Application of Hybrid Absorptive–Diffusive Panels with Variable Acoustic Characteristics Based on Wooden Overlays Designed Using Third-Degree-of-Freedom Bezier Curves

Abstract

1. Introduction

- Esthetics side—as most acoustic absorbers are plain, uniformly formed surfaces, such as textile-covered fiberglass or acoustic perforated panels made of MDF or gypsum board, including sound absorption in the modern design process is complicated and requires considerable flexibility from architects [6,7].

- Material sustainability—although there have been some advancements in this field, especially in novel porous materials [8,9,10], the most common method for achieving partially sustainable properties is mixing raw materials, which can be achieved by recycling and developing well-known materials such as polyester fibers or fiberglass. Using materials such as sustainable wood or pure natural fibers is uncommon and expensive. Some attempts to use natural-origin materials have been made, such as the use of sheep wool [11,12]; however, it has been proven that pure, natural materials do not fit architectural requirements as they do not provide sufficient flame retardancy and hygiene properties.

2. Research Motivation and State-of-the-Art

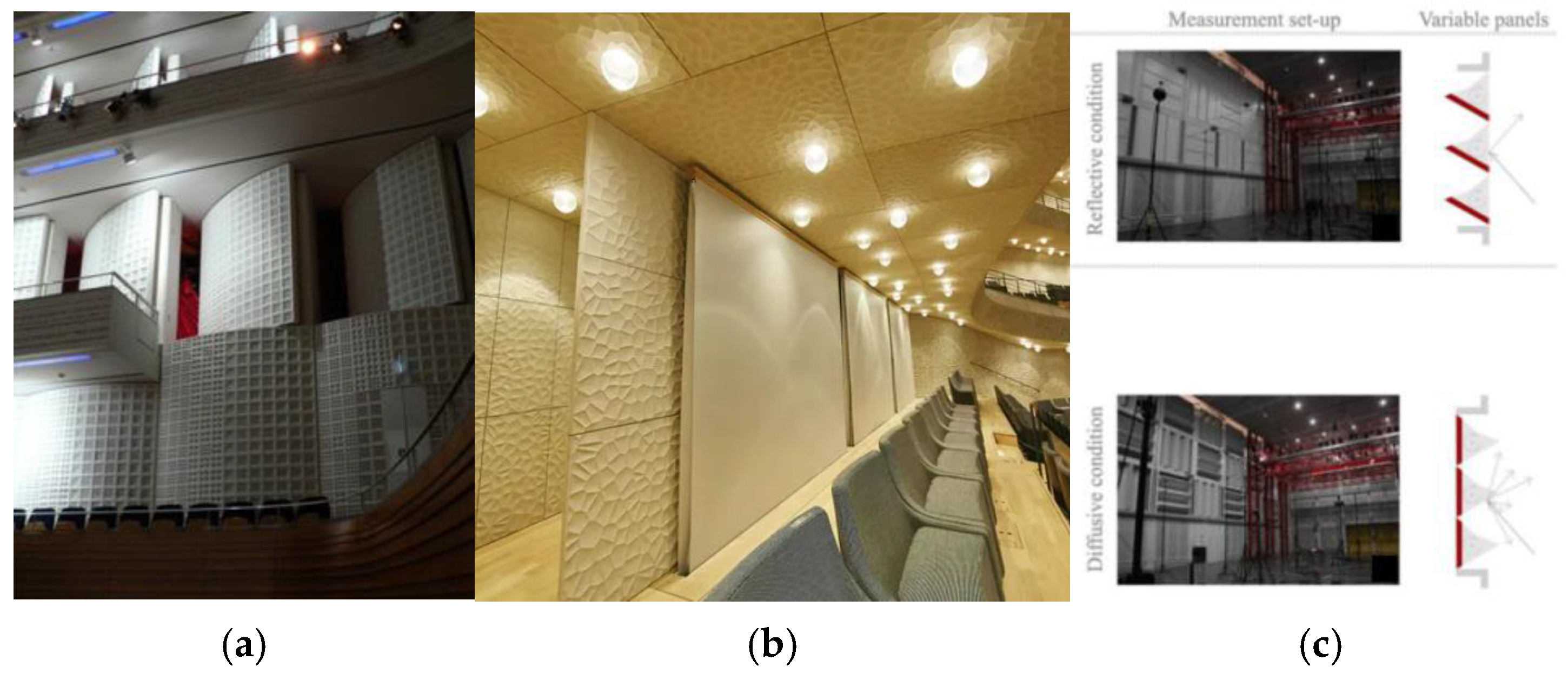

2.1. Overview of Available Solutions for Variable and Hybrid Acoustic Properties

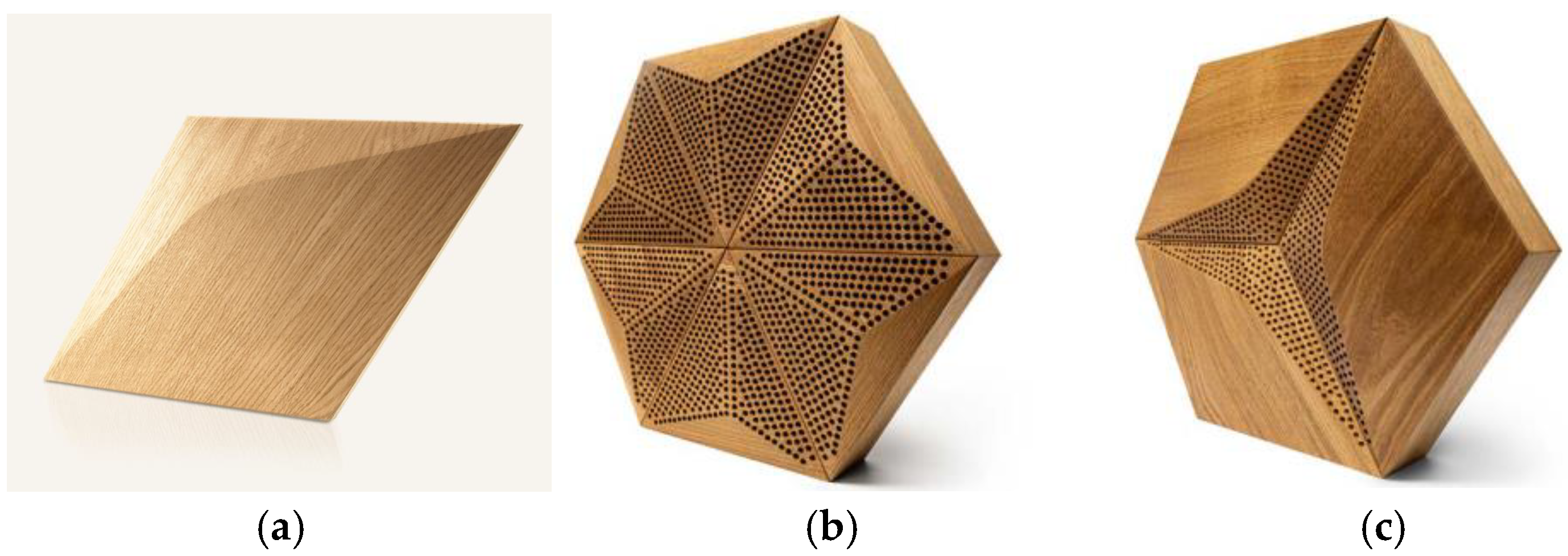

2.2. Hybrid Panels Based on the Wooden Overlays in Third-Degree Curves

3. Acoustic Property Measurements

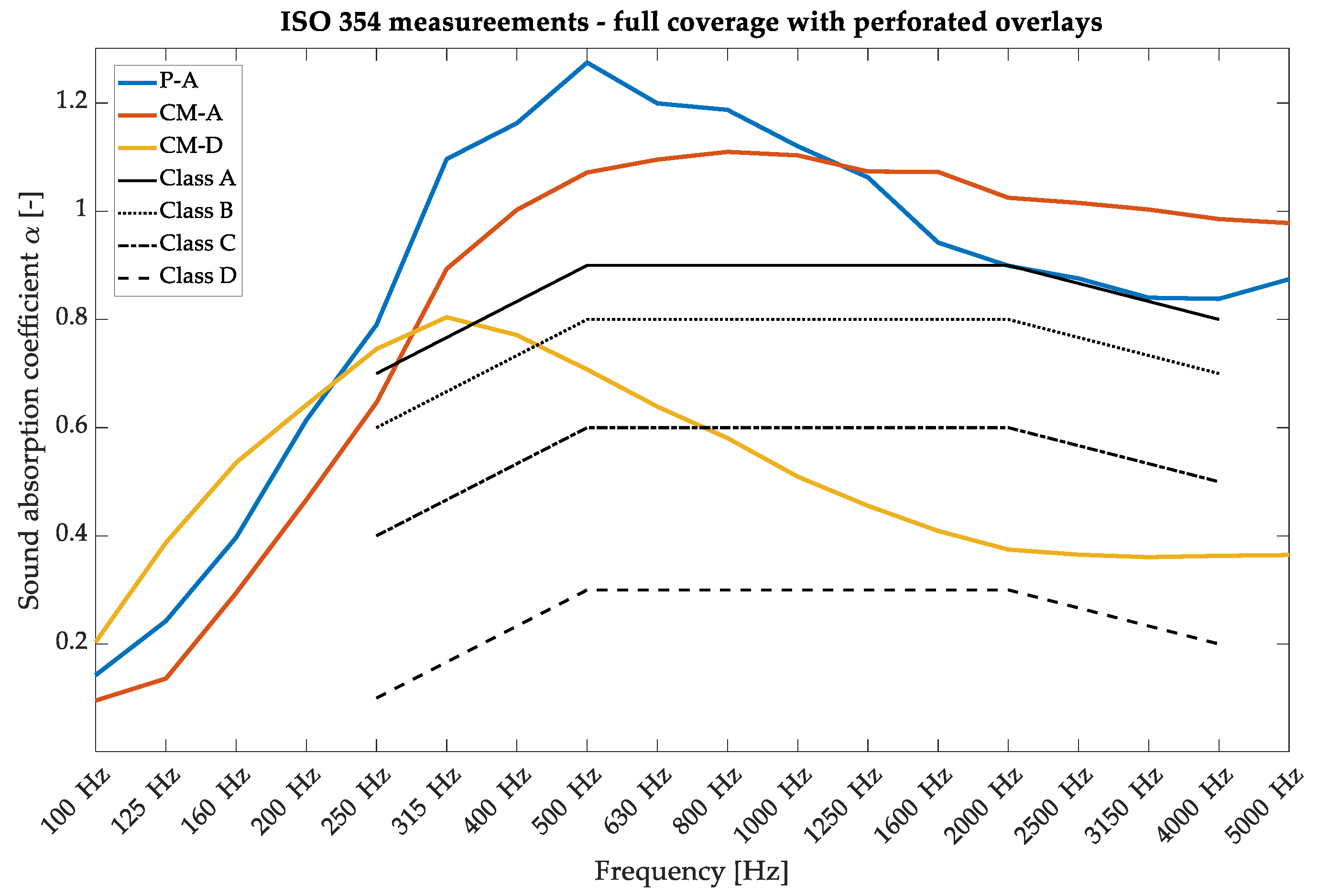

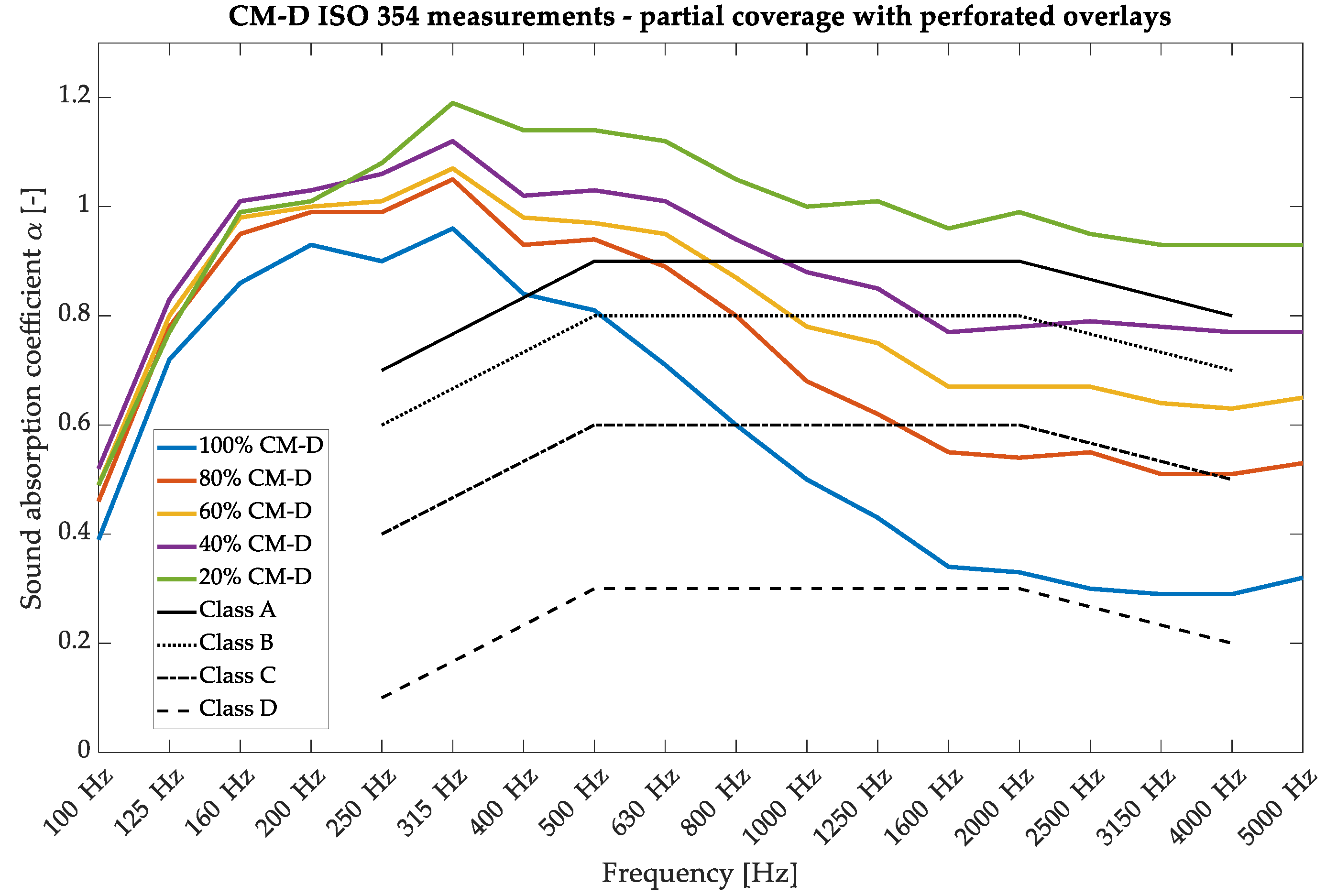

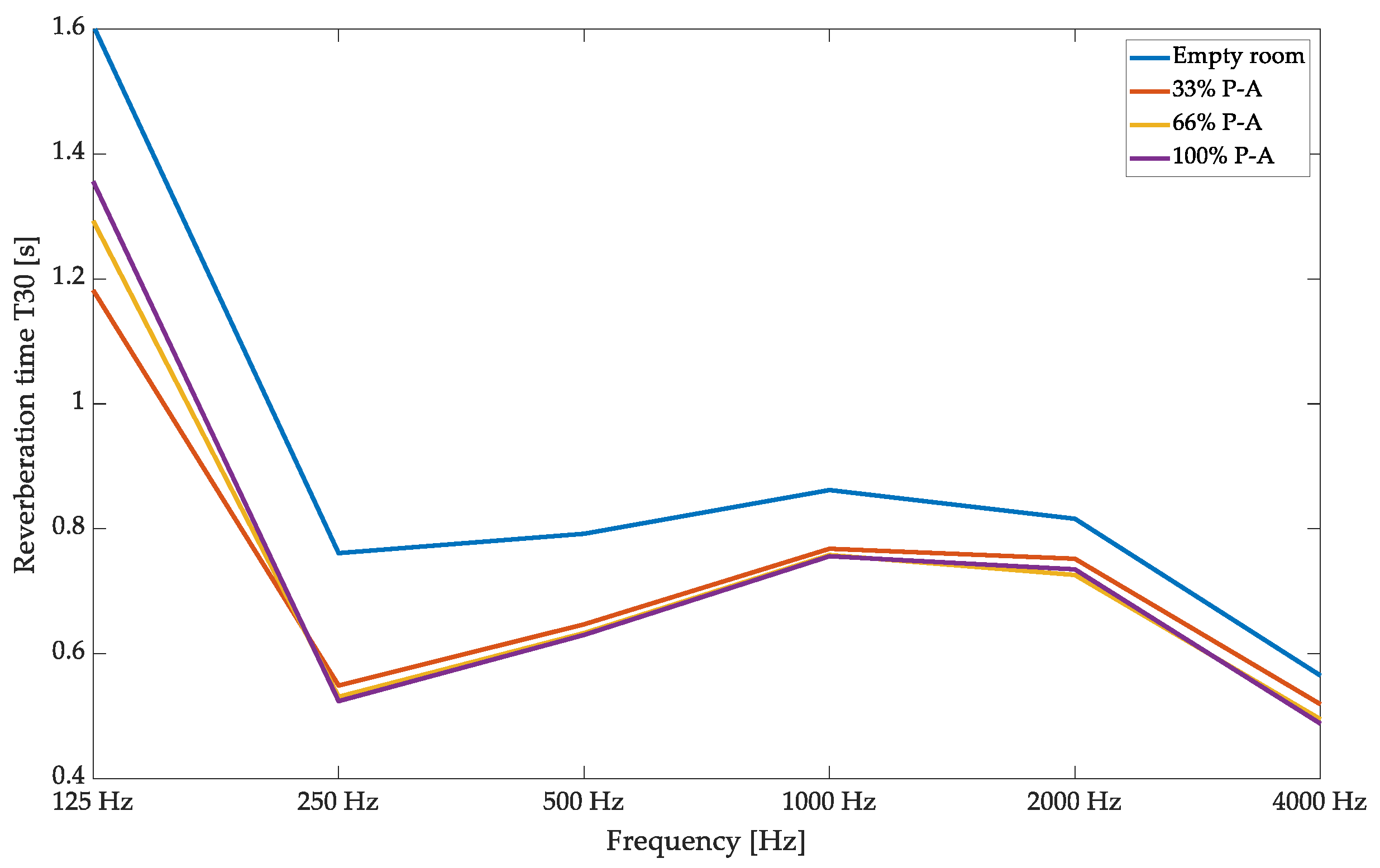

3.1. Sound Absorption in a Reverberation Chamber

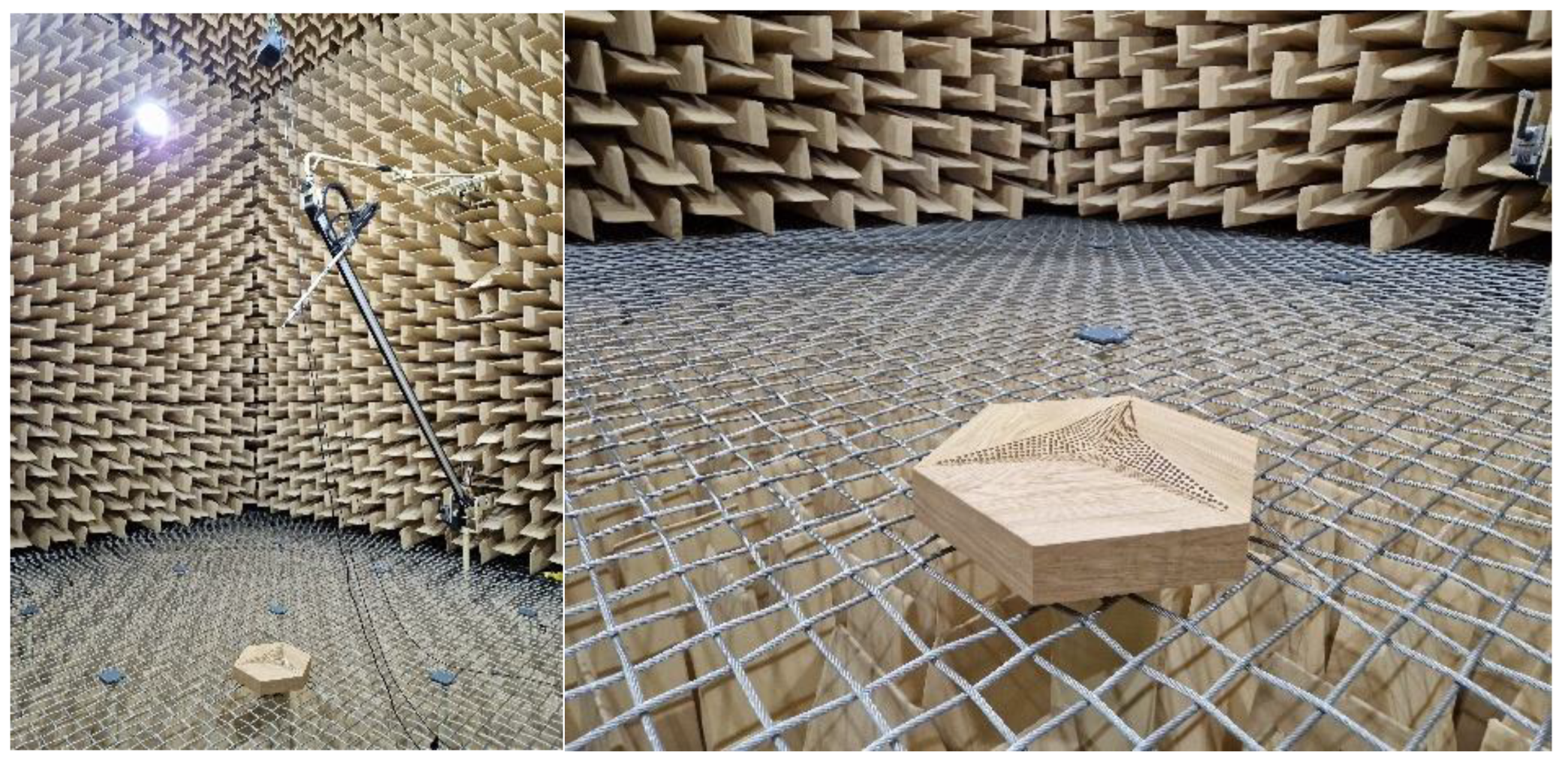

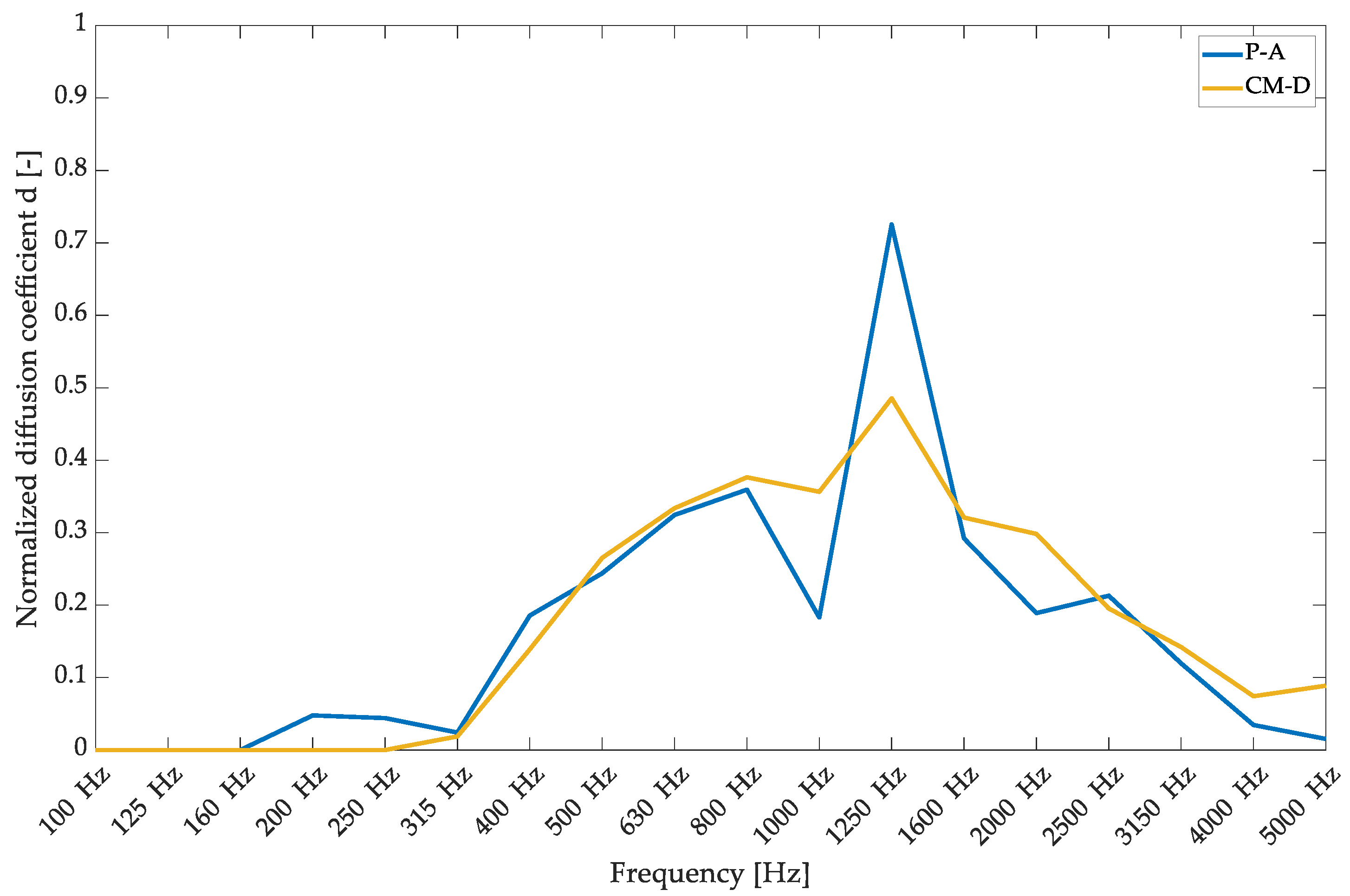

3.2. Sound Diffusion in an Anechoic Chamber

4. In Situ Acoustic Measurements

- ⯀

- GRAS 12AL microphone power supplies (Holte, Denmark);

- ⯀

- An RME Fireface UFX measurement card (Haimhausen, Germany);

- ⯀

- A Lenovo ThinkPad portable computer (Morrisville, NC, USA) with B&K 7841 Dirac 5.0 software;

- ⯀

- A GRAS 46 AE ½″ microphone (Holte, Denmark);

- ⯀

- A Genelec 8030 sound source (Iisalmi, Finland).

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Sheng, P. Sound Absorption Structures: From Porous Media to Acoustic Metamaterials. Annu. Rev. Mater. Res. 2017, 47, 83–114. [Google Scholar] [CrossRef]

- Ghaffarivardavagh, R.; Nikolajczyk, J.; Anderson, S.; Zhang, X. Ultra-Open Acoustic Metamaterial Silencer Based on Fano-like Interference. Phys. Rev. B 2019, 99, 24302. [Google Scholar] [CrossRef]

- Jiménez, N.; Cox, T.J.; Romero-García, V.; Groby, J.P. Metadiffusers: Deep-Subwavelength Sound Diffusers. Sci. Rep. 2017, 7, 5389. [Google Scholar] [CrossRef] [PubMed]

- Jiménez, N.; Romero-García, V.; Pagneux, V.; Groby, J.P. Rainbow-Trapping Absorbers: Broadband, Perfect and Asymmetric Sound Absorption by Subwavelength Panels for Transmission Problems. Sci. Rep. 2017, 7, 13595. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Chen, S.; Fu, C.; Sheng, P. Optimal Sound-Absorbing Structures. Mater. Horiz. 2017, 4, 673–680. [Google Scholar] [CrossRef]

- Forster, P. Investigation of 3D Printed Acoustic Metamaterials. Master’s Thesis, London South Bank University, London, UK, 2018. [Google Scholar]

- Templeton, D. Acoustics in the Built Environment; Architectural Press: Oxford, UK, 1997. [Google Scholar]

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the Sound Absorption Performance of Sustainable Thermal Insulation Materials: Natural Hemp Fibres. Appl. Acoust. 2019, 150, 279–289. [Google Scholar] [CrossRef]

- Salunkhe, S.; Patil, C.; Thakar, C.M. Exploring the Potential of Natural Materials as Eco-Friendly Sound Absorbers. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic Characterization of Natural Fibers for Sound Absorption Applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G.; Di Gabriele, M. Characterization of Sheep Wool Panels for Room Acoustic Applications. Proc. Meet. Acoust. 2016, 28, 015001. [Google Scholar]

- Borlea (Mureşan), S.I.; Tiuc, A.-E.; Nemeş, O.; Vermeşan, H.; Vasile, O. Innovative Use of Sheep Wool for Obtaining Materials with Improved Sound-Absorbing Properties. Materials 2020, 13, 694. [Google Scholar] [CrossRef]

- Vigeant, M.C.; Neal, M.T.; Dick, D.A. Effects of Variable Acoustic Elements on the Spatial Sound Field in Multipurpose Venues. J. Acoust. Soc. Am. 2017, 142, 2688. [Google Scholar] [CrossRef]

- Pereira, A.; Gaspar, A.; Godinho, L.; Amado Mendes, P.; Mateus, D.; Carbajo, J.; Ramis, J.; Poveda, P. On the Use of Perforated Sound Absorption Systems for Variable Acoustics Room Design. Buildings 2021, 11, 543. [Google Scholar] [CrossRef]

- Kuttruff, H. Room Acoustics; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9781482266450. [Google Scholar]

- Beranek, L.L. Concert Halls and Opera Houses: Music, Acoustics, and Architecture; Springer: New York, NY, USA, 2004. [Google Scholar]

- Woszczyk, W. Active Acoustics in Concert Halls—A New Approach. Arch. Acoust. 2011, 36, 379–393. [Google Scholar] [CrossRef]

- Kozłowski, P.Z. Effectiveness of Acoustic Banners Depending on Their Arrangement in the Concert Hall—Case Study. Vib. Phys. Syst. 2019, 30, 2019141. [Google Scholar]

- Aretz, M.; Orlowski, R. Balancing Sound Strength and Reverberation Time in Small Concert Halls by Means of Variable Acoustics. Noise Vib. Worldw. 2010, 41, 11–24. [Google Scholar] [CrossRef]

- Kamisiński, T. Correction of Acoustics in Historic Opera Theatres with the Use of Schroeder Diffuser. Arch. Acoust. 2012, 37, 349–354. [Google Scholar] [CrossRef]

- Xiang, N.; Robinson, P.; Jing, Y. Characterization of Non-Exponential Sound Energy Decays in Multiple Coupled Volumes. In Proceedings of the 20th International Congress on Acoustics 2010, Sydney, Australia, 23–27 August 2010. [Google Scholar]

- Shtrepi, L.; Astolfi, A.; Pelzer, S.; Vitale, R.; Rychtáriková, M. Objective and Perceptual Assessment of the Scattered Sound Field in a Simulated Concert Hall. J. Acoust. Soc. Am. 2015, 138, 1485–1497. [Google Scholar] [CrossRef]

- Shtrepi, L.; Di Blasio, S.; Astolfi, A. Listeners Sensitivity to Different Locations of Diffusive Surfaces in Performance Spaces: The Case of a Shoebox Concert Hall. Appl. Sci. 2020, 10, 4370. [Google Scholar] [CrossRef]

- Szeląg, A.; Rubacha, J.; Pilch, A.; Majchrzak, A.; Kamisiński, T. Reflective Panels with Schroeder Diffusers—A Measure to Broaden the Effective Frequency Range of Sound Reflection from Overhead Stage Canopies. Appl. Acoust. 2020, 157, 107034. [Google Scholar] [CrossRef]

- Jurkiewicz, Y. Variable Acoustics, from Design to Everyday Practice. Can It Really Work? In Forum Acusticum; HAL: Bangalore, India, 2020. [Google Scholar]

- Gerriets Gerriets Roller Baners. Available online: https://www.gerriets.com/gb/page/acoustic-roller-banner-g-sorber-1/ (accessed on 1 October 2024).

- Shtrepi, L.; Astolfi, A.; Puglisi, G.E.; Masoero, M.C. Effects of the Distance from a Diffusive Surface on the Objective and Perceptual Evaluation of the Sound Field in a Small Simulated Variable-Acoustics Hall. Appl. Sci. 2017, 7, 224. [Google Scholar] [CrossRef]

- Chojnacki, B.; Schynol, K.; Halek, M.; Muniak, A. Sustainable Perforated Acoustic Wooden Panels Designed Using Third-Degree-of-Freedom Bezier Curves with Broadband Sound Absorption Coefficients. Materials 2023, 16, 6089. [Google Scholar] [CrossRef] [PubMed]

- Pilch, A. Sources of Measurement Uncertainty in Determination of the Directional Diffusion Coefficient Value. Appl. Acoust. 2018, 129, 268–276. [Google Scholar] [CrossRef]

- Kosała, K. Experimental Tests of the Acoustic Properties of Sound-Absorbing Linings and Cores of Layered Baffles. Vib. Phys. Syst. 2021, 32. [Google Scholar] [CrossRef]

- Kosała, K.; Majkut, L.; Mleczko, D.; Olszewski, R.; Wszołek, T. Accuracy of Prediction Methods for Sound Insulation of Homogeneous Single Baffles. Vib. Phys. Syst. 2020, 31. [Google Scholar]

- ISO 354; Acoustics—Measurement of Sound Absorption in a Reverberation Room. The International Organization for Standardization (ISO): Geneva, Switzerland, 2003.

- Vercammen, M.L.S. How to Improve the Accuracy of the Absorption Measurement in the Reverberation Chamber ? In Proceedings of the NAG/DAGA International Conference on Acoustics, Rotterdam, The Netherlands, 23–26 March 2009. [Google Scholar]

- Mleczko, D.; Wszołek, T. Effect of Diffusing Elements in a Reverberation Room on the Results of Airborne Sound Insulation Laboratory Measurements. Arch. Acoust. 2019, 44, 739–746. [Google Scholar]

- Nolan, M.; Vercammen, M.; Jeong, C.-H. Effects of Different Diffuser Types on the Diffusivity in Reverberation Chambers. In Proceedings of the Euronoise, Maastricht, The Netherlands, 31 May–3 June 2015; pp. 191–196. [Google Scholar]

- Majchrzak, A.; Chojnacki, B.; Sobolewska, M.; Baruch, K.; Pilch, A. The Measurement of Sound Scattering in a 1: 8 Scale-Validation of the Measurement Stand and Procedure. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Chicago, IL, USA, 26–29 August 2018; Volume 258, pp. 3287–3294. [Google Scholar]

- Ciaburro, G.; Romero, V.P.; Iannace, G.; Bravo Moncayo, L. Improving Acoustic Properties of Sandwich Structures Using Recycled Membrane and HoneyComb Composite (RMHCC). Buildings 2024, 14, 2878. [Google Scholar] [CrossRef]

- Iannace, G.; Trematerra, A. Acoustic Measurements and Correction of a Council Room. Noise Vib. Worldw. 2014, 45, 12–16. [Google Scholar] [CrossRef]

- Beranek, L.L. Concert Halls and Opera Houses: Music, Acoustics, and Architecture (Second Edition). J. Acoust. Soc. Am. 2005, 117, 987–988. [Google Scholar] [CrossRef]

- ISO 11654; 1997 Acoustics—Sound Absorbers for Use in Buildings—Rating of Sound Absorption. International Organization for Standardization: Geneva, Switzerland, 1997.

- Pilch, A.; Kamisiński, T. The Effect of Geometrical and Material Modification of Sound Diffusers on Their Acoustic Parameters. Arch. Acoust. 2011, 36, 955–966. [Google Scholar] [CrossRef]

- ISO 17497-1; Acoustics—Sound-Scattering Properties of Surfaces—Part 1: Measurement of the Random-Incidence Scattering Coefficient in a Reverberation Room. International Organization for Standardization: Geneva, Switzerland, 2004.

- Rubacha, J. Analysis of the Possibility of Shaping the Sound Diffusion Coefficient of Diffusers Based on Acoustic Metamaterials. Vib. Phys. Syst. 2022, 33, 2022210. [Google Scholar] [CrossRef]

- ISO 3382; Acoustics—Measurement of Room Acoustic Parameters—Part 1: Performance Spaces. International Organization for Standardization: Geneva, Switzerland, 2009.

| Variant Name and % of Perforation | αw ISO 11654 | Absorption Class ISO 11654 |

|---|---|---|

| 33% P-A | 0.45 (LM) | D |

| 66% P-A | 0.75 (M) | C |

| 100% P-A | 0.95 | A |

| 20% CM-D 80% PET | 1.00 | A |

| 40% CM-D 60% PET | 0.80 | B |

| 60% CM-D 40% PET | 0.70 | C |

| 80% CM-D 20% PET | 0.60 (LM) | C |

| 100% CM-D | 0.40 (LM) | D |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chojnacki, B.; Schynol, K.; Chojnacka, K. Application of Hybrid Absorptive–Diffusive Panels with Variable Acoustic Characteristics Based on Wooden Overlays Designed Using Third-Degree-of-Freedom Bezier Curves. Materials 2024, 17, 5421. https://doi.org/10.3390/ma17225421

Chojnacki B, Schynol K, Chojnacka K. Application of Hybrid Absorptive–Diffusive Panels with Variable Acoustic Characteristics Based on Wooden Overlays Designed Using Third-Degree-of-Freedom Bezier Curves. Materials. 2024; 17(22):5421. https://doi.org/10.3390/ma17225421

Chicago/Turabian StyleChojnacki, Bartlomiej, Kamil Schynol, and Klara Chojnacka. 2024. "Application of Hybrid Absorptive–Diffusive Panels with Variable Acoustic Characteristics Based on Wooden Overlays Designed Using Third-Degree-of-Freedom Bezier Curves" Materials 17, no. 22: 5421. https://doi.org/10.3390/ma17225421

APA StyleChojnacki, B., Schynol, K., & Chojnacka, K. (2024). Application of Hybrid Absorptive–Diffusive Panels with Variable Acoustic Characteristics Based on Wooden Overlays Designed Using Third-Degree-of-Freedom Bezier Curves. Materials, 17(22), 5421. https://doi.org/10.3390/ma17225421