Modified Biomass-Reinforced Polylactic Acid Composites

Abstract

1. Introduction

2. PLA

2.1. Application of PLA

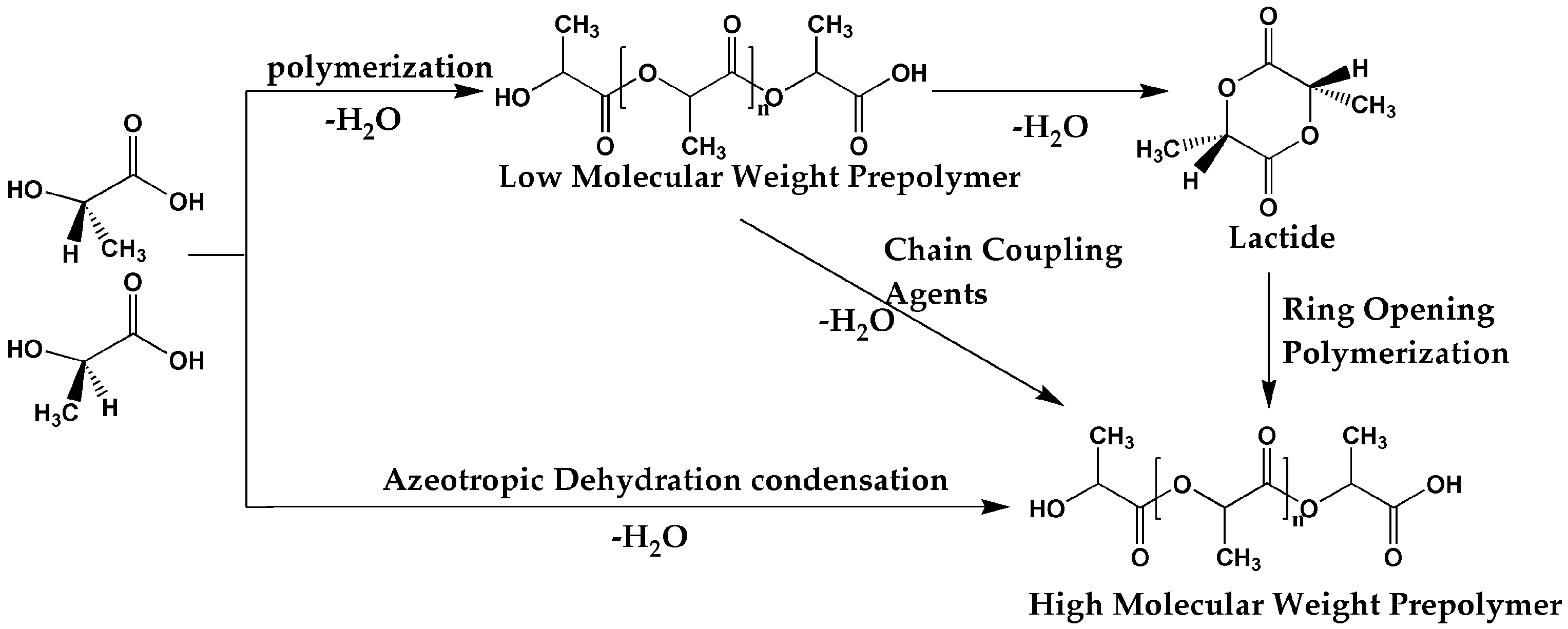

2.2. Synthesis of PLA

2.3. Enhancement of PLA

3. Enhancement of PLA with Modified Biomass

3.1. Enhancement of PLA with Modified Cellulose

3.1.1. Mechanical Properties

3.1.2. Barrier Properties and Antimicrobial Properties

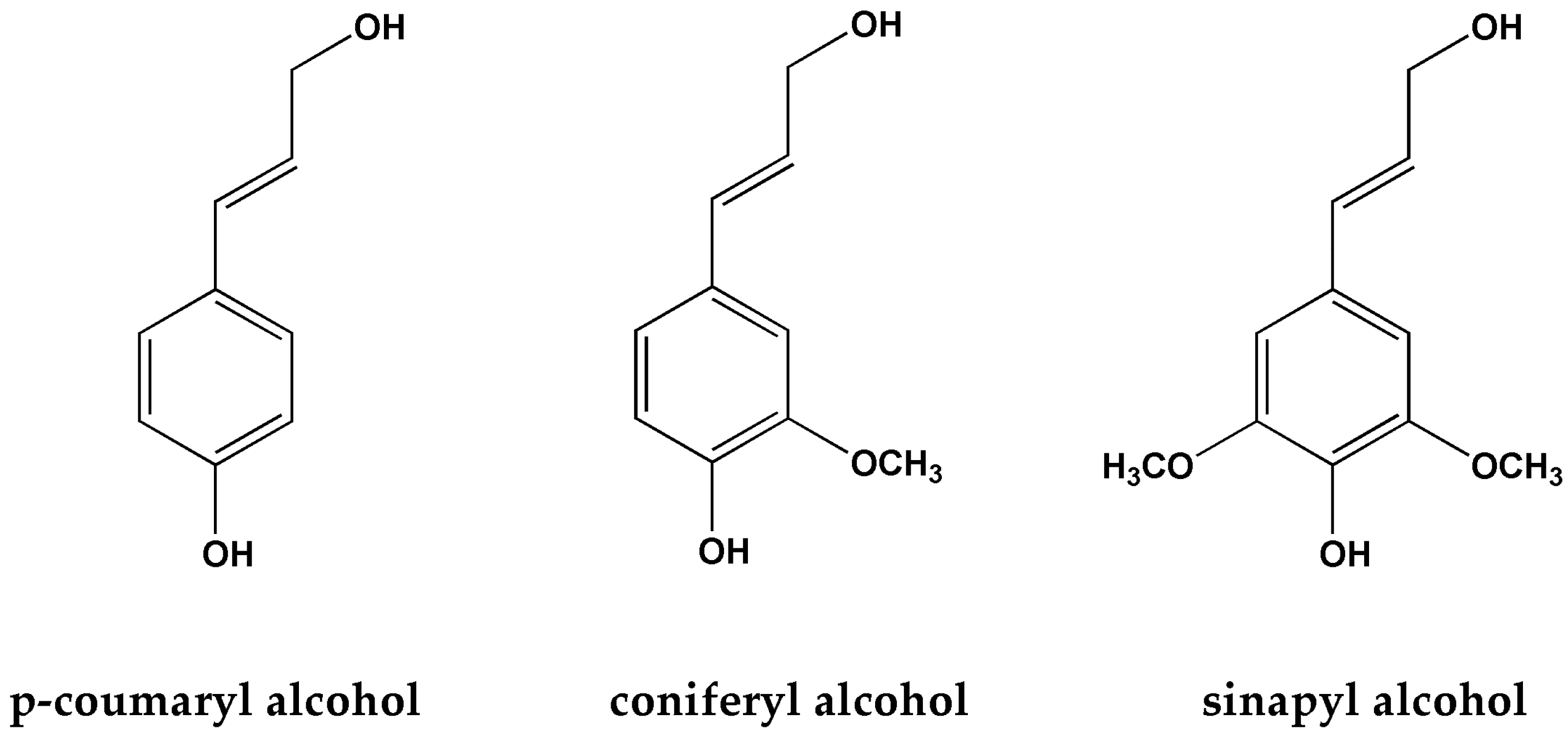

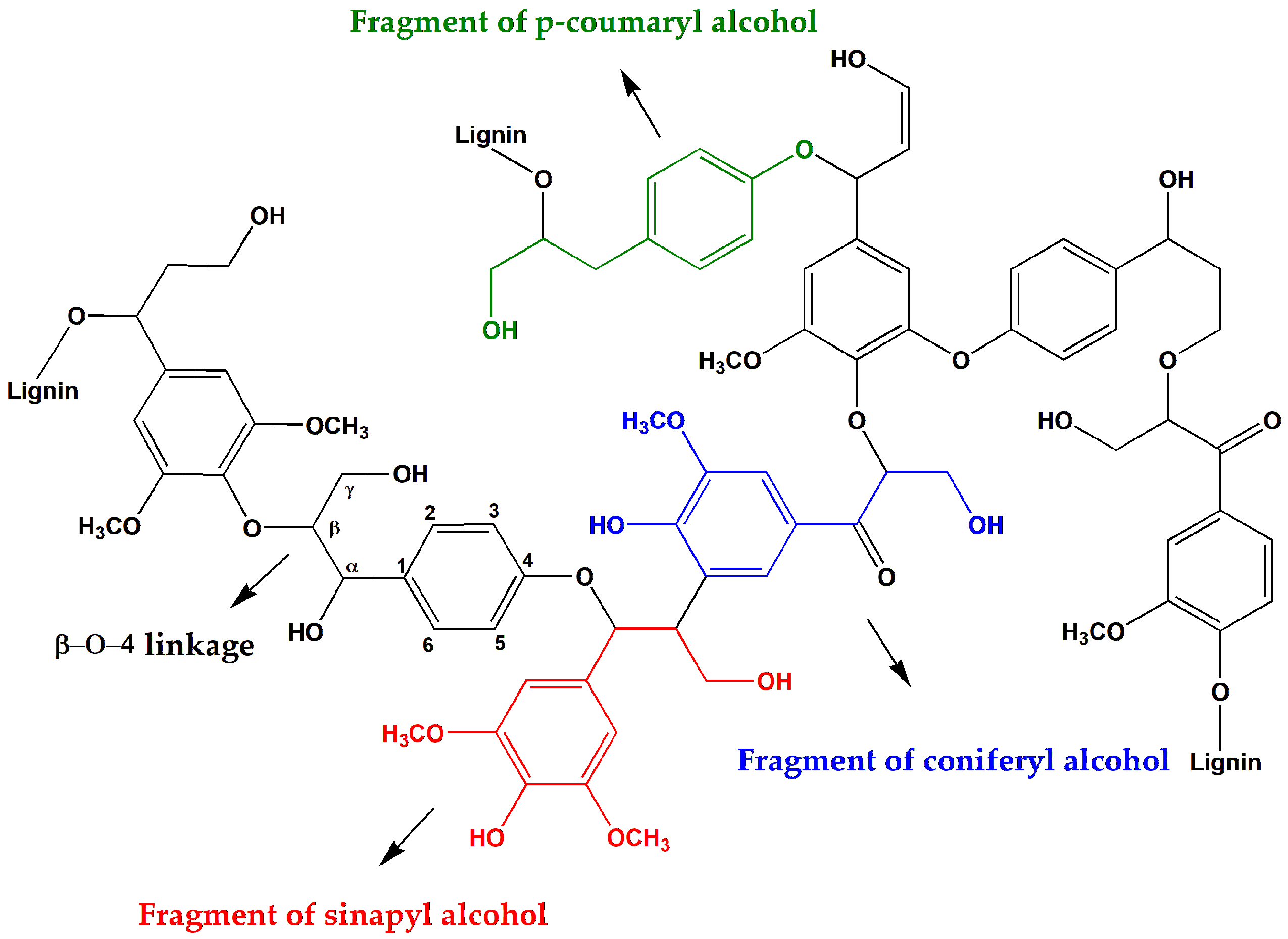

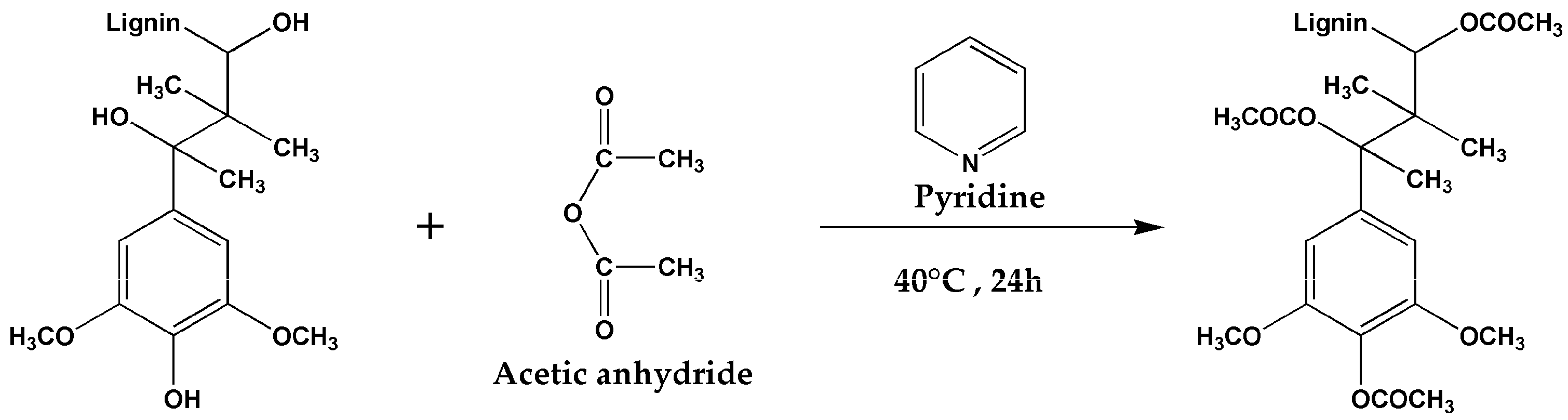

3.2. Enhancement of PLA with Modified Lignin

3.2.1. Mechanical Properties

3.2.2. Thermal Stability

3.2.3. Barrier Properties, UV Protection, and Antimicrobial Properties

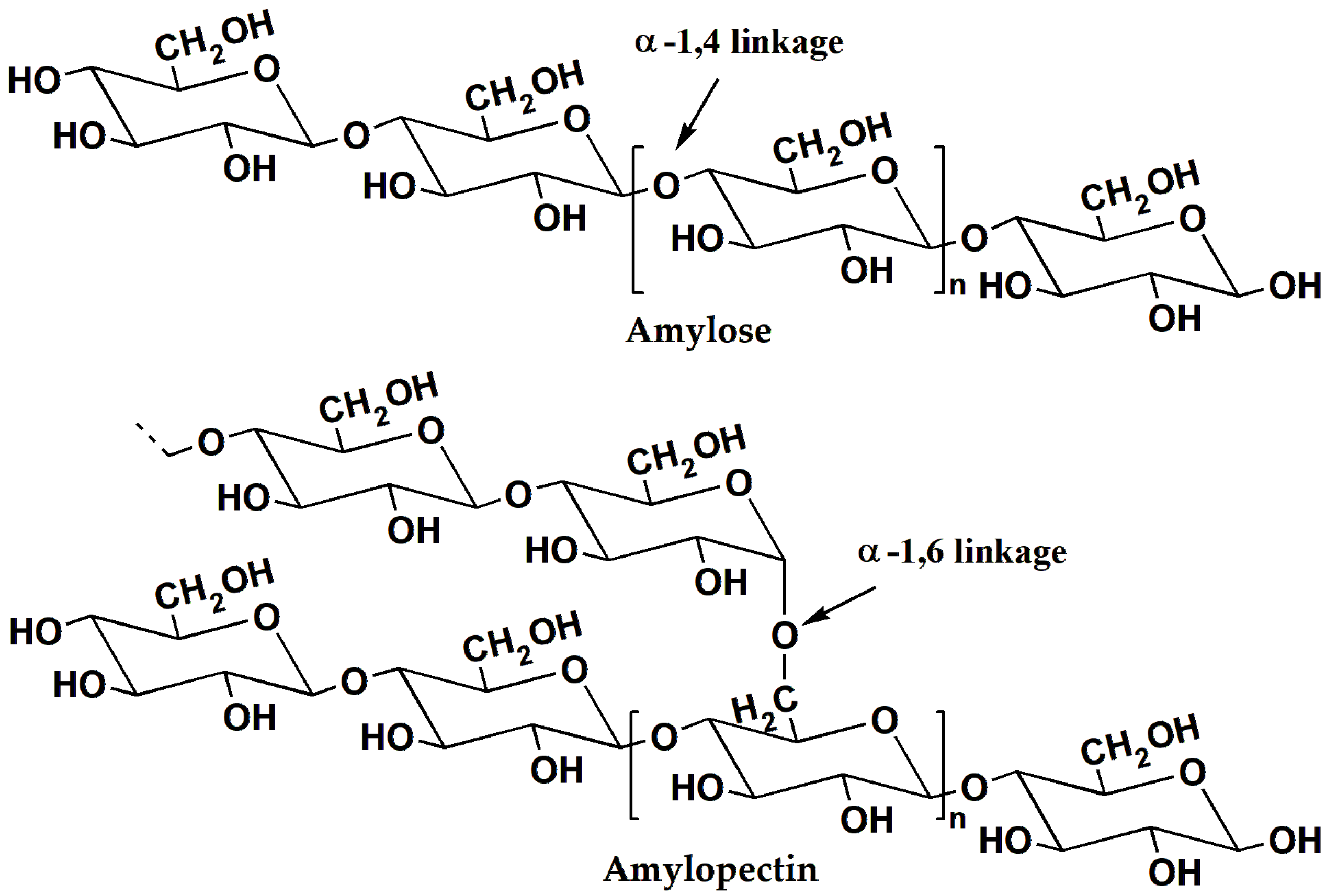

3.3. Enhancement of PLA with Modified Starch

3.3.1. Mechanical Properties

3.3.2. Barrier Properties

4. Biomass Modification Methods

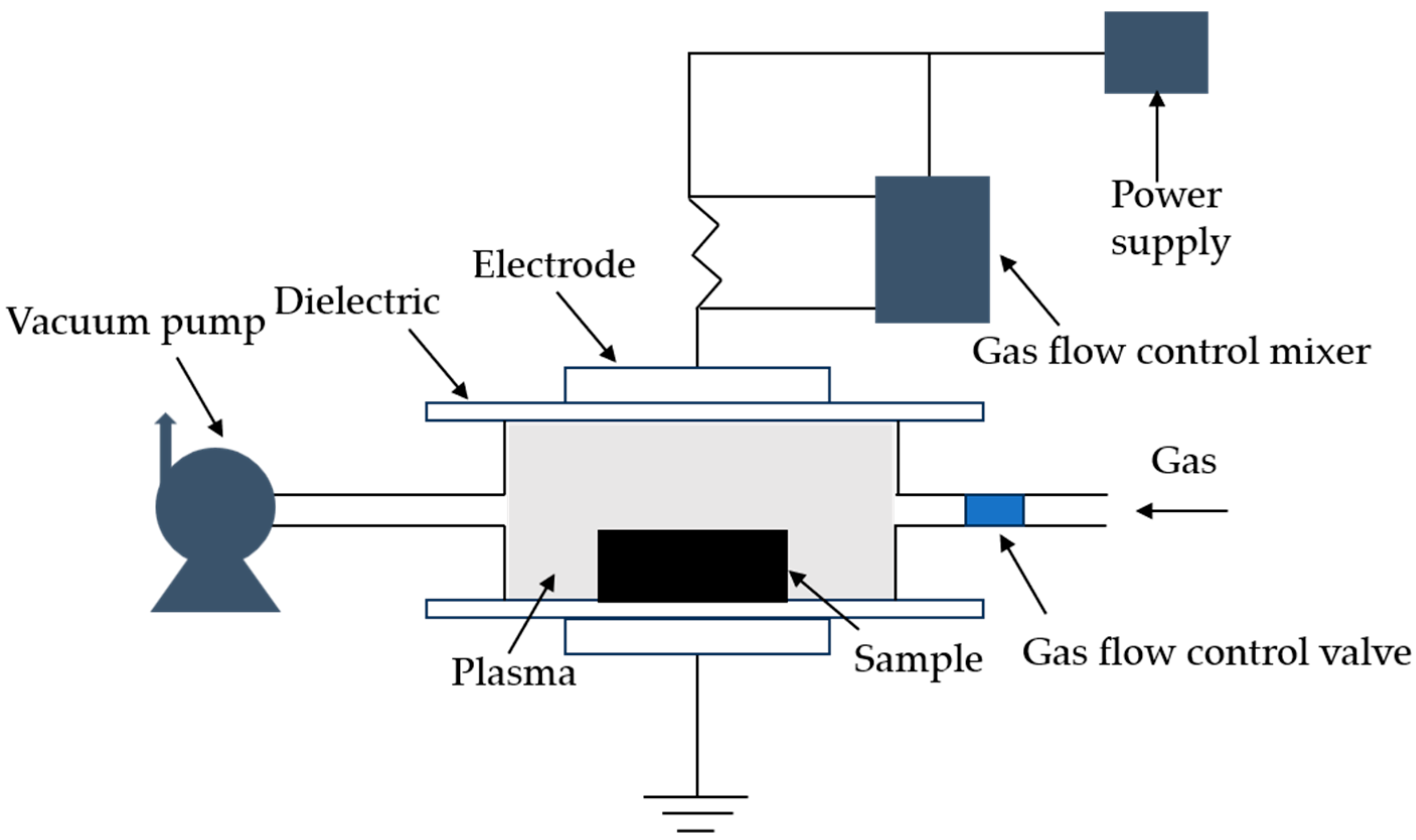

4.1. Plasma Modification

4.2. Mechanisms of Plasma Treatment on Biomass

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties-From Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, J.; Liu, T.; Xi, L.; Sai, T.; Ran, S.; Fang, Z.; Huo, S.; Song, P. A molecularly engineered bioderived polyphosphate for enhanced flame retardant, UV-blocking and mechanical properties of poly(lactic acid). Chem. Eng. J. 2021, 411, 128493. [Google Scholar] [CrossRef]

- Zhou, L.; Ke, K.; Yang, M.-B.; Yang, W. Recent progress on chemical modification of cellulose for high mechanical-performance Poly(lactic acid)/Cellulose composite: A review. Compos. Commun. 2021, 23, 100548. [Google Scholar] [CrossRef]

- Zhang, R.; Lan, W.; Ji, T.; Sameen, D.E.; Ahmed, S.; Qin, W.; Liu, Y. Development of polylactic acid/ZnO composite membranes prepared by ultrasonication and electrospinning for food packaging. LWT 2021, 135, 110072. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose Reinforced Thermoplastic Starch (TPS), Polylactic Acid (PLA), and Polybutylene Succinate (PBS) for Food Packaging Applications. Front. Chem. 2020, 8, 213. [Google Scholar] [CrossRef]

- Saini, P.; Arora, M.; Kumar, M. Poly(lactic acid) blends in biomedical applications. Adv. Drug Deliv. Rev. 2016, 107, 47–59. [Google Scholar] [CrossRef]

- Arul Jeya Kumar, A.; Prakash, M. Thermal properties of basalt/Cissus quadrangularis hybrid fiber reinforced polylactic acid biomedical composites. J. Therm. Anal. Calorim. 2019, 141, 717–725. [Google Scholar] [CrossRef]

- Dadras Chomachayi, M.; Blanchet, P.; Hussain, A. Development of bio-based membranes for building envelope applications from poly(lactic acid) and cellulose microfibers. BioResources 2022, 17, 5707–5727. [Google Scholar] [CrossRef]

- Singhvi, M.S.; Zinjarde, S.S.; Gokhale, D.V. Polylactic acid: Synthesis and biomedical applications. J. Appl. Microbiol. 2019, 127, 1612–1626. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.C. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef] [PubMed]

- Montané, X.; Montornes, J.M.; Nogalska, A.; Olkiewicz, M.; Giamberini, M.; Garcia-Valls, R.; Badia-Fabregat, M.; Jubany, I.; Tylkowski, B. Synthesis and synthetic mechanism of Polylactic acid. Phys. Sci. Rev. 2020, 5, 20190102. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, X.; Wu, J.; Zhou, T.; Nguyen, T.T.; Wang, Y. Biodegradable Polylactic Acid and Its Composites: Characteristics, Processing, and Sustainable Applications in Sports. Polymers 2023, 15, 3096. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Fortunati, E.; Peltzer, M.; Armentano, I.; Jiménez, A.; Kenny, J.M. Combined effects of cellulose nanocrystals and silver nanoparticles on the barrier and migration properties of PLA nano-biocomposites. J. Food Eng. 2013, 118, 117–124. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Li, Y.; Fu, K.; Tong, X.; Cao, B.; Chen, B. 3D printing of cellulose nanofiber/polylactic acid composites via an efficient dispersion method. Compos. Commun. 2023, 43, 101731. [Google Scholar] [CrossRef]

- Kothavade, P.A.; Yadav, P.; Nidhankar, A.D.; Torris, A.; Pol, H.; Kafi, A.; Bateman, S.; Sukumaran, S.B.; Shanmuganathan, K. Luminescent 3D printed poly(lactic acid) nanocomposites with enhanced mechanical properties. Polym. Eng. Sci. 2023, 63, 2059–2072. [Google Scholar] [CrossRef]

- Nonato, R.C.; Mei, L.H.I.; Bonse, B.C.; Leal, C.V.; Levy, C.E.; Oliveira, F.A.; Delarmelina, C.; Duarte, M.C.T.; Morales, A.R. Nanocomposites of PLA/ZnO nanofibers for medical applications: Antimicrobial effect, thermal, and mechanical behavior under cyclic stress. Polym. Eng. Sci. 2022, 62, 1147–1155. [Google Scholar] [CrossRef]

- More, N.; Avhad, M.; Utekar, S.; More, A. Polylactic acid (PLA) membrane—Significance, synthesis, and applications: A review. Polym. Bull. 2022, 80, 1117–1153. [Google Scholar] [CrossRef]

- Li, G.; Zhao, M.; Xu, F.; Yang, B.; Li, X.; Meng, X.; Teng, L.; Sun, F.; Li, Y. Synthesis and Biological Application of Polylactic Acid. Molecules 2020, 25, 5023. [Google Scholar] [CrossRef]

- Ramezani Dana, H.; Ebrahimi, F. Synthesis, properties, and applications of polylactic acid-based polymers. Polym. Eng. Sci. 2022, 63, 22–43. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Yang, H.W.; Deri, F.; Ko, Y.G. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 435–455. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic acid blends: The future of green, light and tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Wang, D. Tailoring crystallization: Towards high-performance poly(lactic acid). Adv. Mater. 2014, 26, 6905–6911. [Google Scholar] [CrossRef] [PubMed]

- Elsawy, M.A.; Kim, K.-H.; Park, J.-W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic Acid: Production, Applications, Nanocomposites, and Release Studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Imre, B.; Pukánszky, B. Compatibilization in bio-based and biodegradable polymer blends. Eur. Polym. J. 2013, 49, 1215–1233. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Al-Othman, O. An Overview on Polylactic Acid, its Cellulosic Composites and Applications. Curr. Org. Synth. 2017, 14, 156–170. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Luo, S.H.; Xiao, Y.; Lin, J.Y.; Chen, Z.H.; Lin, S.T.; Wang, Z.Y. Preparation, characterization and application of maleic anhydride-modified polylactic acid macromonomer based on direct melt polymerization. Mater. Today Chem. 2022, 25, 100986. [Google Scholar] [CrossRef]

- Wang, Z.-Y.; Zhao, Y.-M.; Wang, F. Syntheses of poly(lactic acid)-poly(ethylene glycol) serial biodegradable polymer materials via direct melt polycondensation and their characterization. J. Appl. Polym. Sci. 2006, 102, 577–587. [Google Scholar] [CrossRef]

- Luo, S.-H.; Wang, Q.-F.; Xiong, J.-F.; Wang, Z.-Y. Synthesis of biodegradable material poly(lactic acid-co-sorbitol) via direct melt polycondensation and its reaction mechanism. J. Polym. Res. 2012, 19, 9962. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing Polylactic acid (PLA). Polímeros 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Hazer, B. The Properties of PLA/Oxidized Soybean Oil Polymer Blends. J. Polym. Environ. 2014, 22, 200–208. [Google Scholar] [CrossRef]

- Ordoñez, R.; Atarés, L.; Chiralt, A. Properties of PLA films with cinnamic acid: Effect of the processing method. Food Bioprod. Process. 2022, 133, 25–33. [Google Scholar] [CrossRef]

- Thuy, N.T.; Nam, B.X.; Duc, V.M. Study to improve the properties of polylactic acid by epoxidized crude rubber seed oil. Vietnam J. Chem. 2019, 57, 735–740. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super tough poly(lactic acid) blends: A comprehensive review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef]

- Wu, J.-H.; Kuo, M.C.; Chen, C.-W.; Chen, C.-W.; Kuan, P.-H.; Wang, Y.-J.; Jhang, S.-Y. Crystallization behavior of α-cellulose short-fiber reinforced poly(lactic acid) composites. J. Appl. Polym. Sci. 2013, 129, 3007–3018. [Google Scholar] [CrossRef]

- Xu, W.; Pranovich, A.; Uppstu, P.; Wang, X.; Kronlund, D.; Hemming, J.; Oblom, H.; Moritz, N.; Preis, M.; Sandler, N.; et al. Novel biorenewable composite of wood polysaccharide and polylactic acid for three dimensional printing. Carbohydr. Polym. 2018, 187, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jia, Y.; Liu, Z.; Miao, J. Influence of the Lignin Content on the Properties of Poly(Lactic Acid)/lignin-Containing Cellulose Nanofibrils Composite Films. Polymers 2018, 10, 1013. [Google Scholar] [CrossRef]

- Maskur, M.H.; Wan Nawawi, W.M.F.; Ali, F.; Alkhatib, M.F.R. Crustacean chitin nanomaterial as reinforcement for bio-based polymer. Adv. Mater. Process. Technol. 2020, 8, 96–107. [Google Scholar] [CrossRef]

- Takkalkar, P.; Griffin, G.; Kao, N. Enhanced Mechanical and Barrier Performance of Poly (Lactic Acid) Based Nanocomposites Using Surface Acetylated Starch Nanocrystals. J. Polym. Environ. 2019, 27, 2078–2088. [Google Scholar] [CrossRef]

- Cai, J.; He, Y.; Yu, X.; Banks, S.W.; Yang, Y.; Zhang, X.; Yu, Y.; Liu, R.; Bridgwater, A.V. Review of physicochemical properties and analytical characterization of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2017, 76, 309–322. [Google Scholar] [CrossRef]

- Yoo, C.G.; Meng, X.; Pu, Y.; Ragauskas, A.J. The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment strategies: A comprehensive review. Bioresour. Technol. 2020, 301, 122784. [Google Scholar] [CrossRef] [PubMed]

- Tanpichai, S.; Boonmahitthisud, A.; Soykeabkaew, N.; Ongthip, L. Review of the recent developments in all-cellulose nanocomposites: Properties and applications. Carbohydr. Polym. 2022, 286, 119192. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Jadhav, H.; Jadhav, A.; Takkalkar, P.; Hossain, N.; Nizammudin, S.; Zahoor, M.; Jamal, M.; Mubarak, N.M.; Griffin, G.; Kao, N. Potential of polylactide based nanocomposites-nanopolysaccharide filler for reinforcement purpose: A comprehensive review. J. Polym. Res. 2020, 27, 330. [Google Scholar] [CrossRef]

- Seddiqi, H.; Oliaei, E.; Honarkar, H.; Jin, J.; Geonzon, L.C.; Bacabac, R.G.; Klein-Nulend, J. Cellulose and its derivatives: Towards biomedical applications. Cellulose 2021, 28, 1893–1931. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M.; Ismail, H. Tensile and morphological properties of nanocrystalline cellulose and nanofibrillated cellulose reinforcedPLAbionanocomposites: A review. Polym. Eng. Sci. 2020, 61, 22–38. [Google Scholar] [CrossRef]

- De Amorim, J.D.P.; de Souza, K.C.; Duarte, C.R.; da Silva Duarte, I.; de Assis Sales Ribeiro, F.; Silva, G.S.; de Farias, P.M.A.; Stingl, A.; Costa, A.F.S.; Vinhas, G.M.; et al. Plant and bacterial nanocellulose: Production, properties and applications in medicine, food, cosmetics, electronics and engineering. A review. Environ. Chem. Lett. 2020, 18, 851–869. [Google Scholar] [CrossRef]

- Tafete, G.A.; Abera, M.K.; Thothadri, G. Review on nanocellulose-based materials for supercapacitors applications. J. Energy Storage 2022, 48, 103938. [Google Scholar] [CrossRef]

- Bangar, S.P.; Harussani, M.M.; Ilyas, R.A.; Ashogbon, A.O.; Singh, A.; Trif, M.; Jafari, S.M. Surface modifications of cellulose nanocrystals: Processes, properties, and applications. Food Hydrocoll. 2022, 130, 107689. [Google Scholar] [CrossRef]

- Guo, R.; Zhang, L.; Lu, Y.; Zhang, X.; Yang, D. Research progress of nanocellulose for electrochemical energy storage: A review. J. Energy Chem. 2020, 51, 342–361. [Google Scholar] [CrossRef]

- Niu, W.; Guo, Y.; Huang, W.; Song, L.; Xiao, Z.; Xie, Y.; Wang, Y. Aliphatic chains grafted cellulose nanocrystals with core-corona structures for efficient toughening of PLA composites. Carbohydr. Polym. 2022, 285, 119200. [Google Scholar] [CrossRef] [PubMed]

- Long, S.; Zhong, L.; Lin, X.; Chang, X.; Wu, F.; Wu, R.; Xie, F. Preparation of formyl cellulose and its enhancement effect on the mechanical and barrier properties of polylactic acid films. Int. J. Biol. Macromol. 2021, 172, 82–92. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zheng, D.; Chen, X.; Yao, W.; Wang, Y.; Zheng, Z.; Tan, H.; Zhang, Y. Mussel-inspired polydopamine-modified cellulose nanocrystal fillers for the preparation of reinforced and UV-shielding poly (lactic acid) films. J. Mater. Res. Technol. 2022, 19, 4350–4359. [Google Scholar] [CrossRef]

- Huang, S.; Zou, S.; Wang, Y. Construction of compostable packaging with antibacterial property and improved performance using sprayed coatings of modified cellulose nanocrystals. Carbohydr. Polym. 2023, 305, 120539. [Google Scholar] [CrossRef]

- Lafia-Araga, R.A.; Sabo, R.; Nabinejad, O.; Matuana, L.; Stark, N. Influence of Lactic Acid Surface Modification of Cellulose Nanofibrils on the Properties of Cellulose Nanofibril Films and Cellulose Nanofibril-Poly(lactic acid) Composites. Biomolecules 2021, 11, 1346. [Google Scholar] [CrossRef]

- Nandhini, R.; Sivaprakash, B.; Rajamohan, N.; Vo, D.-V.N. Lignin and polylactic acid for the production of bioplastics and valuable chemicals. Environ. Chem. Lett. 2022, 21, 403–427. [Google Scholar] [CrossRef]

- Yang, J.; Ching, Y.C.; Chuah, C.H. Applications of Lignocellulosic Fibers and Lignin in Bioplastics: A Review. Polymers 2019, 11, 751. [Google Scholar] [CrossRef]

- Liu, J.; Sun, L.; Xu, W.; Wang, Q.; Yu, S.; Sun, J. Current advances and future perspectives of 3D printing natural-derived biopolymers. Carbohydr. Polym. 2019, 207, 297–316. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, R.; Kumar, A.; Singh, S.; Sharma, K. Recent advances and future perspectives of lignin biopolymers. J. Polym. Res. 2022, 29, 222. [Google Scholar] [CrossRef]

- Jablonský, M.; Kočiš, J.; Ház, A.; Sládková, A.; Šurina, I. The approach the isolation of lignins and its characterization. In Proceedings of the 5th International Scientific Conference Renewable Energy Sources, High Tatras, Slovakia, 20–22 May 2014. [Google Scholar]

- Ridho, M.R.; Agustiany, E.A.; Rahmi Dn, M.; Madyaratri, E.W.; Ghozali, M.; Restu, W.K.; Falah, F.; Rahandi Lubis, M.A.; Syamani, F.A.; Nurhamiyah, Y.; et al. Lignin as Green Filler in Polymer Composites: Development Methods, Characteristics, and Potential Applications. Adv. Mater. Sci. Eng. 2022, 2022, 1363481. [Google Scholar] [CrossRef]

- Esakkimuthu, E.S.; DeVallance, D.; Pylypchuk, I.; Moreno, A.; Sipponen, M.H. Multifunctional lignin-poly (lactic acid) biocomposites for packaging applications. Front. Bioeng. Biotechnol. 2022, 10, 1025076. [Google Scholar] [CrossRef]

- Makri, S.P.; Xanthopoulou, E.; Klonos, P.A.; Grigoropoulos, A.; Kyritsis, A.; Tsachouridis, K.; Anastasiou, A.; Deligkiozi, I.; Nikolaidis, N.; Bikiaris, D.N. Effect of Micro- and Nano-Lignin on the Thermal, Mechanical, and Antioxidant Properties of Biobased PLA-Lignin Composite Films. Polymers 2022, 14, 5274. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, L.; Zhao, X.; Zhai, S.; Wang, Q.; Li, C.; Zhang, X. Utilization of lignin upon successive fractionation and esterification in polylactic acid (PLA)/lignin biocomposite. Int. J. Biol. Macromol. 2022, 203, 49–57. [Google Scholar] [CrossRef]

- Gordobil, O.; Egüés, I.; Llano-Ponte, R.; Labidi, J. Physicochemical properties of PLA lignin blends. Polym. Degrad. Stab. 2014, 108, 330–338. [Google Scholar] [CrossRef]

- Cazacu, G.; Darie-Nita, R.N.; Chirila, O.; Totolin, M.; Asandulesa, M.; Ciolacu, D.E.; Ludwiczak, J.; Vasile, C. Environmentally Friendly Polylactic Acid/Modified Lignosulfonate Biocomposites. J. Polym. Environ. 2016, 25, 884–902. [Google Scholar] [CrossRef]

- Boarino, A.; Schreier, A.; Leterrier, Y.; Klok, H.A. Uniformly Dispersed Poly(lactic acid)-Grafted Lignin Nanoparticles Enhance Antioxidant Activity and UV-Barrier Properties of Poly(lactic acid) Packaging Films. ACS Appl. Polym. Mater. 2022, 4, 4808–4817. [Google Scholar] [CrossRef] [PubMed]

- Bužarovska, A.; Blazevska-Gilev, J.; Pérez-Martnez, B.T.; Balahura, L.R.; Pircalabioru, G.G.; Dinescu, S.; Costache, M. Poly(l-lactic acid)/alkali lignin composites: Properties, biocompatibility, cytotoxicity and antimicrobial behavior. J. Mater. Sci. 2021, 56, 13785–13800. [Google Scholar] [CrossRef]

- Kim, Y.; Suhr, J.; Seo, H.-W.; Sun, H.; Kim, S.; Park, I.-K.; Kim, S.-H.; Lee, Y.; Kim, K.-J.; Nam, J.-D. All Biomass and UV Protective Composite Composed of Compatibilized Lignin and Poly (Lactic-acid). Sci. Rep. 2017, 7, 43596. [Google Scholar] [CrossRef]

- Muller, J.; Gonzalez-Martinez, C.; Chiralt, A. Combination of Poly(lactic) Acid and Starch for Biodegradable Food Packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef]

- Martinez Villadiego, K.; Arias Tapia, M.J.; Useche, J.; Escobar Macías, D. Thermoplastic Starch (TPS)/Polylactic Acid (PLA) Blending Methodologies: A Review. J. Polym. Environ. 2021, 30, 75–91. [Google Scholar] [CrossRef]

- Jariyasakoolroj, P.; Chirachanchai, S. Silane modified starch for compatible reactive blend with poly(lactic acid). Carbohydr. Polym. 2014, 106, 255–263. [Google Scholar] [CrossRef]

- Xiong, Z.; Zhang, L.; Ma, S.; Yang, Y.; Zhang, C.; Tang, Z.; Zhu, J. Effect of castor oil enrichment layer produced by reaction on the properties of PLA/HDI-g-starch blends. Carbohydr. Polym. 2013, 94, 235–243. [Google Scholar] [CrossRef]

- Xiong, Z.; Ma, S.; Fan, L.; Tang, Z.; Zhang, R.; Na, H.; Zhu, J. Surface hydrophobic modification of starch with bio-based epoxy resins to fabricate high-performance polylactide composite materials. Compos. Sci. Technol. 2014, 94, 16–22. [Google Scholar] [CrossRef]

- Kulkarni, A.; Narayan, R. Effects of Modified Thermoplastic Starch on Crystallization Kinetics and Barrier Properties of PLA. Polymers 2021, 13, 4125. [Google Scholar] [CrossRef]

- Xu, H.; Xie, L.; Wu, D.; Hakkarainen, M. Immobilized Graphene Oxide Nanosheets as Thin but Strong Nanointerfaces in Biocomposites. ACS Sustain. Chem. Eng. 2016, 4, 2211–2222. [Google Scholar] [CrossRef]

- Ranjha, M.M.A.N.; Shafique, B.; Aadil, R.M.; Manzoor, M.F.; Cheng, J.-H. Modification in cellulose films through ascent cold plasma treatment and polymerization for food products packaging. Trends Food Sci. Technol. 2023, 134, 162–176. [Google Scholar] [CrossRef]

- Lenfeld, P.; Brdlik, P.; Boruvka, M.; Behalek, L.; Habr, J. Effect of Radiation Crosslinking and Surface Modification of Cellulose Fibers on Properties and Characterization of Biopolymer Composites. Polymers 2020, 12, 3006. [Google Scholar] [CrossRef]

- Jang, J.Y.; Jeong, T.K.; Oh, H.J.; Youn, J.R.; Song, Y.S. Thermal stability and flammability of coconut fiber reinforced poly(lactic acid) composites. Compos. Part B Eng. 2012, 43, 2434–2438. [Google Scholar] [CrossRef]

- Siró, I.; Kusano, Y.; Norrman, K.; Goutianos, S.; Plackett, D. Surface modification of nanofibrillated cellulose films by atmospheric pressure dielectric barrier discharge. J. Adhes. Sci. Technol. 2013, 27, 294–308. [Google Scholar] [CrossRef]

- Pereira, G.N.; Cesca, K.; Vieira Cubas, A.L.; de Oliveira, D. Use of non-thermal plasma in lignocellulosic materials: A smart alternative. Trends Food Sci. Technol. 2021, 109, 365–373. [Google Scholar] [CrossRef]

- Dhar, P.; Tarafder, D.; Kumar, A.; Katiyar, V. Effect of cellulose nanocrystal polymorphs on mechanical, barrier and thermal properties of poly(lactic acid) based bionanocomposites. RSC Adv. 2015, 5, 60426–60440. [Google Scholar] [CrossRef]

- Pornbencha, K.; Sringam, S.; Piyanirund, S.; Seubsai, A.; Prapainainar, P.; Niumnuy, C.; Roddecha, S.; Dittanet, P. Functionalization of cellulose nanocrystals extracted from pineapple leaves as a UV-absorbing agent in poly(lactic acid). RSC Adv. 2023, 13, 15311–15321. [Google Scholar] [CrossRef]

- Li, L.; Bao, R.Y.; Gao, T.; Liu, Z.Y.; Xie, B.H.; Yang, M.B.; Yang, W. Dopamine-induced functionalization of cellulose nanocrystals with polyethylene glycol towards poly((L)-lactic acid) bionanocomposites for green packaging. Carbohydr. Polym. 2019, 203, 275–284. [Google Scholar] [CrossRef]

| Modification Method | Treatment or Added Material | Effect | Ref. |

|---|---|---|---|

| Copolymerization | PLAM: lactic acid (LA) and maleic anhydride (MAH) | Tg decreased to 2.3 °C and increase in flexibility Tm decreased from 120 °C to 96.7 °C | [30] |

| PLEG: lactic acid (LA) and polyethylene glycol (PEG) | Tg decreased to 20.7–33.6 °C and increase in flexibility Improving hydrophilicity, and the contact angle is 59.9°–68.7° | [31] | |

| P(LA-co-SB): lactic acid (LA) and sorbitol (SB) | Decrease in crystallinity and Tg decreased to 30–49 °C | [32] | |

| Plasticization | Triethyl citrate (TEC) Acetyl tributyl citrate (ATBC) | Tg decreased to 10.29 °C and 12.21 °C Decrease in storage modulus and increase in flexibility and mobility Decrease in Tm and thermal stability | [35] |

| Oxidized soya oil polymer (PSy-ox) | Increasing the elongation by 10 times Tg decreased to 17–20 °C and increase in plasticity Decrease in tensile strength | [36] | |

| Cinnamic acid (CA) | Thermal resistance is improved, decomposition temperature is increased by more than 40 °C Decrease in Tg and increase in plasticity Improving the mechanical properties and reducing the elastic modulus Increase in the water barrier properties and oxygen barrier properties | [37] | |

| Epoxidized crude rubber seed oil (EcRSO) | Improvement of 815% in elongation at break and 1370% in tensile toughness Improving the thermal stability, and the initial weight loss temperature is increased by 50.15 °C | [38] | |

| Blending | PLA/α-Cellulose | Improving the elongation at break and impact strength Increase in crystallinity | [40] |

| PLA/Lignin-containing cellulose nanofibrils (LCNFs) | Improving the tensile strength by 37% and tensile modulus by 61.1% Increase in the thermal stability Tg decreased to 52.6 °C and increase in flexibility | [42] | |

| PLA/Chitin | Improvement of 275% in tensile strength and 13% in tensile modulus | [43] | |

| PLA/Starch | Increase in the oxygen barrier properties Increase in tensile strength and Young’s modulus | [44] |

| NC Type | Diameter (nm) | Length [55] (um) | Shape | Source Material | Synthesis Method |

|---|---|---|---|---|---|

| CNC | 4–70 | 0.05–0.5 | Acicular, short rodlike | Wood, cotton, etc. | Acid hydrolysis |

| CNF | 5–100 | 0.5–2 | Filiform, mesh | Wood, potato tubers, etc. | Mechanical |

| BC | 20–100 | >1 | Ribbon | Glucose, ethanol, etc. | Microbial reaction |

| Matrix | Filler | Mechanical Properties (Pristine Matrix: 100%) | Ref. | ||

|---|---|---|---|---|---|

| Tensile Strength | Elongation at Break | Young’s Modulus | |||

| PLA (7032D) | EOCNC (1%) | <75% | 675% | - | [56] |

| PLA (Revode 190) | FC (1%) | 148.6% | <70% | 446% | [57] |

| PLA (4032D) | CNC-PDA (1%) | 117.3% | 133.0% | <100% | [58] |

| Type of Lignin | Mn(g/mol) | Glass Transition Temperature (°C) | Separation Process |

|---|---|---|---|

| Kraft lignin [62] | 1000–3000 | 100–150 | Na2S, NaOH |

| Lignosulfonates [65] | 15,000–50,000 | 120–140 | HSO3−, Ca2+, Na+, etc. |

| Soda lignin [66] | 800–3000 | 140–160 | NaOH |

| Organosolv lignin [66] | 500–5000 | 90–110 | Formic acid, ethanol, water, etc. |

| Matrix | Filler | The Initial Degradation Temperature (T5%)/°C | The Maximum Weight Loss Temperature (Tmax)/°C | Ref. |

|---|---|---|---|---|

| PLA (3051D) | - | 264 | 314 | [70] |

| PLA (3051D) | ACL (5%) | 325 | 360 | |

| PLA (3051D) | AOL (5%) | 318 | 365 | |

| PLA (2002D) | - | 321.1 | 376.7 | [71] |

| PLA (2002D) | MLS (7%) | 330.4 | 364.5 |

| Matrix | Filler | Barrier Properties (Pristine Matrix: 100%) | Ref. | |

|---|---|---|---|---|

| Water Vapor Permeability (WVP) | Oxygen Permeability (OP) | |||

| PLA (3001D) | MTPS (1%) | <100% | 73% | [80] |

| PLA | Starch (30%) | - | 60.9% | [81] |

| PLA | GO@ starch (30%) | - | 11.2% | |

| Modification Method | Matrix | Filler | Mechanical Properties (Pristine Matrix: 100%) | Barrier Properties (Pristine Matrix: 100%) | Ref. | ||

|---|---|---|---|---|---|---|---|

| Tensile Strength | Young Modulus | Water Vapor Permeability (WVP) | Oxygen Permeability (OP) | ||||

| Nanometer | PLA (2003D) | CNC I (1%) | 134% | 145% | 62.0% | 31.1% | [87] |

| PLA (2003D) | CNC II (1%) | 172% | 110% | 68.8% | 36.4% | [87] | |

| Plasma modification | PLA (2002D) | LS (7%) | 97.6% | 117.5% | - | - | [71] |

| PLA (2002D) | LS-OA (7%) | 108.7% | 129.4% | - | - | [71] | |

| Esterification | PLA (3052D) | CNC (3%) | <100% | <100% | >46% | >45% | [88] |

| PLA (3052D) | Cin-CNC (3%) | 170% | 137% | 46% | 45% | [88] | |

| Amidation | PLA (Revode 190) | FC (1%) | 148.6% | 446% | 59.4% | - | [57] |

| Graft | PLA (4032D) | CNCs (0.5%) | 107.5% | 104.6% | - | 78.3% | [89] |

| PLA (4032D) | CNCs-PEG (0.5%) | 120.8% | 113.9% | - | 33.6% | [89] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Sun, H.; Yang, B.; Weng, Y. Modified Biomass-Reinforced Polylactic Acid Composites. Materials 2024, 17, 336. https://doi.org/10.3390/ma17020336

Zhu J, Sun H, Yang B, Weng Y. Modified Biomass-Reinforced Polylactic Acid Composites. Materials. 2024; 17(2):336. https://doi.org/10.3390/ma17020336

Chicago/Turabian StyleZhu, Junjie, Hui Sun, Biao Yang, and Yunxuan Weng. 2024. "Modified Biomass-Reinforced Polylactic Acid Composites" Materials 17, no. 2: 336. https://doi.org/10.3390/ma17020336

APA StyleZhu, J., Sun, H., Yang, B., & Weng, Y. (2024). Modified Biomass-Reinforced Polylactic Acid Composites. Materials, 17(2), 336. https://doi.org/10.3390/ma17020336