Characterizing Short-Time Aging Precipitation Behavior of a Novel Nickel–Iron-Based Alloy via Electrical Performance

Abstract

1. Introduction

2. Materials and Methods

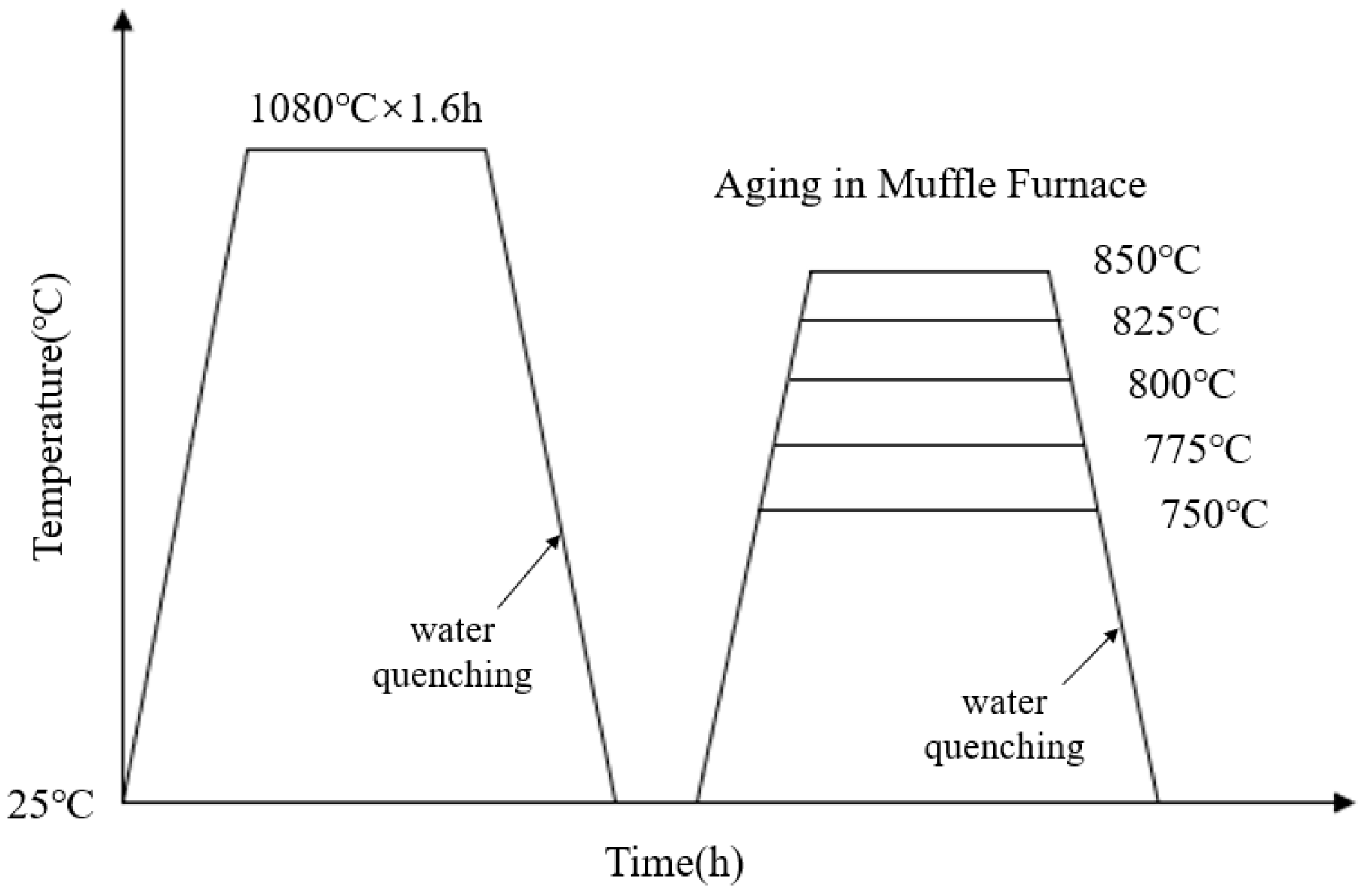

2.1. Materials and Heat Treatment

2.2. Electrical Resistivity Measurement

2.3. Microstructure Characterization

- (1)

- Scanning Electron Microscopy (SEM) Observation

- (2)

- Electron Backscatter Diffraction (EBSD) Tests

- (3)

- X-ray Diffraction (XRD) Analysis

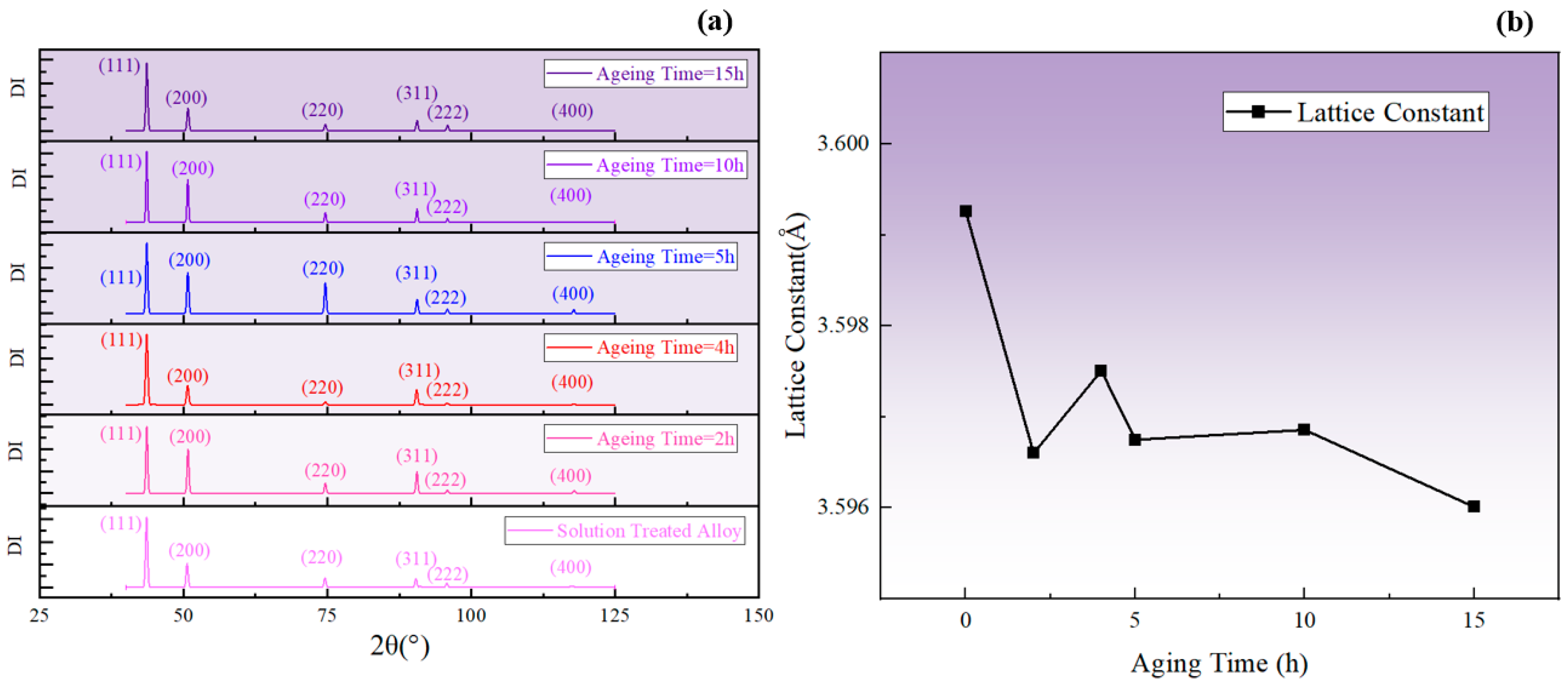

3. Results

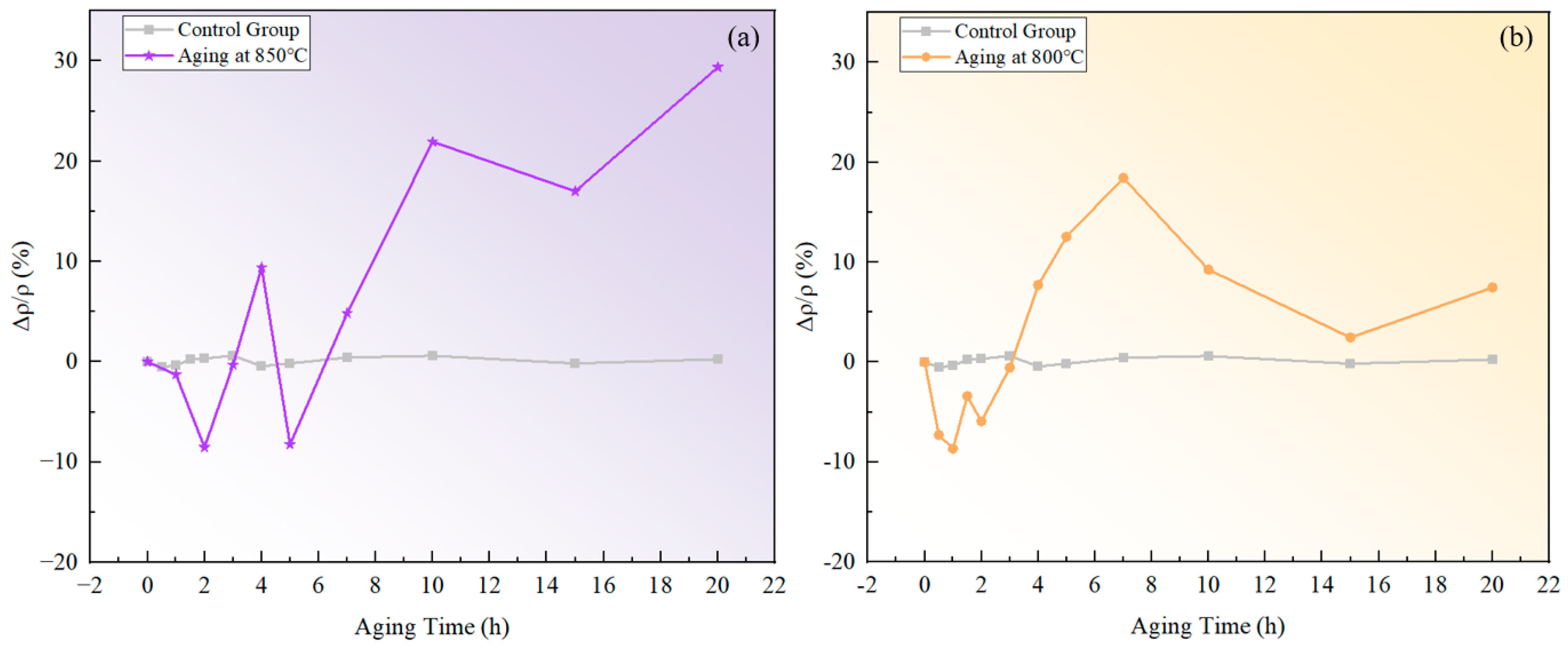

3.1. Resistivity Changes Induced by Aging Treatment

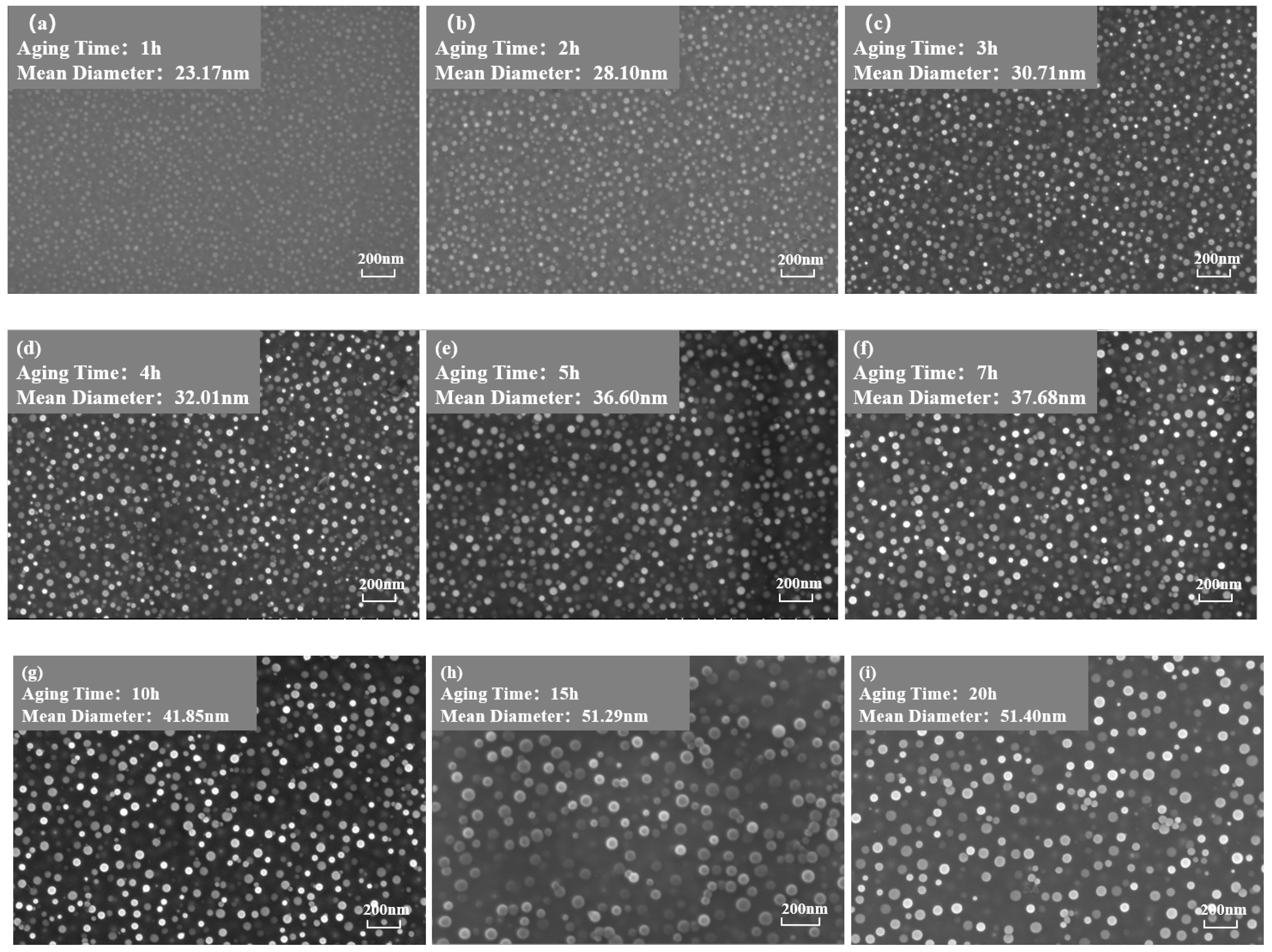

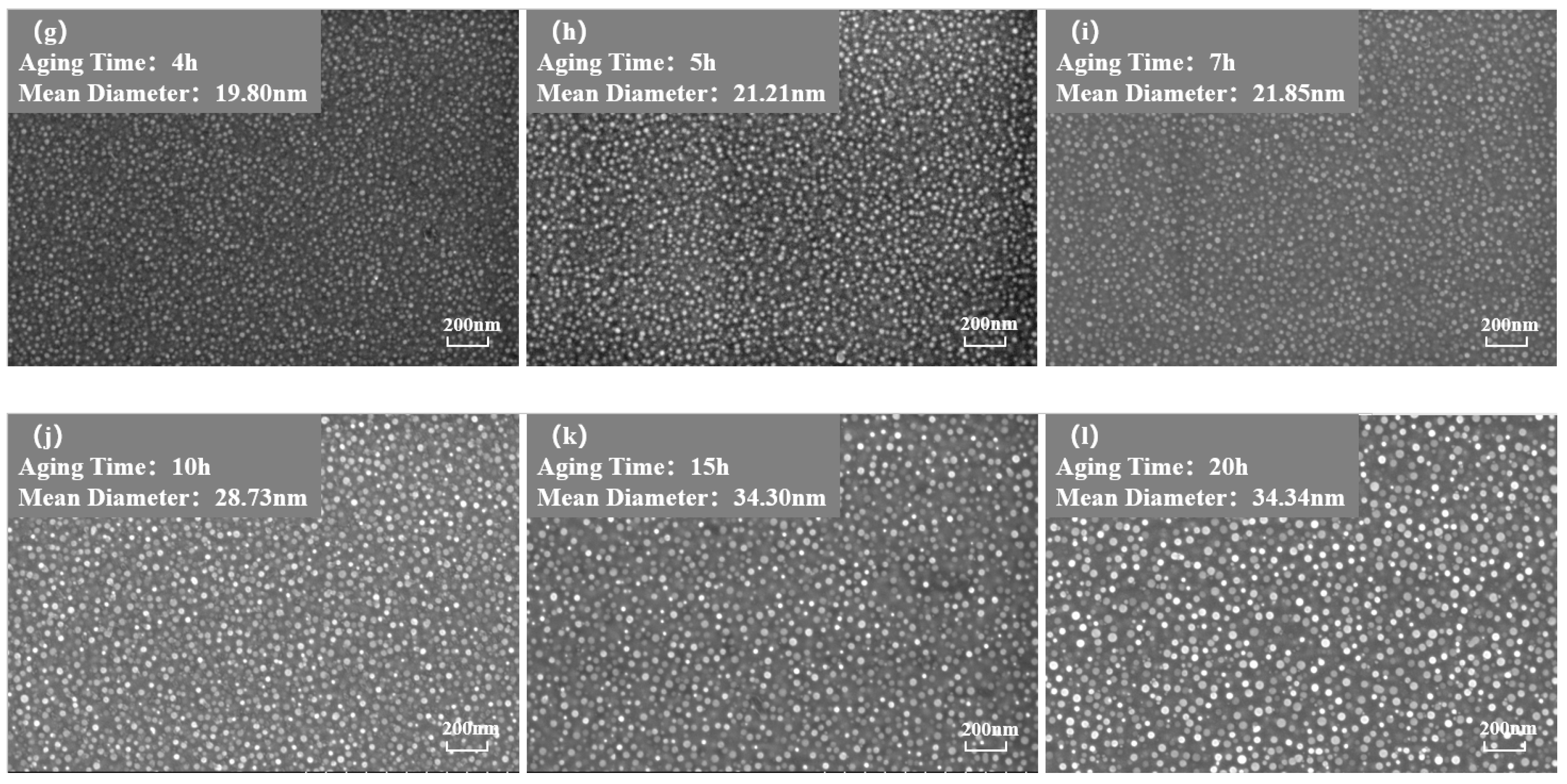

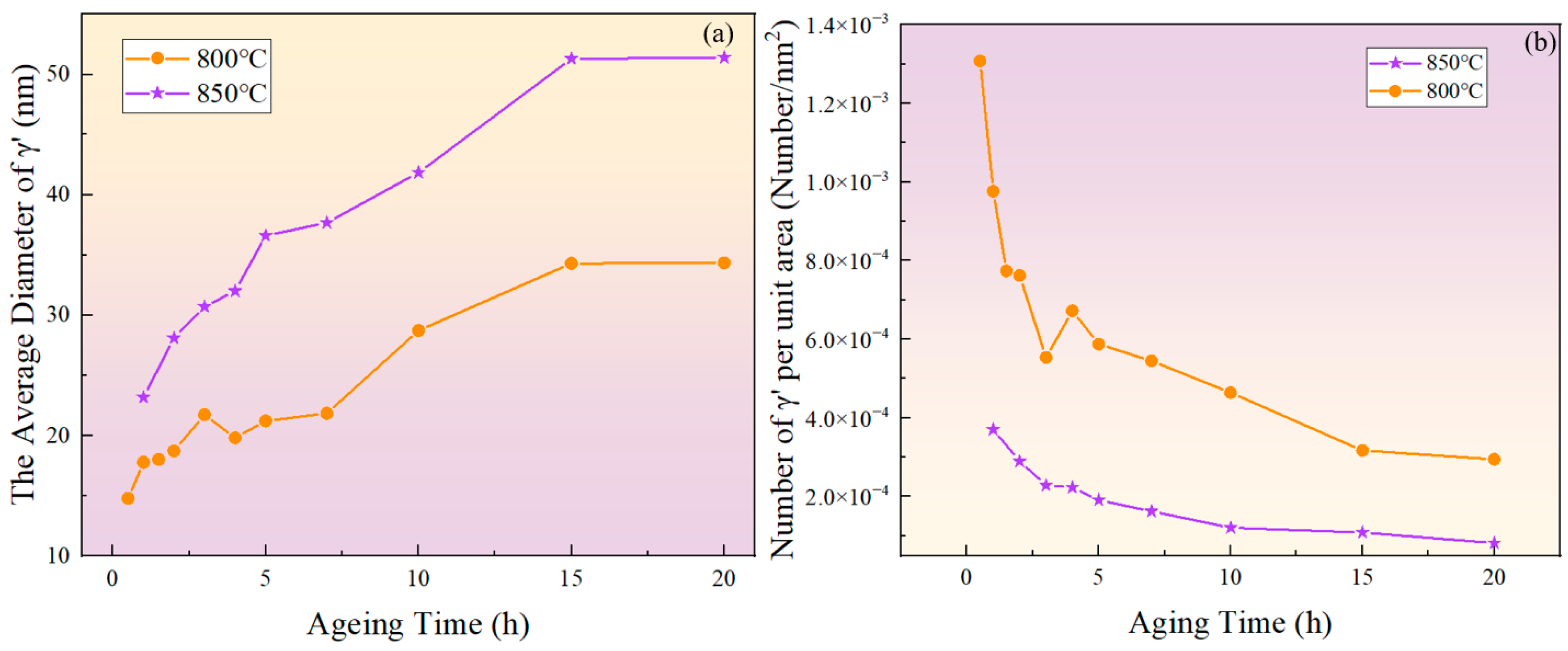

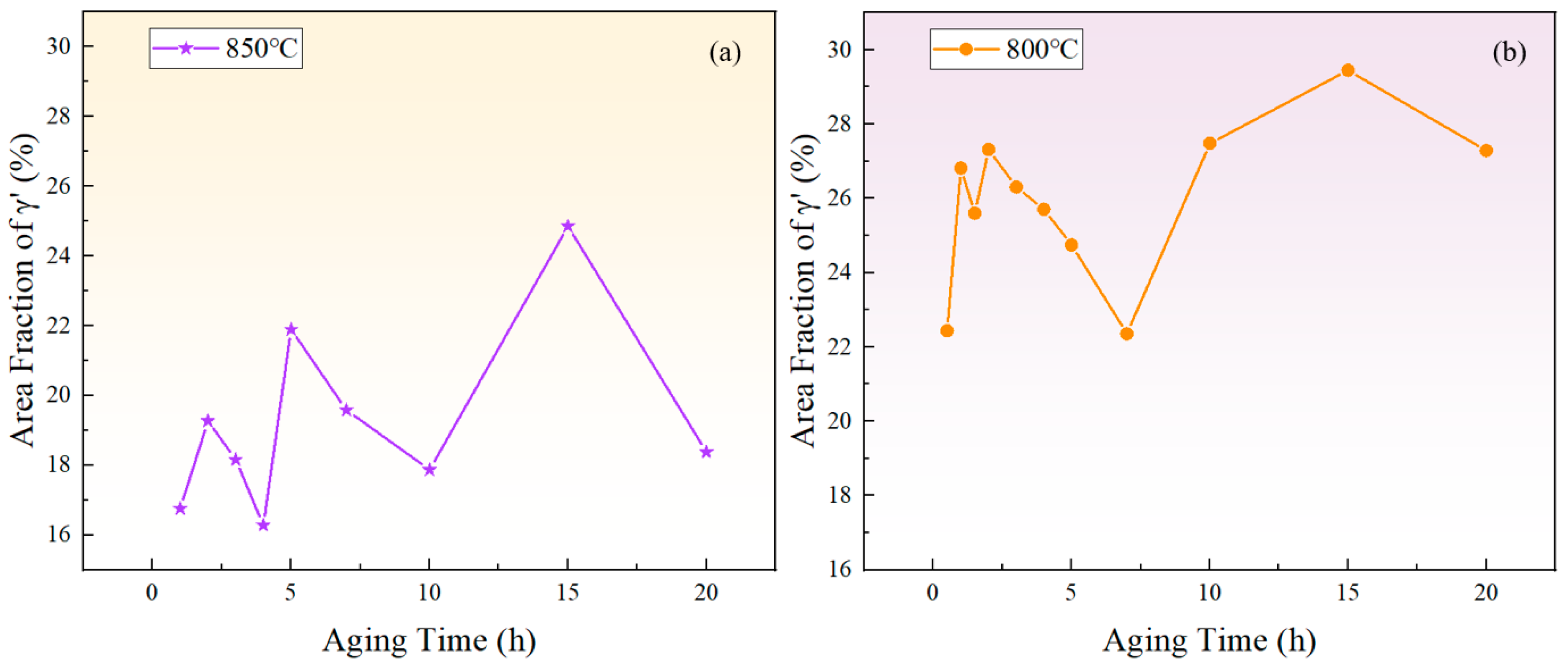

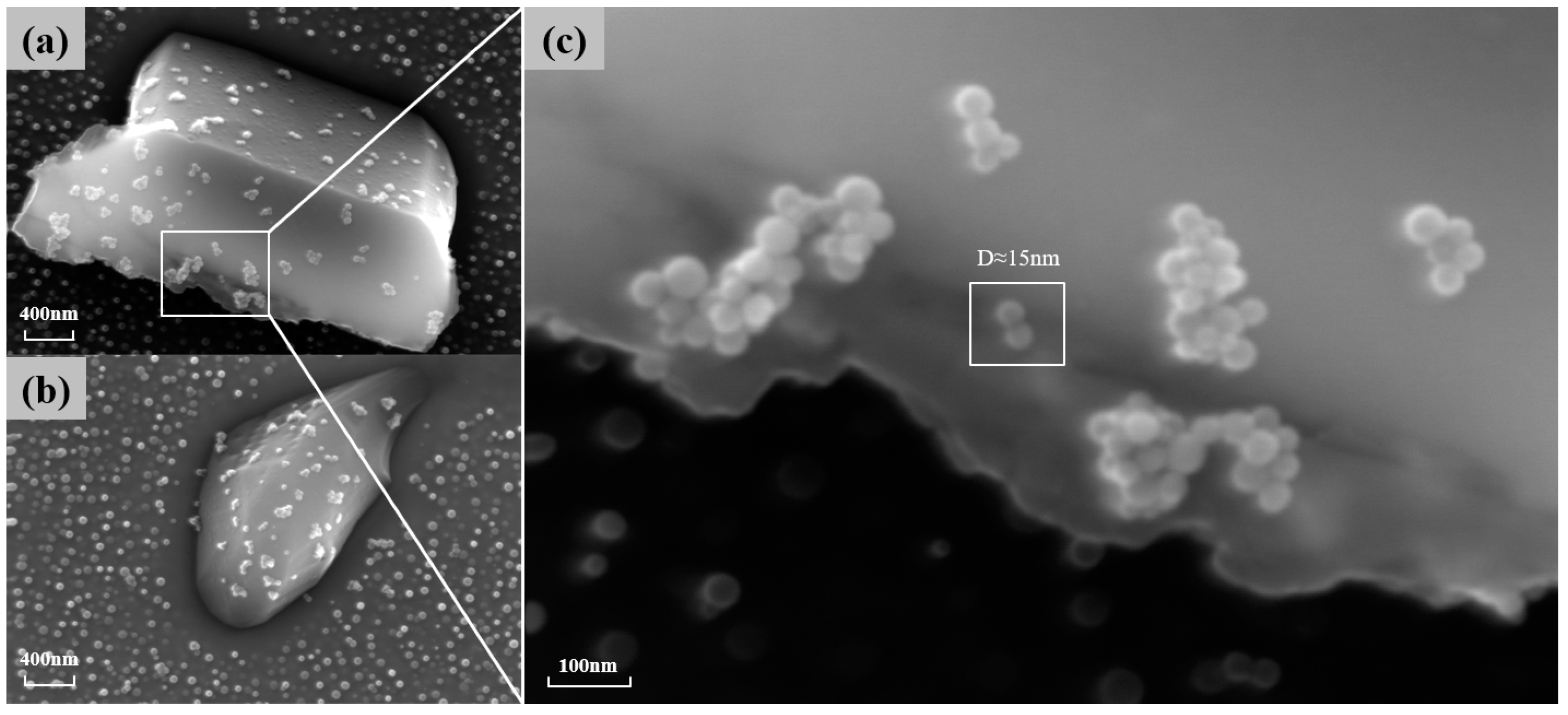

3.2. Evolution of Precipitate Morphology

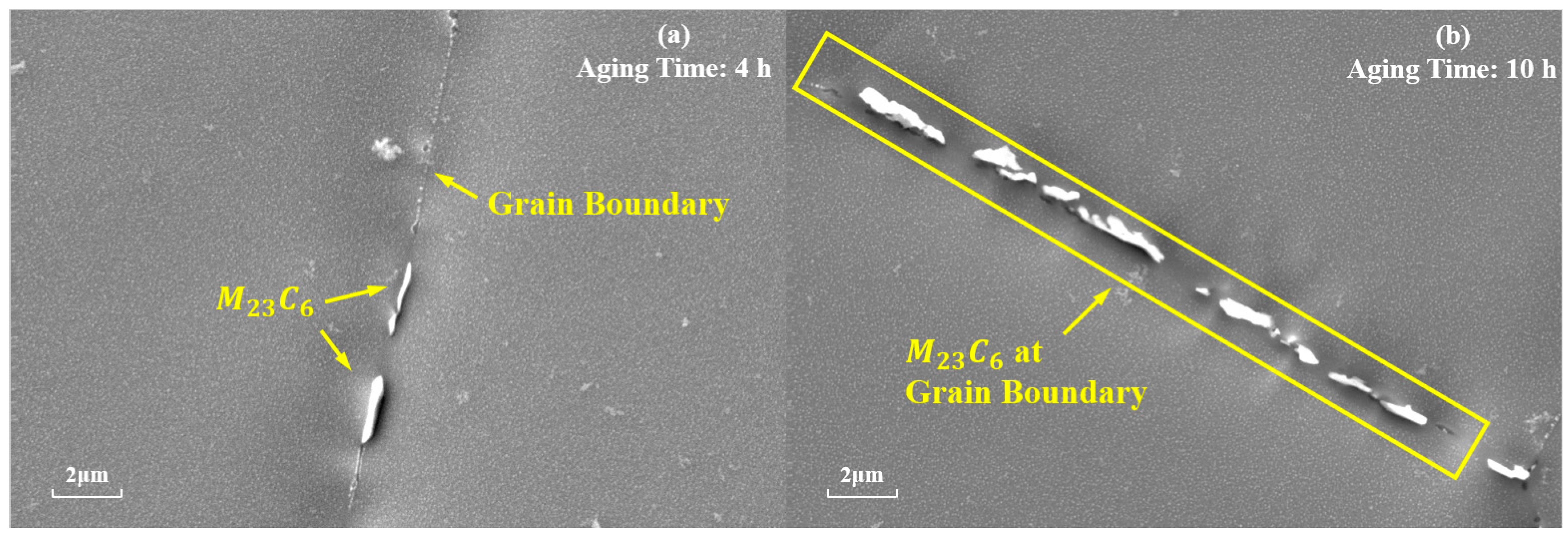

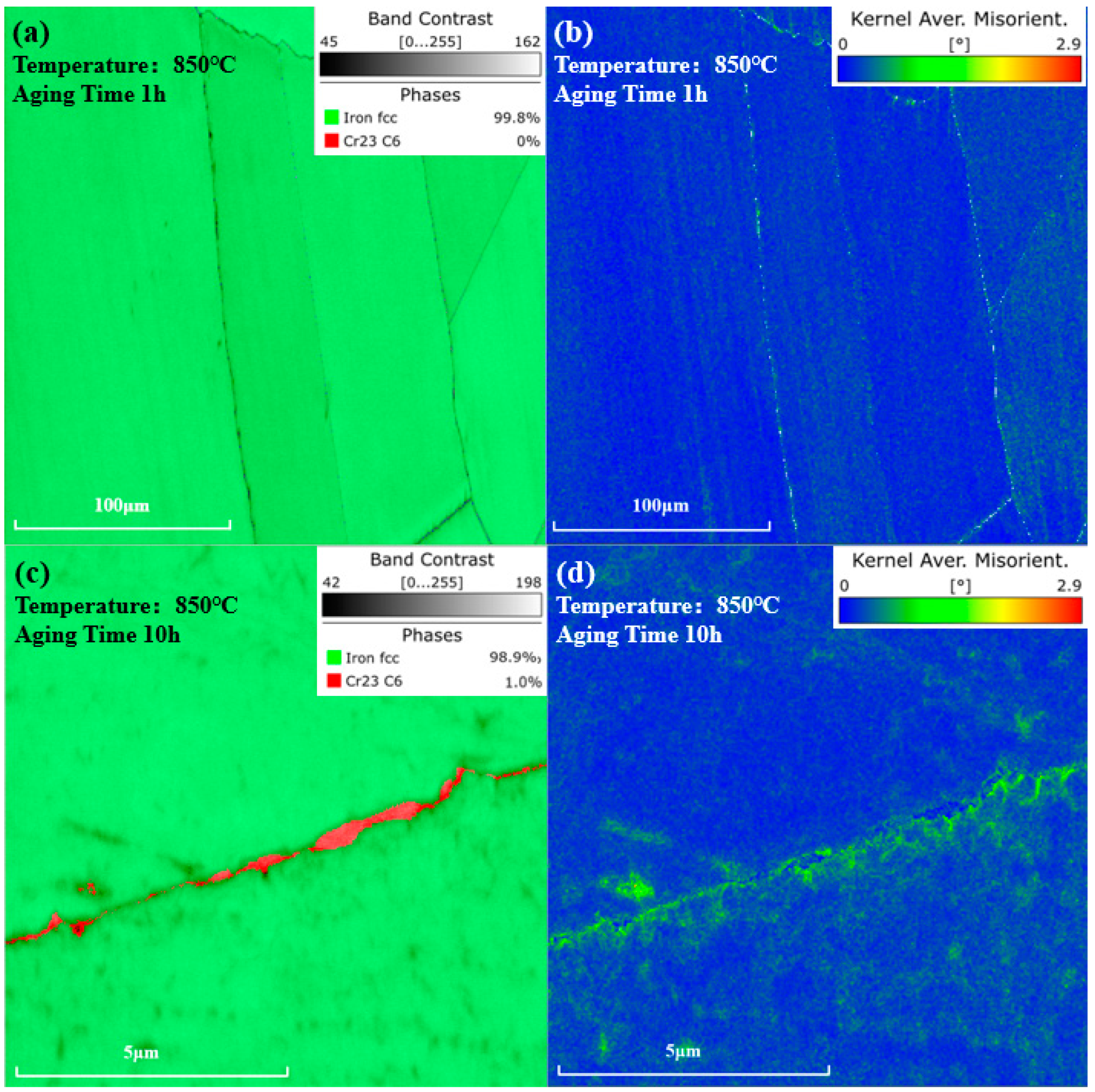

3.3. Evolution of Carbide with Aging Time

4. Discussion

4.1. Causes of the Resistivity Fluctuation

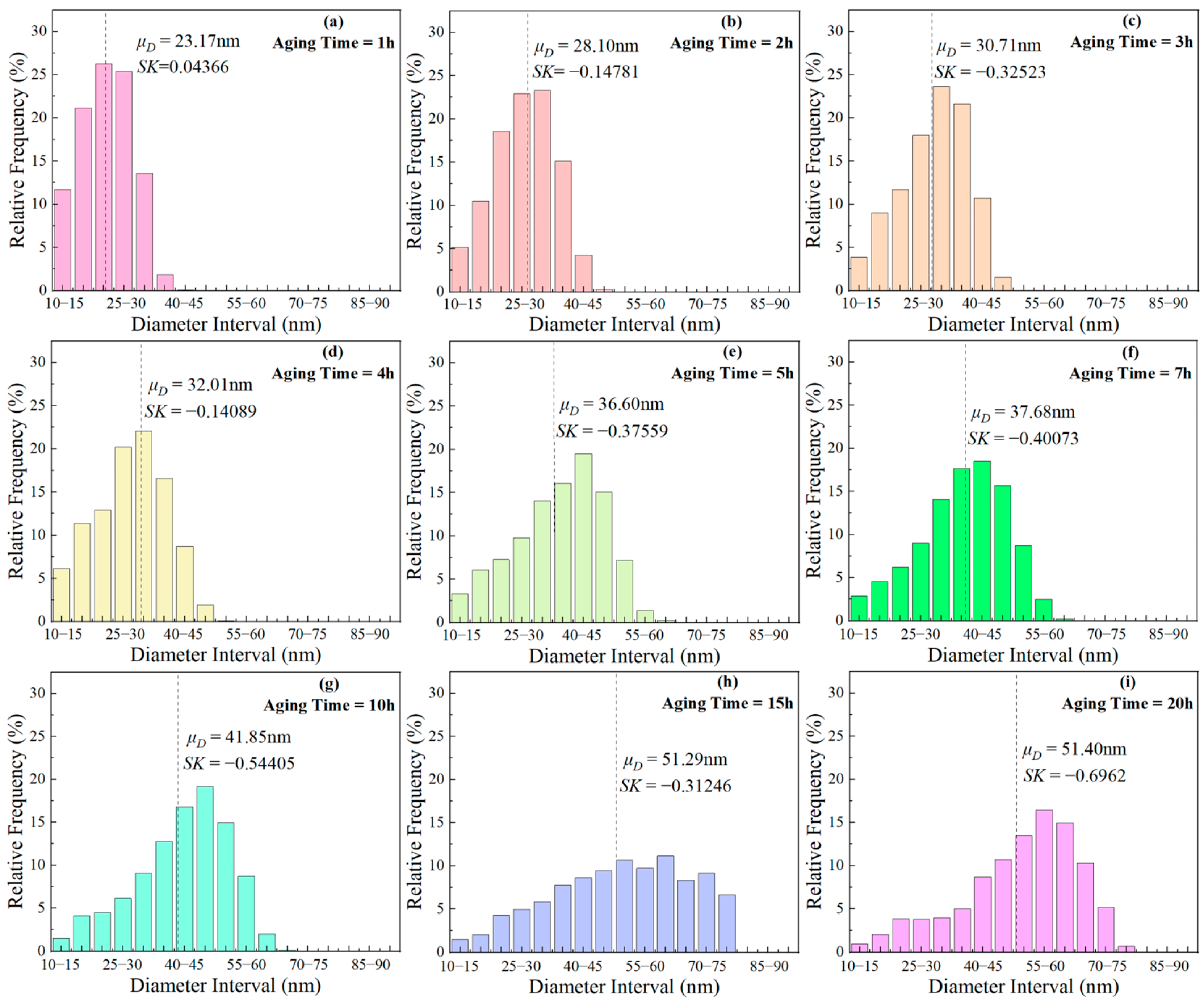

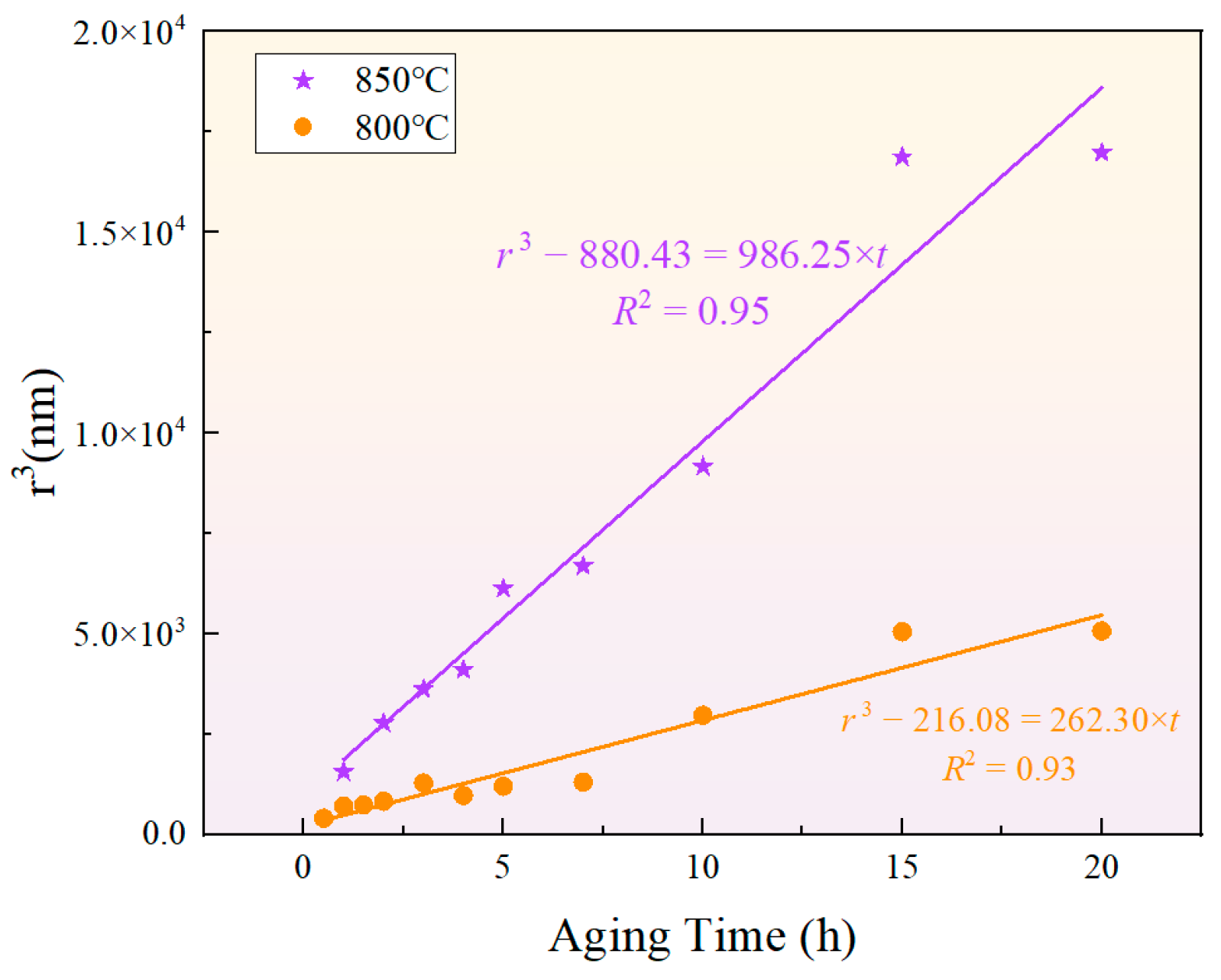

4.2. The Short-Term Aging Coarsening Kinetics of the Phase

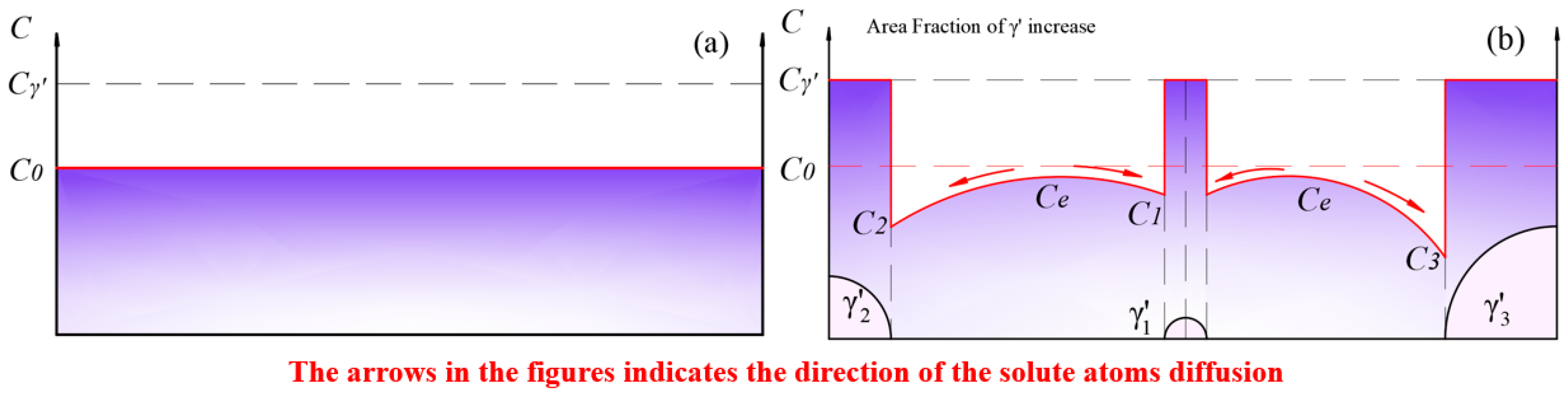

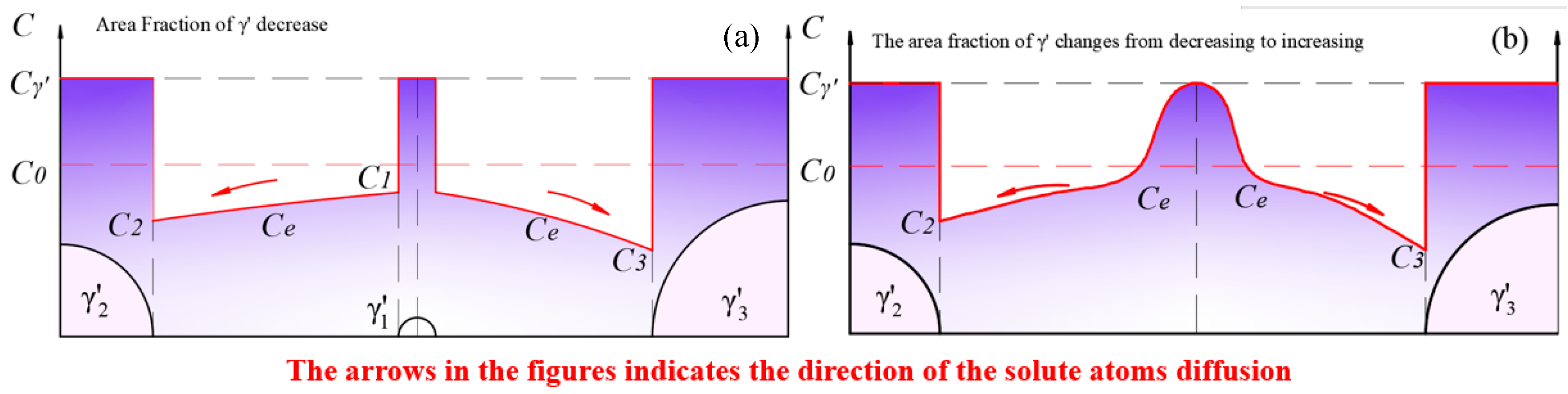

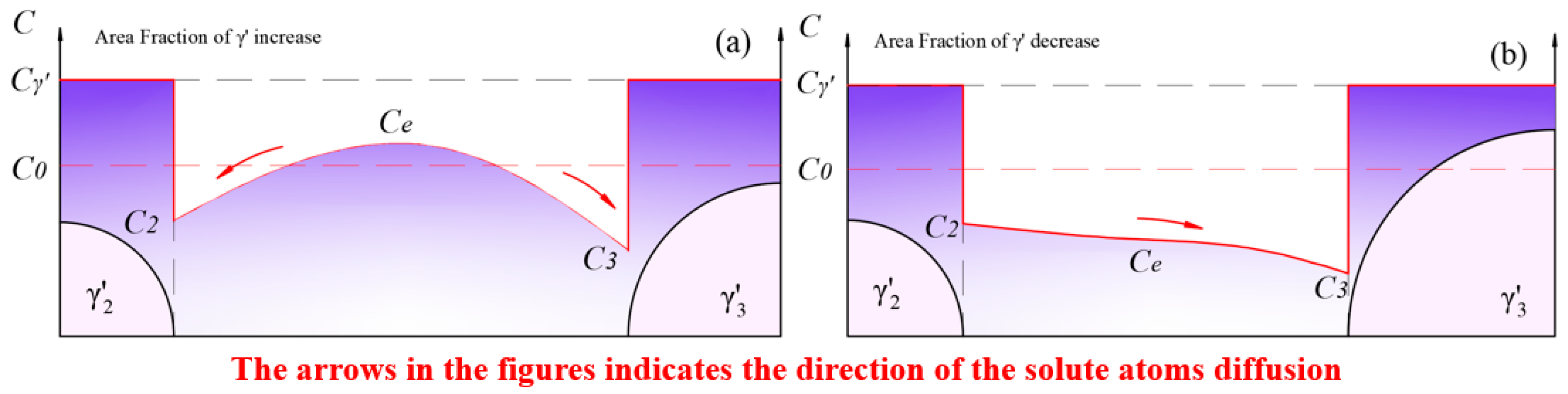

4.3. Analysis of the Fluctuation in the Total Amount of Phase Precipitation

- (1)

- Stage I: the precipitation and growth of the phase.

- (2)

- Stage II: the redissolution of smaller-sized particles and growth of larger-sized particles.

- (3)

- Stage III: a new loop of growth and redissolution process of the phase.

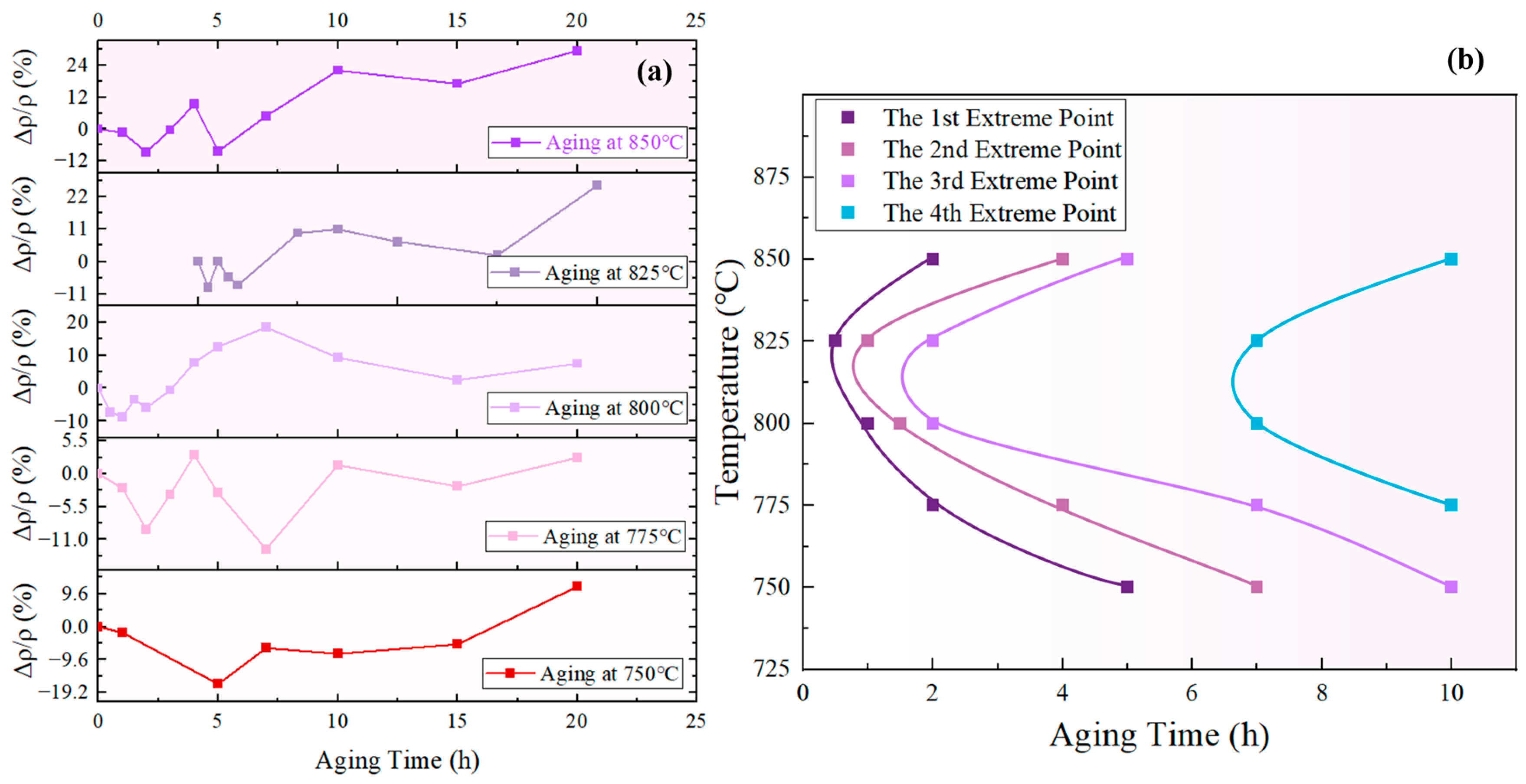

4.4. Characterization of Resistivity and Precipitation during Aging at Other Temperatures

5. Conclusions

- (1)

- The resistivity exhibits fluctuation over aging time and is negatively correlated with the area fraction of the phase. This indicates that the solute concentration in the matrix is the primary factor for the resistivity change. The enrichment of solute atoms led to lattice distortion, facilitating the formation of short-range-ordered structures, which increase electron scattering and thus elevate the resistivity. Additionally, the precipitation and growth of at grain boundaries also contributed to the gradual increase in resistivity over aging time.

- (2)

- The phase exhibited pronounced ripening during the aging process. The LSW ripening theory successfully predicted the size evolution of the phase, and its coarsening activation energy was determined to be 277.59 kJ/mol, indicating that the coarsening of was primarily due to bulk diffusion of Al and Ti elements. Differences in the chemical potential of solute atoms in the matrix near the surfaces of differently sized particles led to interactions between adjacent particles. This resulted in the redissolution of small-sized particles and the growth of large-sized particles. Since the growth rate was not consistent with the dissolution rate, fluctuations appeared in the area fraction of the phase.

- (3)

- By connecting the inflection points of the resistivity change curves at different temperatures, the extrema curves of the total content of the phase were obtained. These curves can be used to determine the total content changes of the phase during aging at a specific temperature and time. This provides a new method for characterizing the fluctuation of the total content of the phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Dong, J.X.; Zhang, M.C.; Xie, X.S. Hot working characteristics of nickel-base superalloy 740H during compression. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2013, 566, 61–70. [Google Scholar] [CrossRef]

- Liu, D.Y.; Yan, L.Y.; Hou, S.X. The evaluation of high temperature corrosion of the Inconel 740H in simulated coal-fired environments. Corros. Sci. 2019, 161, 108150. [Google Scholar] [CrossRef]

- Akbari-Garakani, M.; Mehdizadeh, M. Effect of long-term service exposure on microstructure and mechanical properties of Alloy 617. Mater. Des. 2011, 32, 2695–2700. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, C.; Dong, J.X.; Zhang, M.C. The effect of Mo and Ti elements on long-term microstructure stability of 617B nickel-base superalloy. J. Alloys Compd. 2020, 821, 153217. [Google Scholar] [CrossRef]

- Ganji, D.K.; Rajyalakshmi, G. Influence of Alloying Compositions on the Properties of Nickel-Based Superalloys: A Review. In Proceedings of the 1st National Conference on Advances in Mechanical Engineering (NCAME), National Institute of Technology Delhi, Delhi, India, 16 March 2019; pp. 537–555. [Google Scholar]

- Qin, H.L.; Bi, Z.N.; Li, D.F.; Zhang, R.Y.; Lee, T.L.; Feng, G.; Dong, H.B.; Du, J.H.; Zhang, J. Study of precipitation-assisted stress relaxation and creep behavior during the ageing of a nickel-iron superalloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 742, 493–500. [Google Scholar] [CrossRef]

- Huang, Y.S.; Zhang, R.; Zhou, Z.J.; Zhang, P.; Yan, J.B.; Yuan, Y.; Gu, Y.F.; Cui, C.Y.; Zhou, Y.Z.; Sun, X.F. Microstructure optimization for higher strength of a new Fe-Ni-based superalloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2023, 865, 144632. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, Y.; Zhong, L.; Gu, Y.F.; Yan, J.B.; Lu, J.T.; Yang, Z. Microstructural stability and tensile properties of a new γ′-hardened Ni-Fe-base superalloy. Materialia 2021, 16, 101061. [Google Scholar] [CrossRef]

- Huang, Y.S.; Zhang, R.; Zhou, Z.J.; Yan, J.B.; Yuan, Y.; Gu, Y.F.; Cui, C.Y.; Zhou, Y.Z.; Sun, X.F. Effect of long-term aging on microstructural stability and tensile deformation of a Fe-Ni-based superalloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 847, 143298. [Google Scholar] [CrossRef]

- Wang, Z.T.; Ning, Y.Q.; Yu, H.; Zhang, B.Y.; Xie, B.C.; Huang, S.; Zhang, W.Y.; Zhang, B.J. Mechanical degradation behavior and γ′ coarsening mechanism of a Ni-based superalloy during long-term high-temperature thermal exposure. J. Mater. Res. Technol. 2024, 30, 9510–9520. [Google Scholar] [CrossRef]

- Zhang, X.M.; Shang, H.; Gao, Q.Z.; Ma, Q.S.; Zhang, H.L.; Li, H.J.; Sun, L.L. Coarsening Evolution of γ′ Phase and Failure Mechanism of Co-Ni-Al-Ti-Based Superalloys During Isothermal Aging. Front. Mater. 2022, 9, 863305. [Google Scholar] [CrossRef]

- Fan, X.K.; Li, F.Q.; Liu, L.; Cui, H.C.; Lu, F.G.; Tang, X.H. Evolution of γ′ Particles in Ni-Based Superalloy Weld Joint and Its Effect on Impact Toughness During Long-Term Thermal Exposure. Acta Metall. Sin.-Engl. Lett. 2020, 33, 561–572. [Google Scholar] [CrossRef]

- Xia, X.C.; Peng, Y.Y.; He, X.; Li, C.; Ding, J.; Jiang, S.; Liu, Y.C. Precipitation Behavior of Spherical γ′ Phase in Eutectic Area of Ni3Al-Based Alloy. Adv. Eng. Mater. 2019, 21, 1801318. [Google Scholar] [CrossRef]

- Li, Y.S.; Zhao, W.J.; Chen, X.; Sang, P.; Ju, Y.F. Phase-field simulation of evolution kinetics of second γ′ phase in Ni-Al alloy under tensile stress. J. Mater. Res. Technol. 2022, 17, 1450–1458. [Google Scholar] [CrossRef]

- Yang, W.C.; Zong, H.J.; Yang, C.; Qu, P.F.; Su, H.J.; Dong, Y.; Zhang, J.; Liu, L. The effect of Fe addition on ?’ precipitates during thermal exposure in Ni-Co-based single crystal superalloys. J. Mater. Res. Technol. 2022, 20, 894–904. [Google Scholar] [CrossRef]

- Shi, S.J.; Liu, C.W.; Li, Y.S.; Maqbool, S.; Zhang, X.Y.; Huang, M. Coarsening kinetics of γ′ phase in isothermal aged high Al content Ni-17 at. % Al alloy. Mater. Chem. Phys. 2021, 271, 124902. [Google Scholar] [CrossRef]

- Joseph, J.; Annasamy, M.; Kada, S.R.; Hodgson, P.D.; Barnett, M.R.; Fabijanic, D.M. Optimising the Al and Ti compositional window for the design of γ′ (L12)-strengthened Al-Co-Cr-Fe-Ni-Ti high entropy alloys. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 835, 142620. [Google Scholar] [CrossRef]

- Sauza, D.J.; Dunand, D.C.; Noebe, R.D.; Seidman, D.N. γ′-(L12) precipitate evolution during isothermal aging of a Co-Al-W-Ni superalloy. Acta Mater. 2019, 164, 654–662. [Google Scholar] [CrossRef]

- Jahangiri, M.R.; Arabi, H.; Boutorabi, S.M.A. Comparison of microstructural stability of IN939 superalloy with two different manufacturing routes during long-time aging. Trans. Nonferrous Met. Soc. China 2014, 24, 1717–1729. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.T.; Chen, K.; Sun, N.R.; Shan, A.D. Morphology and chemical composition of γ/γ′ phases in Re-containing Ni-based single crystal superalloy during two-step aging. Trans. Nonferrous Met. Soc. China 2011, 21, 1513–1517. [Google Scholar] [CrossRef]

- Speicher, M.; Kauffmann, F.; Shim, J.H.; Chandran, M. Microstructure evolution in Alloy 617 B after a long-term creep and thermal aging at 700 °C. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2018, 711, 165–174. [Google Scholar] [CrossRef]

- Kim, Y.; Bae, J.; Lee, J.; Kang, H.; Kim, J.G.; Kim, S. Effect of stabilization annealing on fatigue crack propagation behavior of inconel 706 alloy at 25 and 650 °C. J. Mater. Res. Technol. 2024, 30, 7084–7094. [Google Scholar] [CrossRef]

- Hou, J.S.; Guo, J.T.; Zhou, L.Z.; Ye, H.Q. Effects of γ′-precipitate coarseningon tensile properties of Ni base superalloy K44 during long-term aging. Acta Metall. Sin. 2006, 42, 481–486. [Google Scholar]

- Xu, Q.-S.; Cao, T.-S.; Xu, F.-H.; Fang, X.-D.; Cheng, C.-Q.; Zhao, J. Precipitation behavior and mechanical properties of TG70OA alloy during aging. Chin. J. Nonferr. Met. 2018, 28, 1559–1567. [Google Scholar] [CrossRef]

- Pavan, A.H.V.; Narayan, R.L.; Singh, K.; Ramamurty, U. Effect of Ageing on Microstructure, Mechanical Properties and Creep Behavior of Alloy 740H. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2020, 51, 5169–5179. [Google Scholar] [CrossRef]

- Huang, Y.S.; Wang, X.G.; Cui, C.Y.; Li, J.G.; Ye, L.H.; Hou, G.C.; Yang, Y.H.; Liu, J.L.; Liu, J.D.; Zhou, Y.Z.; et al. The effect of coarsening of γ′ precipitate on creep properties of Ni-based single crystal superalloys during long-term aging. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2020, 773, 138886. [Google Scholar] [CrossRef]

- Xu, J.C.; Zhao, X.B.; Li, W.Q.; Liu, H.; Yue, Q.Z.; Duan, H.C.; Gu, Y.F.; Zhang, Z. Aging process design based on the morphological evolution of γ′ precipitates in a 4th generation nickel-based single crystal superalloy. J. Mater. Sci. Technol. 2023, 147, 176–188. [Google Scholar] [CrossRef]

- Pandolfi, G.S.; Martins, S.C.; Buono, V.T.L.; Santos, L.A. Precipitation kinetics of Ti3Ni4 and multistage martensitic transformation in an aged Ni-rich Ni-Ti shape memory alloy. J. Mater. Res. Technol. 2020, 9, 9162–9173. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, Y.; Peng, S.Y.; Pang, X.Y.; Li, S.; Jiang, M.; Li, H.X.; Wang, J.W.; Qin, G.W. Managing mechanical and electrical properties of nanostructured Cu-Fe composite by aging treatment. Mater. Charact. 2023, 196, 112600. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, D.C.; Yu, W.X.; Huang, S.D.; Wu, D.; Xu, Y.H.; Yang, X.J. Short-range ordering in a commercial Ni-Cr-Al-Fe precision resistance alloy. Mater. Des. 2019, 181, 107981. [Google Scholar] [CrossRef]

- Al-Aql, A.A.; Al-Salhi, M.S.; Ansari, M.I. Precipitation in Ni-35 at. pct Cr alloy. J. Mater. Sci. Technol. 2002, 18, 77–79. [Google Scholar]

- Zhang, P.; Yang, X.J.; Wang, Y.; Huang, S.D.; Xu, Y.H.; Song, H. Effect of aging temperature on ordered structure of Ni-Cr-Al-Fe precision resistance alloy. Mater. Charact. 2022, 186, 111798. [Google Scholar] [CrossRef]

- Lee, S.H.; Jung, J.G.; Baik, S.I.; Seidman, D.N.; Kim, M.S.; Lee, Y.K.; Euh, K. Precipitation strengthening in naturally aged Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2021, 803, 140719. [Google Scholar] [CrossRef]

- Zhang, Z.R.; Kang, S.H.; Kim, Y.Y.; Euh, K.; Cho, Y.H.; Son, H.W. Effect of Ag and Ge on the precipitation behavior and resultant properties of AA6061 alloys. J. Mater. Res. Technol. 2024, 28, 1330–1340. [Google Scholar] [CrossRef]

- Yang, J.; Heogh, W.; Ju, H.; Kang, S.; Jang, T.-S.; Jung, H.-D.; Jahazi, M.; Han, S.C.; Park, S.J.; Kim, H.S.; et al. Functionally graded structure of a nitride-strengthened Mg2Si-based hybrid composite. J. Magnes. Alloys 2024, 12, 1239–1256. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Hongyu, L.I.; Lingli, Z.U.O.; Xiping, S.; Yanli, W.; Guoliang, C. γ′ Particles Coarsening Kinetics in Nickel-base Superalloy GH742. J. Mater. Eng. 2007, 8–11. [Google Scholar]

- Dugdale, J.S. The Electrical Properties of Metals and Alloys; Edward Arnold: London, UK, 1977. [Google Scholar]

- Lu, W.J.; Luo, X.; Huang, B.; Li, P.T.; Yang, Y.Q. Excellent thermal stability and their origins in γ′ precipitation-strengthened medium-entropy alloys. Scr. Mater. 2022, 212, 114576. [Google Scholar] [CrossRef]

- Ashcroft, N.W.; Mermin, N.D. Solid State Physics; Saunders College: Philadelphia, PA, USA, 1976. [Google Scholar]

- Kelekanjeri, G.; Kumar, V.S. Non-Destructive Electrical Characterization of Controlled Waspaloy Microstructures. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2007. [Google Scholar]

- Roebuck, B.; Cox, D.; Reed, R. The temperature dependence of γ′ volume fraction in a Ni-based single crystal superalloy from resistivity measurements. Scr. Mater. 2001, 44, 917–921. [Google Scholar] [CrossRef]

- Hummel, R.E. Electronic Properties of Materials, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Schwensfeir, R.J.; Wu, C.T. Determination of the electrical resistivity of monocrystalline Ni3Al from measurements on an aligned off-eutectic alloy. Mater. Sci. Eng. 1971, 8, 284–287. [Google Scholar] [CrossRef]

- Hong, S.I.; Hill, M.A. Mechanical stability and electrical conductivity of Cu–Ag filamentary microcomposites. Mater. Sci. Eng. A 1999, 264, 151–158. [Google Scholar] [CrossRef]

- Gangulee, A. The Structure of Electroplated and Vapor-Deposited Copper Films. J. Appl. Phys. 1972, 43, 867–873. [Google Scholar] [CrossRef]

- McLachlan, D.S.; Blaszkiewicz, M.A.G.; Newnham, R.E. Electrical Resistivity of Composites. J. Am. Ceram. Soc. 1990, 73, 2187–2203. [Google Scholar] [CrossRef]

- Yu, W.; Wang, Y.; Yang, X.; Xu, Y.; Wu, D.; Wang, F. Effect of solution treatment on electrical properties and yield strength of Ni-Cr-Al-Fe alloy. Heat Treat. Met. 2020, 45, 62–68. [Google Scholar]

- Kajimura, H.; Yamanaka, K. Effect of chromium carbides on electrical-resistivity of nickel based alloys by low-temperature aging. Mater. Sci. Technol. 1989, 5, 1128–1134. [Google Scholar] [CrossRef]

- Hidalgo, J.; Findley, K.O.; Santofimia, M.J. Thermal and mechanical stability of retained austenite surrounded by martensite with different degrees of tempering. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 690, 337–347. [Google Scholar] [CrossRef]

- Zribi, Z.; Ktari, H.H.; Herbst, F.; Optasanu, V.; Njah, N. EBSD, XRD and SRS characterization of a casting Al-7wt% Si alloy processed by equal channel angular extrusion: Dislocation density evaluation. Mater. Charact. 2019, 153, 190–198. [Google Scholar] [CrossRef]

- Baldan, A. Review Progress in Ostwald ripening theories and their applications to nickel-base superalloys—Part I: Ostwald ripening theories. J. Mater. Sci. 2002, 37, 2171–2202. [Google Scholar] [CrossRef]

- Baldan, A. Review Progress in Ostwald ripening theories and their applications to the γ′-precipitates in nickel-base superalloys-Part II: Nickel-base superalloys. J. Mater. Sci. 2002, 37, 2379–2405. [Google Scholar] [CrossRef]

- Madras, G.; McCoy, B.J. Continuous distribution theory for Ostwald ripening: Comparison with the LSW approach. Chem. Eng. Sci. 2003, 58, 2903–2909. [Google Scholar] [CrossRef]

- Ellis, C.N.; Gorsulowsky, D.C.; Voorhees, J.J. Experimental therapies for psoriasis. Semin. Dermatol. 1985, 4, 313–319. [Google Scholar]

- Gust, W.; Hintz, M.B.; Lodding, A.; Odelius, H.; Predel, B. Impurity diffusion of Al in Ni single-crystals studied by Secondary Ion Mass-Spectrometry (SIMS). Phys. Status Solidi A-Appl. Res. 1981, 64, 187–194. [Google Scholar] [CrossRef]

- Ardell, A.J.; Nicholso, R.B. On modulated structure of aged Ni-Al alloys. Acta Metall. 1966, 14, 1295–1309. [Google Scholar] [CrossRef]

- Jung, S.B.; Yamane, T.; Minamino, Y.; Hirao, K.; Araki, H.; Saji, S. Interdiffusion and its size effect in nickel solid-solutions of Ni-Co, Ni-Cr and Ni-Ti systems. J. Mater. Sci. Lett. 1992, 11, 1333–1337. [Google Scholar] [CrossRef]

- Swalin, R.A.; Martin, A. Solute diffusion in nickel-base substitutional solid solutions. Trans. Am. Inst. Min. Metall. Eng. 1956, 206, 567–572. [Google Scholar] [CrossRef]

- Million, B.; Ruzickova, J.; Velisek, J.; Vrestal, J. Diffusion-processes in the Fe-Ni system. Mater. Sci. Eng. 1981, 50, 43–52. [Google Scholar] [CrossRef]

- Zhu, Z.; Basoalto, H.; Warnken, N.; Reed, R.C. A model for the creep deformation behaviour of nickel-based single crystal superalloys. Acta Mater. 2012, 60, 4888–4900. [Google Scholar] [CrossRef]

- Pansheng, P.; Minbo, T.; Jianmin, T. Fundamentals of Materials Science; Tsinghua University Press: Beijing, China, 2011. [Google Scholar]

- Akuezue, H.C.; Whittle, D.P. Interdiffusion in Fe-Al system-aluminizing. Met. Sci. 1983, 17, 27–31. [Google Scholar] [CrossRef]

- Wei, H.; Guan, H.; Sun, X.; Zheng, Q.; Hou, G.; Hu, Z. Calculation of interdiffusivity of Ni and Al in aluminide coating formed on k456 superalloy. J. Chin. Soc. Corros. Prot. 2004, 24, 257–261. [Google Scholar]

- Li, H.Y.; Zuo, L.L.; Song, X.P.; Wang, Y.L.; Chen, G.L. Coarsening behavior of γ′ particles in a nickel-base superalloy. Rare Met. 2009, 28, 197–201. [Google Scholar] [CrossRef]

| Element | Fe | Ni | Cr | Al | Ti | Co | Mo | C + Si + Mn + B + Nb + W |

|---|---|---|---|---|---|---|---|---|

| wt.% | 42.82 | Bal. | 16.1 | 1.4 | 2.0 | 2.0 | 0.5 | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, J.; Qian, C.; Huo, X.; Liu, Q.; Li, K.; Ji, W.; Li, Z.; Yang, Z.; Cheng, J.; Fan, M.; et al. Characterizing Short-Time Aging Precipitation Behavior of a Novel Nickel–Iron-Based Alloy via Electrical Performance. Materials 2024, 17, 4143. https://doi.org/10.3390/ma17164143

Cai J, Qian C, Huo X, Liu Q, Li K, Ji W, Li Z, Yang Z, Cheng J, Fan M, et al. Characterizing Short-Time Aging Precipitation Behavior of a Novel Nickel–Iron-Based Alloy via Electrical Performance. Materials. 2024; 17(16):4143. https://doi.org/10.3390/ma17164143

Chicago/Turabian StyleCai, Junjian, Chengkai Qian, Xin Huo, Qu Liu, Kejian Li, Wen Ji, Zheng Li, Zhengang Yang, Jun Cheng, Manjie Fan, and et al. 2024. "Characterizing Short-Time Aging Precipitation Behavior of a Novel Nickel–Iron-Based Alloy via Electrical Performance" Materials 17, no. 16: 4143. https://doi.org/10.3390/ma17164143

APA StyleCai, J., Qian, C., Huo, X., Liu, Q., Li, K., Ji, W., Li, Z., Yang, Z., Cheng, J., Fan, M., & Cai, Z. (2024). Characterizing Short-Time Aging Precipitation Behavior of a Novel Nickel–Iron-Based Alloy via Electrical Performance. Materials, 17(16), 4143. https://doi.org/10.3390/ma17164143