Effect of Processing Route on Microstructure and Mechanical Properties of an Al-12Si Alloy

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

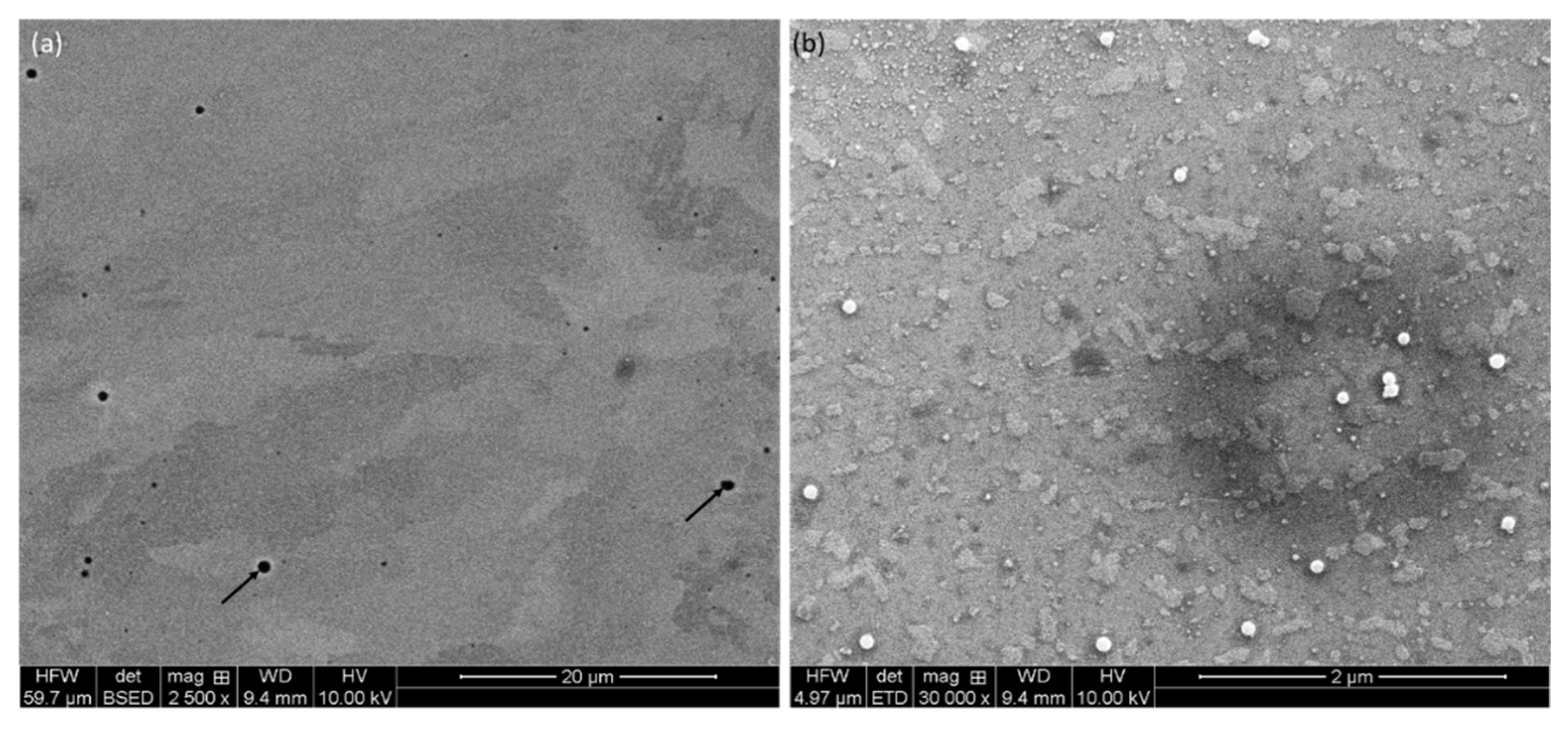

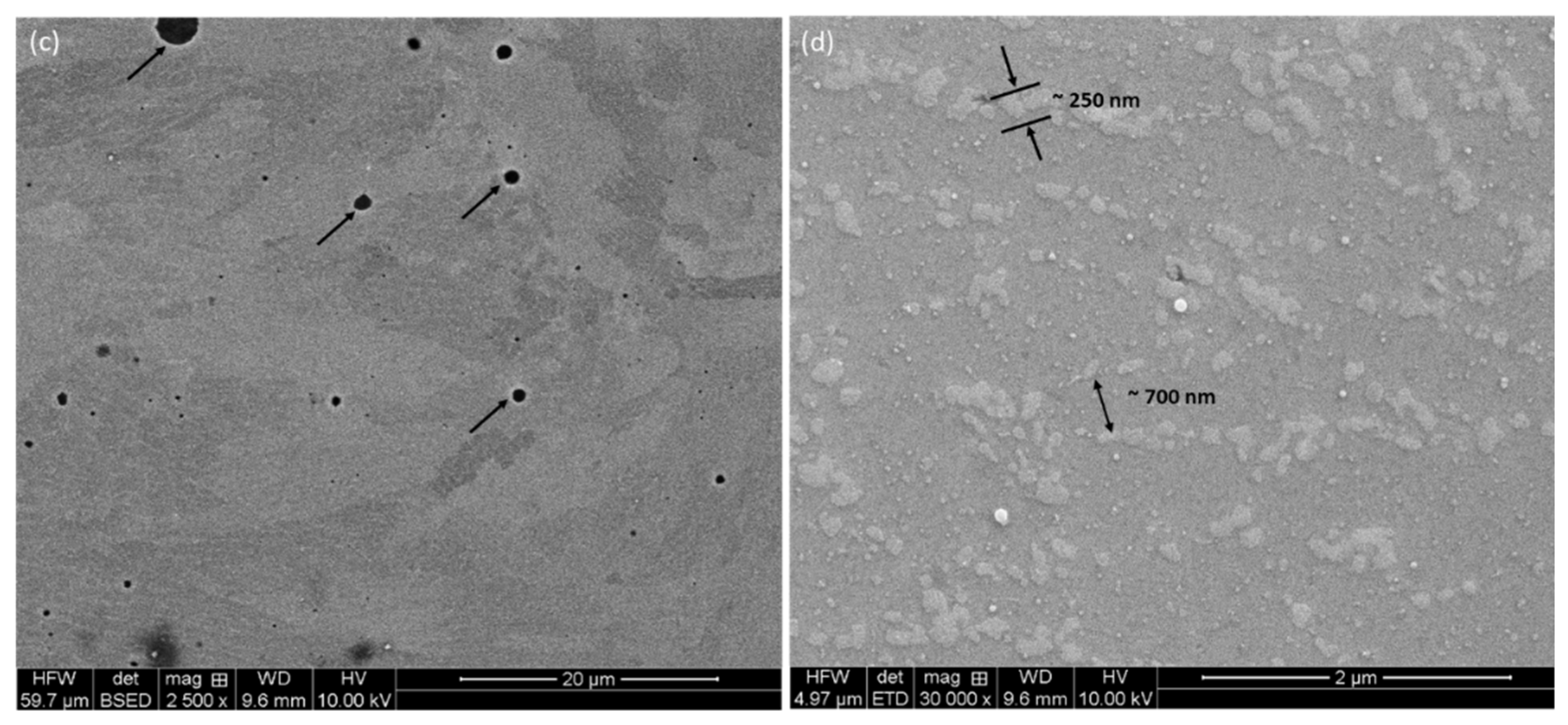

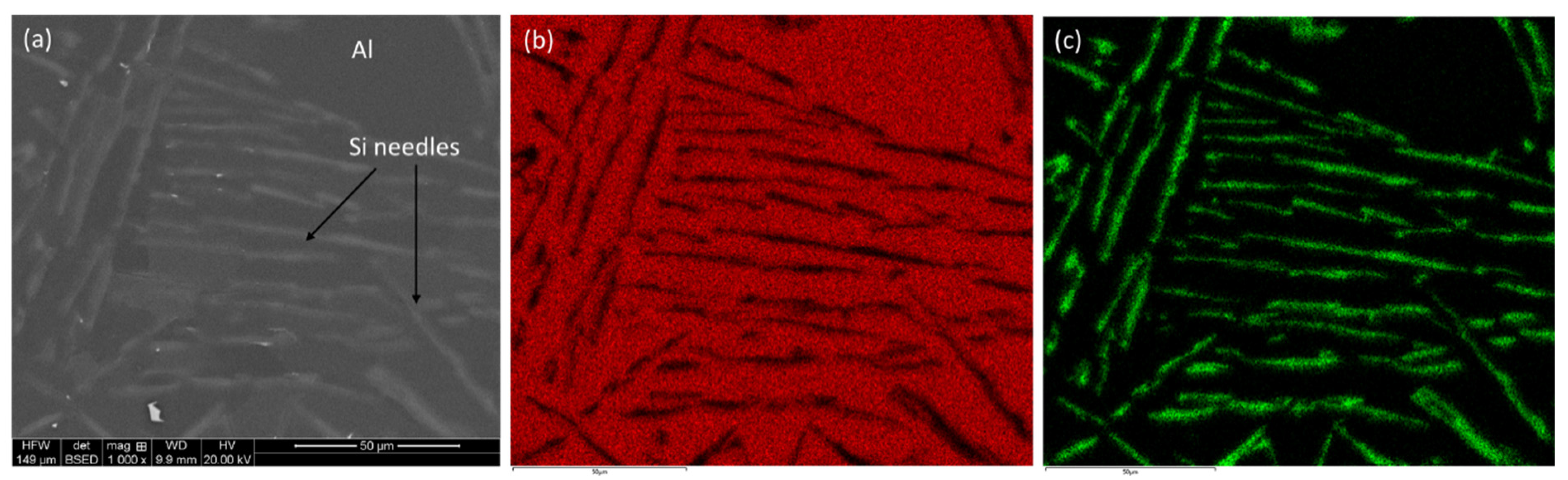

3.1. Microstructure of the Alloys

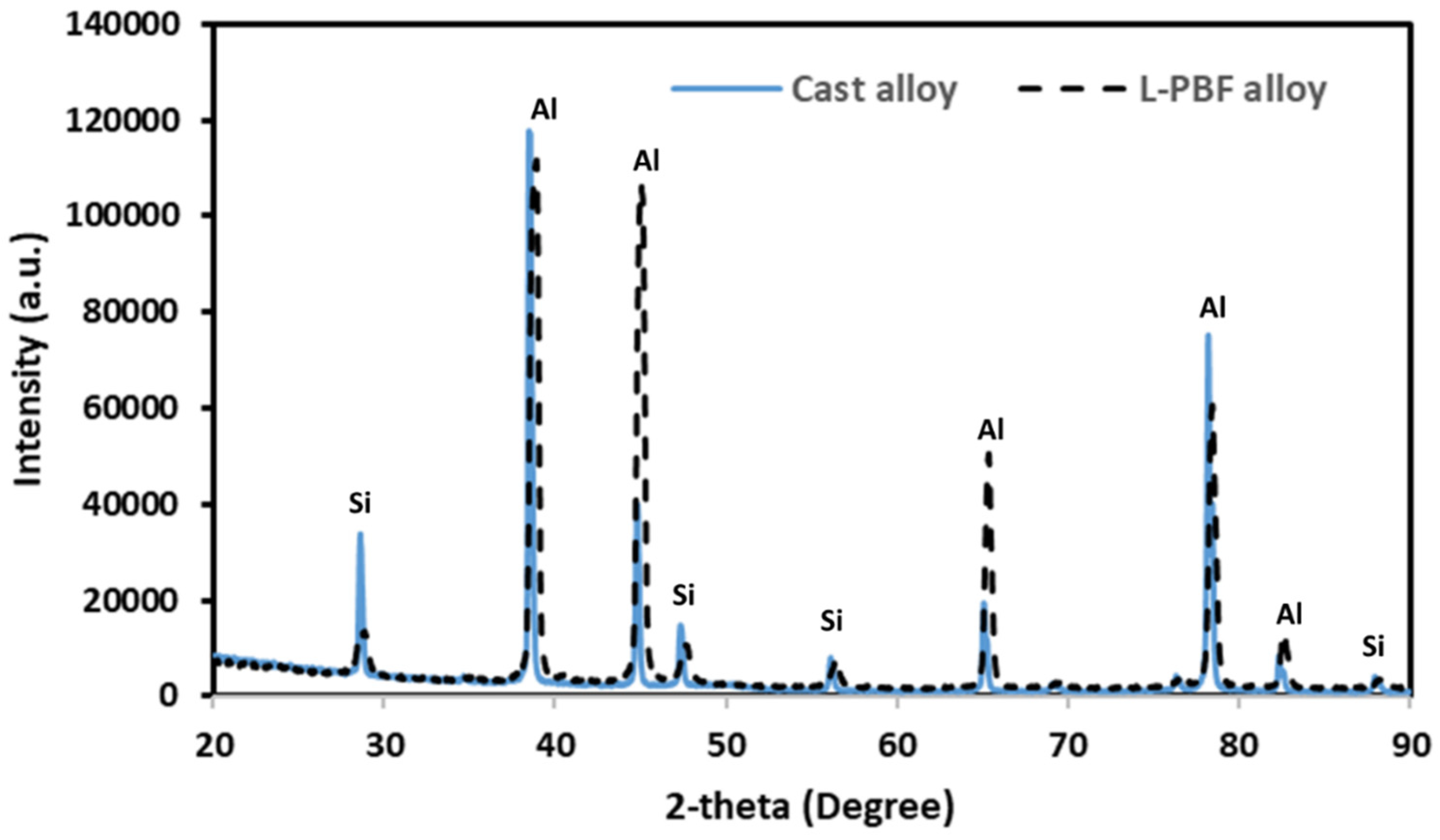

3.2. Phase Characterization

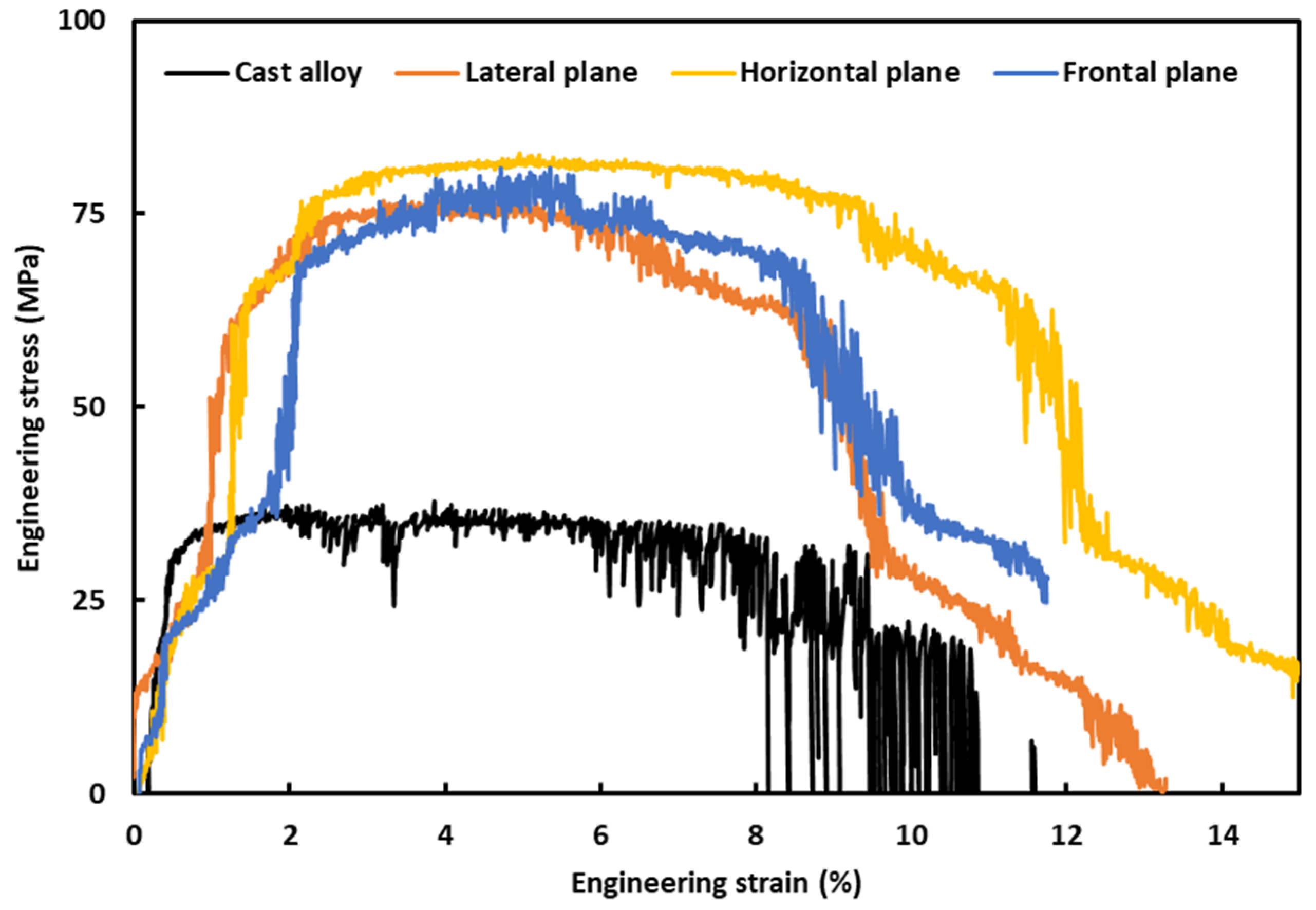

3.3. Mechanical Properties of the Alloys

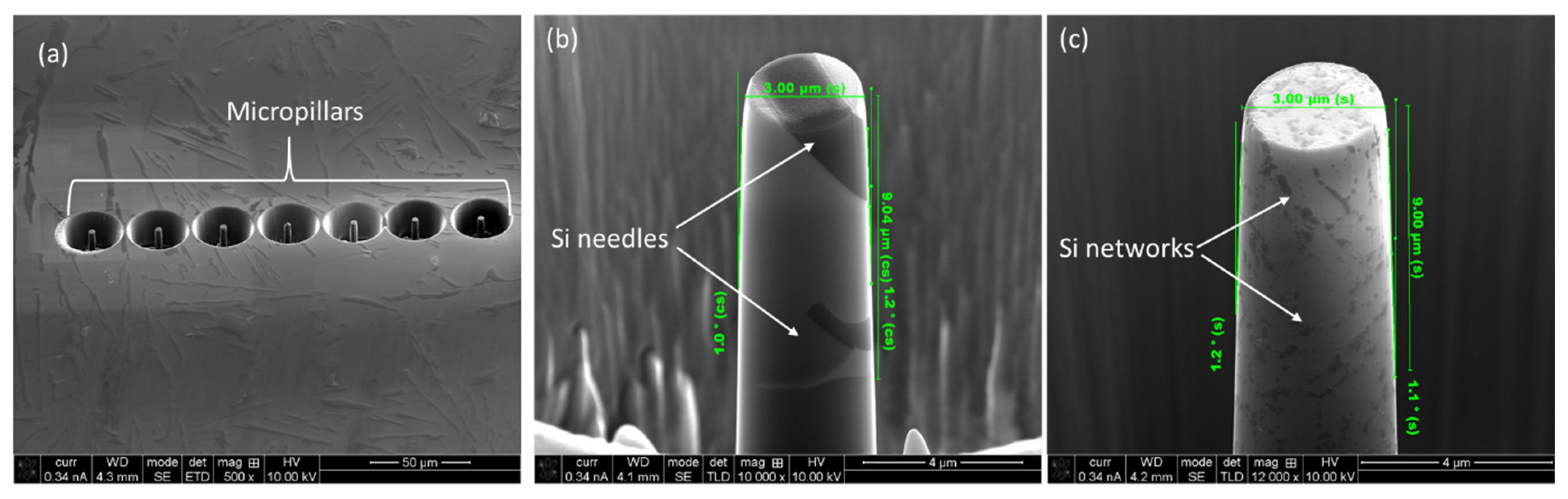

3.3.1. Micro-Pillar Fabrication

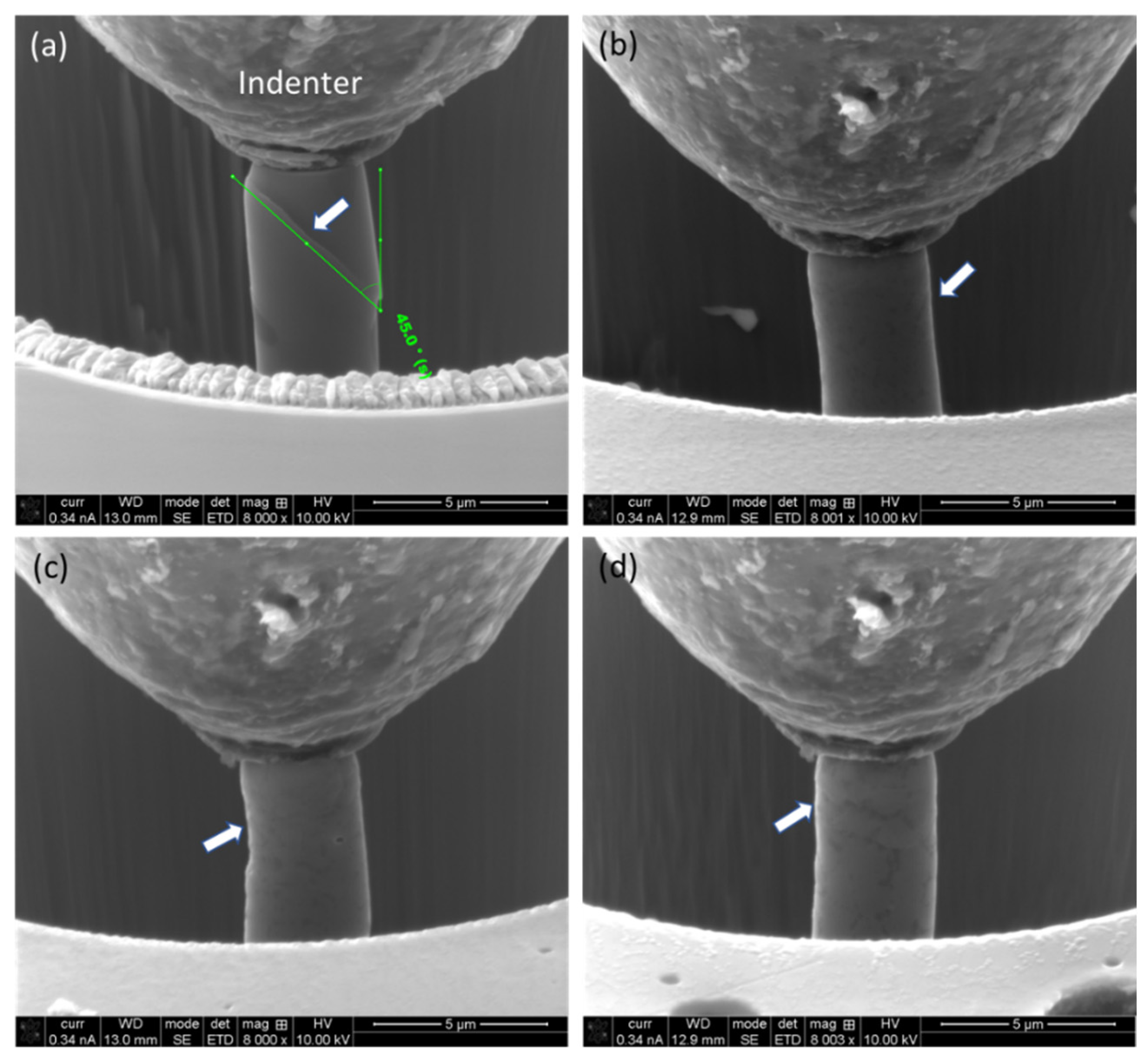

3.3.2. Compression of Micro-Pillars

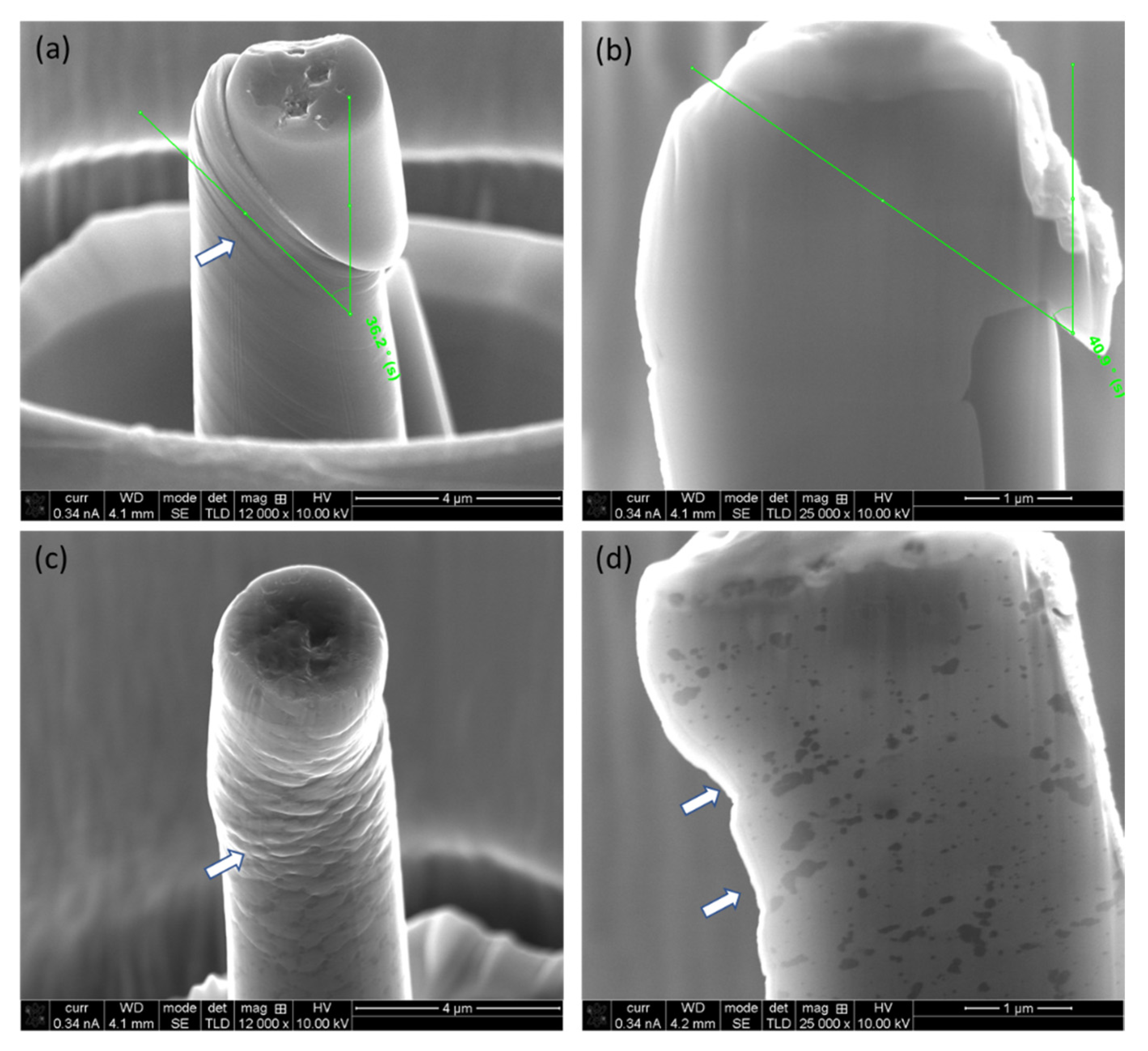

3.3.3. SEM of Compressed Micro-Pillars

3.4. Deformation Mechanism under Compression

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Basak, A.; Pramanik, A.; Islam, M.N. Failure mechanisms of nanoparticle reinforced metal matrix composite. Adv. Mater. Res. 2013, 774, 548–551. [Google Scholar] [CrossRef]

- Basak, A.; Pramanik, A.; Islam, M.N.; Anandakrishnan, V. Challenges and recent developments on nanoparticle-reinforced metal matrix composites. In Fillers and Reinforcements for Advanced Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 349–367. [Google Scholar]

- Singh, S.; Sharma, V.; Sachdeva, A. Progress in selective laser sintering using metallic powders: A review. Mater. Sci. Technol. 2016, 32, 760–772. [Google Scholar] [CrossRef]

- Shiomi, M.; Osakada, K.; Nakamura, K.; Yamashita, T.; Abe, F. Residual stress within metallic model made by selective laser melting process. CIRP Ann. 2004, 53, 195–198. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Hagedorn, Y. Laser additive manufacturing of ceramic components: Materials, processes, and mechanisms. In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 163–180. [Google Scholar]

- Tang, H.; Qian, M.; Liu, N.; Zhang, X.; Yang, G.; Wang, J. Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Ardila, L.; Garciandia, F.; González-Díaz, J.; Álvarez, P.; Echeverria, A.; Petite, M.; Deffley, R.; Ochoa, J. Effect of IN718 recycled powder reuse on properties of parts manufactured by means of selective laser melting. Phys. Procedia 2014, 56, 99–107. [Google Scholar] [CrossRef]

- Wang, Z.; Ummethala, R.; Singh, N.; Tang, S.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G. Selective laser melting of aluminum and its alloys. Materials 2020, 13, 4564. [Google Scholar] [CrossRef]

- Prashanth, K.; Shahabi, H.S.; Attar, H.; Srivastava, V.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Wang, Z.; Qu, R.; Prashanth, K.; Eckert, J.; Scudino, S. Compression behavior of inter-particle regions in high-strength Al84Ni7Gd6Co3 alloy. Mater. Lett. 2016, 185, 25–28. [Google Scholar] [CrossRef]

- Wang, Z.; Prashanth, K.; Scudino, S.; Chaubey, A.; Sordelet, D.; Zhang, W.; Li, Y.; Eckert, J. Tensile properties of Al matrix composites reinforced with in situ devitrified Al84Gd6Ni7Co3 glassy particles. J. Alloys Compd. 2014, 586, S419–S422. [Google Scholar] [CrossRef]

- Markó, D.; Prashanth, K.; Scudino, S.; Wang, Z.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Al-based metal matrix composites reinforced with Fe49.9Co35.1Nb7.7B4.5Si2.8 glassy powder: Mechanical behavior under tensile loading. J. Alloys Compd. 2014, 615, S382–S385. [Google Scholar] [CrossRef]

- Samuel, A.; Garza-Elizondo, G.; Doty, H.; Samuel, F. Role of modification and melt thermal treatment processes on the microstructure and tensile properties of Al–Si alloys. Mater. Des. 2015, 80, 99–108. [Google Scholar] [CrossRef]

- Kumara, B.; Preetham Kumar, G. Influence of Multi-directional Room-temperature Forging Process on Microstructure and Mechanical Behaviour of Eutectic Al-12Si Alloy. Metallogr. Microstruct. Anal. 2022, 11, 175–182. [Google Scholar] [CrossRef]

- Ficici, F.; Keser, M. Effect of casting modification materials on cutting forces of an Al12Si alloy used in aircraft technology. Mater. Test. 2023, 65, 616–628. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Yue, C.; Kong, X.; Hao, Z.; Wang, T.; Li, T. Processing defect, microstructure evolution and mechanical properties of laser powder bed fusion Al-12Si alloys. J. Mater. Res. Technol. 2023, 26, 681–696. [Google Scholar] [CrossRef]

- Suzuki, A.; Sasa, Y.; Kobashi, M.; Kato, M.; Segawa, M.; Shimono, Y.; Nomoto, S. Persistent Homology Analysis of the Microstructure of Laser-Powder-Bed-Fused Al–12Si Alloy. Materials 2023, 16, 7228. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, A.; Miyasaka, T.; Takata, N.; Kobashi, M.; Kato, M. Control of microstructural characteristics and mechanical properties of AlSi12 alloy by processing conditions of laser powder bed fusion. Addit. Manuf. 2021, 48, 102383. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Saunders, M.; Suvorova, A.; Zhang, L.; Liu, Y.; Fang, M.; Huang, Z.; Sercombe, T.B. A selective laser melting and solution heat treatment refined Al–12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility. Acta Mater. 2015, 95, 74–82. [Google Scholar] [CrossRef]

- Liu, M.; Wada, T.; Suzuki, A.; Takata, N.; Kobashi, M.; Kato, M. Effect of annealing on anisotropic tensile properties of Al–12% Si alloy fabricated by laser powder bed fusion. Crystals 2020, 10, 1007. [Google Scholar] [CrossRef]

- Wang, P.; Lao, C.; Chen, Z.; Liu, Y.; Wang, H.; Wendrock, H.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of Al-12Si and Al-3.5 Cu-1.5 Mg-1Si bimetal fabricated by selective laser melting. J. Mater. Sci. Technol. 2020, 36, 18–26. [Google Scholar] [CrossRef]

- Lu, J.; Liu, H.; Tok, E.S.; Sow, C.-H. Interactions between lasers and two-dimensional transition metal dichalcogenides. Chem. Soc. Rev. 2016, 45, 2494–2515. [Google Scholar] [CrossRef] [PubMed]

- Dai, D.; Gu, D.; Zhang, H.; Xiong, J.; Ma, C.; Hong, C.; Poprawe, R. Influence of scan strategy and molten pool configuration on microstructures and tensile properties of selective laser melting additive manufactured aluminum based parts. Opt. Laser Technol. 2018, 99, 91–100. [Google Scholar] [CrossRef]

- Chakrabarti, D.; Laughlin, D.E. Phase relations and precipitation in Al–Mg–Si alloys with Cu additions. Prog. Mater. Sci. 2004, 49, 389–410. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Ciurana, J.; Hernandez, L.; Delgado, J. Energy density analysis on single tracks formed by selective laser melting with CoCrMo powder material. Int. J. Adv. Manuf. Technol. 2013, 68, 1103–1110. [Google Scholar] [CrossRef]

- Sercombe, T.; Li, X. Selective laser melting of aluminium and aluminium metal matrix composites. Mater. Technol. 2016, 31, 77–85. [Google Scholar] [CrossRef]

- Parry, L.; Ashcroft, I.; Wildman, R.D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef]

- Kim, D.-K.; Woo, W.; Hwang, J.-H.; An, K.; Choi, S.-H. Stress partitioning behavior of an AlSi10Mg alloy produced by selective laser melting during tensile deformation using in situ neutron diffraction. J. Alloys Compd. 2016, 686, 281–286. [Google Scholar] [CrossRef]

- Reschetnik, W.; Brüggemann, J.-P.; Aydinöz, M.; Grydin, O.; Hoyer, K.-P.; Kullmer, G.; Richard, H. Fatigue crack growth behavior and mechanical properties of additively processed EN AW-7075 aluminium alloy. Procedia Struct. Integr. 2016, 2, 3040–3048. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Tabbakh, T.; Alshihri, S.; Basak, A.; Kurdi, A. Strength of a 3D Printed Al 7068 Alloy Under Micro-Pillar Compression. Met. Mater. Int. 2022, 28, 2706–2718. [Google Scholar] [CrossRef]

- Kurdi, A.; Basak, A. Micro-mechanical behaviour of selective laser melted Ti6Al4V under compression. Mater. Sci. Eng. A 2021, 826, 141975. [Google Scholar] [CrossRef]

- Monroy, K.; Delgado, J.; Ciurana, J. Study of the pore formation on CoCrMo alloys by selective laser melting manufacturing process. Procedia Eng. 2013, 63, 361–369. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Murray, J.; McAlister, A. The Al-Si (aluminum-silicon) system. Bull. Alloy Phase Diagr. 1984, 5, 74–84. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.; Hoagland, R. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Prenitzer, B.; Urbanik-Shannon, C.; Giannuzzi, L.; Brown, S.; Irwin, R.; Shofner, T.; Stevie, F. The correlation between ion beam/material interactions and practical FIB specimen preparation. Microsc. Microanal. 2003, 9, 216–236. [Google Scholar] [CrossRef][Green Version]

- Basak, A.; Pramanik, A.; Prakash, C. Deformation and strengthening of SiC reinforced Al-MMCs during in-situ micro-pillar compression. Mater. Sci. Eng. A 2019, 763, 138141. [Google Scholar] [CrossRef]

- Sneddon, I.N. The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 1965, 3, 47–57. [Google Scholar] [CrossRef]

- Roylance, D. Stress-Strain Curves; Massachusetts Institute of Technology Study: Cambridge, MA, USA, 2001. [Google Scholar]

- Basak, A.K.; Kurdi, A.; Radhika, N.; Arputharaj, J.; Prakash, C.; Pramanik, A.; Shankar, S. Compressive mechanical properties of thermal sprayed AlCoCrFeNi high entropy alloy coating. J. Alloys Compd. 2024, 1003, 175721. [Google Scholar] [CrossRef]

- Basak, A.K.; Radhika, N.; Prakash, C.; Pramanik, A. Investigation on the Microstructure and Micro-Mechanical Properties of Thermal-Sprayed NiCoCrAlY High Entropy Alloy Coating. Designs 2024, 8, 37. [Google Scholar] [CrossRef]

- Degnah, A.; Tabbakh, T.; Kurdi, A.; Basak, A.K. Role of precipitation and solute segregation on micro-scale deformation of additively manufactured Inconel 718. Mater. Sci. Eng. A 2023, 887, 145762. [Google Scholar] [CrossRef]

- Kurdi, A.; Aldoshan, A.; Alshabouna, F.; Alodadi, A.; Degnah, A.; Alnaser, H.; Tabbakh, T.; Basak, A.K. Investigation into the microstructure and hardness of additively manufactured (3D-Printed) Inconel 718 Alloy. Materials 2023, 16, 2383. [Google Scholar] [CrossRef] [PubMed]

- Vandeperre, L.; Giuliani, F.; Lloyd, S.; Clegg, W. The hardness of silicon and germanium. Acta Mater. 2007, 55, 6307–6315. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Chaudhri, M.M. The influence of grain size on the indentation hardness of high-purity copper and aluminium. Philos. Mag. A 2002, 82, 2071–2080. [Google Scholar] [CrossRef]

| Properties | P-LBF-Processed Al-12Si (wt. %) Alloy | Cast Al-12Si (wt. %) Alloy | ||

|---|---|---|---|---|

| Lateral (YZ) Plane | Frontal (XZ) Plane | Horizontal (XY) Plane | ||

| Density (gm/cc) | 2.60 | 2.63 | ||

| Yield strength (σy), MPa | 23.69 ± 3.35 | 24.61 ± 2.36 | 27.94 ± 4.87 | 31.46 ± 3.25 |

| Ultimate compressive strength (σUTS), MPa | 75.43 ± 8.39 | 78.68 ± 8.98 | 81.21 ± 7.38 | 34.95 ± 6.12 |

| Young’s modulus (GPa) | 36.89 ± 4.35 | 31.89 ± 3.95 | 37.41 ± 4.12 | 80.64 ± 5.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsolami, A.; Zaman, A.; Alshabouna, F.; Kurdi, A.; Degnah, A.; Alfihed, S.; Tabbakh, T.; Basak, A.K. Effect of Processing Route on Microstructure and Mechanical Properties of an Al-12Si Alloy. Materials 2024, 17, 4780. https://doi.org/10.3390/ma17194780

Alsolami A, Zaman A, Alshabouna F, Kurdi A, Degnah A, Alfihed S, Tabbakh T, Basak AK. Effect of Processing Route on Microstructure and Mechanical Properties of an Al-12Si Alloy. Materials. 2024; 17(19):4780. https://doi.org/10.3390/ma17194780

Chicago/Turabian StyleAlsolami, Abdulrahman, Adnan Zaman, Fahad Alshabouna, Abdulaziz Kurdi, Ahmed Degnah, Salman Alfihed, Thamer Tabbakh, and Animesh Kumar Basak. 2024. "Effect of Processing Route on Microstructure and Mechanical Properties of an Al-12Si Alloy" Materials 17, no. 19: 4780. https://doi.org/10.3390/ma17194780

APA StyleAlsolami, A., Zaman, A., Alshabouna, F., Kurdi, A., Degnah, A., Alfihed, S., Tabbakh, T., & Basak, A. K. (2024). Effect of Processing Route on Microstructure and Mechanical Properties of an Al-12Si Alloy. Materials, 17(19), 4780. https://doi.org/10.3390/ma17194780