Experimental and Numerical Insights into the Multi-Impact Response of Cork Agglomerates

Abstract

1. Introduction

2. Materials and Methods

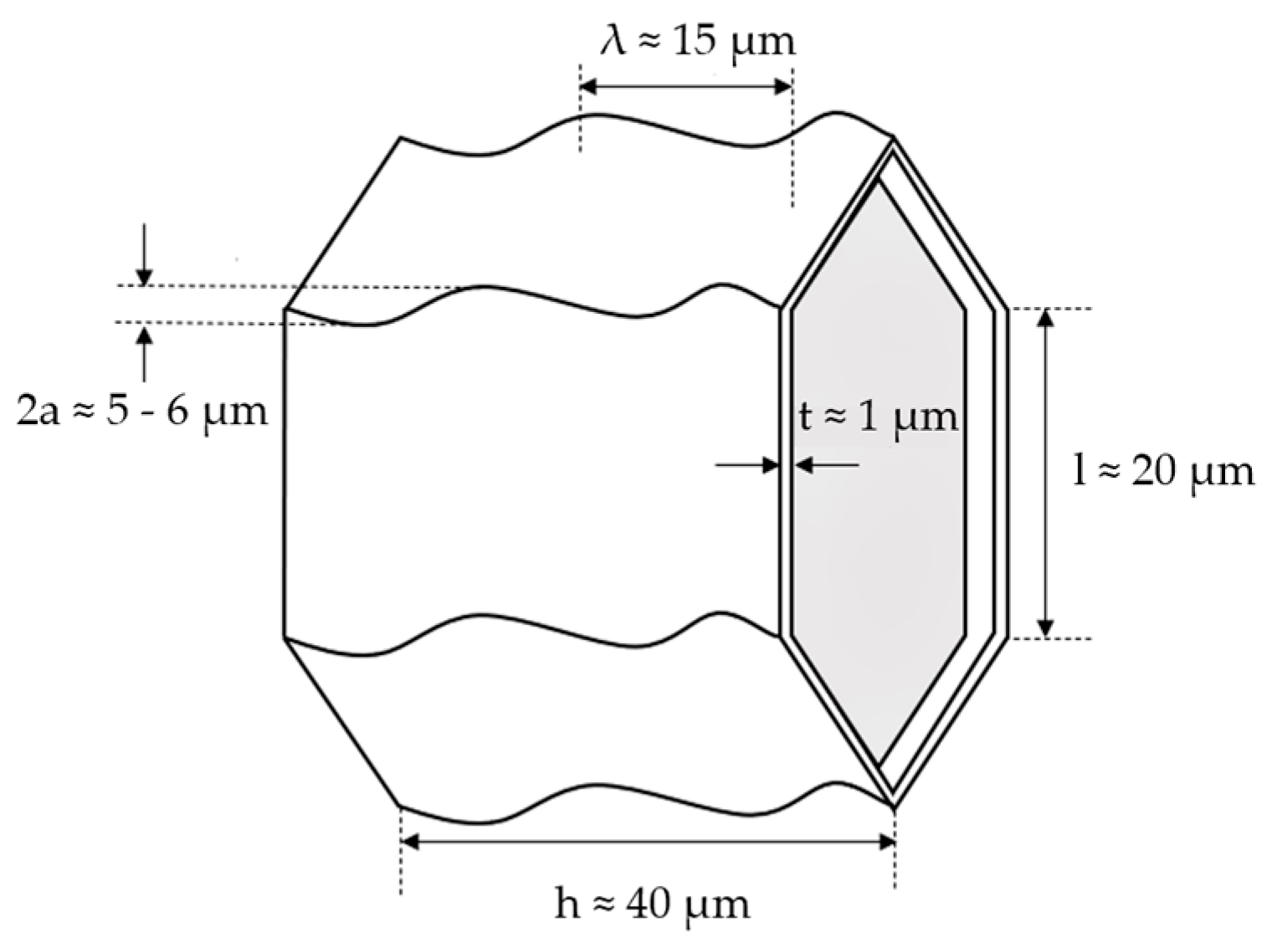

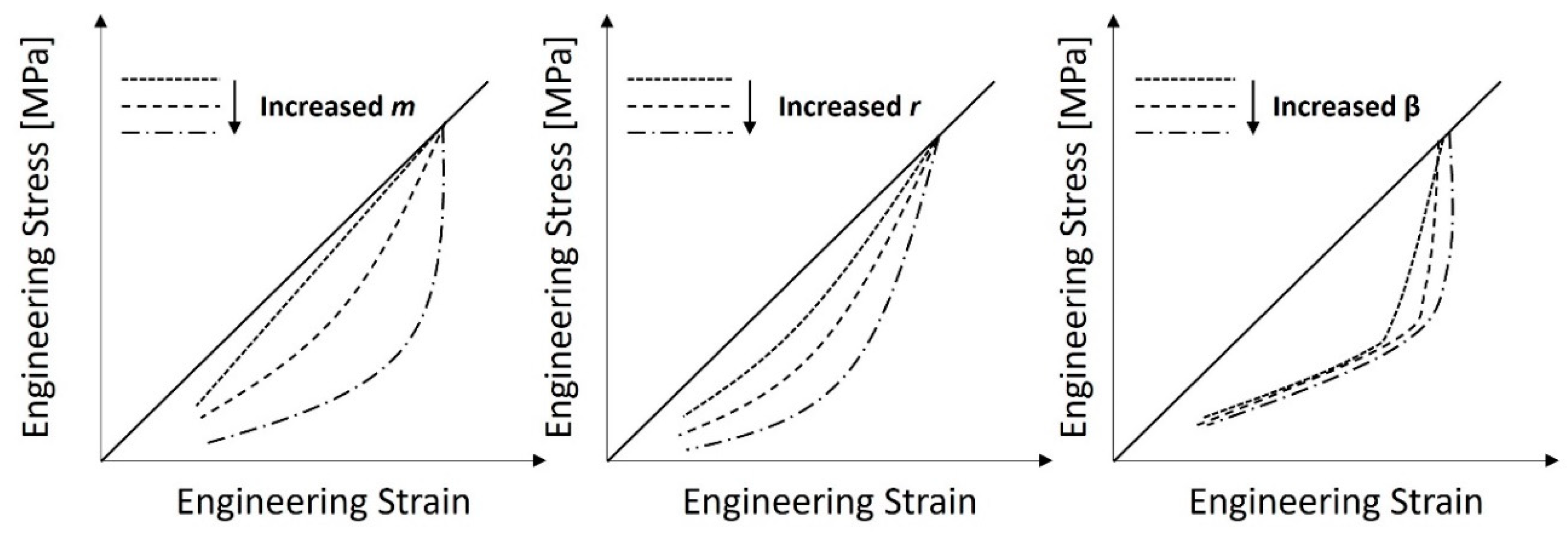

2.1. Fundamentals and Constitutive Laws

2.2. Finite Element Simulation

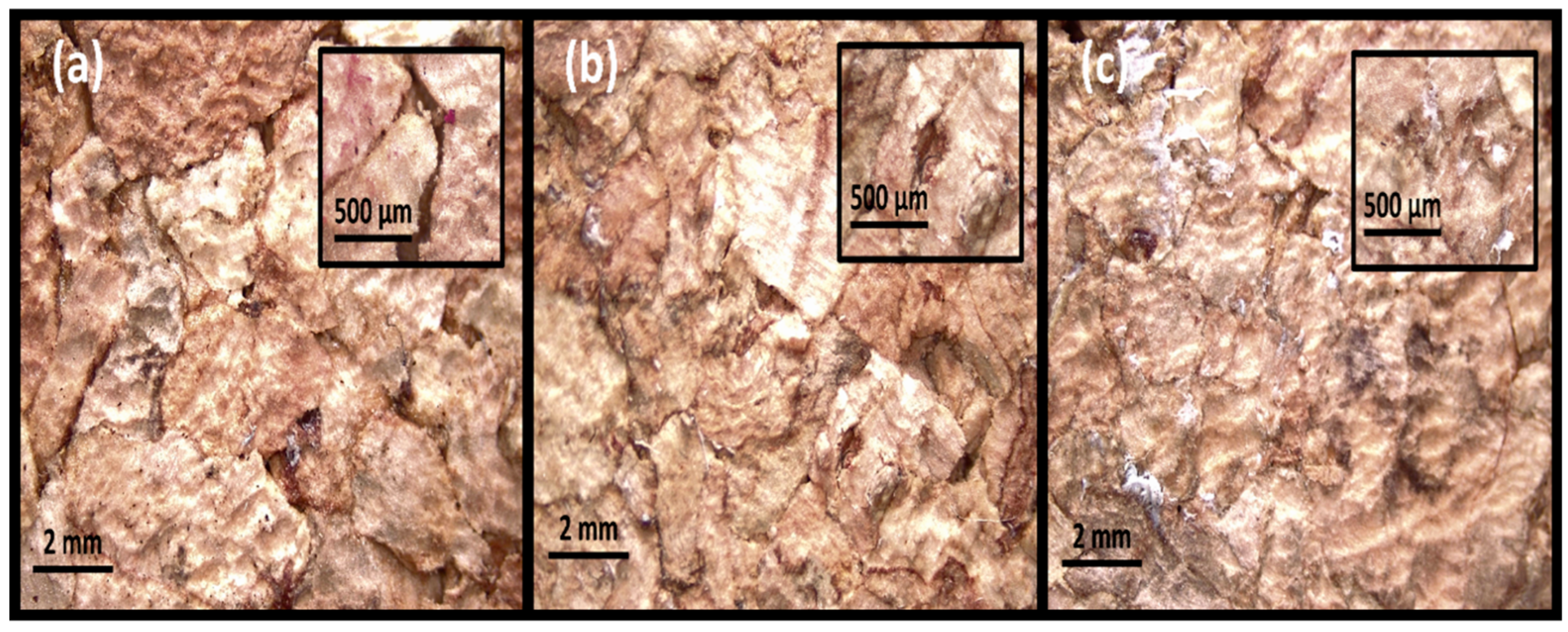

2.3. Agglomerated Cork Samples

3. Experimental Campaign

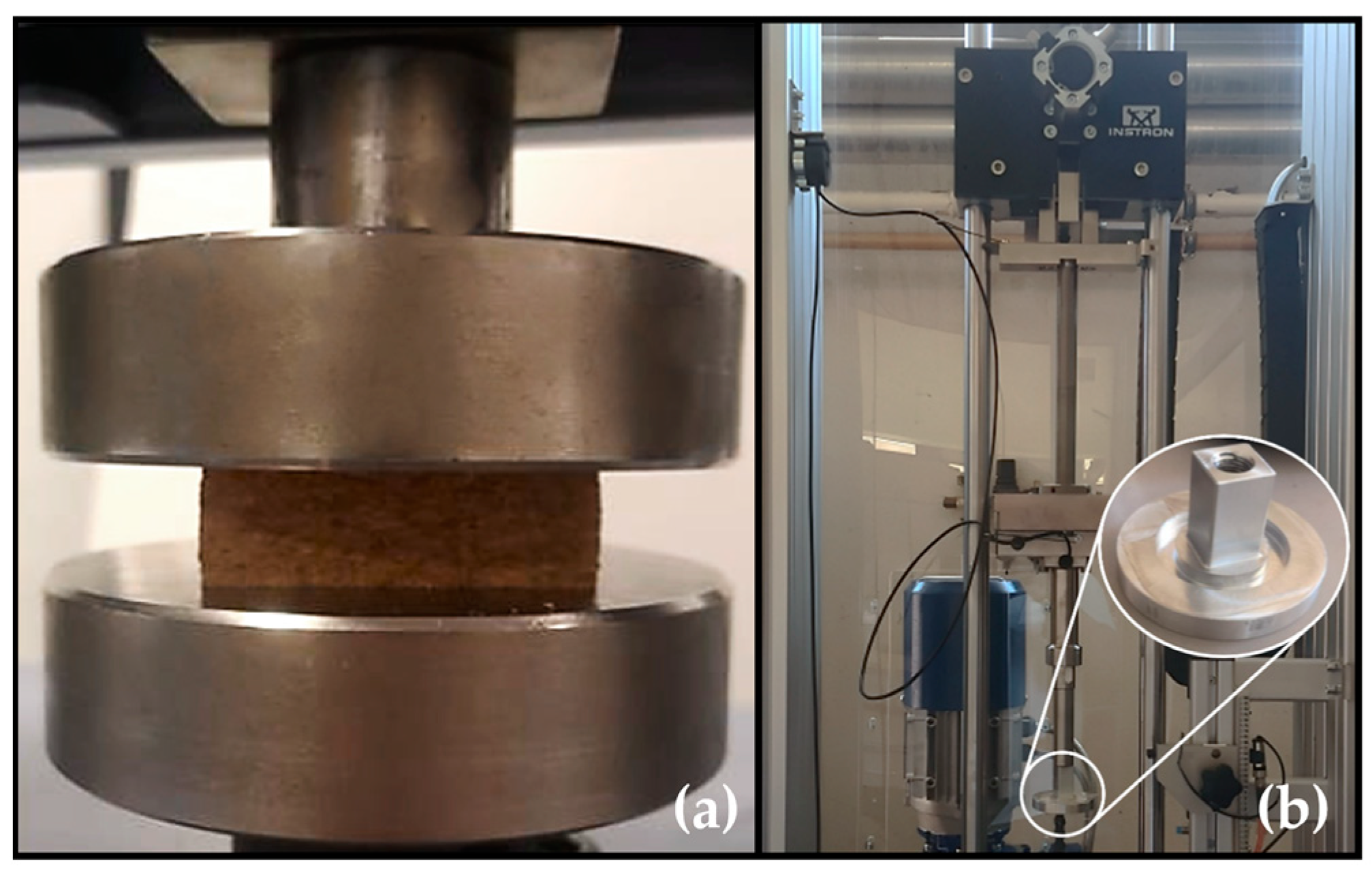

3.1. Uniaxial Quasi-Static Compression Test

3.2. Impact Tests

4. Results and Discussion

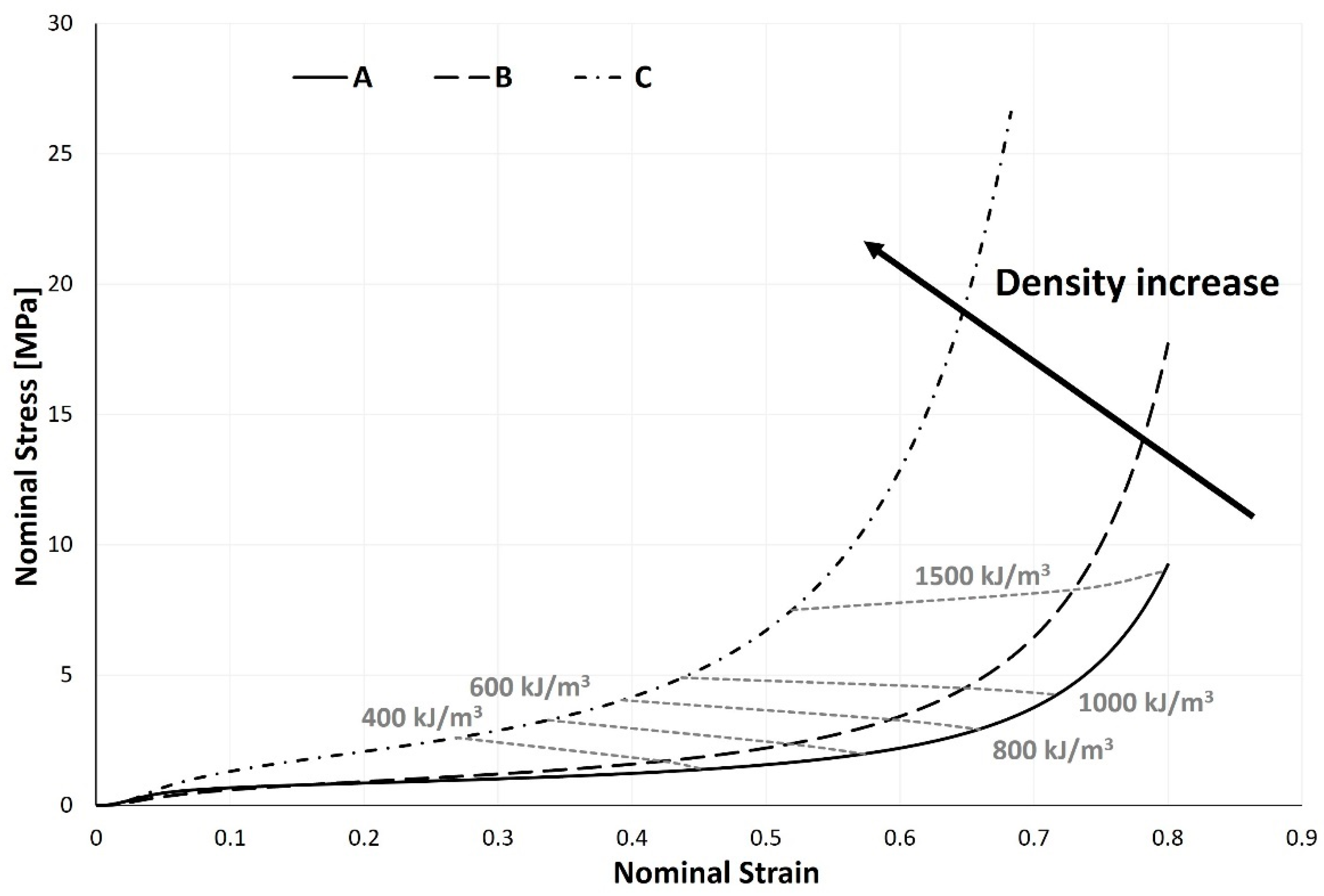

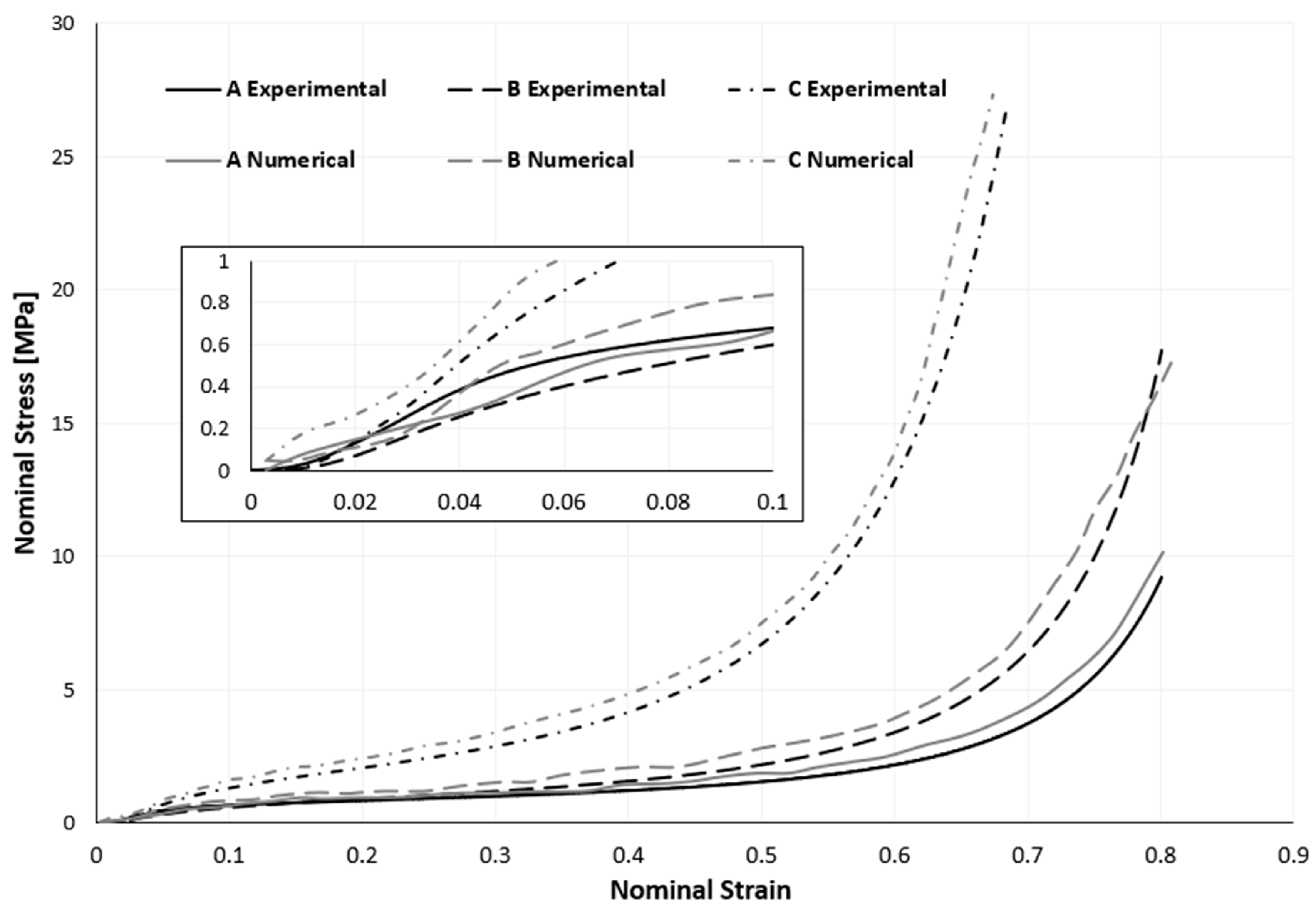

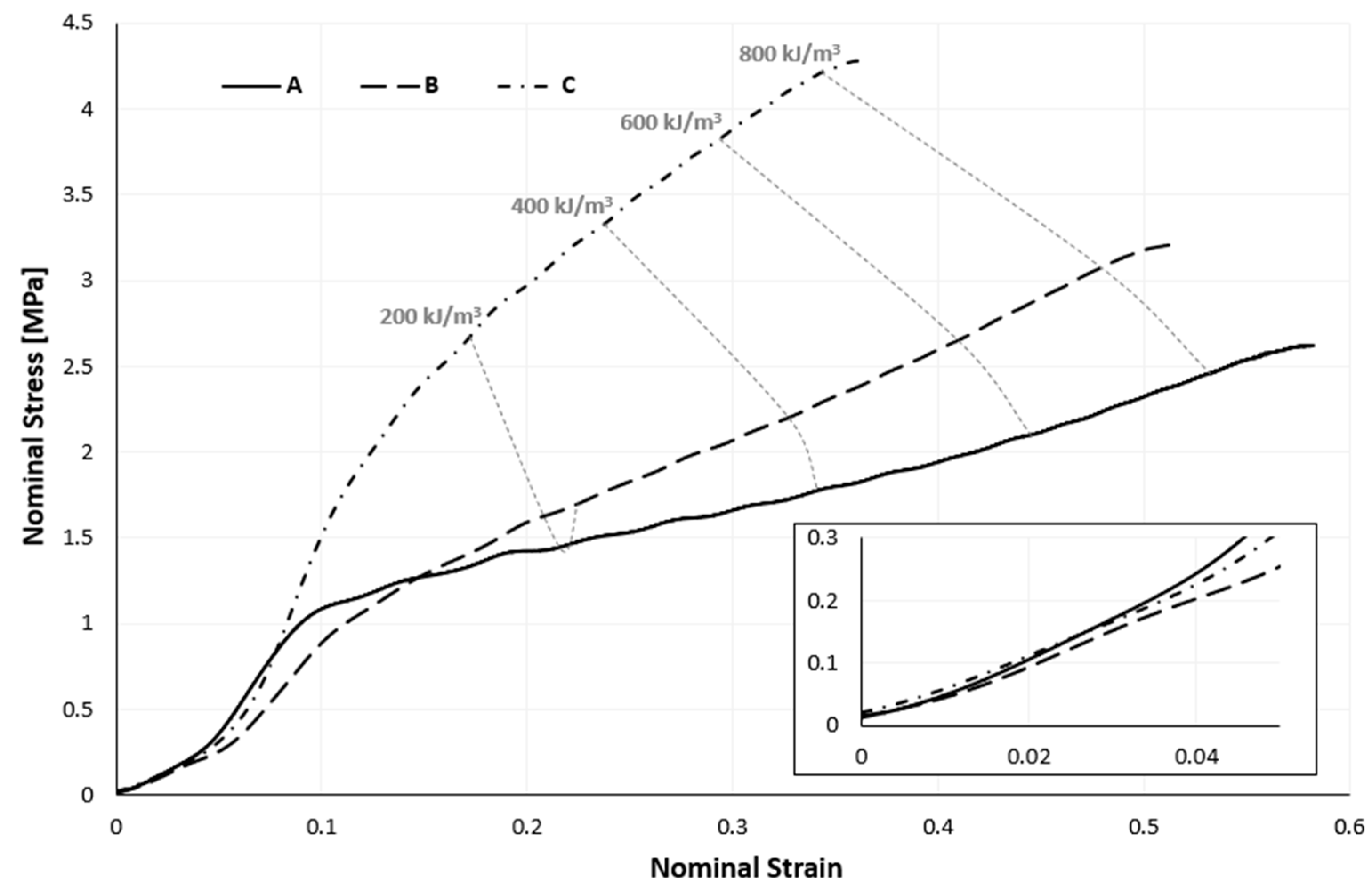

4.1. Uniaxial Quasi-Static Compressive Tests

4.2. Dynamic Impact Tests

4.2.1. Acceleration Peaks

4.2.2. Rebound Velocity and Bounce-Back

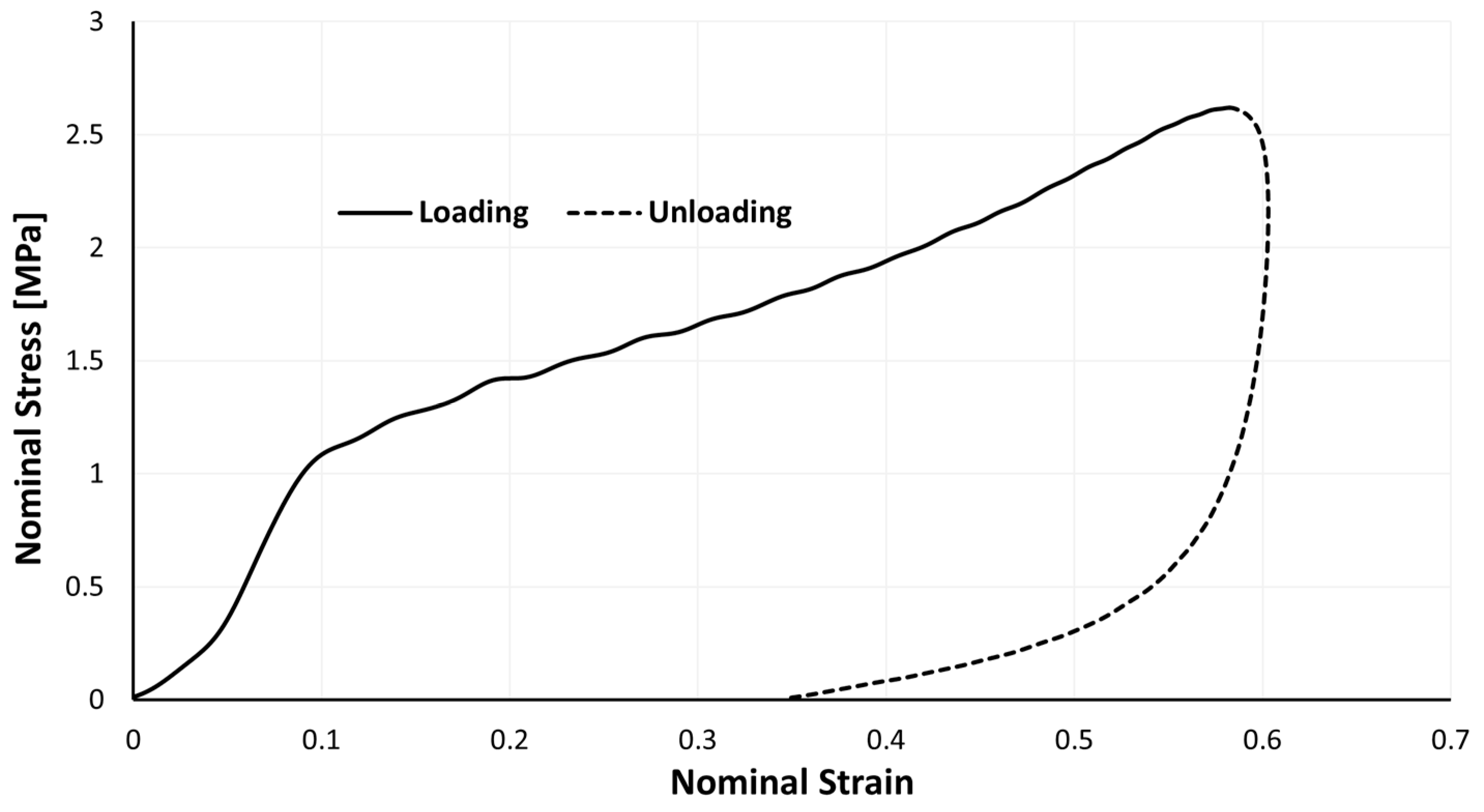

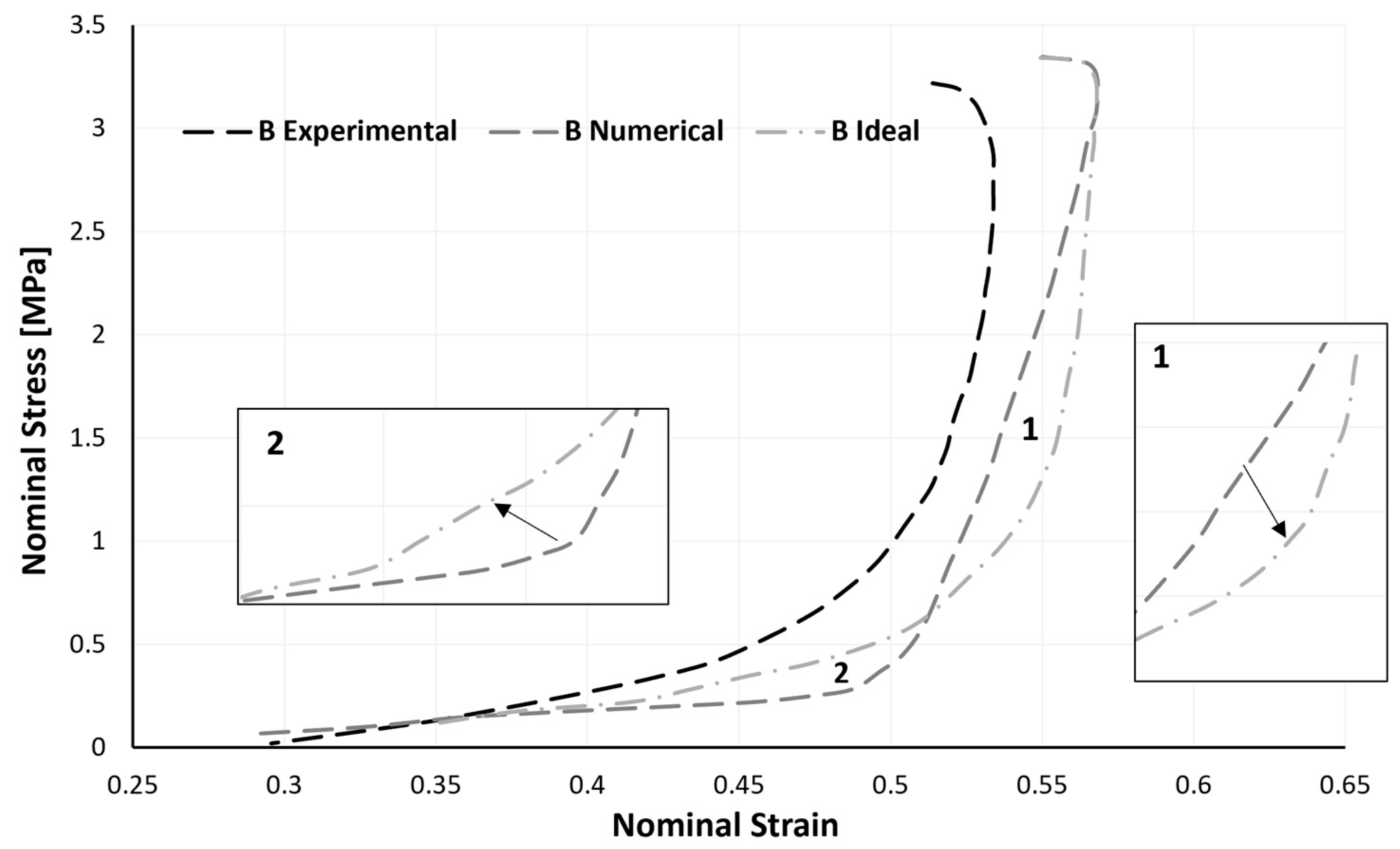

4.2.3. Unloading Phase

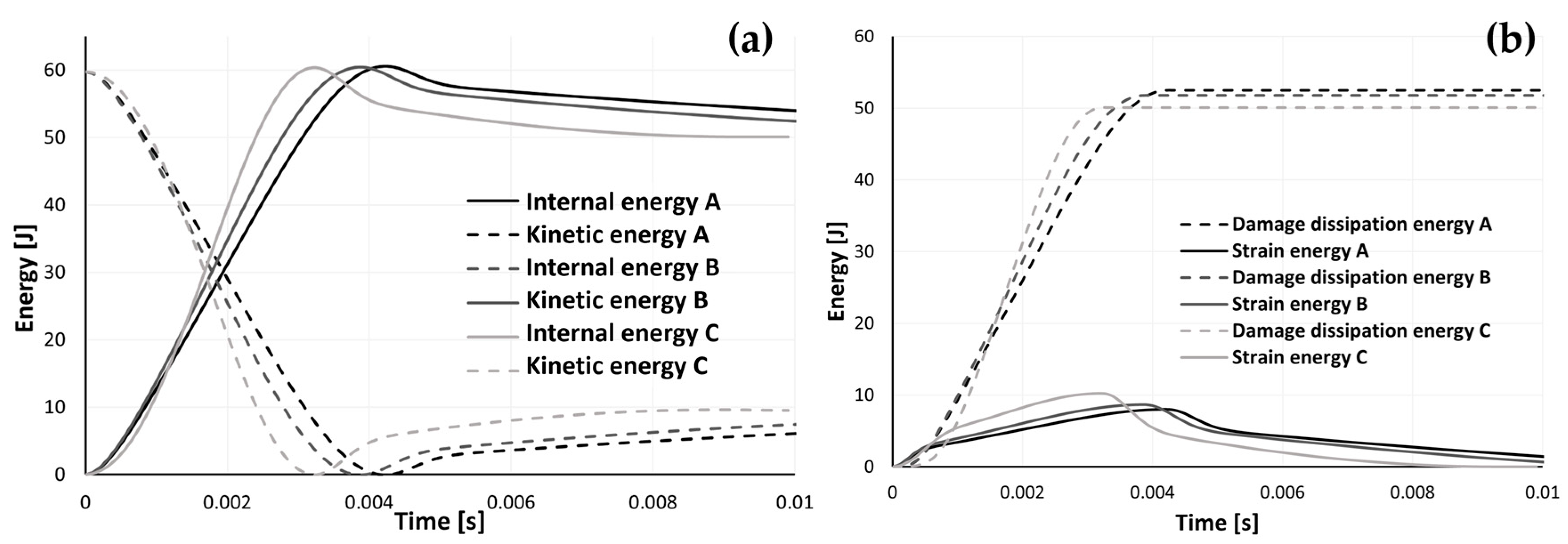

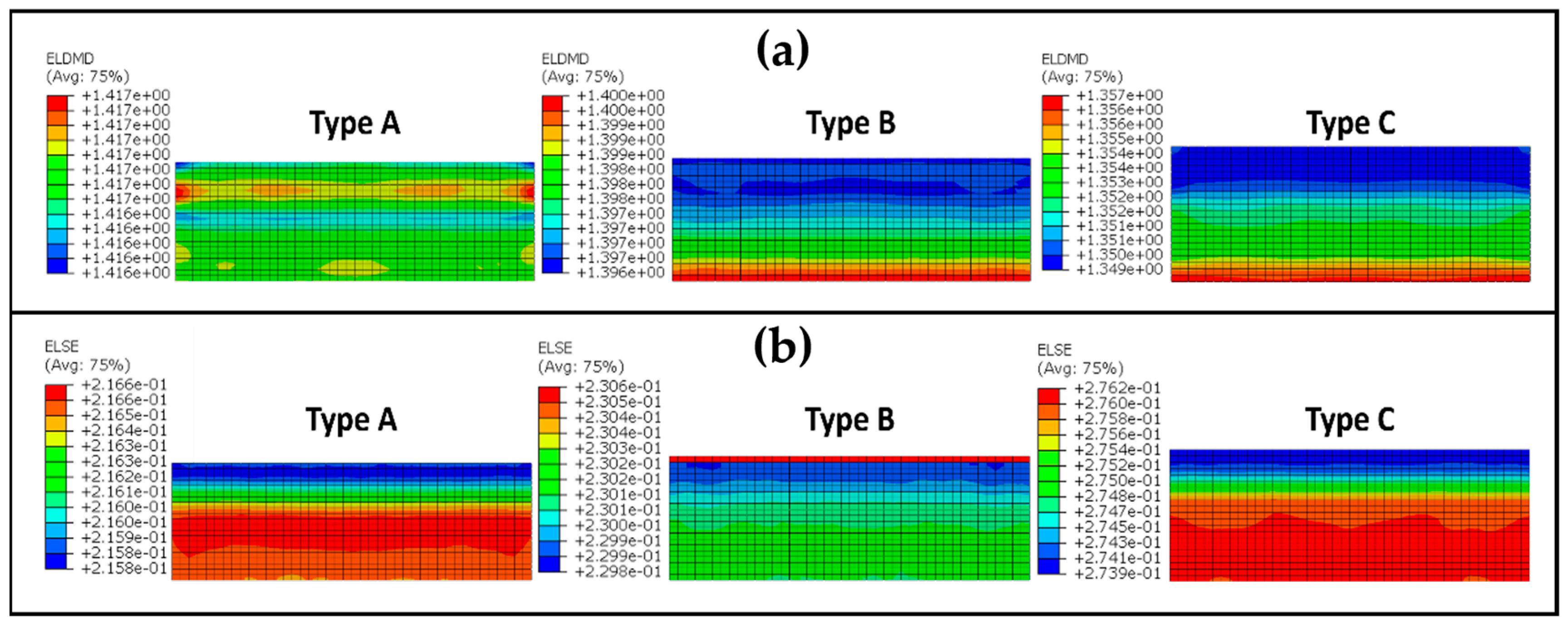

4.2.4. Impact Tests’ Numerical Results

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alcântara, I.; Teixeira-Dias, F.; Paulino, M. Cork composites for the absorption of impact energy. Compos. Struct. 2013, 95, 16–27. [Google Scholar] [CrossRef]

- Paulino, M.; Teixeira-Dias, F. An energy absorption performance index for cellular materials—Development of a side-impact cork padding. Int. J. Crashworthiness 2011, 16, 135–153. [Google Scholar] [CrossRef]

- Gibson, L.; Ashby, M. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge Solid State Science Series; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Fernandes, F.A.O.; Alves de Sousa, R.J. Motorcycle helmets—A state of the art review. Accid. Anal. Prev. 2013, 56, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Landro, D.L.; Sala, G.; Olivieri, D. Deformation mechanisms and energy absorption of polystyrene foams for protective helmets. Polym. Test. 2002, 21, 217–218. [Google Scholar] [CrossRef]

- Mills, N.J.; Stämpfli, R.; Marone, F.; Brühwiler, P.A. Finite elements micromechanics model of impact compression of closed-cell polymer foams. Int. J. Solids Struct. 2009, 46, 677–697. [Google Scholar] [CrossRef]

- Ouellet, S.; Cronin, D.; Worswick, M. Compressive response of polymerics foams under quasi-static, medium and high strain rate conditions. Polym. Test. 2006, 25, 731–743. [Google Scholar] [CrossRef]

- Fernandes, F.A.O.; Jardin, R.T.; Pereira, A.B.; Alves de Sousa, R.J. Comparing the mechanical performance of synthetic and natural cellular materials. Mater. Des. 2015, 82, 335–341. [Google Scholar] [CrossRef]

- Ptak, M.; Kaczynski, P.; Fernandes, F.A.O.; Alves de Sousa, R.J. Assessing impact velocity and temperature effects on crashworthiness properties of cork material. Int. J. Impact Eng. 2017, 106, 238–249. [Google Scholar] [CrossRef]

- Kaczynsky, P.; Ptak, M.; Wilhelm, J.; Fernandes, F.A.O.; Alves de Sousa, R.J. High-energy impact testing of agglomerated cork at extremely low and high temperatures. Int. J. Impact Eng. 2019, 126, 109–116. [Google Scholar] [CrossRef]

- Pereira, H. Cork: Biology, Production and Uses, 1st ed.; Elsevier Science: Amsterdam, The Netherlands, 2007; ISBN 9780080476865. Available online: https://shop.elsevier.com/books/cork-biology-production-anduses/pereira/978-0-444-52967-1 (accessed on 25 September 2023).

- Gil, L. Patent search on cork (2010–2015). Ciência Tecnol. Mater. 2017, 29, 63–64. [Google Scholar] [CrossRef]

- Castro, O.; Silva, J.M.; Devezas, T.; Silva, A.; Gil, L. Cork agglomerates as an ideal core material in lightweight structures. Mater. Des. 2010, 31, 425–432. [Google Scholar] [CrossRef]

- Suffo, M.; Sales, D.L.; Cortés-Triviño; de la Mata, M.; Jiménez, E. Characterization and production of agglomerated cork stoppers for spirits based on a factor analysis method. Food Packag. Shelf Lide 2022, 31, 1008–1015. [Google Scholar] [CrossRef]

- Serra, G.; Fernandes, F.A.O.; Alves de Sousa, R.J.; Noronha, E.; Ptak, M. New hybrid cork-STF (shear thickening fluid) polymeric composites to enhance head safety in micro-mobility accidents. Compos. Struct. 2022, 301, 1138–1161. [Google Scholar] [CrossRef]

- Buil, R.M.; Angulo, D.R.; Ivens, J.; Blasco, J.O.A. Experimental study of natural cork and cork agglomerates as a substitute for expanded polystyrene foams under compressive loads. Wood Sci. Technol. 2021, 55, 419–443. [Google Scholar] [CrossRef]

- Antunes e Sousa, G.J.; Rocha, A.; Serra, G.; Fernandes, F.A.O.; Alves de Sousa, R.J. Shear thickening fluids in cork agglomerates: An exploration of advantages and drawbacks. Sustainability 2023, 15, 6764. [Google Scholar] [CrossRef]

- Fortes, M.A.; Nogueira, M.T. The poison effect in cork. Mater. Sci. Eng. A 1989, 122, 227–232. [Google Scholar] [CrossRef]

- Anjos, O.; Pereira, H.; Rosa, M.E. Effect of quality, porosity and density on the compression properties of cork. Eur. J. Wood Wood Prod. 2008, 66, 295–301. [Google Scholar] [CrossRef]

- Sanchez-Saez, S.; Barbero, E.; Garcia-Castillo, S.K.; Ivañez, I.; Cirne, J. Experimental response of agglomerated cork under multi-impact loads. Mater. Lett. 2015, 160, 327–330. [Google Scholar] [CrossRef]

- Anjos, O.; Rodrigues, C.; Morais, J.; Pereira, H. Effect of density on the compression behaviour of cork. Mater. Des. 2014, 53, 1089–1096. [Google Scholar] [CrossRef]

- Santos, P.T.; Marques, P.A.A.P.; Pereira, A.B.; Alves de Sousa, R.J. Agglomerated cork: A way to tailor its mechanical properties. Compos. Struct. 2017, 178, 277–287. [Google Scholar] [CrossRef]

- Gameiro, C.P.; Cirne, J.; Gary, G.; Miranda, V.; Pinho-da-Cruz, J.; Teixeira-Dias, F. Numerical and experimental study of the dynamic behaviour of cork. In 3rd Light-Weight Armour Group Workshop: Design and Use of Light-Weight Materials; HAL: Aveiro, Portugal, 2006; pp. 65–84. Available online: https://hal.science/hal-00119990v1 (accessed on 25 September 2023).

- Fernandes, F.A.O.; Pascoal, R.J.S.; Alves de Sousa, R.J. Modelling impact response of agglomerated cork. Mater. Des. 2014, 58, 499–507. [Google Scholar] [CrossRef]

- Gomez, A.; Barbero, H.; Sanchez-Saez, S. Modelling of carbon/epoxy sandwich panels with agglomerated cork core subjected to impact loads. Int. J. Impact Eng. 2022, 159, 1040–1047. [Google Scholar] [CrossRef]

- Johnson, A.F. Modelling fabric reinforced composites under impact loads. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1197–1206. [Google Scholar] [CrossRef]

- Ladeveze, P.; Ledantec, E. Damage modelling of the elementary ply for laminated composites. Compos. Sci. Technol. 1992, 43, 257–267. [Google Scholar] [CrossRef]

- Tsai, S.W.; Wu, E.M. A General Theory of Strength for Anisotropic Materials. J. Compos. Mater. 1971, 5, 58–80. [Google Scholar] [CrossRef]

- Sergi, C.; Boria, S.; Sarasini, F.; Russo, P.; Vitiello, L.; Barbero, E.; Sanchez-Saez, S.; Tirillò, J. Experimental and finite element analysis of the impact response of agglomerated cork and its intraply hybrid flax/basalt sandwich structures. Compos. Struct. 2021, 272, 1110–1124. [Google Scholar] [CrossRef]

- Sergi, C.; Sarasini, F.; Russo, P.; Vitiello, L.; Barbero, E.; Sanchez-Saez, S.; Tirillò, J. Experimental and numerical analysis of the ballistic response of agglomerated cork and its bio-based sandwich structures. Eng. Fail. Anal. 2022, 131, 1040–1059. [Google Scholar] [CrossRef]

- ABAQUS 6.10 Documentation; Hibbitt, Karlsson & Sorensen, Inc.: Providence, RI, USA, 2010.

- Hacket, R.M. Strain-Energy Function. In Hyperelasticity Primer, 1st ed.; Springer International: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Smith, M. ABAQUS/Standard User’s Manual, Version 6.9; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2009. [Google Scholar]

- PolymerFEM. Parametric Study of the Mullins Effect Model. 2021. Available online: https://polymerfem.com/parametric-study-of-the-mullins-effect-model/ (accessed on 24 June 2023).

| Material | Density [kg/m3] | Grain Size [mm] | Binder | Binder Content [wt.%] |

|---|---|---|---|---|

| A | 210 | 2–4 | PU Rigid | 15 |

| B | 300 | 2–5 | PU Rigid | 14 |

| C | 400 | 2–4 | PU Rigid | 12 |

| Material | Densification Strain | Energy Density [MJ/m3] |

|---|---|---|

| Type A | 0.718 | 0.929 |

| Type B | 0.698 | 1.276 |

| Type C | 0.502 | 1.374 |

| Material | Density [kg/m3] | Peak Force [N] | SD Force | Peak Acceleration [g] | SD Acceleration | Peak Strain | SD Strain |

|---|---|---|---|---|---|---|---|

| Type A | 210 | 6549.05 | 9.33 | 81.94 | 0.12 | 0.583 | 0.00346 |

| Type B | 300 | 8022.17 | 101.37 | 100.37 | 1.26 | 0.516 | 0.00531 |

| Type C | 400 | 10717.18 | 386.80 | 134.09 | 4.84 | 0.365 | 0.00575 |

| Impact Energy [J] | 60 | 120 | ||

|---|---|---|---|---|

| Material | Strain | Energy Density [MJ/m3] | Strain | Energy Density [MJ/m3] |

| A | 0.584 | 0.931 | 0.776 | 1.882 |

| B | 0.515 | 0.912 | 0.675 | 1.845 |

| C | 0.364 | 0.889 | 0.514 | 1.838 |

| Material | Density [kg/m3] | Poisson Ratio | N | r | m | β |

|---|---|---|---|---|---|---|

| Type A | 210 | ≈0 | 2 | 1.1 | 0.07 | 0.01 |

| Type B | 300 | 0.08 | 0.02 | |||

| Type C | 400 | 0.14 | 0.01 |

| Material | Peak Force [N] | Peak Acceleration [g] | Peak Strain | |||

|---|---|---|---|---|---|---|

| Exp. | Num. | Exp. | Num. | Exp. | Num. | |

| Type A | 6459.05 | 6789.98 | 81.94 | 86.13 | 0.364 | 0.365 |

| Type B | 8022.17 | 8363.25 | 101.37 | 105.68 | 0.521 | 0.551 |

| Type C | 10,717.18 | 11,813.88 | 134.09 | 147.81 | 0.591 | 0.627 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antunes e Sousa, G.J.; Silva, A.J.C.; Serra, G.F.; Fernandes, F.A.O.; Silva, S.P.; Alves de Sousa, R.J. Experimental and Numerical Insights into the Multi-Impact Response of Cork Agglomerates. Materials 2024, 17, 4772. https://doi.org/10.3390/ma17194772

Antunes e Sousa GJ, Silva AJC, Serra GF, Fernandes FAO, Silva SP, Alves de Sousa RJ. Experimental and Numerical Insights into the Multi-Impact Response of Cork Agglomerates. Materials. 2024; 17(19):4772. https://doi.org/10.3390/ma17194772

Chicago/Turabian StyleAntunes e Sousa, Guilherme J., Afonso J. C. Silva, Gabriel F. Serra, Fábio A. O. Fernandes, Susana P. Silva, and Ricardo J. Alves de Sousa. 2024. "Experimental and Numerical Insights into the Multi-Impact Response of Cork Agglomerates" Materials 17, no. 19: 4772. https://doi.org/10.3390/ma17194772

APA StyleAntunes e Sousa, G. J., Silva, A. J. C., Serra, G. F., Fernandes, F. A. O., Silva, S. P., & Alves de Sousa, R. J. (2024). Experimental and Numerical Insights into the Multi-Impact Response of Cork Agglomerates. Materials, 17(19), 4772. https://doi.org/10.3390/ma17194772