Numerical Study of Tangential Traction Mechanism between Pattern Blocks of Agricultural Radial Tires and Soft Soil

Abstract

1. Introduction

2. Materials and Methods

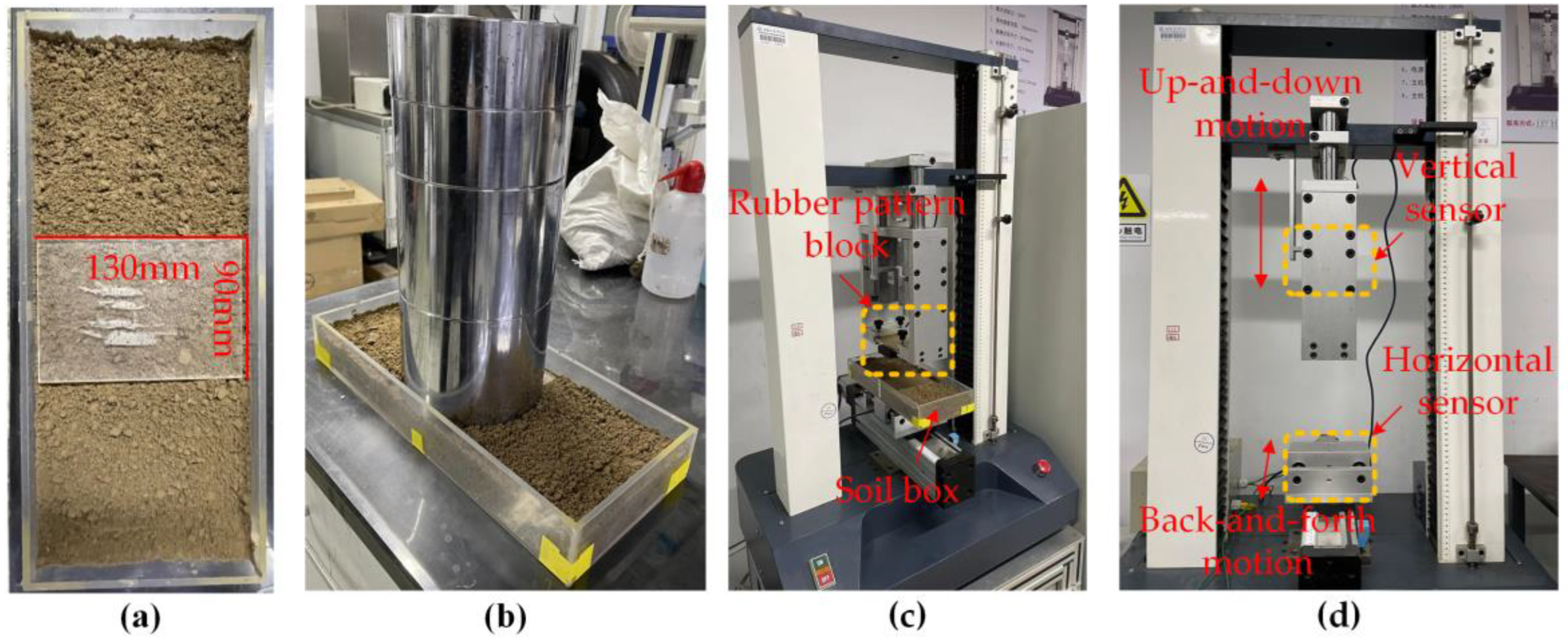

2.1. Materials

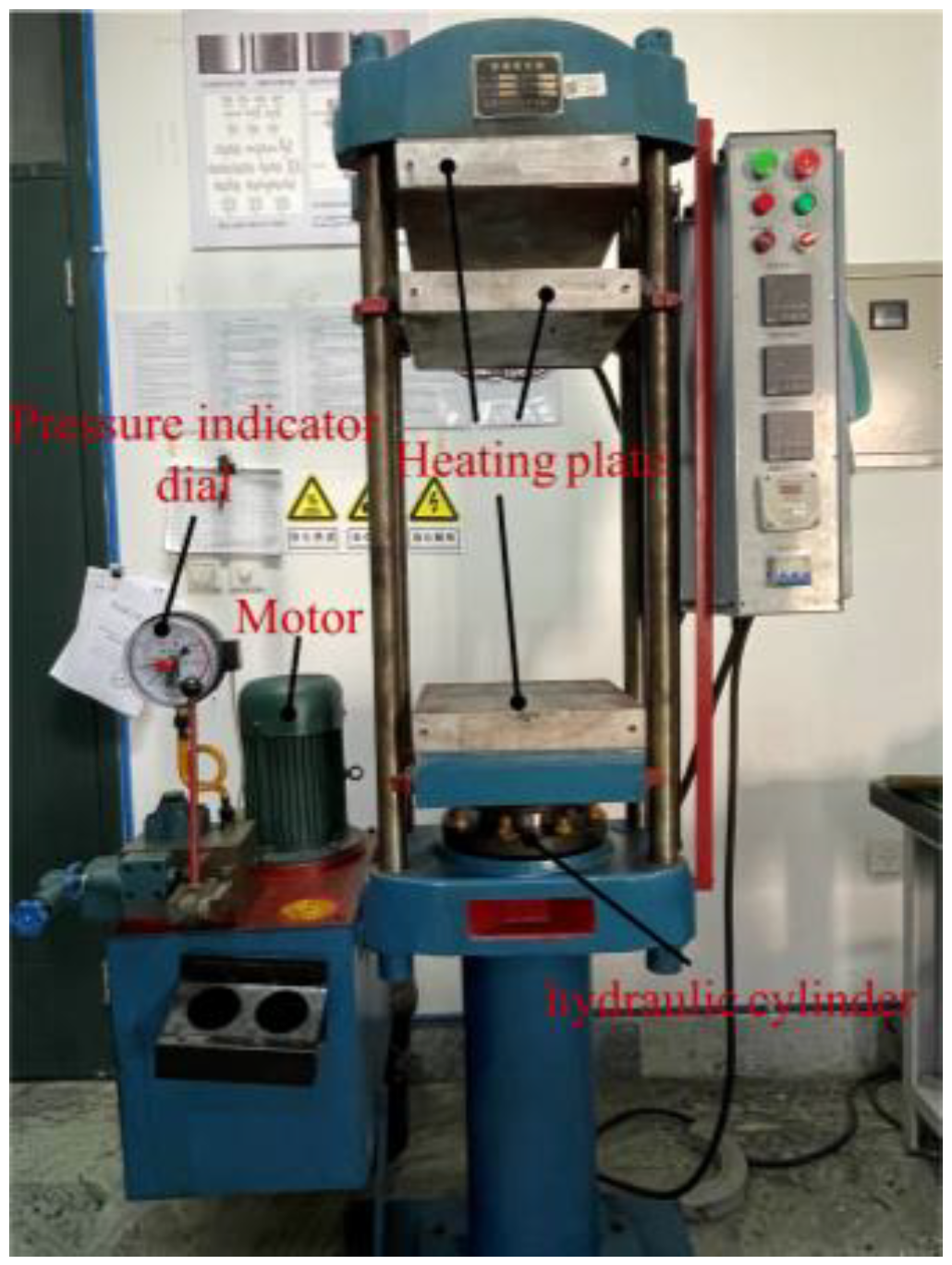

2.2. Contact Behavior Testing Methods

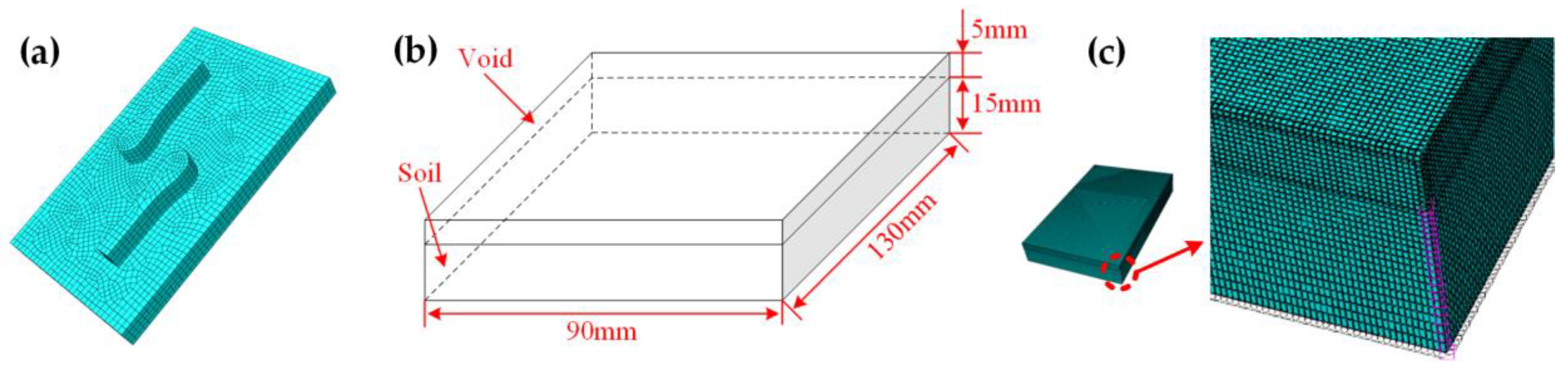

3. Finite Element Contact Modeling

3.1. Constitutive Model

3.2. Meshing

3.3. Load and Boundaries

4. Results and Discussion

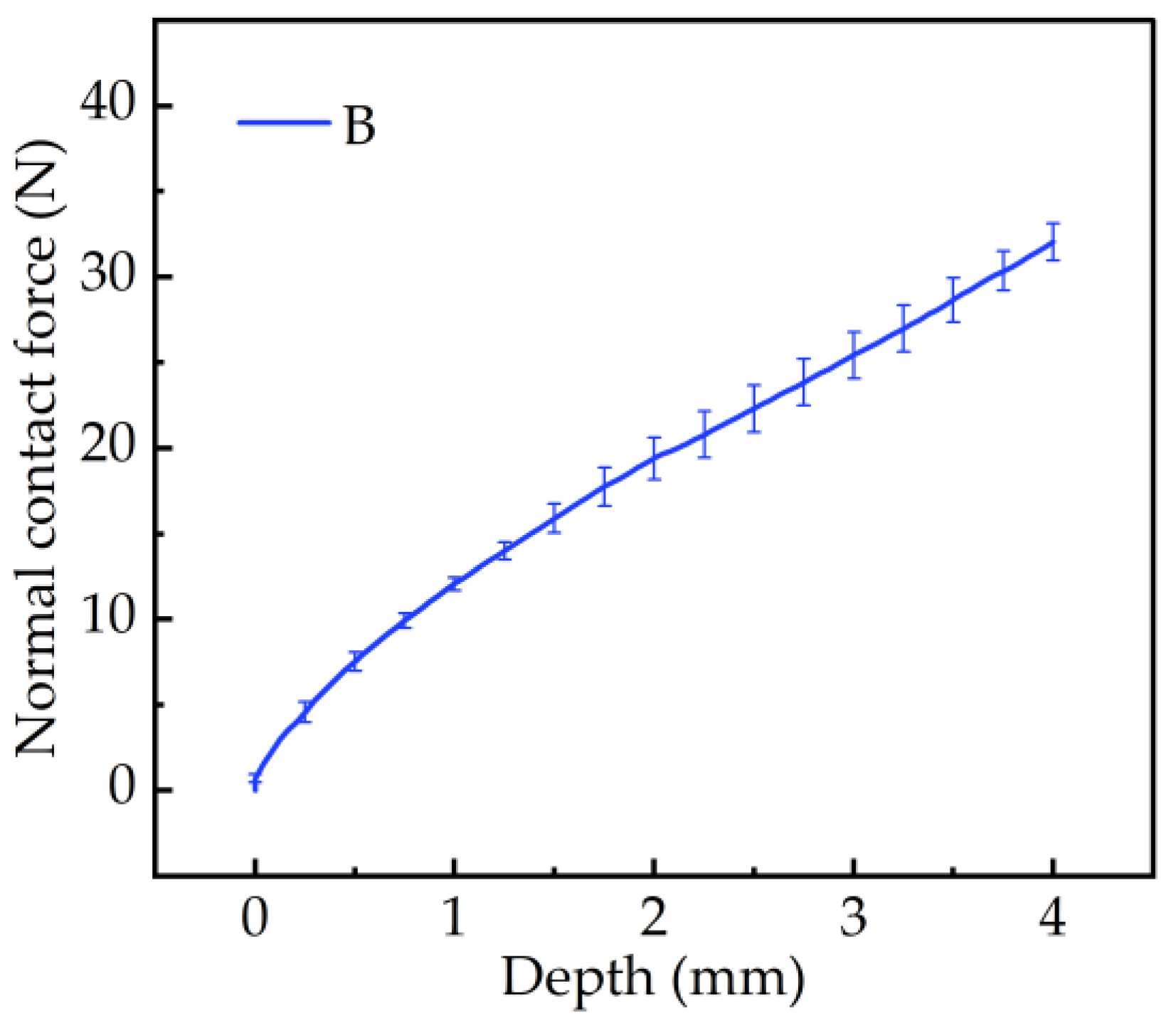

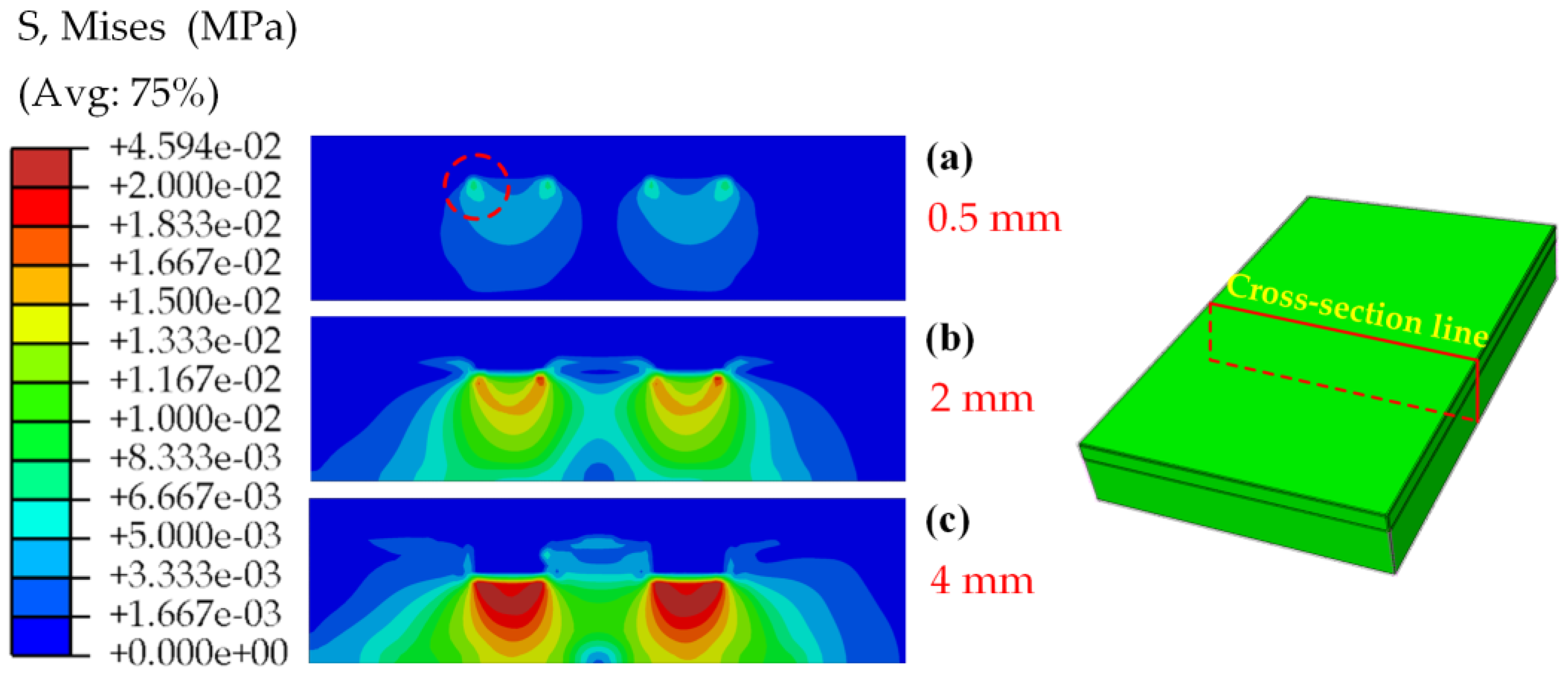

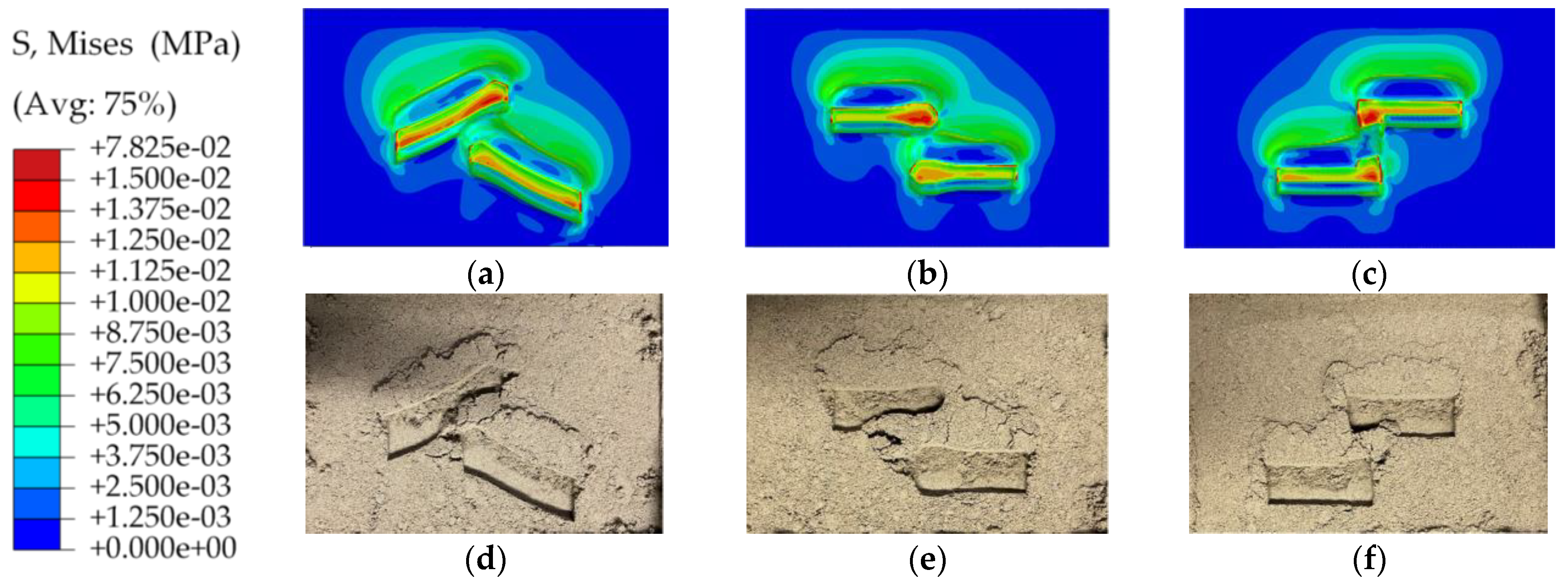

4.1. Compaction Process

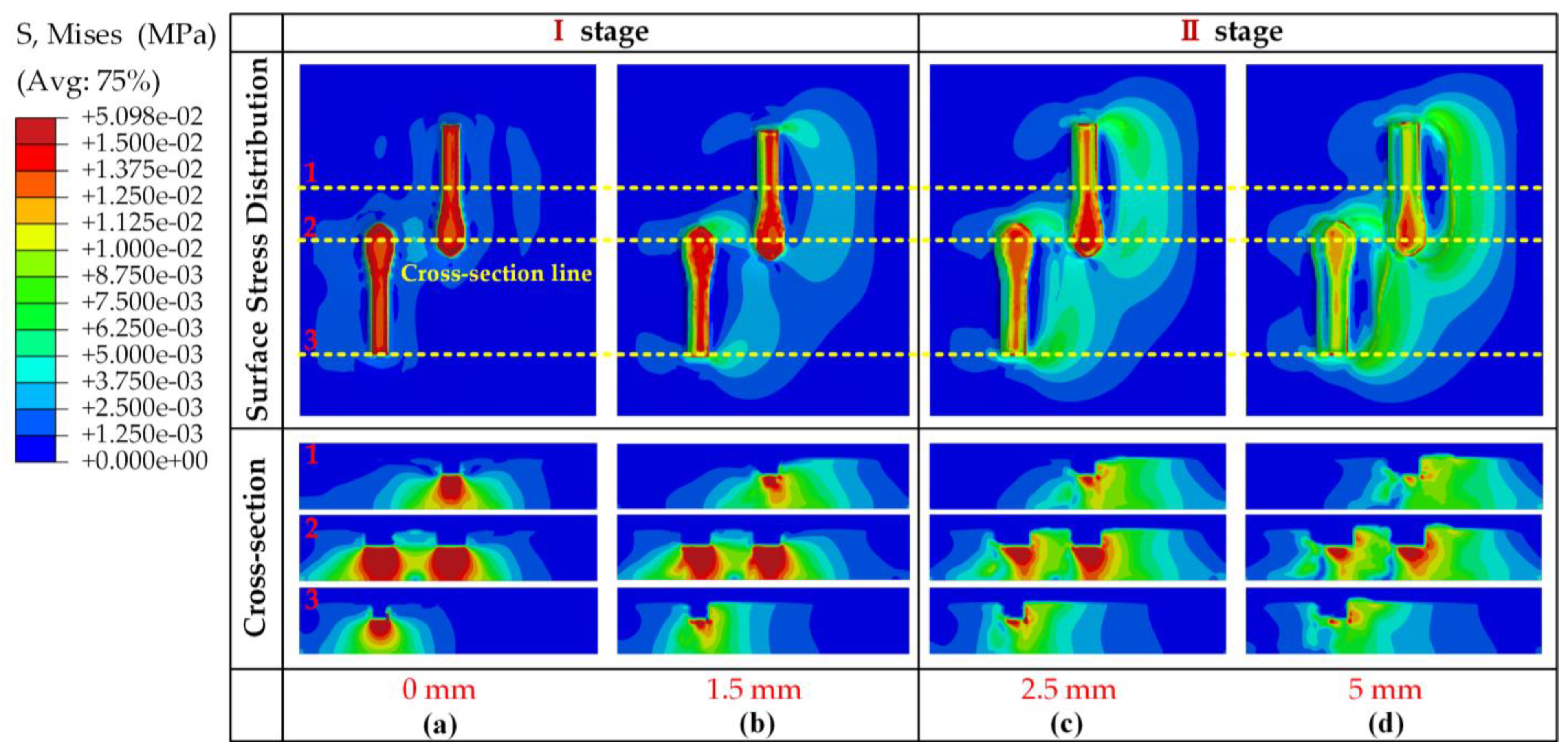

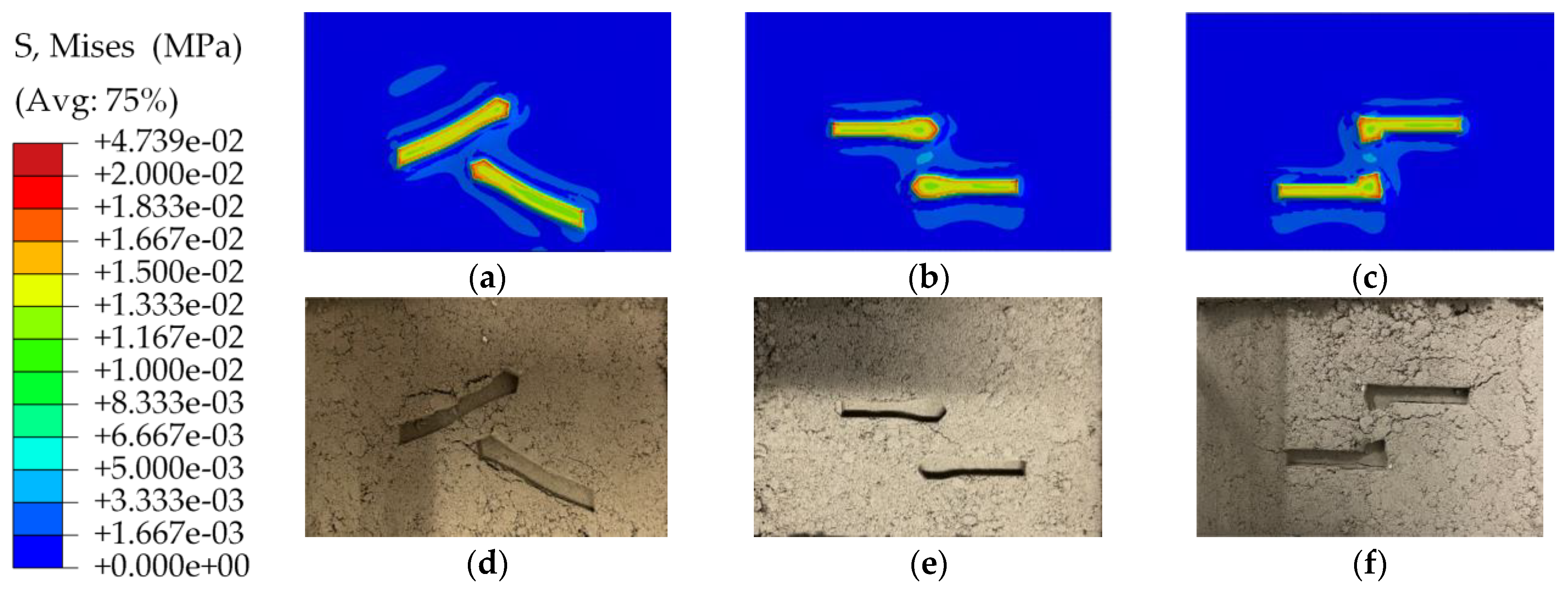

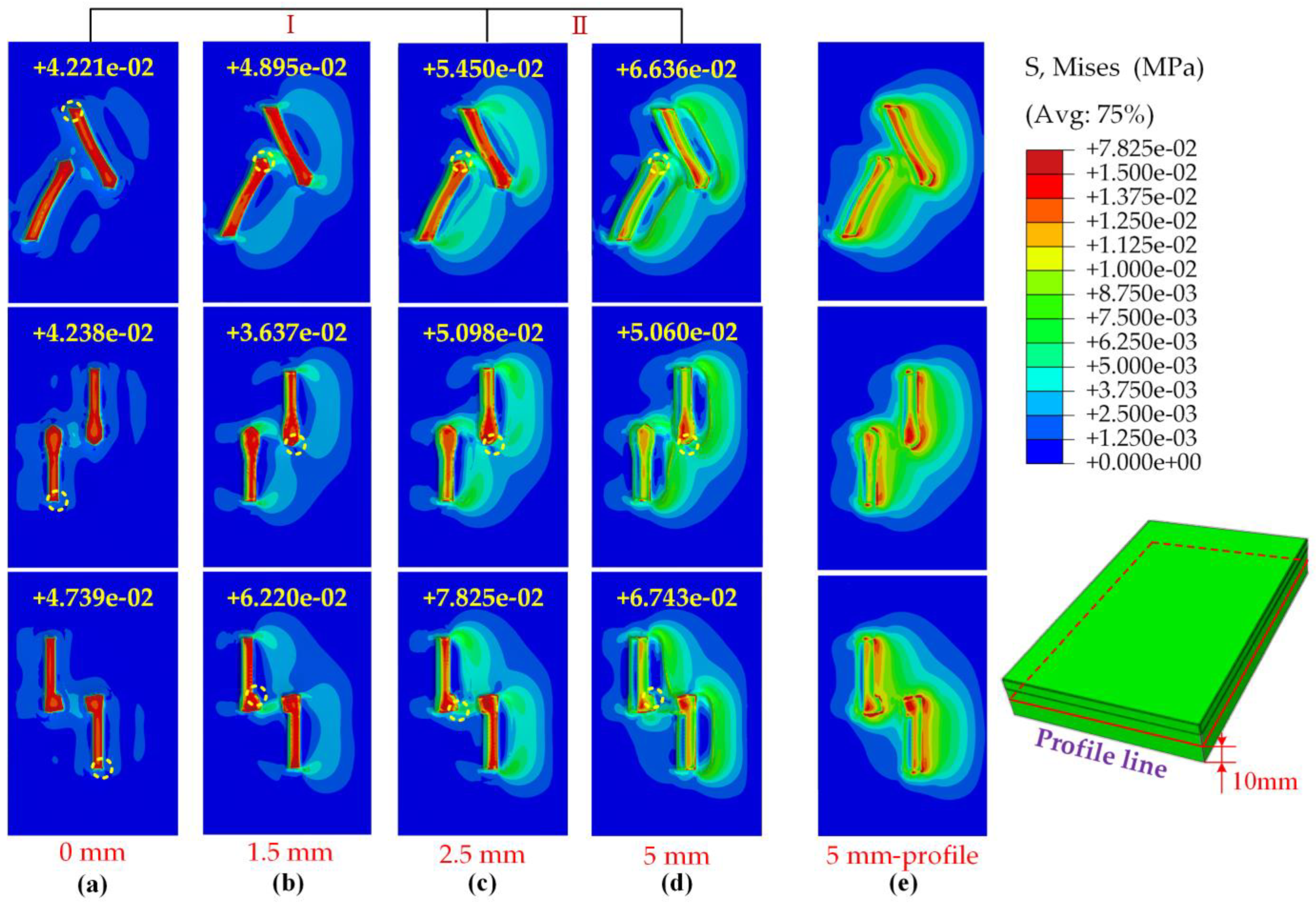

4.2. Shear Slip Process

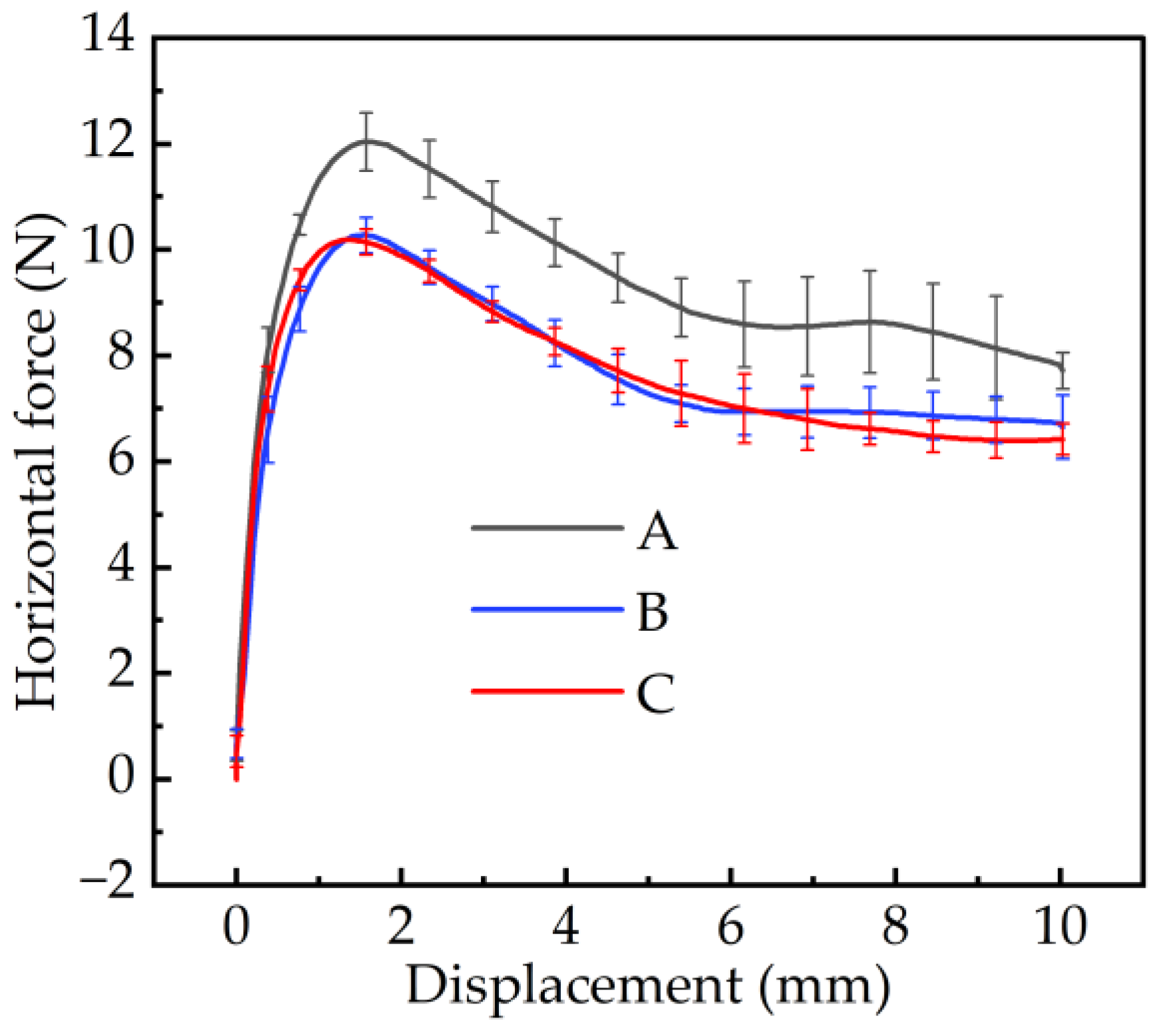

4.3. Effect of Pattern on Contact Behavior

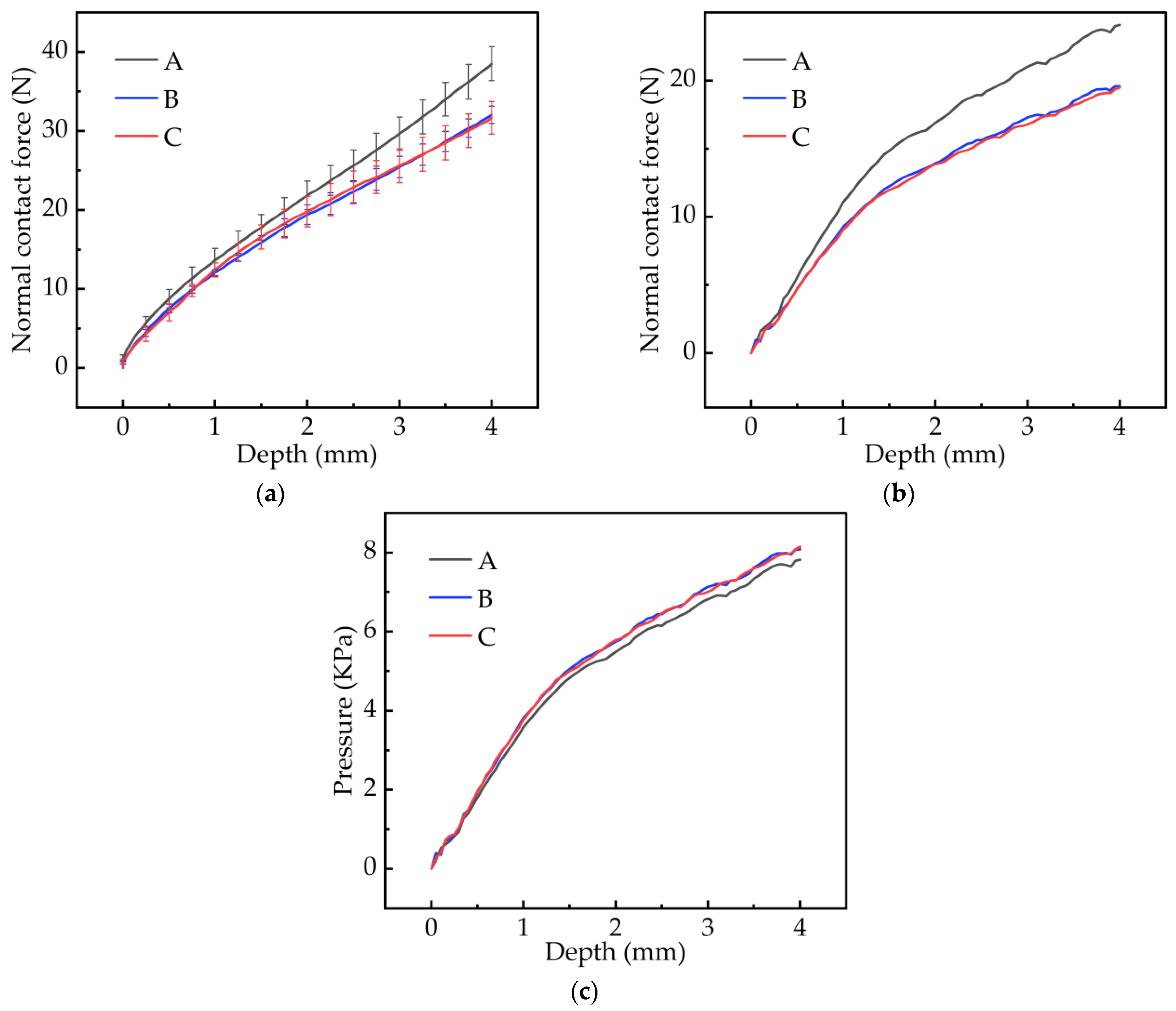

4.3.1. Contact Behavior in the Compaction Process

4.3.2. Contact Behavior in the Shear Slip Process

5. Conclusions

- When a pattern block was pressed into the soil, the stress in the soil increased from the edge and propagated downward. The horizontal force on the patterned blocks was mainly affected by the soil shear force during slipping.

- With the downward of the pattern blocks, the Normal contact force-depth curve slope of the A, B, and C pattern blocks were 8.48 N/mm, 7.11 N/mm, and 7.10 N/mm, respectively. That means at the same pressure depth, the A pattern block had the greatest contact force and the B and C pattern blocks had very similar contact forces. Thus, the A type performed better in soil compaction.

- When moving horizontally, the pattern blocks needed to first overcome the force of the destroyed soil. Among the three pattern types, the shear force generated by the A pattern block was the greatest, approximately 17.94% greater than the other two types, which meant that the A pattern block in the actual tire could generate more excellent traction.

- The proposed CEL method provides new possibilities for simulating soil–tire interaction, which can contribute to a better understanding of the process of interaction between soil and tire patterns and improve the design of tire tread patterns.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Keller, T.; Sandin, M.; Colombi, T.; Horn, R.; Or, D. Historical increase in agricultural machinery weights enhanced soil stress levels and adversely affected soil functioning. Soil Tillage Res. 2019, 194, 104293. [Google Scholar] [CrossRef]

- Sheludchenko, B.; Sarauskis, E.; Kukharets, S.; Zabrodskyi, A. Graphic analytical optimization of design and operating parameters of tires for drive wheels of agricultural machinery. Soil Tillage Res. 2022, 215, 105227. [Google Scholar] [CrossRef]

- Sivarajan, S.; Maharlooei, M.; Bajwa, S.G.; Nowatzki, J. Impact of soil compaction due to wheel traffic on corn and soybean growth, development and yield. Soil Tillage Res. 2018, 175, 234–243. [Google Scholar] [CrossRef]

- Rula, A.; Nuttall, C. An Analysis of Ground Mobility Models; US Army Engineer Waterways Experiment Station: Vicksburg, MS, USA, 1971. [Google Scholar]

- Lessem, A.S.; Murphy, N.R. Studies of the Dynamics of Tracked Vehicles; Waterways Experiment Station: Vicksburg, MS, USA, 1972.

- Allen, R.; Chrstos, J.; Rosenthal, T. A tire model for use with vehicle dynamics simulations on pavement and off-road surfaces. Veh. Syst. Dyn. 1997, 27, 318–321. [Google Scholar] [CrossRef]

- Allen, R.W.; Rosenthal, T.J.; Chrstos, J.P. A Vehicle Dynamics Tire Model for Both Pavement and Off-Road Conditions; 0148-7191; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Bekker, M.G. Theory of Land Locomotion; University of Michigan Press: Ann Arbor, MI, USA, 1956. [Google Scholar]

- Wong, J.-Y.; Reece, A. Prediction of rigid wheel performance based on the analysis of soil-wheel stresses: Part II. Performance of towed rigid wheels. J. Terramech. 1967, 4, 7–25. [Google Scholar] [CrossRef]

- Keller, T.; Berli, M.; Ruiz, S.; Lamande, M.; Arvidsson, J.; Schjonning, P.; Selvadurai, A.P.S. Transmission of vertical soil stress under agricultural tyres: Comparing measurements with simulations. Soil Tillage Res. 2014, 140, 106–117. [Google Scholar] [CrossRef]

- Helwany, S. Applied Soil Mechanics with ABAQUS Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Sun, P.; Lu, H.; Yang, J.; Liu, M.; Li, S.; Zhang, B. Numerical study on shear interaction between the track plate of deep-sea mining vehicle and the seafloor sediment based on CEL method. Ocean Eng. 2022, 266, 112785. [Google Scholar] [CrossRef]

- Zhang, L.; Cai, Z.; Wang, L.; Zhang, R.; Liu, H. Coupled Eulerian-Lagrangian finite element method for simulating soil-tool interaction. Biosyst. Eng. 2018, 175, 96–105. [Google Scholar] [CrossRef]

- Zeng, H.; Zhao, C.; Chen, S.; Xu, W.; Zang, M. Numerical simulations of tire-soil interactions: A Comprehensive Review. Arch. Comput. Methods Eng. 2023, 30, 4801–4829. [Google Scholar] [CrossRef]

- Armin, A.; Fotouhi, R.; Szyszkowski, W. On the FE modeling of soil–blade interaction in tillage operations. Finite Elem. Anal. Des. 2014, 92, 1–11. [Google Scholar] [CrossRef]

- Barr, J.B.; Ucgul, M.; Desbiolles, J.M.; Fielke, J.M. Simulating the effect of rake angle on narrow opener performance with the discrete element method. Biosyst. Eng. 2018, 171, 1–15. [Google Scholar] [CrossRef]

- Gürsoy, S.; Chen, Y.; Li, B. Measurement and modelling of soil displacement from sweeps with different cutting widths. Biosyst. Eng. 2017, 161, 1–13. [Google Scholar] [CrossRef]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Milkevych, V.; Munkholm, L.J.; Chen, Y.; Nyord, T. Modelling approach for soil displacement in tillage using discrete element method. Soil Tillage Res. 2018, 183, 60–71. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Li, P.; Lee, S.-H.; Desbiolles, J.M. Analyzing the mixing performance of a rotary spader using digital image processing and discrete element modelling (DEM). Comput. Electron. Agric. 2018, 151, 1–10. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y.; Zhang, X. Modelling the interaction of a deep tillage tool with heterogeneous soil. Comput. Electron. Agric. 2017, 143, 130–138. [Google Scholar] [CrossRef]

- Coetzee, C.; Els, D. Calibration of discrete element parameters and the modelling of silo discharge and bucket filling. Comput. Electron. Agric. 2009, 65, 198–212. [Google Scholar] [CrossRef]

- Shmulevich, I. State of the art modeling of soil–tillage interaction using discrete element method. Soil Tillage Res. 2010, 111, 41–53. [Google Scholar] [CrossRef]

- Coetzee, C.J. Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Bojanowski, C. Numerical modeling of large deformations in soil structure interaction problems using FE, EFG, SPH, and MM-ALE formulations. Arch. Appl. Mech. 2014, 84, 743–755. [Google Scholar] [CrossRef]

- Chaabani, L.; Piquard, R.; Abnay, R.; Fontaine, M.; Gilbin, A.; Picart, P.; Thibaud, S.; D’acunto, A.; Dudzinski, D. Study of the influence of cutting edge on micro cutting of hardened steel using FE and SPH modeling. Micromachines 2022, 13, 1079. [Google Scholar] [CrossRef] [PubMed]

- Swamy, V.S.; Pandit, R.; Yerro, A.; Sandu, C.; Rizzo, D.M.; Sebeck, K.; Gorsich, D. Review of modeling and validation techniques for tire-deformable soil interactions. J. Terramech. 2023, 109, 73–92. [Google Scholar] [CrossRef]

- Monaghan, J.J. Smoothed particle hydrodynamics. Rep. Prog. Phys. 2005, 68, 1703. [Google Scholar] [CrossRef]

- Xu, H.; He, X.; Shan, F.; Niu, G.; Sheng, D. 3D Simulation of Debris Flows with the Coupled Eulerian–Lagrangian Method and an Investigation of the Runout. Mathematics 2023, 11, 3493. [Google Scholar] [CrossRef]

- Shen, J.; Wang, X.; Chen, Q.; Ye, Z.; Gao, Q.; Chen, J. Numerical Investigations of Undrained Shear Strength of Sensitive Clay Using Miniature Vane Shear Tests. J. Mar. Sci. Eng. 2023, 11, 1094. [Google Scholar] [CrossRef]

- Tatnell, L.; Dyson, A.P.; Tolooiyan, A. Coupled Eulerian-Lagrangian simulation of a modified direct shear apparatus for the measurement of residual shear strengths. J. Rock Mech. Geotech. Eng. 2021, 13, 1113–1123. [Google Scholar] [CrossRef]

- Zhang, S.; Yi, J.T. Application of the Coupled Eulerian-Lagrangian finite element method on piezocone penetration test in clays. In Proceedings of the 2nd International Workshop on Renewable Energy and Development (IWRED), Guilin, China, 20–22 April 2018; p. 052054. [Google Scholar]

- Ko, J.; Jeong, S.; Kim, J. Application of a Coupled Eulerian-Lagrangian Technique on Constructability Problems of Site on Very Soft Soil. Appl. Sci. 2017, 7, 1080. [Google Scholar] [CrossRef]

- Wang, C.; Ye, G.L.; Meng, X.N.; Wang, Y.Q.; Peng, C. A Eulerian-Lagrangian Coupled Method for the Simulation of Submerged Granular Column Collapse. J. Mar. Sci. Eng. 2021, 9, 617. [Google Scholar] [CrossRef]

- Jasoliya, D.; Untaroiu, A.; Untaroiu, C. A review of soil modeling for numerical simulations of soil-tire/agricultural tools interaction. J. Terramech. 2024, 111, 41–64. [Google Scholar] [CrossRef]

- Wu, J.; Chen, L.; Chen, D.; Wang, Y.; Su, B.; Cui, Z. Experiment and Simulation Research on the Fatigue Wear of Aircraft Tire Tread Rubber. Polymers 2021, 13, 1143. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Su, B.; Dong, J.; Cui, Z.; Gond, B.K. Prediction of tread pattern block deformation in contact with road. Polym. Test. 2017, 58, 208–218. [Google Scholar] [CrossRef]

- Hofstetter, K.; Grohs, C.; Eberhardsteiner, J.; Mang, H.A. Sliding behaviour of simplified tire tread patterns investigated by means of FEM. Comput. Struct. 2006, 84, 1151–1163. [Google Scholar] [CrossRef]

- Drucker, D.C.; Prager, W. Soil mechanics and plastic analysis or limit design. Q. Appl. Math. 1952, 10, 157–165. [Google Scholar] [CrossRef]

- ABAQUS. ABAQUS/CAE 6.13 User’s Manual; Online Documentation Help; ABAQUS: Providence, RI, USA, 2013. [Google Scholar]

- Sumith, S.; Shankar, K.; Kannan, K. Numerical study of traction at grouser–soft seabed interface incorporating experimentally validated constitutive model. In Advances in Mechanical and Materials Technology; Select Proceedings of EMSME 2020; Springer: Singapore, 2022; pp. 1079–1090. [Google Scholar]

- Naderi-Boldaji, M.; Alimardani, R.; Hemmat, A.; Sharifi, A.; Keyhani, A.; Tekeste, M.Z.; Keller, T. 3D finite element simulation of a single-tip horizontal penetrometer–soil interaction. Part I: Development of the model and evaluation of the model parameters. Soil Tillage Res. 2013, 134, 153–162. [Google Scholar] [CrossRef]

- Nasiri, M.; Soltani, M.; Motlagh, A.M. Determination of agricultural soil compaction affected by tractor passing using 3D finite element. Agric. Eng. Int. CIGR J. 2013, 15, 11–16. [Google Scholar]

- Benson, D.J.; Okazawa, S. Contact in a multi-material Eulerian finite element formulation. Comput. Methods Appl. Mech. Eng. 2004, 193, 4277–4298. [Google Scholar] [CrossRef]

- Li, H.; Schindler, C. Analysis of soil compaction and tire mobility with finite element method. Proc. Inst. Mech. Eng. Part K-J. Multi-Body Dyn. 2013, 227, 275–291. [Google Scholar] [CrossRef]

| Parameter Name | Parameter Value |

|---|---|

| Young’s Modulus (MPa) | 0.10 |

| Poisson’s Ratio | 0.35 |

| Density (kg/m3) | 1700 |

| Angle of Friction (°) | 26 |

| Flow Stress Ratio | 0.861 |

| Dilation Angle (°) | 0 |

| Yield Stress (MPa) | 0.01 |

| Parameter Name | Parameter Value |

|---|---|

| Water content (%) | 13.04 |

| Granular diameter (mm) | 0.005–0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wu, J.; Wan, Y.; Su, B.; Wang, Y. Numerical Study of Tangential Traction Mechanism between Pattern Blocks of Agricultural Radial Tires and Soft Soil. Materials 2024, 17, 3906. https://doi.org/10.3390/ma17163906

Li S, Wu J, Wan Y, Su B, Wang Y. Numerical Study of Tangential Traction Mechanism between Pattern Blocks of Agricultural Radial Tires and Soft Soil. Materials. 2024; 17(16):3906. https://doi.org/10.3390/ma17163906

Chicago/Turabian StyleLi, Sheng, Jian Wu, Yang Wan, Benlong Su, and Youshan Wang. 2024. "Numerical Study of Tangential Traction Mechanism between Pattern Blocks of Agricultural Radial Tires and Soft Soil" Materials 17, no. 16: 3906. https://doi.org/10.3390/ma17163906

APA StyleLi, S., Wu, J., Wan, Y., Su, B., & Wang, Y. (2024). Numerical Study of Tangential Traction Mechanism between Pattern Blocks of Agricultural Radial Tires and Soft Soil. Materials, 17(16), 3906. https://doi.org/10.3390/ma17163906