Application of Product of Vitrification of Asbestos-Cement Waste and CRT Glass Cullet as Reinforcing Phase in Surface Composites Produced by FSP Method

Highlights

- The vitrified material can be used as a reinforcing phase in composites.

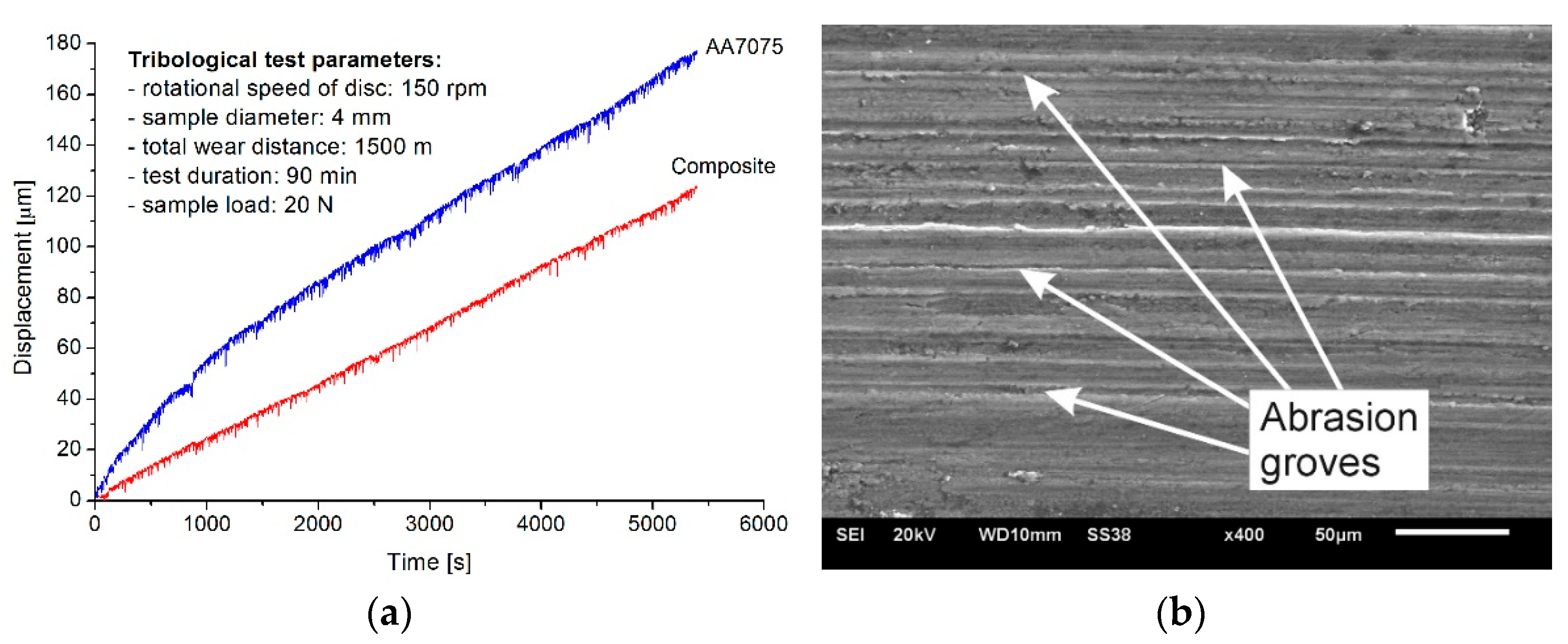

- The use of vitrified material leads to an increase in hardness and wear resistance.

- The use of vitrified material as a reinforcing phase is fully justified.

Abstract

1. Introduction

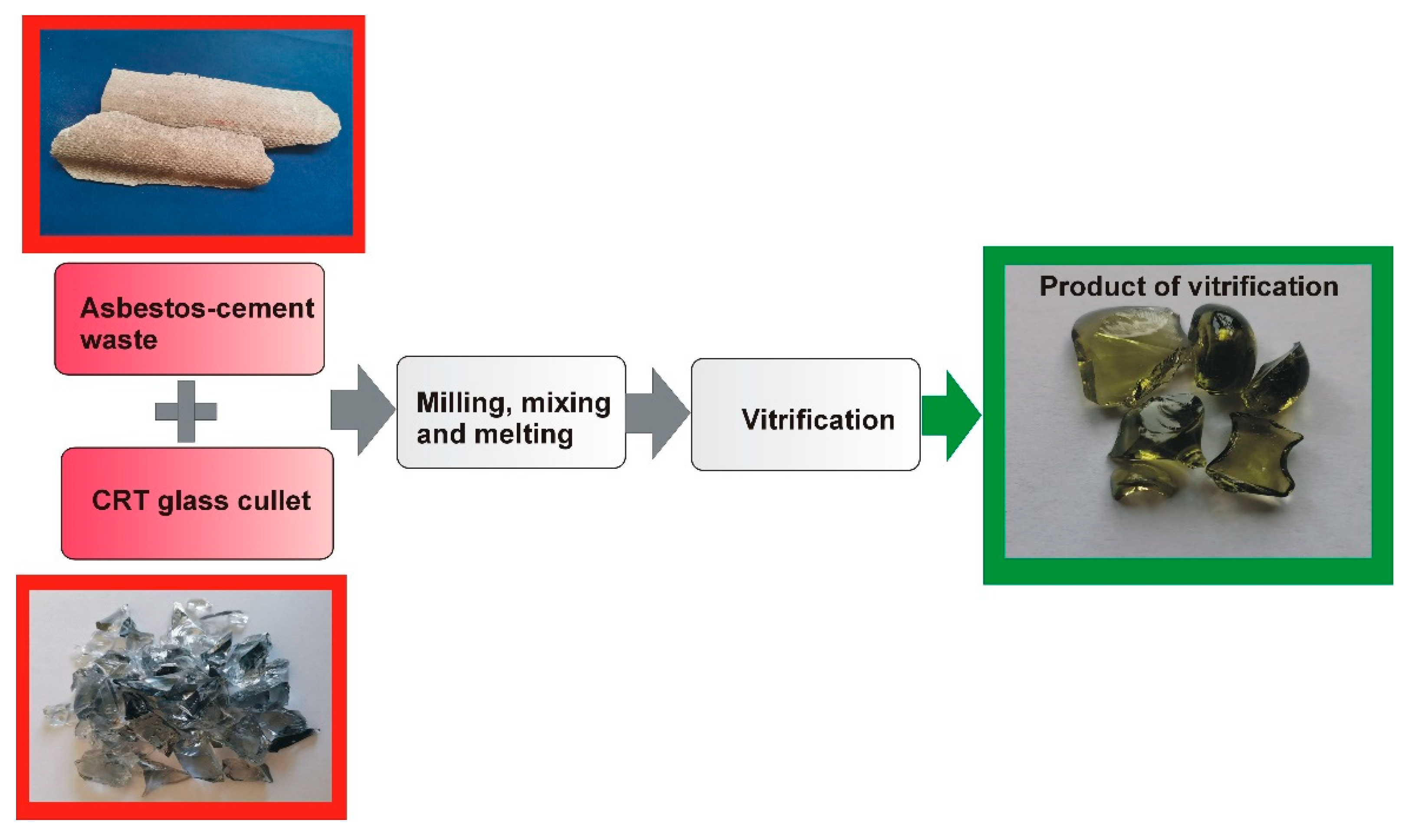

2. Materials and Research Methodology

3. Methodology of Composite Production

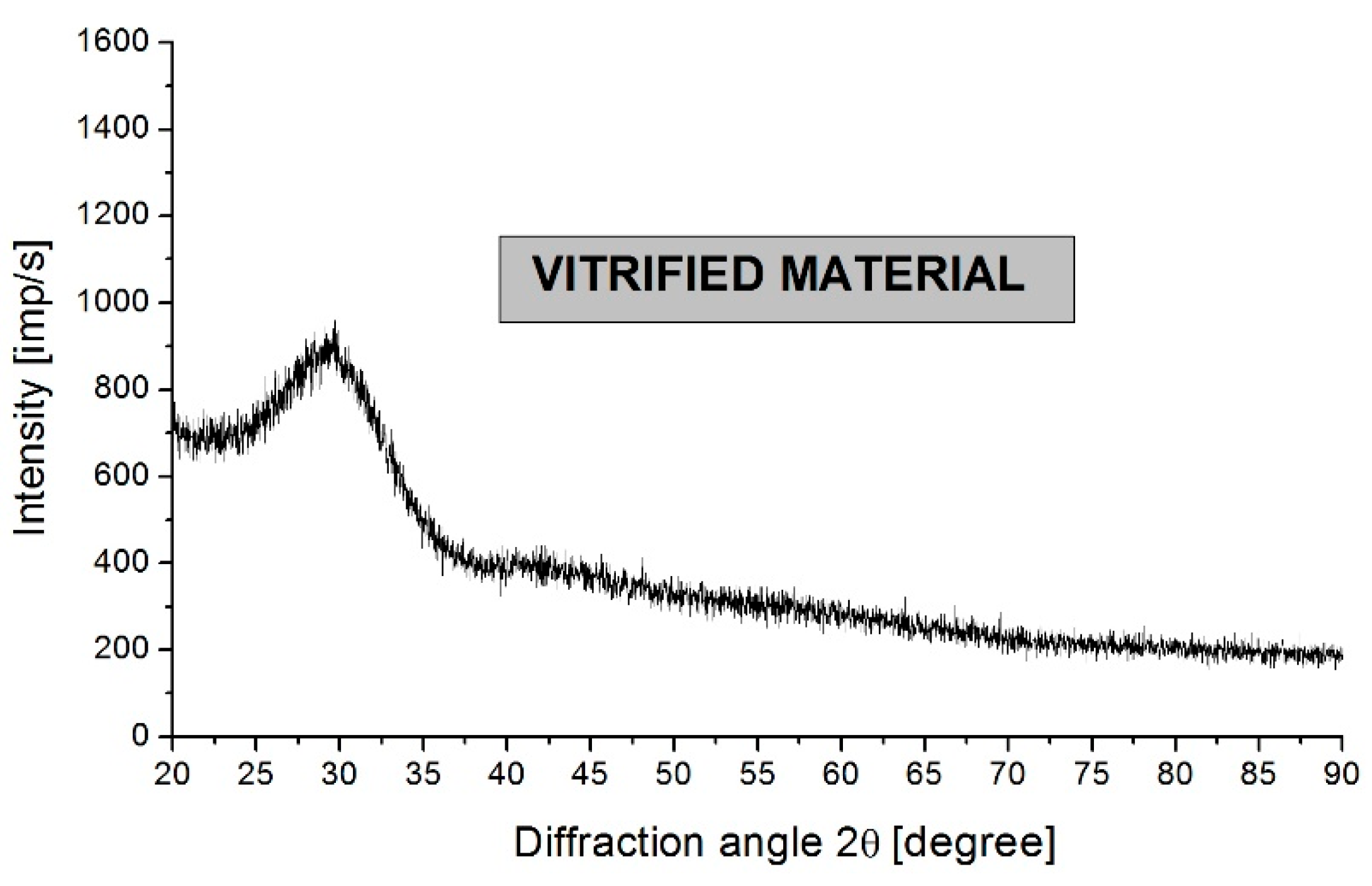

4. Results and Discussion

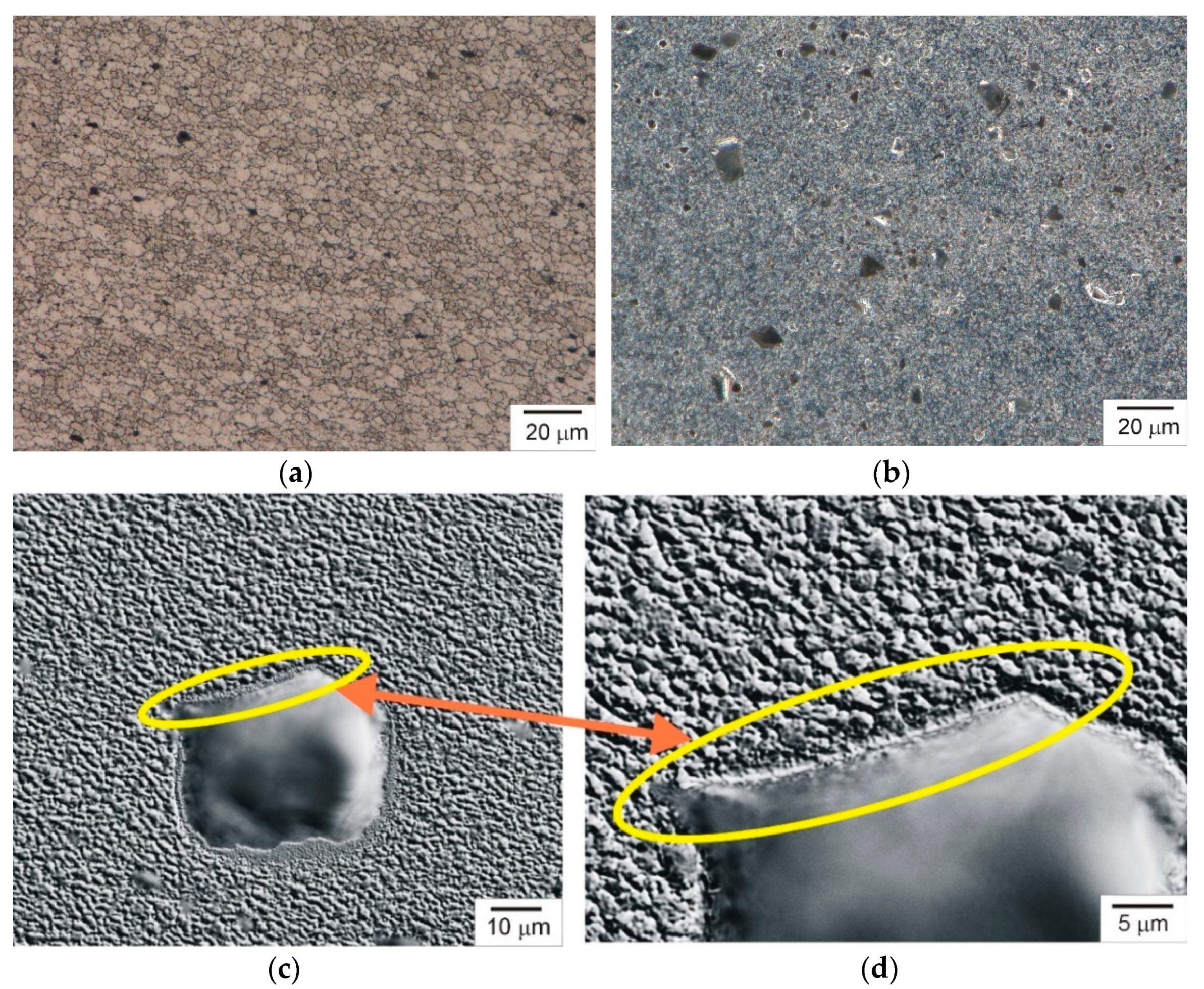

4.1. Microstructural Studies

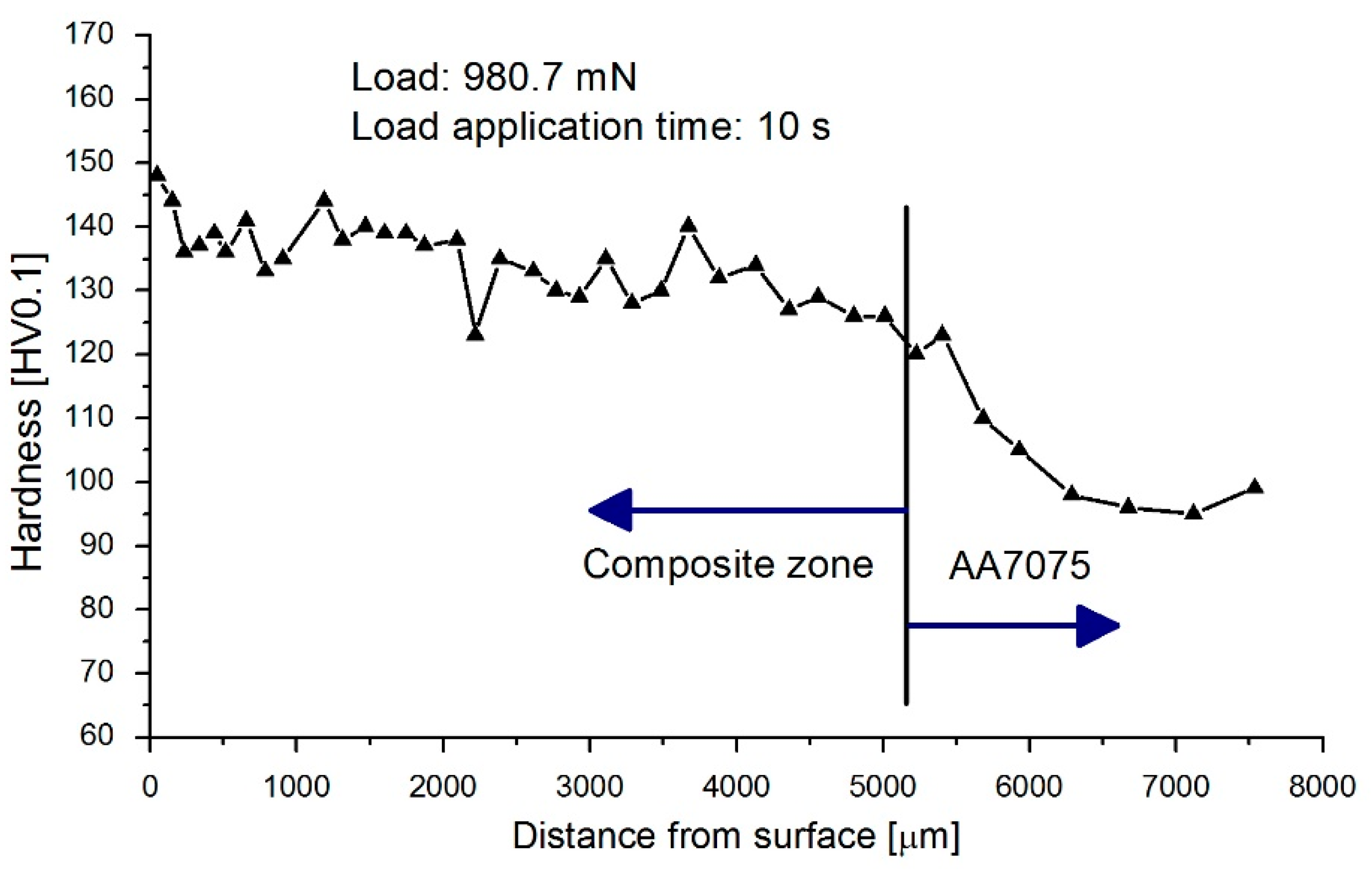

4.2. Hardness Measurements

4.3. Wear Resistance Tests

5. Conclusions

- The product of the vitrification of asbestos-cement waste and glass cullet from a CRT can be used as a reinforcing phase in the production of composites and constitutes a substitute material for other currently used materials.

- The introduction of vitrified particles into the AA7075 aluminum alloy matrix, combined with strong grain refinement, raised the hardness of the material by approximately 39%, from 97 HV0.1 to approximately 135 HV0.1.

- Favorable changes in the microstructure of the material increase the abrasive wear resistance of the vitrified-material-reinforced composite by 30.4% compared to the wear resistance of the AA7075 aluminum alloy.

- The use of vitrified material as a reinforcing phase allows a high-quality surface composite to be obtained. The use of the vitrified material as a strengthening phase in composites is therefore fully justified and advisable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, Y.; Bao, S.; Zhang, Y. Recycling of granite powder and waste marble produced from stone processing for the preparation of architectural glass–ceramic. Constr. Build. Mater. 2022, 346, 128408. [Google Scholar] [CrossRef]

- Marini, P.; Bellopede, R.; Zanotti, G.; Ramon, V. Waste of the secondary glass waste (glass waste): New solutions for a sustainable industrial recovery. In Proceedings of the 15th International Conference on Environmental Science and Technology, Rhodes, Greece, 31 August–2 September 2017. CEST2017_00488. [Google Scholar]

- Thives, L.P.; Ghisi, E.; Thives Júnior, J.J.; Vieira, A.S. Is asbestos still a problem in the world? A current review. J. Environ. Manag. 2022, 319, 115716. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Bonilla, J.P.; Cely-García, M.F.; Giraldo, M.; Comba, P.; Terracini, B.; Pasetto, R.; Marsili, D.; Ascoli, V.; Lysaniuk, B.; Rodríguez, M.C.; et al. An asbestos contaminated town in the vicinity of an asbestos-cement facility: The case study of Sibat’e, Colombia. Environ. Res. 2019, 176, 108464. [Google Scholar] [CrossRef] [PubMed]

- Szułczyńska, D. Determinants of the perception of asbestos. Saf. Fire Technol. 2019, 53, 144–161. [Google Scholar] [CrossRef]

- Łuniewski, S.; Rogowska, W.; Łozowicka, B.; Iwaniuk, P. Plants, Microorganisms and their metabolites in supporting asbestos detoxification–a biological perspective in asbestos treatment. Materials 2024, 17, 1644. [Google Scholar] [CrossRef]

- Kusiorowski, R.; Zaremba, T.; Piotrowski, J.; Adamek, J. Thermal decomposition of different types of asbestos. J. Therm. Anal. Calorim. 2012, 109, 693–704. [Google Scholar] [CrossRef]

- Iwaszko, J. Making asbestos-cement products safe using heat treatment. Case Stud. Constr. Mater. 2019, 10, e00221. [Google Scholar] [CrossRef]

- Dellisanti, E.; Rossi, P.L.; Valdre, G. Remediation of asbestos containing materials by Joule heating vitrification performed in a pre-pilot apparatus. Inter. J. Miner. Process. 2009, 91, 61–67. [Google Scholar] [CrossRef]

- Kasai, G.; Goto, H.; Mase, Y. Vitrification treatment of asbestos waste with incineration ash of solid waste. High Temp. Mater. Proc. 2011, 30, 353–357. [Google Scholar] [CrossRef]

- Iwaszko, J.; Lubas, M.; Sitarz, M.; Zajemska, M.; Nowak, A. Production of vitrified material from hazardous asbestos-cement waste and CRT glass cullet. J. Clean. Prod. 2021, 317, 128345. [Google Scholar] [CrossRef]

- Kasprzyk, K.; Kordylewski, W.; Zacharczuk, W. Modification of fly-ash by vitrification. Arch. Combust. 2003, 23, 21–30. [Google Scholar]

- Colombo, P.; Brusatin, G.; Bernardo, E.; Scarinci, G. Inertization and reuse of waste materials by vitrification and fabrication of glass-based products. Curr. Opin. Solid State Mater. Sci. 2003, 7, 225–239. [Google Scholar] [CrossRef]

- Borowski, G. Vitrification process for sewage sludge treatment. In Environmental Engineering. Part IV; Pawłowski, A., Pawłowska, M., Pawłowski, L., Eds.; CRC Press Taylor & Francis Grp.: London, UK, 2013; pp. 185–190. [Google Scholar]

- Valderrama, D.M.A.; Cuaspud, J.A.G.; Roether, J.A.; Boccaccini, A.R. Development and characterization of glass-ceramics from combinations of slag, fly ash, and glass cullet without adding nucleating agents. Materials 2019, 12, 2032. [Google Scholar] [CrossRef] [PubMed]

- Kjeldsen, J.; Smedskjaer, M.M.; Potuzak, M.; Yue, Y.Z. Role of elastic deformation in determining the mixed alkaline earth effect of hardness in silicate glasses. J. App. Phys. Lett. 2015, 117, 034903. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W. Friction stir processing: A new grain refinement technique to achieve high strain rate superplasticity in commercial alloys. Mater. Sci. Forum 2001, 357–359, 507–514. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. International Patent Application No. PCT/GB92/02203 and GB Patent Application No. 9125978.8. December 1991. [Google Scholar]

- Janeczek, A.; Tomków, J.; Aghajani Derazkola, H.; Łyczkowska, K.; Fydrych, D. Effect of underwater friction stir welding parameters on AA5754 alloy joints: Experimental studies. Int. J. Adv. Manuf. Tech. 2024, 134, 5643–5655. [Google Scholar] [CrossRef]

- Mohammed, M.M.; Abdullah, M.E.; Rohim, M.N.M.; Kubit, A.; Aghajani Derazkola, H. AA5754–Al2O3 Nanocomposite Prepared by Friction Stir Processing: Microstructural Evolution and Mechanical Performance. J. Manuf. Mater. Process. 2024, 8, 58. [Google Scholar] [CrossRef]

- Iwaszko, J.; Kudła, K.; Fila, K. Technological aspects of friction stir processing of AlZn5.5MgCu aluminum alloy. Bull. Pol. Acad. Sci. Tech. Sci. 2018, 66, 713–719. [Google Scholar]

- Sato, Y.S.; Park, S.H.C.; Kokawa, H. Microstructural factors governing hardness in friction-stir welds of solid-solution-hardened Al alloys. Metall. Mater. Trans. 2001, 32, 3033–3042. [Google Scholar] [CrossRef]

- Thangaraju, S.; Heilmaier, M.; Murty, B.S.; Vadlamani, S.S. On the estimation of true Hall-Petch constants and their role on the superposition law exponent in Al alloys. Adv. Eng. Mater. 2012, 14, 892–897. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, W.; Guo, X.; Yang, X.; Li, J.; Ren, J.; Xue, H.; Tang, F. Strengthening mechanism of NiCoAl alloy induced by nanotwin under Hall-Petch effect. Int. J. Mech. Sci. 2023, 255, 108478. [Google Scholar]

- Iwaszko, J.; Kudła, K. Evolution of microstructure and properties of air-cooled friction-stir-processed 7075 aluminum alloy. Materials 2022, 15, 2633. [Google Scholar] [CrossRef] [PubMed]

| Sample | Element Content (wt%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | Fe2O3 | BaO | SrO | SO3 | K2O | Na2O | ZrO2 | Rest | |

| ACW | 69.92 | 14.80 | 4.15 | 2.47 | 4.44 | - | - | 2.57 | 0.27 | - | - | 1.38 * |

| CRT glass cullet | 0.10 | 60.49 | 0.05 | 3.05 | 0.06 | 8.37 | 7.77 | 0.13 | 6.24 | 9.49 | 2.57 | 1.68 ** |

| Sample | Element Content (wt%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | Fe2O3 | BaO | SrO | SO3 | K2O | Na2O | ZrO2 | Rest | |

| Vitrified material | 34.01 | 29.52 | 1.59 | 3.91 | 2.31 | 5.86 | 11.09 | 0.19 | 3.37 | 1.80 | 3.88 | 2.47 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iwaszko, J.; Kudła, K.; Lubas, M. Application of Product of Vitrification of Asbestos-Cement Waste and CRT Glass Cullet as Reinforcing Phase in Surface Composites Produced by FSP Method. Materials 2024, 17, 5508. https://doi.org/10.3390/ma17225508

Iwaszko J, Kudła K, Lubas M. Application of Product of Vitrification of Asbestos-Cement Waste and CRT Glass Cullet as Reinforcing Phase in Surface Composites Produced by FSP Method. Materials. 2024; 17(22):5508. https://doi.org/10.3390/ma17225508

Chicago/Turabian StyleIwaszko, Józef, Krzysztof Kudła, and Małgorzata Lubas. 2024. "Application of Product of Vitrification of Asbestos-Cement Waste and CRT Glass Cullet as Reinforcing Phase in Surface Composites Produced by FSP Method" Materials 17, no. 22: 5508. https://doi.org/10.3390/ma17225508

APA StyleIwaszko, J., Kudła, K., & Lubas, M. (2024). Application of Product of Vitrification of Asbestos-Cement Waste and CRT Glass Cullet as Reinforcing Phase in Surface Composites Produced by FSP Method. Materials, 17(22), 5508. https://doi.org/10.3390/ma17225508