Micronized Shell-Bioaggregates as Mechanical Reinforcement in Organic Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Production

2.3. Characterization

3. Results and Discussion

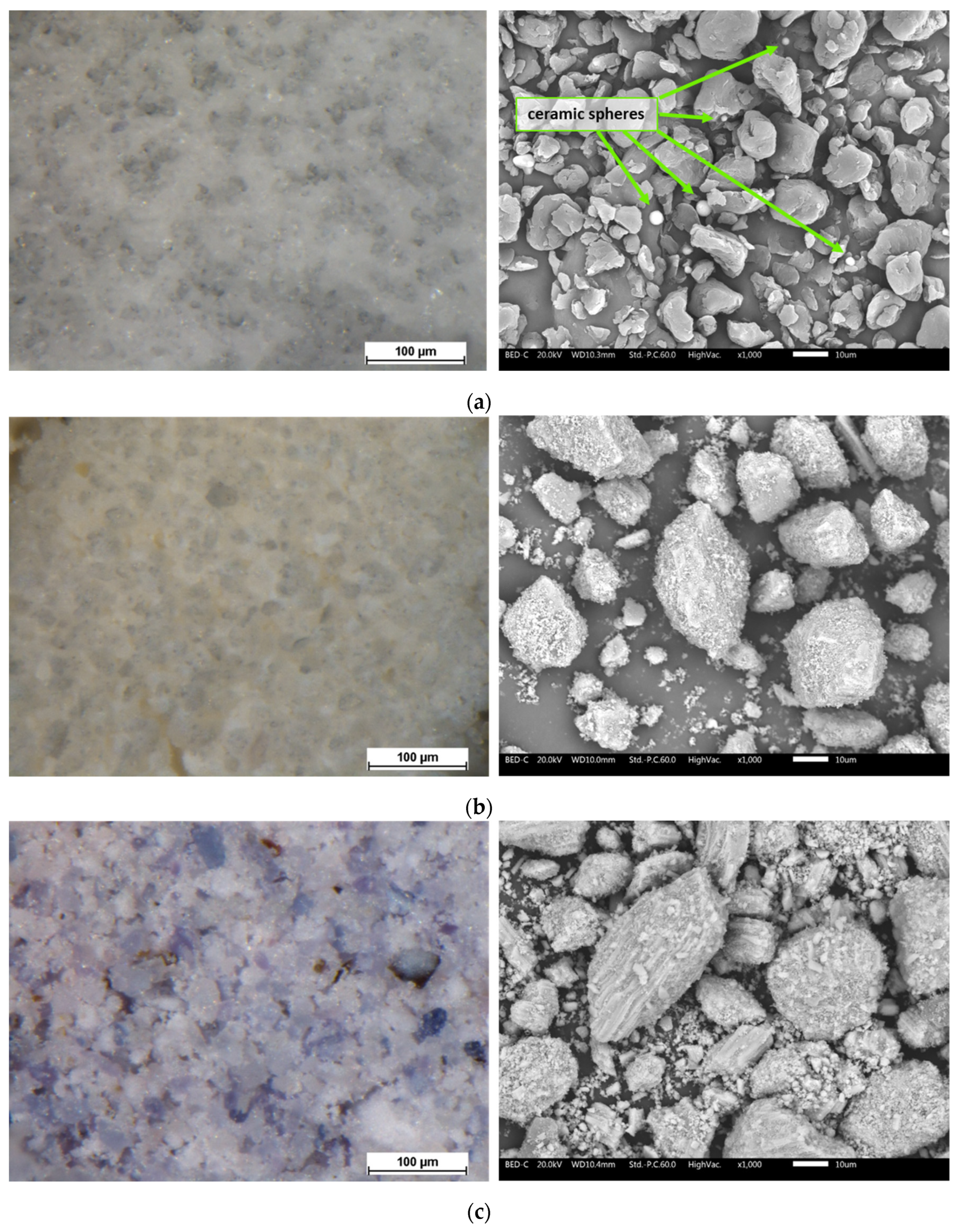

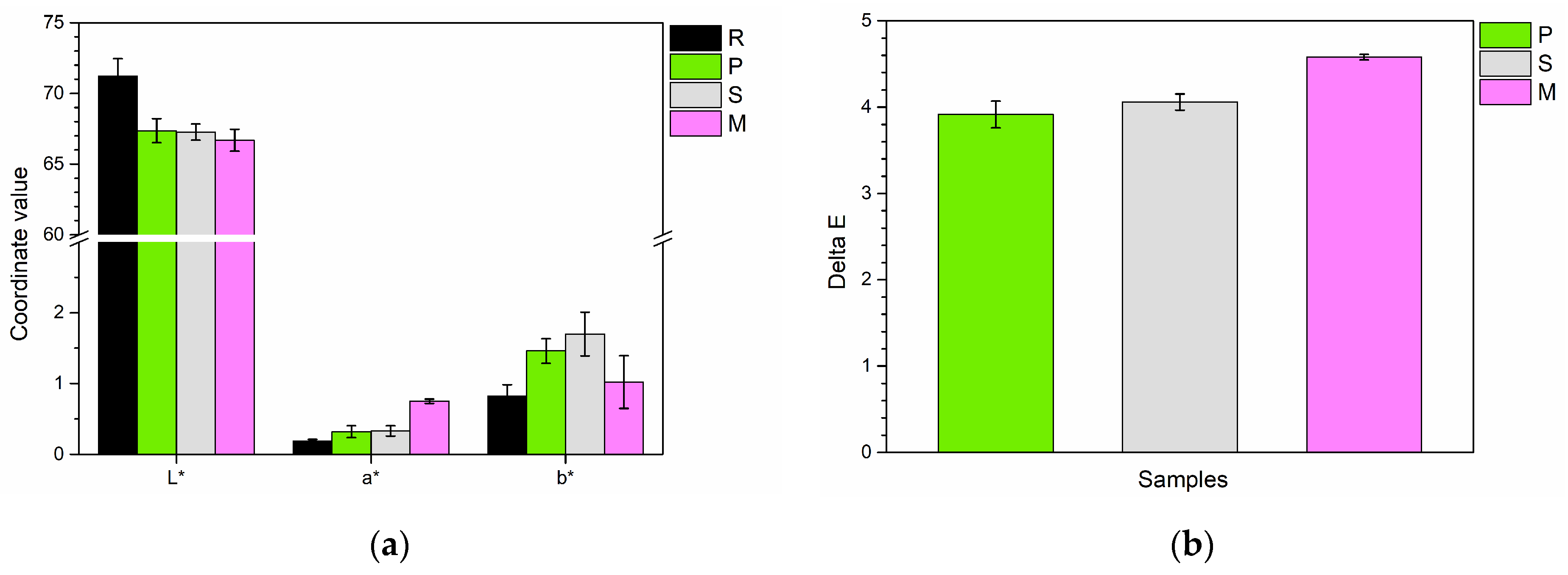

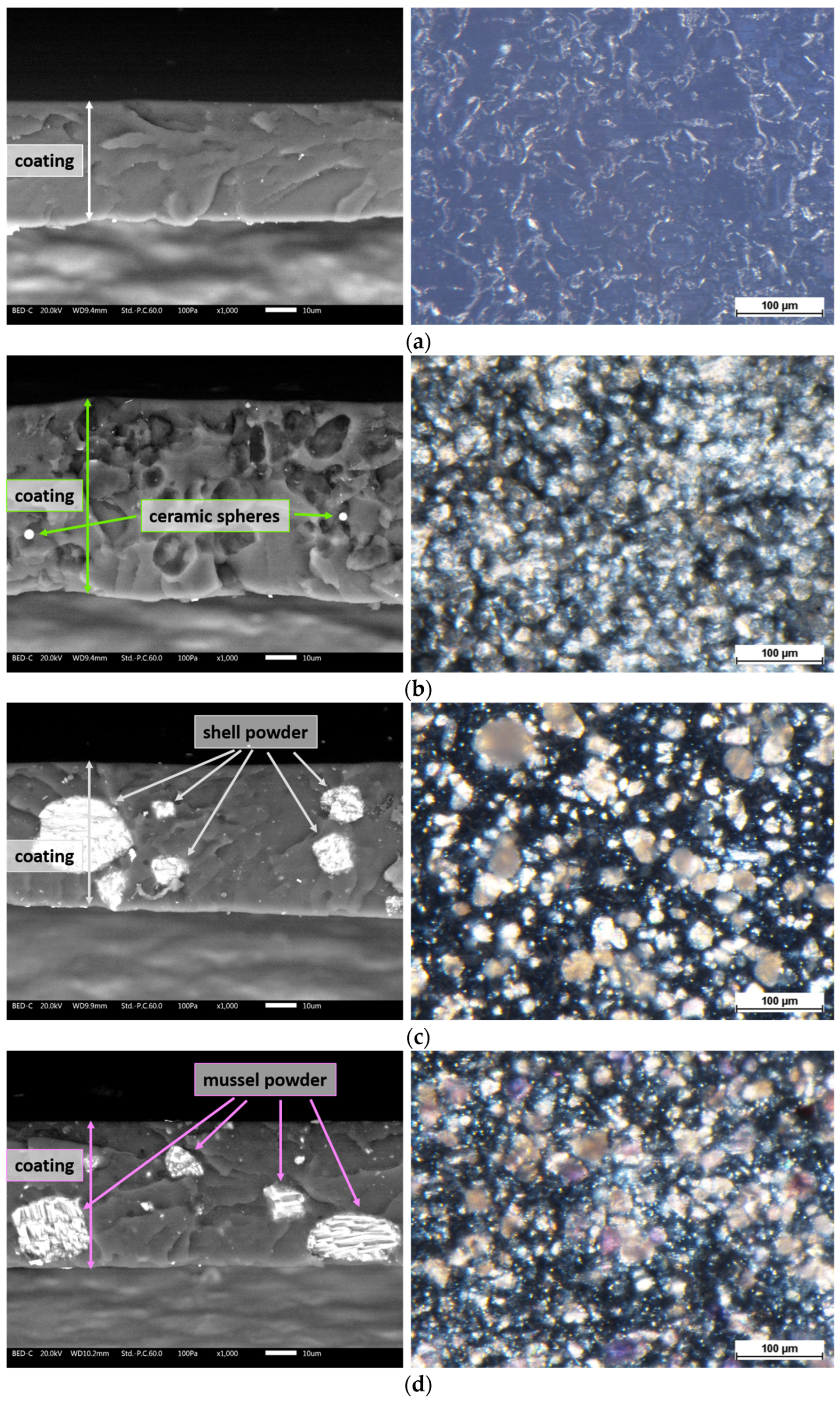

3.1. Fillers and Coatings Appearance

- L* represents lightness, ranging from 0 (black) to 100 (white);

- a* denotes the red-green axis, with positive values indicating red and negative values showing green;

- b* reflects the yellow-blue axis, where positive values represent yellow and negative values denote blue.

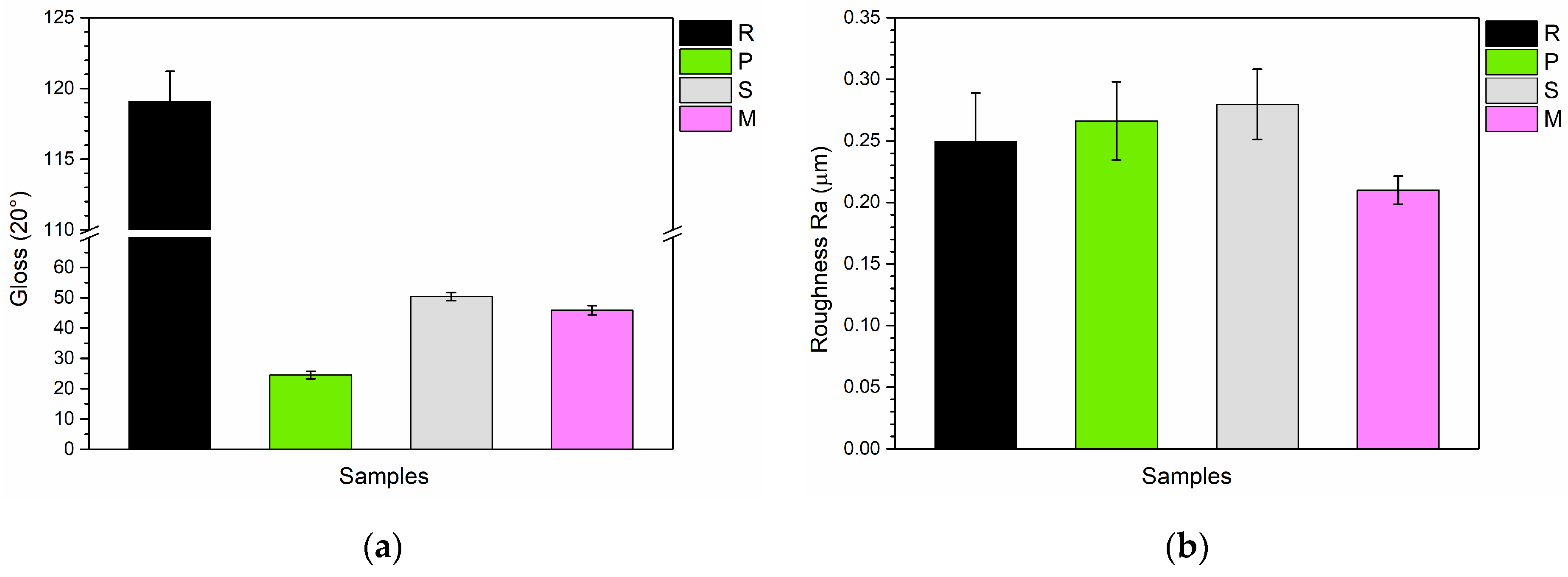

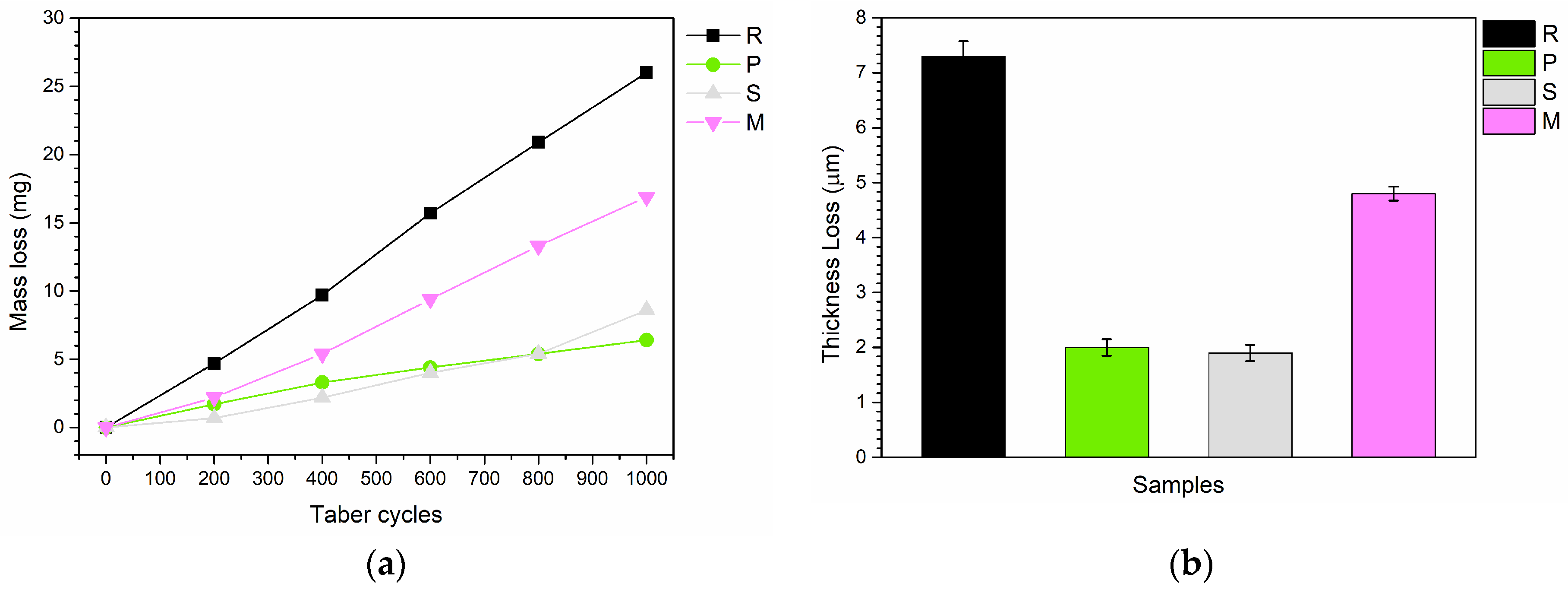

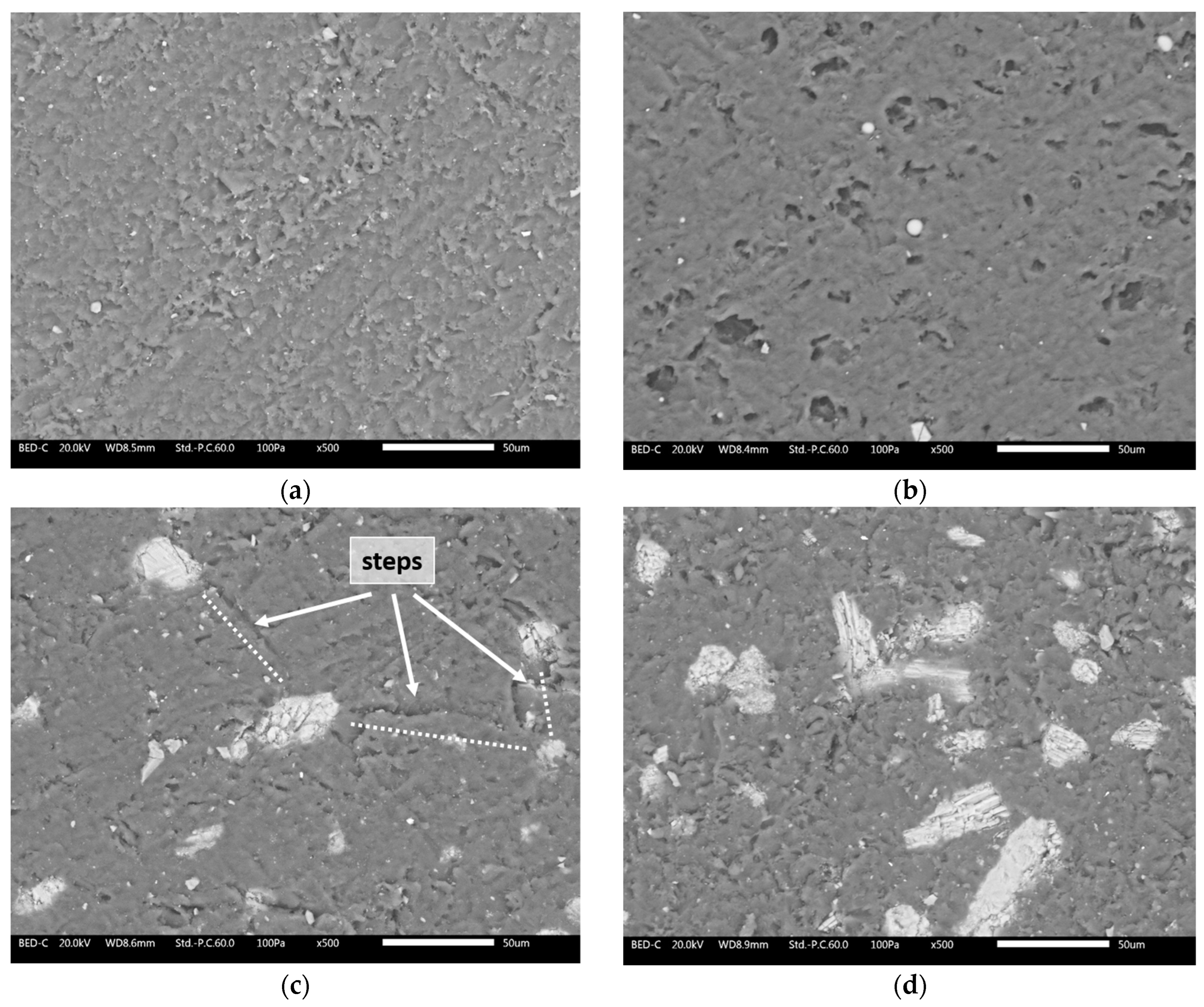

3.2. Impact of the Additive on the Coating’s Mechanical Characteristics

3.3. Impact of the Additive on the Coating’s Durability in Aggressive Environments

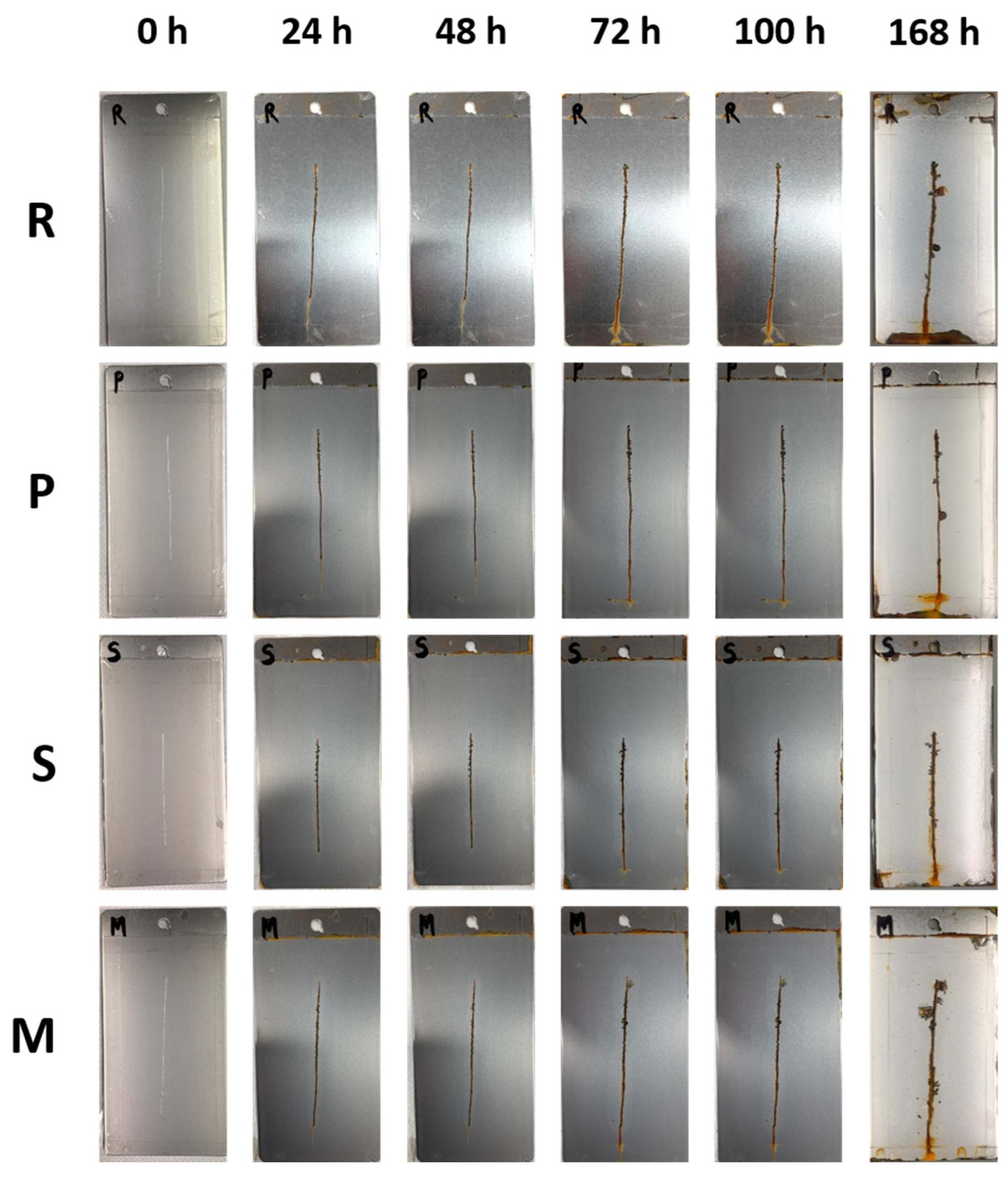

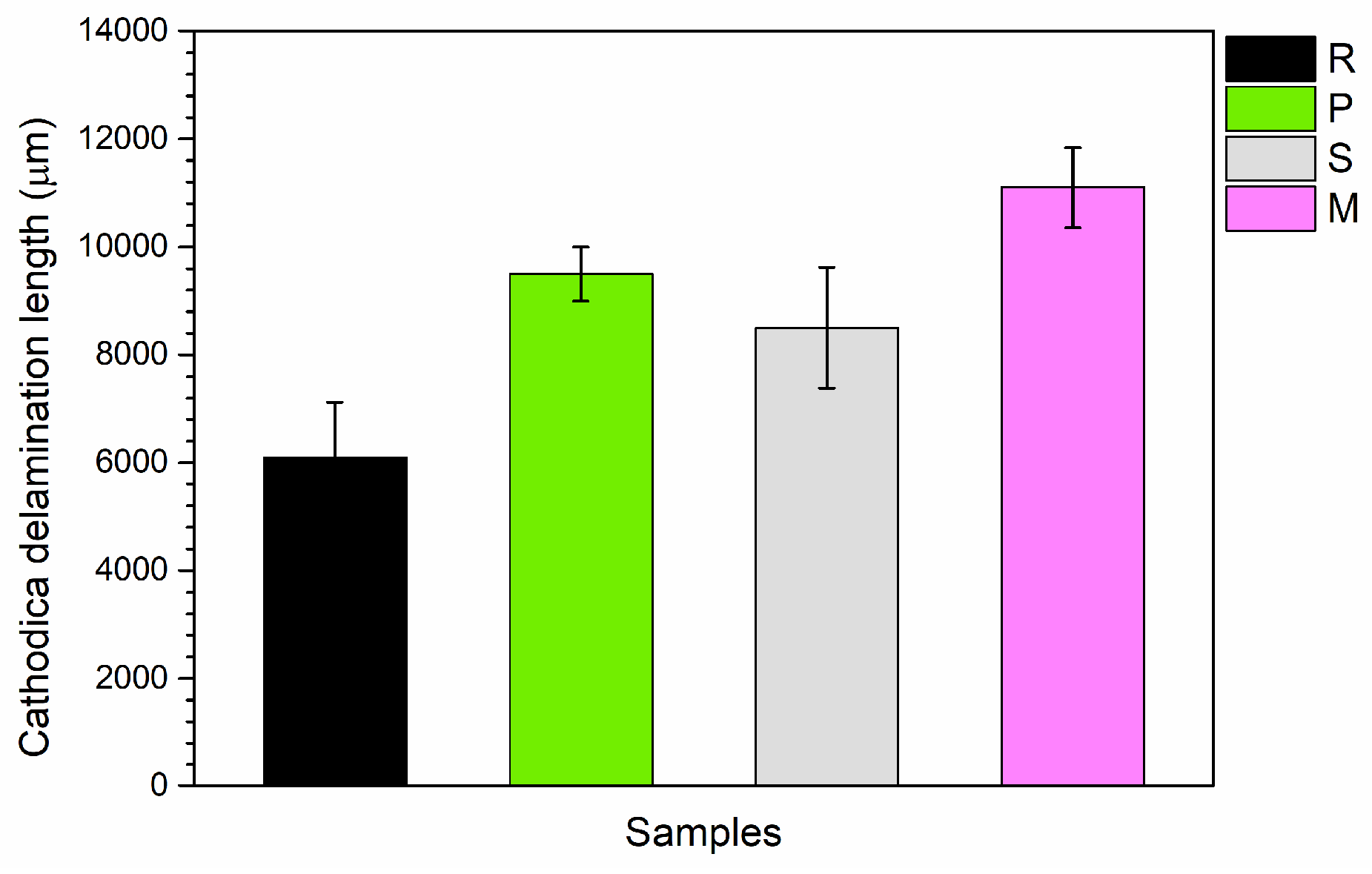

3.3.1. Salt Spray Chamber Exposure

3.3.2. UV-B Chamber Exposure

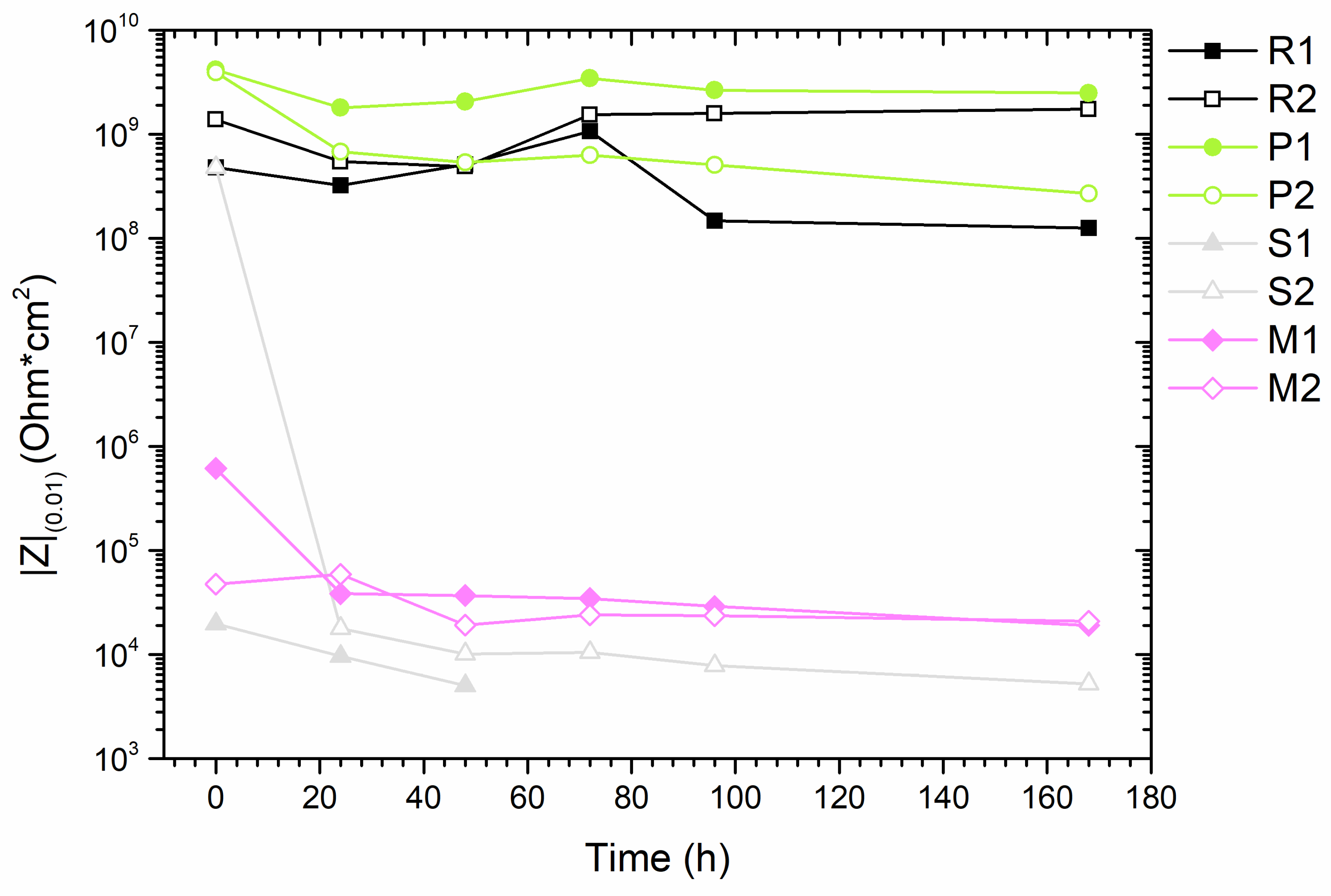

3.3.3. Electrochemical Impedance Spectroscopy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, L.; Guo, X.; Zhang, J. Abrasive resistant coatings—A review. Lubricants 2014, 2, 66–89. [Google Scholar] [CrossRef]

- Larsen, T.Ø.; Andersen, T.L.; Thorning, B.; Horsewell, A.; Vigild, M.E. Changes in the tribological behavior of an epoxy resin by incorporating CuO nanoparticles and PTFE microparticles. Wear 2008, 265, 203–213. [Google Scholar] [CrossRef]

- Spencer, K.; Fabijanic, D.; Zhang, M.-X. The influence of Al2O3 reinforcement on the properties of stainless steel cold spray coatings. Surf. Coat. Technol. 2012, 206, 3275–3282. [Google Scholar] [CrossRef]

- Bui, T.M.A.; Nguyen, T.V.; Nguyen, T.M.; Hoang, T.H.; Nguyen, T.T.H.; Lai, T.H.; Tran, T.N.; Hoang, V.H.; Le, T.L.; Dang, T.C. Investigation of crosslinking, mechanical properties and weathering stability of acrylic polyurethane coating reinforced by SiO2 nanoparticles issued from rice husk ash. Mat. Chem. Phys. 2020, 241, 122445. [Google Scholar] [CrossRef]

- Jakab, B.; Panaitescu, I.; Gamsjäger, N. The action of fillers in the enhancement of the tribological performance of epoxy composite coatings. Polym. Test. 2021, 100, 107243. [Google Scholar] [CrossRef]

- Bagherzadeh, M.; Mahdavi, F. Preparation of epoxy–clay nanocomposite and investigation on its anti-corrosive behavior in epoxy coating. Prog. Org. Coat. 2007, 60, 117–120. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Mirabedini, S.; Kabiri, K.; Jamali, S. Corrosion performance of epoxy coatings containing silane treated ZrO2 nanoparticles on mild steel in 3.5% NaCl solution. Corros. Sci. 2011, 53, 89–98. [Google Scholar] [CrossRef]

- Calovi, M.; Zanardi, A.; Rossi, S. Recent Advances in Bio-Based Wood Protective Systems: A Comprehensive Review. Appl. Sci. 2024, 14, 736. [Google Scholar] [CrossRef]

- Peter, N.J.; Griesshaber, E.; Reisecker, C.; Hild, S.; Oliveira, M.V.; Schmahl, W.W.; Schneider, A.S. Biocrystal assembly patterns, biopolymer distribution and material property relationships in Mytilus galloprovincialis, Bivalvia, and Haliotis glabra, Gastropoda, shells. Materialia 2023, 28, 101749. [Google Scholar] [CrossRef]

- Karakaş, F.; Çelik, M. Effect of quantity and size distribution of calcite filler on the quality of water borne paints. Prog. Org. Coat. 2012, 74, 555–563. [Google Scholar] [CrossRef]

- Tressmann, D.M.G.A.; Pedroti, L.G.; de Carvalho, A.F.; Ribeiro, J.C.L.; de Paula Cardoso, F.; Lopes, M.M.S.; de Oliveira, A.F.; Ferreira, S.O. Research into the use of marble waste as mineral filler in soil pigment-based paints and as an active pigment in waterborne paints. Constr. Build. Mater. 2020, 241, 117976. [Google Scholar] [CrossRef]

- Fombuena, V.; Bernardi, L.; Fenollar, O.; Boronat, T.; Balart, R. Characterization of green composites from biobased epoxy matrices and bio-fillers derived from seashell wastes. Mater. Des. 2014, 57, 168–174. [Google Scholar] [CrossRef]

- Yao, Z.; Xia, M.; Ge, L.; Chen, T.; Li, H.; Ye, Y.; Zheng, H. Mechanical and thermal properties of polypropylene (PP) composites filled with CaCO3 and shell waste derived bio-fillers. Fibers Polym. 2014, 15, 1278–1287. [Google Scholar] [CrossRef]

- Moustafa, H.; Youssef, A.M.; Duquesne, S.; Darwish, N.A. Characterization of bio-filler derived from seashell wastes and its effect on the mechanical, thermal, and flame retardant properties of ABS composites. Polym. Compos. 2017, 38, 2788–2797. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.; Yan, L.; Feng, Y. Comparative Study of Fire Resistance and Anti-Ageing Properties of Intumescent Fire-Retardant Coatings Reinforced with Conch Shell Bio-Filler. Polymers 2021, 13, 2620. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Feng, Y.; Xu, Z.; Yan, L.; Xie, X.; Wang, Z. Synergistic effect of clam shell bio-filler on the fire-resistance and char formation of intumescent fire-retardant coatings. J. Mater. Res. Technol. 2020, 9, 14718–14728. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Merlo, A.; Lavagna, L.; Nisticò, R.; Pavese, M. Mechanical properties of mortar containing recycled Acanthocardia tuberculata seashells as aggregate partial replacement. Boletin De La Soc. Espanola De Ceram. Y Vidr. 2021, 60, 206–210. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E.; Li, L. Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J. Clean. Prod. 2019, 220, 235–252. [Google Scholar] [CrossRef]

- de Freitas, J.J.G.; Vieira, C.M.F.; Natalli, J.F.; Lavander, H.D.; de Azevedo, A.R.G.; Marvila, M.T. Cleaner Production of Cementitious Materials Containing Bioaggregates Based on Mussel Shells: A Review. Sustainability 2024, 16, 5577. [Google Scholar] [CrossRef]

- Hasan, K.; Karim, A.; Islam, M.T.; Ali, M.B.; Rahman, M.T.; Rahman, M.M.; Yahaya, F.M. A review of the mechanical properties and durability of concrete containing recycled seashells as a partial cement replacement. J. Mater. Cycles Waste Manag. 2023, 25, 3192–3216. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Carro-López, D.; Martínez-Abella, F. Design and properties of cement coating with mussel shell fine aggregate. Constr. Build. Mater. 2019, 215, 494–507. [Google Scholar] [CrossRef]

- ASTM D523-14; Standard Test Method for Specular Gloss. ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–12.

- ISO 2815-2000; Determinazione Della Durezza con il Metodo di Penetrazione Buchholz. UNI—Ente Nazionale Italiano di Unificazione: Rome, Italy, 2000; pp. 1–10.

- ASTM D4060; Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser. ASTM International: West Conshohocken, PA, USA, 2010; pp. 1–13.

- ASTM B117:2011; Operating Salt Spray (Fog) Apparatus. ASTM International: West Conshohocken, PA, USA, 2011; pp. 1–12.

- ASTM D4587-11(2019)e1; Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings. ASTM International: West Conshohocken, PA, USA, 2019; pp. 1–6.

- Yu, Y.; Jiang, M.; Wang, S.; Guo, Y.; Jiang, T.; Zeng, W.; Zhuang, Y. Impact of particle size on performance of selective laser sintering walnut shell/co-pes powder. Materials 2021, 14, 448. [Google Scholar] [CrossRef]

- Fan, G.; Liu, H.; Liu, C.; Xue, Y.; Ju, Z.; Ding, S.; Zhang, Y.; Li, Y. Analysis of the influence of waste seashell as modified materials on asphalt pavement performance. Materials 2022, 15, 6788. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, H.; Mu, T.; Pan, Y. Research and application of shell powder. IOP Conf. Ser. Earth Environ. Sci. 2018, 170, 032031. [Google Scholar] [CrossRef]

- Chakraborty, A.; Parveen, S.; Chanda, D.K.; Aditya, G. An insight into the structure, composition and hardness of a biological material: The shell of freshwater mussels. RSC Adv. 2020, 10, 29543–29554. [Google Scholar] [CrossRef]

- Gigante, V.; Cinelli, P.; Righetti, M.C.; Sandroni, M.; Tognotti, L.; Seggiani, M.; Lazzeri, A. Evaluation of mussel shells powder as reinforcement for PLA-based biocomposites. Int. J. Mol. Sci. 2020, 21, 5364. [Google Scholar] [CrossRef]

- Srichanachaichok, W.; Pissuwan, D. Micro/Nano structural investigation and characterization of mussel shell waste in Thailand as a feasible bioresource of CaO. Materials 2023, 16, 805. [Google Scholar] [CrossRef] [PubMed]

- ASTM-E308-18; Standard Practice for Computing the Colors of Objectives by Using the CIE System. ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–45.

- Mokrzycki, W.; Tatol, M. Colour difference ∆E—A survey. Mach. Graph Vis. 2011, 20, 383–411. [Google Scholar]

- Laxminarayan, T.; Truncali, A.; Rajagopalan, N.; Weinell, C.E.; Johansson, M.; Kiil, S. Chemically-resistant epoxy novolac coatings: Effects of size-fractionated technical Kraft lignin particles as a structure-reinforcing component. Prog. Org. Coat. 2023, 183, 107793. [Google Scholar] [CrossRef]

- Song, X.; Zhu, Z.; Chi, X.; Tang, S.; Han, G.; Cheng, W. Efficient downstream valorization of lignocellulose after organosolv fractionation: Synergistic enhancement of waterborne coatings by co-assembled lignin@ cellulose nanocrystals. Int. J. Biol. Macromol. 2023, 227, 1325–1335. [Google Scholar] [CrossRef]

- Pezzana, L.; Emanuele, A.; Sesana, R.; Delprete, C.; Malmström, E.; Johansson, M.; Sangermano, M. Cationic UV-curing of isosorbide-based epoxy coating reinforced with macadamia nut shell powder. Prog. Org. Coat. 2023, 185, 107949. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. Olive pit powder as multifunctional pigment for waterborne paint: Influence of the bio-based filler on the aesthetics, durability and mechanical features of the polymer matrix. Ind. Crops Prod. 2023, 194, 116326. [Google Scholar] [CrossRef]

- Momber, A.; Irmer, M.; Marquardt, T. Effects of polymer hardness on the abrasive wear resistance of thick organic offshore coatings. Prog. Org. Coat. 2020, 146, 105720. [Google Scholar] [CrossRef]

- Momber, A.; Irmer, M. Taber abrasive wear resistance of organic offshore wind power coatings at varying normal forces. J. Coat. Technol. Res. 2021, 18, 729–740. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. Exploring polyamide 11 as a novel renewable resource-based filler in wood paint: Investigating aesthetic aspects and durability impact of the composite coating. Prog. Org. Coat. 2024, 188, 108262. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. Enhancing wood coatings with red beetroot-derived pigments: Investigating synergy with UV absorber and composite filler for improved durability and aesthetics. Prog. Org. Coat. 2024, 192, 108529. [Google Scholar] [CrossRef]

- Hochmańska-Kaniewska, P.; Janiszewska, D.; Oleszek, T. Enhancement of the properties of acrylic wood coatings with the use of biopolymers. Prog. Org. Coat. 2022, 162, 106522. [Google Scholar] [CrossRef]

- Kaboorani, A.; Auclair, N.; Riedl, B.; Landry, V. Mechanical properties of UV-cured cellulose nanocrystal (CNC) nanocomposite coating for wood furniture. Prog. Org. Coat. 2017, 104, 91–96. [Google Scholar] [CrossRef]

- Bautista, A. Filiform corrosion in polymer-coated metals. Prog. Org. Coat. 1996, 28, 49–58. [Google Scholar] [CrossRef]

- Cristoforetti, A.; Rossi, S.; Deflorian, F.; Fedel, M. An electrochemical study on the mechanism of filiform corrosion on acrylic-coated carbon steel. Prog. Org. Coat. 2023, 179, 107525. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. Functional olive pit powders: The role of the bio-based filler in reducing the water uptake phenomena of the waterborne paint. Coatings 2023, 13, 442. [Google Scholar] [CrossRef]

- Groeneveld, I.; Kanelli, M.; Ariese, F.; van Bommel, M.R. Parameters that affect the photodegradation of dyes and pigments in solution and on substrate–An overview. Dyes Pigm. 2023, 210, 110999. [Google Scholar] [CrossRef]

- Plota-Pietrzak, A.; Masek, A. Influence of organic and inorganic fillers on the photoaging behavior of polyolefins. Polym. Degrad. Stab. 2024, 219, 110598. [Google Scholar] [CrossRef]

- Kabacinska, Z.; Yate, L.; Wencka, M.; Krzyminiewski, R.; Tadyszak, K.; Coy, E. Nanoscale effects of radiation (UV, X-ray, and γ) on calcite surfaces: Implications for its mechanical and physico-chemical properties. J. Phys. Chem. C 2017, 121, 13357–13369. [Google Scholar] [CrossRef]

- Macedo, M.; Margarit-Mattos, I.C.P.; Fragata, F.d.L.; Jorcin, J.-B.; Pébère, N.; Mattos, O.R. Contribution to a better understanding of different behaviour patterns observed with organic coatings evaluated by electrochemical impedance spectroscopy. Corros. Sci. 2009, 51, 1322–1327. [Google Scholar] [CrossRef]

- Sultan, M.; Atta, S.; Bhatti, H.N.; Islam, A.; Jamil, T.; Bibi, I.; Gull, N. Synthesis, characterization, and application studies of polyurethane acrylate thermoset coatings: Effect of hard segment. Polym.-Plast. Technol. Eng. 2017, 56, 1608–1618. [Google Scholar] [CrossRef]

- Amirudin, A.; Thieny, D. Application of electrochemical impedance spectroscopy to study the degradation of polymer-coated metals. Prog. Org. Coat. 1995, 26, 1–28. [Google Scholar] [CrossRef]

- Meng, F.; Liu, L.; Tian, W.; Wu, H.; Li, Y.; Zhang, T.; Wang, F. The influence of the chemically bonded interface between fillers and binder on the failure behaviour of an epoxy coating under marine alternating hydrostatic pressure. Corros. Sci. 2015, 101, 139–154. [Google Scholar] [CrossRef]

- Miszczyk, A.; Darowicki, K. Water uptake in protective organic coatings and its reflection in measured coating impedance. Prog. Org. Coat. 2018, 124, 296–302. [Google Scholar] [CrossRef]

| Samples Nomenclature | Additives (5 wt.%) Introduced in the Paint Formulation |

|---|---|

| R | / |

| P | PolyTuf® 1229 |

| S | Seashell powder |

| M | Mussels powder |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Gómez, F.J.; Calovi, M.; Rossi, S. Micronized Shell-Bioaggregates as Mechanical Reinforcement in Organic Coatings. Materials 2024, 17, 4134. https://doi.org/10.3390/ma17164134

Rodríguez-Gómez FJ, Calovi M, Rossi S. Micronized Shell-Bioaggregates as Mechanical Reinforcement in Organic Coatings. Materials. 2024; 17(16):4134. https://doi.org/10.3390/ma17164134

Chicago/Turabian StyleRodríguez-Gómez, Francisco Javier, Massimo Calovi, and Stefano Rossi. 2024. "Micronized Shell-Bioaggregates as Mechanical Reinforcement in Organic Coatings" Materials 17, no. 16: 4134. https://doi.org/10.3390/ma17164134

APA StyleRodríguez-Gómez, F. J., Calovi, M., & Rossi, S. (2024). Micronized Shell-Bioaggregates as Mechanical Reinforcement in Organic Coatings. Materials, 17(16), 4134. https://doi.org/10.3390/ma17164134