Effects of Scanning Speed on the Microstructure and Wear Properties of Rockit 606 Coating Layer by Disk Laser Cladding

Abstract

1. Introduction

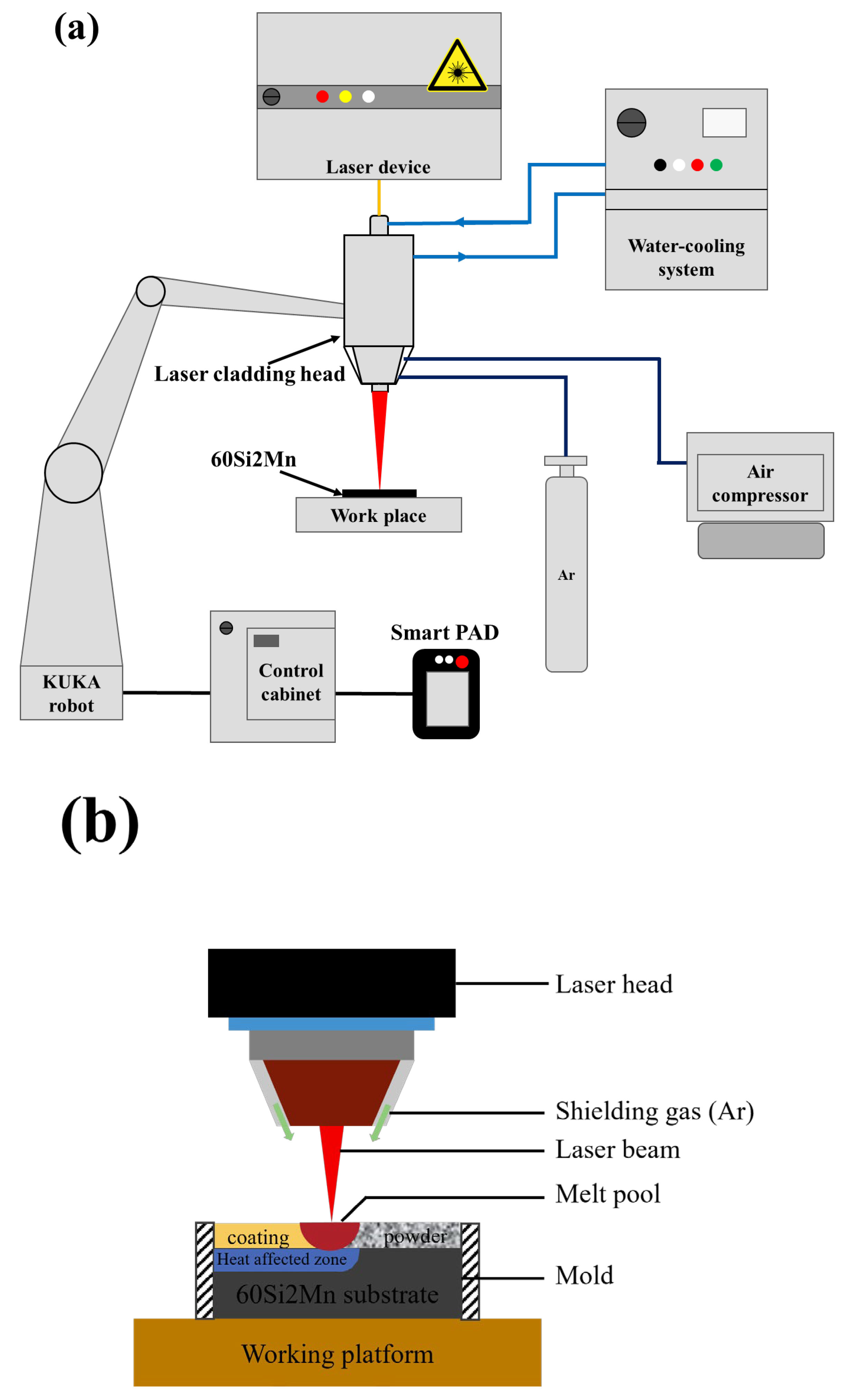

2. Materials and Methods

2.1. Materials

2.2. Laser Cladding

2.3. Sample Characterization

3. Results and Discussion

3.1. Macroscopic Morphology Analysis

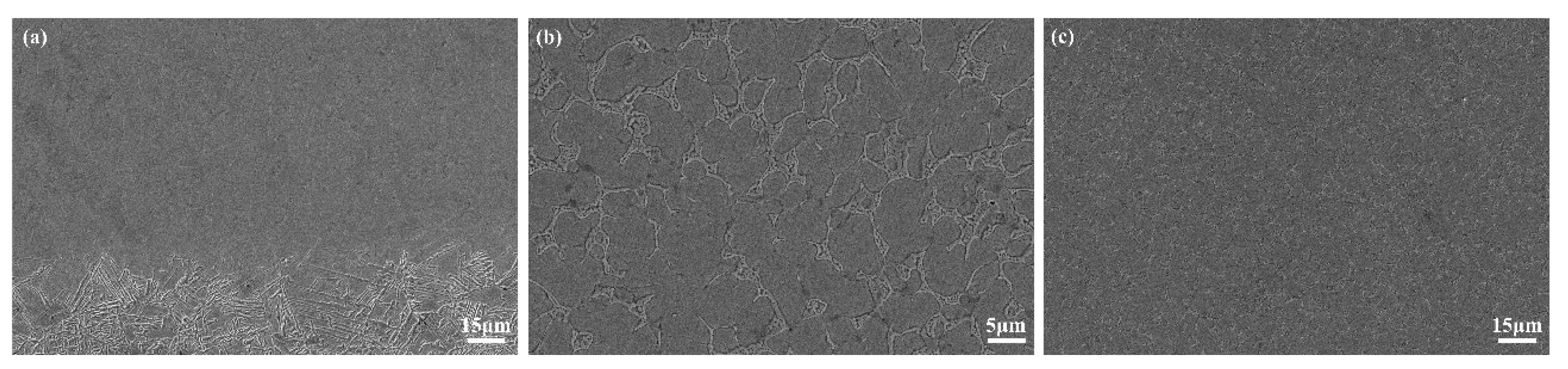

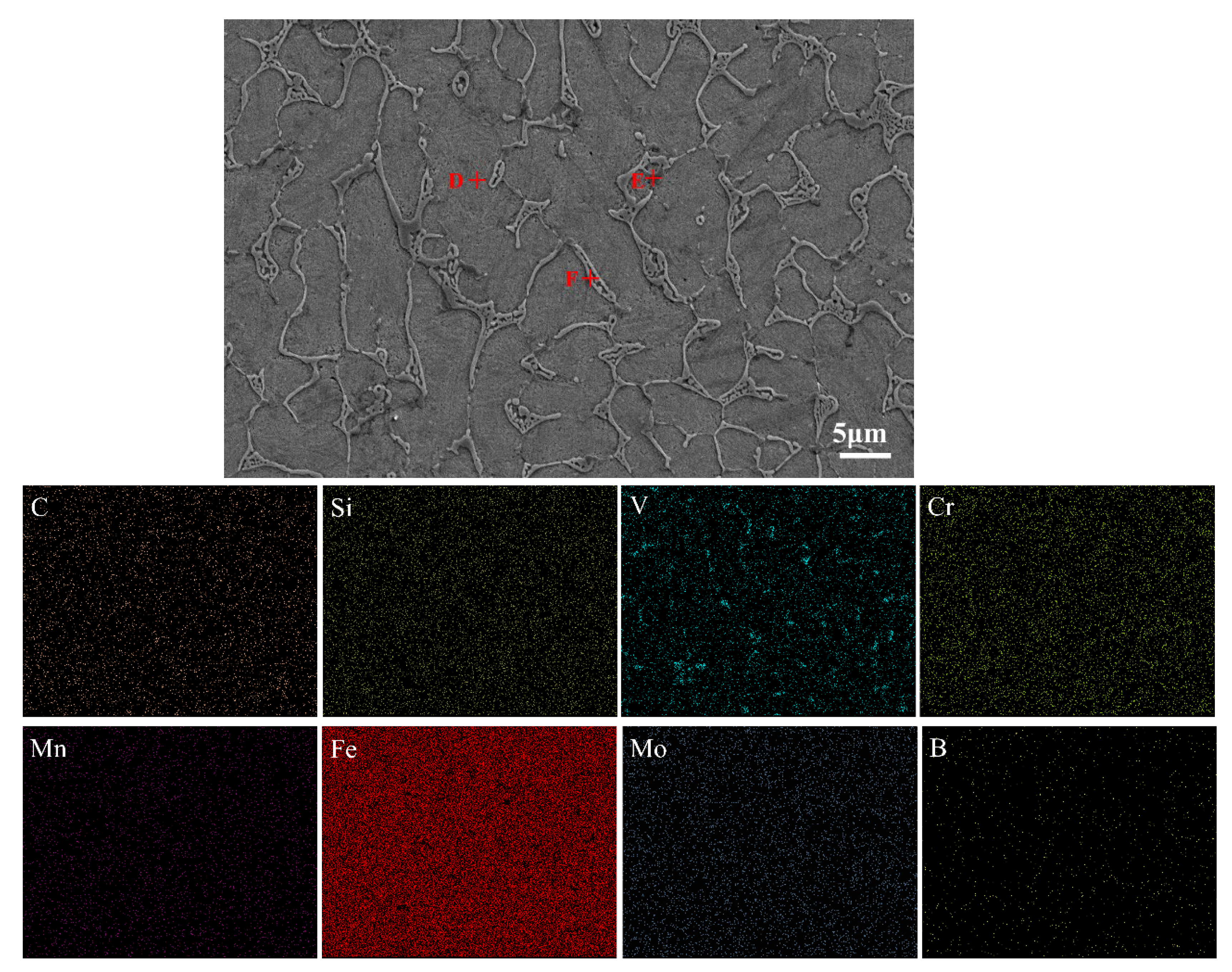

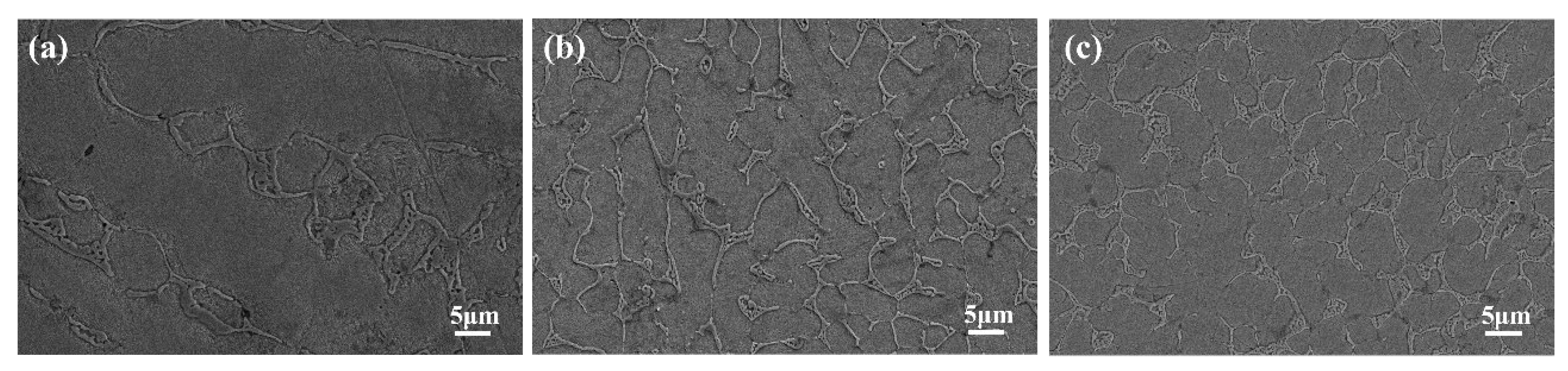

3.2. Microstructure Evaluation

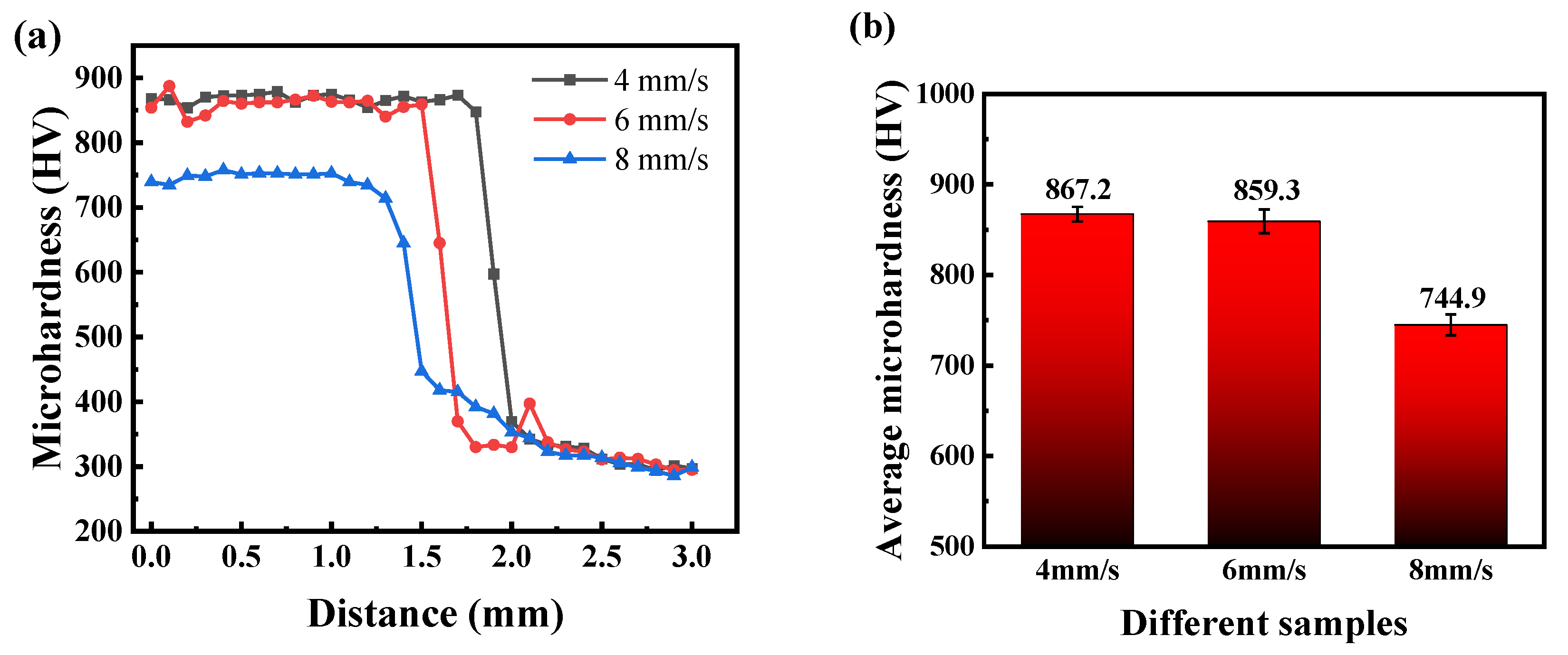

3.3. Microhardness

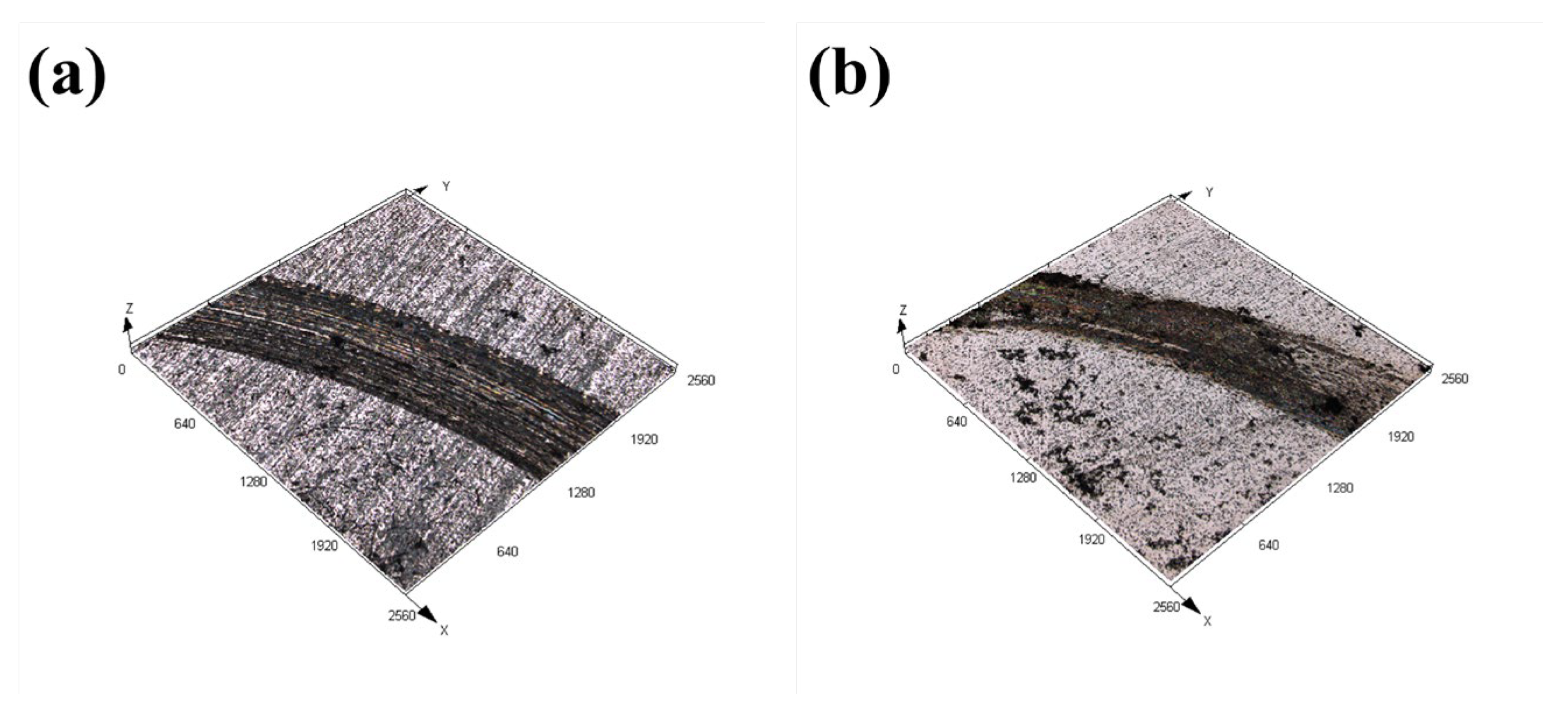

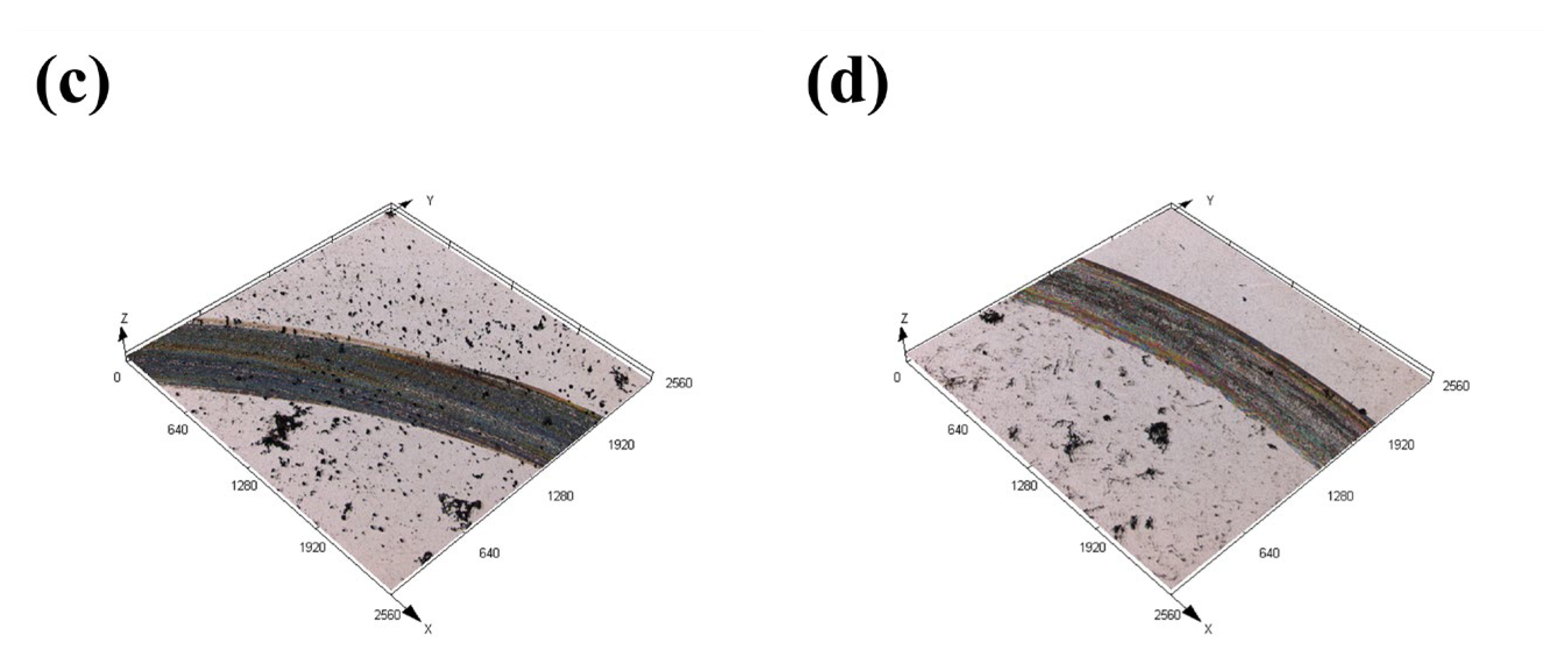

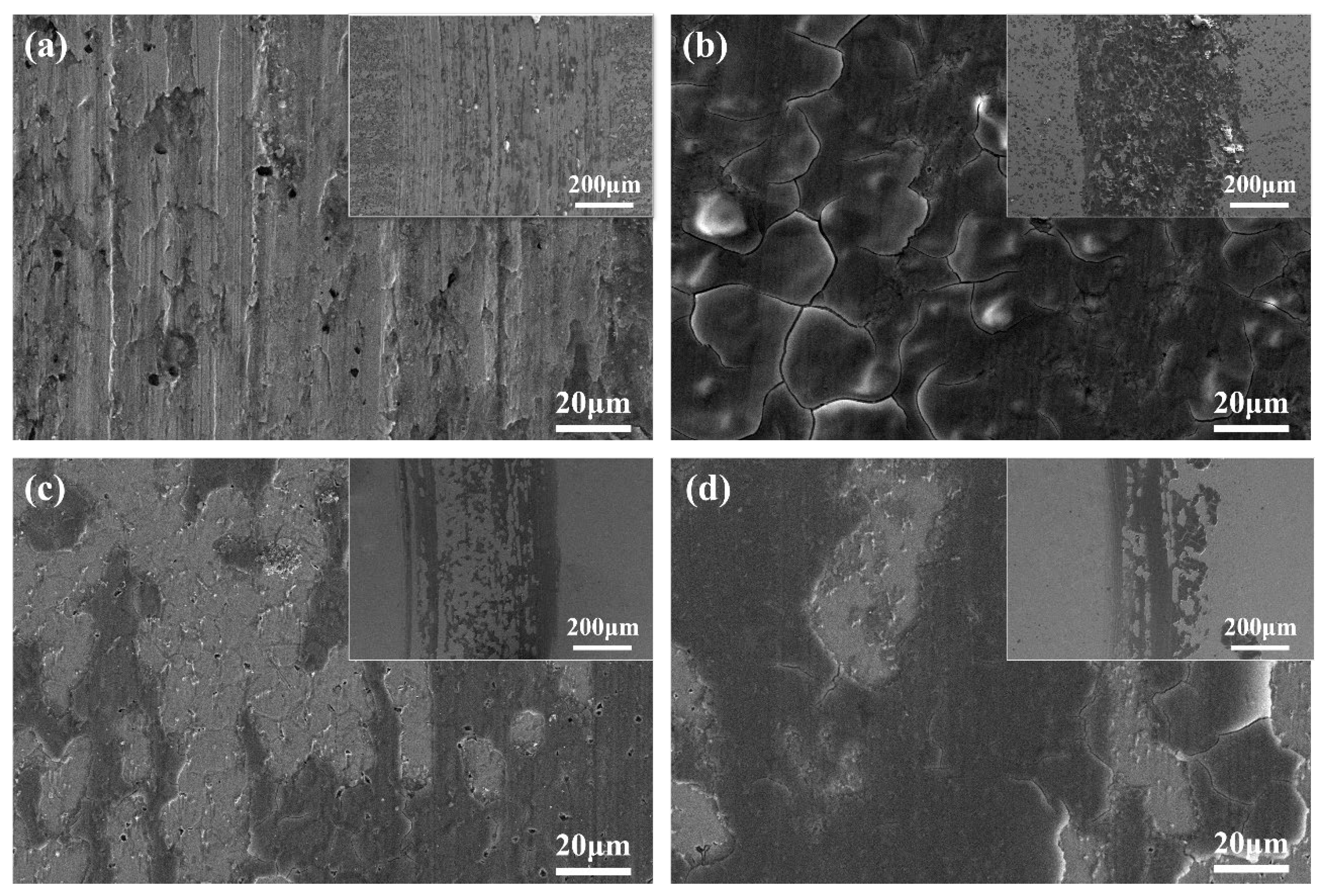

3.4. Wear Performance

3.5. Corrosion Behavior

4. Conclusions

- The Rockit 606 alloy coatings are prepared by laser cladding under scanning speeds. There is a clear transition zone between 60Si2Mn steel substrate and Rockit 606 alloy coatings. There are no obvious cracks and pores in the coatings. The microstructure Rockit 606 alloy coating consists of γ-Fe, V8C7, and Cr7C3.

- The microhardness of the Rockit 606 alloy coatings decreases with an increase in the scanning speed. When the scanning speed is 4 mm/s, the highest microhardness value reaches 867.2 HV, which is about three times of that of the substrate.

- The average coefficients of friction (COFs) of the coatings decreased with an increase in the scanning speed, which led to the corresponding decrease of the wear rate. The best wear resistance of the prepared coatings was obtained at a scanning speed of 4 mm/s. When the scanning speed is 4 mm/s, the wear behavior of the coating is mainly oxidative wear and a small amount of adhesive wear. With the increase in scanning speed, the wear forms become oxidative wear and peeling wear, accompanied by a small amount of abrasive wear.

- The self-corrosion current density of the coatings prepared by laser cladding in 3.5 wt.% NaCl solution is one order of magnitude lower than that of the substrate, indicating that the coatings have better corrosion resistance properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeng, Y.; Qin, Z.; Su, C.; Li, M.; Sun, C.; Yuan, X.; Ren, P.; Zhang, X. Effect of Rainfall PH Value on Fretting Corrosion Characteristics of 60Si2Mn Steel for High-Speed Railway Track Fastener Clips. Eng. Fail. Anal. 2023, 144, 106954. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Li, D.; Jing, P.; Yin, H.; Wu, H.; Xie, Y.; Wang, X. Effect of Nano-La2O3 Doping on the Tribological Behavior of Laser Cladded WC-12Co Coating on 65Mn Steel under Water Lubrication Condition. Tribol. Int. 2022, 169, 107428. [Google Scholar] [CrossRef]

- Mora-Mendoza, J.L.; Hernández-Gayosso, M.J.; Morales-Serrat, D.A.; Roque-Oms, O.; Del Angel, D.A.; Zavala-Olivares, G. Evaluation of Stress Corrosion Cracking Damage to an API 5L X52 Pipeline Transporting Ammonia: A Case Study. Mater. Sci. Appl. 2016, 7, 610–622. [Google Scholar] [CrossRef][Green Version]

- Zhang, N.; Fu, C.; Jiang, B.; Sun, L.; Liu, Y. Failure Analysis of Fatigue Fracture for 60Si2Mn Steel Fastening Clip in the Track of High-Speed Railway. Eng. Fail. Anal. 2022, 142, 106757. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, J.; Pan, W.; Wang, W.; Tang, C. Research Progress in Surface Strengthening Technology of Carbide-Based Coating. J. Alloys Compd. 2022, 905, 164062. [Google Scholar] [CrossRef]

- Richert, M. Thermally Sprayed Coatings for the Protection of Industrial Fan Blades. Materials 2024, 17, 3903. [Google Scholar] [CrossRef]

- Yu, L.; He, F.; Liu, X.; Jiang, Y.; Sui, M.; Cao, X.; Meng, Z. The Preparation, Microstructure, and Wet Wear Properties of an Fe55-Based Welding Layer with the Co-Addition of 0.01 Wt% CeO2 and 1.5 Wt% SiC Particles Using the Plasma Beam Spraying Method. Materials 2023, 16, 7439. [Google Scholar] [CrossRef]

- Xu, Q.; Deng, Z.; Sun, Q.; Tu, R.; Zhang, S.; Yang, M.; Li, Q.; Zhang, L.; Goto, T.; Ohmori, H. Electrically Conducting Graphene/SiC(111) Composite Coatings by Laser Chemical Vapor Deposition. Carbon 2018, 139, 76–84. [Google Scholar] [CrossRef]

- Fu, A.; Xie, Z.; Wang, J.; Cao, Y.; Wang, B.; Li, J.; Fang, Q.; Li, X.; Liu, B.; Liu, Y. Controlling of Cellular Substructure and Its Effect on Mechanical Properties of FeCoCrNiMo0.2 High Entropy Alloy Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2024, 901, 146547. [Google Scholar] [CrossRef]

- Abramovskis, V.; Drunka, R.; Csáki, Š.; Lukáč, F.; Veverka, J.; Illkova, K.; Gavrilovs, P.; Shishkin, A. Preparation and Characteristics of High-Performance, Low-Density Metallo–Ceramics Composite. Materials 2023, 16, 7523. [Google Scholar] [CrossRef]

- Ksiazek, M.; Łyp-Wrońska, K. An HVOF-Sprayed (Cr3C2-NiCr+Co) Composite Coating on Ductile Cast Iron: Microstructure, Mechanical Properties, and Scratch Resistance. Materials 2024, 17, 1484. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in Additive Manufacturing on New Materials: A Review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Liu, C.; Li, C.; Zhang, Z.; Sun, S.; Zeng, M.; Wang, F.; Guo, Y.; Wang, J. Modeling of Thermal Behavior and Microstructure Evolution during Laser Cladding of AlSi10Mg Alloys. Opt. Laser Technol. 2020, 123, 105926. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Barekat, M.; Hashemi, S.H. Friction and Wear Behavior of Laser Cladded WC-Co and Ni/WC-Co Deposits at High Temperature. Int. J. Refract. Metals Hard Mater. 2019, 81, 137–148. [Google Scholar] [CrossRef]

- Liu, H.; Xu, Q.; Wang, C.; Zhang, X. Corrosion and Wear Behavior of Ni60CuMoW Coatings Fabricated by Combination of Laser Cladding and Mechanical Vibration Processing. J. Alloys Compd. 2015, 621, 357–363. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, L.; Ma, G.; Li, G.; Zhao, H.; Wang, H. Microstructure and Excellent Arc Ablation Resistance of Ni–8Al Coating on Copper Substrate by High-Speed Laser Cladding. J. Mater. Res. Technol. 2024, 31, 606–617. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, C.; Li, L.; Chen, H.; Yang, Y. Effects of Tungsten Addition on the Microstructure and Properties of FeCoCrNiAl High-Entropy Alloy Coatings Fabricated via Laser Cladding. Materials 2024, 17, 3592. [Google Scholar] [CrossRef]

- Kim, G.; Kim, Y.C.; Cho, J.E.; Yim, C.H.; Yun, D.S.; Lee, T.G.; Park, N.K.; Chung, R.H.; Hong, D.G. Microstructural Evolution, Hardness and Wear Resistance of WC-Co-Ni Composite Coatings Fabricated by Laser Cladding. Materials 2024, 17, 2116. [Google Scholar] [CrossRef]

- Adamiak, M.; Appiah, A.N.S.; Żelazny, R.; Batalha, G.F.; Czupryński, A. Experimental Comparison of Laser Cladding and Powder Plasma Transferred Arc Welding Methods for Depositing Wear-Resistant NiSiB + 60% WC Composite on a Structural-Steel Substrate. Materials 2023, 16, 3912. [Google Scholar] [CrossRef]

- Liu, W.; Li, L.; Mi, G.; Wang, J.; Pan, Y. Effect of Fe Content on Microstructure and Properties of Laser Cladding Inconel 625 Alloy. Materials 2022, 15, 8200. [Google Scholar] [CrossRef]

- Aramide, B.; Pityana, S.; Jamiru, T.; Popoola, P.; Sadiku, R. Influence of Vanadium-Chromium Carbide on the Microstructure of Reinforced FeCrV15 Hardfacing during Laser Cladding Deposit. J. Mater. Eng. Perform. 2022, 31, 514–523. [Google Scholar] [CrossRef]

- Aramide, B.; Popoola, P.; Sadiku, R.; Jamiru, T.; Pityana, S. Influence of Extra Chromium Addition on the Microstructure, Hardness, and Corrosion Behaviour of High Carbon Ferrochrome FeCrV15 Deposited through Laser Cladding on Steel Baseplate for Tillage Application. Surf. Topogr. 2021, 9, 045029. [Google Scholar] [CrossRef]

- ASTM E3-11; Standard Guide for Preparation of Metallographic Specimens. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM E766; Standard Practice for Calibrating the Magnification of a Scanning Electron Microscope. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM E3294; Standard Guide for Forensic Analysis of Geological Materials by Powder X-Ray Diffraction. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM E384; Standard Test Method for Microindentation Hardness of Materials. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM G99; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM G5; Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM E407; Standard Practice for Microetching Metals and Alloys. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM G31; Standard Guide for Laboratory Immersion Corrosion Testing of Metals. ASTM: West Conshohocken, PA, USA, 2021.

- Yang, J.; Heogh, W.; Ju, H.; Kang, S.; Jang, T.S.; Jung, H.D.; Jahazi, M.; Han, S.C.; Park, S.J.; Kim, H.S.; et al. Functionally Graded Structure of a Nitride-Strengthened Mg2Si-Based Hybrid Composite. J. Magnes. Alloys 2024, 12, 1239–1256. [Google Scholar] [CrossRef]

- Günther, K.; Bergmann, J.P. Influencing Microstructure of Vanadium Carbide Reinforced FeCrVC Hardfacing during Gas Metal Arc Welding. Metals 2020, 10, 1345. [Google Scholar] [CrossRef]

- Meng, B.; Wang, J.; Chen, M.; Zhu, S.; Wang, F. Study on the Oxidation Behavior of a Novel Thermal Barrier Coating System Using the Nanocrystalline Coating as Bonding Coating on the Single-Crystal Superalloy. Corros. Sci. 2023, 225, 111591. [Google Scholar] [CrossRef]

- Cui, M.; Shi, G.; Deng, L.; Guo, H.; Xiong, S.; Tan, L.; Yao, C.; Zhang, D.; Deguchi, Y. Microstructure Classification of Steel Samples with Different Heat-Treatment Processes Based on Laser-Induced Breakdown Spectroscopy (LIBS). J. Anal. At. Spectrom. 2024, 39, 1361–1374. [Google Scholar] [CrossRef]

| Component | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | B | V | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60Si2Mn | 0.56~0.64 | 1.5~2.0 | 0.7~1.0 | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.025 | - | - | - | Bal. |

| Rockit 606 | 1.9 | 1.1 | 0.5 | - | - | 4.7 | - | - | 0.6 | 0.8 | 6.0 | Bal. |

| Serial Number | Substrate Material | Powder Used | Laser Beam Power (W) | Scanning Speed (mm/s) |

|---|---|---|---|---|

| 1 | 60Si2Mn | Rockit 606 | 1600 | 4 |

| 2 | 6 | |||

| 3 | 8 |

| Point | B | C | Si | V | Cr | Mn | Fe | Mo | Possible Phase |

|---|---|---|---|---|---|---|---|---|---|

| D | 0.85 | 10.31 | 2.76 | 1.76 | 1.98 | 0.30 | 81.96 | 0.09 | γ-Fe |

| E | 0.15 | 13.72 | 1.49 | 3.26 | 4.30 | 0.99 | 75.15 | 0.36 | Cr7C3, V8C7 |

| F | 0.08 | 37.82 | 0.52 | 43.55 | 1.30 | 0.30 | 16.13 | 0.29 | V8C7 |

| Sample | Self-Corrosion Potential (V) | Corrosion Current Density (A/cm2) |

|---|---|---|

| 60Si2Mn | −0.986 | 3.956 × 10−6 |

| 4 mm/s | −0.845 | 5.417 × 10−7 |

| 6 mm/s | −0.645 | 2.243 × 10−7 |

| 8 mm/s | −0.834 | 4.308 × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Bi, Z.; Lei, Y. Effects of Scanning Speed on the Microstructure and Wear Properties of Rockit 606 Coating Layer by Disk Laser Cladding. Materials 2024, 17, 4758. https://doi.org/10.3390/ma17194758

Li T, Bi Z, Lei Y. Effects of Scanning Speed on the Microstructure and Wear Properties of Rockit 606 Coating Layer by Disk Laser Cladding. Materials. 2024; 17(19):4758. https://doi.org/10.3390/ma17194758

Chicago/Turabian StyleLi, Tianqing, Zhiwei Bi, and Yucheng Lei. 2024. "Effects of Scanning Speed on the Microstructure and Wear Properties of Rockit 606 Coating Layer by Disk Laser Cladding" Materials 17, no. 19: 4758. https://doi.org/10.3390/ma17194758

APA StyleLi, T., Bi, Z., & Lei, Y. (2024). Effects of Scanning Speed on the Microstructure and Wear Properties of Rockit 606 Coating Layer by Disk Laser Cladding. Materials, 17(19), 4758. https://doi.org/10.3390/ma17194758