Effects of Mix Components on Fracture Properties of Seawater Volcanic Scoria Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

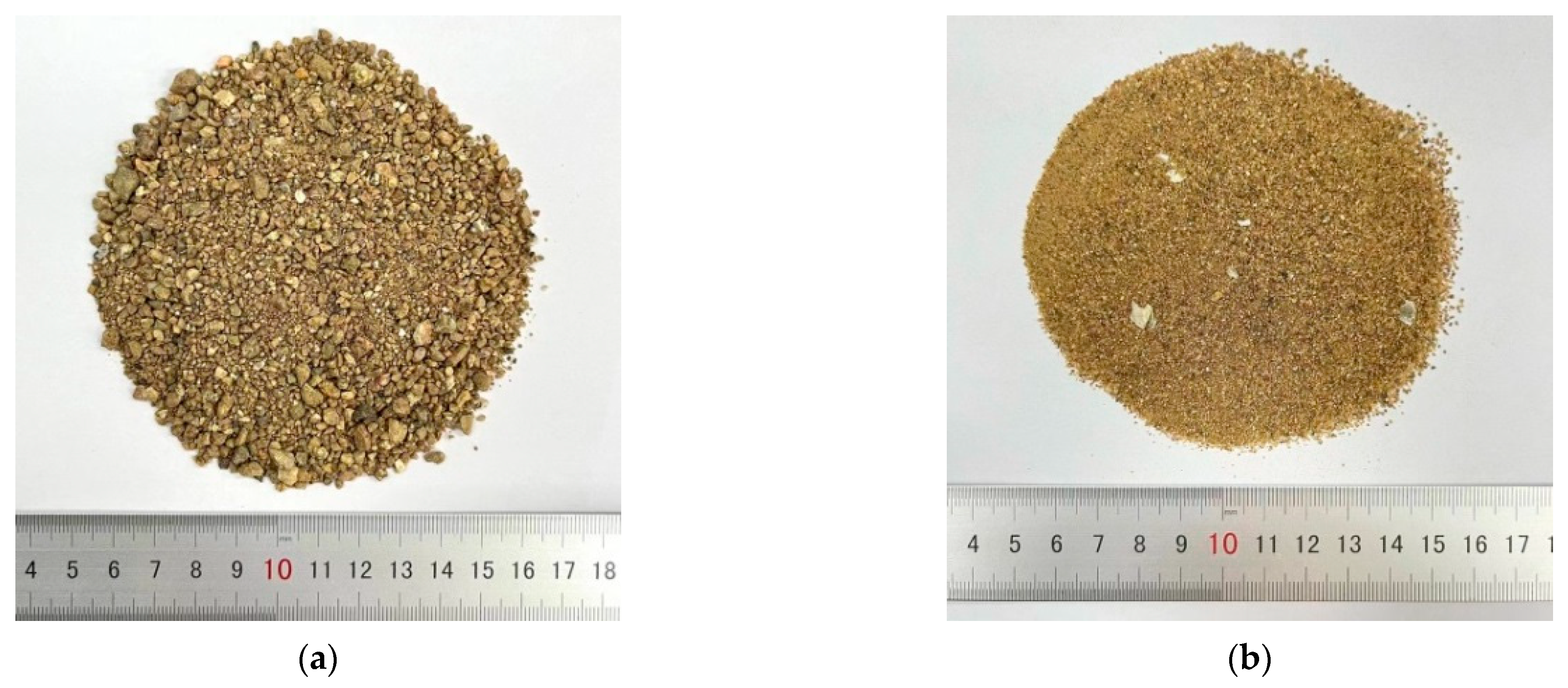

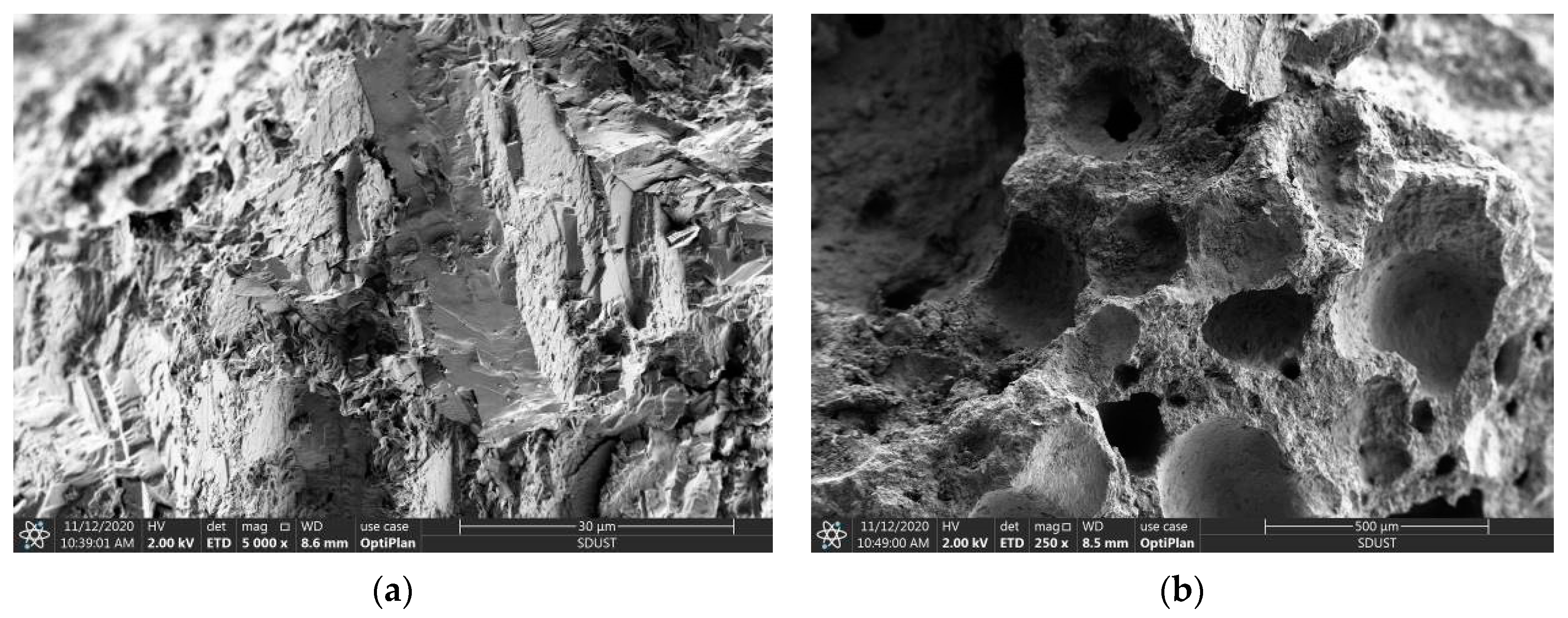

2.1. Raw Materials

2.2. Concrete Mix

2.3. Experiment Design

2.3.1. Specimen Design and Fabrication

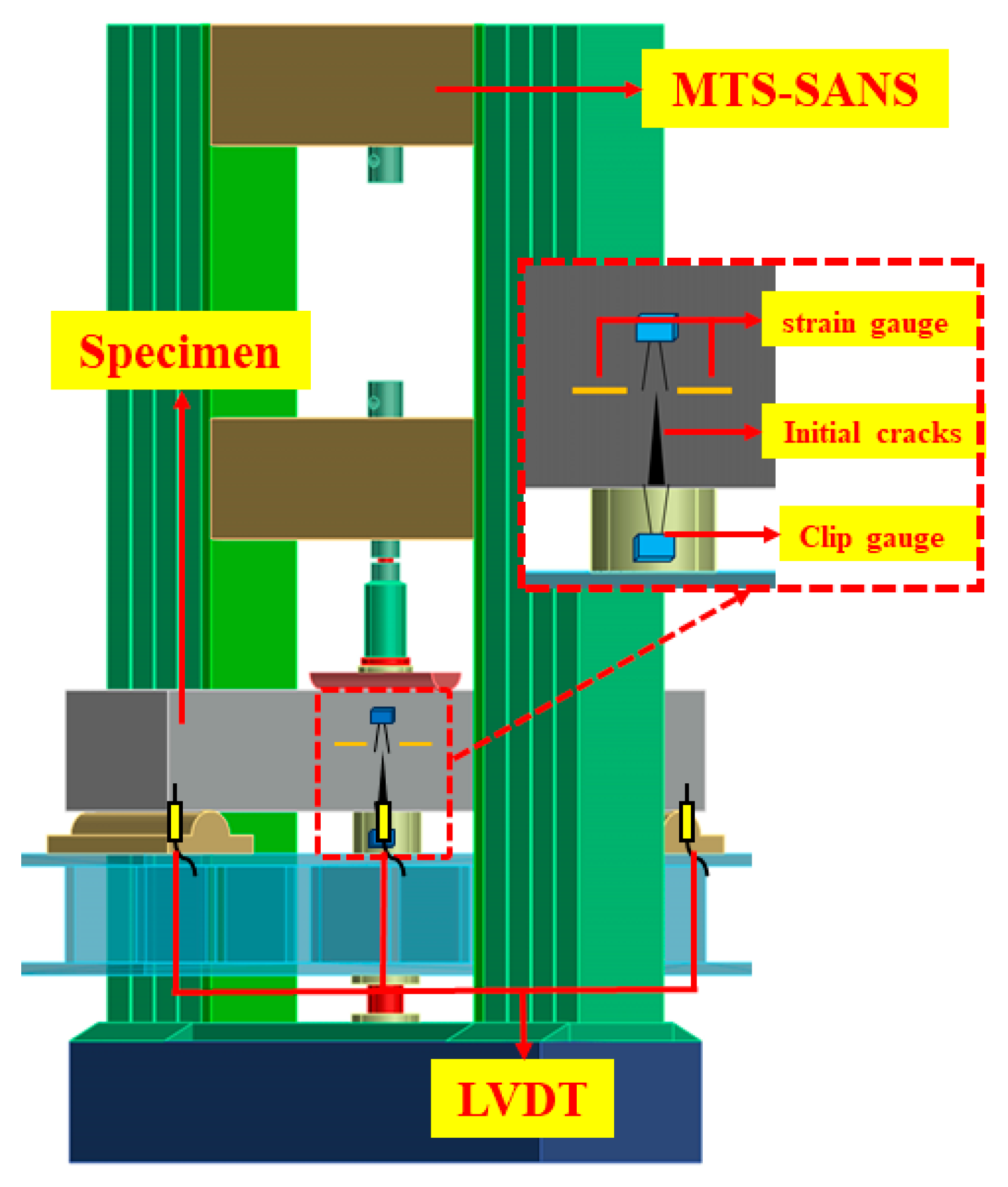

2.3.2. Loading Setup and Program

3. Results

3.1. Failure Phenomenon

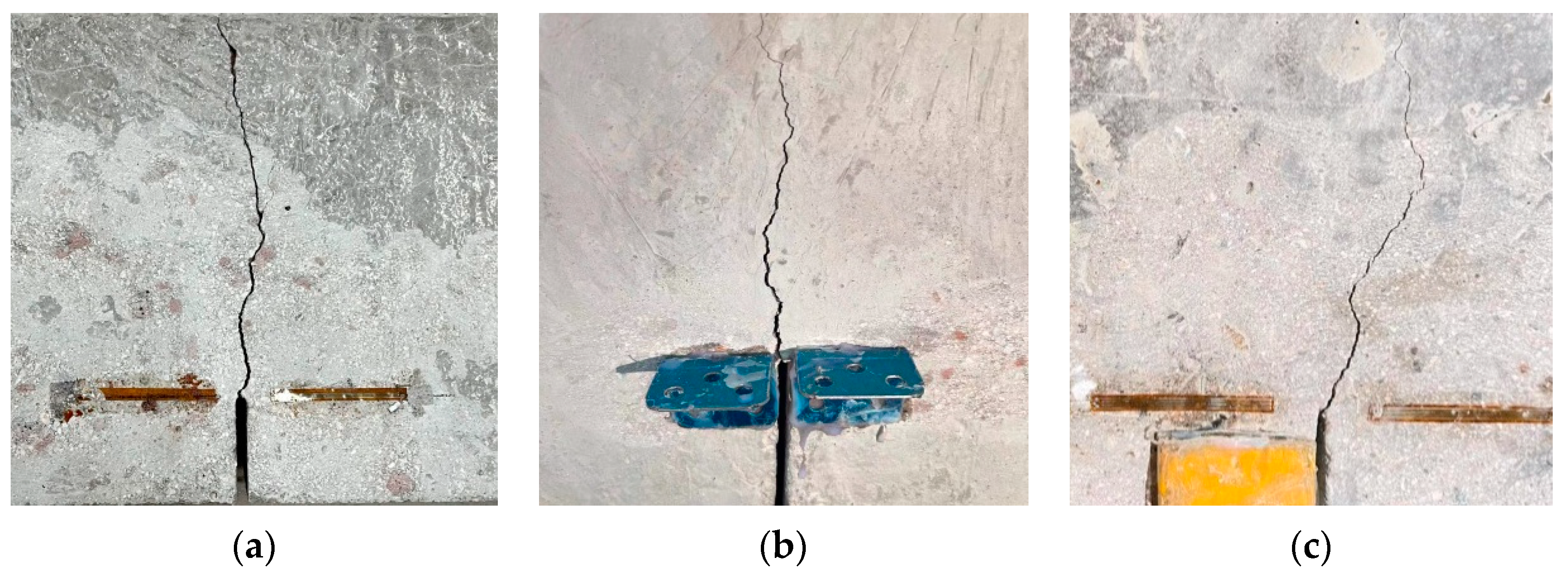

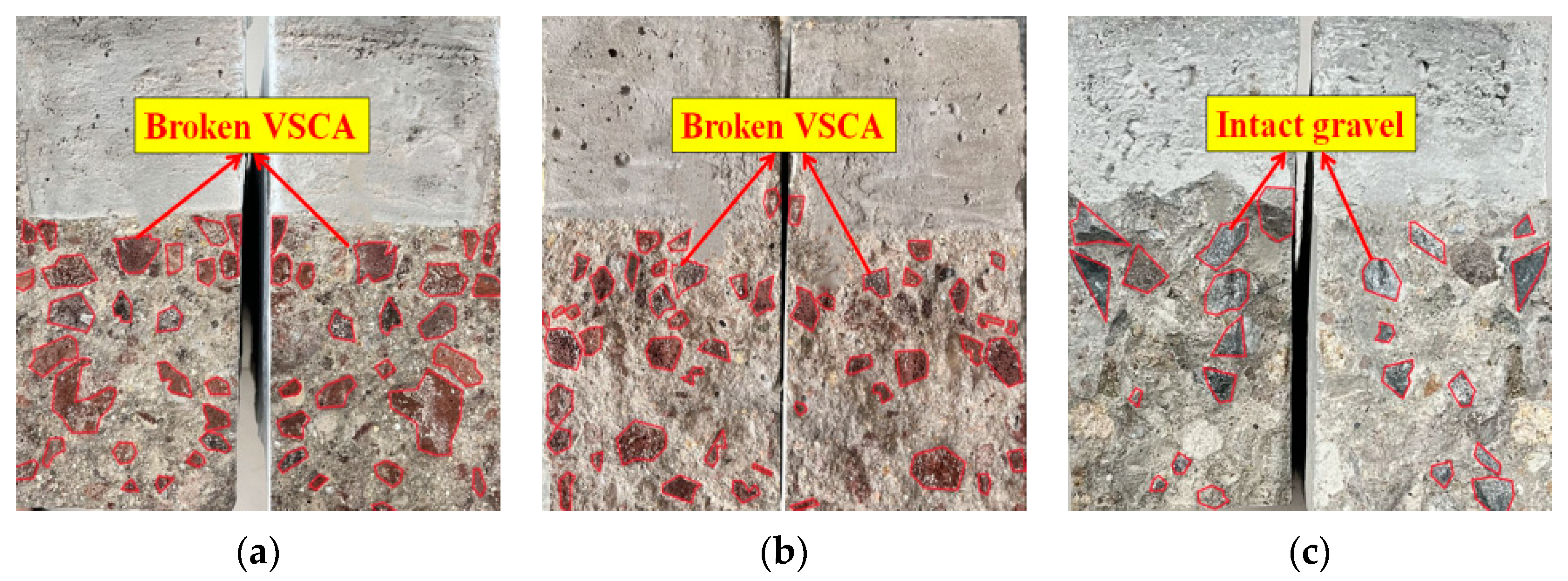

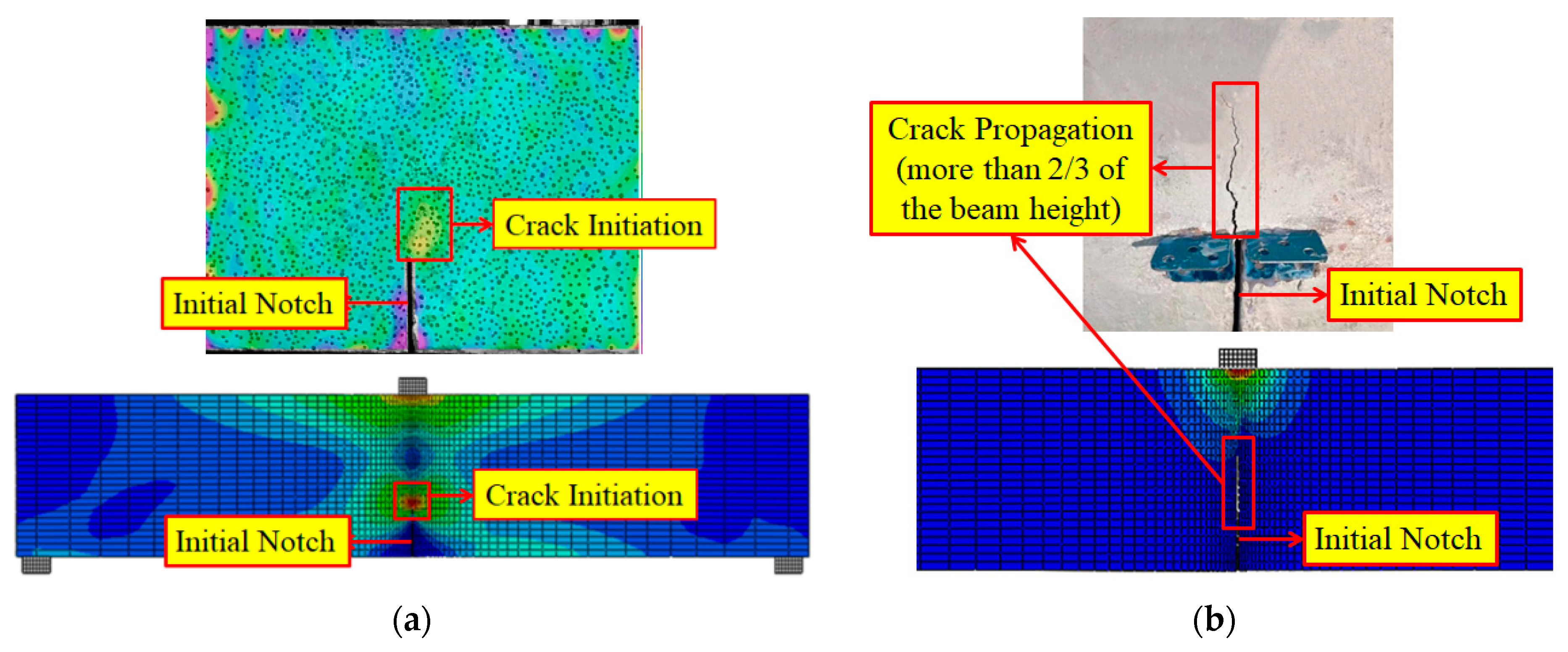

3.1.1. Failure Pattern

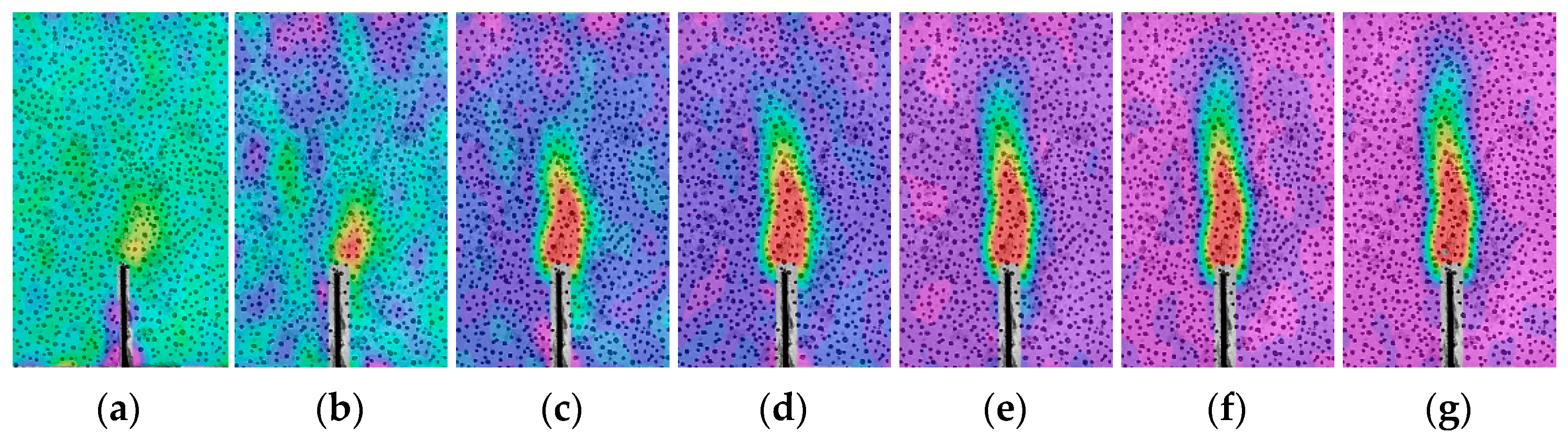

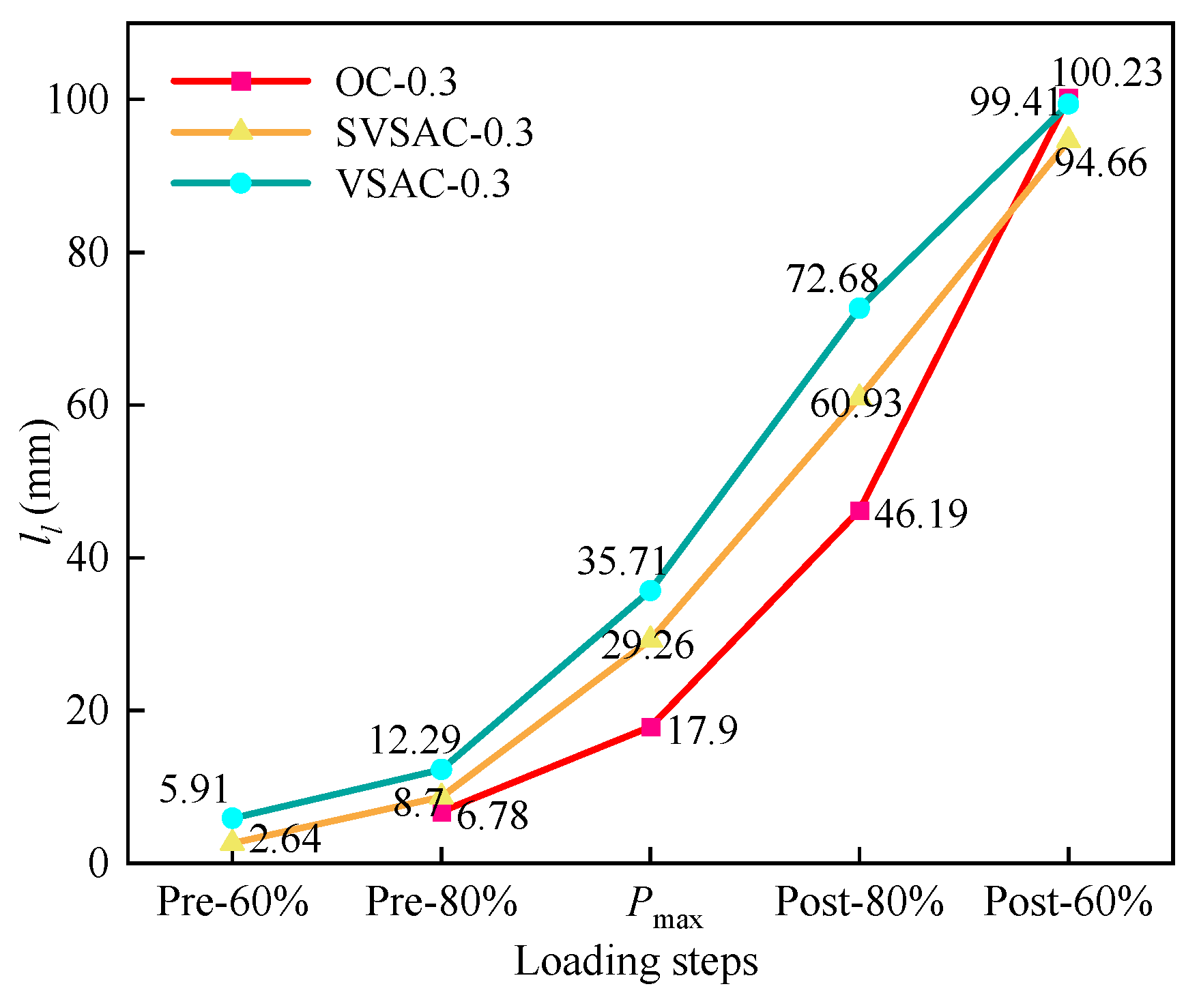

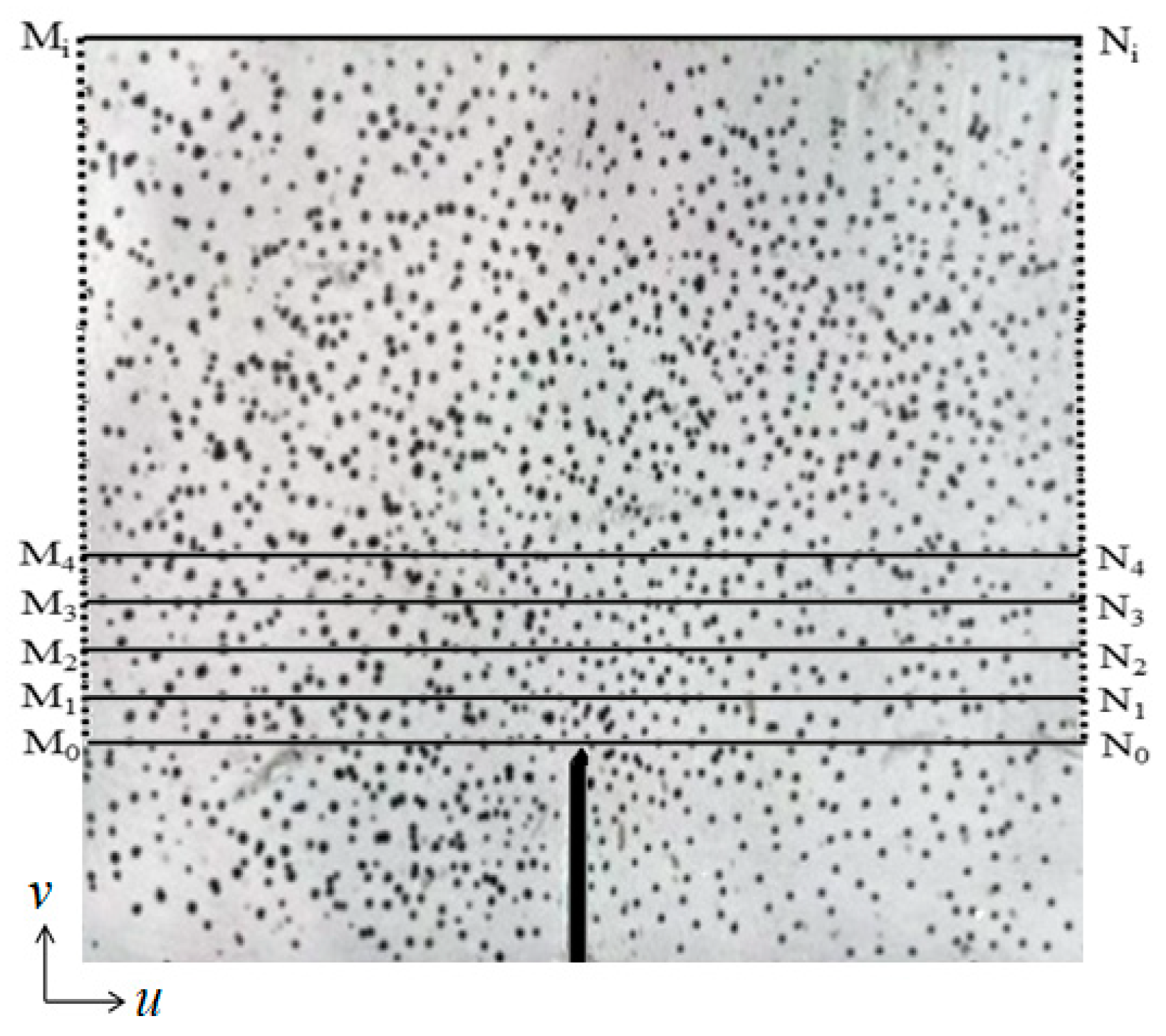

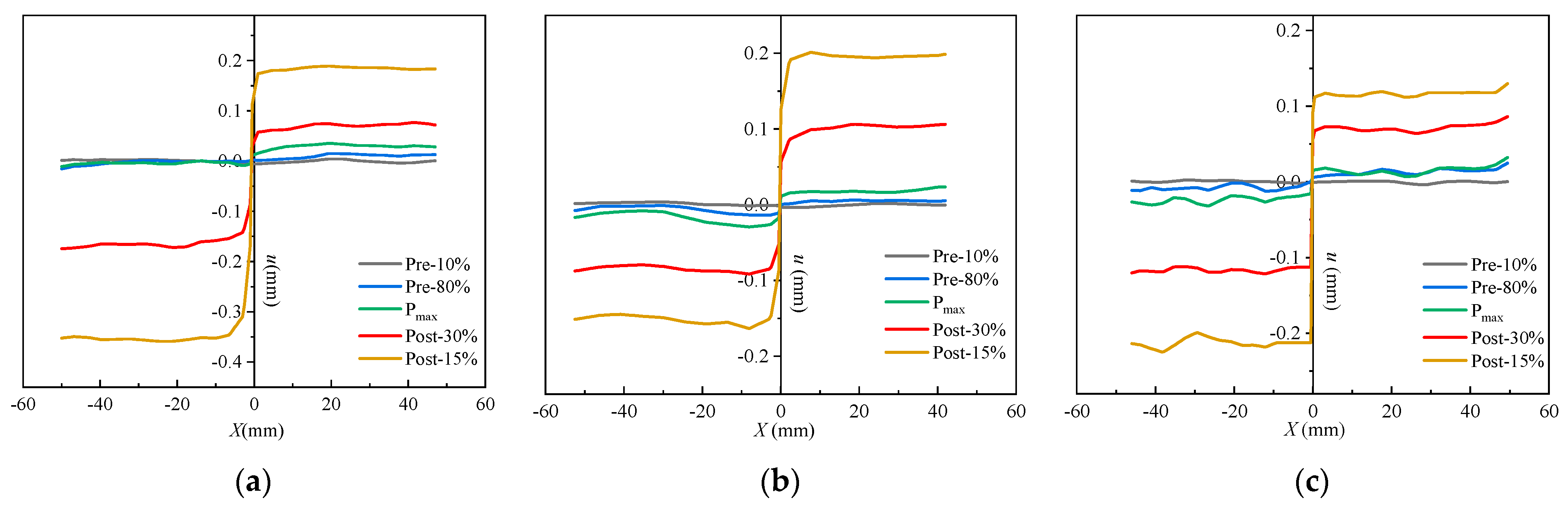

3.1.2. Crack Propagation and Characteristics

- Crack propagation pattern;

- 2.

- Crack characteristics.

3.2. Physical Properties of SVSAC

3.3. Fracture Characteristic Loads

3.3.1. Pini

3.3.2. Pmax

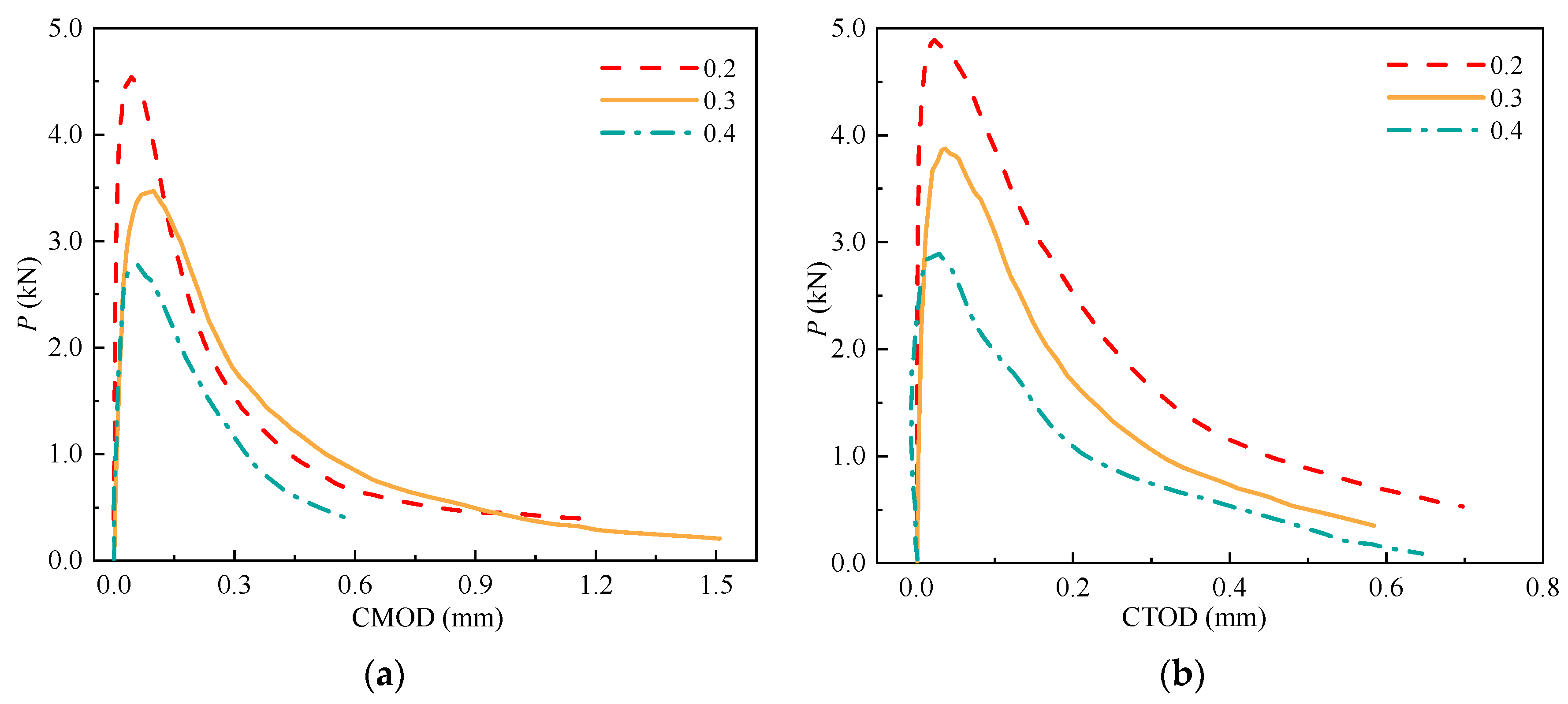

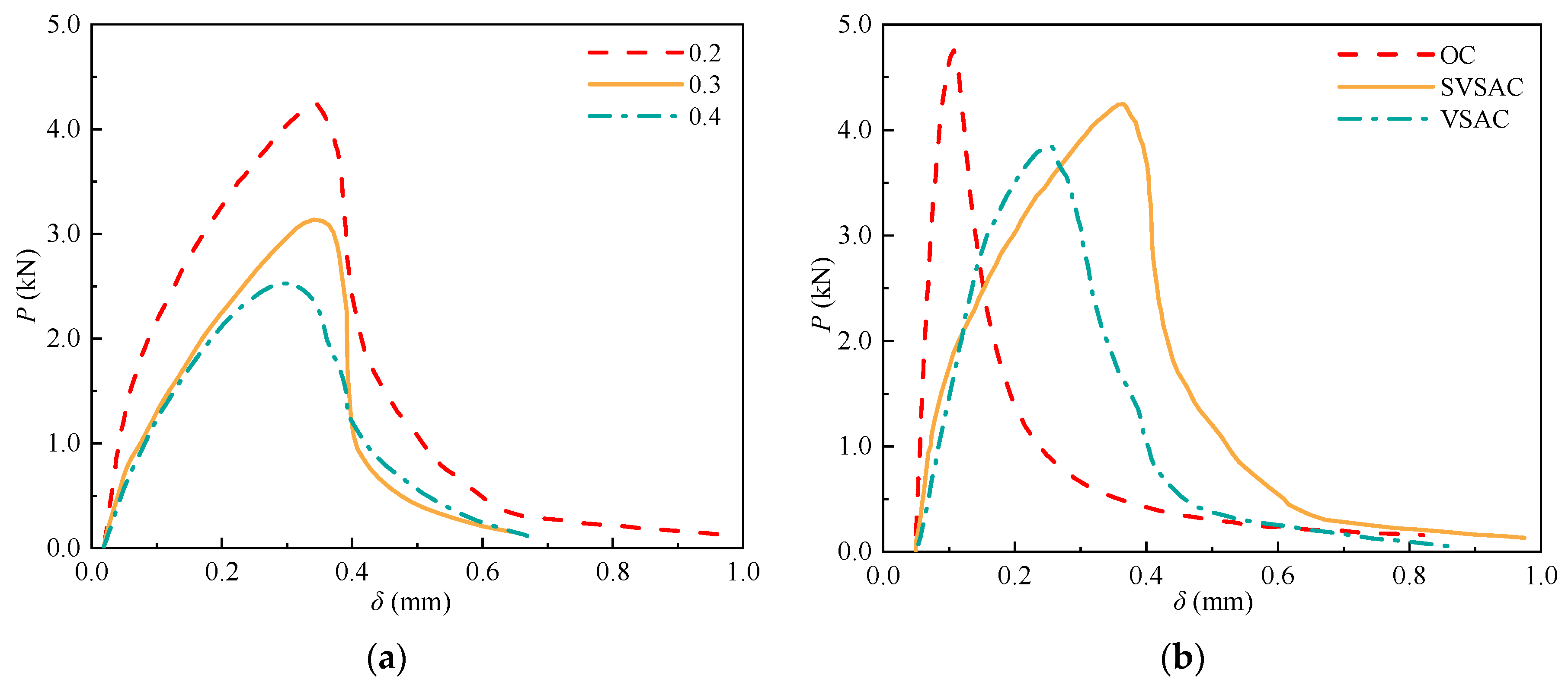

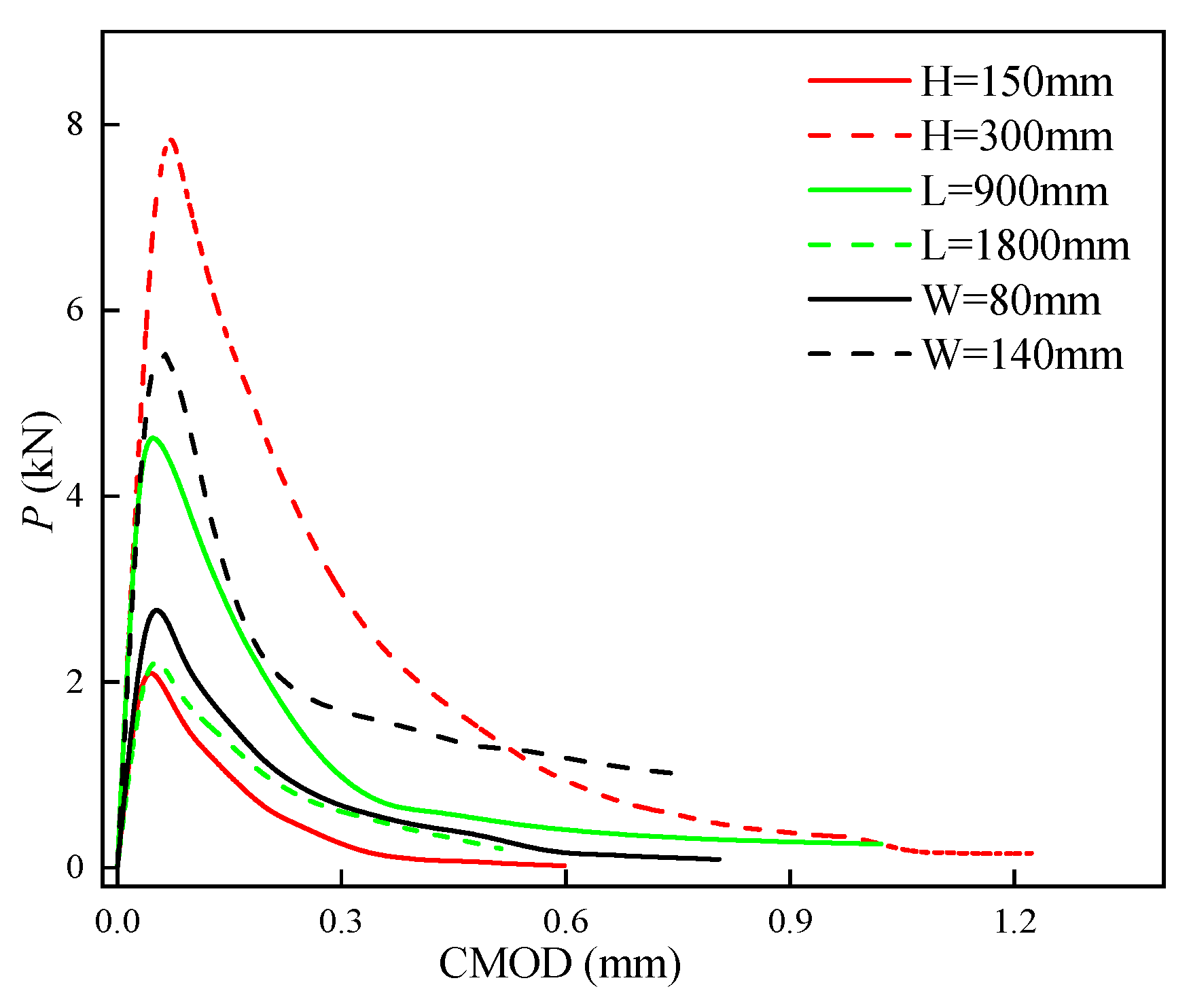

3.4. P-CMOD and P-CTOD Curves

3.5. Fracture Energy and Characteristic Length

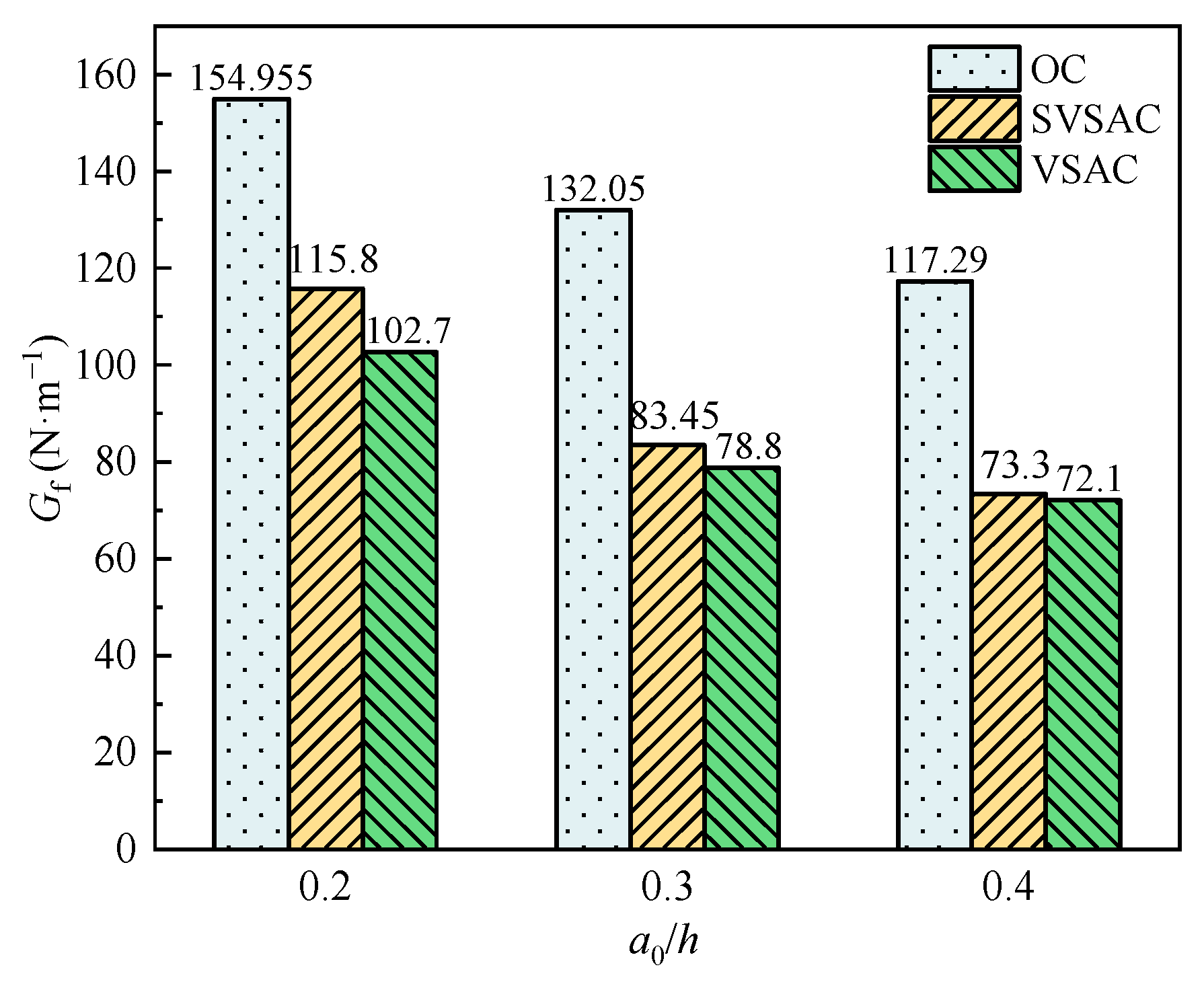

3.5.1. Fracture Energy

3.5.2. Characteristic Length

3.6. Double-K Fracture Parameters and Tension-Softening (σ-CTOD) Relations

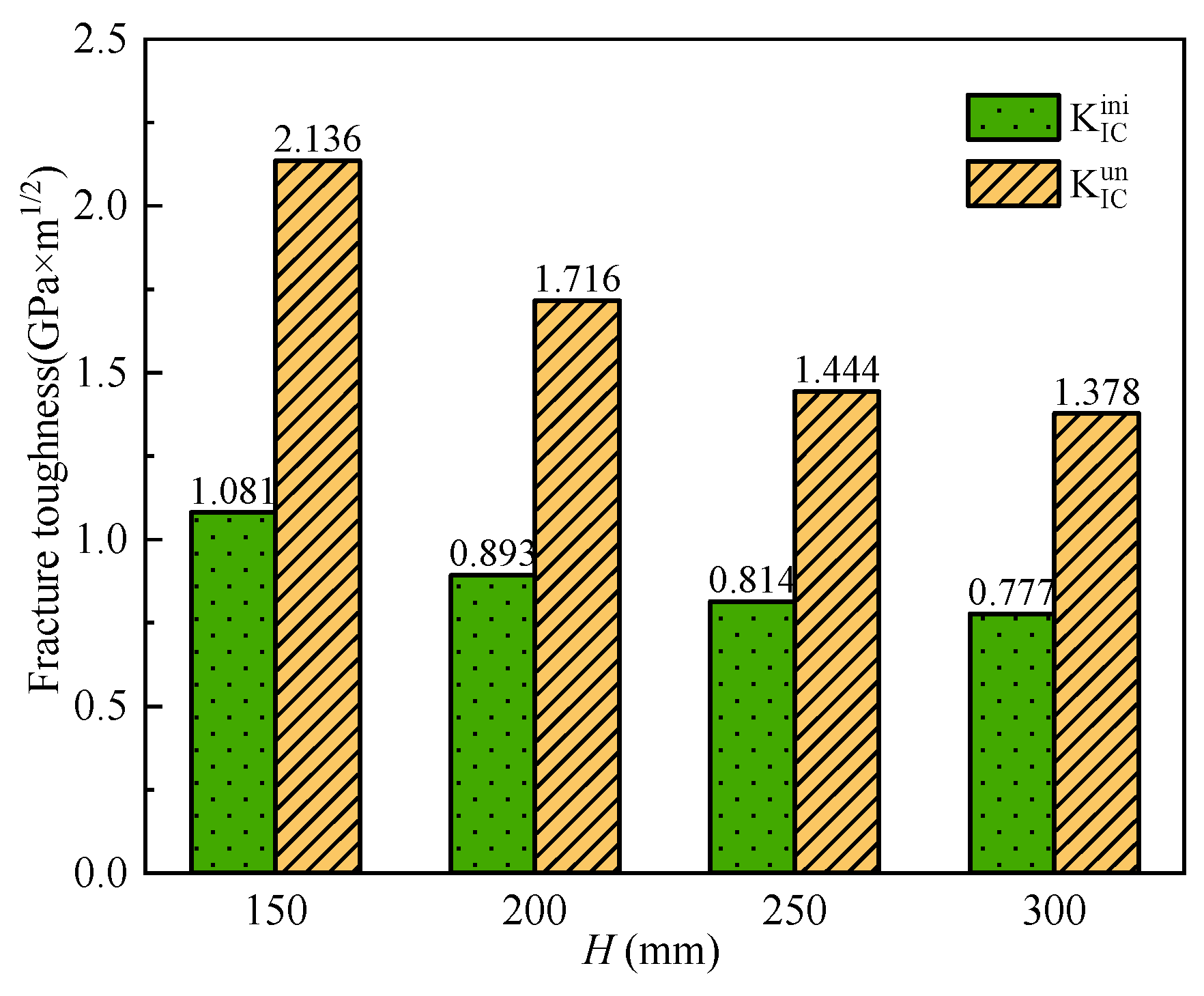

3.6.1. Double-K Fracture Toughness

- Determination of fracture toughness;

- 2.

- Fracture toughness.

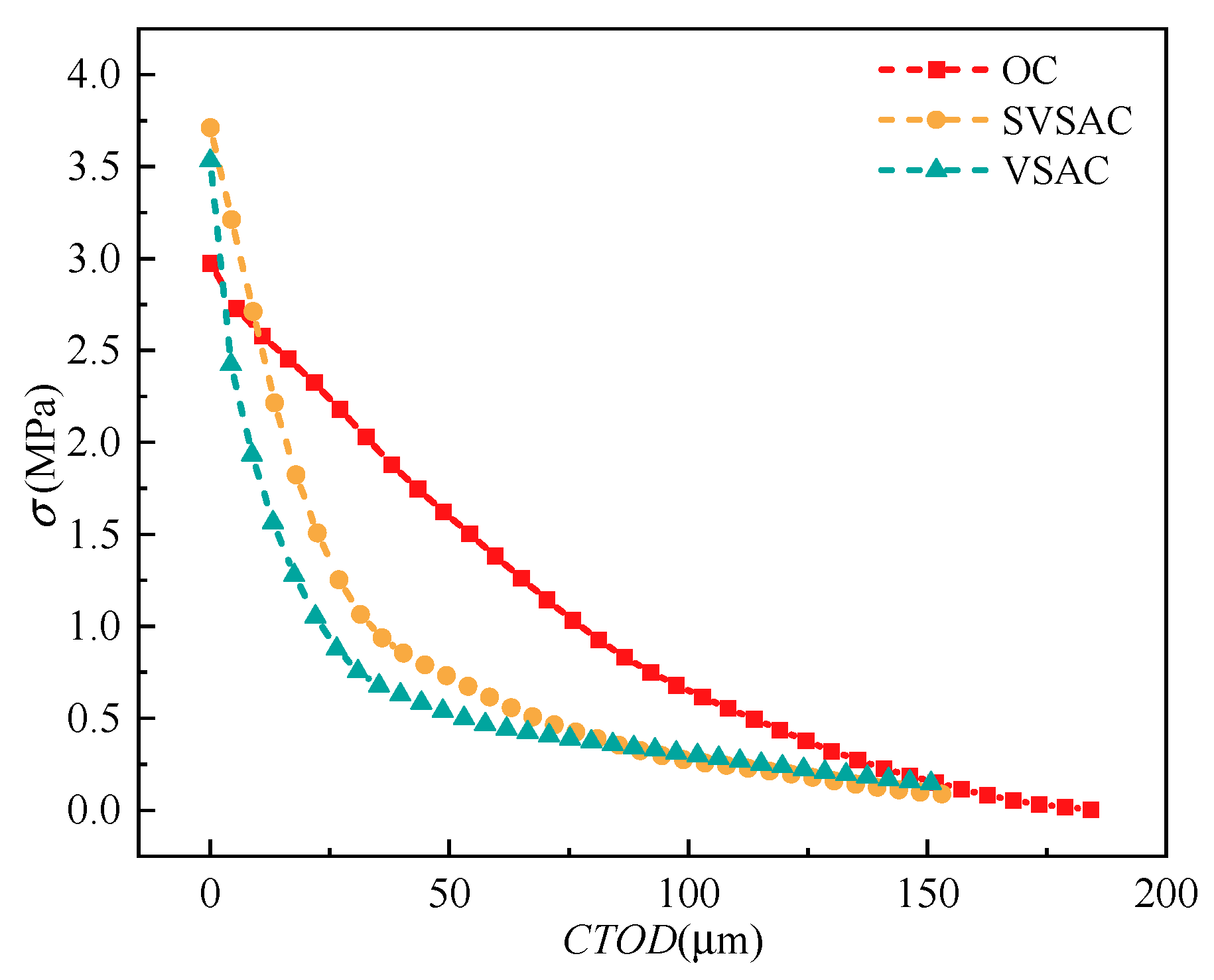

3.6.2. σ-CTOD Relations

4. Theoretical Analyses of Tension-Softening Curve

4.1. General Expression

4.2. Critical Parameters

5. Numerical Simulation Analyses of Fracture

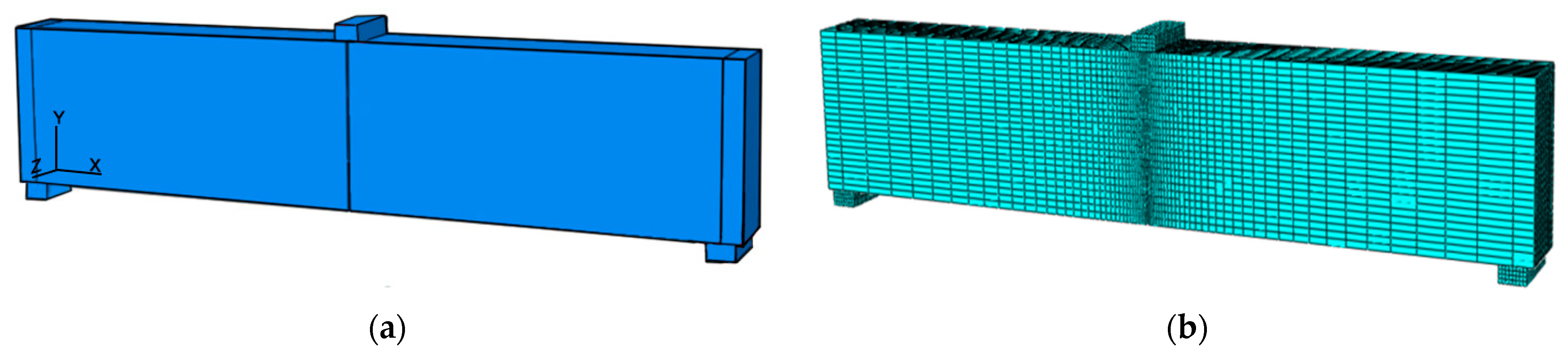

5.1. FE Model of SVSAC Specimen

5.1.1. FE Types and Material Properties

5.1.2. Establishment of FE Model of Fracture Specimen

5.1.3. Validity of FE Model

5.2. Numerical Results of SVSAC

5.3. Analytical Model of Fracture Toughness Considering Size Effect and Mix Component

6. Conclusions

- (1)

- The failure characteristics of three-point bending beams were significantly changed after adopting VSCA. Compared to the OC specimen, the crack initiation of SVSAC was earlier (60% of Pmax), and the cracking width and length of the SVSAC specimen increased by 4.88% and 28.32%, respectively. The adoption of VSCA accelerated the crack initiation and propagation of concrete, while SW and SS could inhabit its influence before 80% of Pmax (post peak point).

- (2)

- The fracture characteristic loads (i.e., Pini and Pmax), Gf, and Lch of the SVSAC specimen decreased with increasing a0/h, and VSCA enhanced these effects. The Pini (Pmax) of specimens adopting VSCA was 10.94% (9.47%) inferior to that of the OC specimen, and this difference became small (4%) after using SW and SS. The fracture energies of the SVSAC and VSAC specimens were significantly decreased. Generally, the Lch value of SVSAC was, on average, 59.49% lower than that of OC.

- (3)

- The P-CTOD and σ-CTOD curves of SVSAC were characterized by rapid decline. The effect of a0/h on fracture toughness was minor, while the and of SVSAC decreased by 8.55% and 36.17% in comparison with those of OC, respectively. The tensile stress transmitted by the cracking surface of specimens adopting VSCA was significantly inferior to OC under a similar crack width, and this difference can be partly improved through using SW and SS in the early stage of loading. The improvements of SW and SS on the cracking and σ transmission of SVSAC became negligible when CTOD reached 0.1 mm.

- (4)

- A finite element model was developed to analyze the fracture behavior of SVSAC. The numerical results showed that the fracture toughness ( and ) was greatly improved through changing the size of the specimen, i.e., beam height, length, and width. The P-CMOD curves of SVSAC became steep after increasing the specimen height and width.

- (5)

- Analytical models for the double-K fracture toughness and σ-CTOD relation of SVSAC considering the effects of mix components and specimen size were established. The fracture properties of SVSAC would be efficiently predicted by the models.

- (6)

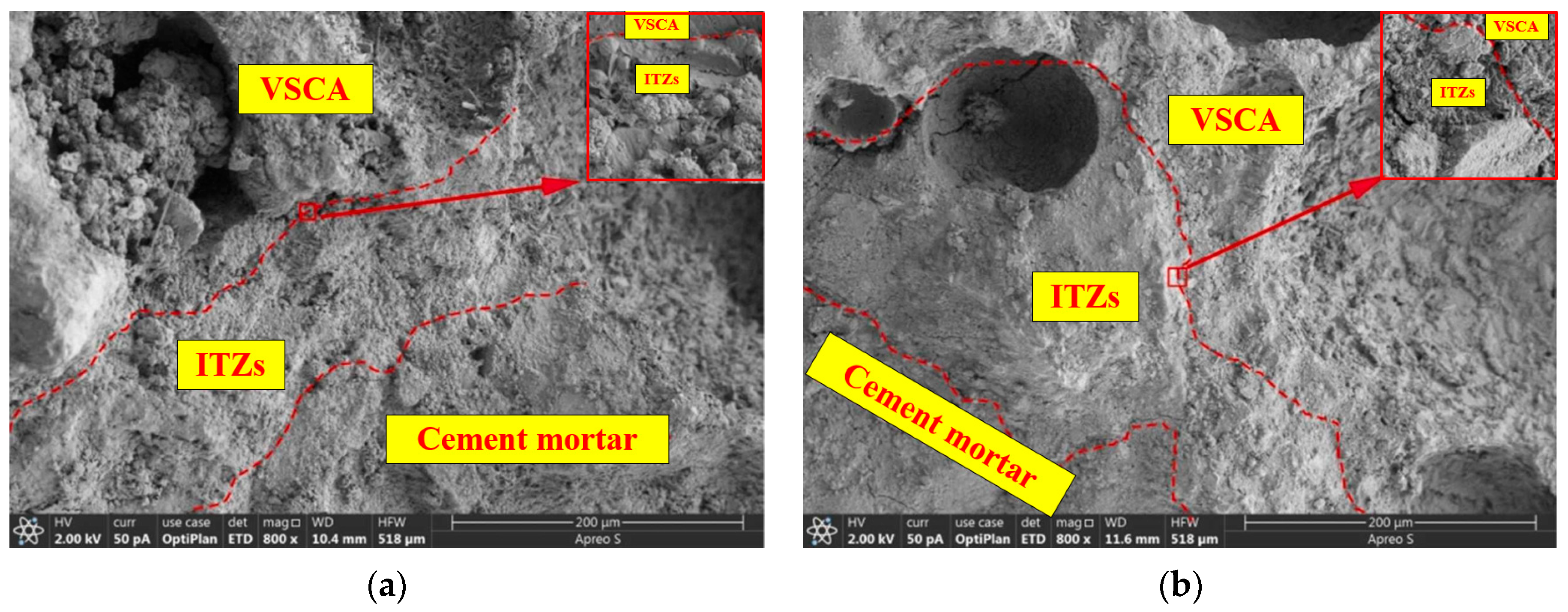

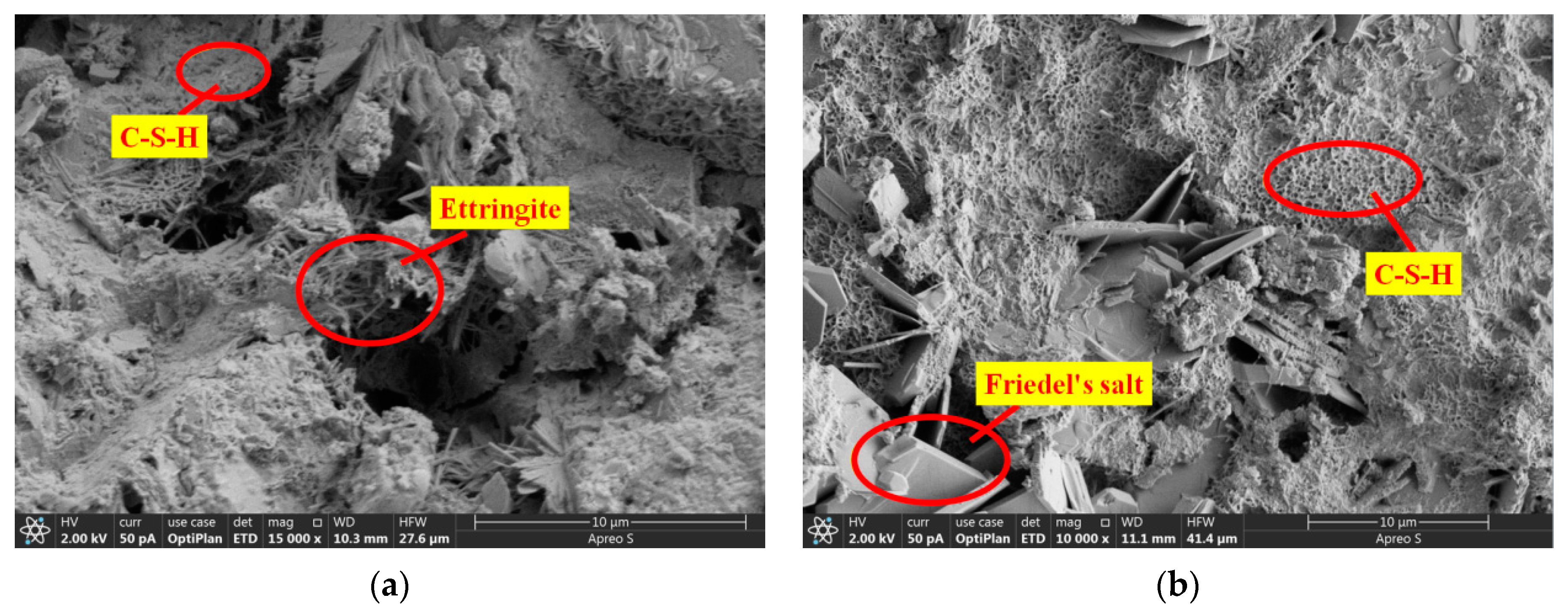

- The VSCA, SW, and SS could change the micro- and macrostructures of concrete, causing variations in the fracture of SVSAC. Thus, further research works should be performed together with more testing techniques (e.g., XRF, XRD, X-ray spectroscopy) to deeply and completely investigate the performance of SVSAC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mai, G.H.; Li, L.J.; Chen, X.P.; Xiong, Z.; Liang, J.P. Fatigue performance of basalt fibre-reinforced polymer bar-reinforced sea sand concrete slabs. J. Mater. Res. Technol.-JMRT 2023, 22, 706–727. [Google Scholar] [CrossRef]

- Huang, Y.J.; Dong, L.; Qi, X.B.; Wang, T.C.; Li, P.; Zhong, J.T. Effects of mix components on mechanical properties of marine volcanic-scoria concrete under axial compression. Case Stud. Constr. Mater. 2023, 18, e01837. [Google Scholar] [CrossRef]

- Bogas, J.A.; Cunha, D. Non-structural lightweight concrete with volcanic scoria aggregates for lightweight fill in building’s floors. Constr. Build. Mater. 2017, 135, 151–163. [Google Scholar] [CrossRef]

- Willy, J.T.; Toufik, H.C.; Moulay, L.A.; Luiz, P. Mechanical properties of lightweight aggregates concrete made with cameroonian volcanic scoria: Destructive and non-destructive characterization. J. Build. Eng. 2018, 16, 134–145. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, T. Mechanical and durability behaviour of structural lightweight concrete produced with volcanic scoria. Arab. J. Sci. Eng. 2015, 40, 705–717. [Google Scholar] [CrossRef]

- Maragh, J.M.; Weaver, J.C.; Masic, A. Large-scale micron-order 3D surface correlative chemical imaging of ancient Roman concrete. PLoS ONE 2019, 14, e0210710. [Google Scholar] [CrossRef] [PubMed]

- Jackson, M.D.; Chae1, S.R.; Mulcahy, S.R.; Meral, C.; Taylor, R.; Li, P.H.; Emwas, A.-H.; Moon, J.; Yoon, S.; Vola, G.; et al. Unlocking the secrets of Al-tobermorite in Roman seawater concrete. Am. Mineral. 2013, 98, 1669–1687. [Google Scholar] [CrossRef]

- Jackson, M.D.; Moon, J.; Gotti, E.; Taylor, R.; Chae, S.R.; Kunz, M.; Emwas, A.H.; Meral, C.; Guttmann, P.; Levitz, P.; et al. Material and elastic properties of Al-tobermorite in ancient Roman seawater concrete. J. Am. Ceram. Soc. 2013, 96, 2598–2606. [Google Scholar] [CrossRef]

- Stanislao, C.; Rispoli, C.; Vola, G.; Cappelletti, P.; Morra, V.; Gennaro, M.D. Contribution to the knowledge of ancient Roman seawater concretes: Phlegrean pozzolan adopted in the construction of the harbour at Soli-Pompeiopolis (Mersin, Turkey). Periodi. Mineral. 2021, 80, 471–478. [Google Scholar]

- Celik, K.; Jackson, M.D.; Mancio, M.; Meral, C.; Emwas, A.-H.; Mehta, P.K.; Monteiro, P.J.M. High-volume natural volcanic pozzolan and limestone powder as partial replacements for Portland cement in self-compacting and sustainable concrete. Periodi. Mineral. 2014, 45, 136–147. [Google Scholar] [CrossRef]

- Palomoa, A.; Monteirob, P.; Martauzc, P.; Bilekd, V.; Fernandez-Jimenez, A. Hybrid binders: A journey from the past to a sustainable future (opus caementicium futurum). Cement Concre. Comp. 2019, 124, 105829. [Google Scholar] [CrossRef]

- Topçu, İ.B. Semi lightweight concretes produced by volcanic slags. Cem. Concr. Res. 1997, 27, 15–21. [Google Scholar] [CrossRef]

- Demirdag, S.; Gunduz, L. Strength properties of volcanic slag aggregate lightweight concrete for high performance masonry units. Constr. Build. Mater. 2008, 22, 135–142. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Qiang, C.B.; Nanni, A.; Zhang, K.J. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Properties of volcanic scoria based lightweight concrete. Mag. Concr. Res. 2004, 56, 111–120. [Google Scholar] [CrossRef]

- Bideci, A.; Bideci, Ö.S.; Ashour, A. Mechanical and thermal properties of lightweight concrete produced with polyester-coated pumice aggregate. Constr. Build. Mater. 2023, 394, 132204. [Google Scholar] [CrossRef]

- Rajaonarison, E.F.; Gacoin, A.; Randrianja, R. Effect of scoria on various specific aspects of lightweight concrete. Int. J. Concr. Struct. Mater. 2017, 11, 541–555. [Google Scholar] [CrossRef][Green Version]

- Kapoor, K.; Singh, S.P.; Singh, B. Durability of self-compacting concrete made with Recycled Concrete Aggregates and mineral admixtures. Constr. Build. Mater. 2016, 128, 67–76. [Google Scholar] [CrossRef]

- Wan, D.S.L.M.; Aslani, F.; Ma, G. Lightweight self-compacting concrete incorporating perlite, scoria, and polystyrene aggregates. J. Mater. Civ. Eng. 2018, 30, 04018178. [Google Scholar] [CrossRef]

- Warati, G.K.; Darwish, M.M.; Feyessa, F.F. Suitability of scoria as fine aggregate and its effect on the properties of concrete. Sustainability 2019, 11, 4647. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Ghataora, G.; Khan, M.I.; Dirar, S. Novel lightweight concrete containing manufactured plastic aggregate. Constr. Build. Mater. 2017, 148, 386–397. [Google Scholar] [CrossRef]

- Li, T.Y.; Liu, X.Y.; Zhang, Y.M.; Yang, H.; Zhi, Z.H. Preparation of sea water sea sand high performance concrete (SHPC) and serving performance study in marine environment. Constr. Build. Mater. 2020, 254, 119114. [Google Scholar] [CrossRef]

- Ge, L.C.; Feng, Z.X.; Usama, S.; Haitao, L. Research on the performance of seawater sea-sand concrete: A review. Constr. Build. Mater. 2023, 409, 133921. [Google Scholar] [CrossRef]

- Wei, J.H.; Xu, J.J.; Xue, J.Y.; Zhao, J.Q.; Chen, Z.P. Effect of replacing freshwater river-sand with seawater sea-sand on dynamic compressive mechanical properties of concrete. Constr. Build. Mater. 2024, 419, 135473. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.F.; Ma, H.Y.; Wu, Z.Y. Reinforcement corrosion research based on the linear polarization resistance method for coral aggregate seawater concrete in a marine environment. Anti-Corros. Methods Mater. 2018, 65, 458–470. [Google Scholar] [CrossRef]

- Xiao, S.M.; Cheng, H.B.; Que, Z.C.; Liu, T.J.; Zou, D.J. Enhancing marine anti-washout concrete: Optimal silica fume usage for improved compressive strength and abrasion resistance. Constr. Build. Mater. 2024, 428, 136262. [Google Scholar] [CrossRef]

- Huang, Y.J.; Li, X.W.; Lu, Y.; Wang, H.C.; Wang, Q.; Sun, H.S.; Li, D.Y. Effect of mix component on the mechanical properties of coral concrete under axial compression. Constr. Build. Mater. 2019, 223, 736–754. [Google Scholar] [CrossRef]

- Syahrul, S.; Nurdin, A. White cement and concrete compressive strength in sea water curing. Int. J. Adv. Eng. Res. Sci. 2022, 12, 433–440. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Sang, Z.Q.; Zhang, L.Y.; Ma, Z.X.; Zhang, Y. Experimental research on durability of concrete made by seawater and sea-sand. Adv. Mater. Res. 2013, 641, 385–388. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Lu, F. Fracture properties of slag-based alkali-activated seawater coral aggregate concrete. Theor. Appl. Fract. Mech. 2021, 115, 103071. [Google Scholar] [CrossRef]

- Wang, W.; Su, H.; Zhao, H.; Yu, L.; Wu, C. Experimental investigation on mode I fracture behavior of sandstone after grouting filling under three-point bending. Eng. Fract. Mech. 2023, 291, 109578. [Google Scholar] [CrossRef]

- Gui, W.; Hu, X.; Liang, L. Normal distribution analysis of fracture parameters of alkali-activated slag seawater column coral aggregate concrete. Theor. Appl. Fract. Mech. 2020, 110, 102794. [Google Scholar] [CrossRef]

- Zang, C.H.; Yang, S.T.; Jin, L.L. Determination of double K fracture parameters of seawater sea sand concrete. Ocean Eng. 2019, 37, 142–150. [Google Scholar] [CrossRef]

- Zhou, L.Z.; Zheng, Y.; Huo, L.S. Fracture behaviors of HVFA-SCC mixed with seawater and sea-sand under three-point bending. Adv. Struct. Eng. 2022, 25, 716–735. [Google Scholar] [CrossRef]

- Zhou, L.L.; Guo, S.C.; Ma, W.B.; Xu, F.; Shi, C.J.; Yi, Y.; Zhu, D. Internal curing effect of saturated coral coarse aggregate in high-strength seawater sea sand concrete. Constr. Build. Mater. 2022, 331, 127280. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for the Design of Mixing Ratio of Ordinary Concrete. Ministry of Construction of the PR China: Beijing, China, 2011.

- JGJ/T 12-2019; Technical Standard for Lightweight Aggregate Concrete Application. Ministry of Construction of the PR China: Beijing, China, 2019.

- Rilem, D.R. Determination of the fracture energy of mortar and concrete by means of three-point bend tests on notched beams. Mater. Struct. 1985, 18, 287–290. [Google Scholar] [CrossRef]

- Lian, H.H.; Sun, X.J.; Yu, Z.P.; Lian, Y.J.; Xie, L. Study on the dynamic fracture properties and size effect of concrete based on DIC technology. Eng. Fract. Mech. 2022, 274, 108789. [Google Scholar] [CrossRef]

- Tang, J.H.; Chen, X.D.; Dai, F. Experimental study on the crack propagation and acoustic emission characteristics of notched rock beams under post-peak cyclic loading. Eng. Fract. Mech. 2020, 226, 106890. [Google Scholar] [CrossRef]

- GB/T 14685-2011; Pebble and Crushed Stone for Construction. Ministry of Construction of the PR China: Beijing, China, 2011.

- GB/T 17431.2-2010; Lightweight Aggregates and Its Test Methods Part 2: Test Methods for Lightweight Aggregates. Ministry of Construction of the PR China: Beijing, China, 2010.

- Ahmad, I.; Qing, L.B.; Khan, S.; Cao, G.R.; Ijaz, N. Experimental investigations on fracture parameters of random and aligned steel fiber reinforced cementitious composites. Constr. Build. Mater. 2021, 284, 122680. [Google Scholar] [CrossRef]

- Trusilewicz; Natalia, L. Thermal stability of Friedel’s salt from metakaolin origin by DSC and HTXRD techniques. J. Therm. Anal. Calorim. 2018, 134, 371–380. [Google Scholar] [CrossRef]

- Swartz, S.E.; Yap, S.T. The influence of dead load on fracture energy measurements using RILEM method. Mater. Struct. 1988, 21, 410–415. [Google Scholar] [CrossRef]

- Roesler, J.; Paulino, G.H.; Park, K.; Gaedicke, C. Concrete fracture prediction using bilinear softening. Cem. Concr. Compos. 2007, 29, 300–312. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Xu, S.L. Concrete Fracture Mechanics; Science Press: Beijing, China, 2011; pp. 224–270. [Google Scholar]

- Xu, S.L.; Li, Q.H.; Wu, Y.; Dong, L.X.; Lyu, Y. Influential factors for double-K fracture parameters analyzed by the round robin tests of RILEM TC265-TDK. Mater. Struct. 2021, 54, 227. [Google Scholar] [CrossRef]

- Li, V.C.; Chan, C.M.; Leung, C.K.Y. Experimental determination of the tension-softening relations for cementitious composites. Cem. Concr. Res. 1987, 17, 441–452. [Google Scholar] [CrossRef]

- Jia, M.D.; Wu, Z.M.; Wang, H.W.; Yu, R.C.; Zhang, X.X. Analytical method for predicting mode I crack propagation process of concrete under low-cycle fatigue loading. Eng. Fract. Mech. 2023, 286, 109320. [Google Scholar] [CrossRef]

- Wu, Z.M.; Xu, S.L.; Wang, J.L.; Liu, Y. Double-K fracture parameter of concrete and its size effect by using three-point bending beam method. J. Hydraul. Eng.-ASCE. 2000, 4, 35–39. [Google Scholar] [CrossRef]

- Nie, R.F.; Huang, Y.J.; Wang, S.W.; Zhang, F.X.; Wang, Q. Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression. Rev. Adv. Mater. Sci. 2023, 62, 20230151. [Google Scholar] [CrossRef]

- Sun, X.J.; Gao, Z.; Cao, P.; Zhou, C.J.; Ling, Y.F. Fracture performance and numerical simulation of basalt fiber concrete using three-point bending test on notched beam. Constr. Build. Mater. 2019, 225, 788–800. [Google Scholar] [CrossRef]

- Afshar, R.; Faramarzi, L.; Mirsayar, M.; Ebrahimi, B.J. Aggregate size effects on fracture behavior of concrete SCB specimens. Constr. Build. Mater. 2023, 389, 131628. [Google Scholar] [CrossRef]

- Liu, N.; Li, S.H.; Wang, X.Q. Mechanism of coupling polymer thickness and interfacial interactions on strength and toughness of non-covalent nacre-inspired graphene nanocomposites. Compos. Sci. Technol. 2023, 241, 110124. [Google Scholar] [CrossRef]

- Wu, Z.M.; Xu, S.L.; Ding, Y.; Lu, X.J.; Liu, J.Y. The double-K fracture parameter of concrete for non-standard three point bending beam specimens. Eng. Sci. 2001, 4, 76–81. [Google Scholar]

- Yang, S.Y.; Zhou, M.; Zhang, Y.Z.; Zhang, Y.Q.; Zhang, B.Q. Effect of spontaneous combustion coal gangue coarse aggregate replacement ratio on fracture properties of three-point bending concrete beam. J. Build. Mater. 2020, 23, 858–864. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.B.; Jin, R.Y.; Chen, H.Z. Mechanical properties of recycled aggregate concrete modified by nano-particles. Constr. Build. Mater. 2020, 241, 118030. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Comelissen, H.A.W.; Hordijk, D.A. Tensile tests and failure analysis of concrete. J. Struct. Eng. 1986, 112, 2462–2477. [Google Scholar] [CrossRef]

- Xu, S.L.; Wang, Q.M.; Lyu, Y.; Li, Q.H.; Reinhardt, H.W. Prediction of fracture parameters of concrete using an artificial neural network approach. Eng. Fract. Mech. 2021, 258, 0013–7944. [Google Scholar] [CrossRef]

| Materials | Size (mm) | ρb (kg·m−3) | ρa (kg·m−3) | ωa (kg·m−3) | CL (%) | CR (%) | α (%) |

|---|---|---|---|---|---|---|---|

| Gravel | 5.0–31.5 | 1560 | 2590 | 1.2 | - | 8.49 | - |

| VSCA | 5.0–31.5 | 708 | 1647 | 14.81 | - | 26.4 | - |

| SS | 0.15–4.75 | 1579 | - | - | 0.72 | - | 1.8 |

| RS | 0.15–4.75 | 1611 | - | - | 2.90 | - | - |

| Concrete Type | Cement | FW | SW | RS | SS | Gravel | VSCA | Water-Reducing Agent |

|---|---|---|---|---|---|---|---|---|

| OC | 285 | 190 | - | 676 | - | 1202 | - | - |

| SVSAC | 459 | - | 265 | - | 834 | - | 638 | 0.4 |

| VSAC | 459 | 256 | - | 834 | - | - | 638 | 0.4 |

| Specimen Number | Coarse Aggregates | Fine Aggregates | Water | a0/h |

|---|---|---|---|---|

| OC-0.2 | Gravel | RS | FW | 0.2 |

| OC-0.3 | Gravel | RS | FW | 0.3 |

| OC-0.4 | Gravel | RS | FW | 0.4 |

| SVSAC-0.2 | VSCA | SS | SW | 0.2 |

| SVSAC-0.3 | VSCA | SS | SW | 0.3 |

| SVSAC-0.4 | VSCA | SS | SW | 0.4 |

| VSAC-0.2 | VSCA | RS | FW | 0.2 |

| VSAC-0.3 | VSCA | RS | FW | 0.3 |

| VSAC-0.4 | VSCA | RS | FW | 0.4 |

| Specimen Number | Concrete Type | fcu (MPa) | fc (MPa) | ft (MPa) | Ec (GPa) | ρd (kg·m−3) | Pini (kN) | Pmax (kN) | (MPa·m1/2) | (MPa·m1/2) | ac (mm) | Gf (N·m−1) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OC-0.2 | OC | 38.3 | 33.2 | 2.83 | 24.2 | 2208 | 2.73 | 4.77 | 0.92 | 2.815 | 0.097 | 154.955 |

| OC-0.3 | 2.16 | 3.72 | 0.96 | 2.79 | 0.1165 | 132.05 | ||||||

| OC-0.4 | 1.62 | 2.86 | 0.99 | 2.64 | 0.127 | 117.29 | ||||||

| SVSAC-0.2 | SVSAC | 39.2 | 37.2 | 3.22 | 17.1 | 1836 | 2.66 | 4.31 | 0.765 | 1.83 | 0.0865 | 115.8 |

| SVSAC-0.3 | 1.94 | 3.50 | 0.89 | 1.785 | 0.0895 | 83.45 | ||||||

| SVSAC-0.4 | 1.40 | 2.62 | 0.975 | 1.65 | 0.099 | 73.3 | ||||||

| VSAC-0.2 | VSAC | 37.5 | 36.6 | 3.14 | 16.6 | 1809 | 2.53 | 3.95 | 0.745 | 1.495 | 0.076 | 102.7 |

| VSAC-0.3 | 1.87 | 3.13 | 0.845 | 1.375 | 0.079 | 78.8 | ||||||

| VSAC-0.4 | 1.32 | 2.19 | 0.965 | 1.32 | 0.0915 | 72.1 |

| Specimen Number | H (mm) | L (mm) | W (mm) | Pmax (kN) | (MPa·m1/2) | (MPa·m1/2) |

|---|---|---|---|---|---|---|

| 1 | 150 | 1190 | 100 | 2.093 | 1.081 | 2.136 |

| 2 | 200 | 1190 | 100 | 3.477 | 0.893 | 1.716 |

| 3 | 250 | 1190 | 100 | 5.166 | 0.814 | 1.444 |

| 4 | 300 | 1190 | 100 | 7.834 | 0.777 | 1.378 |

| 5 | 200 | 900 | 100 | 4.627 | 0.754 | 1.146 |

| 6 | 200 | 1190 | 100 | 3.477 | 0.893 | 1.716 |

| 7 | 200 | 1500 | 100 | 2.695 | 1.188 | 2.433 |

| 8 | 200 | 1800 | 100 | 2.206 | 1.528 | 3.351 |

| 9 | 200 | 1190 | 80 | 2.771 | 0.929 | 1.714 |

| 10 | 200 | 1190 | 100 | 3.477 | 0.893 | 1.716 |

| 11 | 200 | 1190 | 120 | 4.161 | 0.919 | 1.712 |

| 12 | 200 | 1190 | 140 | 5.544 | 0.986 | 1.741 |

| Specimen | γ (g/L) | k (%) | Test Value (MPa·m1/2) | Calculated Value (MPa·m1/2) | Test Value (MPa·m1/2) | Calculated Value (MPa·m1/2) |

|---|---|---|---|---|---|---|

| OC | 0 | 8.49 | 0.957 | 0.927 | 2.748 | 2.739 |

| VSAC | 0 | 26.4 | 0.852 | 0.711 | 1.397 | 1.119 |

| SVSAC | 2.08 | 26.4 | 0.877 | 0.880 | 1.755 | 1.660 |

| HHL-0.4 [32] | 1.84 | 9.605 | 0.980 | 0.923 | 2.000 | 2.022 |

| C40-1 [57] | 0 | / | 0.847 | 0.849 | 1.504 | 1.598 |

| SE30-1 [58] | 0 | / | 0.802 | 0.845 | 1.560 | 1.550 |

| 0.3-1 [59] | 0 | / | 1.034 | 1.034 | 2.072 | 2.073 |

| MG100 [60] | 0 | 26.2 | 0.680 | 0.718 | 0.890 | 9.048 |

| RAC100 [61] | 0 | 13 | 0.472 | 0.472 | 1.143 | 1.135 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Zheng, L.; Li, P.; Wang, Q.; Zhang, Y. Effects of Mix Components on Fracture Properties of Seawater Volcanic Scoria Aggregate Concrete. Materials 2024, 17, 4100. https://doi.org/10.3390/ma17164100

Huang Y, Zheng L, Li P, Wang Q, Zhang Y. Effects of Mix Components on Fracture Properties of Seawater Volcanic Scoria Aggregate Concrete. Materials. 2024; 17(16):4100. https://doi.org/10.3390/ma17164100

Chicago/Turabian StyleHuang, Yijie, Lina Zheng, Peng Li, Qing Wang, and Yukun Zhang. 2024. "Effects of Mix Components on Fracture Properties of Seawater Volcanic Scoria Aggregate Concrete" Materials 17, no. 16: 4100. https://doi.org/10.3390/ma17164100

APA StyleHuang, Y., Zheng, L., Li, P., Wang, Q., & Zhang, Y. (2024). Effects of Mix Components on Fracture Properties of Seawater Volcanic Scoria Aggregate Concrete. Materials, 17(16), 4100. https://doi.org/10.3390/ma17164100