Influence of Strain Rate on Barkhausen Noise in Trip Steel

Abstract

1. Introduction

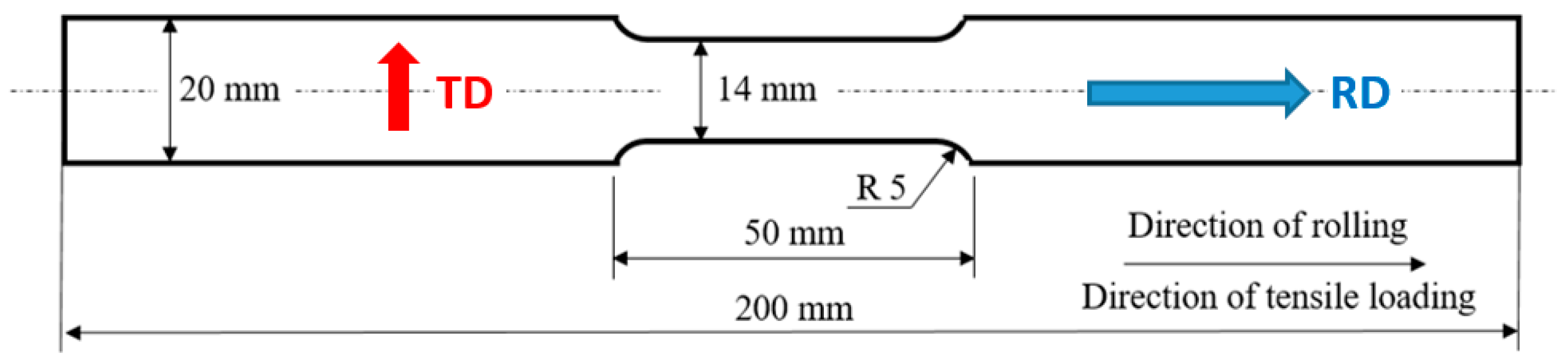

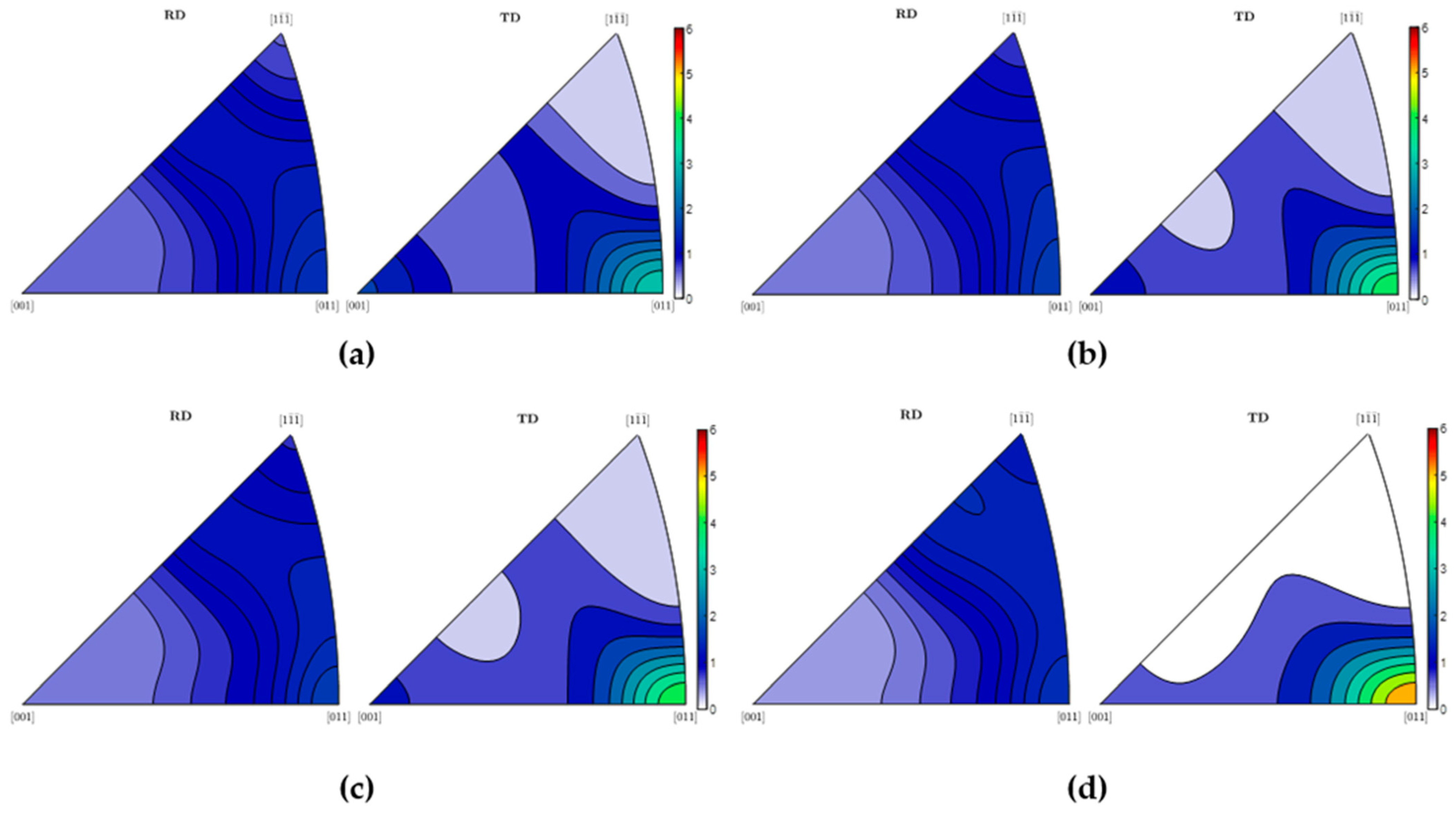

2. Materials and Methods

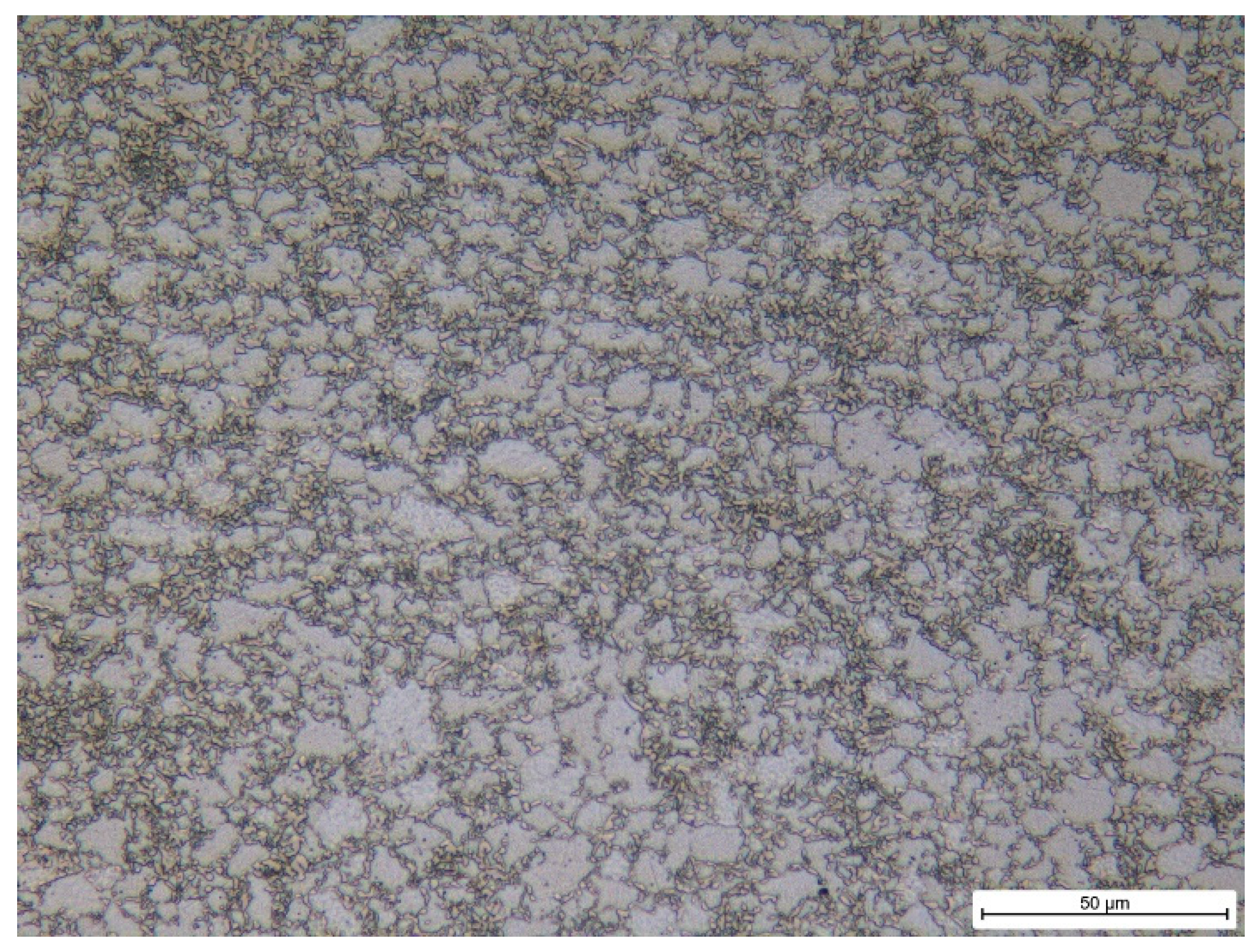

2.1. Materials

2.2. MBN Measurements

2.3. Microhardness and Temperature Measurements

2.4. XRD Measurements

2.5. Experimental Plan

- In situ measurements during the tensile test such as

- (a)

- Stress–strain evolution;

- (b)

- MBN measurements in the RD and TD;

- (c)

- Temperature measurements.

- Post situ measurements after the tensile test such as the following:

- (a)

- Non-destructive measurements such as

- -

- MBN measurements in the RD and TD;

- -

- XRD measurements in the RD and TD.

- (b)

- Destructive measurements such as

- -

- Microhardness measurements.

3. Results of Experiments and Their Discussion

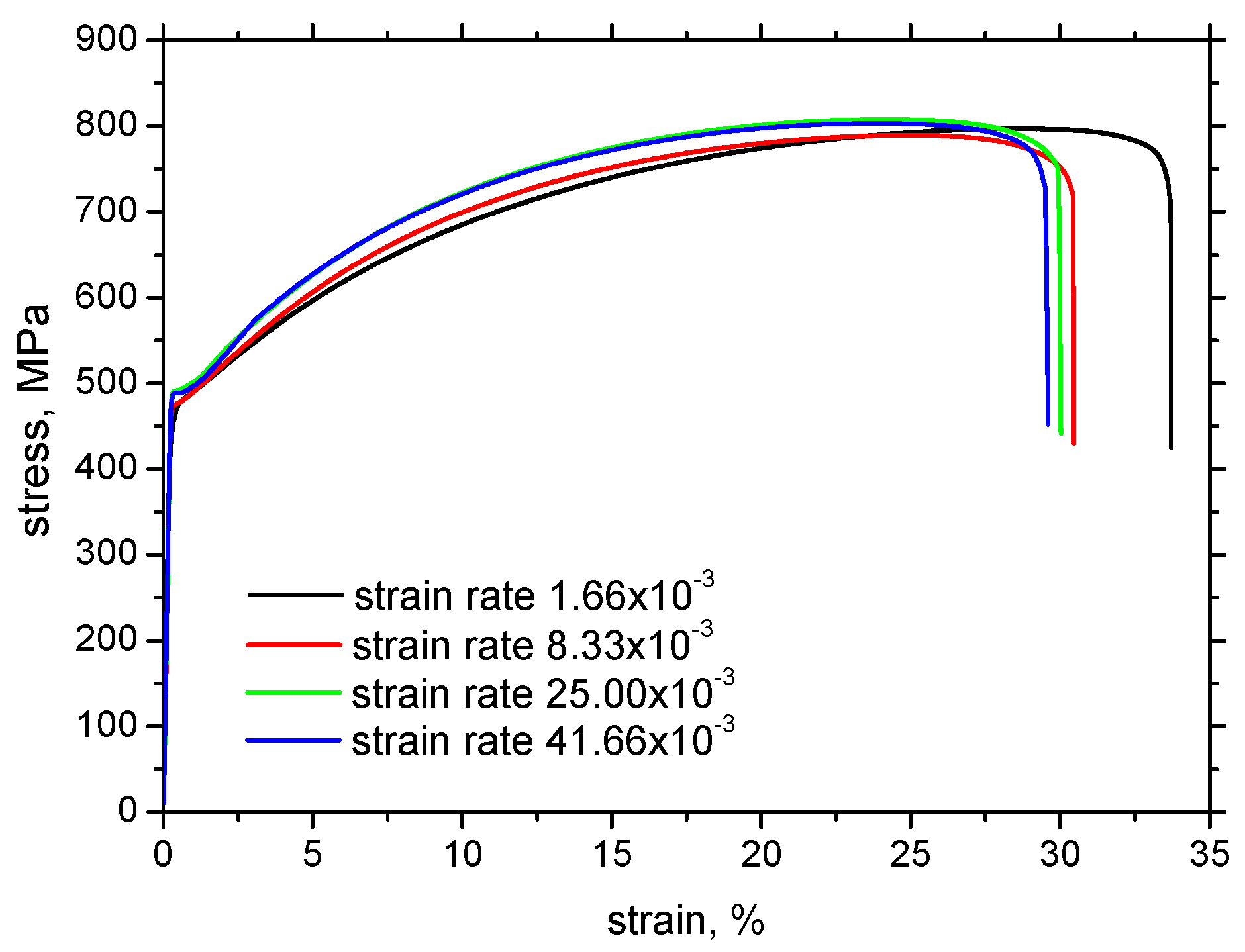

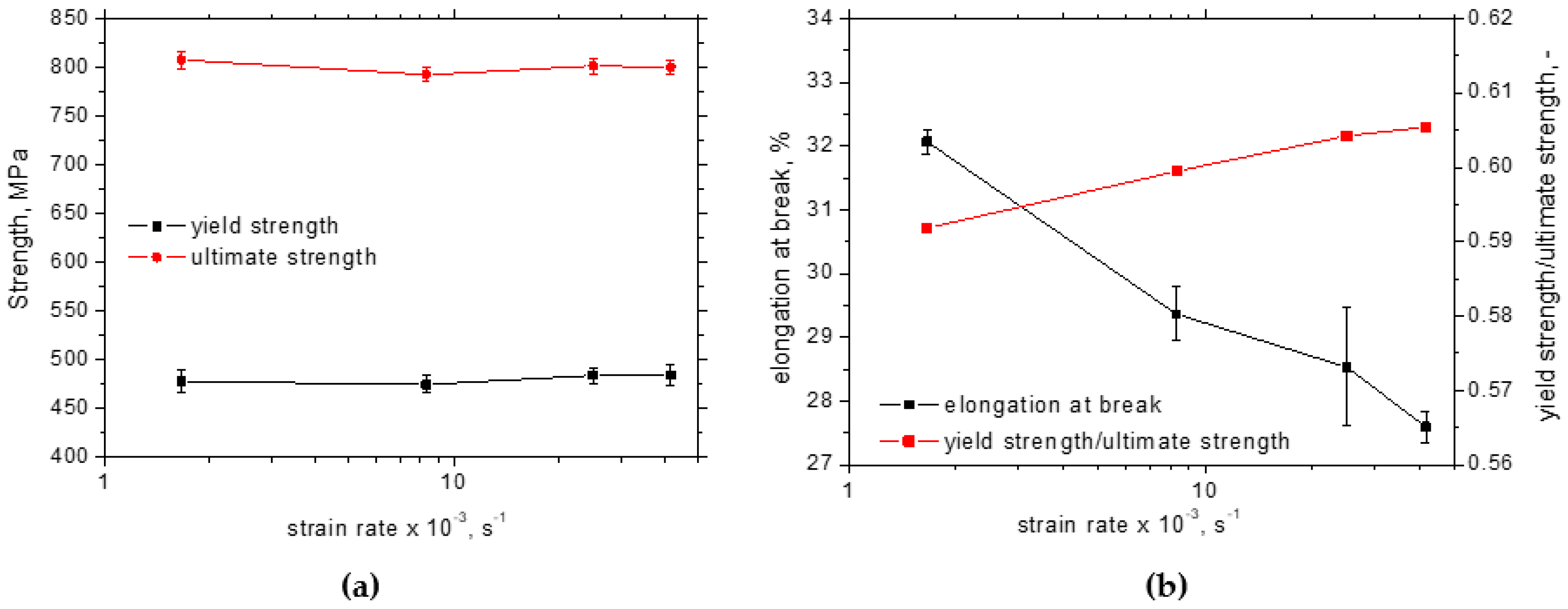

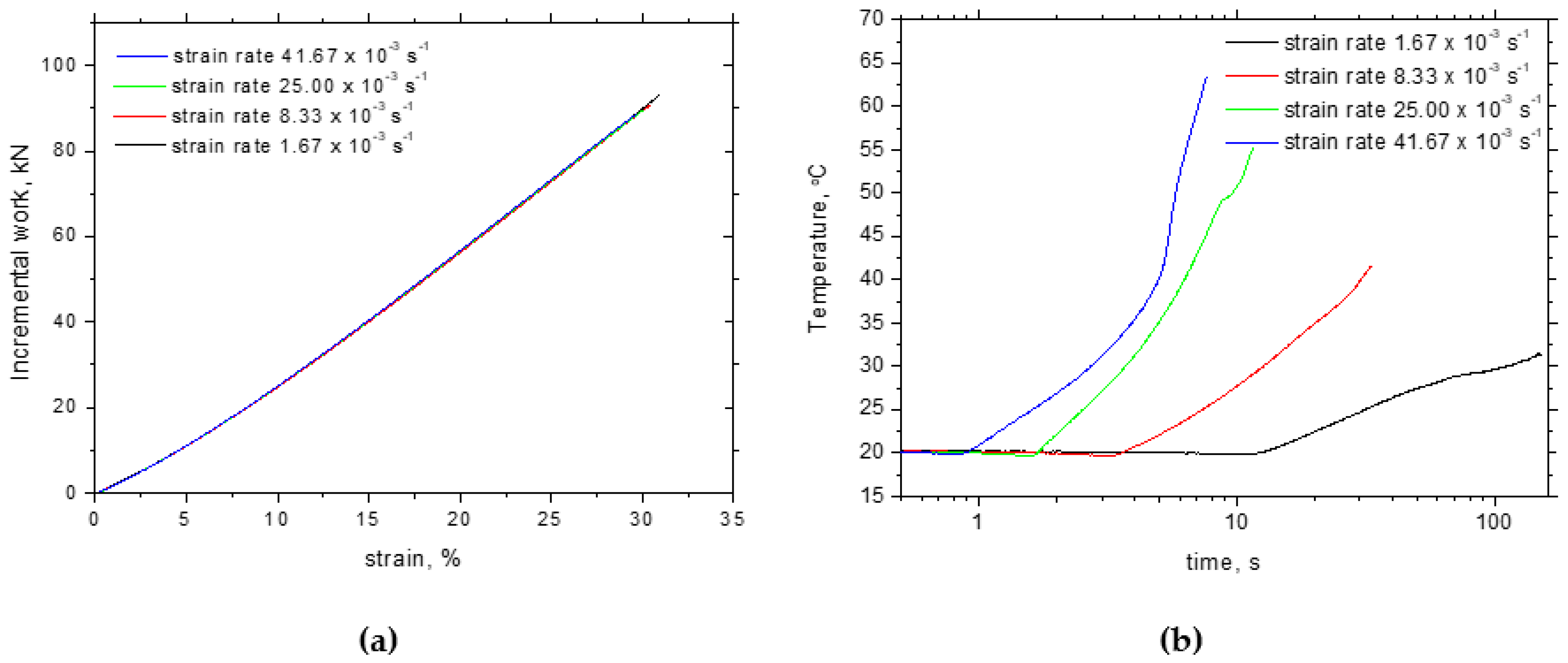

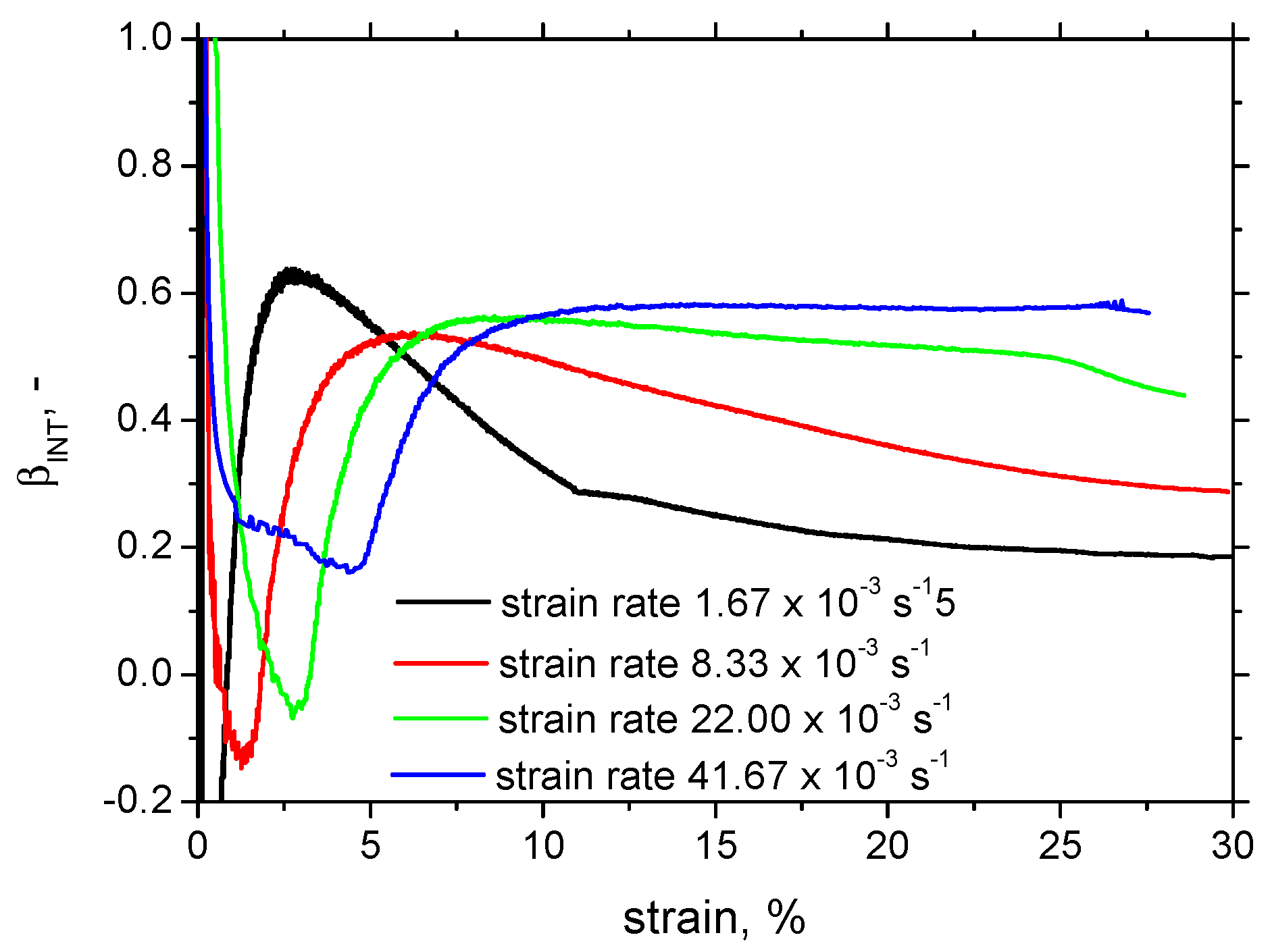

3.1. Mechanical Properties and the Taylor–Quinney Coefficient

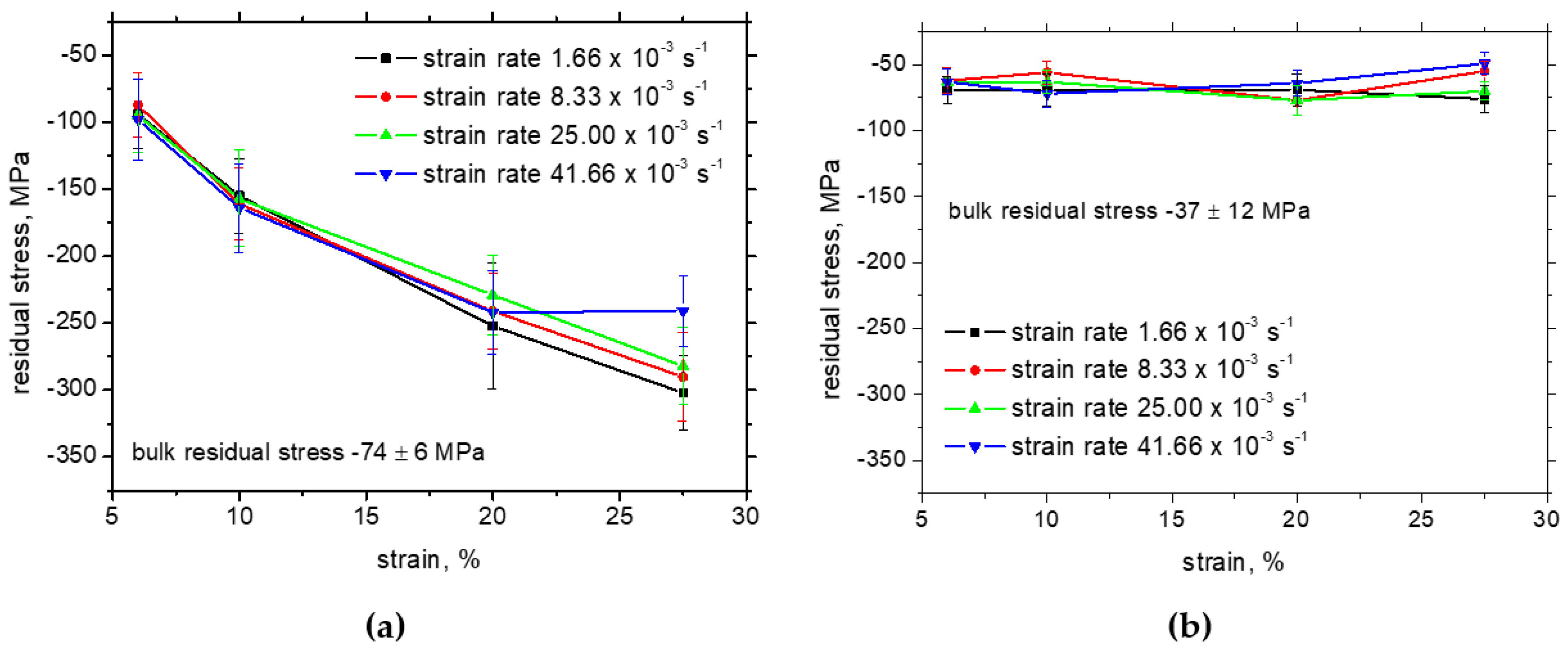

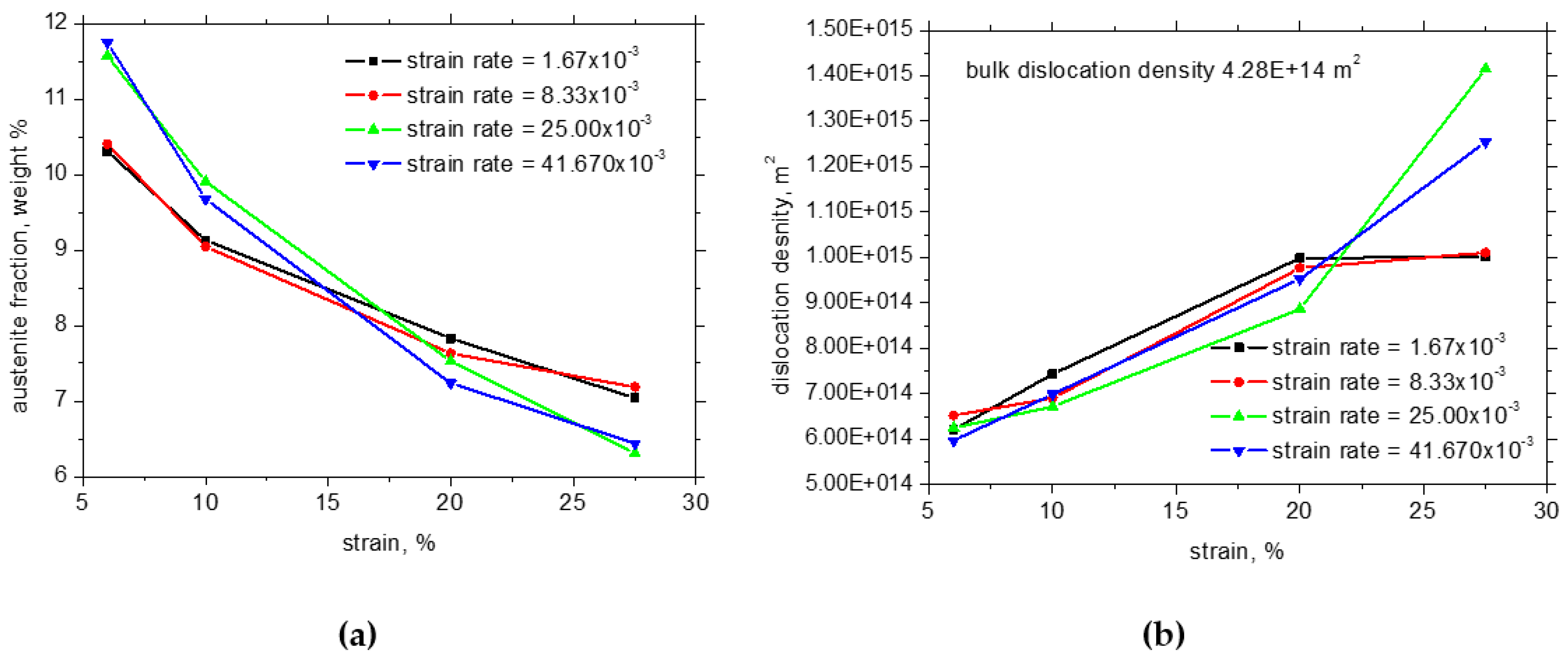

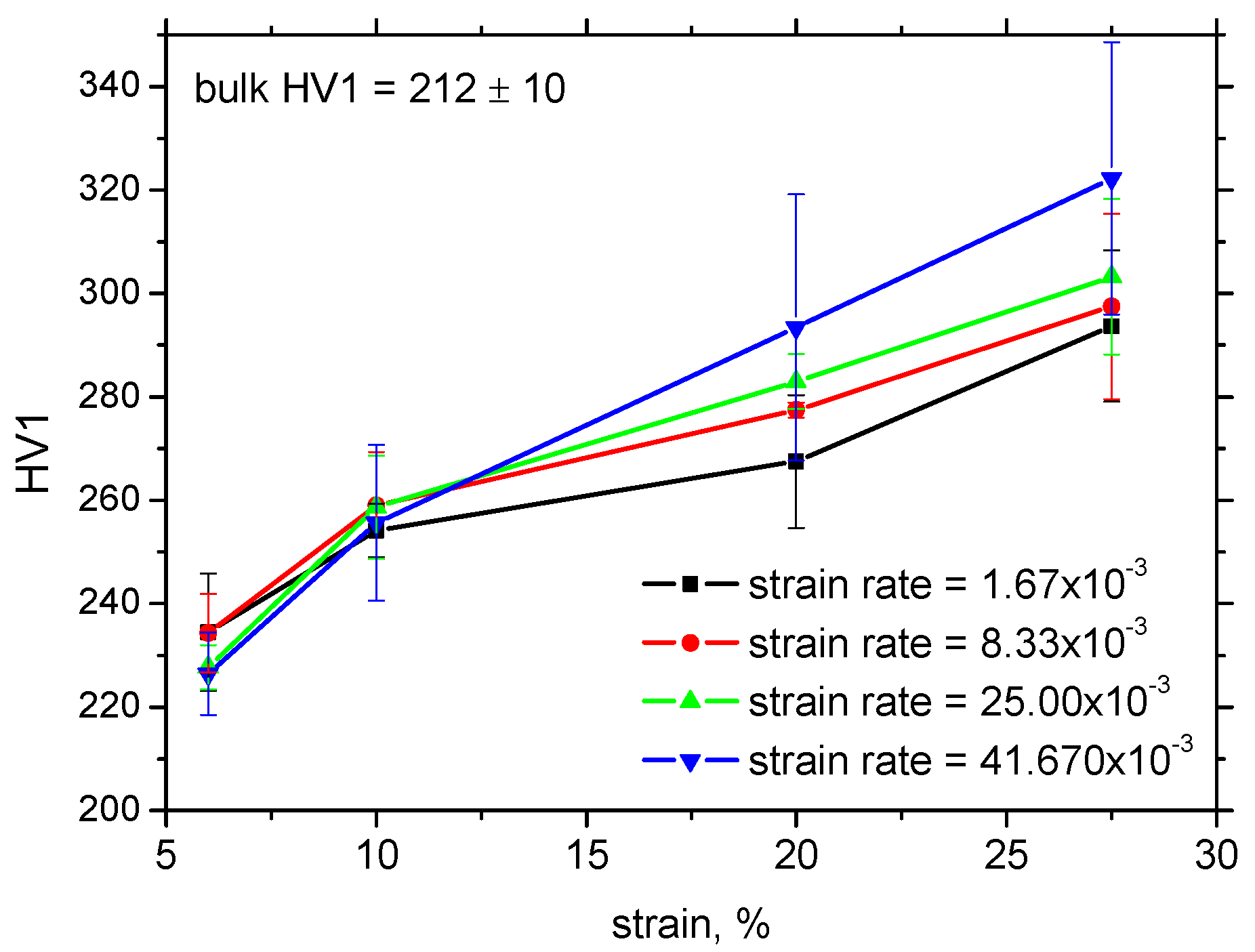

3.2. XRD and Hardness Measurements

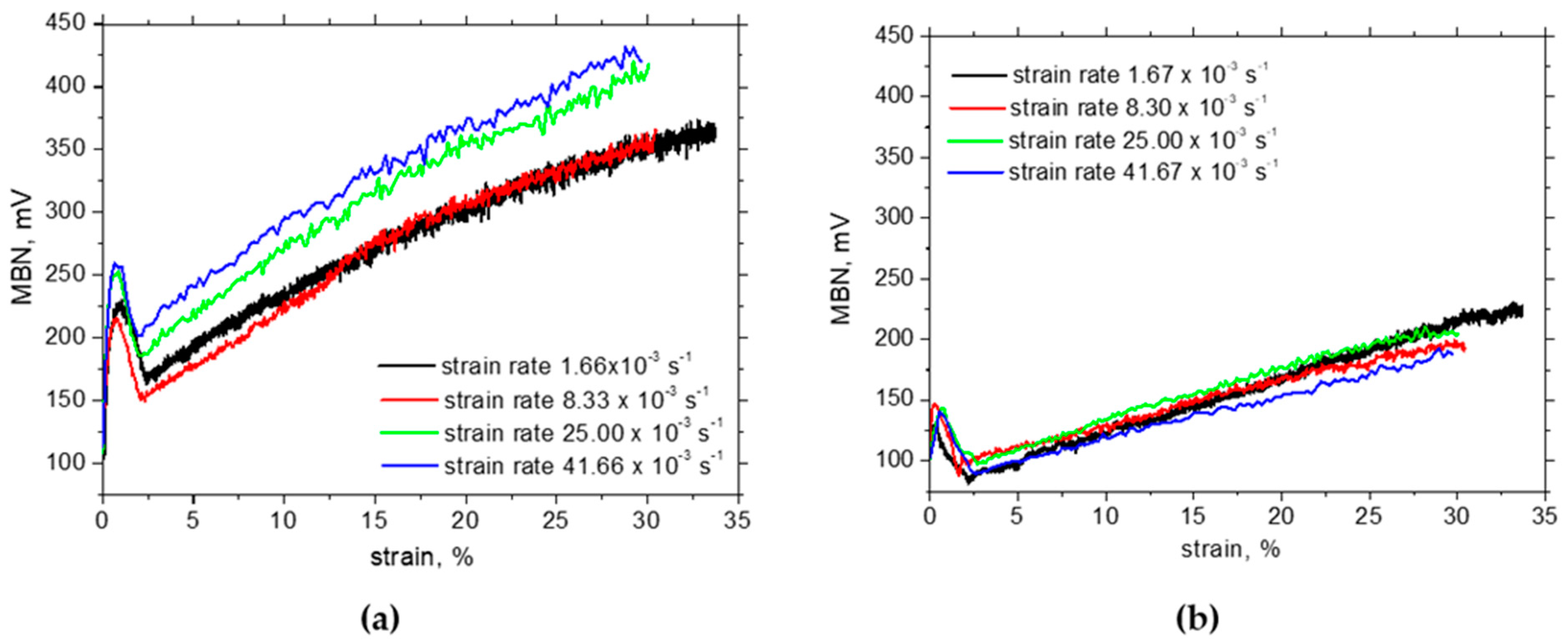

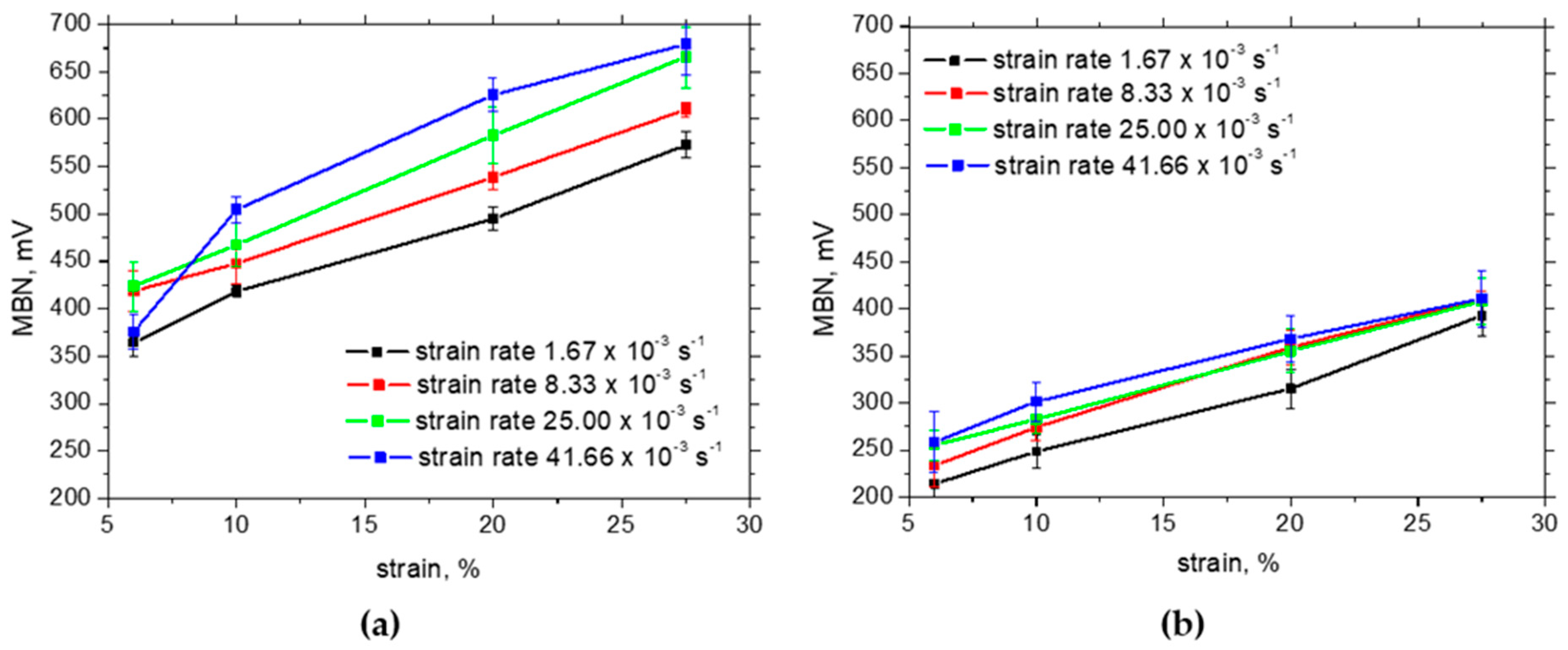

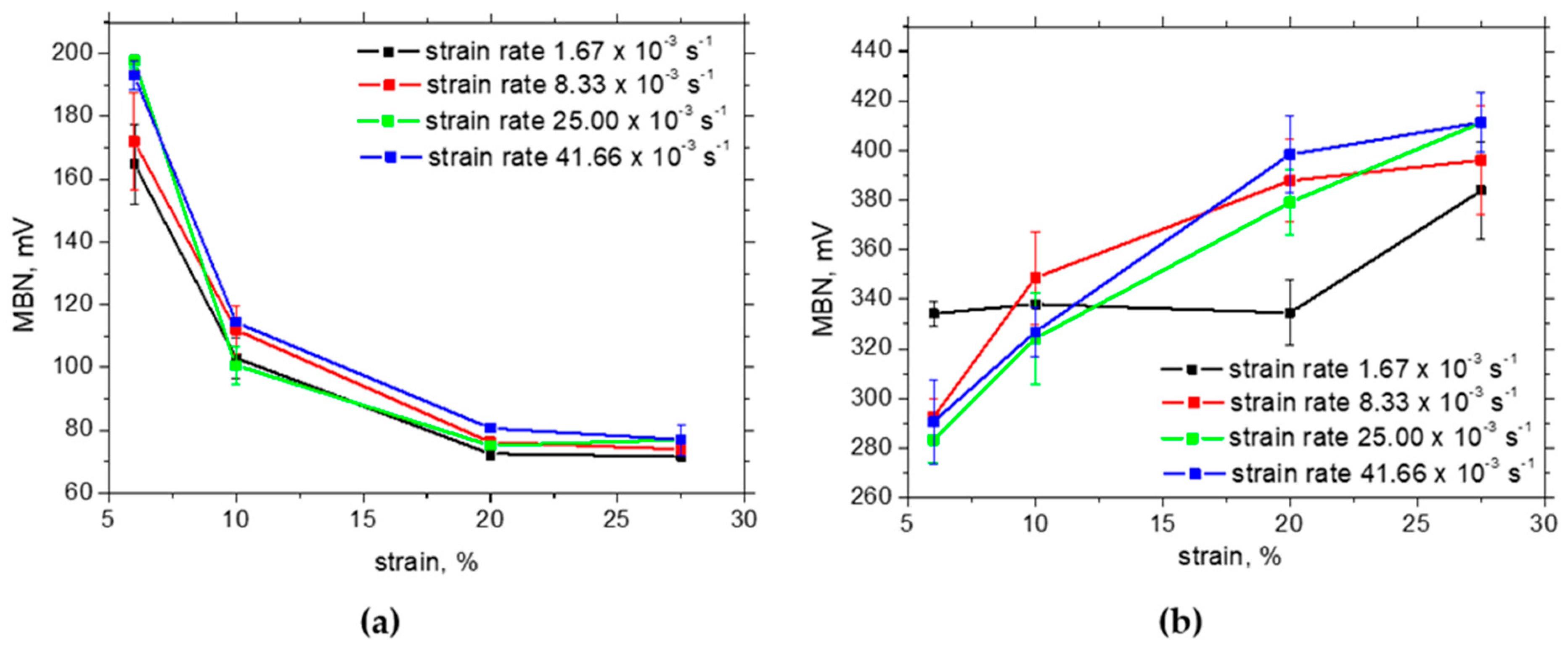

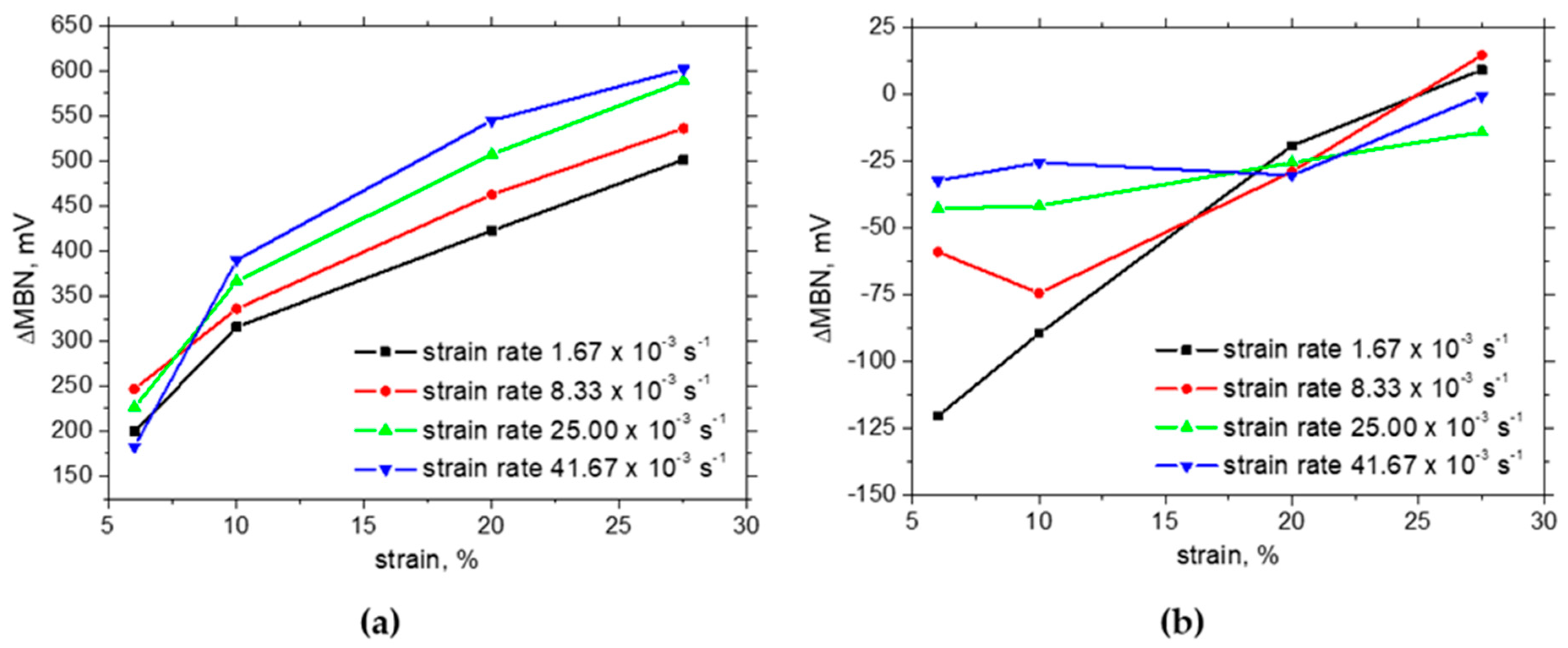

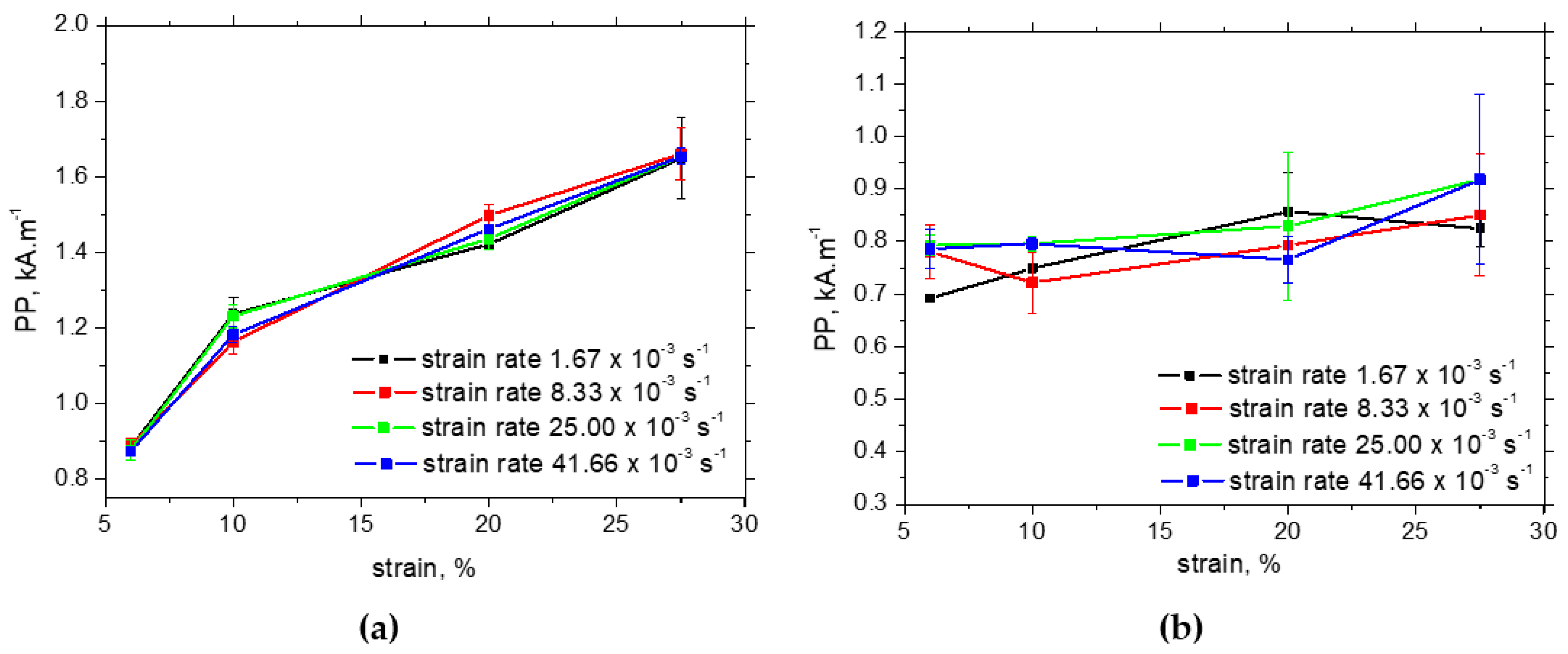

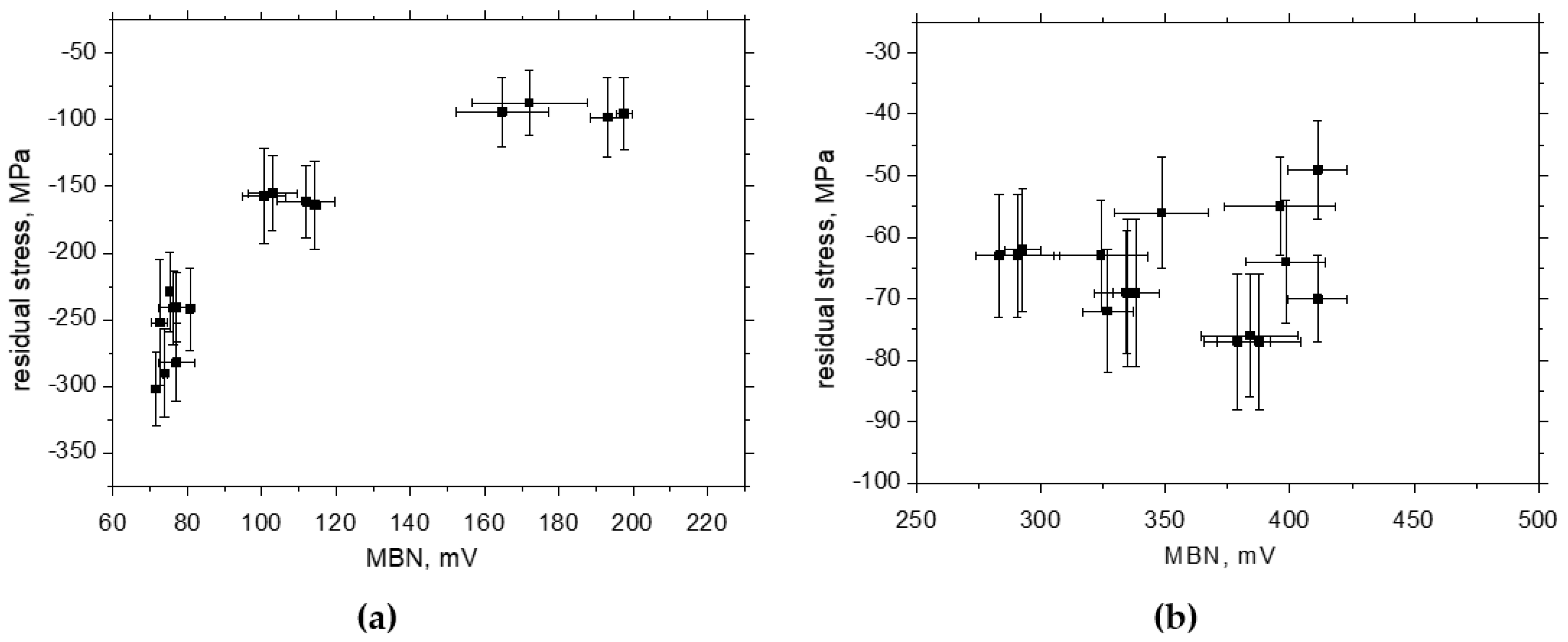

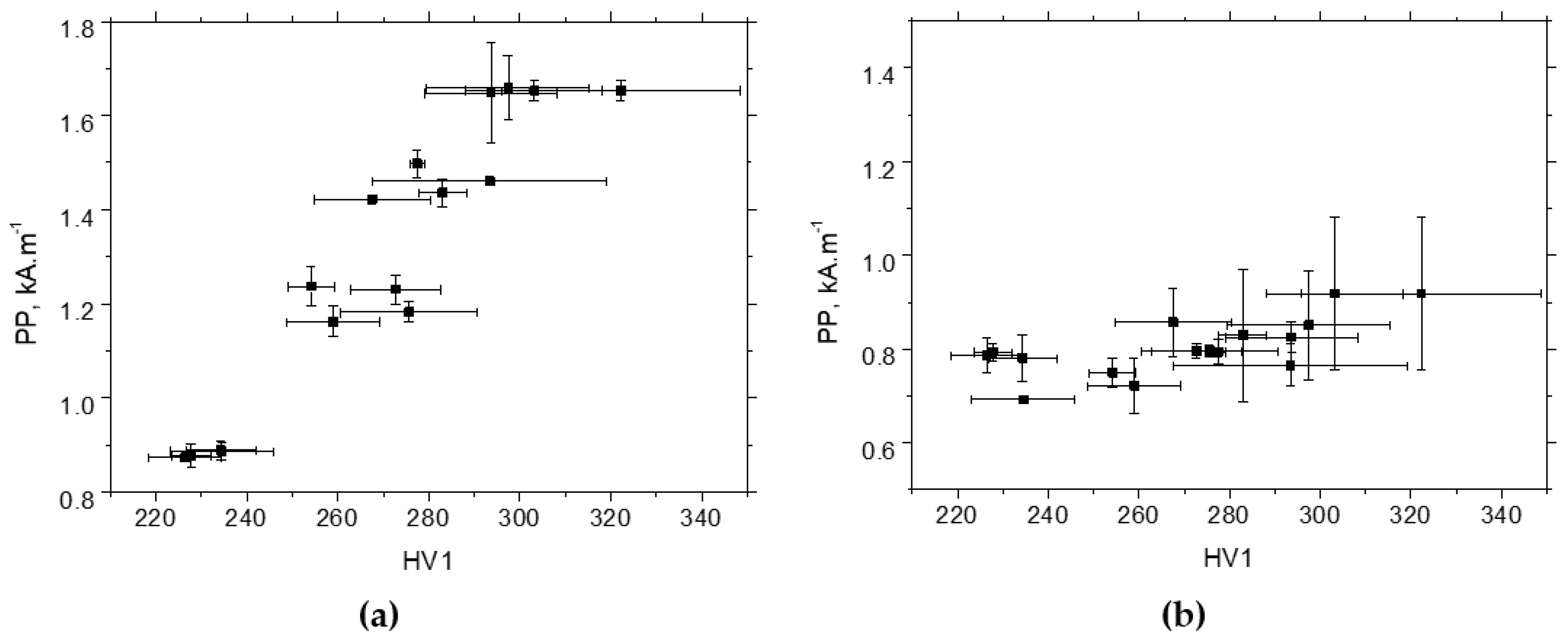

3.3. Barkhausen Noise Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, L.W.; Wang, Y.J.; Chen, Y.; Wang, H.Y.; Dai, L.H. Dislocation nucleation and evolution at the ferrite-cementite interface under cyclic loadings. Acta Mater. 2020, 186, 267–277. [Google Scholar] [CrossRef]

- Yaddanapudi, K.; Knezevic, M.; Mahajan, S.; Beyerlein, I.J. Plasticity and structure evolution of ferrite and martensite in DP 1180 during tension and cyclic bending under tension to large strains. Mater. Sci. Eng. A 2021, 820, 141536. [Google Scholar] [CrossRef]

- Saberipour, S.; Hanzaki, A.Z.; Abedi, H.R.; Moallemi, M. Interplay of austenite and ferrite deformation mechanisms to enhance the strength and ductility of a duplex low-density steel. J. Mater. Res. Technol. 2022, 18, 755–768. [Google Scholar] [CrossRef]

- Zackey, V.; Parker, E.; Fahr, D.; Busch, R. The enhancement of ductility in high strength steels. Trans. ASME 1967, 60, 252–259. [Google Scholar]

- Fonstein, N. Advanced High Strength Sheet Steels, 1st ed.; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Mangonon, P.L.; Thomas, G. The martensite phases in 304 stainless steel. Metall. Trans. 1970, 1, 1577–1578. [Google Scholar] [CrossRef]

- Tilak Kumar, J.V.; Sudha, J.; Padmanabhan, K.A.; Frolova, A.V.; Stolyarov, V.V. Influence of strain rate and strain at temperature on TRIP effect in metastable austenitic stainless steel. Mater. Sci. Eng. A 2020, 777, 139046. [Google Scholar] [CrossRef]

- Zaera, R.; Rodríguez-Martínez, J.A.; Rittel, D. On the Taylor-Quinney coefficient in dynamically phase transforming materials application to 304 stainless steel. Int. J. Plast. 2013, 40, 185–201. [Google Scholar] [CrossRef]

- Tan, X.; He, H.; Lu, W.; Yang, L.; Tang, B.; Yan, J.; Xu, Y.; Wu, D. Effect of matrix structures on TRIP effect and mechanical properties of low-C low-Si Al-added hot-rolled TRIP steels. Mater. Sci. Eng. A 2020, 771, 138629. [Google Scholar] [CrossRef]

- Wang, M.; Huang, M.X. Abnormal TRIP effect on the work hardening behaviour of a quenching and partitioning steel at high strain rate. Acta Mater. 2020, 188, 551–559. [Google Scholar] [CrossRef]

- Haušild, P.; Kolařík, K.; Karlík, M. Characterization of strain-induced martensitic transformation in A301 stainless steel by Barkhausen noise measurement. Mater. Des. 2013, 44, 548–554. [Google Scholar] [CrossRef]

- Tan, X.; Ponge, D.; Lu, W.; Xu, Y.; He, H.; Yan, J.; Wu, D.; Raabe, D. Joint investigation of strain partitioning and chemical partitioning in ferrite-containing TRIP-assisted steels. Acta Mater. 2020, 186, 374–388. [Google Scholar] [CrossRef]

- Kuziak, R.; Kawalla, R.; Waengler, S. Advanced high strength steels for automotive industry. Archiv. Civ. Mech. Eng. 2008, 8, 103–117. [Google Scholar] [CrossRef]

- Soares, G.C.; Patnamsetty, M.; Peura, P.; Hokka, M. Effect of adiabatic heating and strain rate on the dynamic response of a CoCrFeMnNi high entropy alloy. J. Dyn. Behav. 2019, 5, 320–330. [Google Scholar] [CrossRef]

- Haušild, P.; Davydov, V.; Drahokoupil, J.; Landa, M.; Pilvin, P. Characterization of strain-induced martensitic transformation in a metastable stainless steel. Mater. Des. 2010, 31, 1821–1827. [Google Scholar] [CrossRef]

- Chiang, J.; Lawrence, B.; Boyd, J.D.; Pilkey, A.K. Effect of microstructure on retained austenite stability and work hardening of TRIP steels. Mater. Sci. Eng. A 2011, 528, 4516–4521. [Google Scholar] [CrossRef]

- Sakuma, Y.; Itami, A.; Kawano, O.; Kimura, N. Next generation high strength sheet steel utilizing transformation induced plasticity. Nippon. Steel Tech. Rep. 1995, 64, 20–25. [Google Scholar]

- Lloyd, J.T.; Field, D.M.; Limmer, K.R. A four parameter hardening model for TWIP and TRIP steels. Mater. Des. 2020, 194, 108878. [Google Scholar] [CrossRef]

- Kong, H.; Chao, Q.; Rolfe, B.; Beladi, H. One-step quenching and partitioning treatment of a tailor welded blank of boron and TRIP steels for automotive applications. Mater. Des. 2019, 174, 107799. [Google Scholar] [CrossRef]

- Rittel, D.; Zhang, L.H.; Osovski, S. The dependence of the Taylor-Quinney coefficient on the dynamic loading mode. J. Mech. Phys. Solids 2017, 107, 96–114. [Google Scholar] [CrossRef]

- Smith, J.L. Full-Field Determination of the Taylor-Quinney Coefficient in Tension Tests of Ti-6Al-4V Aluminum 2024-T351, and Inconel 718 at Various Strain Rates. Ph.D. Dissertation, The Ohio State University, Columbus, OH, USA, 2019. [Google Scholar]

- Rittel, D. On the conversion of plastic work to heat during high strain rate deformation of glassy polymers. Mech. Mater. 1999, 31, 131–139. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to the Magnetic Materials, 2nd ed.; IEEE Press: New Jersey, NJ, USA, 2009. [Google Scholar]

- Jiles, D. Introduction to Magnetizm and Magnetic Materials, 3rd ed.; Taylor & Francis Group: New York, NY, USA, 2016. [Google Scholar]

- Chikazumi, S. Physics of Ferromagnetizm, 2nd ed.; Oxford University Press: Oxford, UK, 2005. [Google Scholar]

- Liu, J.; Tian, G.Y.; Gao, B.; Zeng, K.; Zheng, Y.; Chen, J. Micro-macro characteristics between domain wall motion and magnetic Barkhausen noise under tensile stress. J. Magn. Magn. Mater. 2020, 493, 165719. [Google Scholar] [CrossRef]

- Górka, J.; Przybyła, M. Research on the Influence of HMFI and PWHT Treatments on the Properties and Stress States of MAG-Welded S690QL Steel Joints. Materials 2024, 17, 3560. [Google Scholar] [CrossRef]

- Neslušan, M.; Čížek, J.; Kolařík, K.; Minárik, P.; Čilliková, M.; Melikhová, O. Monitoring of grinding burn via Barkhausen noise emission in case-hardened steel in large-bearing production. J. Mater. Process. Technol. 2017, 240, 104–117. [Google Scholar] [CrossRef]

- Ghanei, S.; Kashefi, M.; Mazinani, M. Comparative study of eddy current and Barkhausen noise non destructive testing methods in microstructural examination of ferrite-martensite dual-phase steel. J. Magn. Magn. Mater. 2014, 356, 103–110. [Google Scholar] [CrossRef]

- Jarrahi, F.; Kashefi, M.; Ahmadzade-Beiraki, E. An investigation into the applicability of Barkhausen noise technique in evaluation of machining properties of high carbon steel parts with different degrees of spheroidization. J. Magn. Magn. Mater. 2015, 385, 107–111. [Google Scholar] [CrossRef]

- Ktena, A.; Hristoforou, E.; Gerhardt, G.J.L.; Missell, F.P.; Landgraf, F.J.G.; Rodrigues, D.L.; Albertis-Campos, M. Barkhausen noise as a microstructure characterization tool. Physica B Condensed Matter. 2014, 435, 109–112. [Google Scholar] [CrossRef]

- Neslušan, M.; Minárik, P.; Čilliková, M.; Kolařík, K.; Rubešová, K. Barkhausen noise emission in tool steel X210Cr12 after semi-solid processing. Mater. Charact. 2019, 157, 109891. [Google Scholar] [CrossRef]

- Lindgren, M.; Lepistö, T. Effect of prestraining on Barkhausen noise vs. stress relation. NDT&E Int. 2001, 34, 337–344. [Google Scholar] [CrossRef]

- Neslušan, M.; Pitoňák, M.; Čapek, J.; Kejzlar, P.; Trško, L.; Zgútová, K.; Slota, J. Measurement of the rate of transformation induced plasticity in TRIP steel by the use of Barkhausen noise emission as a function of plastic straining. ISA Trans. 2022, 125, 318–329. [Google Scholar] [CrossRef]

- Vértesy, G.; Mészáros, I.; Tomáš, I. Nondestructive magnetic characterization of TRIP steels. NDT&E Int. 2013, 54, 107–114. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Noris, L.F.; Pardal, J.M.; da Silva, M.R. Temper embrittlement of super martensitic stainless steel and non-destructive inspection by magnetic Barkhausen noise. Eng. Fail. Anal. 2019, 100, 322–328. [Google Scholar] [CrossRef]

- Matěj, Z.; Kužel, R.; Nichtová, L. XRD total pattern fitting applied to study of microstructure of TiO2 films. Powder Diff. 2010, 25, 125–131. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1955, 1, 34–46. [Google Scholar] [CrossRef]

- Neslušan, M.; Jurkovič, M.; Kalina, T.; Pitoňák, M.; Zgútová, K. Monitoring of S235 steel over-stressing by the use of Barkhausen noise technique. Eng. Fail. Anal. 2020, 117, 104843. [Google Scholar] [CrossRef]

- Smallman, R.E.; Ngan, A.H.W. Modern Physical Metalugry, 8th ed.; Butterworth-Heinemann: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Roskosz, M.; Fryczowski, K.; Schabowicz, K. Evaluation of ferromagnetic steel hardness based on an analysis of the Barkhausen noise number of events. Materials 2020, 13, 2059. [Google Scholar] [CrossRef]

| Fe | C | Mn | Cr | Si | Al | P | Ni | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|

| Bal. | 0.20 | 1.68 | 0.06 | 0.20 | 1.73 | 0.02 | 0.02 | 0.01 | 0.03 |

| Yield Strength | Ultimate Strength | Elongation at Break | Strain Hardening Coefficient | Young’s Modulus |

|---|---|---|---|---|

| 440 MPa | 770 MPa | 28% | 0.29 | 210 GPa |

| Residual Stress | HV1 | Dislocation Density | ||

|---|---|---|---|---|

| MBN | RD | 0.91 | −0.85 | −0.73 |

| TD | −0.02 | 0.9 | 0.85 | |

| PP | RD | 0.94 | 0.88 | |

| TD | 0.73 | 0.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pitoňák, M.; Mičietová, A.; Moravec, J.; Čapek, J.; Neslušan, M.; Ganev, N. Influence of Strain Rate on Barkhausen Noise in Trip Steel. Materials 2024, 17, 5330. https://doi.org/10.3390/ma17215330

Pitoňák M, Mičietová A, Moravec J, Čapek J, Neslušan M, Ganev N. Influence of Strain Rate on Barkhausen Noise in Trip Steel. Materials. 2024; 17(21):5330. https://doi.org/10.3390/ma17215330

Chicago/Turabian StylePitoňák, Martin, Anna Mičietová, Ján Moravec, Jiří Čapek, Miroslav Neslušan, and Nikolaj Ganev. 2024. "Influence of Strain Rate on Barkhausen Noise in Trip Steel" Materials 17, no. 21: 5330. https://doi.org/10.3390/ma17215330

APA StylePitoňák, M., Mičietová, A., Moravec, J., Čapek, J., Neslušan, M., & Ganev, N. (2024). Influence of Strain Rate on Barkhausen Noise in Trip Steel. Materials, 17(21), 5330. https://doi.org/10.3390/ma17215330