Analysis of Tribological Properties of Engine Lubricants Used in Hybrid Vehicles

Abstract

1. Introduction

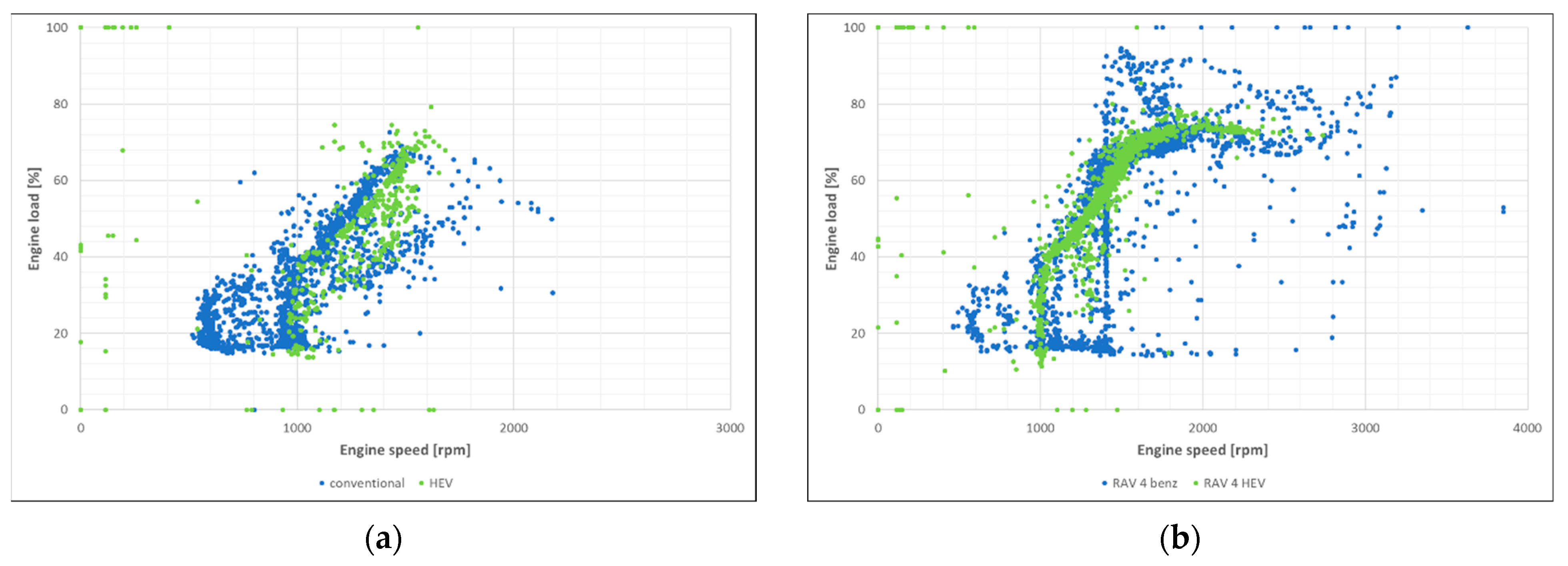

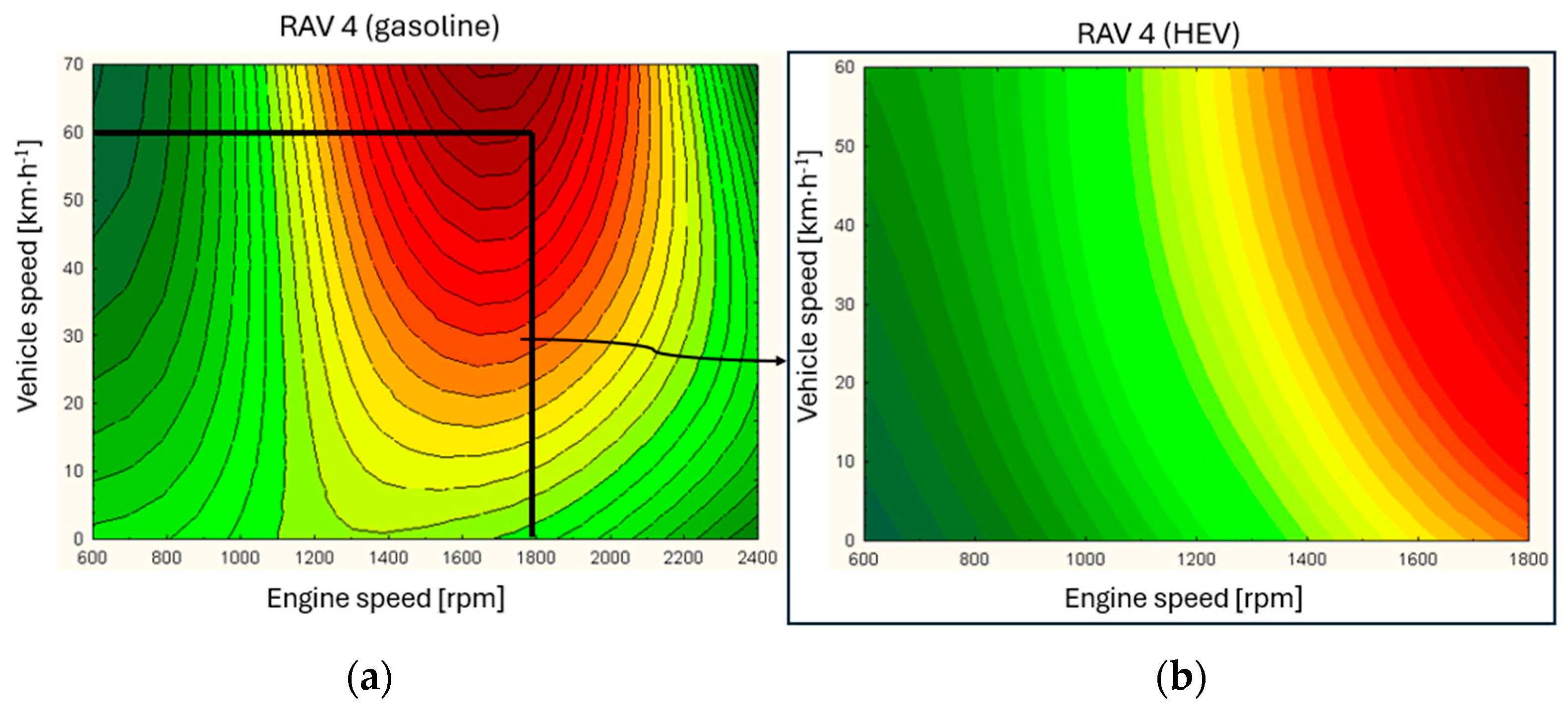

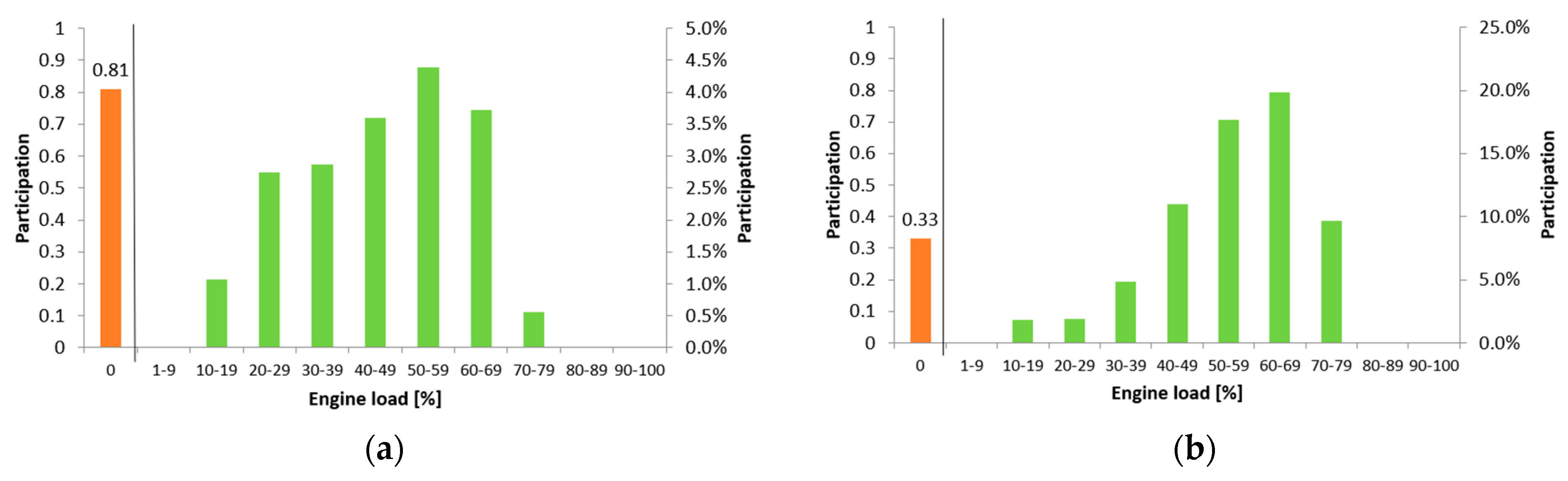

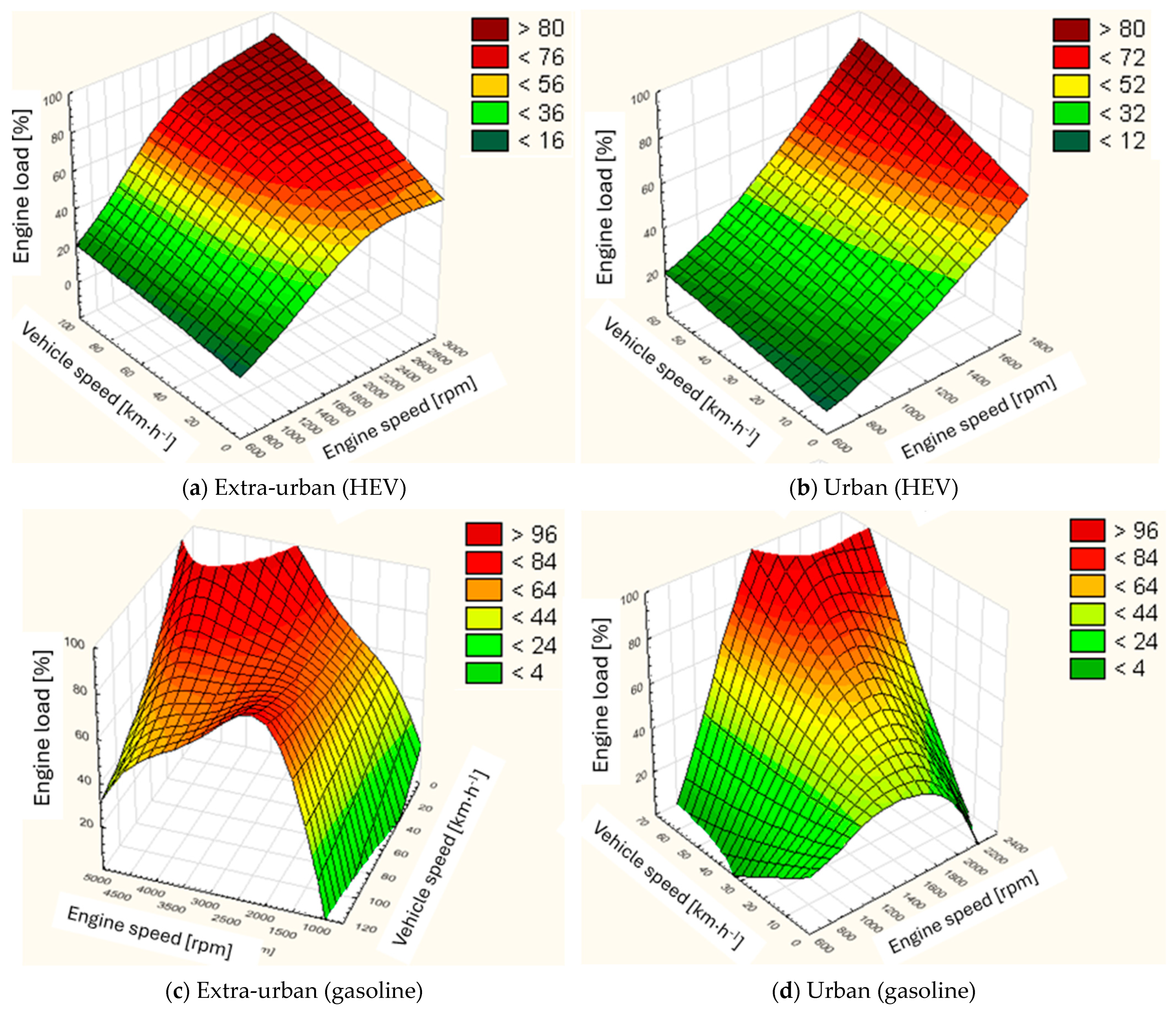

2. Analysis of the Differences in Operating Modes of HEVs and Conventional Combustion Engines

2.1. Comparison of Operational Test Results for Conventional and HEV Engines

2.2. XRF Fluorescence Spectrometric Testing

3. Materials and Methods

4. Test Results

4.1. Results of Rheological Tests

4.2. Tribological Test Results

4.3. Importance of Fuel Admixtures to Oil Under Operating Conditions

5. Discussion

6. Conclusions

- (1)

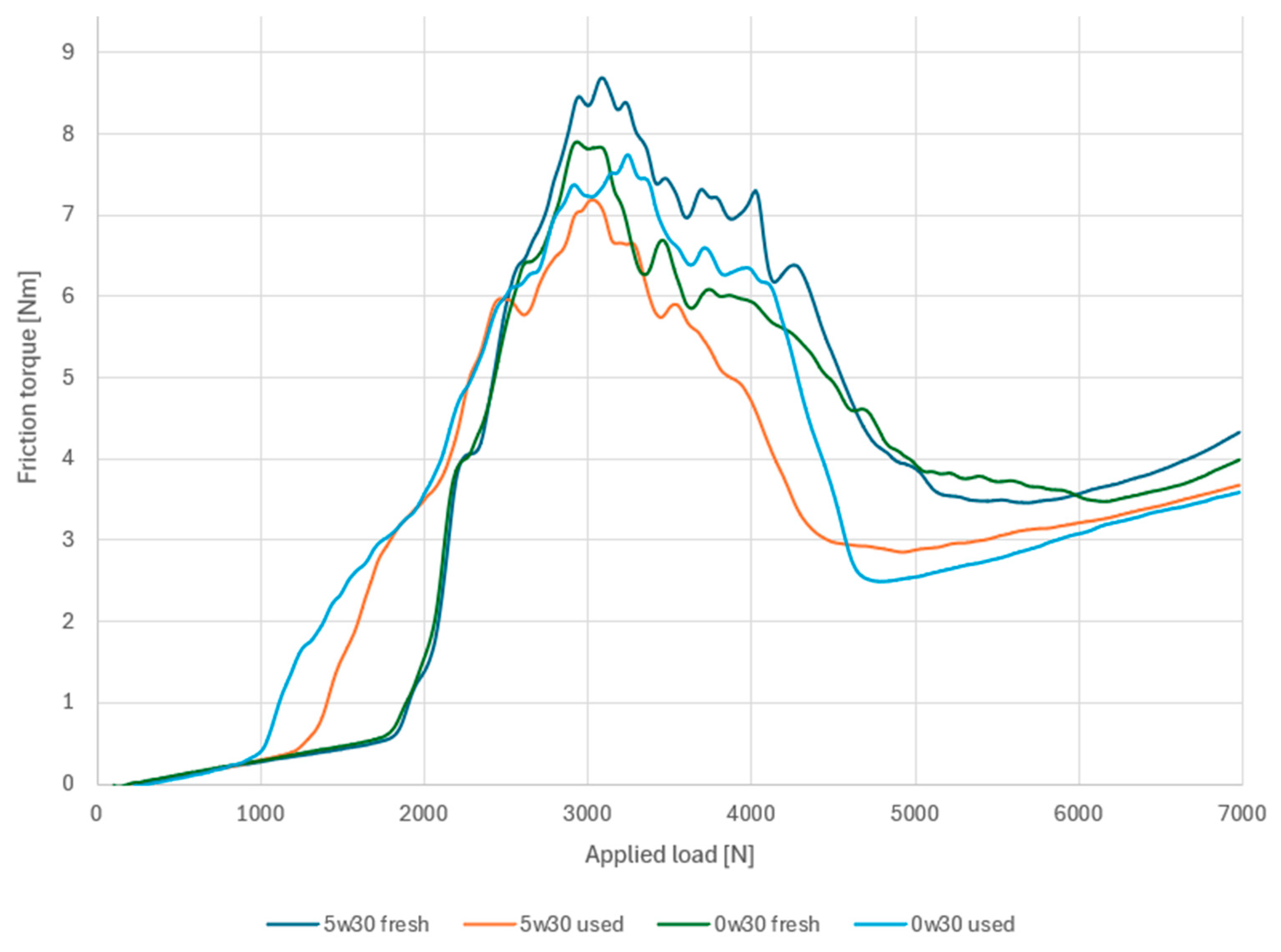

- The higher load on the drive unit in extra-urban traffic is also evidenced by the results of the analysis of the chemical composition of the oils, from which a faster depletion of the anti-wear additives in extra-urban traffic can be observed. In addition, as a result of comparing the chemical composition of oils subjected to service with different viscosity classes, an increased molybdenum content (by more than 10 times) was noted in the 5W30 oil relative to the 0W30 oil, indicating more efficient generation and maintenance of the oil film in the area of mashing loads and in the area of maximum friction torque. However, this is not an indicator of the overall effectiveness of the engine oil, as this aspect would also need to be analysed based on the content of elements such as Ca (calcium) and Zn (zinc). The overall assessment of the lubricity of the 0W30 oil, as well as the results of tribological tests, were affected by the depletion of anti-wear additives, as well as a higher content of metallic wear products relative to the 5W30 in use.

- (2)

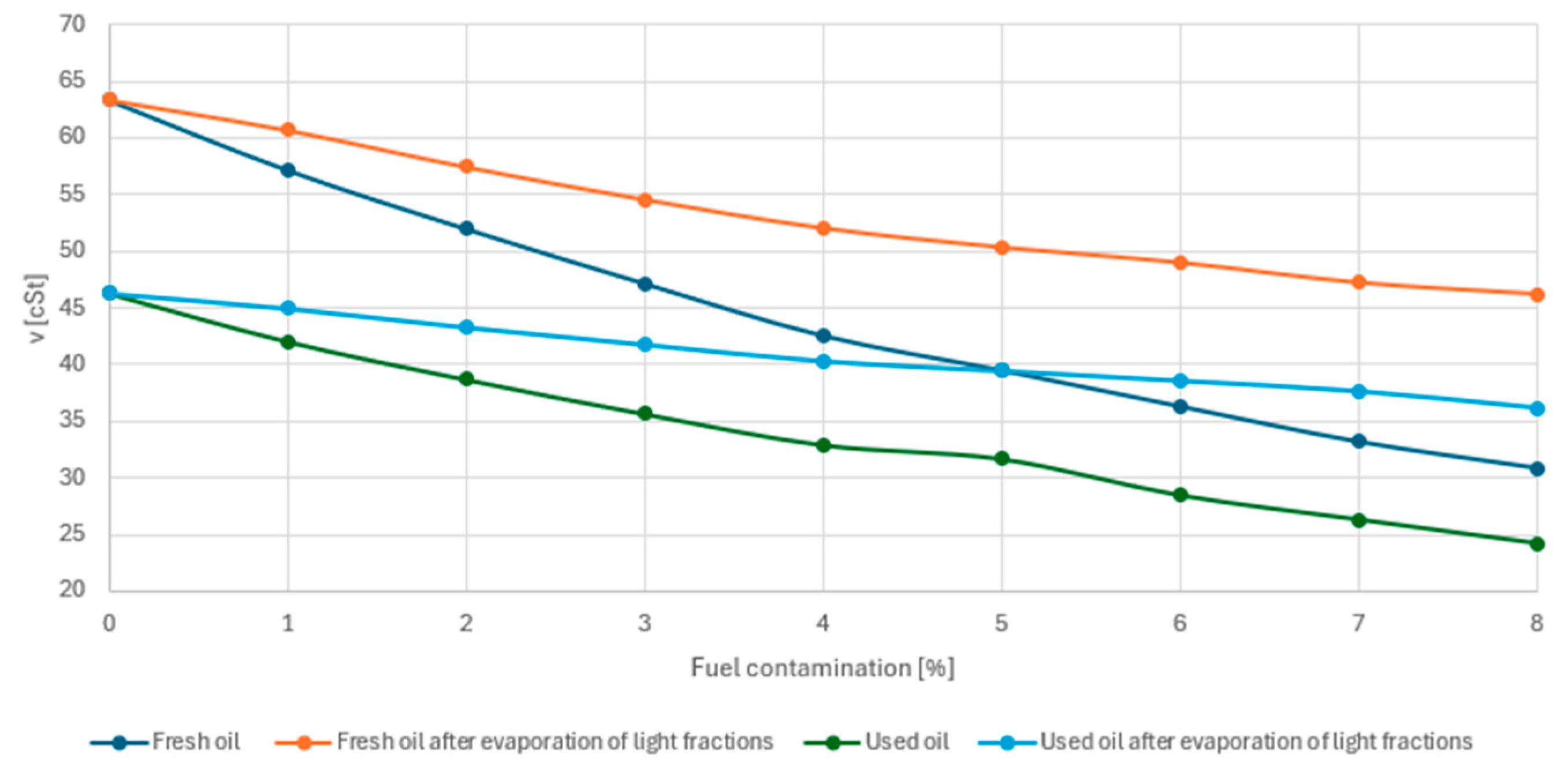

- A study of the effect of fuel admixture on the characteristics and condition of engine oils was also conducted. It was observed that the nature of viscosity changes in engine oil depends on whether one is dealing with fresh or used oil. Viscosity changes caused by fuel dilution in the case of used oil are characterised by a smaller amplitude than is the case with fresh oil. For fresh oil, the decrease in viscosity at the highest fuel admixture compared to a non-fuel-diluted sample was 27.07%, while the corresponding value for used oil was 21.92%.

- (3)

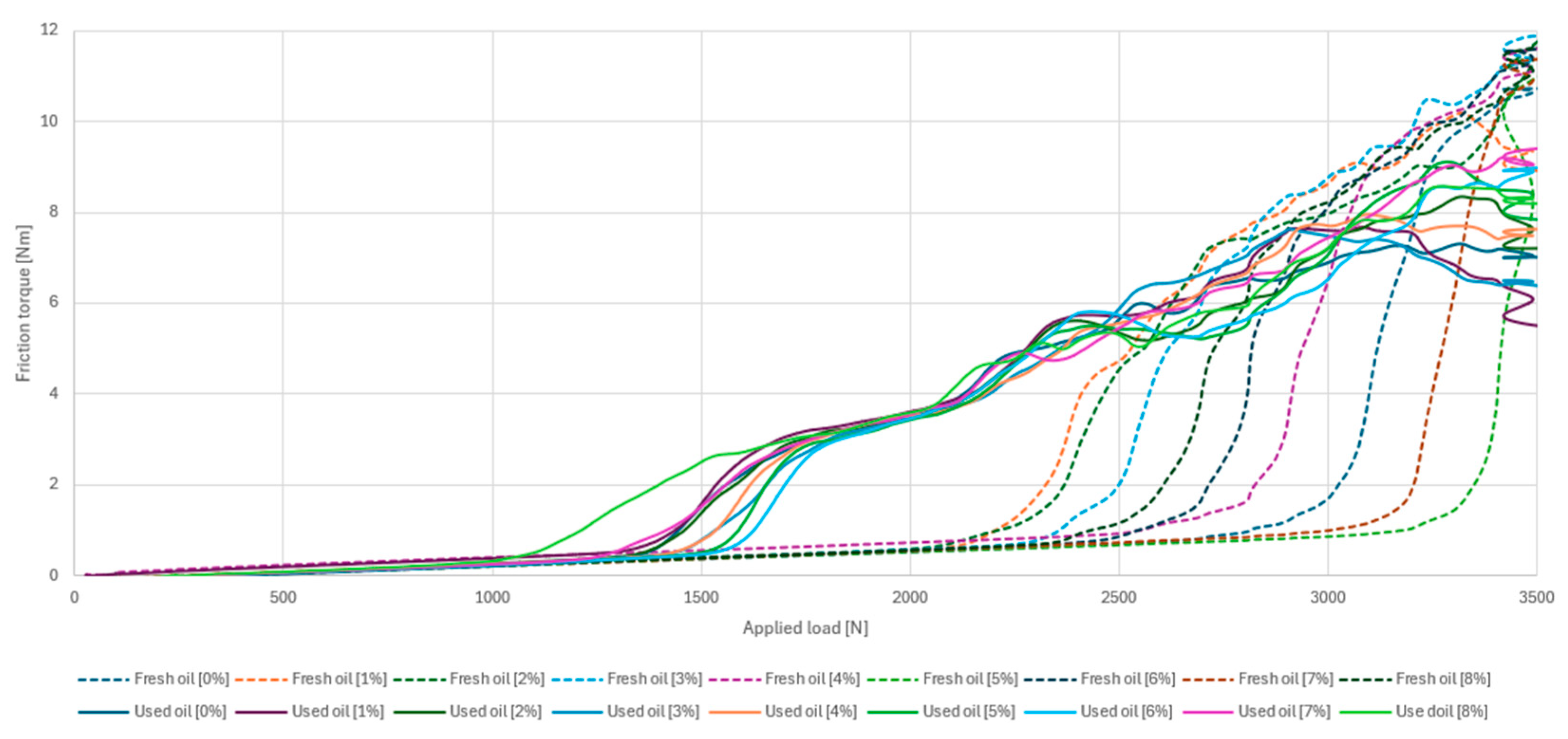

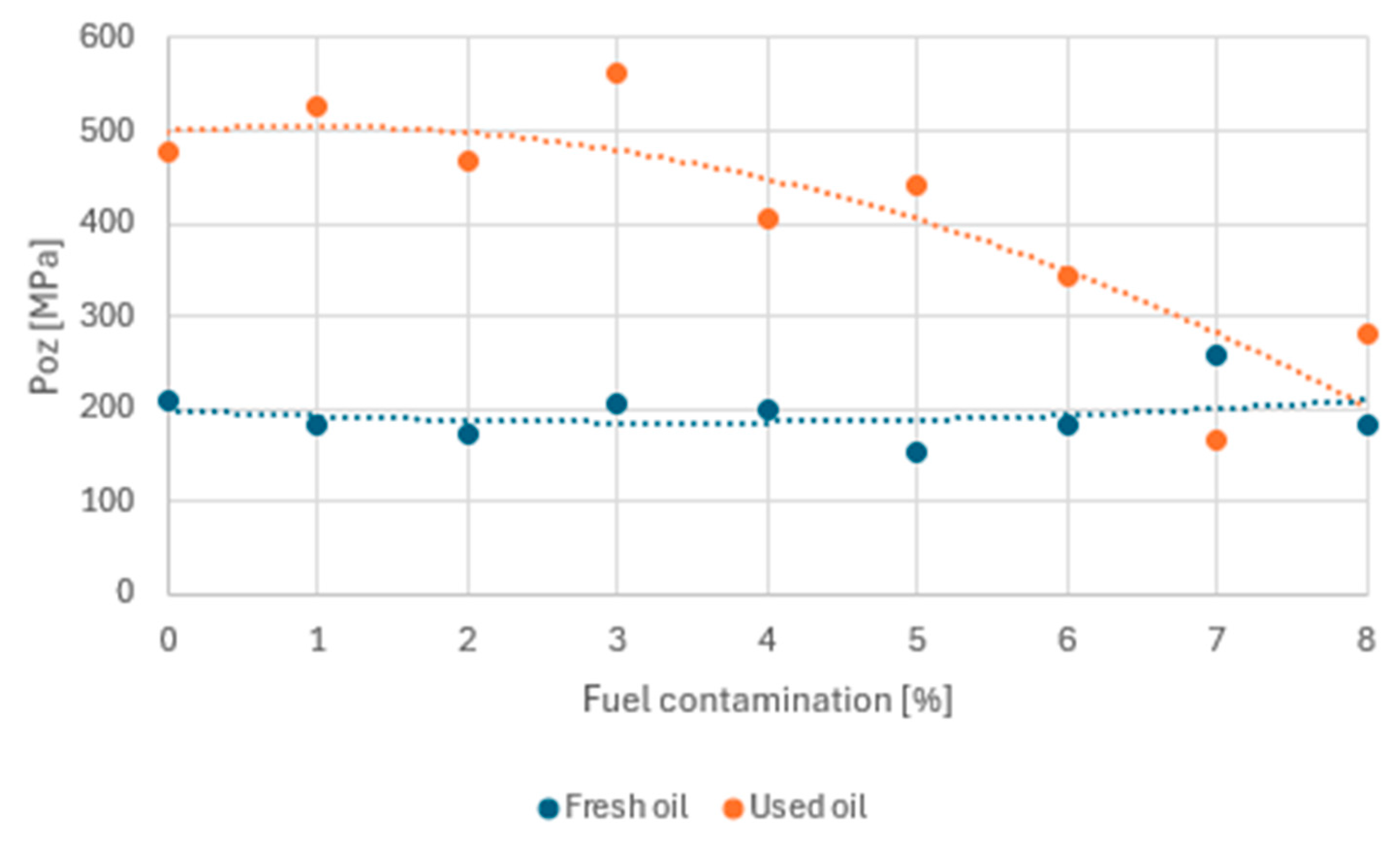

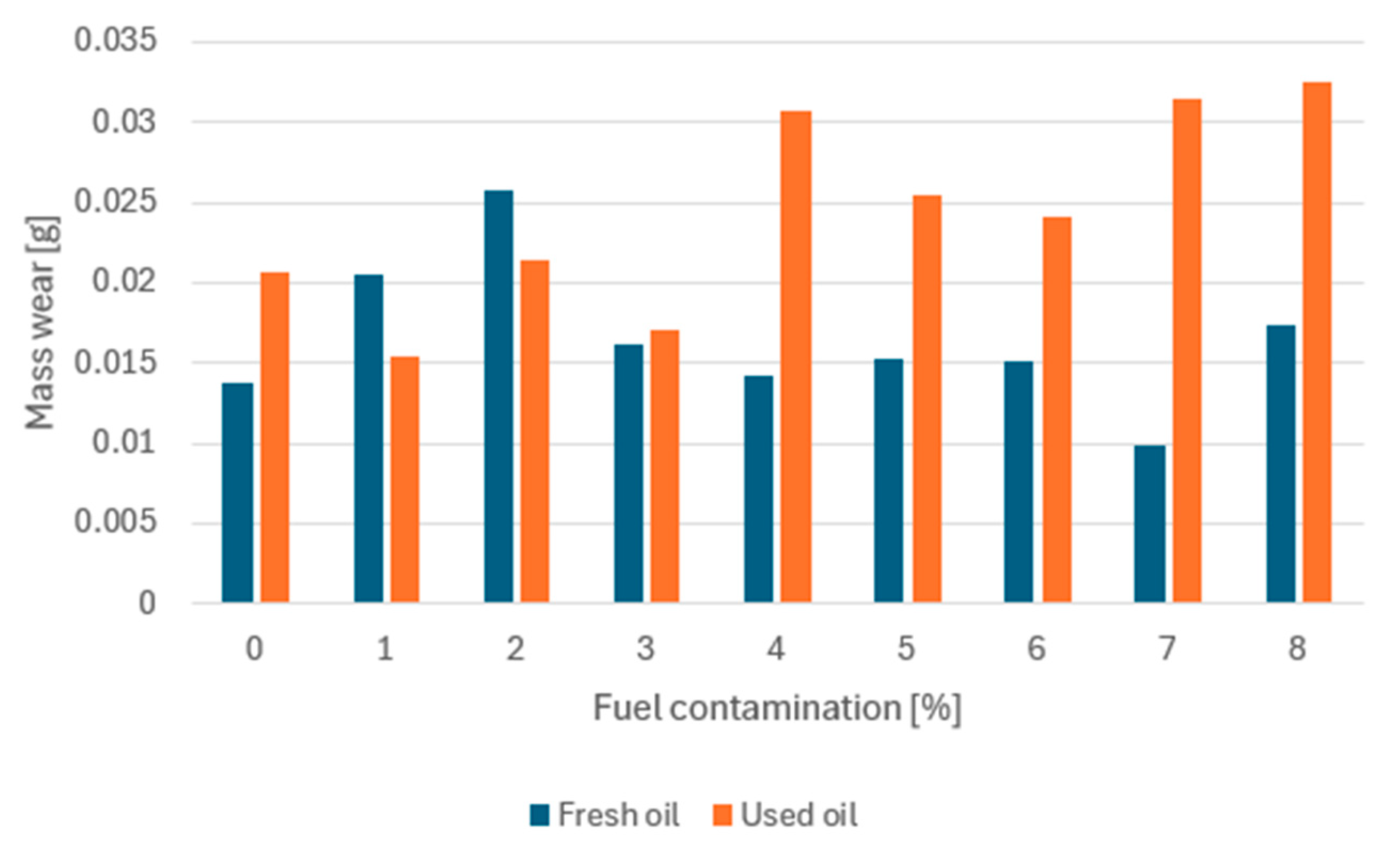

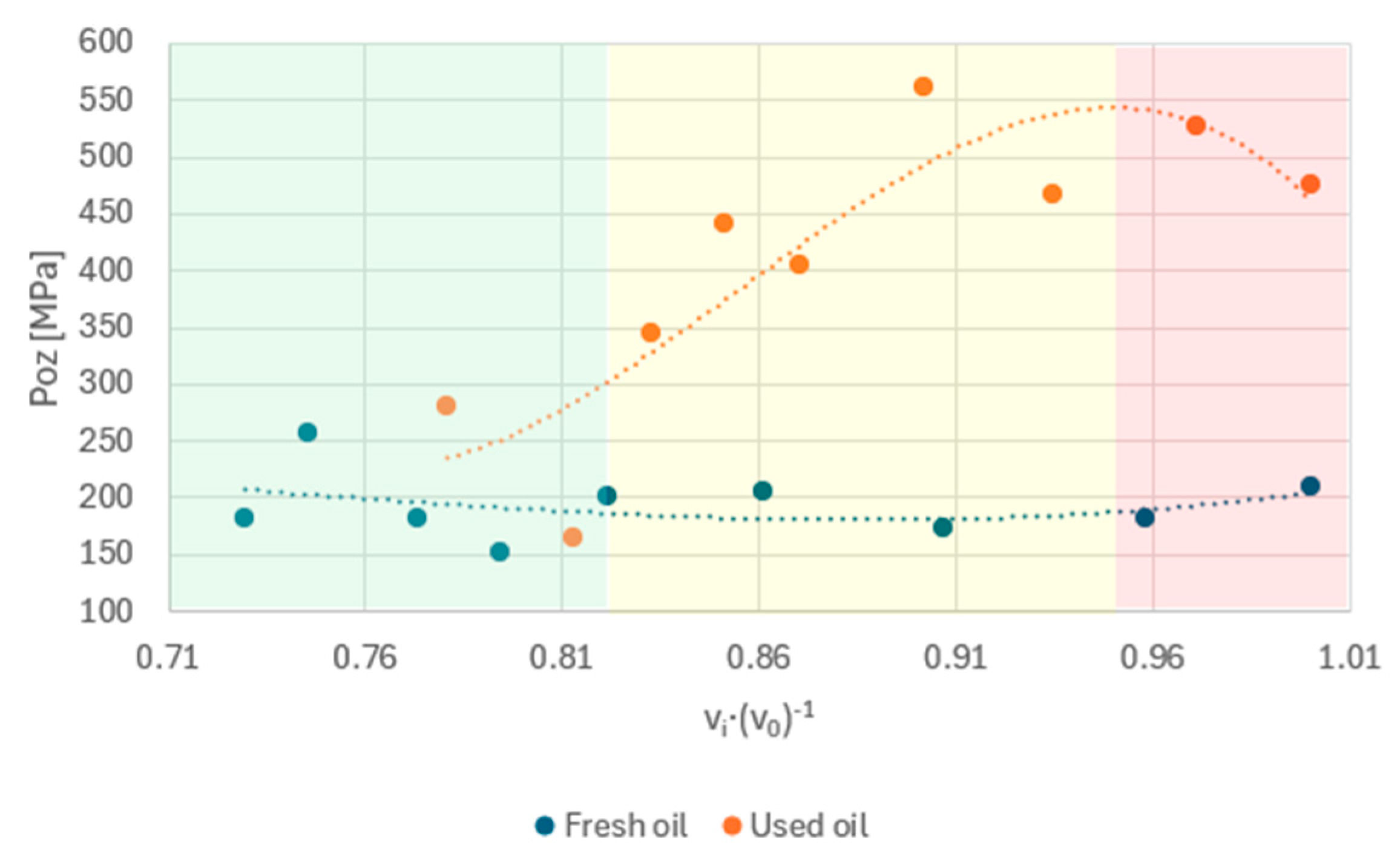

- The operated oil group contaminated with fuel showed a smaller spread of scuffing load values Pt (1048–1548 N) than the fresh oil group (Pt 2134–3177 N). At the same time, the junction obliteration process in the case of the operated oil took place in a lower load range than for the fresh oils. The limiting seizure pressure Poz determined for each sample was at a similar level (around 200 MPa) for fresh oil depending on the percentage of fuel contamination and was lower than the non-linear characteristic determined for treated oil.

- (4)

- In addition, increasing the fuel contamination of the used oil drastically reduces the pressure responsible for maintaining the oil film, and this in turn determines the increase in mass consumption. On the basis of the measurements carried out, it was observed that, once fuel contamination exceeds 5%, there is an intensification of mass consumption, which undoubtedly indicates accelerated wear of the drive unit.

- (5)

- Therefore, in view of the varying driving modes, rheological parameters and lower ambient temperatures hindering the evaporation of petrol from the engine oil, a value of 4% should be taken as an acceptable limit for fuel contamination. In view of the above, it should be assumed that when operating HEVs in urban conditions and at ambient temperatures that make it difficult to reach the operating temperature of the power unit, it is advisable to carry out extra-urban driving at higher speeds in order to evaporate the fuel from the engine oil and thus improve the lubricant performance, or to adopt a shorter oil change interval than recommended by the manufacturer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Malik, M.A.I.; Usman, M.; Hayat, N.; Zubair, S.W.H.; Bashir, R.; Ahmed, E. Experimental evaluation of methanol-gasoline fuel blend on performance, emissions and lubricant oil deterioration in SI engine. Adv. Mech. Eng. 2021, 13, 16878140211025213. [Google Scholar] [CrossRef]

- Usman, M.; Saqib, S.; Zubair, S.W.H.; Irshad, M.; Kazmi, A.H.; Noor, A.; Zaman, H.U.; Nasir, Z.; Malik, M.A.I. Experimental assessment of regenerated lube oil in spark-ignition engine for sustainable environment. Adv. Mech. Eng. 2020, 12, 1687814020940451. [Google Scholar] [CrossRef]

- Tormos, B.; Martín, J.; Carreño, R.; Ramírez, L. A general model to evaluate mechanical losses and auxiliary energy consumption in reciprocating internal combustion engines. Tribol. Int. 2018, 123, 161–179. [Google Scholar] [CrossRef]

- Omar, A.A.S.; Salehi, F.M.; Farooq, U.; Morina, A.; Neville, A. Chemical and physical assessment of engine oils degradation and additive depletion by soot. Tribol. Int. 2021, 160, 107054. [Google Scholar] [CrossRef]

- Baskov, V.; Ignatov, A.; Polotnyanschikov, V. Assessing the influence of operating factors on the properties of engine oil and the environmental safety of internal combustion engine. Transp. Res. Procedia 2020, 50, 37–43. [Google Scholar] [CrossRef]

- Smigins, R.; Amatnieks, K.; Birkavs, A.; Górski, K.; Kryshtopa, S. Studies on Engine Oil Degradation Characteristics in a Field Test with Passenger Cars. Energies 2023, 16, 7955. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Besser, C.; Dörr, N. Comprehensive assessment of oil degradation patterns in petrol and diesel engines observed in a field test with passenger cars–Conventional oil analysis and fuel dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- Mohammed, M.K.; Balla, H.H.; Al-Dulaimi, Z.M.H.; Kareem, Z.S.; Al-Zuhairy, M.S. Effect of ethanol-gasoline blends on SI engine performance and emissions. Case Stud. Therm. Eng. 2021, 25, 100891. [Google Scholar] [CrossRef]

- Mariani, V.; Bianchi, G.M.; Cazzoli, G.; Falfari, S. A one-dimensional model for the motor oil-fuel dilution under gasoline engine boundary conditions. In Proceedings of the 75th National ATI Congress—#7 Clean Energy for All (ATI 2020), Rome, Italy, 15–16 September 2020; Volume 197. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, J.; Joedicke, A.; Reddyhoff, T. Experimental investigation into the effects of diesel dilution on engine lubrication. Tribol. Int. 2021, 156, 106828. [Google Scholar] [CrossRef]

- Kollman, K.; Gürtler, T.; Land, K.; Warnecke, W.; Müller, H.D. Extended Oil Drain Intervals—Conservation of Resources or Reduction of Engine Life (Part II); SAE Technical Paper; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Bergstra, R.J.; Givens, W.A.; Maxwell, W.L.; Richman, W.H. Advanced Synthetic Passenger Vehicle Engine Oils for Extended Oil Drain Performance; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Murakami, Y.; Aihara, H. Effects of NOx and Unburned Gasoline on Low Temperature Sludge Formation in Engine Oil; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1991. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Z.; Feng, Y.; Diao, Z.; Liu, Z. The Effects of Ultra-Low Viscosity Engine Oil on Mechanical Efficiency and Fuel Economy. Energies 2021, 14, 2320. [Google Scholar] [CrossRef]

- Taylor, R.I. Energy Efficiency, Emissions, Tribological Challenges and Fluid Requirements of Electrified Passenger Car Vehicles. Lubricants 2021, 9, 66. [Google Scholar] [CrossRef]

- Fan, Q.; Wang, Y.; Xiao, J.; Wang, Z.; Li, W.; Jia, T.; Zheng, B.; Taylor, R. Effect of Oil Viscosity and Driving Mode on Oil Dilution and Transient Emissions Including Particle Number in Plug-In Hybrid Electric Vehicle; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Clarke, D. Understanding Lubricant Requirements of Hybrid-Electric Vehicles; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance Characteristics of Lubricants in Electric and Hybrid Vehicles: A Review of Current and Future Needs. Front. Mech. Eng. 2020, 6, 571464. [Google Scholar] [CrossRef]

- Leach, B.; Pearson, R. Engine Lubrication and Cooling During Hybrid Vehicle Operation; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Grytsyuk, O.; Vrublevskyi, O. Method of Accelerated Testing of Crankshaft Shells of the Combustion Engine in the Operating Process. Tribol. Ind. 2019, 41, 526–536. [Google Scholar] [CrossRef]

- Kurniawan, D.A.; Puspitasari, P.; Fikri, A.A.; Permanasari, A.A.; Razak, J.A.; Pramono, D.D. Influence of additive nano calcium carbonate (CaCO3) on SAE 10W-30 engine oil: A study on thermophysical, rheological and performance. Mech. Eng. Soc. Ind. 2024, 4, 123–137. [Google Scholar] [CrossRef]

- Zhang, J.; Ueda, M.; Campen, S.; Spikes, H. Boundary Friction of ZDDP Tribofilms. Tribol. Lett. 2021, 69, 1–17. [Google Scholar] [CrossRef]

- Hassan, M.U.; Usman, M.; Bashir, R.; Shah, A.N.; Malik, M.A.I.; Mujtaba, M.; Elkhatib, S.E.; Kalam, A. Tribological Analysis of Molybdenum Disulfide (MOS2) Additivated in the Castor and Mineral Oil Used in Diesel Engine. Sustainability 2022, 14, 10485. [Google Scholar] [CrossRef]

- Kallas, M.M.; Al Sabek, M.S.; Saoud, Y. Experimental Comparison of the Effect of Using Synthetic, Semi-Synthetic, and Mineral Engine Oil on Gasoline Engine Parts Wear. Adv. Tribol. 2024, 2024, 5997292. [Google Scholar] [CrossRef]

- Khan, A.A.; Kaiser, M.S. Wear studies on Al-Si automotive alloy under dry, fresh and used engine oil sliding environments. Res. Eng. Struct. Mater. 2023, 9, 1–18. [Google Scholar] [CrossRef]

- Aguirre, M.; Canals, A.; López-García, I.; Hernández-Córdoba, M. Determination of cadmium in used engine oil, gasoline and diesel by electrothermal atomic absorption spectrometry using magnetic ionic liquid-based dispersive liquid-liquid microextraction. Talanta 2020, 220, 121395. [Google Scholar] [CrossRef]

- Available online: https://global.toyota/en/detail/14384561 (accessed on 24 August 2024).

- Available online: https://www.orlen.pl/content/dam/internet/orlen/pl/pl/dla-biznesu/produkty/paliwa/benzyna/doklumenty/Benzyny%20hanlowe%20PL%2031.01.2024.pdf (accessed on 24 August 2024).

- Łukasiewicz Instytut Technologii Eksploatacji. Uniwersalny aparat czterokulowy T-02U do tribologicznych badań środków smarowych i materiałów konstrukcyjnych. In Instrukcja Obsługi; Sieć badawcza Łukasiewicz–Instytut Technologii Eksploatacji: Radom, Poland, 2022. [Google Scholar]

- Rostek, E.; Babiak, M. The experimental analysis of engine oil degradation utilizing selected thermoanalytical methods. Transp. Res. Procedia 2019, 40, 82–89. [Google Scholar] [CrossRef]

- Khuong, L.S.; Masjuki, H.H.; Zulkiflia, N.W.M.; Niza Mohamada, E.; Kalama, M.A.; Abdullah Alabdulkaremb Arslana, A.; Mosarofa, M.H.; Syahir, A.Z.; Jamshaida, M. Effect of gasoline–bioethanol blends on the properties and lubrication characteristics of commercial engine oil. R. Soc. Chem. 2017, 7, 15005–15019. [Google Scholar] [CrossRef]

- Chybowski, L.; Kowalak, P.; Dąbrowski, P. Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability. Energies 2023, 16, 5056. [Google Scholar] [CrossRef]

- Pugi, L.; Conti, R.; Nocciolini, D.; Galardi, E.; Rindi, A.; Rossin, S. A Tool for the Simulation of Turbo-Machine Auxiliary Lubrication Plants. Int. J. Fluid Power 2014, 15, 87–100. [Google Scholar] [CrossRef]

| Element | 5W30 (Fresh) | Precision | 5W30 (Used) | Precision | 0W30 (Fresh) | Precision | 0W30 (Used) | Precision |

|---|---|---|---|---|---|---|---|---|

| Method: soil | ||||||||

| Ca [ppm] | 16,892.00 | 138.00 | 8821.50 | 112.33 | 8353.67 | 97.33 | 7415.33 | 91.67 |

| Zn [ppm] | 5369.33 | 27.00 | 4158.50 | 24.33 | 4234.00 | 23.00 | 4004.33 | 22.67 |

| Mo [ppm] | 12.33 | 2.00 | 1500.00 | 4.67 | 193.67 | 3.00 | 165.00 | 3.00 |

| Sn [ppm] | 38.67 | 9.00 | 44.00 | 9.00 | 41.00 | 9.00 | 45.00 | 8.00 |

| Cd [ppm] | 16.33 | 7.00 | 28.50 | 7.00 | 17.33 | 7.00 | 14.33 | 6.00 |

| Method: mining | ||||||||

| Ca [%] | 22.24 | 0.19 | 14.42 | 0.18 | 15.57 | 0.19 | 15.02 | 0.19 |

| Zn [%] | 13.70 | 0.25 | 10.81 | 0.24 | 13.96 | 0.28 | 14.42 | 0.30 |

| Sn [%] | 0.80 | 0.18 | 1.31 | 0.23 | 1.067 | 0.27 | 1.54 | 0.30 |

| Cd [%] | 0.43 | 0.11 | 0.62 | 0.13 | 0.64 | 0.16 | 0.61 | 0.18 |

| Method: alloy | ||||||||

| Zn [%] | 32.36 | 0.30 | 23.86 | 0.27 | 30.28 | 0.31 | 31.02 | 0.33 |

| Mo [%] | 0.28 | 0.06 | 18.65 | 0.11 | 2.97 | 0.08 | 2.89 | 0.09 |

| Fe [%] | 0.57 | 0.13 | 0.95 | 0.14 | 0.72 | 0.15 | 1.47 | 0.19 |

| Pb [%] | 0.32 | 0.04 | 0.14 | 0.03 | 0.26 | 0.03 | 0.22 | 0.03 |

| Si [%] | 0.99 | 0.14 | 0.79 | 0.13 | 0.73 | 0.14 | 0.70 | 0.16 |

| Method: precious metals | ||||||||

| Zn [%] | 42.03 | 0.21 | 26.14 | 0.17 | 34.08 | 0.19 | 34.09 | 0.19 |

| Mo [%] | 0.43 | 0.04 | 21.33 | 0.07 | 3.54 | 0.05 | 3.18 | 0.05 |

| Fe [%] | 0.74 | 0.36 | 1.28 | 0.18 | 0.81 | 0.10 | 1.65 | 0.11 |

| Cu [%] | 0.12 | 0.03 | 0.18 | 0.03 | 0.14 | 0.03 | 0.36 | 0.03 |

| Ni [%] | 0.14 | 0.03 | 0.12 | 0.03 | 0.17 | 0.04 | 0.24 | 0.04 |

| Toyota RAV 4–A25A Engine | |

|---|---|

| Displacement | 2494 cm3 |

| Engine type | SI Atkinson cycle |

| Drive type | hybrid |

| Engine power | 176 HP/163 kW (5700 rpm) |

| Maximum torque | 221 Nm (3600–5200 rpm) |

| Number of cylinders | 4 |

| Cylinder system | in-line |

| Number of valves | 16 |

| Cylinder diameter × piston stroke | 87.5 × 103.4 mm |

| Injection system | Combined injection D-4S (dual) |

| Fresh Oil | Used Oil | |||||

|---|---|---|---|---|---|---|

| Fuel Contamination [%] | Viscosity Increase After Evaporation [cSt] | Δνf [%] | Δνfg [-] | Viscosity Increase After Evaporation [cSt] | Δνu [%] | Δνug [-] |

| 0 | - | - | - | - | - | - |

| 1 | 3.52 | 4.21 | 4.21 | 2.39 | 2.89 | 2.89 |

| 2 | 5.46 | 9.34 | 4.67 | 4.62 | 6.51 | 3.26 |

| 3 | 7.41 | 13.89 | 4.63 | 6.14 | 8.82 | 3.27 |

| 4 | 9.50 | 17.87 | 4.47 | 7.43 | 12.99 | 3.25 |

| 5 | 10.86 | 20.55 | 4.11 | 7.79 | 14.87 | 2.97 |

| 6 | 12.69 | 22.68 | 3.78 | 10.12 | 16.74 | 2.79 |

| 7 | 14.04 | 25.47 | 3.64 | 11.35 | 18.73 | 2.68 |

| 8 | 15.36 | 27.07 | 3.38 | 11.97 | 21.92 | 2.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skonieczna, D.; Vrublevskyi, O.; Janulin, M.; Szczyglak, P. Analysis of Tribological Properties of Engine Lubricants Used in Hybrid Vehicles. Materials 2024, 17, 5304. https://doi.org/10.3390/ma17215304

Skonieczna D, Vrublevskyi O, Janulin M, Szczyglak P. Analysis of Tribological Properties of Engine Lubricants Used in Hybrid Vehicles. Materials. 2024; 17(21):5304. https://doi.org/10.3390/ma17215304

Chicago/Turabian StyleSkonieczna, Daria, Oleksandr Vrublevskyi, Michał Janulin, and Piotr Szczyglak. 2024. "Analysis of Tribological Properties of Engine Lubricants Used in Hybrid Vehicles" Materials 17, no. 21: 5304. https://doi.org/10.3390/ma17215304

APA StyleSkonieczna, D., Vrublevskyi, O., Janulin, M., & Szczyglak, P. (2024). Analysis of Tribological Properties of Engine Lubricants Used in Hybrid Vehicles. Materials, 17(21), 5304. https://doi.org/10.3390/ma17215304