Study on the Damage Mechanism of an H62-Cu/7075-Al Tribo-Pair Under the Influences of Current Direction and Density

Abstract

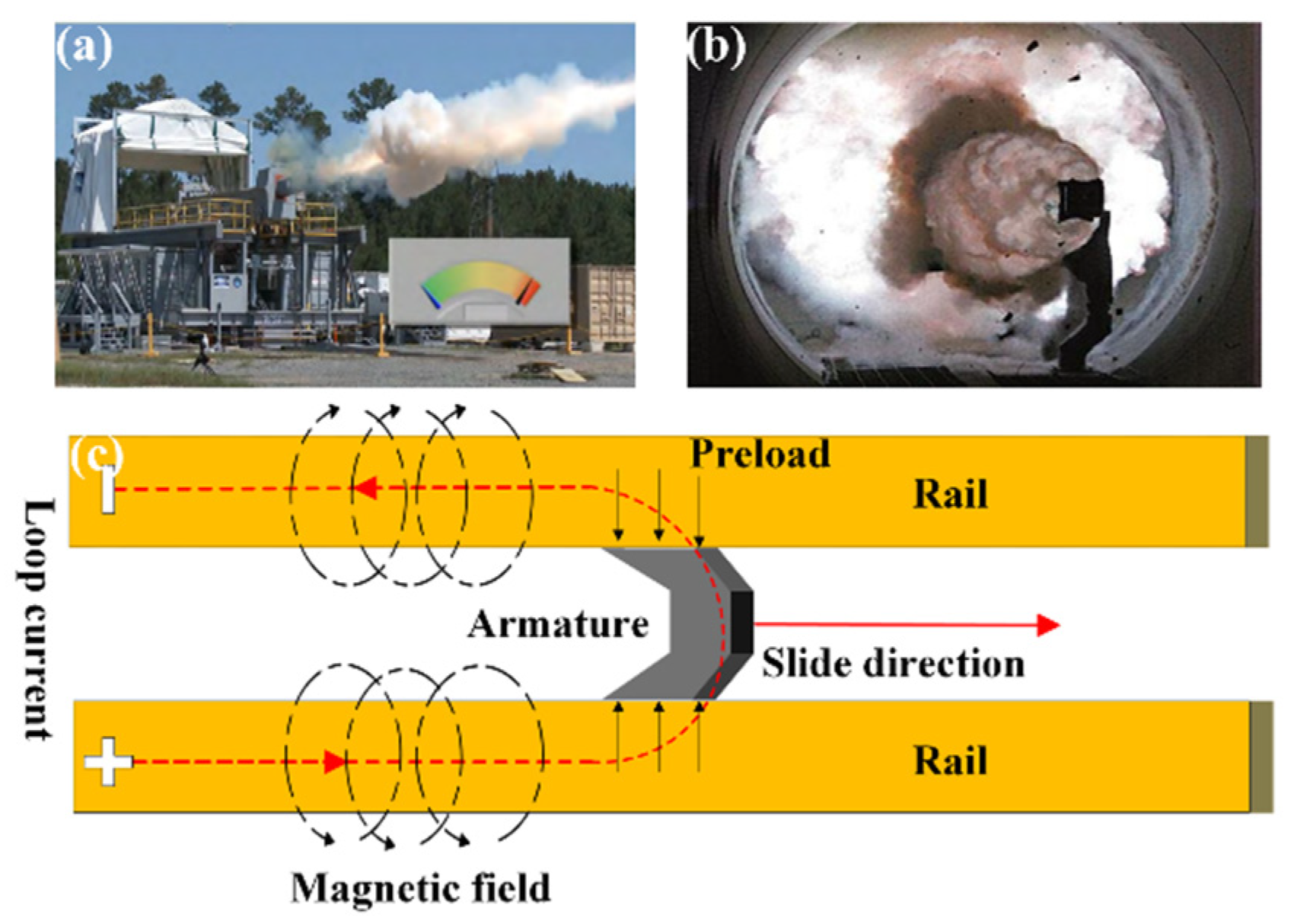

1. Introduction

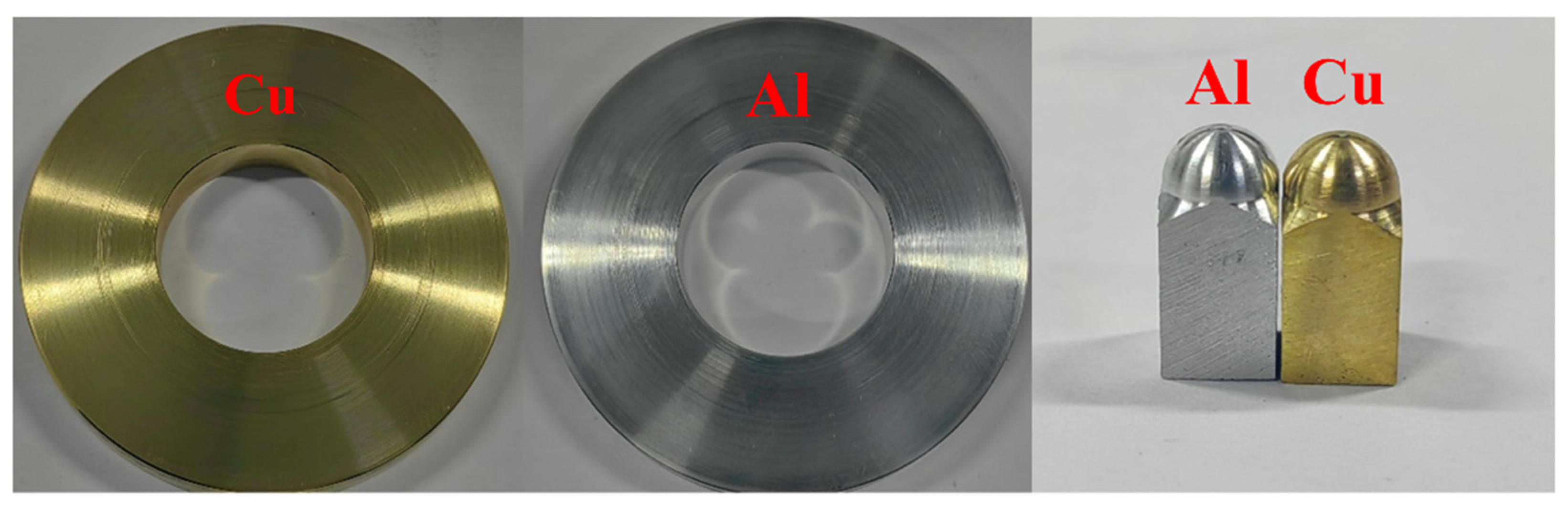

2. Materials and Methods

2.1. Test Equipment and Materials

2.2. Test Method

2.3. Microscopic Characterization

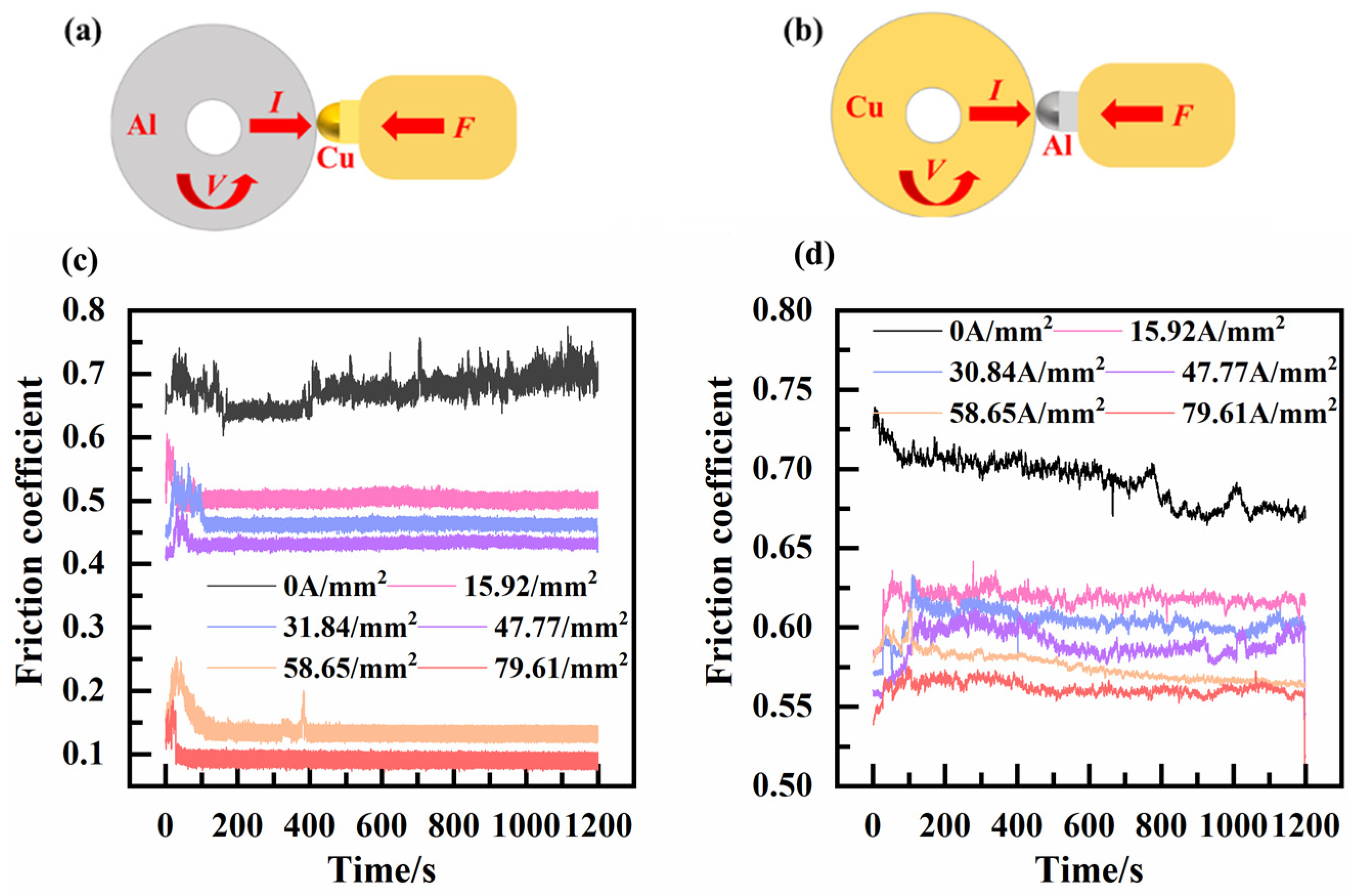

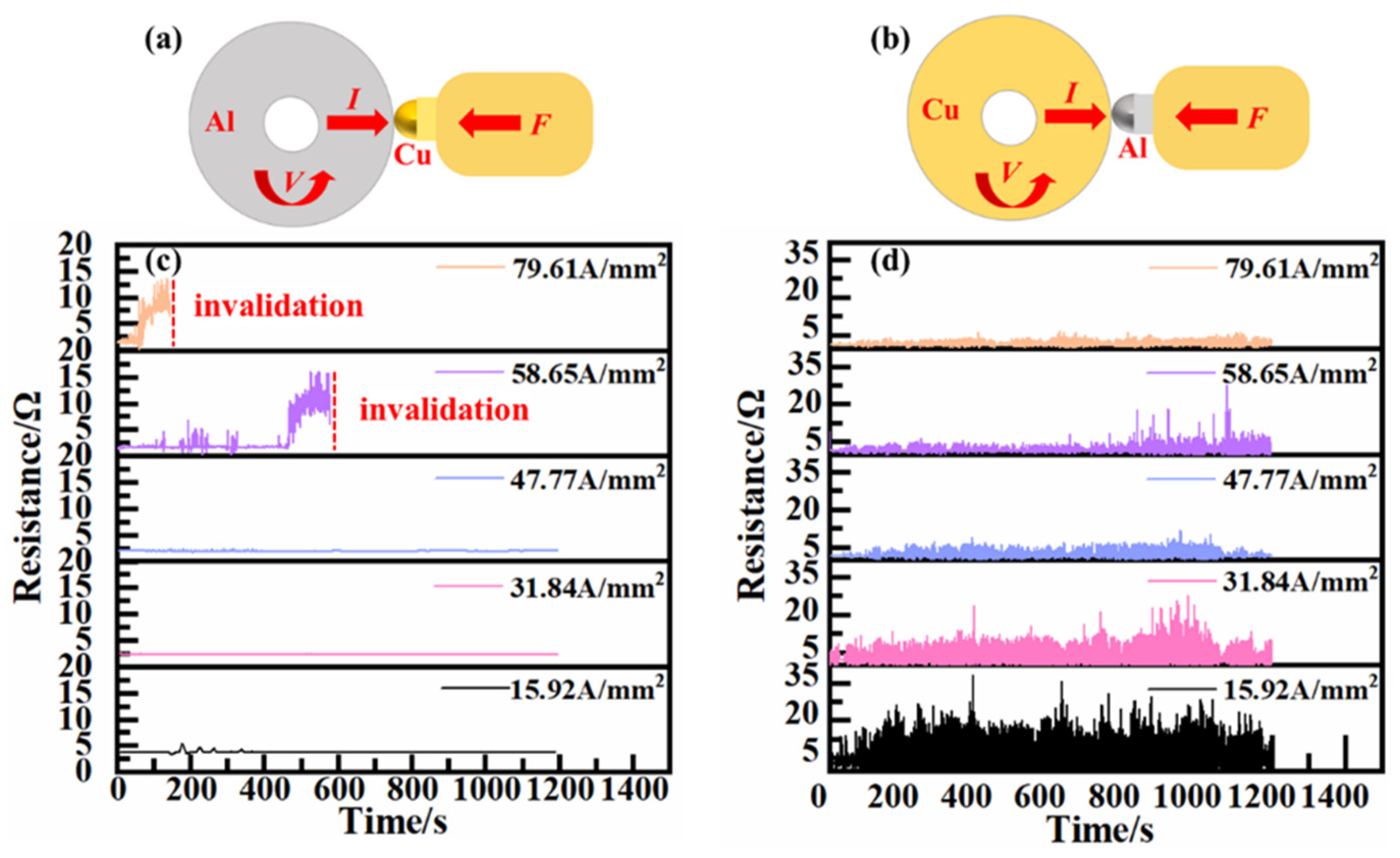

3. Results and Discussion

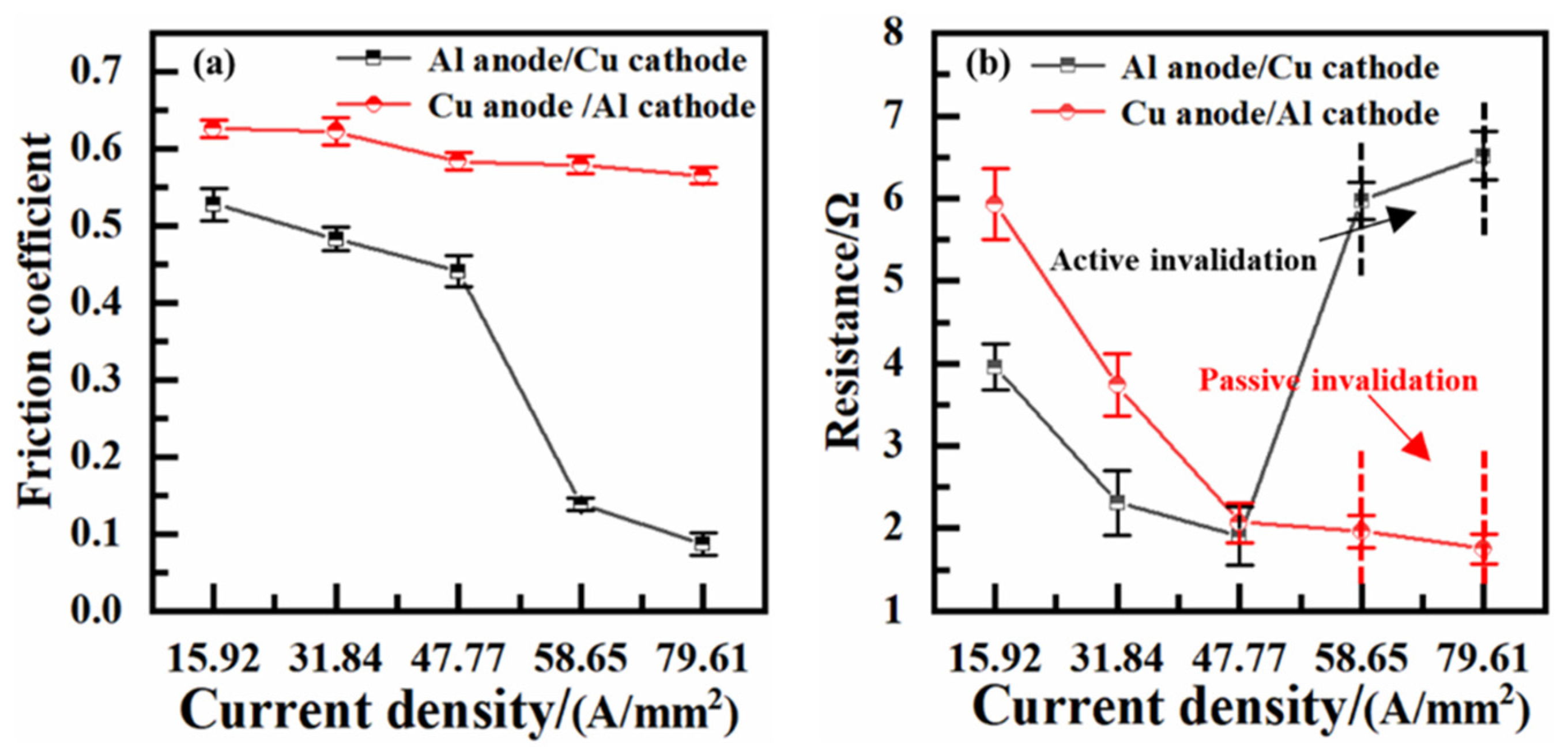

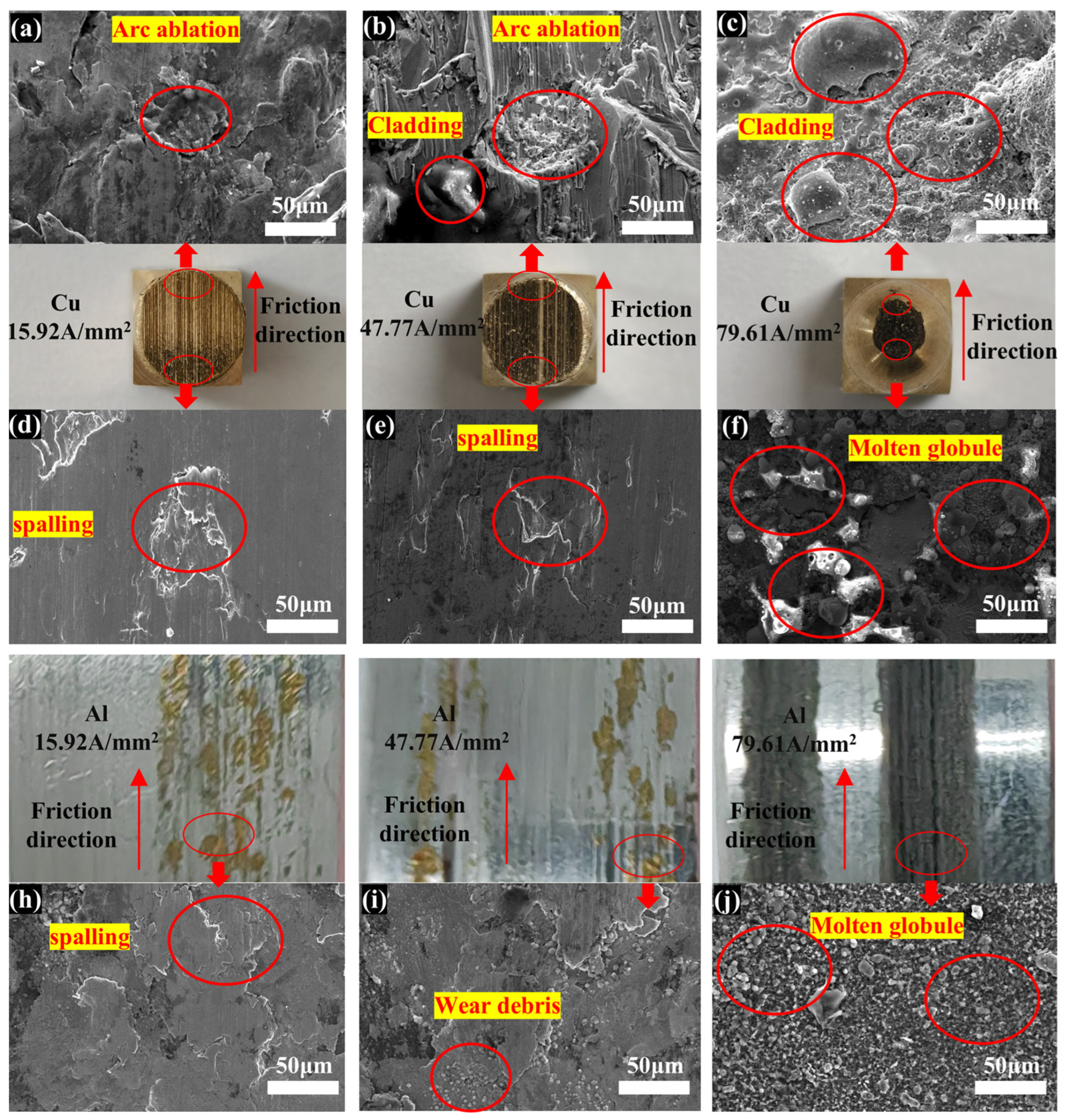

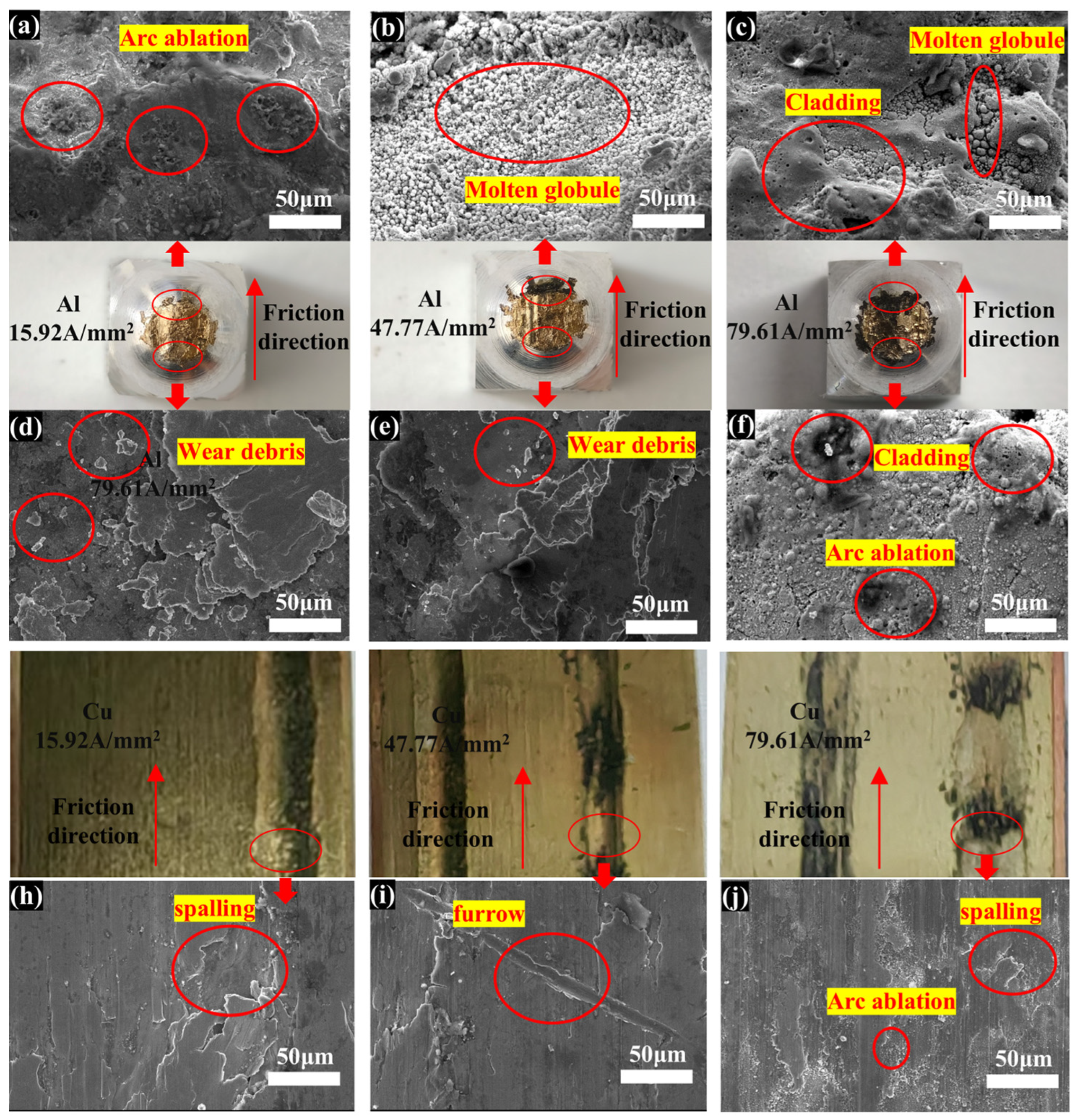

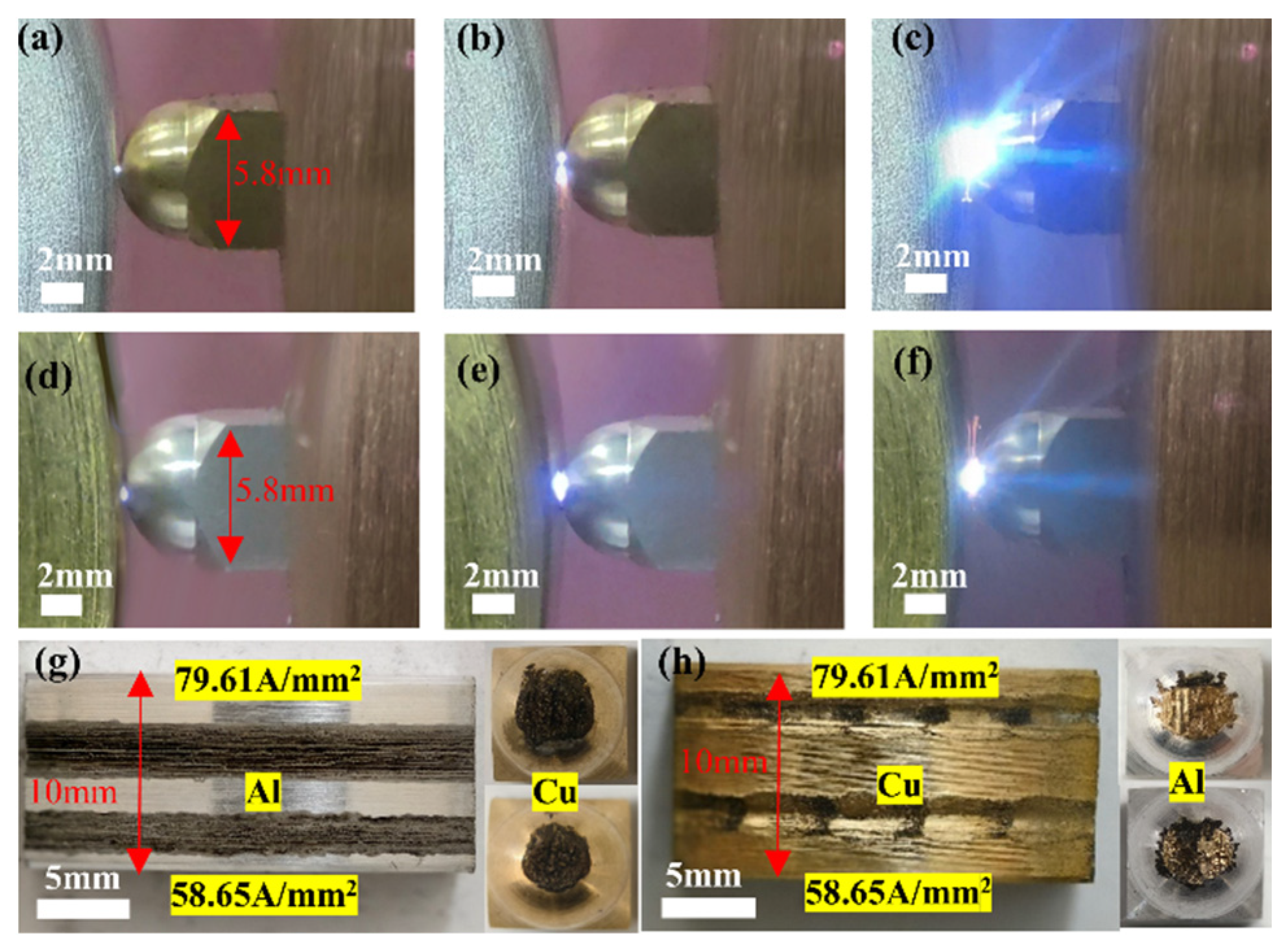

3.1. Contact Surface Damage Mechanisms

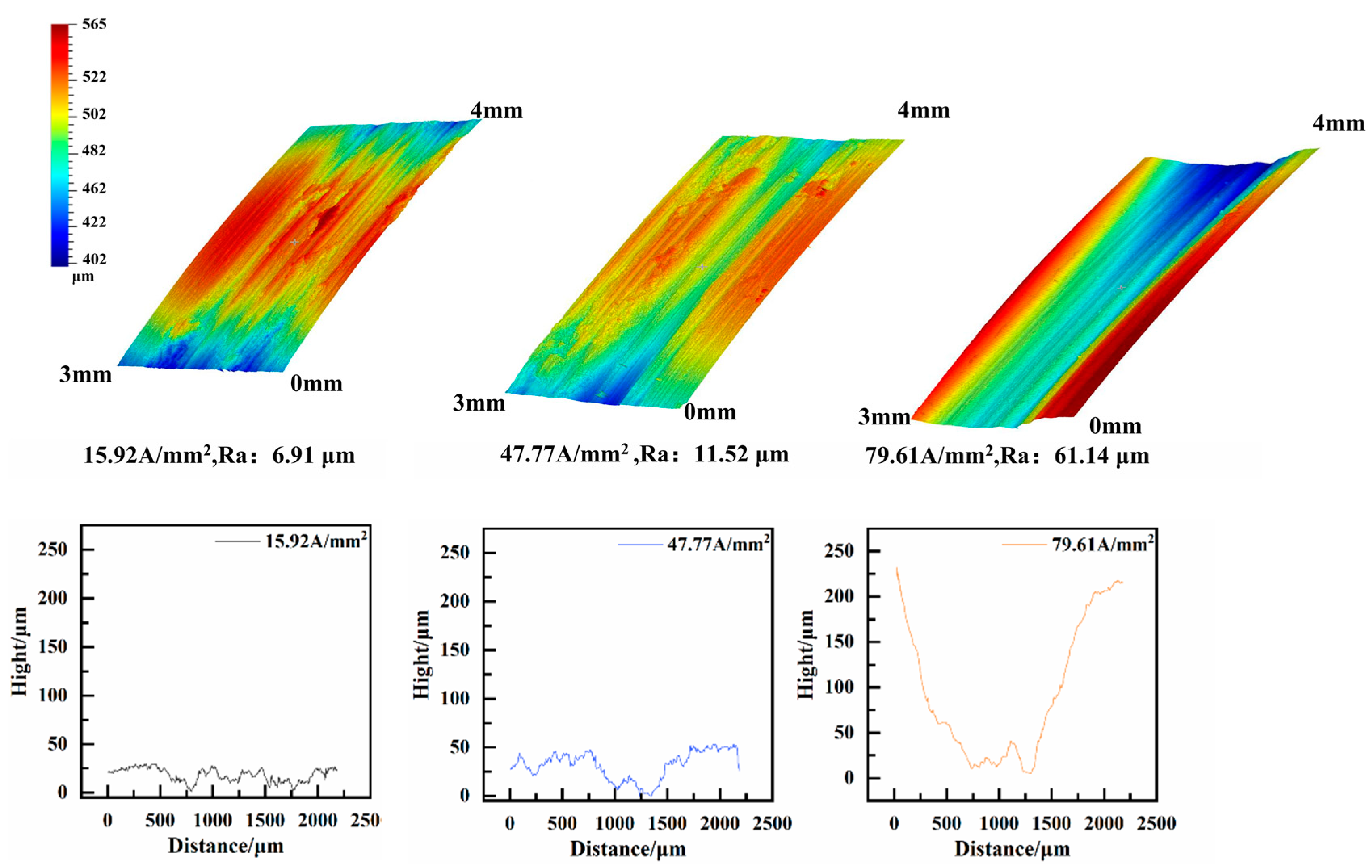

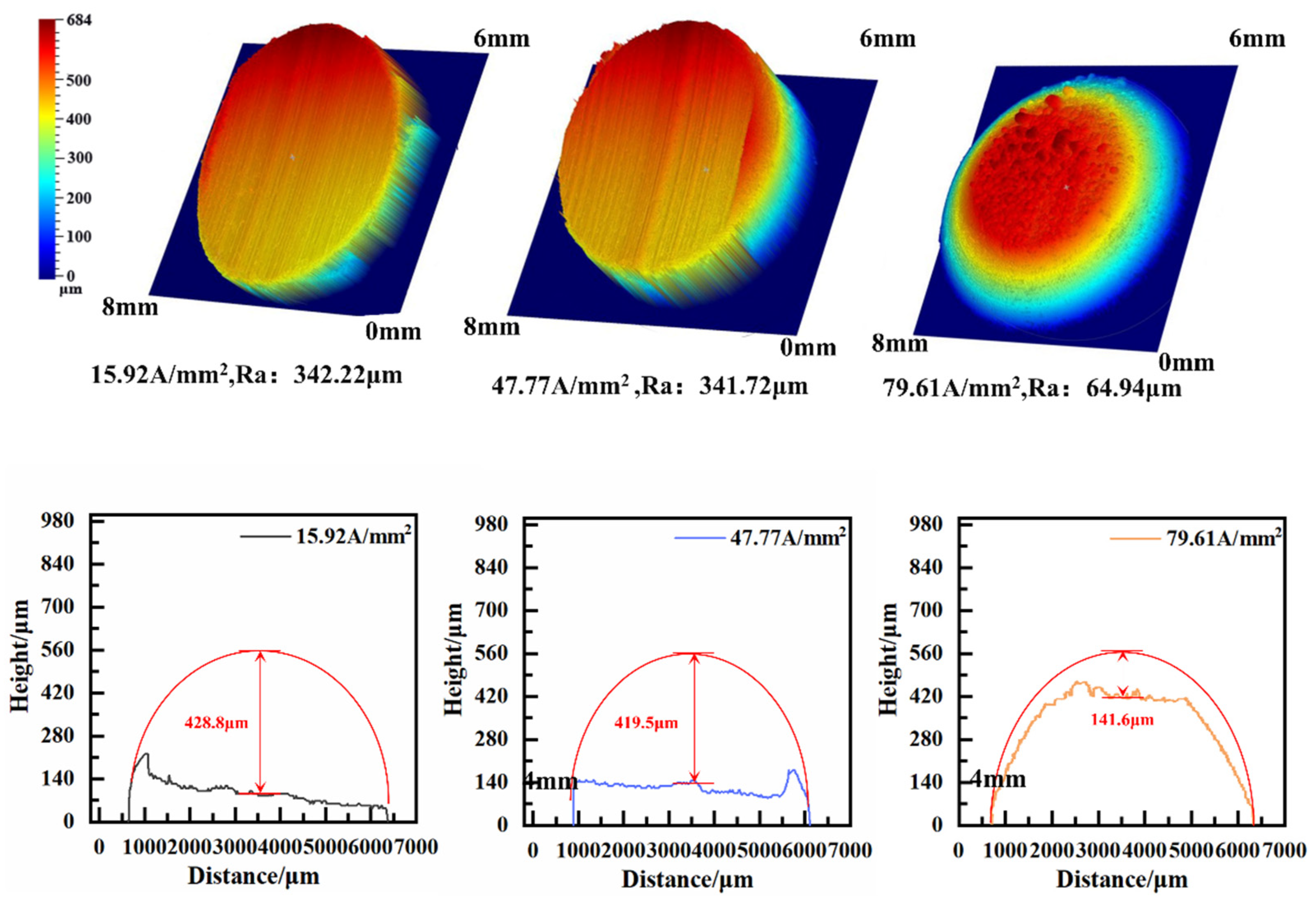

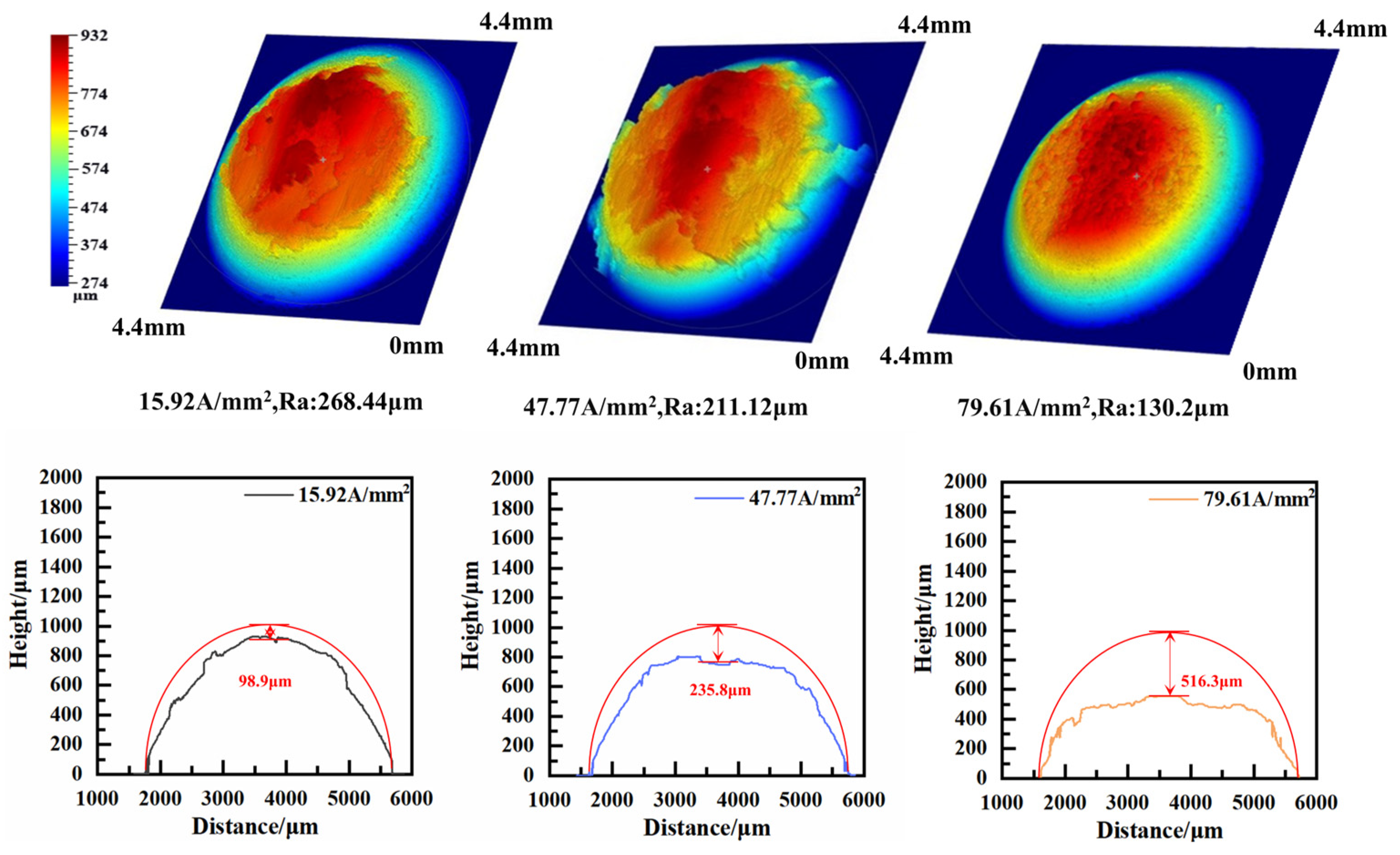

3.1.1. Surface Morphology

3.1.2. Ablation Damage

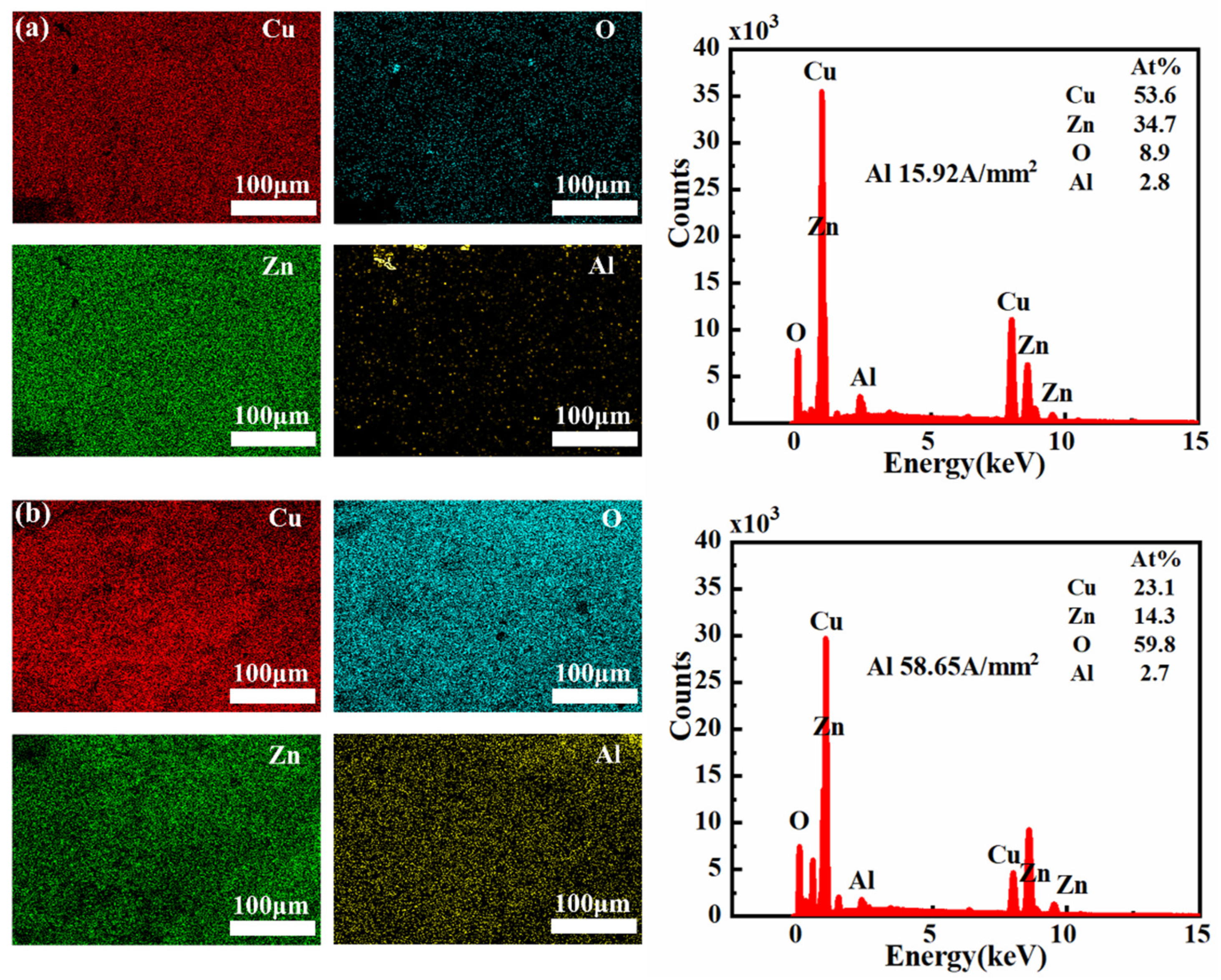

3.1.3. Surface Oxidation

4. Conclusions

- (1)

- When the current flowed from 7075-Al to H62-Cu, the effects of current density were different. Shear force resulted in serious mechanical damage at a low current density. Arc erosion was produced at a high current density. Under subjection to strong arc heat and friction heat, 7075-Al melted and vaporized. It was then oxidated and deposited on the surface of H62-Cu. The friction coefficient was therefore reduced, promoting the lubrication of the oxides. At the same time, there was a deterioration in electrical conductivity, because of the poor conductivity of the oxides.

- (2)

- When the current flowed from H62-Cu to 7075-Al, the electrical transport property was much improved, compared with when the current flowed from 7075-Al to H62-Cu. Under the influence of electro-plasticity, the plastic deformation ability of H62-Cu was enhanced. It peeled off and adhered to the surface of the 7075-Al. Cu and its oxides adhered even more heavily to the 7075-Al sample.

- (3)

- In the 7075-Al (cathode)/H62-Cu (anode) pair, the material surface was severely eroded due to the large arc. A dense oxide film formed on the material contact surface, leading to the failure of electrical conduction between the materials. In the H62-Cu (anode)/7075-Al (cathode) pair, the copper material suffered severe mechanical damage. The stability of contact between materials decreased, resulting in Hertzian contact failure.

- (4)

- Non-uniform damage was detected on the worn surfaces of the tribo-pairs along the sliding direction. Forms of mechanical damage, such as spalling, wear debris, and furrows, were always observed at the initial positions of the worn surfaces. On the other hand, arc erosion was always produced at the ends of the worn surfaces.

5. Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Walls, W.A.; Weldon, W.F. Application of electromagnetic guns to future naval platforms. IEEE Trans. Magn. 1999, 35, 262–267. [Google Scholar] [CrossRef]

- Colombo, G.R.; Otooni, M.; Evangelisti, M.P.; Colon, N. Application of coatings for electromagnetic gun technology. IEEE Trans. Magn. 1993, 316, 704–708. [Google Scholar] [CrossRef]

- Wan, X.; Yang, S.; Li, Y.; Li, B. Inductance gradient in electromagnetic launcher under channel cooling condition. IEEE Trans. Plasma Sci. 2023, 51, 1312–1319. [Google Scholar] [CrossRef]

- Yan, R.; An, K.; Yang, Q.; Jiang, J. Study of Dynamic Inductance Gradient of Augmented Electromagnetic Rail Launcher Considering High-Speed Motion of Armature. Appl. Sci. 2023, 13, 9028. [Google Scholar] [CrossRef]

- Jin, L.; Gong, D.; Yan, Y.; Zhang, C. Armature electromagnetic force extrapolation prediction method for electromagnetic railgun at high speed. Appl. Sci. 2023, 13, 3819. [Google Scholar] [CrossRef]

- Yang, Y.; Dai, K.; Yin, Q.; Liu, P.; Zhang, H. In-Bore Dynamic Measurement and Mechanism Analysis of Multi-Physics Environment for Electromagnetic Railguns. IEEE Access 2021, 9, 16999–17010. [Google Scholar] [CrossRef]

- Ma, W.; Lu, J.; Liu, Y. Research Progress of Electromagnetic Launch Technology. IEEE Trans. Plasma Sci. 2019, 47, 2197–2205. [Google Scholar] [CrossRef]

- Li, J.; Yan, P.; Yuan, W. Electromagnetic gun technology and its development. High Volt. Eng. 2014, 40, 1052–1064. [Google Scholar]

- Zhang, H.; Dai, K.; Yin, Q. Ammunition Reliability Against the Harsh Environments during the Launch of an Electromagnetic Gun: A Review. IEEE Access 2019, 7, 45322–45339. [Google Scholar] [CrossRef]

- Ge, X.; Cao, B.; Wang, Z.; Pei, P.; Huang, K.; Chen, Y.; Fan, W.; Zhang, T. Research on the Contact Characteristics Between Armature and Rail of the Enhanced Electromagnetic Rail Gun Based on the New Aluminum Alloy Armature. IEEE Trans. Plasma Sci. 2023, 51, 3703–3708. [Google Scholar] [CrossRef]

- Ma, S.; Lu, S.; Ma, H.; Wang, H.; Nong, A.; Ma, D.; Yan, C.; Liu, C. Investigation on the Spatial-Temporal Distribution of Electromagnetic Gun Rail Temperature in Single and Continuous Launch Modes. IEEE Trans. Plasma Sci. 2022, 50, 2270–2278. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, L.; Xia, S.; Li, C. Experiments and analysis of downslope low-voltage transition in C-type solid armature rail gun. IEEE Trans. Plasma Sci. 2020, 48, 2601–2607. [Google Scholar] [CrossRef]

- Chen, J.-C.; Vook, R. Characterization of sliding Al-Cu electrical contacts. IEEE Trans. Compon. Hybrids Manuf. Technol. 1986, 9, 17–22. [Google Scholar] [CrossRef]

- Bansal, D.G.; Streator, J.L. Behavior of copper-aluminum tribological pair under high current densities. In Proceedings of the IEEE 2008 14th Symposium on Electromagnetic Launch Technology, Victoria, BC, Canada, 10–13 June 2008; pp. 1–6. [Google Scholar]

- Yue, Y.; Sun, Y.; Song, C.; Pang, X.; Zhang, Y. Effect of Load and Voltage on the Tribo-electric Behaviour of Rolling Cu Pairs. Mocaxue Xuebao Tribol. 2018, 38, 67–74. [Google Scholar]

- Jiawei, L.; Yanyan, Z.; Chenfei, S.; Yixiang, S.; Tianhua, C.; Yongzhen, Z. Arc Behavior and Electrical Damage of Rolling Current-carrying Cu Pairs at Different Rotating Speeds. J. Mech. Eng. 2021, 57, 168–176. [Google Scholar]

- Chen, T.; Song, C.; Liu, Z.; Wang, L.; Hou, X.; Lu, H.; Zhang, Y. Current-carrying tribological properties of an elastic roll ring under different currents. Wear 2023, 514, 204590. [Google Scholar] [CrossRef]

- Wu, R.; Song, C.; Wu, H.; Lv, B.; Zhang, Y.; Zhang, Y. Effect of relative humidity on the current-carrying tribological properties of Cu–C sliding contact pairs. Wear 2022, 492, 204219. [Google Scholar] [CrossRef]

- Li, S.; Jia, C.; Guo, X.; Song, K.; Wang, X.; Guo, H.; Su, J. Enhancement mechanism of carbon fiber on the current-carrying tribological properties of Cf-Al2O3/Cu composites. Wear 2023, 530, 205033. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Breese, P.P.; Lutz, B.S.; Pantano, M.; Nalam, Y.; Bela, K.; Kamps, T.; Volpp, J.; Kaplan, A.F. Porosity in wire arc additive manufacturing of aluminium alloys. Addit. Manuf. 2021, 41, 101993. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Breese, P.P.; Nalam, Y.; Joshi, K.S.; Bela, K.; Kamps, T.; Volpp, J.; Kaplan, A.F. Oxidation in wire arc additive manufacturing of aluminium alloys. Addit. Manuf. 2021, 41, 101958. [Google Scholar] [CrossRef]

- Ramadan, M.A. Friction and wear of sand-contaminated lubricated sliding. Friction 2018, 6, 457–463. [Google Scholar] [CrossRef]

- Sahin, M.; Akata, H.E.; Ozel, K. An experimental study on joining of severe plastic deformed aluminium materials with friction welding method. Mater. Des. 2008, 29, 265–274. [Google Scholar] [CrossRef]

- Liu, X.-L.; Zhou, C.-W.; Zhou, X.-J.; Hu, M.-J.; Wang, D.-Y.; Xiao, Q.; Guan, X.; Zhang, W.-L.; Zhang, S.; Xu, Z.-B. Influence of different arc erosion durations on the wear properties of carbon skateboards/contact wires under low temperature. Wear 2023, 516, 204600. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, H.; Cui, X.; Wang, Y.; Han, Z.; Meli, E.; Wang, W. Experimental investigation on the effect of contact forces on uneven longitudinal wear of rail material. Wear 2023, 532, 205108. [Google Scholar] [CrossRef]

- Stefani, F.; Parker, J.V. Experiments to measure wear in aluminum armatures [in railguns]. IEEE Trans. Magn. 2002, 35, 100–106. [Google Scholar] [CrossRef]

- Dutta, I.; Delaney, L.; Cleveland, B.; Persad, C.; Tang, F. Electric-Current-Induced Liquid Al Deposition, Reaction, and Flow on Cu Rails at Rail–Armature Contacts in Railguns. IEEE Trans. Magn. 2009, 45, 272–277. [Google Scholar] [CrossRef]

- Harding, J.; Kaplan, R.; Pierson, H.; Tuffias, R.; Upshaw, J. Chemically vapor deposited materials for railguns. IEEE Trans. Magn. 1986, 22, 1506–1509. [Google Scholar] [CrossRef]

- Hsieh, P.Y.; Persad, C.; Ghosh, G.; Chung, Y.W.; Wang, Q. Mechanism of Porosity Formation in Transfer Films in Electromagnetic Launchers. IEEE Trans. Magn. 2009, 45, 319–321. [Google Scholar] [CrossRef]

- Persad, C.; Castro, Z. Railgun Tribology: Characterization and Control of Multishot Wear Debris. IEEE Trans. Magn. 2006, 43, 173–177. [Google Scholar] [CrossRef]

- Xue, P.; Chen, C.; Fan, X.; Diao, D. Current-carrying friction in carbon coated ball bearing. Friction 2023, 11, 2008–2020. [Google Scholar] [CrossRef]

- Yang, Z.; Ge, Y.; Zhang, X.; Shangguan, B.; Zhang, Y.; Zhang, J. Effect of Carbon Content on Friction and Wear Properties of Copper Matrix Composites at High Speed Current-Carrying. Materials 2019, 12, 2881. [Google Scholar] [CrossRef]

- Gennari, C.; Pezzato, L.; Simonetto, E.; Gobbo, R.; Forzan, M.; Calliari, I. Investigation of Electroplastic Effect on Four Grades of Duplex Stainless Steels. Materials 2019, 12, 1911. [Google Scholar] [CrossRef] [PubMed]

- Adabala, S.; Cherukupally, S.; Guha, S.; Raju, D.; Verma, R.K.; Reddy, V. Importance of machine compliance to quantify electro-plastic effect in electric pulse aided testing: An experimental and numerical study. J. Manuf. Process. 2022, 75, 268–279. [Google Scholar] [CrossRef]

- Dimitrov, N.K.; Liu, Y.; Horstemeyer, M.F. Experimental Observation and Modelling of the Electroplastic Effect in Nonferromagnetic Ductile Metals. Exp. Tech. 2021, 45, 735–748. [Google Scholar] [CrossRef]

- Pakhomov, M.; Stolyarov, V. Specific features of electroplastic effect in mono-and polycrystalline aluminum. Met. Sci. Heat Treat. 2021, 63, 236–242. [Google Scholar] [CrossRef]

- Tian, H.; Ahn, W.; Maize, K.; Si, M.; Ye, P.; Alam, M.A.; Shakouri, A.; Bermel, P. Thermoreflectance imaging of electromigration evolution in asymmetric aluminum constrictions. J. Appl. Phys. 2018, 123, 035107. [Google Scholar] [CrossRef]

- Shao, J.; Deng, S.; Zhao, H.; Lou, L.; Shi, B.; Chen, L.; Xu, L.J.I. Electromigration enhanced growth kinetics of intermetallics at the Cu/Al interface. Intermetallics 2024, 164, 108110. [Google Scholar] [CrossRef]

- Tai, K.L.; Sun, P.H.; Ohring, M. Lateral self-diffusion and electromigration in thin metal films. Thin Solid Films 1975, 25, 343–352. [Google Scholar]

- Cheng, J.; Zhou, Z.; Liu, Z.; Zhang, Y.; Tan, J. Thermo-mechanical coupling analysis of a high-speed actuating mechanism based on a new thermal contact resistance model. Appl. Therm. Eng. 2018, 140, 487–497. [Google Scholar] [CrossRef]

- Shi, X.; Yan, W.; Yang, Z.; Ren, Y.; Yang, K. Effect of Cu Alloying on Strain Capacity of Cu-bearing Pipeline Steels. ISIJ Int. 2020, 60, 792–798. [Google Scholar] [CrossRef]

- Jiang, S.S.; Gan, K.F.; Huang, Y.J.; Xue, P.; Ning, Z.L.; Sun, J.F.; Ngan, A.H.W. Stochastic deformation and shear transformation zones of the glassy matrix in CuZr-based metallic-glass composites. Int. J. Plast. 2020, 125, 52–62. [Google Scholar] [CrossRef]

- Lehmann, J.S.; Schwaiger, R.; Rinke, M.; Greiner, C. How Tribo-Oxidation Alters the Tribological Properties of Copper and Its Oxides. Adv. Mater. Interfaces 2021, 8, 2001673. [Google Scholar] [CrossRef]

- Youting, H.; Xiaolong, Z.; Nengbin, H.; Wumei, Q.; Wenzhe, C. High temperature friction and wear behavior of tungsten—Copper alloys. Int. J. Refract. Met. Hard Mater. 2018, 77, 105–112. [Google Scholar]

- Bayer, R.G.; Schumacher, R.A.J.W. On the significance of surface fatigue in sliding wear. Wear 1968, 12, 173–183. [Google Scholar] [CrossRef]

- Zutter, B.; Mecklenburg, M.; Aloni, S.; Regan, B.C. Electromigration of Copper in Lithographically-Defined Aluminum Nanowires. Microsc. Microanal. 2018, 24, 2190–2191. [Google Scholar] [CrossRef]

- Ma, T.; Li, H.; Gao, J.; Li, Y. Diffusion Behavior of Cu in Carbon Steel and Its Influence on Corrosion Resistance of Carbon Steel. Cailiao Yanjiu Xuebao Chin. J. Mater. Res. 2019, 33, 225–231. [Google Scholar]

- Ma, T.; Li, H.; Gao, J.; Li, Y. Corrosion Behaviour of Cu/Carbon Steel Gradient Material. Crystals 2021, 11, 1091. [Google Scholar] [CrossRef]

- Hummza, R.A.; Al-Zubidy, E.A.S. Corrosion Behavior of Copper and Carbon Steel in Acidic Media. Baghdad Sci. J. 2014, 11, 1577–1582. [Google Scholar]

- Wild, B.; Schuppler, C.; Alouahabi, F.; Schneider, M.; Hoffman, R. The Influence of the Rail Material on the Multishot Performance of the Rapid Fire Railgun. IEEE Trans. Plasma Sci. 2015, 43, 2095–2099. [Google Scholar] [CrossRef]

- Poltanov, A.; Jygailo, N. Study of new materials for railgun launchers. IEEE Trans. Magn. 1997, 33, 406–409. [Google Scholar] [CrossRef]

- Hahne, J.J.; Herbst, J.H. Fabrication and testing of a 30 mm and 90 mm laminated, high L’ railgun designed and built at CEM-UT. IEEE Trans. Magn. 1995, 31, 303–308. [Google Scholar] [CrossRef]

- Xie, H.B.; Yang, H.Y.; Yu, J.; Gao, M.Y.; Shou, J.D.; Fang, Y.T.; Liu, J.B.; Wang, H.T. Research progress on advanced rail materials for electromagnetic railgun technology. Def. Technol. 2021, 17, 429–439. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | |

| 7075Al | 0.40 | 0.50 | 1.2–2.0 | 0.30 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | 0.05 | 0.20 |

| Cu | Fe | Pb | Si | Ni | B | As | Zn | ||

| H62 | 63.5 | 0.15 | 0.08 | - | - | - | - | tolerance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.; Zhang, Y.; Song, C. Study on the Damage Mechanism of an H62-Cu/7075-Al Tribo-Pair Under the Influences of Current Direction and Density. Materials 2024, 17, 5395. https://doi.org/10.3390/ma17225395

Chen P, Zhang Y, Song C. Study on the Damage Mechanism of an H62-Cu/7075-Al Tribo-Pair Under the Influences of Current Direction and Density. Materials. 2024; 17(22):5395. https://doi.org/10.3390/ma17225395

Chicago/Turabian StyleChen, Pengfei, Yanyan Zhang, and Chenfei Song. 2024. "Study on the Damage Mechanism of an H62-Cu/7075-Al Tribo-Pair Under the Influences of Current Direction and Density" Materials 17, no. 22: 5395. https://doi.org/10.3390/ma17225395

APA StyleChen, P., Zhang, Y., & Song, C. (2024). Study on the Damage Mechanism of an H62-Cu/7075-Al Tribo-Pair Under the Influences of Current Direction and Density. Materials, 17(22), 5395. https://doi.org/10.3390/ma17225395