Wear Analysis of NiTi Sand Screens Using Altair Discrete Element Method

Abstract

1. Introduction

1.1. Wear Control

1.2. Wear Model

2. Materials and Methods

2.1. Material Selection and Description

| Mechanical Property | Review Ranges | Simulation Parameter | Reference |

|---|---|---|---|

| Poisson’s Ratio (v) | 0.28–0.37 | 0.32 | [37] |

| 0.32 longitudinal & 0.47 transverse | [38] | ||

| <0.499 | [39] | ||

| Solid Density (ρ) | 6.45–6.6 g/cm3 | 6.5 | [40,41,42] |

| Shear Modulus (G) | 16–45 GPa | 35 | [43,44] |

| Young Modulus (E) | 68 GPa | 69 | [45] |

| 70 GPa | [46] | ||

| 68.5 GPa | [40] |

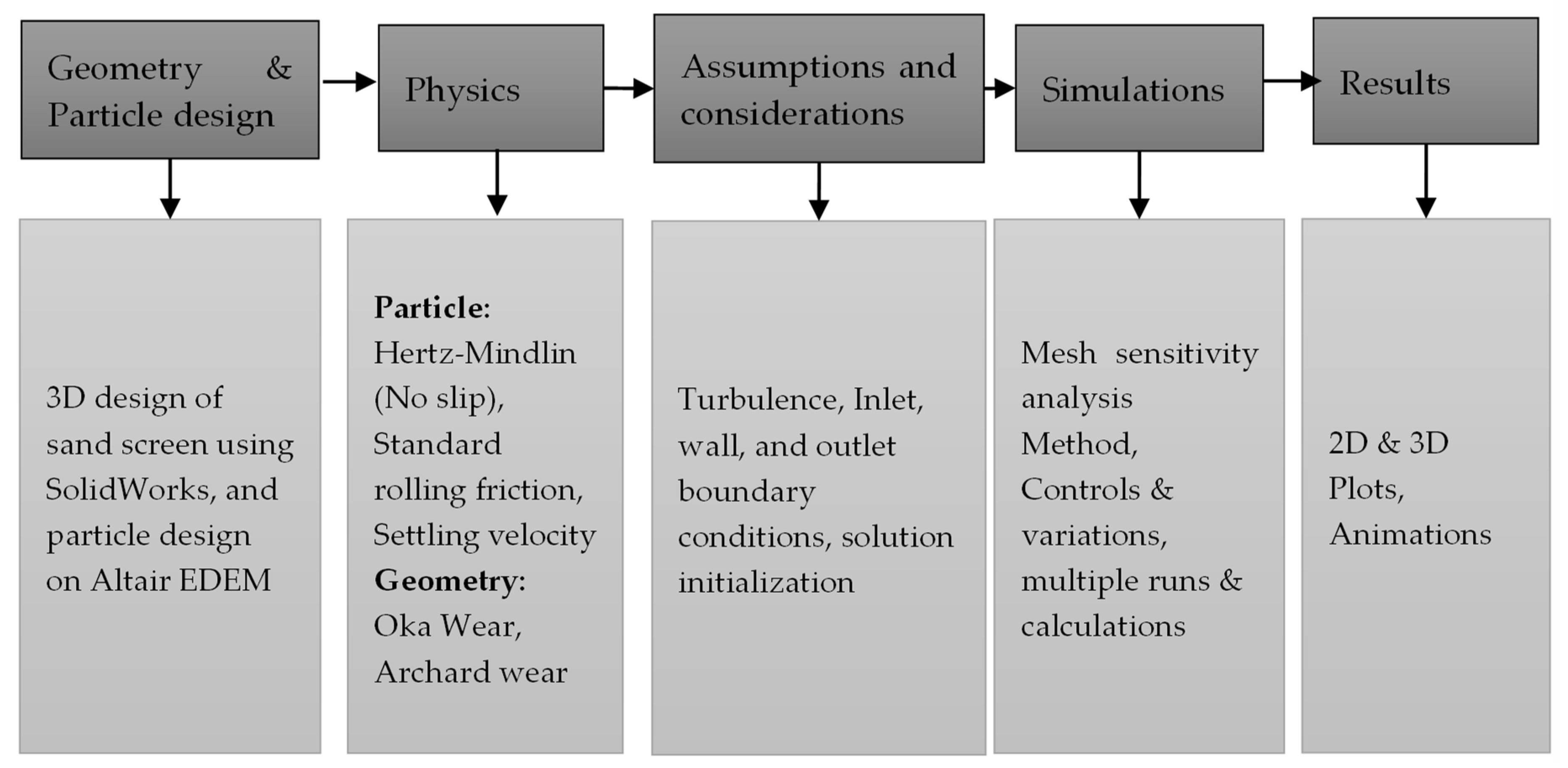

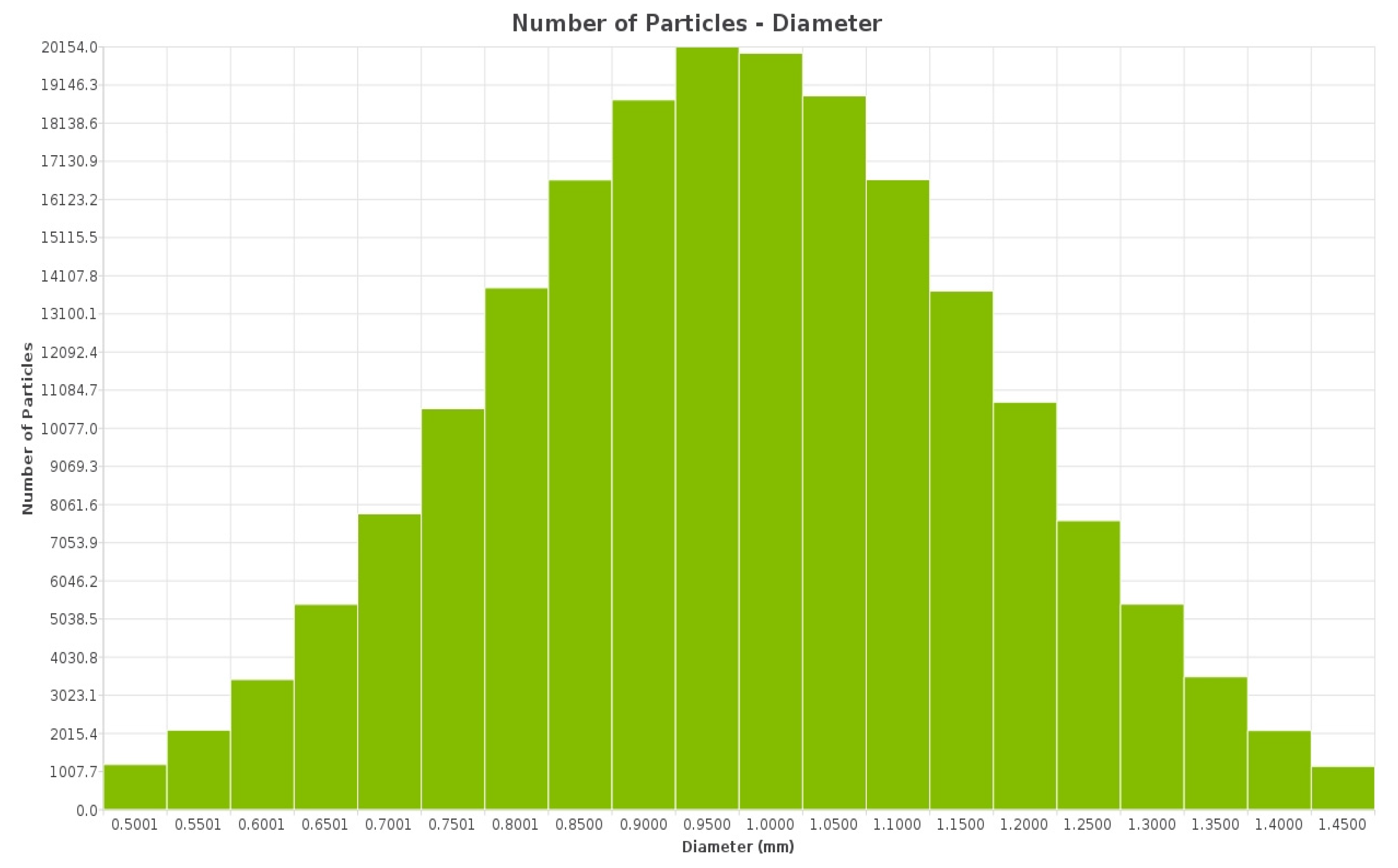

2.2. Altair EDEM Simulation

3. Results and Discussion

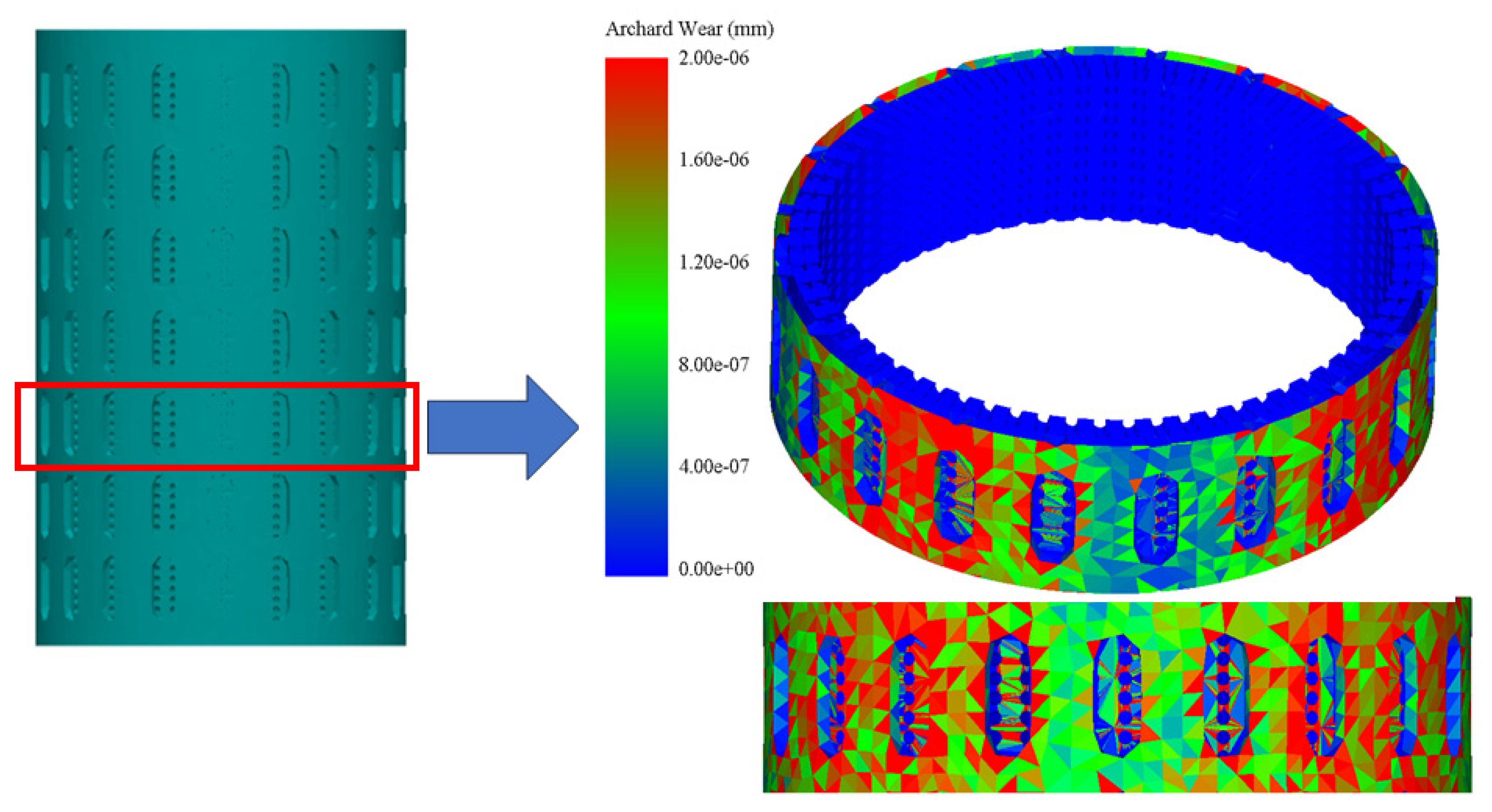

3.1. Wear Analysis of SMAs

3.2. Comparison of Wear Performance Using Oka and Archard on NiTi SMAs

3.3. SMA Microstructural Nature of Nitinol Influencing Wear Resistance

3.4. Validation of the Numerical Simulation with Experimental Findings

4. Conclusions and Recommendations

4.1. Summary of Key Findings, Significance, and Contributions of the Study

4.2. Limitations and Future Research Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, H.; Chang, M.; Liu, X.; Gabayno, J.L.; Chen, H.T. Design and Implementation of Shape Memory Alloy-Actuated Nanotweezers for Nanoassembly. J. Micromech. Microeng. 2014, 24, 095012. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, F.; Wu, J.; Lu, Y.; Shi, Z.; Wang, C.; Liu, X. Superelasticity and Shape Memory Effect in Cu–Al–Mn–V Shape Memory Alloys. Mater. Des. 2017, 115, 17–25. [Google Scholar] [CrossRef]

- Czechowicz, A.; Langbein, S. Shape Memory Alloy Valves: Basics, Potentials, Design. In Shape Memory Alloy Valves: Basics, Potentials, Design; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–214. [Google Scholar] [CrossRef]

- Mehta, K.; Gupta, K. Fabrication and Processing of Shape Memory Alloys; Springer Briefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Abduljabbar, A.; Mohyaldinn, M.E.; Younis, O.; Alghurabi, A.; Alakbari, F.S. Erosion of Sand Screens by Solid Particles: A Review of Experimental Investigations. J. Pet. Explor. Prod. Technol. 2022, 12, 2329–2345. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, K.J.; Choi, E. Flexural Capacity and Crack-Closing Performance of NiTi and NiTiNb Shape-Memory Alloy Fibers Randomly Distributed in Mortar Beams. Compos. B Eng. 2018, 153, 264–276. [Google Scholar] [CrossRef]

- Li, G.; Yu, T.; Wu, P.; Chen, M. Molecular Dynamics Simulation of Phase Transformation and Wear Behavior of Ni35Al30Co35 High Temperature Shape Memory Alloy. Wear 2023, 522, 204849. [Google Scholar] [CrossRef]

- Oikawa, K.; Omori, T.; Sutou, Y.; Kainuma, R.; Ishida, K. Development of the Co-Ni-Al Ferromagnetic Shape Memory Alloys. J. De Phys. IV JP 2003, 112, 1017–1020. [Google Scholar] [CrossRef]

- Sangal, S.; Singhal, M.K.; Saini, R.P. Hydro-Abrasive Erosion in Hydro Turbines: A Review. Int. J. Green Energy 2018, 15, 232–253. [Google Scholar] [CrossRef]

- Shahali, H.; Ghasemi, H.M.; Abedini, M. Contributions of Corrosion and Erosion in the Erosion-Corrosion of Sanicro28. Mater. Chem. Phys. 2019, 233, 366–377. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, X.; Yan, Y.; Wang, J.; Yan, F. Tribocorrosion Behaviors of 304SS: Effect of Solution PH. RSC Adv. 2015, 5, 17676–17682. [Google Scholar] [CrossRef]

- Cheng, X.; Li, Z.; Xiang, G. Dry Sliding Wear Behavior of TiNi Alloy Processed by Equal Channel Angular Extrusion. Mater. Des. 2007, 28, 2218–2223. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, D.; Zhang, J.; Lin, P.; Dong, G. Self-Recovery of Worn Surface of TiNi Shape Memory Alloy. Appl. Surf. Sci. 2014, 321, 371–377. [Google Scholar] [CrossRef]

- Farhat, Z.N.; Zhang, C. The Role of Reversible Martensitic Transformation in the Wear Process of TiNi Shape Memory Alloy. Tribol. Trans. 2010, 53, 917–926. [Google Scholar] [CrossRef]

- ASTM G171-03(2017); Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus. ASTM: West Conshohocken, PN, USA, 2017.

- Oka, Y.I.; Okamura, K.; Yoshida, T. Practical Estimation of Erosion Damage Caused by Solid Particle Impact. Wear 2005, 259, 95–101. [Google Scholar] [CrossRef]

- Adedeji, O.E.; Yu, W.; Sanders, R.S. Analysis of Local Wear Variables for High-Precision Erosion Modelling in Complex Geometries. Wear 2019, 426–427, 562–569. [Google Scholar] [CrossRef]

- Brink, T.; Frérot, L.; Molinari, J.-F. A Parameter-Free Mechanistic Model of the Adhesive Wear Process of Rough Surfaces in Sliding Contact. J. Mech. Phys. Solids 2021, 147, 104238. [Google Scholar] [CrossRef]

- Tan, L.; Gao, D. Casing Wear Prediction Model Based on Casing Ellipticity in Oil & Gas Well-Drilling With Complex Structures. J. Appl. Mech. 2018, 85, 101005. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A. The Relation Between Wear and Irreversible Entropy Generation in the Dry Sliding of Metals; Cornell University: Ithaca, NY, USA, 2010. [Google Scholar]

- Manini, N.; Mistura, G.; Paolicelli, G.; Tosatti, E.; Vanossi, A. Current Trends in the Physics of Nanoscale Friction. Adv. Phys. X 2017, 2, 569–590. [Google Scholar] [CrossRef]

- Tangpatjaroen, C.; Grierson, D.; Shannon, S.; Jakes, J.E.; Szlufarska, I. Size Dependence of Nanoscale Wear of Silicon Carbide. ACS Appl. Mater. Interfaces 2017, 9, 1929–1940. [Google Scholar] [CrossRef]

- Tang, C.; Yang, Y.-C.; Liu, P.-Z.; Kim, Y.-J. Prediction of Abrasive and Impact Wear Due to Multi-Shaped Particles in a Centrifugal Pump via CFD-DEM Coupling Method. Energies 2021, 14, 2391. [Google Scholar] [CrossRef]

- Hu, J.; Song, H.; Sandfeld, S.; Liu, X.; Wei, Y. Breakdown of Archard Law Due to Transition of Wear Mechanism from Plasticity to Fracture. Tribol. Int. 2022, 173, 107660. [Google Scholar] [CrossRef]

- Altair Engineering Inc. The Oka Wear Model. Available online: https://help.altair.com/EDEM/Creator/Physics/Additional_Models/Impact_Wear.htm (accessed on 5 April 2023).

- Messa, G.V.; Malavasi, S. The Effect of Sub-Models and Parameterizations in the Simulation of Abrasive Jet Impingement Tests. Wear 2017, 370–371, 59–72. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 2004, 24, 981. [Google Scholar] [CrossRef]

- Schramm, F.; Kalácska, A.; Pfeiffer, V.; Sukumaran, J.; De Baets, P.; Frerichs, L. Modelling of Abrasive Material Loss at Soil Tillage via Scratch Test with the Discrete Element Method. J. Terramech 2020, 91, 275–283. [Google Scholar] [CrossRef]

- Abduljabbar, A.; Mohyaldinn, M.; Younis, O.; Alghurabi, A. A Numerical CFD Investigation of Sand Screen Erosion in Gas Wells: Effect of Fine Content and Particle Size Distribution. J. Nat. Gas Sci. Eng. 2021, 95, 104228. [Google Scholar] [CrossRef]

- Altair Engineering Inc. The Archard Wear Model. Available online: https://help.altair.com/EDEM/Creator/Physics/Additional_Models/Archard_Wear.htm (accessed on 5 April 2023).

- Foroozesh, J.; Parvaz, F.; Hosseini, S.H.; Ahmadi, G.; Elsayed, K.; Babaoğlu, N.U. Computational Fluid Dynamics Study of the Impact of Surface Roughness on Cyclone Performance and Erosion. Powder Technol. 2021, 389, 339–354. [Google Scholar] [CrossRef]

- Parkash, O.; Kumar, A.; Sikarwar, B.S. Computational Erosion Wear Model Validation of Particulate Flow Through Mitre Pipe Bend. Arab. J. Sci. Eng. 2021, 46, 12373–12390. [Google Scholar] [CrossRef]

- Molina, N.; Walczak, M.; Kalbarczyk, M.; Celentano, D. Erosion under Turbulent Slurry Flow: Effect of Particle Size in Determining Impact Velocity and Wear Correlation by Inverse Analysis. Wear 2021, 474–475, 203651. [Google Scholar] [CrossRef]

- Ozarde, A.P.; McNay, G.H.; Gautam, S.S. Comparative Fretting Fatigue Life Evaluation between Critical Plane Based and Deviatoric Strain Amplitude Based Methods Corrected for Surface Wear Damage. SAE Int. J. Mater. Manuf. 2021, 15, 111–132. [Google Scholar] [CrossRef]

- Peng, Z.; Ji, H.; Huang, X.; Wang, B.; Xiao, W.; Wang, S. Numerical Analysis and Parameter Optimization of Wear Characteristics of Titanium Alloy Cross Wedge Rolling Die. Metals 2021, 11, 1998. [Google Scholar] [CrossRef]

- Xin, H.; Zhang, L.; Diao, H.; Jia, J.; Jin, Z. Numerical Wear Study of Metal-on-Ultrahigh Molecular Weight Polyethylene-Based Cervical Total Disc Arthroplasty by Coupling Finite Element Analysis and Multi-Body Dynamics. Biosurf. Biotribol. 2021, 7, 251–260. [Google Scholar] [CrossRef]

- Li, Y.F.; Tang, S.L.; Gao, Y.M.; Ma, S.Q.; Zheng, Q.L.; Cheng, Y.H. Mechanical and Thermodynamic Properties of Intermetallic Compounds in the Ni–Ti System. Int. J. Mod. Phys. B 2017, 31, 1750161. [Google Scholar] [CrossRef]

- Young, M.L.; Gollerthan, S.; Baruj, A.; Frenzel, J.; Schmahl, W.W.; Eggeler, G. Strain Mapping of Crack Extension in Pseudoelastic NiTi Shape Memory Alloys during Static Loading. Acta Mater. 2013, 61, 5800–5806. [Google Scholar] [CrossRef]

- Xiao, Y.; Jiang, D. Effects of Structural Geometry on the Localized Deformation of Superelastic NiTi Sheets. Int. J. Solids Struct. 2022, 257, 111762. [Google Scholar] [CrossRef]

- Wang, X.; Speirs, M.; Kustov, S.; Vrancken, B.; Li, X.; Kruth, J.P.; Van Humbeeck, J. Selective Laser Melting Produced Layer-Structured NiTi Shape Memory Alloys with High Damping Properties and Elinvar Effect. Scr. Mater. 2018, 146, 246–250. [Google Scholar] [CrossRef]

- Cui, J.; Wu, Y.; Muehlbauer, J.; Hwang, Y.; Radermacher, R.; Fackler, S.; Wuttig, M.; Takeuchi, I. Demonstration of High Efficiency Elastocaloric Cooling with Large ΔT Using NiTi Wires. Appl. Phys. Lett. 2012, 101, 073904. [Google Scholar] [CrossRef]

- Chekotu, J.C.; Goodall, R.; Kinahan, D.; Brabazon, D. Control of Ni-Ti Phase Structure, Solid-State Transformation Temperatures and Enthalpies via Control of L-PBF Process Parameters. Mater. Des. 2022, 218, 110715. [Google Scholar] [CrossRef]

- Wang, J.; Sehitoglu, H. Martensite Modulus Dilemma in Monoclinic NiTi-Theory and Experiments. Int. J. Plast. 2014, 61, 17–31. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Mokshin, A.V. Mechanical Response of Mesoporous Amorphous NiTi Alloy to External Deformations. Int. J. Solids Struct. 2021, 224, 111047. [Google Scholar] [CrossRef]

- Sgambitterra, E.; Maletta, C.; Furgiuele, F. Modeling and Simulation of the Thermo-Mechanical Response of NiTi-Based Belleville Springs. J. Intell. Mater. Syst. Struct. 2014, 27, 81–91. [Google Scholar] [CrossRef]

- Thomasová, M.; Sedlák, P.; Seiner, H.; Janovská, M.; Kabla, M.; Shilo, D.; Landa, M. Young’s Moduli of Sputter-Deposited NiTi Films Determined by Resonant Ultrasound Spectroscopy: Austenite, R-Phase, and Martensite. Scr. Mater. 2015, 101, 24–27. [Google Scholar] [CrossRef]

- Ellendt, N.; Lumanglas, A.M.; Moqadam, S.I.; Mädler, L. A Model for the Drag and Heat Transfer of Spheres in the Laminar Regime at High Temperature Differences. Int. J. Therm. Sci. 2018, 133, 98–105. [Google Scholar] [CrossRef]

- Yan, T.; Qu, J.-Y.; Sun, X.-F.; Li, W.; Chen, Y.; Hu, Q.-B. A Novel Predictive Model of Drag Coefficient and Settling Velocity of Drill Cuttings in Non-Newtonian Drilling Fluids. Pet. Sci. 2021, 18, 1729–1738. [Google Scholar] [CrossRef]

- Younes, A.; Nnamchi, P.; Medina, J.; Pérez, P.; Villapún, V.M.; Badimuro, F.; Kamnis, S.; Jimenez-Melero, E.; González, S. Wear Rate at RT and 100 °C and Operating Temperature Range of Microalloyed Cu50Zr50 Shape Memory Alloy. J. Alloys Compd. 2020, 817, 153330. [Google Scholar] [CrossRef]

- Sun, Y. Sliding Wear Behaviour of Surface Mechanical Attrition Treated AISI 304 Stainless Steel. Tribol. Int. 2013, 57, 67–75. [Google Scholar] [CrossRef]

- Levintant-Zayonts, N.; Starzynski, G.; Kopec, M.; Kucharski, S. Characterization of NiTi SMA in Its Unusual Behaviour in Wear Tests. Tribol. Int. 2019, 137, 313–323. [Google Scholar] [CrossRef]

- Gao, S.; Weng, F.; Bodunde, O.P.; Qin, M.; Liao, W.H.; Guo, P. Spatial Characteristics of Nickel-Titanium Shape Memory Alloy Fabricated by Continuous Directed Energy Deposition. J. Manuf. Process. 2021, 71, 417–428. [Google Scholar] [CrossRef]

- Huang, G.Q.; Yan, Y.F.; Wu, J.; Shen, Y.F.; Gerlich, A.P. Microstructure and Mechanical Properties of Fine-Grained Aluminum Matrix Composite Reinforced with Nitinol Shape Memory Alloy Particulates Produced by Underwater Friction Stir Processing. J. Alloys Compd. 2019, 786, 257–271. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Gupta, A.K.; Padisala, S.K.; Poluri, K. Characterization of Mechanical and Microstructural Properties of Constrained Groove Pressed Nitinol Shape Memory Alloy for Biomedical Applications. Mater. Sci. Eng. C 2019, 102, 730–742. [Google Scholar] [CrossRef]

- Huang, Z.; Li, G.; Yan, X.; Wang, K.; Shen, R.; Jin, L. Comparison Experiment on Steel and Non-Steel Slotted Screen Pipes Used in Coalbed Methane Wells. Pet. Explor. Dev. 2012, 39, 522–527. [Google Scholar] [CrossRef]

- Warerkar, S.; Schmitz, S.; Goettsche, J.; Hoffschmidt, B.; Reißel, M.; Tamme, R. Air-Sand Heat Exchanger for High-Temperature Storage. J. Sol. Energy Eng. Trans. ASME 2011, 133, 21010. [Google Scholar] [CrossRef]

- Al-Janabi, Y.T. An Overview of Corrosion in Oil and Gas Industry. In Corrosion Inhibitors in the Oil and Gas Industry; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2020; pp. 1–39. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, R.; Li, Y.; Geng, B. Characteristics of Dynamic Recrystallization in Semi-Solid CuSn10P1 Alloy during Hot Deformation. Mater. Charact. 2020, 159, 109996. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Lu, J. Effects of Crystallographic Orientations and Grain Boundaries on Nanoscratching Behaviour of Unique Bi-Crystal Cu. Wear 2022, 498–499, 204313. [Google Scholar] [CrossRef]

- Wu, J.; Ebrahimi, M.; Attarilar, S.; Gode, C.; Zadshakoyan, M. Cyclic Extrusion Compression Process for Achieving Ultrafine-Grained 5052 Aluminum Alloy with Eminent Strength and Wear Resistance. Metals 2022, 12, 1627. [Google Scholar] [CrossRef]

- Cinca, N.; Lima, C.R.C.; Guilemany, J.M. An Overview of Intermetallics Research and Application: Status of Thermal Spray Coatings. J. Mater. Res. Technol. 2013, 2, 75–86. [Google Scholar] [CrossRef]

- Zakrzewska, D.E.; Krella, A.K. Cavitation Erosion Resistance Influence of Material Properties. Adv. Mater. Sci. 2019, 19, 18–34. [Google Scholar] [CrossRef]

- Halfa, H. Microstructure–Wear Resistance Relationship of Nitrogen-Containing High-Speed Tool Steel, AISIM41: Non-Equilibrium Solidification. Metallogr. Microstruct. Anal. 2022, 11, 495–512. [Google Scholar] [CrossRef]

- Atamert, S.; Stekly, J. Microstructure, Wear Resistance, and Stability of Cobalt Based and Alternative Iron Based Hardfacing Alloys. Surf. Eng. 2013, 9, 231–240. [Google Scholar] [CrossRef]

- Liu, R.; Li, D.Y. Modification of Archard’s Equation by Taking Account of Elastic/Pseudoelastic Properties of Materials. Wear 2001, 251, 956–964. [Google Scholar] [CrossRef]

- Altair Engineering. Archard Wear. Available online: https://2022.help.altair.com/2022/EDEM/Creator/Physics/Additional_Models/Archard_Wear.htm (accessed on 5 November 2023).

- MacLean, M.; Farhat, Z.; Jarjoura, G.; Fayyad, E.; Abdullah, A.; Hassan, M. Fabrication and Investigation of the Scratch and Indentation Behaviour of New Generation Ni-P-Nano-NiTi Composite Coating for Oil and Gas Pipelines. Wear 2019, 426–427, 265–276. [Google Scholar] [CrossRef]

- Xu, J.J.; Cheng, X.Y.; Dong, K.; Sun, Y.Q. The Effect of Mechanical Property on the Erosive Behaviour of NiTi SMAs. Key Eng. Mater. 2007, 334–335, 1057–1060. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Fu, C.; Zeng, C.; Wu, X.; Li, W.; Ma, X. Structural, Mechanical, and Thermodynamic Properties of Ni–Ti Intermetallic Compounds: First-Principle Calculation. J. Appl. Phys. 2023, 134, 085107. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, W.; Lu, S.; Zhao, S.; Ma, Y.; Hu, H.; Fu, T.; Peng, X. Effect of Material Parameters on the Indentation Mechanical Behavior of Superelastic NiTi Shape Memory Alloy. J. Mater. Eng. Perform. 2023, 1–16. [Google Scholar] [CrossRef]

- Fang, Y.; Li, X.; Hao, S.; Liu, H.; Yang, Y.; Guo, Y. Failure Analysis of Slurry TBM Discharge Pipe in Complex Strata Combined with Wear and Vibration Characteristics. Eng. Fail. Anal. 2023, 150, 107307. [Google Scholar] [CrossRef]

- Khan, R.; Ya, H.H.; Pao, W.; bin Abdullah, M.Z.; Dzubir, F.A. Influence of Sand Fines Transport Velocity on Erosion-Corrosion Phenomena of Carbon Steel 90-Degree Elbow. Metals 2020, 10, 626. [Google Scholar] [CrossRef]

- Kang, C.; Cao, Q.; Teng, S.; Liu, H.; Ding, K. Wear Characteristics of a Centrifugal Pump Transporting Solid–Liquid Mixture: An Experimental and Numerical Study. Ain Shams Eng. J. 2023, 102277. [Google Scholar] [CrossRef]

- Yin, W.; Liu, X.; Pan, P.; Wang, L. Sand Erosion Behaviors and Mechanism of Pseudoelastic TiNi Shape Memory Alloy. In Advances in Mechanical Design; Springer: Singapore, 2022; pp. 217–224. [Google Scholar] [CrossRef]

- Fernandez, J.; Isalgue, A.; Cinca, N.; Dosta, S.; Ventayol, J. Wear and Corrosion of Metal-Matrix (Stainless Steel or NiTi)-TiC Coatings. Phys. Procedia 2010, 10, 77–80. [Google Scholar] [CrossRef][Green Version]

| Wear Model | Focus | Limitation | Ref. |

|---|---|---|---|

| Oka wear | The influence of particle impact angle, particle velocity, and particle size distribution on wear in a pipe bend. | The study adopted Oka, McLaury, Finnie, and Generic wear models in its investigation of a pipe bend, suggesting that researchers are constantly seeking models’ best fit for specific wear scenarios. However, the clarification regarding whether the wear observed at the extrados of the pipe near the bend exit was primarily influenced by impact and abrasion was not explicitly addressed. Variation in particulate sizes of spherical-shaped sand particles in the discrete phase model was rather primary, potentially necessitating a critical review of the wear mechanisms for a more comprehensive understanding of wear phenomena in pipe bends. | [31] |

| To investigate the effect of particle size on wear in turbulent slurry flow using empirical (Oka and Huang) and analytical (Cheng) wear models. | Oka, Huang, and Cheng wear models were all used in the inverse analysis study despite their similar impact-driven wear nature. The scenario involved rotation which might have tilted towards abrasion influence, but models like Archard were not considered. Though results gave irregular impact velocities, the study still suggested the Oka wear model as the most reliable in performance prediction. Other limitations identified in the study were reference speed and removal of plastic damage. | [32] | |

| The focus was on the effect of surface roughness on the velocity, pressure, and particle trajectories within a cyclone. | An increase in wall roughness resulted in a decreasing wear rate using the Oka wear model in this case. The nature of the material used for the cyclone was not specified or compared to help the researcher opine whether there are microstructural characteristics necessary for the resistance to wear as roughness increases. Particle size influence was less significant. Unlike this [33], in the later part of this paper, the present study characterized the SMA sample to reflect the response due to wear. | [33] | |

| Archard wear | The paper compares the critical plane-based method and the deviatoric strain amplitude-based method for evaluating fretting fatigue life and corrects for surface wear damage using the Archard wear model. | The limitation of the paper with respect to Archard wear is that the authors assume a linear relationship between wear volume and time, which may not hold for all materials, contact energies, and wear conditions. The paper does not consider the effect of wear debris accumulation and the potential for third-body abrasive wear, which can significantly affect the fretting fatigue behavior of a material. | [34] |

| The paper uses numerical analysis to simulate the wear behavior of a die and applies the Archard wear model to predict the wear volume and wear rate of the die. | The limitation of this research was that the authors assumed a constant wear coefficient for the titanium alloy material throughout the simulations, which may not accurately reflect the wear behavior of the material under different conditions. The paper does not consider the effect of adhesive wear or abrasive wear, which can also contribute to the wear of the die. Finally, the study is focused on a specific application and material, so the findings may not be directly applicable to other materials or applications. | [35] | |

| The paper uses a combination of finite element analysis (FEA) and multi-body dynamics (MBD) to simulate the contact and wear behavior of the cervical total disc arthroplasty and applies the Archard wear model to predict the wear volume and wear rate of the ultrahigh-molecular-weight polyethylene insert. | The authors assume a constant wear coefficient for the UHMWPE material throughout the simulations, which may not accurately reflect the wear behavior of the material under different conditions. Wear predictions were made based on sliding distance and contact stresses as unique to the Archard model. A comparison of other wear model responses would have been more informative for the disc prosthesis being studied. This study clarified that the wear models are not limited to metals or alloys, making it evident to continuously investigate unique responses of materials to wear. | [36] |

| Materials | Wear Loss in an Experiment (mm) | Wear Loss in Theory (mm) | ||||

|---|---|---|---|---|---|---|

| Low Load | Mid Load | High Load | Low Load | Mid Load | High Load | |

| Stainless steel | 12.00 | 19.00 | 29.00 | 11.95 | 19.46 | 27.15 |

| Al alloy | 19.00 | 30.00 | 42.00 | 23.66 | 34.51 | 43.67 |

| NiTi | 10.00 | 14.00 | 21.00 | 15.04 | 20.97 | 28.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amadi, A.H.; Mohyaldinn, M.; Abduljabbar, A.; Ridha, S.; Avilala, P.; Owolabi, G.T. Wear Analysis of NiTi Sand Screens Using Altair Discrete Element Method. Materials 2024, 17, 281. https://doi.org/10.3390/ma17020281

Amadi AH, Mohyaldinn M, Abduljabbar A, Ridha S, Avilala P, Owolabi GT. Wear Analysis of NiTi Sand Screens Using Altair Discrete Element Method. Materials. 2024; 17(2):281. https://doi.org/10.3390/ma17020281

Chicago/Turabian StyleAmadi, Azubuike Hope, Mysara Mohyaldinn, Abdullah Abduljabbar, Syahrir Ridha, Prasad Avilala, and Gabriel Tayo Owolabi. 2024. "Wear Analysis of NiTi Sand Screens Using Altair Discrete Element Method" Materials 17, no. 2: 281. https://doi.org/10.3390/ma17020281

APA StyleAmadi, A. H., Mohyaldinn, M., Abduljabbar, A., Ridha, S., Avilala, P., & Owolabi, G. T. (2024). Wear Analysis of NiTi Sand Screens Using Altair Discrete Element Method. Materials, 17(2), 281. https://doi.org/10.3390/ma17020281