Prediction of Resilient Modulus Value of Cohesive and Non-Cohesive Soils Using Artificial Neural Network

Abstract

1. Introduction

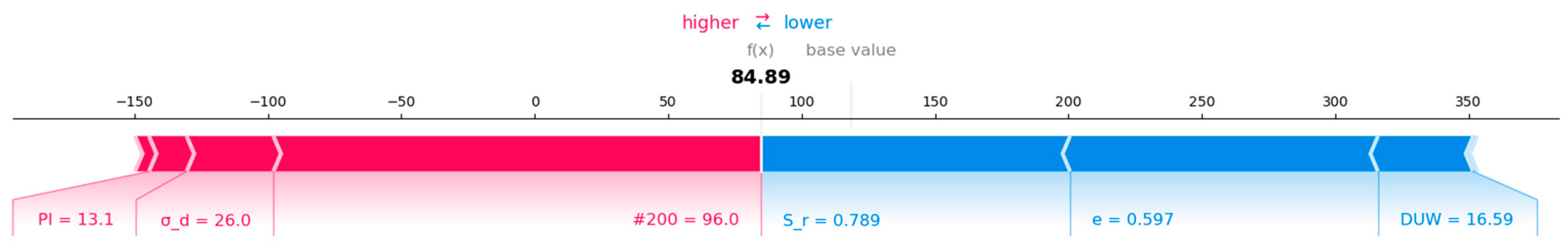

2. Material Properties and Objectives

2.1. Data Extraction

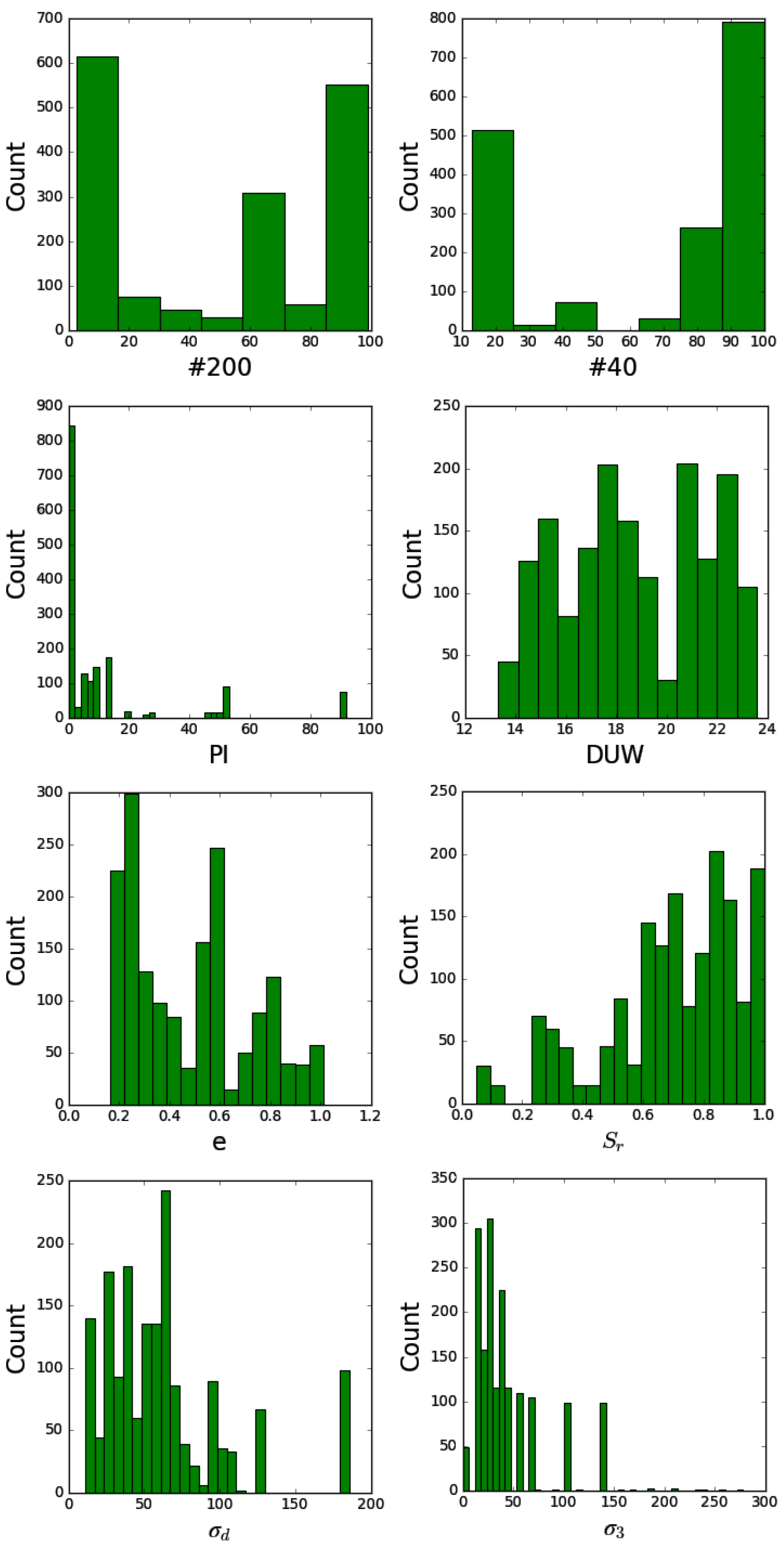

- Percent passing the No. 200 sieve—75 µm (#200), percent passing the No. 40 sieve—425 μm (#40) is a result of soil sieve analysis;

- Plasticity Index (PI)—a measure of the plasticity of soil which is a range of moisture content over which the soil exhibits plastic behavior, indicating its ability to deform without cracking or changing volume, which is calculated as the difference between its liquid limit (LL) and plastic limit (PL);

- Dry unit weight (DUW)—the weight of soil per unit volume when the soil is completely dry. DUW helps assess soil compaction, stability, and bearing capacity;

- Void ratio (e)—a measure of the volume of voids (spaces between soil particles) in a soil sample relative to the volume of solid soil particles. A higher void ratio indicates a greater proportion of voids, leading to lower density and potentially weaker soil,

- Saturation ratio (Sr)—a measure of the degree to which the voids in a soil sample are filled with water. Sr of 0.0 indicates completely dry soil, while Sr = 1.0 signifies fully saturated soil;

- Deviator stress (σd)—the difference between the axial stress and the confining pressure acting on a soil sample. It represents the stress that causes shear deformation;

- Confining pressure (σ’3)—the pressure applied to the soil sample in the lateral direction, effectively simulating the stress conditions that exist in the ground.

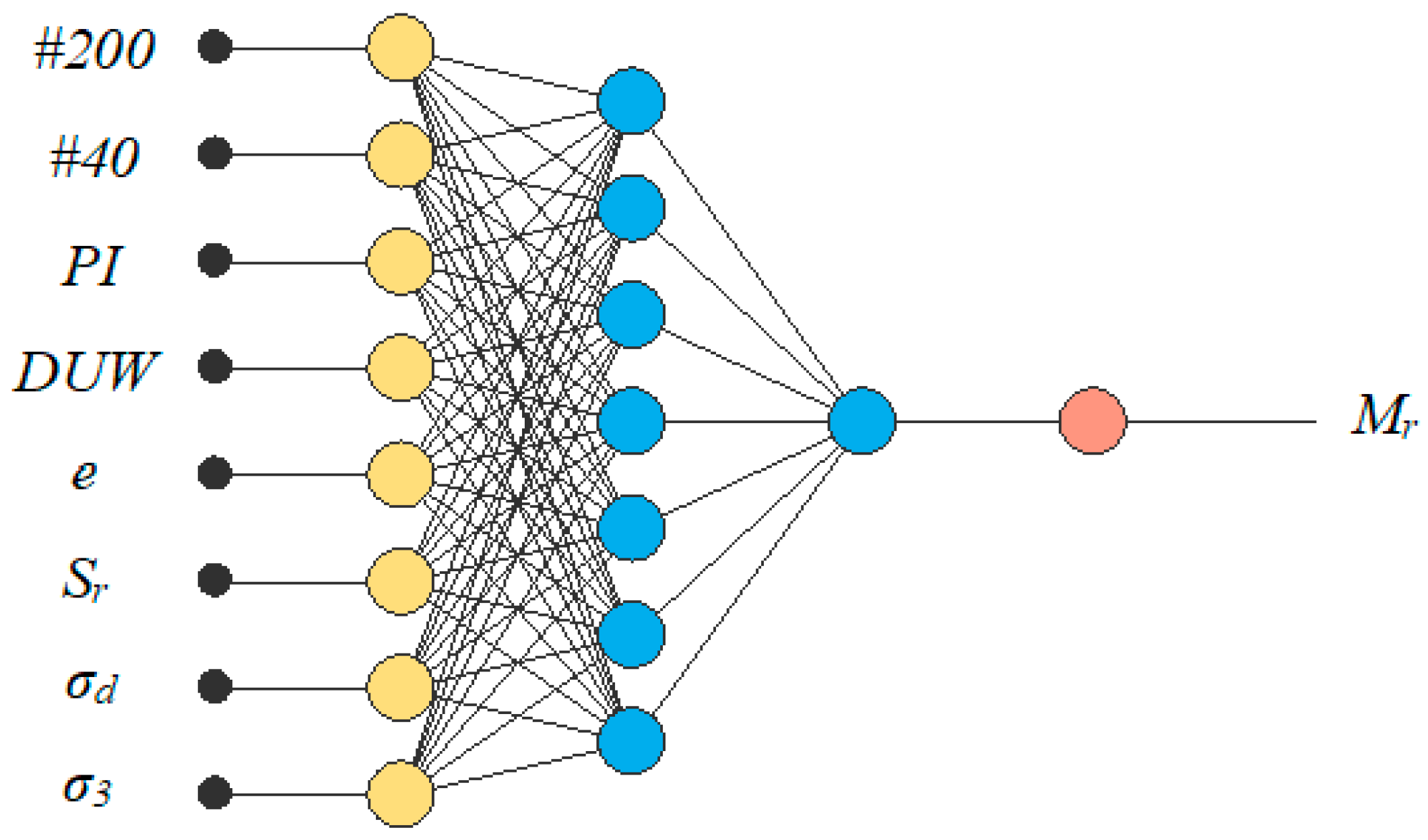

2.2. Artificial Neural Network

2.3. ANN Model Architecture and Training

2.4. Model Evaluation and Sensitivity Analysis

3. Results

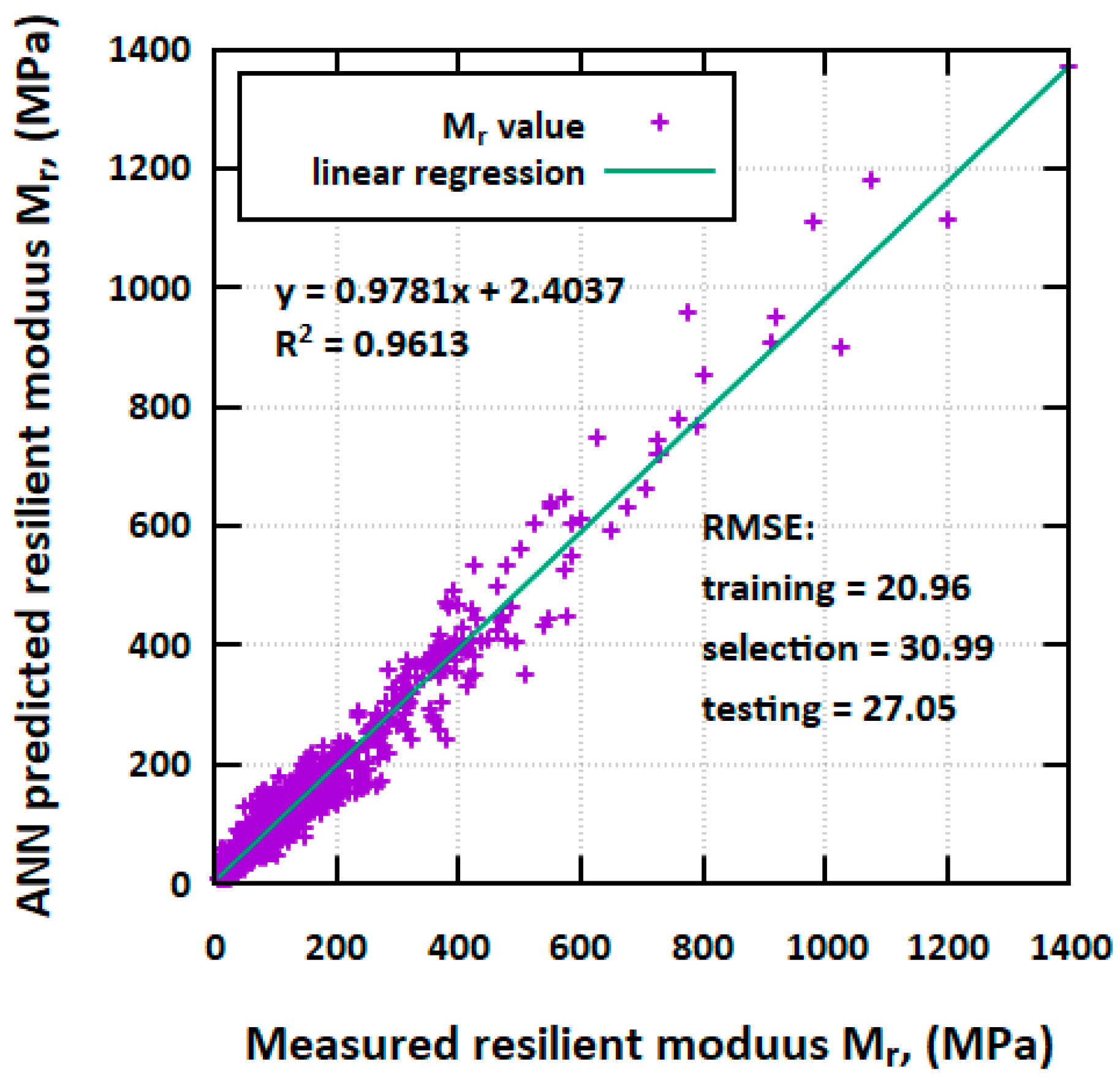

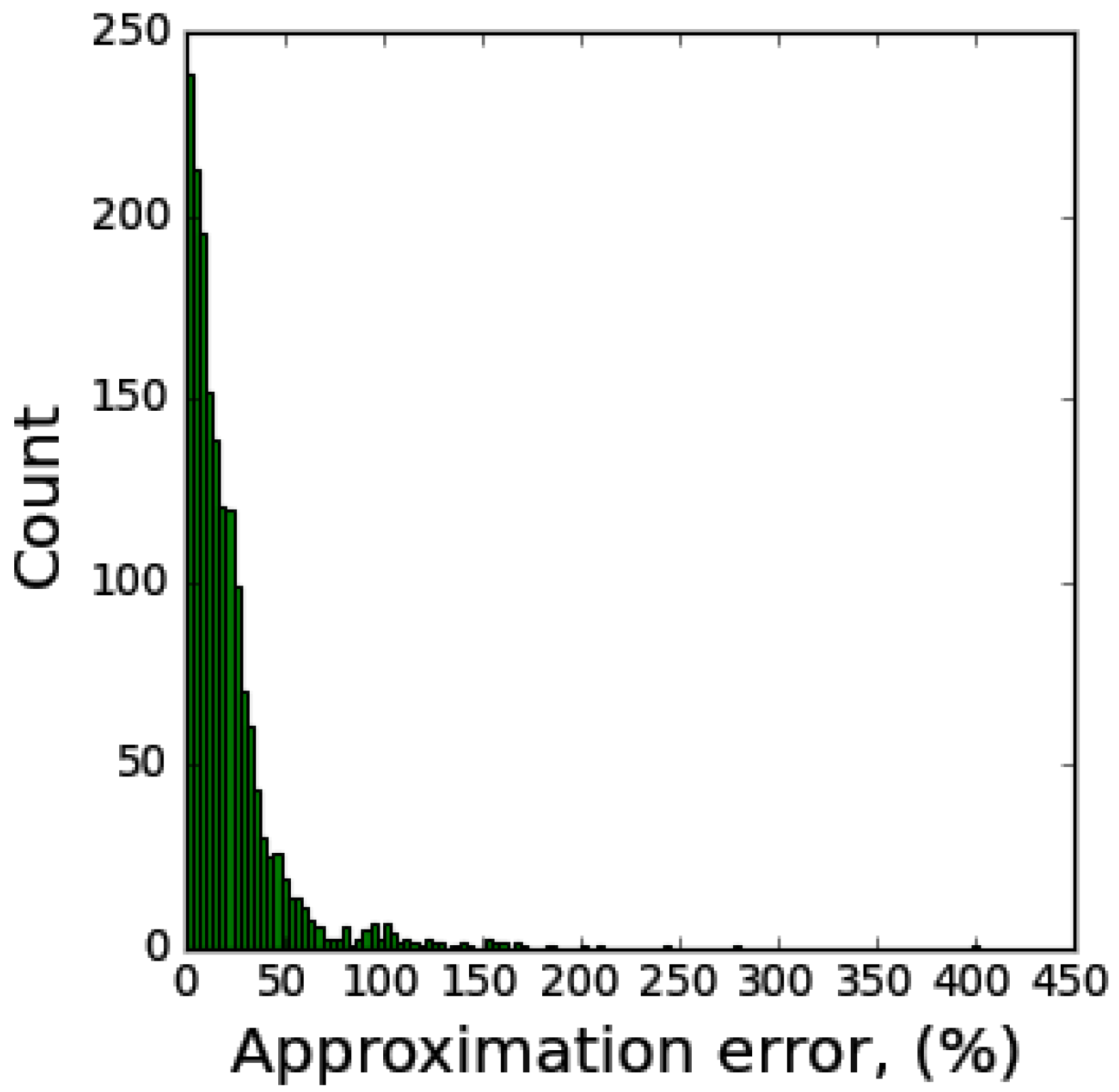

3.1. ANN Modeling

3.2. Sensitivity Analysis

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- AASHTO. Standard Specifications for Transportation Materials and Methods of Sampling and Testing; AASHTO: Washington DC, USA, 1986. [Google Scholar]

- Brown, S.F.; Loach, S.C.; O’Reilly, M.P. Repeated Loading of Fine Grained Soils; Transportation Research Laboratory: Wokingham, UK, 1987. [Google Scholar]

- Głuchowski, A.; Gabryś, K.; Soból, E.; Šadzevičius, R.; Sas, W. Geotechnical Properties of Anthropogenic Soils in Road Engineering. Sustainability 2020, 12, 4843. [Google Scholar] [CrossRef]

- Ševelová, L.; Florian, A.; Hrůza, P. Using Resilient Modulus to Determine the Subgrade Suitability for Forest Road Construction. Forests 2020, 11, 1208. [Google Scholar] [CrossRef]

- Khoury, N.; Brooks, R.; Boeni, S.Y.; Yada, D. Variation of Resilient Modulus, Strength, and Modulus of Elasticity of Stabilized Soils with Postcompaction Moisture Contents. J. Mater. Civ. Eng. 2013, 25, 160–166. [Google Scholar] [CrossRef]

- Moossazadeh, J.; Witczak, M.W. Prediction of Subgrade Moduli for Soil That Exhibits Nonlinear Behavior. Transp. Res. Rec. 1981, 00345301. [Google Scholar]

- Uzan, J. Characterization of Granular Material. Transp. Res. Rec. 1985, 1022, 52–59. [Google Scholar]

- Ni, B.; Hopkins, T.C.; Sun, L.; Beckham, T.L. Modeling the Resilient Modulus of Soils. In Bearing Capacity of Roads, Railways and Airfields; Correia, A.G., Branco, F.E.F., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 1131–1142. ISBN 978-1-00-307882-1. [Google Scholar]

- George, K.P. Prediction of Resilient Modulus from Soil Index Properties; University of Mississippi: Oxford, MS, USA, 2004. [Google Scholar]

- Xiao, Y.; Tutumluer, E.; Siekmeier, J. Resilient Modulus Behavior Estimated from Aggregate Source Properties. In Proceedings of the Geo-Frontiers, Dallas, TX, USA, 13–16 March 2011; American Society of Civil Engineers: Dallas, TX, USA, 2011; pp. 4843–4852. [Google Scholar]

- Murana, A.A. Default K-Values for Estimating Resilient Modulus of Coarse-Grained Nigerian Subgrade Soils. In Soil Testing, Soil Stability and Ground Improvement; Frikha, W., Varaksin, S., Viana Da Fonseca, A., Eds.; Sustainable Civil Infrastructures; Springer International Publishing: Cham, Switzerland, 2018; pp. 210–226. ISBN 978-3-319-61901-9. [Google Scholar]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S.; Bo, M.W. Development of Genetic-Based Models for Predicting the Resilient Modulus of Cohesive Pavement Subgrade Soils. Soils Found. 2020, 60, 398–412. [Google Scholar] [CrossRef]

- Ikeagwuani, C.C.; Nwonu, D.C. Model Performance Assessment in Resilient Modulus Modelling: A Multimodel Approach. Road Mater. Pavement Des. 2021, 22, 2310–2328. [Google Scholar] [CrossRef]

- Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures: Final Report; National Research Council (U.S.), Transportation Research Board: Washington, DC, USA, 2004.

- Fredlund, D.G.; Bergan, A.T.; Wong, P.K. Relation between Resilient Modulus and Stress Conditions for Cohesive Subgrade Soils. Transp. Res. Rec. 1977, 642, 73–81. [Google Scholar]

- Kim, D.; Kim, J.R. Resilient Behavior of Compacted Subgrade Soils under the Repeated Triaxial Test. Constr. Build. Mater. 2007, 21, 1470–1479. [Google Scholar] [CrossRef]

- Drumm, E.C.; Boateng-Poku, Y.; Johnson Pierce, T. Estimation of Subgrade Resilient Modulus from Standard Tests. J. Geotech. Eng. 1990, 116, 774–789. [Google Scholar] [CrossRef]

- Han, Z.; Vanapalli, S.K. State-of-the-Art: Prediction of Resilient Modulus of Unsaturated Subgrade Soils. Int. J. Geomech. 2016, 16, 04015104. [Google Scholar] [CrossRef]

- Han, Z.; Ding, L.; Feng, H.; Yang, G.; Zou, W. Resilient Modulus of a Compacted Clay with Different Moisture and Temperature Histories. Int. J. Pavement Eng. 2023, 24, 2177852. [Google Scholar] [CrossRef]

- Chu, X.; Dawson, A.; Thom, N. Prediction of Resilient Modulus with Consistency Index for Fine-Grained Soils. Transp. Geotech. 2021, 31, 100650. [Google Scholar] [CrossRef]

- Luan, Y.; Lu, W.; Fu, K. Research on Resilient Modulus Prediction Model and Equivalence Analysis for Polymer Reinforced Subgrade Soil under Dry–Wet Cycle. Polymers 2023, 15, 4187. [Google Scholar] [CrossRef]

- Rahman, M.M.; Gassman, S.L.; Islam, K.M. Effect of Moisture Content on Subgrade Soils Resilient Modulus for Predicting Pavement Rutting. Geosciences 2023, 13, 103. [Google Scholar] [CrossRef]

- Bilodeau, J.-P.; Pérez-González, E.L.; Saeidi, A. Modelling of the Variation of Granular Base Materials Resilient Modulus with Material Characteristics and Humidity Conditions. J. Road Eng. 2024, 4, 27–35. [Google Scholar] [CrossRef]

- Hao, J.; Cui, X.; Bao, Z.; Jin, Q.; Li, X.; Du, Y.; Zhou, J.; Zhang, X. Dynamic Resilient Modulus of Heavy-Haul Subgrade Silt Subjected to Freeze-Thaw Cycles: Experimental Investigation and Evolution Analysis. Soil Dyn. Earthq. Eng. 2023, 173, 108092. [Google Scholar] [CrossRef]

- Chen, W.-B.; Feng, W.-Q.; Yin, J.-H. Effects of Water Content on Resilient Modulus of a Granular Material with High Fines Content. Constr. Build. Mater. 2020, 236, 117542. [Google Scholar] [CrossRef]

- Ekblad, J.; Isacsson, U. Influence of Water on Resilient Properties of Coarse Granular Materials. Road Mater. Pavement Des. 2006, 7, 369–404. [Google Scholar] [CrossRef]

- Yang, S.-R.; Lin, H.-D.; Kung, J.H.S.; Huang, W.-H. Suction-Controlled Laboratory Test on Resilient Modulus of Unsaturated Compacted Subgrade Soils. J. Geotech. Geoenviron. Eng. 2008, 134, 1375–1384. [Google Scholar] [CrossRef]

- Qian, J.S.; Lu, H. Effect of Compaction Degree on Soil-Water Characteristic Curve of Chongming Clay. AMM 2011, 90–93, 701–706. [Google Scholar] [CrossRef]

- Caicedo, B.; Coronado, O.; Fleureau, J.M.; Correia, A.G. Resilient Behaviour of Non Standard Unbound Granular Materials. Road Mater. Pavement Des. 2009, 10, 287–312. [Google Scholar] [CrossRef]

- Salour, F.; Erlingsson, S. Resilient Modulus Modelling of Unsaturated Subgrade Soils: Laboratory Investigation of Silty Sand Subgrade. Road Mater. Pavement Des. 2015, 16, 553–568. [Google Scholar] [CrossRef]

- Coleri, E.; Guler, M.; Gungor, A.G.; Harvey, J.T. Prediction of Subgrade Resilient Modulus Using Genetic Algorithm and Curve-Shifting Methodology: Alternative to Nonlinear Constitutive Models. Transp. Res. Rec. 2010, 2170, 64–73. [Google Scholar] [CrossRef]

- Saha, S.; Gu, F.; Luo, X.; Lytton, R.L. Use of an Artificial Neural Network Approach for the Prediction of Resilient Modulus for Unbound Granular Material. Transp. Res. Rec. 2018, 2672, 23–33. [Google Scholar] [CrossRef]

- Hanandeh, S.; Ardah, A.; Abu-Farsakh, M. Using Artificial Neural Network and Genetics Algorithm to Estimate the Resilient Modulus for Stabilized Subgrade and Propose New Empirical Formula. Transp. Geotech. 2020, 24, 100358. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, J.; Peng, J.; Fan, H.; Zhou, C. Prediction of Resilient Modulus for Subgrade Soils Based on ANN Approach. J. Cent. South Univ. 2021, 28, 898–910. [Google Scholar] [CrossRef]

- Kim, S.-H.; Yang, J.; Jeong, J.-H. Prediction of Subgrade Resilient Modulus Using Artificial Neural Network. KSCE J. Civ. Eng. 2014, 18, 1372–1379. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.; Zhang, X.; Saboundjian, S. Resilient Modulus Characterization of Alaska Granular Base Materials. Transp. Res. Rec. 2011, 2232, 44–54. [Google Scholar] [CrossRef]

- Papp, W.J.; Maher, A.; Bennert, T.; Gucunski, N. Resilient Modulus Properties of New Jersey Subgrade Soils; Federal Highway Administration: Washington, DC, USA, 2000. [Google Scholar]

- Gupta, G.; Ranaivoson, A.; Edil, T.; Benson, C.; Sawangsuriya, A. Pavement Design Using Unsaturated Soil Technology; University of Minnesota: Minneapolis, MN, USA, 2007. [Google Scholar]

- Malla, R.B.; Joshi, S. Subgrade Resilient Modulus Prediction Models for Coarse and Fine-Grained Soils Based on Long-Term Pavement Performance Data. Int. J. Pavement Eng. 2008, 9, 431–444. [Google Scholar] [CrossRef]

- Liang, R.Y.; Rabab’ah, S.; Khasawneh, M. Predicting Moisture-Dependent Resilient Modulus of Cohesive Soils Using Soil Suction Concept. J. Transp. Eng. 2008, 134, 34–40. [Google Scholar] [CrossRef]

- Banerjee, A.; Puppala, A.J.; Congress, S.S.C.; Chakraborty, S.; Likos, W.J.; Hoyos, L.R. Variation of Resilient Modulus of Subgrade Soils over a Wide Range of Suction States. J. Geotech. Geoenviron. Eng. 2020, 146, 04020096. [Google Scholar] [CrossRef]

- Pereira, C.; Nazarian, S.; Correia, A.G. Extracting Damping Information from Resilient Modulus Tests. J. Mater. Civ. Eng. 2017, 29, 04017233. [Google Scholar] [CrossRef]

- Hanittinan, W. Resilient Modulus Prediction Using Neural Network Algorithm. Doctoral Thesis, Ohio State University, Columbus, OH, USA, 2007. [Google Scholar]

- McCulloch, W.S.; Pitts, W. A Logical Calculus of the Ideas Immanent in Nervous Activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Qi, X.; Wei, Y.; Mei, X.; Chellali, R.; Yang, S. Comparative Analysis of the Linear Regions in ReLU and LeakyReLU Networks. In Neural Information Processing; Luo, B., Cheng, L., Wu, Z.-G., Li, H., Li, C., Eds.; Communications in Computer and Information Science; Springer Nature Singapore: Singapore, 2024; Volume 1962, pp. 528–539. ISBN 978-981-9981-31-1. [Google Scholar]

| Data Source | PI (%) | #200 (%) | #40 (%) | OMC (%) | DUW (kN/m3) | Classification by AASHTO |

|---|---|---|---|---|---|---|

| George [9] Total observations: 50 | 6.1 | 55 | 100 | 13.8 | 18.1 | A-4 |

| 8 | 56 | 100 | 14.1 | 17.82 | A-4 | |

| 7 | 40 | 100 | 12.9 | 18.56 | A-4 | |

| 12.4 | 60 | 90 | 13.8 | 18.14 | A-6 | |

| 13.1 | 96 | 99 | 17.8 | 16.59 | A-6 | |

| 1 | 28 | 100 | 11.0 | 18.53 | A2-4 | |

| 4.9 | 42 | 100 | 12.0 | 18.67 | A-4 | |

| 13.3 | 98 | 99 | 18.6 | 16.67 | A-6 | |

| Li et al. [36] Total observations: 513 | 0 | 10 | 19.5 | 5.5 | 23.59 | A-1-a |

| 0 | 8 | 18 | 5.4 | 22.15 | A-1-a | |

| 0 | 6 | 15.5 | 5.3 | 23.44 | A-1-a | |

| 0 | 3.15 | 13 | 5.3 | 23.06 | A-1-a | |

| Maher et al. [37] Total observations: 118 | 0 | 7.6 | 39 | 8.75 | 18.72 | A-1-b |

| 3 | 30.1 | 76 | 8.5 | 19.37 | A-2-4 | |

| 0 | 33.3 | 75 | 9.0 | 18.15 | A-2-4 | |

| 0 | 9.9 | 83 | 9.0 | 17.37 | A-3 | |

| 1.5 | 36.6 | 77 | 8.25 | 19.26 | A-4 | |

| 4 | 43 | 77 | 8.5 | 19.29 | A-4 | |

| 18.9 | 97.5 | 99 | 14.5 | 17.08 | A-6 | |

| 27.4 | 97.7 | 99 | 22.5 | 15.67 | A-7 | |

| Gupta et al. [38] Total observations: 383 | 11 | 85.3 | 95 | 13.5 | 17.9 | A-4 |

| 24 | 91.3 | 97 | 22.0 | 15.87 | A-7-6 | |

| 9 | 58.6 | 86 | 16.0 | 17.36 | A-4 | |

| 52 | 96.4 | 98 | 27.5 | 14.4 | A-7-6 | |

| Han and Vanapalli [18] Total observations: 21 | 6 | 96.5 | 99.5 | 12.75 | 19.5 | A-4 |

| 19 | 77 | 96 | 13.2 | 19.39 | A-6 | |

| 26 | 79.5 | 94 | 23.5 | 16.16 | A-6 | |

| Malla and Joshi [39] Total observations: 193 | 0 | 5 | 35 | 11.2 | 18.41 | A-1-a |

| 6 | 23.3 | 39 | 10.3 | 19.02 | A-2-4 | |

| 6 | 26.9 | 46 | 11.1 | 18.86 | A-2-5 | |

| 6 | 22.8 | 38 | 10.0 | 18.98 | A-1-b | |

| 0 | 3.1 | 79.3 | 14.7 | 15.63 | A-3 | |

| 0 | 4 | 69.4 | 12.5 | 15.67 | A-3 | |

| 0 | 2.6 | 75.5 | 13.8 | 15.62 | A-3 | |

| 51 | 99 | 99.6 | 30.3 | 13.33 | A-7-6 | |

| 47 | 98.3 | 99.4 | 30.5 | 13.32 | A-7-7 | |

| 49 | 98.8 | 99.6 | 30.4 | 13.4 | A-7-8 | |

| 8 | 81.9 | 94.5 | 14.2 | 17.72 | A-6 | |

| 8 | 77.6 | 93.6 | 15.5 | 17.15 | A-6 | |

| 8 | 84.3 | 96.8 | 16.1 | 16.76 | A-6 | |

| Liang et al. [40] Total observations: 50 | 8 | 56.3 | 75.7 | 14.2 | 17.75 | A-4-a |

| 12.3 | 68.8 | 81.1 | 16.5 | 17.7 | A-6-a | |

| Banerjee et al. [41] Total observations: 30 | 0 | 90 | 99.5 | 14.8 | 16.5 | A-4 |

| 92 | 95 | 99.9 | 22.9 | 14.4 | A-7-6 | |

| Pereira et al. [42] Total observations: 16 | 0 | 3 | 50 | 8.9 | 21.14 | A-1-b |

| Hanittinan [43] Total observations: 309 | 9 | 62 | 100 | 12.4 | 20.58 | A-4 |

| 8 | 64 | 100 | 12.6 | 18.85 | A-4 | |

| 6 | 59 | 100 | 12.1 | 20.67 | A-4 |

| Variable x | Minimum min(x) | Maximum max(x) | Mean ) | |

|---|---|---|---|---|

| #200 (%) | 2.6 | 99 | 49.72 | 37.07 |

| #40 (%) | 13 | 100 | 67.48 | 36.24 |

| PI (%) | 0.0 | 92 | 12.06 | 22.11 |

| DUW (kN/m3) | 13.32 | 23.59 | 18.7 | 2.87 |

| e (–) | 0.16 | 1.0 | 0.48 | 0.24 |

| Sr (–) | 0.05 | 1.0 | 0.689 | 0.226 |

| σd (kPa) | 11.0 | 186.16 | 61.34 | 41.34 |

| σ3 (kPa) | 0.0 | 278.41 | 43.66 | 35.59 |

| Mr (MPa) | 9.2 | 1400 | 111.07 | 124.25 |

| #200 | #40 | PI | DUW | e | Sr | σd | σ₃ | Mr | |

| #200 | 1 | 0.89 | 0.56 | –0.8 | 0.72 | 0.31 | 0.3 | –0.34 | –0.22 |

| #40 | 0.89 | 1 | 0.44 | –0.79 | 0.63 | 0.38 | 0.42 | –0.47 | –0.32 |

| PI | 0.56 | 0.44 | 1 | –0.63 | 0.64 | 0.13 | –0.18 | –0.19 | –0.21 |

| DUW | –0.8 | –0.79 | –0.63 | 1 | –0.95 | 0.17 | 0.34 | 0.35 | 0.23 |

| e | 0.72 | 0.63 | 0.64 | –0.95 | 1 | 0.11 | –0.21 | –0.23 | –0.2 |

| Sr | 0.31 | 0.38 | 0.13 | –0.17 | 0.11 | 1 | –0.21 | –0.2 | –0.66 |

| σd | 0.3 | 0.42 | –0.18 | 0.34 | –0.21 | –0.21 | 1 | 0.58 | 0.26 |

| σ₃ | –0.34 | –0.47 | –0.19 | 0.35 | –0.23 | –0.2 | 0.58 | 1 | 0.37 |

| Mr | –0.22 | –0.32 | –0.21 | 0.23 | –0.2 | –0.66 | 0.26 | 0.37 | 1 |

| Error | Training | Selection | Testing |

|---|---|---|---|

| Sum squared error (SSE) | 455,010 | 393,835 | 330,403 |

| Mean squared error (MSE) | 449.6 | 1168.7 | 980.4 |

| Root mean squared error (RMSE) | 21.20 | 34.19 | 31.31 |

| Normalized squared error (NSE) | 0.034 | 0.052 | 0.065 |

| Minkowski error (EMinkowski) | 78,746.4 | 48,206.9 | 42,154.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Głuchowski, A. Prediction of Resilient Modulus Value of Cohesive and Non-Cohesive Soils Using Artificial Neural Network. Materials 2024, 17, 5200. https://doi.org/10.3390/ma17215200

Głuchowski A. Prediction of Resilient Modulus Value of Cohesive and Non-Cohesive Soils Using Artificial Neural Network. Materials. 2024; 17(21):5200. https://doi.org/10.3390/ma17215200

Chicago/Turabian StyleGłuchowski, Andrzej. 2024. "Prediction of Resilient Modulus Value of Cohesive and Non-Cohesive Soils Using Artificial Neural Network" Materials 17, no. 21: 5200. https://doi.org/10.3390/ma17215200

APA StyleGłuchowski, A. (2024). Prediction of Resilient Modulus Value of Cohesive and Non-Cohesive Soils Using Artificial Neural Network. Materials, 17(21), 5200. https://doi.org/10.3390/ma17215200