Polarization-Doped InGaN LEDs and Laser Diodes for Broad Temperature Range Operation

Abstract

1. Introduction

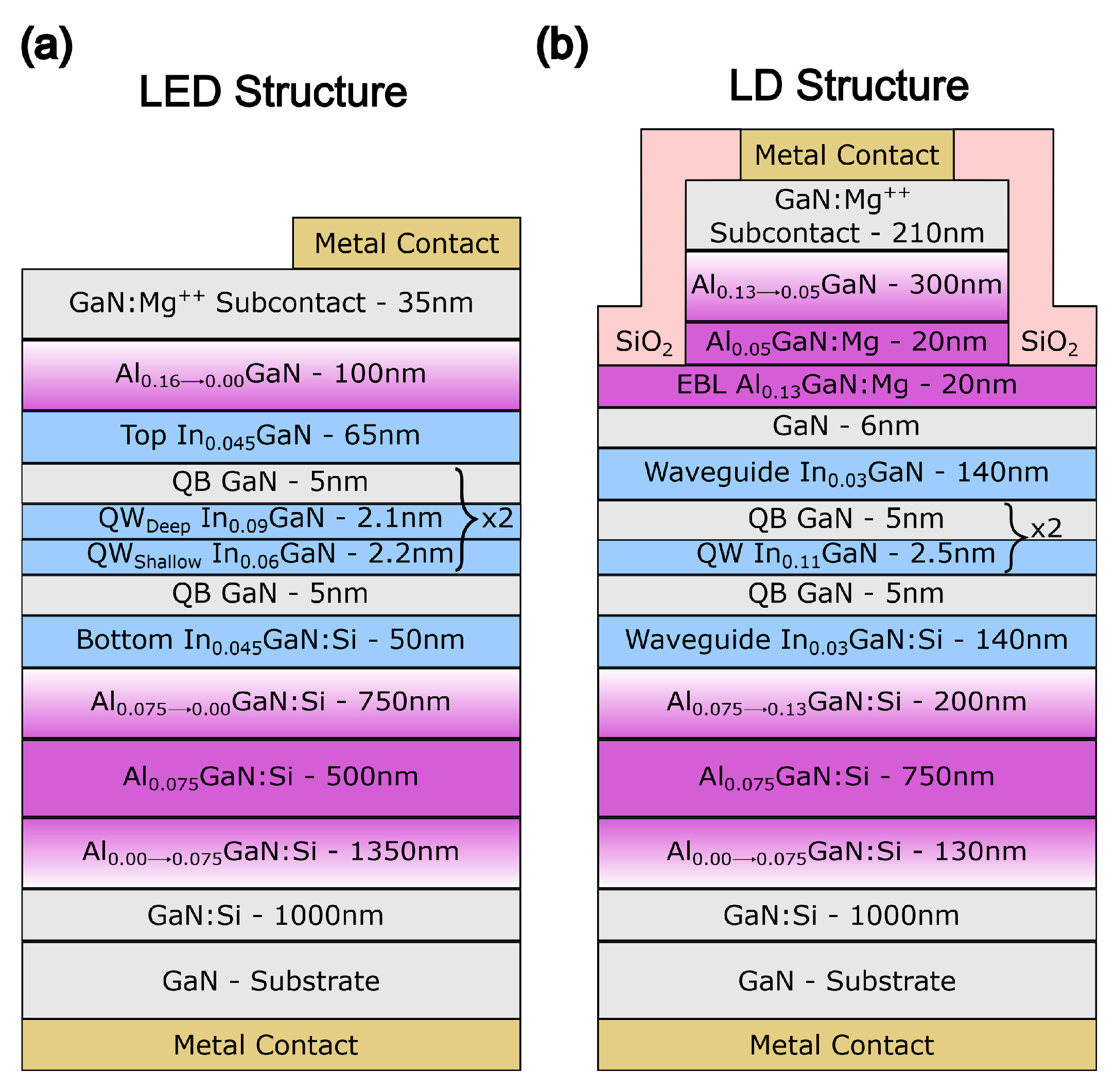

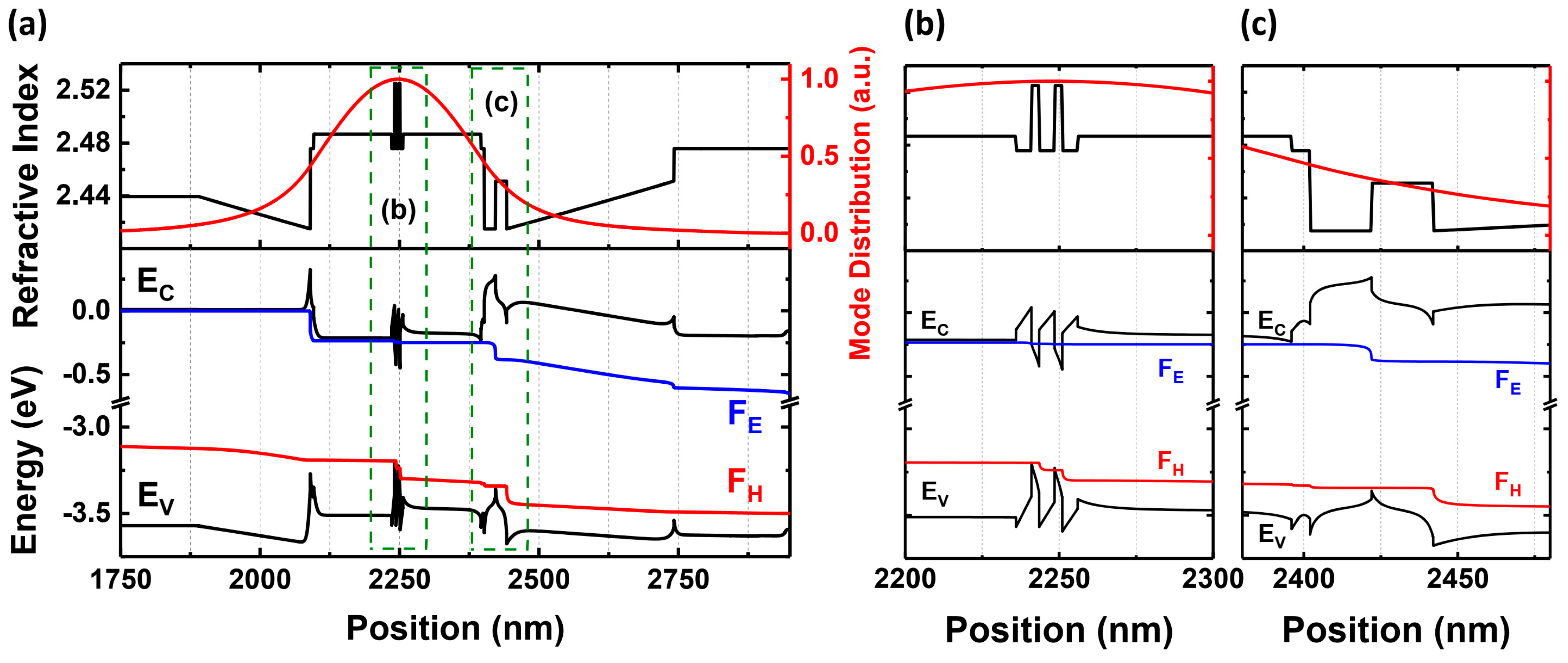

2. Materials and Methods

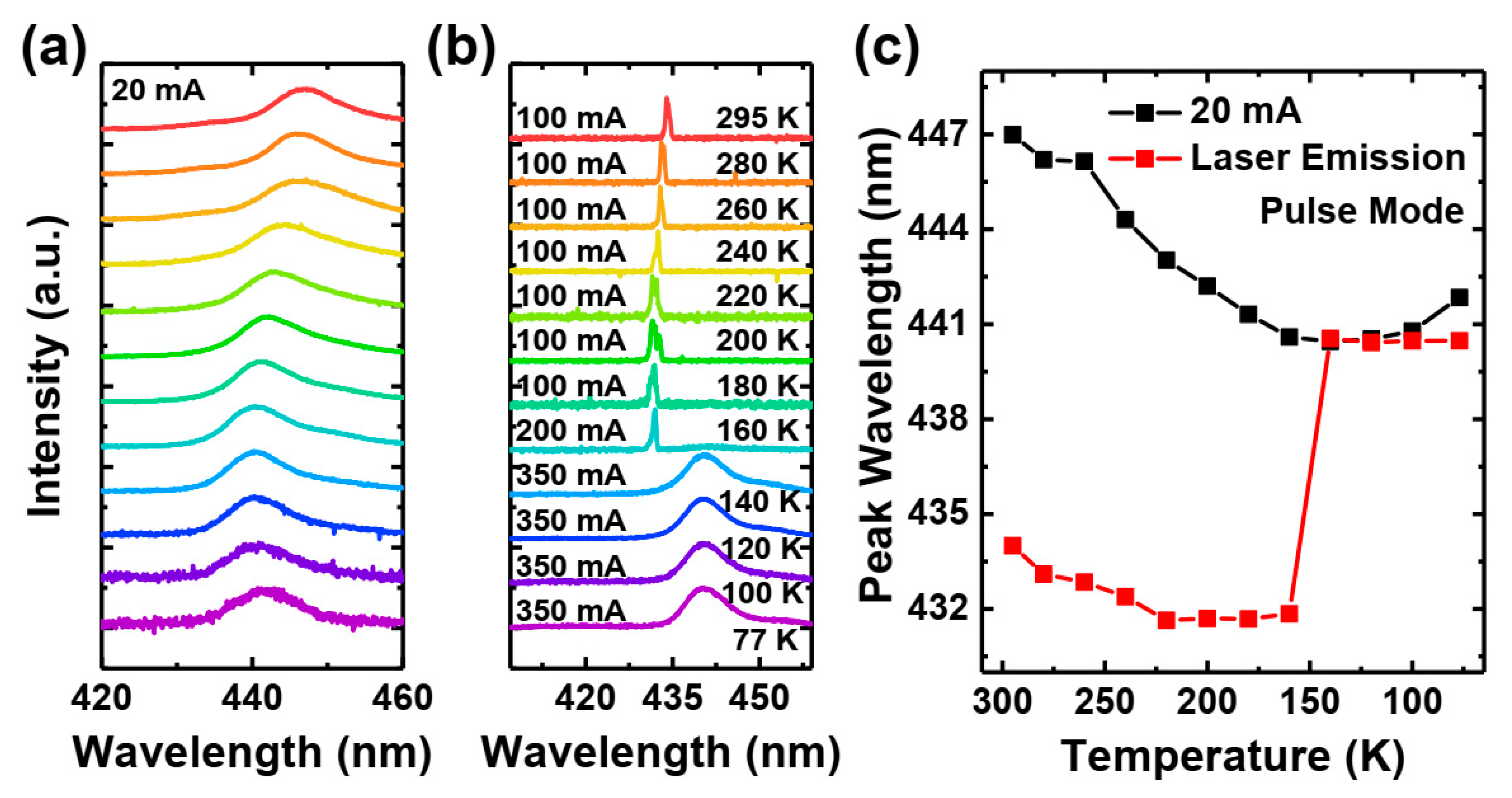

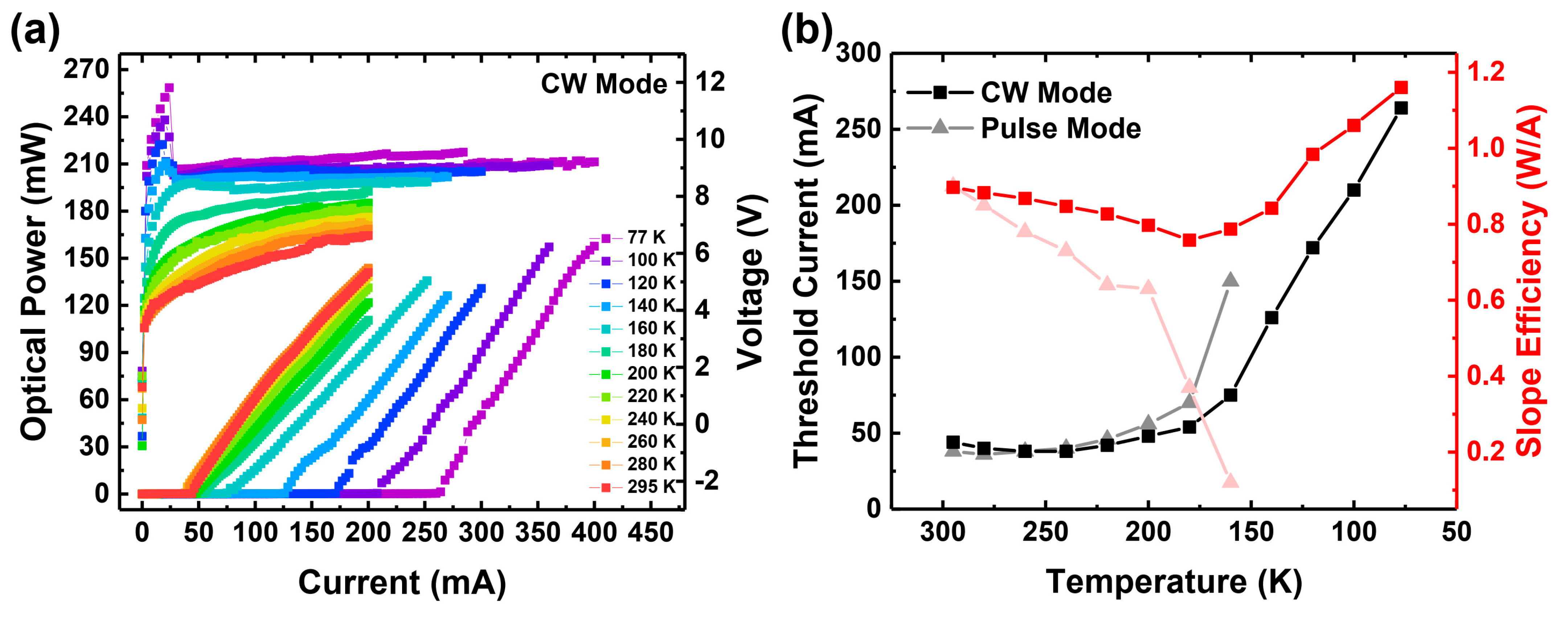

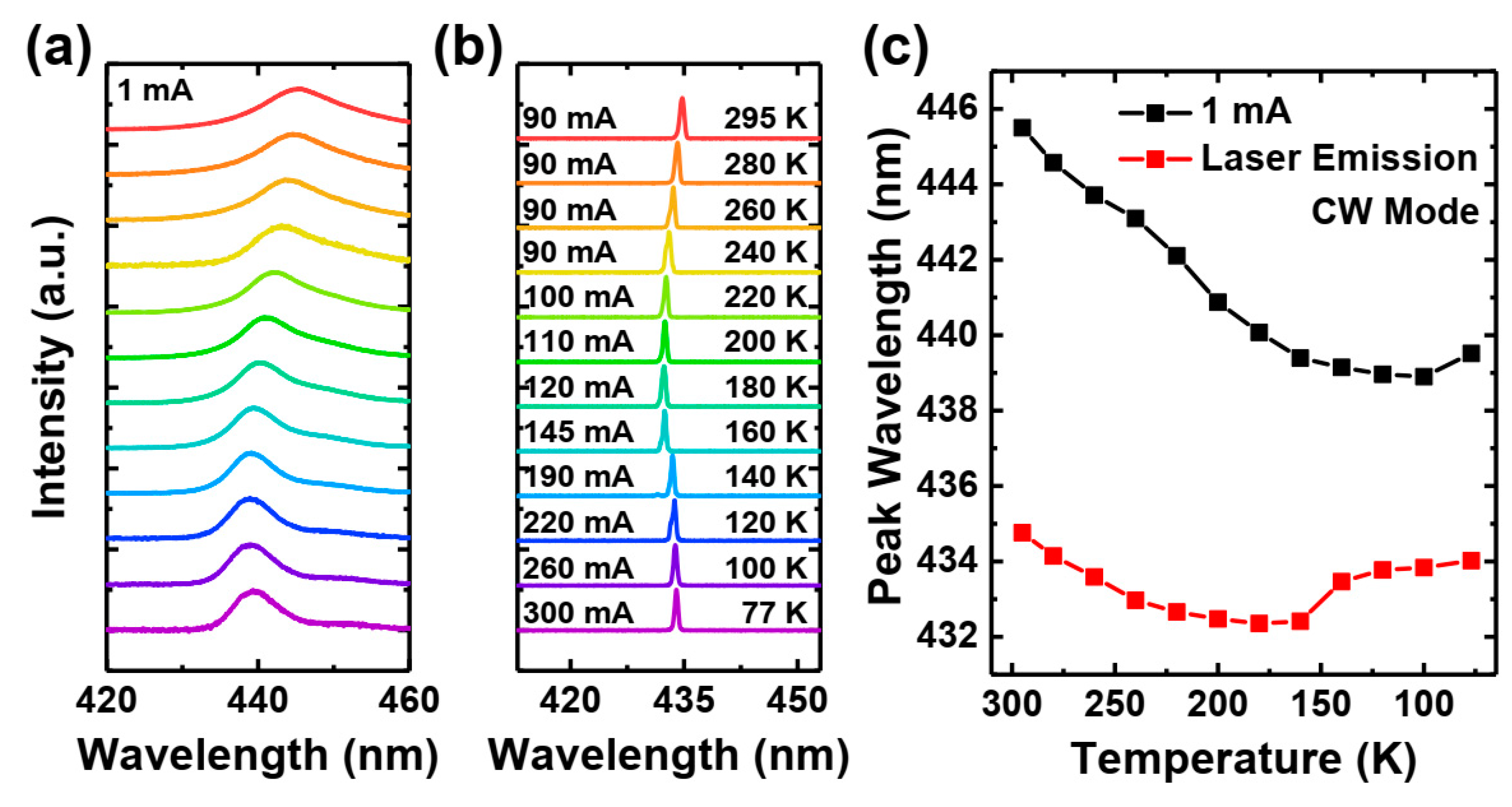

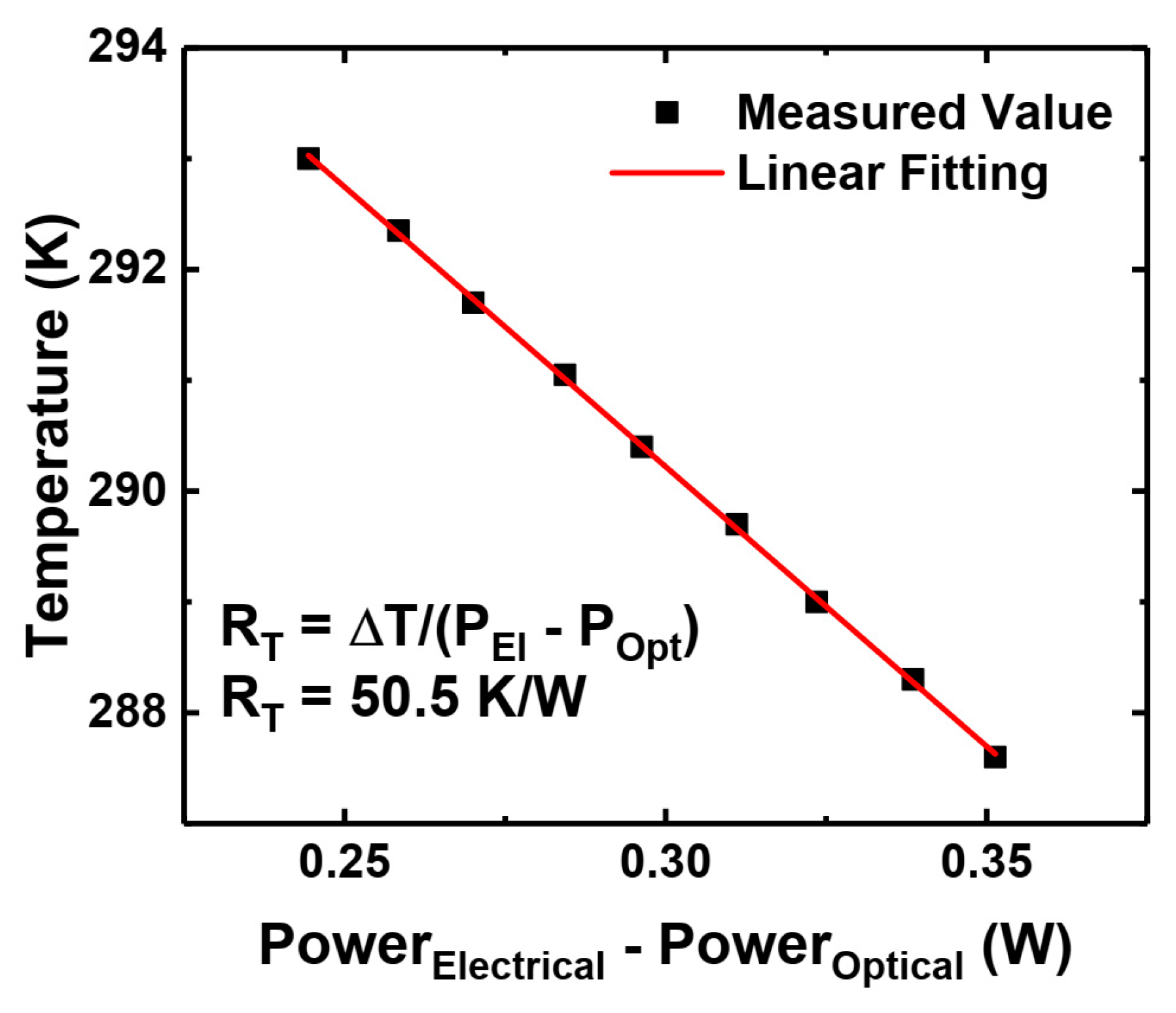

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DenBaars, S.P.; Feezell, D.; Kelchner, K.; Pimputkar, S.; Pan, C.-C.; Yen, C.-C.; Tanaka, S.; Zhao, Y.; Pfaff, N.; Farrell, R. Development of gallium-nitride-based light-emitting diodes (LEDs) and laser diodes for energy-efficient lighting and displays. Acta Mater. 2013, 61, 945–951. [Google Scholar] [CrossRef]

- Kuritzky, L.Y.; Speck, J.S. Lighting for the 21st century with laser diodes based on non-basal plane orientations of GaN. MRS Commun. 2015, 5, 463–473. [Google Scholar] [CrossRef]

- Miyoshi, T.; Kozaki, T.; Yanamoto, T.; Fujimura, Y.; Nagahama, S.; Mukai, T. GaN-based high-output-power blue laser diodes for display applications. J. Soc. Inf. Disp. 2007, 15, 157–160. [Google Scholar] [CrossRef]

- CBasu, C.; Meinhardt-Wollweber, M.; Roth, B. Lighting with laser diodes. Adv. Opt. Technol. 2013, 2, 313–321. [Google Scholar] [CrossRef]

- Perlin, P.; Stańczyk, S.; Najda, S.; Suski, T.; Wiśniewski, P.; Makarowa, I.; Marona, Ł.; Kafar, A.; Bojarska, A.; Czernecki, R. Development of the Nitride Laser Diode Arrays for Video and Movie Projectors. MRS Adv. 2016, 1, 103–108. [Google Scholar] [CrossRef]

- Pai, K.-J. Temperature Rise Effects on Dynamic Resistances for Laser Diodes With a Wavelength of 450 nm for Vehicle Headlight Applications. IEEE Trans. Veh. Technol. 2019, 68, 9529–9542. [Google Scholar] [CrossRef]

- Donati, S.; Cheng, W.-H.; Liu, C.-N.; Shih, H.-K.; Pei, Z. Embedding LiDAR and smart laser headlight in a compact module for autonomous driving. OSA Contin. 2021, 4, 1587. [Google Scholar] [CrossRef]

- Bruder, F.; Fäcke, T. Materials in optical data storage. Int. J. Mater. Res. 2010, 101, 199–215. [Google Scholar] [CrossRef]

- Wu, T.-C.; Chi, Y.-C.; Wang, H.-Y.; Tsai, C.-T.; Lin, G.-R. Blue Laser Diode Enables Underwater Communication at 12.4 Gbps. Sci. Rep. 2017, 7, 40480. [Google Scholar] [CrossRef]

- Watson, S.; Viola, S.; Giuliano, G.; Najda, S.P.; Perlin, P.; Suski, T.; Marona, L.; Leszczyński, M.; Wisniewski, P.; Czernecki, R. High speed visible light communication using blue GaN laser diodes. In Proceedings of the SPIE Security + Defence, Edinburgh, UK, 16–19 September 2024; p. 99910A. [Google Scholar] [CrossRef]

- Najda, S.P.; Perlin, P.; Suski, T.; Marona, L.; Bockowski, M.; Leszczyński, M.; Wisniewski, P.; Czernecki, R.; Kucharski, R.; Targowski, G. AlGaInN laser diode technology for systems applications. In Proceedings of the Gallium Nitride Materials and Devices XI, San Francisco, CA, USA, 15–18 February 2016; p. 974819. [Google Scholar] [CrossRef]

- Nasim, H.; Jamil, Y. Diode lasers: From laboratory to industry. Opt. Laser Technol. 2014, 56, 211–222. [Google Scholar] [CrossRef]

- Hasan, S.; Mehedi, I.M.; Reza, S.M.F.; Kaysir, R.; Islam, R. Analytical investigation of activation energy for Mg-doped p-AlGaN. Opt. Quantum Electron. 2020, 52, 348. [Google Scholar] [CrossRef]

- Suzuki, M.; Nishio, J.; Onomura, M.; Hongo, C. Doping characteristics and electrical properties of Mg-doped AlGaN grown by atmospheric-pressure MOCVD. J. Cryst. Growth 1998, 189–190, 511–515. [Google Scholar] [CrossRef]

- Arakawa, Y.; Ueno, K.; Kobayashi, A.; Ohta, J.; Fujioka, H. High hole mobility p-type GaN with low residual hydrogen concentration prepared by pulsed sputtering. APL Mater. 2016, 4, 086103. [Google Scholar] [CrossRef]

- Nikishin, S.; Chary, I.; Borisov, B.; Kuryatkov, V.; Kudryavtsev, Y.; Asomoza, R.; Karpov, S.Y.; Holtz, M. Mechanism of carrier injection in (Ni/Au)/p-AlxGa1−xN:Mg (≤ x <0.1) Ohmic contacts. Appl. Phys. Lett. 2009, 95, 163502. [Google Scholar] [CrossRef]

- Kozodoy, P.; Hansen, M.; DenBaars, S.P.; Mishra, U.K. Enhanced Mg doping efficiency in Al0.2Ga0.8N/GaN superlattices. Appl. Phys. Lett. 1999, 74, 3681–3683. [Google Scholar] [CrossRef]

- Hori, A.; Yasunaga, D.; Satake, A.; Fujiwara, K. Temperature and injection current dependence of electroluminescence intensity in green and blue InGaN single-quantum-well light-emitting diodes. J. Appl. Phys. 2003, 93, 3152–3157. [Google Scholar] [CrossRef][Green Version]

- Cao, X.A.; Leboeuf, S.F.; Rowland, L.B.; Liu, H. Temperature-dependent electroluminescence in InGaN/GaN multiple-quantum-well light-emitting diodes. J. Electron. Mater. 2003, 32, 316–321. [Google Scholar] [CrossRef]

- Grzanka, S.; Franssen, G.; Targowski, G.; Krowicki, K.; Suski, T.; Czernecki, R.; Perlin, P.; Leszczyński, M. Role of the electron blocking layer in the low-temperature collapse of electroluminescence in nitride light-emitting diodes. Appl. Phys. Lett. 2007, 90, 103507. [Google Scholar] [CrossRef]

- Lee, J.-C.; Wu, Y.-F.; Wang, Y.-P.; Nee, T.-E. Temperature and current dependences of electroluminescence from InGaN/GaN multiple quantum wells. J. Cryst. Growth 2008, 310, 5143–5146. [Google Scholar] [CrossRef]

- Moe, C.G.; Garrett, G.A.; Rotella, P.; Shen, H.; Wraback, M.; Shatalov, M.; Sun, W.; Deng, J.; Hu, X.; Bilenko, Y. Impact of temperature-dependent hole injection on low-temperature electroluminescence collapse in ultraviolet light-emitting diodes. Appl. Phys. Lett. 2012, 101, 253512. [Google Scholar] [CrossRef]

- Wood, C.; Jena, D. (Eds.) Polarization Effects in Semiconductors; Springer: Boston, MA, USA, 2008. [Google Scholar] [CrossRef]

- Bernardini, F.; Fiorentini, V.; Vanderbilt, D. Spontaneous polarization and piezoelectric constants of III-V nitrides. Phys. Rev. B 1997, 56, R10024–R10027. [Google Scholar] [CrossRef]

- Aktas, M.; Kafar, A.; Stanczyk, S.; Marona, Ł.; Schiavon, D.; Grzanka, S.; Wiśniewski, P.; Perlin, P. Optimization of p-cladding layer utilizing polarization doping for Blue-Violet InGaN laser diodes. Opt. Laser Technol. 2024, 177, 111144. [Google Scholar] [CrossRef]

- Simon, J.; Protasenko, V.; Lian, C.; Xing, H.; Jena, D. Polarization-induced hole doping in wide-band-gap uniaxial semiconductor heterostructures. Science 2010, 327, 60–64. [Google Scholar] [CrossRef] [PubMed]

- Sato, K.; Yamada, K.; Sakowski, K.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Kangawa, Y.; Kempisty, P.; Krukowski, S.; Piechota, J. Effects of Mg dopant in Al-composition-graded AlxGa1−xN (0.45 ≤ x) on vertical electrical conductivity of ultrawide bandgap AlGaN p–n junction. Appl. Phys. Express 2021, 14, 096503. [Google Scholar] [CrossRef]

- Sato, K.; Yasue, S.; Yamada, K.; Tanaka, S.; Omori, T.; Ishizuka, S.; Teramura, S.; Ogino, Y.; Iwayama, S.; Miyake, H. Room-temperature operation of AlGaN ultraviolet-B laser diode at 298 nm on lattice-relaxed Al 0.6 Ga 0.4 N/AlN/sapphire. Appl. Phys. Express 2020, 13, 031004. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, J.; Hu, L.; Zhang, L.; Tian, A.; Xiong, W.; Ren, X.; Huang, S.; Zhou, W.; Ikeda, M. Reduced threshold current density of GaN-based green laser diode by applying polarization doping p-cladding layer. Chin. Opt. Lett. 2021, 19, 121404. [Google Scholar] [CrossRef]

- Zhang, Z.; Kushimoto, M.; Sakai, T.; Sugiyama, N.; Schowalter, L.J.; Sasaoka, C.; Amano, H. A 271.8 nm deep-ultraviolet laser diode for room temperature operation. Appl. Phys. Express 2019, 12, 124003. [Google Scholar] [CrossRef]

- Yue, W.; Li, Z.; Li, P.; Zhou, X.; Dong, H.; Wang, Y.; Wu, J.; Luo, X.; Bai, J. 395 nm Light-Emitting Diode with 647 mW Output Power Realized Using a Double p-Type Aluminum Composition Gradient with Polarization-Induced Hole Doping. Integr. Ferroelectr. 2021, 213, 174–181. [Google Scholar] [CrossRef]

- Jena, D.; Heikman, S.; Green, D.; Buttari, D.; Coffie, R.; Xing, H.; Keller, S.; DenBaars, S.; Speck, J.S.; Mishra, U.K. Realization of wide electron slabs by polarization bulk doping in graded III–V nitride semiconductor alloys. Appl. Phys. Lett. 2002, 81, 4395–4397. [Google Scholar] [CrossRef]

- Simon, J.; Wang, A.; Xing, H.; Rajan, S.; Jena, D. Carrier transport and confinement in polarization-induced three-dimensional electron slabs: Importance of alloy scattering in AlGaN. Appl. Phys. Lett. 2006, 88, 1–3. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, K.; Yan, J.C.; Wang, J.X.; Zeng, Y.P.; Wei, T.B.; Li, Y.Y.; Sun, B.J.; Duan, R.F.; Li, J.M. Three-dimensional hole gas induced by polarization in (0001)-oriented metal-face III-nitride structure. Appl. Phys. Lett. 2010, 97, 062103. [Google Scholar] [CrossRef]

- Zhao, H.; Dierolf, V.; Liu, G.; Huang, G.; Li, X.-H.; Poplawsky, J.; Arif, R.; Penn, S.T.; Tansu, N. Design and characteristics of staggered InGaN quantum-well light-emitting diodes in the green spectral regime. IET Optoelectron. 2009, 3, 283–295. [Google Scholar] [CrossRef]

- Arif, R.A.; Ee, Y.-K.; Tansu, N. Polarization engineering via staggered InGaN quantum wells for radiative efficiency enhancement of light emitting diodes. Appl. Phys. Lett. 2007, 91, 091110. [Google Scholar] [CrossRef]

- Chlipala, M.; Turski, H.; Siekacz, M.; Pieniak, K.; Nowakowski-Szkudlarek, K.; Suski, T.; Skierbiszewski, C. Nitride light-emitting diodes for cryogenic temperatures. Opt. Express 2020, 28, 30299. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Zhao, D.G.; Zhu, J.J.; Liu, Z.S.; Jiang, D.S.; Chen, P.; Liang, F.; Liu, S.T.; Xing, Y. Effect of Mg doping concentration of electron blocking layer on the performance of GaN-based laser diodes. Appl. Phys. B 2019, 125, 235. [Google Scholar] [CrossRef]

- Marona, L.; Schiavon, D.; Baranowski, M.; Kudrawiec, R.; Gorczyca, I.; Kafar, A.; Perlin, P. Kinetics of the radiative and nonradiative recombination in polar and semipolar InGaN quantum wells. Sci. Rep. 2020, 10, 1235. [Google Scholar] [CrossRef]

- Cho, Y.-H.; Gainer, G.H.; Fischer, A.J.; Song, J.J.; Keller, S.; Mishra, U.K.; DenBaars, S.P. ‘S-shaped’ temperature-dependent emission shift and carrier dynamics in InGaN/GaN multiple quantum wells. Appl. Phys. Lett. 1998, 73, 1370–1372. [Google Scholar] [CrossRef]

- Feng, S.-W.; Cheng, Y.-C.; Chung, Y.-Y.; Yang, C.C.; Lin, Y.-S.; Hsu, C.; Ma, K.-J.; Chyi, J.-I. Impact of localized states on the recombination dynamics in InGaN/GaN quantum well structures. J. Appl. Phys. 2002, 92, 4441–4448. [Google Scholar] [CrossRef]

- Kuc, M. Modelowanie Zjawisk Fizycznych w Krawędziowych Laserach Azotkowych Oraz Ich Matrycach. 2016. Available online: https://bibliotekanauki.pl/books/2021476 (accessed on 12 August 2024).

- Stańczyk, S. Physical Mechanisms Determining the Maximum Optical Power Emitted from InGaN Laser Diodes. Institute of High Pressure Physics of the Polish Academy of Sciences, Warsaw, 2020. Available online: https://bip.unipress.waw.pl/images/stories/doktoraty/stanczykszymon.pdf (accessed on 12 August 2024).

- Sizov, D.; Bhat, R.; Zah, C.-E. Optical absorption of Mg-doped layers and InGaN quantum wells on c-plane and semipolar GaN structures. J. Appl. Phys. 2013, 113, 203108. [Google Scholar] [CrossRef]

- Scheibenzuber, W.G.; Schwarz, U.T.; Lermer, T.; Lutgen, S.; Strauss, U. Thermal resistance, gain, and antiguiding factor of GaN-based cyan laser diodes. Phys. Status Solidi (A) 2011, 208, 1600–1602. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aktas, M.; Grzanka, S.; Marona, Ł.; Goss, J.; Staszczak, G.; Kafar, A.; Perlin, P. Polarization-Doped InGaN LEDs and Laser Diodes for Broad Temperature Range Operation. Materials 2024, 17, 4502. https://doi.org/10.3390/ma17184502

Aktas M, Grzanka S, Marona Ł, Goss J, Staszczak G, Kafar A, Perlin P. Polarization-Doped InGaN LEDs and Laser Diodes for Broad Temperature Range Operation. Materials. 2024; 17(18):4502. https://doi.org/10.3390/ma17184502

Chicago/Turabian StyleAktas, Muhammed, Szymon Grzanka, Łucja Marona, Jakub Goss, Grzegorz Staszczak, Anna Kafar, and Piotr Perlin. 2024. "Polarization-Doped InGaN LEDs and Laser Diodes for Broad Temperature Range Operation" Materials 17, no. 18: 4502. https://doi.org/10.3390/ma17184502

APA StyleAktas, M., Grzanka, S., Marona, Ł., Goss, J., Staszczak, G., Kafar, A., & Perlin, P. (2024). Polarization-Doped InGaN LEDs and Laser Diodes for Broad Temperature Range Operation. Materials, 17(18), 4502. https://doi.org/10.3390/ma17184502