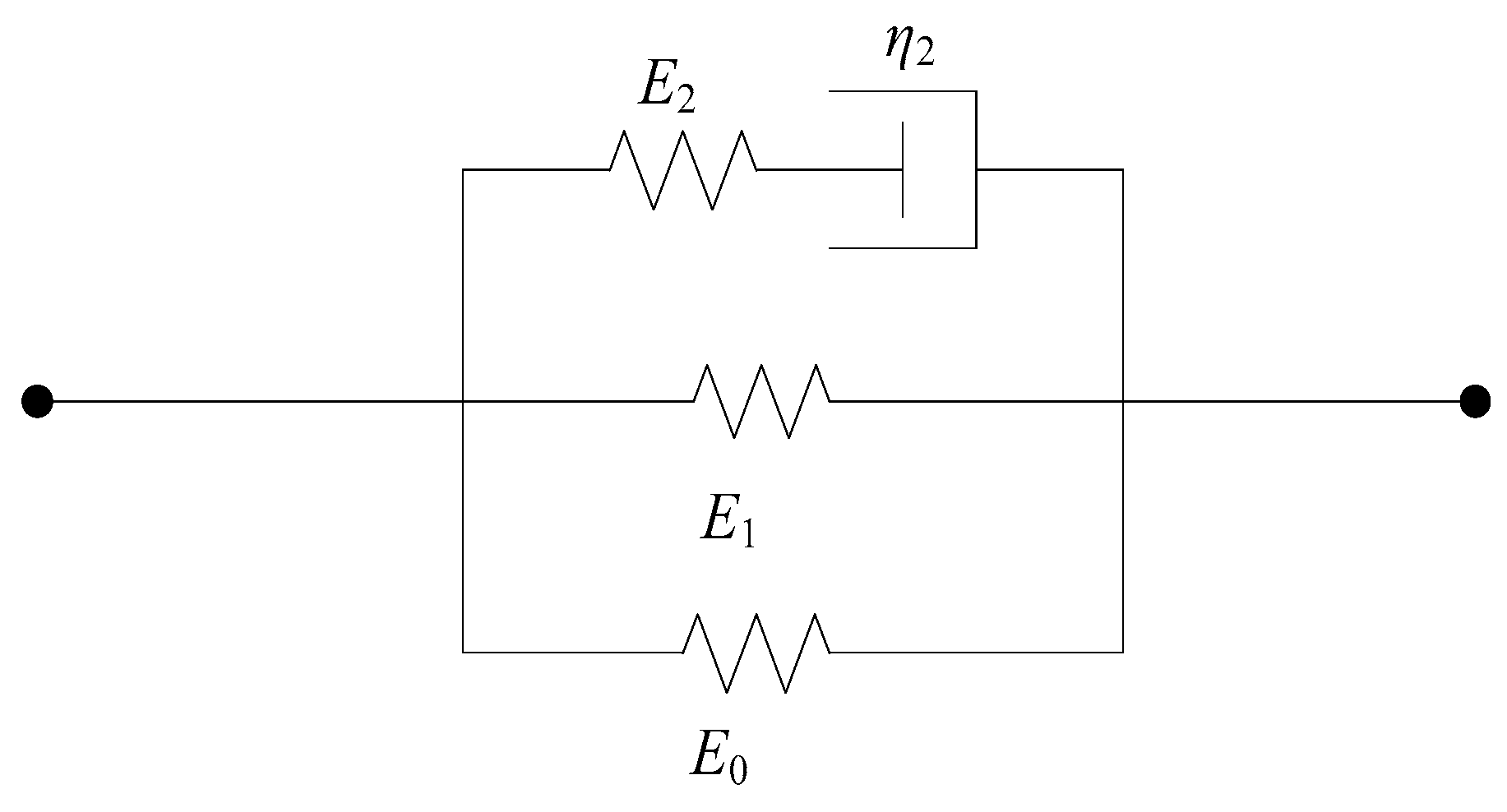

- In the dynamic loading tests of steel fiber-reinforced concrete discussed in this paper, the impact loading duration is extremely brief. The loading time scale for the low-frequency Maxwell body ranges from 100 to 102 s. Consequently, the loading duration in this experiment is several orders of magnitude smaller than that of the low-frequency Maxwell body, which remains unrelaxed by the time the dynamic load is applied. Therefore, the low-frequency Maxwell body in the second term of the Zhu-Wang-Tang constitutive model can be represented by a simple spring. The simplified physical model is shown in Figure 13. The Zhu-Wang-Tang constitutive model equation is further simplified to:

- (3)

- During the production of composite material concrete, achieving completely uniform distribution of materials is not feasible. From a microscopic perspective, disordered distributions of micro-pores and micro-cracks exist within the material; thus, it is essential to consider damage factors when establishing the constitutive model. The distribution patterns of micro-pores and micro-cracks in concrete are highly complex and exhibit significant discreteness. A continuous damage mechanics approach is adopted to simplify the model, treating composite material concrete as a constant medium. By introducing a macro damage variable (D) to assess the damage extent, the primary form of the constitutive model is derived based on Lemaitre’s strain equivalence principle as follows:

5. Application of Dynamic Damage Ontology Modeling in Experimentation

Application of Dynamic Damage Principal Model to Steel Fiber Concrete Testing

- (1)

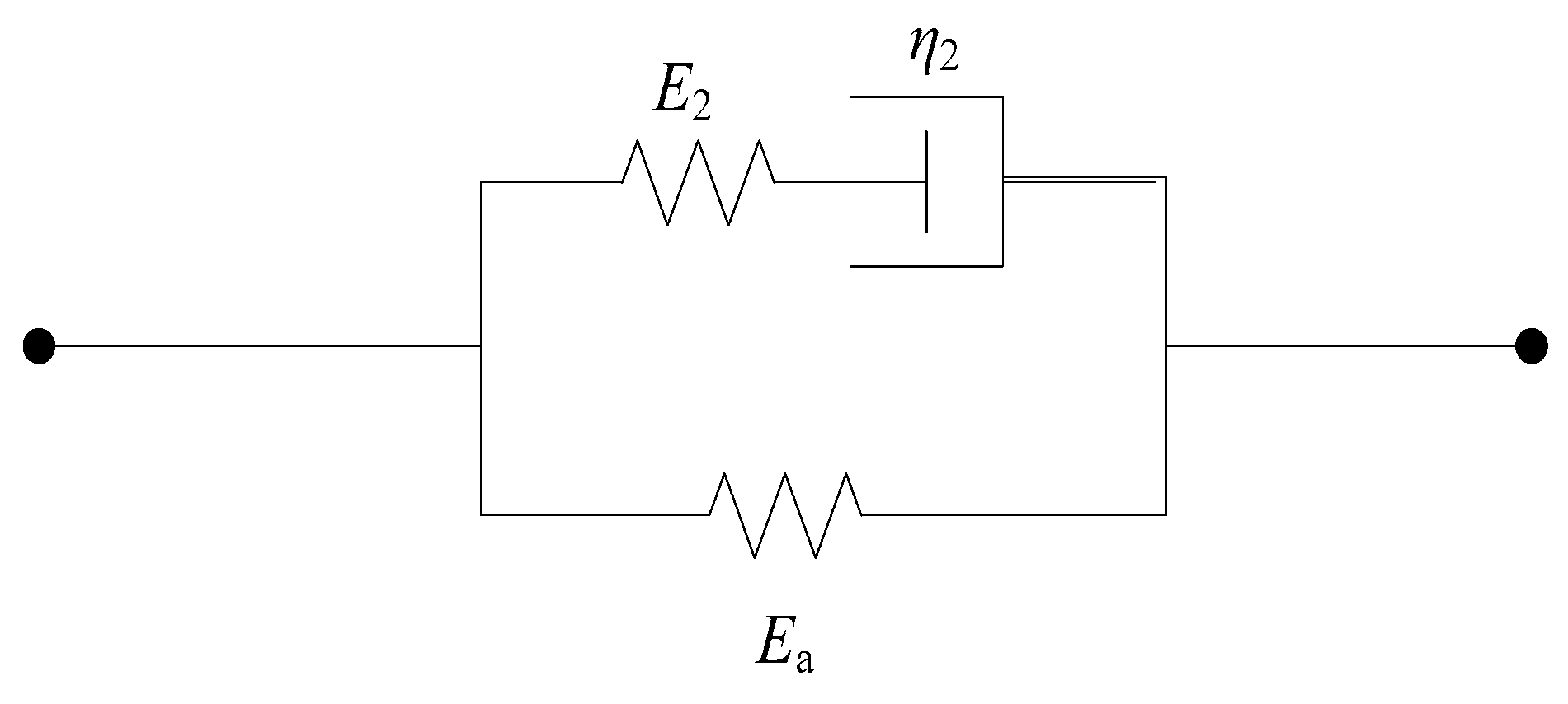

- Linear Term Coefficient EaThe relationship between the elastic constant Ea and strain rate is shown in Figure 16, represented as:where A = 1.61e7; B = −2556; C = 147702.

- (2)

- Elastic Constant E2

6. Conclusions

- (1)

- Under static loading conditions, SFRC demonstrates a marked improvement in performance relative to PC. Specifically, the maximum bearing capacity of SFRC is 2.16 times greater, and its energy absorption capacity is 3.83 times higher than that of PC, highlighting its superior toughness and resistance to damage. Under dynamic loading conditions, both materials exhibit strain rate sensitivity; however, the energy absorption capacity of SFRC is further enhanced, reaching 6.36 times that of PC. These results underscore the exceptional performance of SFRC in high strain rate environments.

- (2)

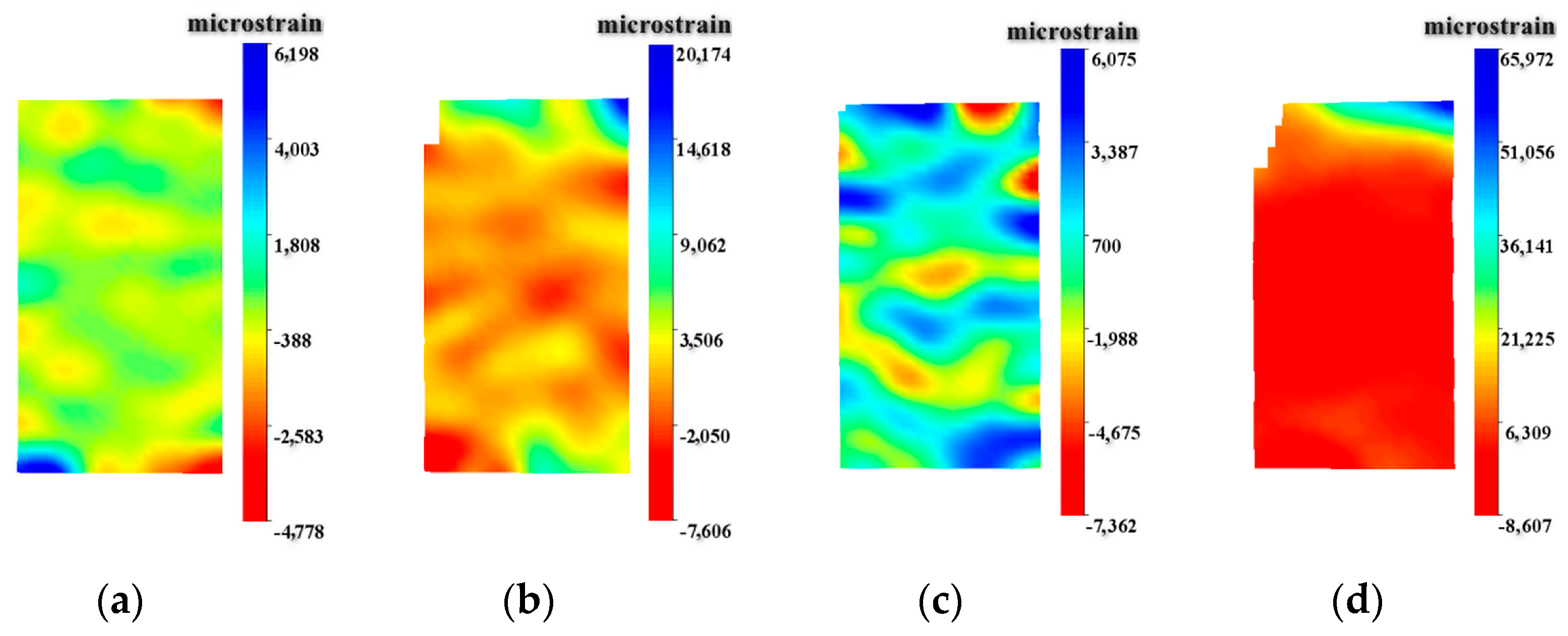

- The failure process of SFRC at various strain rates was investigated through impact tests employing the SHPB combined with DIC techniques. The results indicate that the failure of SFRC is primarily driven by splitting tensile failure. The failure process can be categorized into four distinct stages: the stress equilibrium stage, the tensile strain failure stage, the splitting tensile failure stage, and the crushing failure stage. These findings provide a crucial foundation for understanding the damage mechanisms of SFRC under dynamic loading conditions.

- (3)

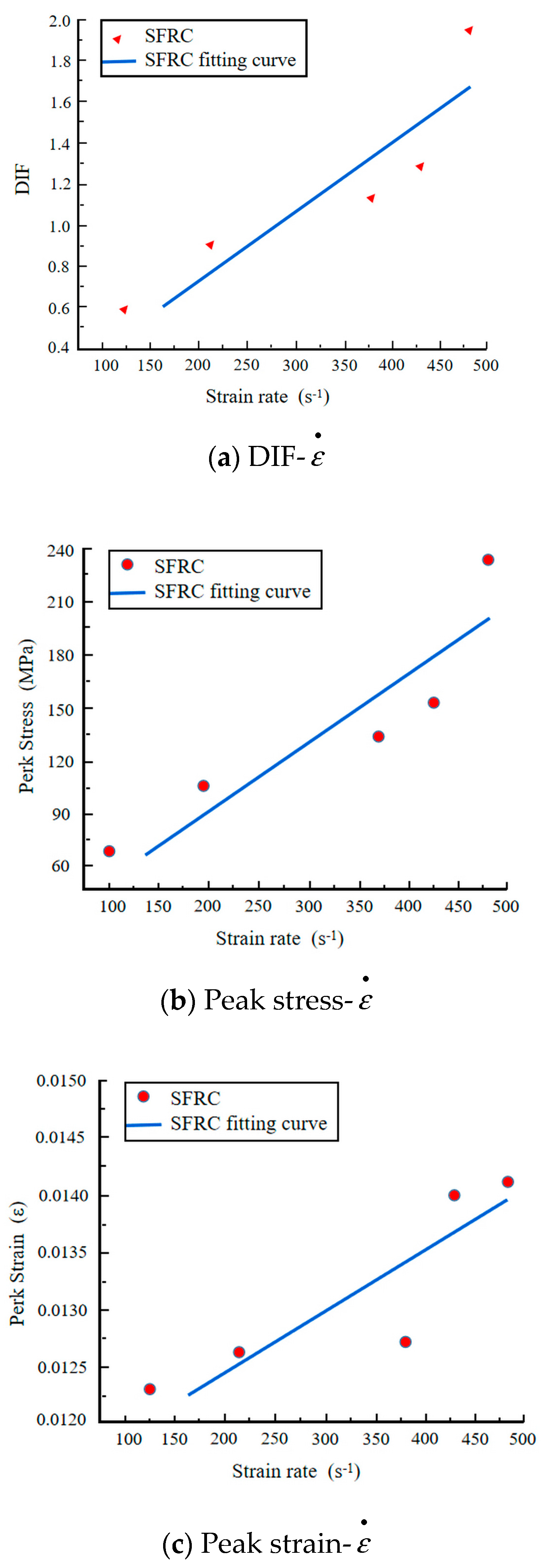

- In the high strain rate range (123.92 s−1 to 483.12 s−1), the dynamic enhancement factor (DIF), peak stress, and peak strain of SFRC exhibit a linear relationship with the strain rate, while its energy absorption capacity demonstrates nonlinear growth. These results further corroborate the superior energy absorption and impact resistance of SFRC under high strain rate conditions, highlighting its suitability for applications that demand high dynamic performance.

- (4)

- Based on the impact dynamic characteristics of SFRC, a simplified dynamic viscoelastic constitutive model with four parameters is proposed. This model effectively captures the dynamic mechanical behavior of SFRC while significantly enhancing computational efficiency. Additionally, a damage-based viscoelastic constitutive model, incorporating seven parameters, was developed by integrating damage factors and correction coefficients. The model’s broad applicability was validated through experimental data. This simplified constitutive model not only facilitates generalization, but also provides a practical framework for future research to derive stress–strain relationships at specific strain rates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Camille, C.; Mirza, O.; Kirkland, B.; Clarke, T. Structural behaviour of prestressed concrete sleepers reinforced with high-performance macro synthetic fibres. Eng. Fail. Anal. 2022, 141, 106671. [Google Scholar] [CrossRef]

- Lämmlein, T.D.; Justs, J.; Terrasi, G.P.; Lura, P. Prestressing low clinker structural concrete elements by ultra-high modulus carbon fibre reinforced polymer tendons. Mater. Struct. 2021, 54, 51. [Google Scholar] [CrossRef]

- Ren, X.; Li, J. Multi-scale based fracture and damage analysis of steel fiber reinforced concrete. Eng. Fail. Anal. 2013, 35, 253–261. [Google Scholar] [CrossRef]

- Feng, D.C.; Ren, X. Implicit gradient-enhanced force-based Timoshenko fiber element formulation for reinforced concrete structures. Int. J. Numer. Methods Eng. 2021, 122, 325–347. [Google Scholar] [CrossRef]

- Abbas, H.; Abadel, A.; Almusallam, T.; Al-Salloum, Y. Experimental and analytical study of flexural performance of concrete beams rein-forced with hybrid of GFRP and steel rebars. Eng. Fail. Anal. 2022, 138, 106397. [Google Scholar] [CrossRef]

- Ren, X.; Yue, Q. Reliability assessment of reinforced concrete structures based on random damage model. Struct. Infrastruct. Eng. 2018, 14, 780–790. [Google Scholar] [CrossRef]

- Kos, Ž.; Kroviakov, S.; Kryzhanovskyi, V.; Grynyova, I. Research of Strength, Frost Resistance, Abrasion Resistance and Shrinkage of Steel Fiber Concrete for Rigid Highways and Airfields Pavement Repair. Appl. Sci. 2022, 12, 1174. [Google Scholar] [CrossRef]

- Gao, X.; Xiang, D.; Li, J.; Ren, X. Decomposition of the Shear Capacity of Steel Fiber–Reinforced Concrete Coupling Beams. J. Struct. Eng. 2021, 11, 4021176. [Google Scholar] [CrossRef]

- Ali, B.; Raza, S.S.; Kurda, R.; Alyousef, R. Synergistic effects of fly ash and hooked steel fibers on strength and durability properties of high strength recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 168, 105444. [Google Scholar] [CrossRef]

- Parashar, A.K.; Gupta, A. Investigation of the effect of bagasse ash, hooked steel fibers and glass fibers on the mechanical prop-erties of concrete. Mater. Today Proc. 2021, 44, 801–807. [Google Scholar] [CrossRef]

- Kim, J.; Yoo, D.; Banthia, N. Benefits of curvilinear straight steel fibers on the rate-dependent pullout resistance of ultra-high-performance concrete. Cem. Concr. Compos. 2021, 118, 103965. [Google Scholar] [CrossRef]

- Spelter, A.; Bergmann, S.; Bielak, J.; Hegger, J. Long-Term Durability of Carbon-Reinforced Concrete: An Overview and Experimental Investigations. Appl. Sci. 2019, 9, 1651. [Google Scholar] [CrossRef]

- Enfedaque, A.; Cendón, D.; Gálvez, F.; Sánchez-Gálvez, V. Failure and impact behavior of facade panels made of glass fiber reinforced cement (GRC). Eng. Fail. Anal. 2011, 18, 1652–1663. [Google Scholar] [CrossRef]

- Sabău, E.; Udroiu, R.; Bere, P.; Buranský, I.; Miron-Borzan, C. A Novel Polymer Concrete Composite with GFRP Waste: Applications, Morphology, and Porosity Characterization. Appl. Sci. 2020, 10, 2060. [Google Scholar] [CrossRef]

- Kožar, I.; Bede, N.; Mrakovčić, S.; Božić, Ž. Verification of a fracture model for fiber reinforced concrete beams in bending. Eng. Fail. Anal. 2022, 138, 106378. [Google Scholar] [CrossRef]

- Kan, W.; Yang, Z.; Yu, L. Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete. Appl. Sci. 2022, 12, 3823. [Google Scholar] [CrossRef]

- Mahakavi, P.; Chithra, R. Impact resistance, microstructures and digital image processing on self-compacting concrete with hooked end and crimped steel fiber. Constr. Build. Mater. 2019, 220, 651–666. [Google Scholar] [CrossRef]

- Pham, L.; Tran, P.; Sanjayan, J. Steel fibres reinforced 3D printed concrete: Influence of fibre sizes on mechanical performance. Constr. Build. Mater. 2020, 250, 118785. [Google Scholar] [CrossRef]

- Erdem, S.; Dawson, A.R.; Thom, N.H. Microstructure-linked strength properties and impact response of conventional and recycled concrete reinforced with steel and synthetic macro fibres. Constr. Build. Mater. 2011, 25, 4025–4036. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul-Hussein, M.L.; Ayoob, N.S.; Ali, S.H.; Kadhum, A.L. Repeated drop-weight impact tests on self-compacting concrete reinforced with micro-steel fiber. Heliyon 2020, 6, e3198. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Shi, C.; Chen, X. Experimental and numerical study on tensile strength and failure pattern of high performance steel fiber reinforced concrete under dynamic splitting tension. Constr. Build. Mater. 2020, 259, 119796. [Google Scholar] [CrossRef]

- Li, C.; Li, Q.; Li, X.; Zhang, X.; Zhao, S. Elasto-plastic Bending Behaviors of Steel Fiber Reinforced Expanded-shale Lightweight Concrete Beams Analyzed by Nonlinear Finite-element Method. Case Stud. Constr. Mater. 2020, 13, e00372. [Google Scholar] [CrossRef]

- Ceccato, C.; Teng, J.G.; Cusatis, G. Numerical prediction of the ultimate condition of circular concrete columns confined with a fiber reinforced polymer jacket. Compos. Struct. 2020, 241, 112103. [Google Scholar] [CrossRef]

- Carvalho, M.R.; Barros, J.A.; Zhang, Y.; Dias-Da-Costa, D. A computational model for simulation of steel fibre reinforced concrete with explicit fibres and cracks. Comput. Methods Appl. Mech. Eng. 2020, 363, 112879. [Google Scholar] [CrossRef]

- Chi, Y.; Yu, M.; Huang, L.; Xu, L. Finite element modeling of steel-polypropylene hybrid fiber reinforced concrete using modified concrete damaged plasticity. Eng. Struct. 2017, 148, 23–35. [Google Scholar] [CrossRef]

- Valenzuela, M.; Leiva, J.; Salas, A.; Ciudad, G.; Cárdenas, J.P.; Oñate, A.; Hunter, R.; Attia, S.; Tuninetti, V. CEBs with GRC: Fabrication, characterization, modeling, and correlation with micro-structural fracture features. Mater. Today Commun. 2023, 37, 107028. [Google Scholar] [CrossRef]

- Chen, C.; Geng, P.; Yang, Q.; Zhao, Y.; Gu, W.; He, C.; Zhang, J. Dynamic constitutive modeling of steel fiber reinforced concrete considering damage evolution under high strain rate. Constr. Build. Mater. 2024, 440, 137433. [Google Scholar] [CrossRef]

- Lv, Y.; Wu, H.; Dong, H.; Zhao, H.; Li, M.; Huang, F. Experimental and numerical simulation study of fiber-reinforced high strength concrete at high strain rates. J. Build. Eng. 2023, 65, 105812. [Google Scholar] [CrossRef]

- Du, Y.; Wei, J.; Liu, K.; Huang, D.; Lin, Q.; Yang, B. Research on dynamic constitutive model of ultra-high performance fiber-reinforced concrete. Constr. Build. Mater. 2020, 234, 117386. [Google Scholar] [CrossRef]

- Yang, L.; Lin, X.; Li, H.; Gravina, R.J. A new constitutive model for steel fibre reinforced concrete subjected to dynamic loads. Compos. Struct. 2019, 221, 110849. [Google Scholar] [CrossRef]

- Ye, Z.B.; Huang, R.Y.; Li, Y.C.; Lv, L.; Zhao, K.; Zhang, Y.L.; Ma, J.; Lin, J.J. Steel fiber-reinforced concrete under impact loading dynamic constitutive equation. Constr. Build. Mater. 2018, 190, 1049–1055. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Carkon-Azad, R.; Singh, S.; Kaushik, S. Impact resistance of steel fibrous concrete containing fibres of mixed aspect ratio. Constr. Build. Mater. 2009, 23, 183–189. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture and Building Press: Beijing, China, 2019. (In Chinese)

- Lok, T.S.; Li, X.B.; Liu, D.; Zhao, P.J. Testing and Response of Large Diameter Brittle Materials Subjected to High Strain Rate. J. Mater. Civ. Eng. 2002, 14, 262–269. [Google Scholar] [CrossRef]

- Li, S.; Shi-Sheng, H. Two-wave and three-wave method in SHPB data processing. Exp. Shock. Waves 2005, 25, 368–373. [Google Scholar]

- Wang, T.-T.; Shang, B. Three-Wave Mutual-Checking Method for Data Processing of SHPB Experiments of Concrete. J. Mech. 2014, 30, N5–N10. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, S.; Wang, L. An analysis of stress uniformity for concrete-like specimens during SHPB tests. Int. J. Impact Eng. 2009, 36, 61–72. [Google Scholar] [CrossRef]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024.

- Li, M.; Hao, H.; Shi, Y.; Hao, Y. Specimen shape and size effects on the concrete compressive strength under static and dynamic tests. Constr. Build. Mater. 2018, 161, 84–93. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Z.; Zhong, W.; Wang, S.; Zhang, R.; Yao, X. Effects of steel fibers on the dynamic properties and failure process of ultra-high performance concrete. J. Build. Eng. 2022, 62, 105415. [Google Scholar] [CrossRef]

- Grote, D.L.; Park, S.W.; Zhou, M. Dynamic behavior of concrete at high strain rates and pressures: I. experimental characterization. Int. J. Impact Eng. 2001, 25, 869–886. [Google Scholar] [CrossRef]

- Song, B.; Chen, W. Energy for Specimen Deformation in a Split Hopkinson Pressure Bar Experiment. Exp. Mech. 2006, 46, 407–410. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J. Study on dynamic characteristics of marble under impact loading and high temperature. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2013, 62, 51–58. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Kou, S.Q.; Jiang, L.G.; Lindqvist, P.A. Effects of loading rate on rock fracture: Fracture characteristics and energy partitioning. J. Rock Mech. Min. Sci. 2000, 37, 745–762. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Chang, M.; Guo, K.; Han, Y.F.; He, L.; Xu, M.; Tang, E. Zhu-Wang-Tang constitutive model of reinforced Al/PTFE materials at medium strain rate. Polym. Compos. 2022, 43, 2089–2102. [Google Scholar] [CrossRef]

- Liu, W.; Xu, X.; Mu, C. Development of Damage Type Viscoelastic Ontological Model for Soft and Hard Materials under High-Strain-Rate Conditions. Appl. Sci. 2022, 12, 8407. [Google Scholar] [CrossRef]

- Liu, W.; Mu, C.; Liu, J.; Cai, T. Study on static and dynamic mechanical properties of steel fiber self-compacting concrete after heating in a high-temperature. J. Build. Eng. 2023, 73, 106790. [Google Scholar] [CrossRef]

| Number | Strain Rate (s−1) | Peak Stress (MPa) | Peak Strain (10−2) |

|---|---|---|---|

| 1 | 123.92 | 80.87 | 1.23 |

| 2 | 214.86 | 108.21 | 1.26 |

| 3 | 380.84 | 135.11 | 1.27 |

| 4 | 430.58 | 154.61 | 1.40 |

| 5 | 483.12 | 233.66 | 1.41 |

| Strain Rate (s−1) | A | α | β | E2 | |||

|---|---|---|---|---|---|---|---|

| 123.92 | 3 | 0.9 | 0.8 | 142,519.37 | −142,523.36 | 3 | 0.001 |

| 214.86 | 3 | 0.9 | 0.8 | 164,298.04 | −164,300.99 | 3 | 0.001 |

| 380.84 | 3 | 0.9 | 0.8 | 184,109.75 | −184,111.75 | 3 | 0.001 |

| 430.58 | 3 | 0.9 | 0.8 | 236,492.57 | −236,494.82 | 3 | 0.001 |

| 483.12 | 3 | 0.9 | 0.8 | 290,941.01 | −290,943.51 | 3 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Bai, Z.; Liu, W.; He, Y. Research on Compression Failure Characteristics and Damage Constitutive Model of Steel Fiber-Reinforced Concrete with 2% Copper-Coated Fibers Under Impact Load. Materials 2024, 17, 5724. https://doi.org/10.3390/ma17235724

Liu G, Bai Z, Liu W, He Y. Research on Compression Failure Characteristics and Damage Constitutive Model of Steel Fiber-Reinforced Concrete with 2% Copper-Coated Fibers Under Impact Load. Materials. 2024; 17(23):5724. https://doi.org/10.3390/ma17235724

Chicago/Turabian StyleLiu, Guangkun, Zhengxiong Bai, Wei Liu, and Yajie He. 2024. "Research on Compression Failure Characteristics and Damage Constitutive Model of Steel Fiber-Reinforced Concrete with 2% Copper-Coated Fibers Under Impact Load" Materials 17, no. 23: 5724. https://doi.org/10.3390/ma17235724

APA StyleLiu, G., Bai, Z., Liu, W., & He, Y. (2024). Research on Compression Failure Characteristics and Damage Constitutive Model of Steel Fiber-Reinforced Concrete with 2% Copper-Coated Fibers Under Impact Load. Materials, 17(23), 5724. https://doi.org/10.3390/ma17235724