The Evolution of Dilatant Shear Bands in High-Pressure Die Casting for Al-Si Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

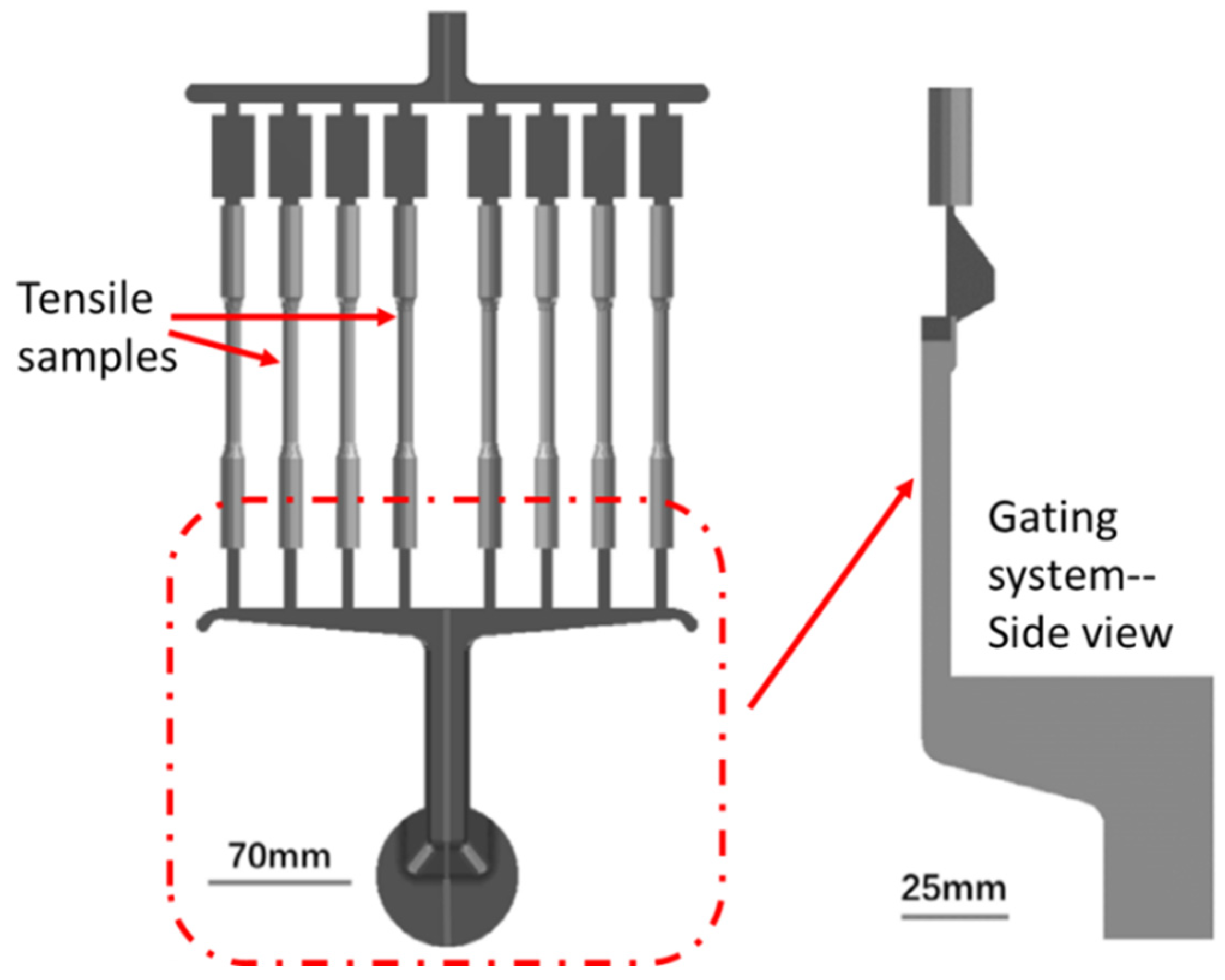

2.2. Casting Technologies and Parameters

2.3. Tensile Test

2.4. Microstructure Characterization

3. Results

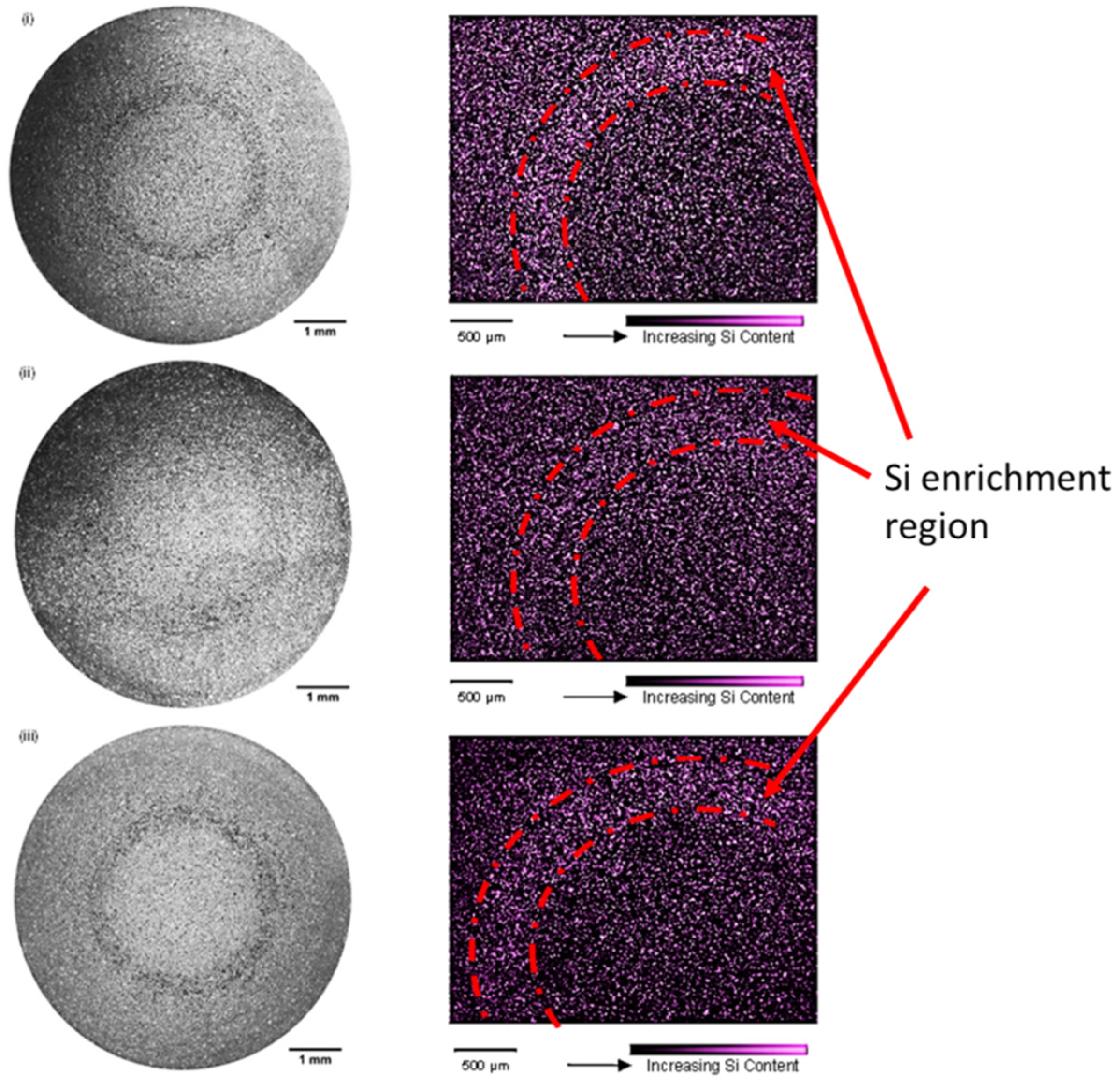

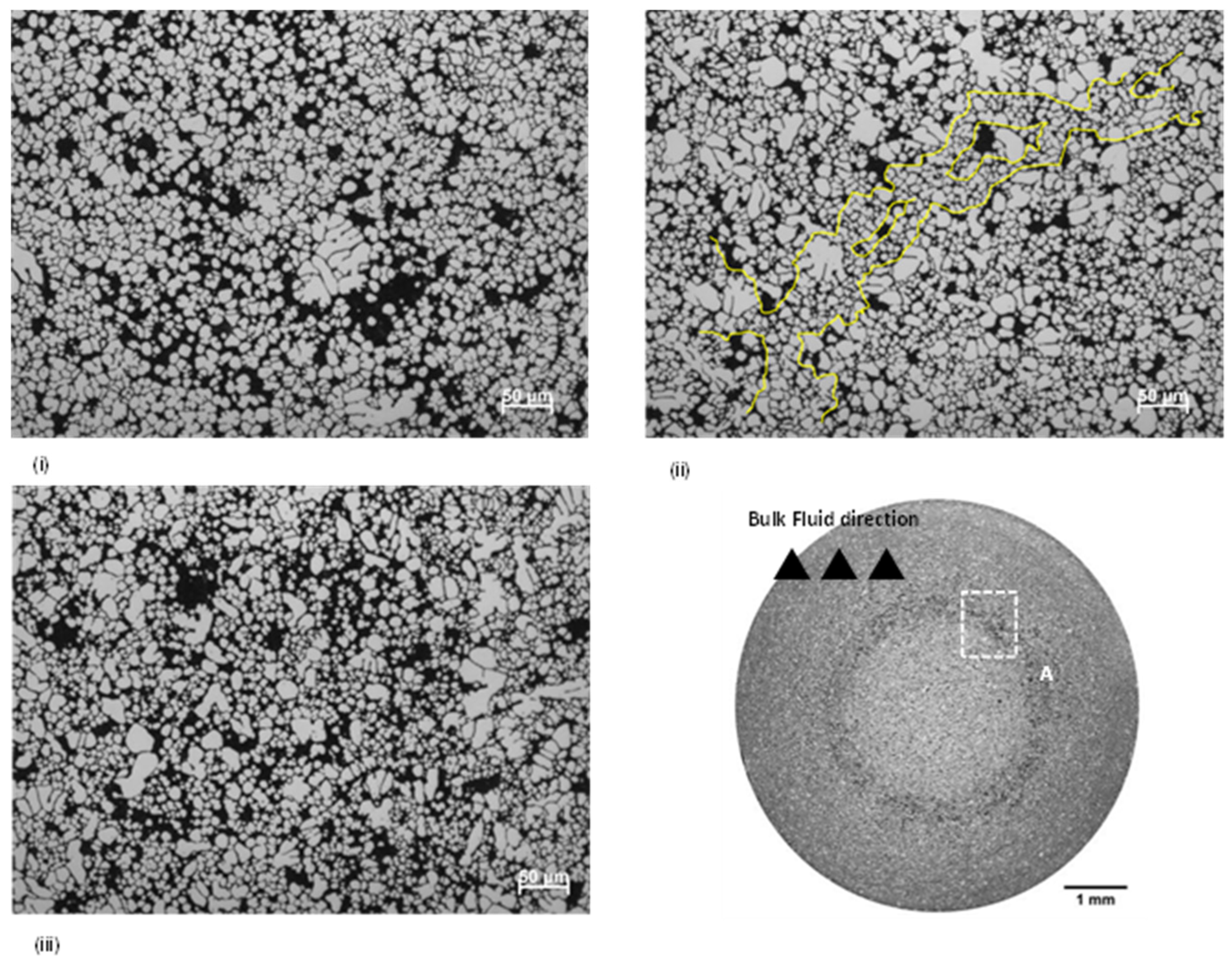

3.1. Dilatant Shear Bands and ESC Morphology

3.2. Grain Size and Mechanical Properties

4. Discussion

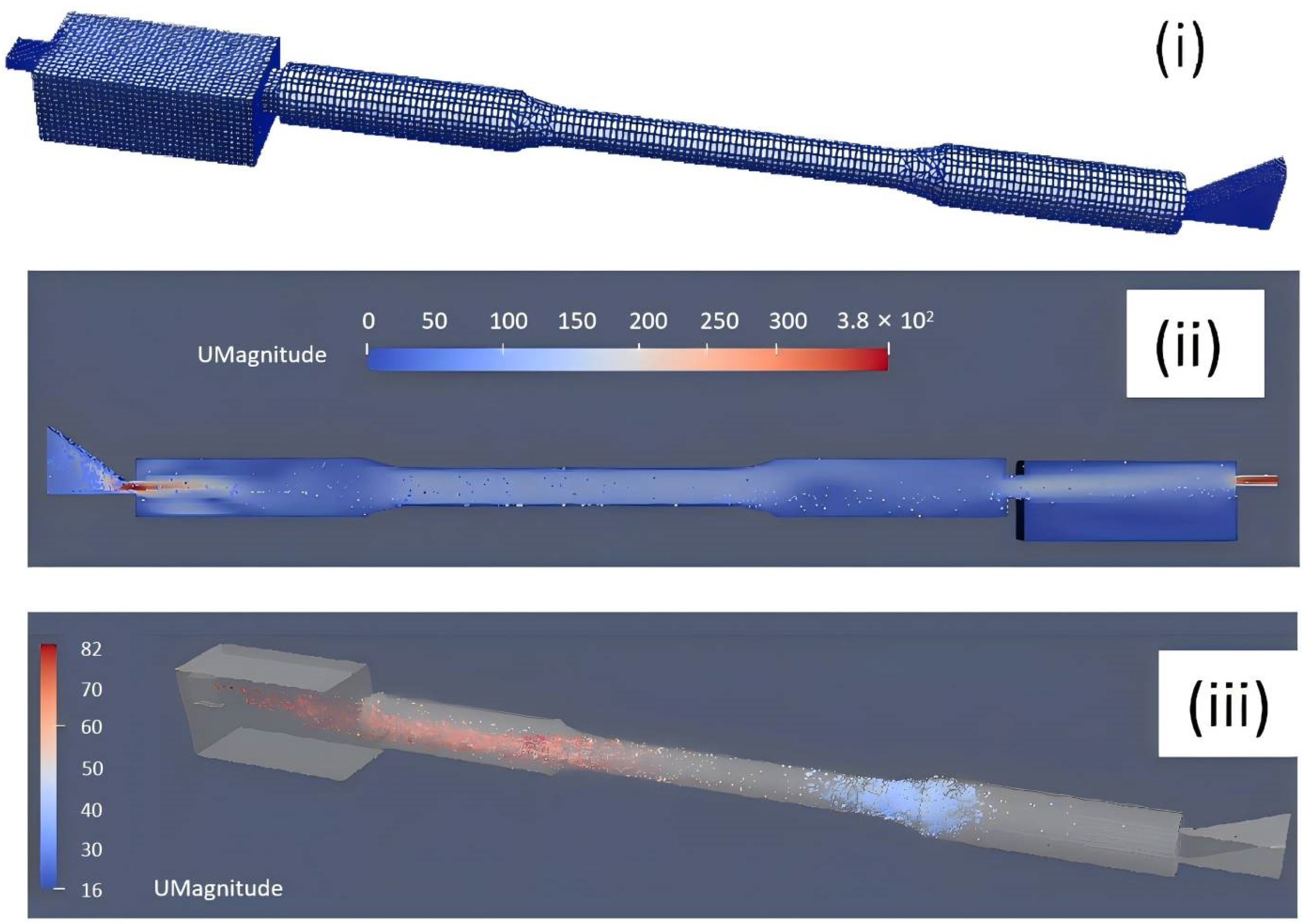

- (1)

- In Figure 8i, the presence of large crystals within the force chain leads to a decrease in the total number of contacts and increases the volume of interstitial fluid. The force chain is therefore more susceptible to buckling, enhancing dilation within the shear band;

- (2)

- Particles within the shear band experience a transverse lift force, due to the existence of a non-uniform pressure distribution. This lift force encourages crystals to migrate towards the region of lowest shear stress [27] (i.e., the centreline of the band). An increase in particle size is followed with a rise in lift force. According to the lift force models in [31,32], an increase in particle size from 50 to 100 µm will lead to an increase of 2.5 × 10−9 N in lift force. Within the band, ESCs that comprise the outermost regions of the force chain will effectively act as pivots (Figure 8ii), with the applied moment resulting from the aforementioned slip-shear lift forces;

- (3)

- Within a given velocity gradient, increasing the particle size will increase the energy dissipated upon collision. In Figure 8iii, a large crystal traveling at high velocity may possess the potential to dislodge a segment of the force chain, provided the energy dissipated upon collision is sufficient to encourage local particle rearrangement. This phenomenon is likely to occur towards the centreline of the shear band where resistance to flow is at a minimum, and particle momentum is likely to be at a maximum.

5. Conclusions

- (1)

- Stacking faults introduced by the presence of large crystals within the force chain reduce the total number of contacts and increase the volume of interstitial fluid, weakening the structure;

- (2)

- Crystals located towards the outermost region of the band are drawn inwards by slip–shear lift forces. A force chain comprising large crystals at its pivots will experience a greater moment, increasing susceptibility to buckling;

- (3)

- A larger crystal travelling at increasing piston velocity from 2.2 ms−1 to 4.2 ms−1 may possess the potential to dislodge a segment of a given force chain, provided the energy dissipated upon collision is sufficient to incite local particle rearrangements. The optimal piston velocity is 3.6 ms−1, under which the average ESC size reaches the minimum and the average yield stress and overall product of strength and elongation reach the maximum values of 144.6 MPa and 3.664 GPa%, respectively;

- (4)

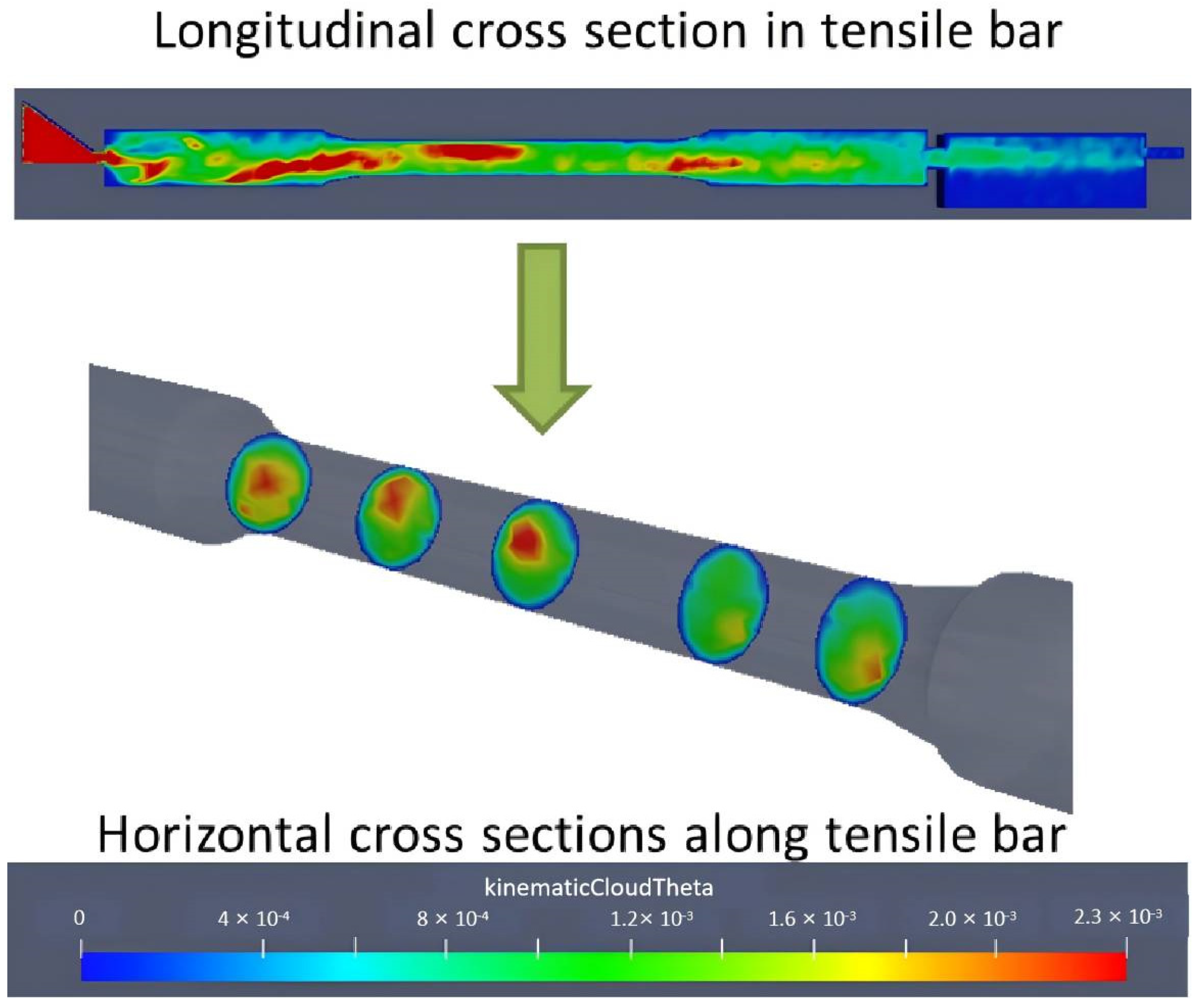

- Force chain buckling has been studied with sophisticated DEM-type simulations using OpenFOAM platform, which is able to accurately predict the evolution of dilatant shear bands in compacted granular assemblies. By applying the physics of granular materials to equiaxed solidifying alloys, unique opportunities are presented for process optimization and microstructure modeling once the further testing of other alloys has been conducted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaneuchi, T.; Nakano, H. Effect of J-value for internal quality of HPDC products at various casting alloys. Jpn. Die Cast. Congr. Trans. 2008, 131–136. [Google Scholar]

- Kaneuchi, T.; Motegi, K.; Imamura, T. Properties of castings produced by high vacuum die cast process. Jpn. Die Cast. Congr. Trans. 2004, 277–282. [Google Scholar]

- Yamada, Y.; Yoshii, H.; Mochizuki, S. Evaluation of J Factor and Leakage Quality for High Pressure Die Casting Applied to Closed-Deck Type Cylinder Block; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Koya, E.; Nakagawa, M.; Kitagawa, S.; Ishimoto, J.; Nakano, Y.; Ochiai, N. Research of Atomization Phenomena in HPDC-Step 1 Feature of Gas Porosity Dispersion and Photography of Atomized Flow; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Koya, E.; Nakagawa, M.; Kitagawa, S.; Ishimoto, J.; Nakano, Y.; Ochiai, N. Atomization in High-Pressure Die Casting-Step 2 Simulation of Atomized Flow of Molten Aluminum by LES-VOF Method; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018; pp. 1–10. [Google Scholar] [CrossRef]

- Otarawanna, S.; Gourlay, C.M.; Laukli, H.I.; Dahle, A.K. Agglomeration and bending of equiaxed crystals during solidification of hypoeutectic Al and Mg alloys. Acta Mater. 2010, 58, 261–271. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Babu, N.H.; Zhang, H.; Arumuganathar, S.; Fan, Z. Solidification behavior of intensively sheared hypoeutectic Al-Si alloy liquid. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 1117–1126. [Google Scholar] [CrossRef]

- Cao, H.; Wessén, M. Characteristics of microstructure and banded defects in die cast AM50 magnesium components. Int. J. Cast Met. Res. 2005, 18, 377–384. [Google Scholar] [CrossRef]

- Wu, M.; Li, X.; Guo, Z.; Xiong, S. Effects of process parameters on morphology and distribution of externally solidified crystals in microstructure of magnesium alloy die castings. China Foundry 2018, 15, 139–144. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; Xiong, S. Influence of melt flow on the formation of defect band in high pressre die casting of AZ91D magnesium alloy. Mater. Charact. 2017, 129, 344–352. [Google Scholar] [CrossRef]

- Gourlay, C.M.; Laukli, H.I.; Dahle, A.K. Defect band characteristics in Mg-Al and Al-Si high-pressure die castings. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2007, 38, 1833–1844. [Google Scholar] [CrossRef]

- Dahle, A.K.; StJohn, D.H. Rheological behaviour of the mushy zone and its effect on the formation of casting defects during solidification. Acta Mater. 1998, 47, 31–41. [Google Scholar] [CrossRef]

- Gourlay, C.M.; Meylan, B.; Dahle, A.K. Shear mechanisms at 0–50% solid during equiaxed dendritic solidification of an AZ91 magnesium alloy. Acta Mater. 2008, 56, 3403–3413. [Google Scholar] [CrossRef]

- Gourlay, C.M.; Dahle, A.K. Dilatant shear bands in solidifying metals. Nature 2007, 445, 70–73. [Google Scholar] [CrossRef] [PubMed]

- Otarawanna, S.; Gourlay, C.M.; Laukli, H.I.; Dahle, A.K. The thickness of defect bands in high-pressure die castings. Mater. Charact. 2009, 60, 1432–1441. [Google Scholar] [CrossRef]

- Gjestland, H.; Sannes, S.; Svalestuen, J.; Westengen, H. Optimizing the Magnesium Die Casting Process to Achieve Reliability in Automotive Applications; SAE Tech. Pap. Ser. SAE 2005-0; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Otarawanna, S.; Laukli, H.I.; Gourlay, C.M.; Dahle, A.K. Feeding mechanisms in high-pressure die castings. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 1836–1846. [Google Scholar] [CrossRef]

- Tordesillas, A.; Shi, J.; Tshaikiwsky, T. Stress–dilatancy and force chain evolution. Int. J. Numer. Anal. Meth. Geomech. 2011, 35, 264–292. [Google Scholar] [CrossRef]

- Tordesillas, A. Force chain buckling, unjamming transitions and shear banding in dense granular assemblies. Philos. Mag. 2007, 87, 4987–5016. [Google Scholar] [CrossRef]

- ASTM E8-04; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2010. Available online: https://www.astm.org/standards/e8 (accessed on 8 October 2024).

- Lordan, E.; Lazaro-Nebreda, J.; Zhang, Y.; Fan, Z. Effective Degassing for Reduced Variability in High-Pressure Die Casting Performance. JOM 2018, 71, 824–830. [Google Scholar] [CrossRef]

- Radjai, F.; Wolf, D.E.; Jean, M.; Moreau, J.J. Bimodal Character of Stress Transmission in Granular Packings. Phys. Rev. Lett. 1998, 80, 61. [Google Scholar] [CrossRef]

- Walker, D.M.; Vo, K.; Tordesillas, A. On Reynolds’ Dilatancy and Shear Band Evolution: A New Perspective. Int. J. Bifurc. Chaos 2013, 23, 1330034. [Google Scholar] [CrossRef]

- Oda, M.; Konishi, J.; Nemat-Nasser, S. Experimental micromechanical evaluation of the strength of granular materials: Effects of particle rolling. Stud. Appl. Mech. 1983, 7, 21–30. [Google Scholar] [CrossRef]

- Iwashita, K.; Oda, M. Micro-deformation mechanism of shear banding process based on modified distinct element method. Powder Technol. 2000, 109, 192–205. [Google Scholar] [CrossRef]

- Majmudar, T.S.; Behringer, R.P. Contact force measurements and stress-induced anisotropy in granular materials. Nature 2005, 435, 1079–1082. [Google Scholar] [CrossRef] [PubMed]

- Laukli, H.I.; Gourlay, C.M.; Dahle, A.K. Migration of crystals during the filling of semi-solid castings. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2005, 36, 805–818. [Google Scholar] [CrossRef]

- Andersson, H.I.; Zhao, L.; Barri, M. Torque-coupling and particle-turbulence interactions. J. Fluid Mech. 2012, 696, 319–329. [Google Scholar] [CrossRef]

- Bi, C.; Xiong, S.; Li, X.; Guo, Z. Development of a Fluid-Particle Model in Simulating the Motion of External Solidified Crystals and the Evolution of Defect Bands in High-Pressure Die Casting. Metall. Mater. Trans. B 2016, 47, 939–947. [Google Scholar] [CrossRef]

- Li, X.; Yu, W.; Wang, J.; Xiong, S. Influence of melt flow in the gating system on microstructure and mechanical properties of high pressure die casting AZ91D magnesium alloy. Mater. Sci. Eng. A 2018, 736, 219–227. [Google Scholar] [CrossRef]

- Dou, K.; Lordan, E.; Zhang, Y.; Jacot, A.; Fan, Z. A complete computer aided engineering (CAE) modelling and optimization of high pressure die casting (HPDC) process. J. Manuf. Process. 2020, 60, 435–446. [Google Scholar] [CrossRef]

- Dou, K.; Lordan, E.; Zhang, Y.; Jacot, A.; Fan, Z. A novel approach to optimize mechanical properties for aluminium alloy in High pressure die casting (HPDC) process combining experiment and modelling. J. Mater. Process. Technol. 2021, 296, 117193. [Google Scholar] [CrossRef]

- Graco Inc. Atomization Concept and Theory; Graco Inc.: Minneapolis, MN, USA, 1995. [Google Scholar]

| Filling Velocity (ms−1) | Average ESC Φ (µm) | Average in Cavity Grain Φ (µm) |

|---|---|---|

| 2.2 | 41 | 8.1 |

| 3.6 | 27 | 8.1 |

| 4.2 | 33 | 7.3 |

| Average | ||||

|---|---|---|---|---|

| Casting Parameters | YS (MPa) | UTS (MPa) | Elongation [%] | Product of Strength and Elongation (GPa%) |

| 0.4–0.6, 2.2 m/s | 143.0 | 288.5 | 11.5 | 3.318 |

| 0.4–0.6, 3.6 m/s | 144.6 | 288.5 | 12.7 | 3.664 |

| 0.4–0.6, 4.2 m/s | 143.7 | 292.8 | 11.3 | 3.309 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Lordan, E.; Zhang, Y.; Fan, Z.; Wang, W.; Dou, K. The Evolution of Dilatant Shear Bands in High-Pressure Die Casting for Al-Si Alloys. Materials 2024, 17, 5001. https://doi.org/10.3390/ma17205001

Lu J, Lordan E, Zhang Y, Fan Z, Wang W, Dou K. The Evolution of Dilatant Shear Bands in High-Pressure Die Casting for Al-Si Alloys. Materials. 2024; 17(20):5001. https://doi.org/10.3390/ma17205001

Chicago/Turabian StyleLu, Jingzhou, Ewan Lordan, Yijie Zhang, Zhongyun Fan, Wanlin Wang, and Kun Dou. 2024. "The Evolution of Dilatant Shear Bands in High-Pressure Die Casting for Al-Si Alloys" Materials 17, no. 20: 5001. https://doi.org/10.3390/ma17205001

APA StyleLu, J., Lordan, E., Zhang, Y., Fan, Z., Wang, W., & Dou, K. (2024). The Evolution of Dilatant Shear Bands in High-Pressure Die Casting for Al-Si Alloys. Materials, 17(20), 5001. https://doi.org/10.3390/ma17205001